engine NISSAN NOTE 2016 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 1128 of 3641

EC-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION EC

A

EC

N

O P

CONTENTS

ENGINE CONTROL SYSTEM

HR16DE

PRECAUTION ....... ........................................

8

PRECAUTIONS .............................................. .....8

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

8

On Board Diagnostic (OBD) System of Engine

and CVT ....................................................................

8

General Precautions .................................................9

PREPARATION ...........................................12

PREPARATION .............................................. ....12

Special Service Tools .......................................... ....12

Commercial Service Tools ......................................12

SYSTEM DESCRIPTION .............................14

COMPONENT PARTS ................................... ....14

ENGINE CONTROL SYSTEM ............................... ....14

ENGINE CONTROL SYSTEM :

Component Parts Location ....................................

14

ENGINE CONTROL SYSTEM : Component De-

scription ............................................................... ....

17

Accelerator Pedal Position Sensor ..........................18

Air Fuel Ratio Sensor 1 ...........................................19

Air Fuel Ratio Sensor 1 Heater ...............................19

Camshaft Position Sensor .......................................19

Clutch Pedal Position Switch ..................................20

Cooling Fan .............................................................20

Crankshaft Position Sensor .....................................20

ECM .................................................................... ....20

Electric Throttle Control Actuator ............................21

Engine Coolant Temperature Sensor ......................21

Engine Oil Pressure Sensor ....................................21

Engine Oil Temperature Sensor ..............................21

EVAP Canister Purge Volume Control Solenoid

Valve ................................................................... ....

22

EVAP Canister Vent Control Valve .........................22

EVAP Control System Pressure Sensor ..................22

Exhaust Valve Timing Cont rol Solenoid Valve ........23

Fuel Injector ......................................................... ....23

Fuel Pump ...............................................................23

Heated Oxygen Sensor 2 ........................................24

Heated Oxygen Sensor 2 Heater ............................24

Ignition Coil With Power Transistor .........................24

Intake Air Temperature Sensor ...............................24

Intake Valve Timing Control Solenoid Valve ...........25

Knock Sensor ...................................................... ....25

Battery Current Sensor (With Battery Tempera-

ture Sensor) .............................................................

25

Malfunction Indicator Lamp (MIL) ............................26

Mass Air Flow Sensor ..............................................26

Oil Pressure Warning Lamp ....................................26

Refrigerant Pressure Sensor ............................... ....27

Stop Lamp Switch & ASCD Brake Switch ...............27

Throttle Control Motor .......................................... ....27

Throttle Control Motor Relay ...................................27

Throttle Position Sensor ..........................................27

ASCD Steering Switch .............................................27

STRUCTURE AND OPERATION .....................28

Positive Crankcase Ventilation ................................28

On Board Refueling Vapor Recovery (ORVR) ........29

SYSTEM ............................................................30

ENGINE CONTROL SYSTEM ........................ ...........30

ENGINE CONTROL SYSTEM : System Diagram ....30

ENGINE CONTROL SYSTEM : System Descrip-

tion ...........................................................................

31

MULTIPORT FUEL INJECTION SYSTEM ................31

MULTIPORT FUEL INJECTION SYSTEM :

System Diagram ................................................. ....

32

MULTIPORT FUEL INJECTION SYSTEM : Sys-

tem Description ........................................................

32

ELECTRIC IGNITION SYSTEM .................................35

ELECTRIC IGNITION SYSTEM :

System Diagram ................................................. ....

35

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1129 of 3641

EC-2

ELECTRIC IGNITION SYSTEM : System De-

scription ............................................................... ...

35

AIR CONDITIONING CUT CONTROL ................... ...36

AIR CONDITIONING CUT CONTROL : System

Diagram ..................................................................

37

AIR CONDITIONING CUT CONTROL : System

Description ..............................................................

37

CAN COMMUNICATION ........................................ ...38

CAN COMMUNICATION : System Description ......38

COOLING FAN CONTROL .................................... ...38

COOLING FAN CONTROL : System Diagram .......38

COOLING FAN CONTROL : System Description ...38

EVAPORATIVE EMISSION SYSTEM .................... ...40

EVAPORATIVE EMISSION SYSTEM : System

Diagram ............................................................... ...

40

EVAPORATIVE EMISSION SYSTEM : System

Description ........................................................... ...

40

INTAKE VALVE TIMING CONTROL ..................... ...41

INTAKE VALVE TIMING CONTROL : System Di-

agram .................................................................. ...

41

INTAKE VALVE TIMING CONTROL : System De-

scription ............................................................... ...

41

EXHAUST VALVE TIMING CONTROL ................. ...42

EXHAUST VALVE TIMING CONTROL : System

Diagram ............................................................... ...

42

EXHAUST VALVE TIMING CONTROL : System

Description ........................................................... ...

42

ENGINE PROTECTION CONTROL AT LOW EN-

GINE OIL PRESSURE ..............................................

43

ENGINE PROTECTION CONTROL AT LOW EN-

GINE OIL PRESSURE : S ystem Diagram ..............

43

ENGINE PROTECTION CONTROL AT LOW EN-

GINE OIL PRESSURE : S ystem Description .........

43

FUEL FILLER CAP WARNING SYSTEM .............. ...44

FUEL FILLER CAP WARNING SYSTEM :

System Diagram ....................................................

44

FUEL FILLER CAP WARNING SYSTEM : System

Description ........................................................... ...

44

AUTOMATIC SPEED CONTROL DEVICE (ASCD) ...45

AUTOMATIC SPEED CONTROL DEVICE (AS-

CD) : System Diagram ............................................

45

AUTOMATIC SPEED CONTROL DEVICE (AS-

CD) : System Description .......................................

45

OPERATION ......................................................47

AUTOMATIC SPEED CONTROL DEVICE (ASCD) ...47

AUTOMATIC SPEED CONTROL DEVICE (AS-

CD) : Switch Name and Function ...........................

47

ON BOARD DIAGNOSTIC (OBD) SYSTEM .....49

Diagnosis Description .......................................... ...49

GST (Generic Scan Tool) .......................................49

DIAGNOSIS SYSTEM (ECM) ............................50

DIAGNOSIS DESCRIPTION .................................. ...50

DIAGNOSIS DESCRIPTION : 1st Trip Detection

Logic and Two Trip Detection Logic ........................

50

DIAGNOSIS DESCRIPTION : DTC and Freeze

Frame Data .......................................................... ...

50

DIAGNOSIS DESCRIPTION : Counter System ......51

DIAGNOSIS DESCRIPTION : Driving Pattern ..... ...54

DIAGNOSIS DESCRIPTION : System Readiness

Test (SRT) Code .................................................. ...

55

DIAGNOSIS DESCRIPTION : Permanent Diag-

nostic Trouble Code (Permanent DTC) ..................

56

DIAGNOSIS DESCRIPTION : Malfunction Indica-

tor Lamp (MIL) ..................................................... ...

57

On Board Diagnosis Function .................................57

CONSULT Function ................................................60

ECU DIAGNOSIS INFORMATION .............71

ECM ...................................................................71

Reference Value .................................................. ...71

Fail Safe .................................................................83

DTC Inspection Priority Chart ...............................85

DTC Index ..............................................................87

Test Value and Test Limit .......................................90

WIRING DIAGRAM ....................................99

ENGINE CONTROL SYSTEM ........................ ...99

Wiring Diagram .................................................... ...99

BASIC INSPECTION .................................120

DIAGNOSIS AND REPAIR WORKFLOW ...... ..120

Work Flow ............................................................ .120

Diagnostic Work Sheet .........................................123

ADDITIONAL SERVICE WHEN REPLACING

ECM ..................................................................

125

Description ........................................................... .125

Work Procedure ....................................................125

VIN REGISTRATION ........................................127

Description ........................................................... .127

Work Procedure ....................................................127

ACCELERATOR PEDAL RELEASED POSI-

TION LEARNING ............................................ ..

128

Description ........................................................... .128

Work Procedure ....................................................128

THROTTLE VALVE CLOSED POSITION

LEARNING .......................................................

129

Description ........................................................... .129

Work Procedure ....................................................129

IDLE AIR VOLUME LEARNING .......................130

Description ........................................................... .130

Work Procedure ....................................................130

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1132 of 3641

EC-5

C

DE

F

G H

I

J

K L

M

EC A

N

O P

P0444, P0445 EVAP CANISTER PURGE

VOLUME CONTROL SOLENOID VALVE ..... ..

300

DTC Logic ........................................................... ..300

Diagnosis Procedure .............................................300

Component Inspection ..........................................301

P0447 EVAP CANISTER VENT CONTROL

VALVE ..............................................................

303

DTC Logic ........................................................... ..303

Diagnosis Procedure .............................................303

Component Inspection ..........................................304

P0448 EVAP CANISTER VENT CONTROL

VALVE ..............................................................

307

DTC Logic ........................................................... ..307

Diagnosis Procedure .............................................307

Component Inspection ..........................................309

P0451 EVAP CONTROL SYSTEM PRES-

SURE SENSOR ................................................

311

DTC Logic ........................................................... ..311

Diagnosis Procedure .............................................312

Component Inspection ..........................................313

P0452 EVAP CONTROL SYSTEM PRES-

SURE SENSOR ................................................

315

DTC Logic ........................................................... ..315

Diagnosis Procedure .............................................315

Component Inspection ..........................................317

P0453 EVAP CONTROL SYSTEM PRES-

SURE SENSOR ................................................

318

DTC Logic ........................................................... ..318

Diagnosis Procedure .............................................318

Component Inspection ..........................................321

P0456 EVAP CONTROL SYSTEM ..................322

DTC Logic ........................................................... ..322

Diagnosis Procedure .............................................323

Component Inspection ..........................................327

P0460 FUEL LEVEL SENSOR ........................328

DTC Logic ........................................................... ..328

Diagnosis Procedure .............................................328

P0461 FUEL LEVEL SENSOR ........................329

DTC Logic ........................................................... ..329

Component Function Check ..................................329

Diagnosis Procedure .............................................330

P0462, P0463 FUEL LEVEL SENSOR ............331

DTC Logic ........................................................... ..331

Diagnosis Procedure .............................................331

P0500 VSS .......................................................332

Description .......................................................... ..332

DTC Logic .............................................................332

Component Function Check ..................................333

Diagnosis Procedure .............................................333

P0506 ISC SYSTEM .........................................334

Description ........................................................... ..334

DTC Logic ..............................................................334

Diagnosis Procedure .............................................334

P0507 ISC SYSTEM ........................................335

Description .............................................................335

DTC Logic ..............................................................335

Diagnosis Procedure .............................................335

P050A, P050B, P050E COLD START CON-

TROL ...............................................................

337

Description .............................................................337

DTC Logic ..............................................................337

Diagnosis Procedure .............................................338

P0520 EOP SENSOR ......................................339

DTC Logic ..............................................................339

Diagnosis Procedure .............................................339

Component Inspection ...........................................340

P0524 ENGINE OIL PRESSURE ....................341

DTC Logic ..............................................................341

Diagnosis Procedure .............................................342

Component Inspection ...........................................343

P059F ACTIVE GRILLE SHUTTER ................344

DTC Logic ..............................................................344

Diagnosis Procedure .............................................344

Component Inspection (Active Grille Shutter) .......347

Component Inspection (Active Grille Shutter Re-

lay) ....................................................................... ..

347

P0603 ECM .....................................................349

DTC Logic ..............................................................349

Diagnosis Procedure .............................................349

P0604 ECM .....................................................350

DTC Logic ..............................................................350

Diagnosis Procedure .............................................350

P0605 ECM .....................................................351

DTC Logic ..............................................................351

Diagnosis Procedure .............................................351

P0606 ECM .....................................................352

DTC Logic ..............................................................352

Diagnosis Procedure .............................................352

P0607 ECM .....................................................353

DTC Logic ..............................................................353

Diagnosis Procedure .............................................353

P060A ECM .....................................................354

DTC Logic ..............................................................354

Diagnosis Procedure .............................................354

P060B ECM .....................................................355

DTC Logic ..............................................................355

Diagnosis Procedure .............................................355

P0643 SENSOR POWER SUPPLY ................356

DTC Logic ..............................................................356

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1133 of 3641

EC-6

Diagnosis Procedure .............................................356

P0850 PNP SWITCH .......................................358

Description ........................................................... ..358

DTC Logic ..............................................................358

Component Function Check ..................................359

Diagnosis Procedure .............................................359

P1078 EVT CONTROL POSITION SENSOR ..361

DTC Logic ............................................................ ..361

Diagnosis Procedure .............................................361

Component Inspection ...........................................363

P1148 CLOSED LOOP CONTROL .................364

DTC Logic ............................................................ ..364

Diagnosis Procedure .............................................364

P1212 TCS COMMUNICATION LINE .............365

Description ........................................................... ..365

DTC Logic ..............................................................365

Diagnosis Procedure .............................................365

P1217 ENGINE OVER TEMPERATURE .........366

DTC Logic ............................................................ ..366

Component Function Check ..................................366

Diagnosis Procedure .............................................367

P1225 TP SENSOR .........................................369

DTC Logic ............................................................ ..369

Diagnosis Procedure .............................................369

P1226 TP SENSOR .........................................370

DTC Logic ............................................................ ..370

Diagnosis Procedure .............................................370

P1550 BATTERY CURRENT SENSOR ..........371

DTC Logic ............................................................ ..371

Diagnosis Procedure .............................................371

Component Inspection ...........................................372

P1551, P1552 BATTERY CURRENT SEN-

SOR ..................................................................

373

DTC Logic ............................................................ ..373

Diagnosis Procedure .............................................373

Component Inspection ...........................................374

P1553 BATTERY CURRENT SENSOR ..........375

DTC Logic ............................................................ ..375

Diagnosis Procedure .............................................375

Component Inspection ...........................................376

P1554 BATTERY CURRENT SENSOR ..........377

DTC Logic ............................................................ ..377

Component Function Check ..................................377

Diagnosis Procedure .............................................378

Component Inspection ...........................................379

P1564 ASCD STEERING SWITCH .................380

DTC Logic ............................................................ ..380

Diagnosis Procedure .............................................380

Component Inspection ...........................................382

P1572 ASCD BRAKE SWITCH ........................383

DTC Logic ............................................................ .383

Diagnosis Procedure .............................................384

Component Inspection (ASCD Brake Switch) .......386

Component Inspection (Stop Lamp Switch) ..........386

P1574 ASCD VEHICLE SPEED SENSOR .......388

Description ........................................................... .388

DTC Logic .............................................................388

Diagnosis Procedure .............................................388

P159F ACTIVE GRILLE SHUTTER .................390

DTC Logic .............................................................390

Diagnosis Procedure .............................................391

P1715 INPUT SPEED SENSOR .......................392

Description ........................................................... .392

DTC Logic .............................................................392

Diagnosis Procedure .............................................392

P1720 VSS ........................................................394

Description ........................................................... .394

DTC Logic .............................................................394

Diagnosis Procedure .............................................394

P1805 BRAKE SWITCH ................................. ..396

DTC Logic ............................................................ .396

Diagnosis Procedure .............................................396

Component Inspection ..........................................397

P2096, P2097 A/F SENSOR 1 .........................398

DTC Logic ............................................................ .398

Diagnosis Procedure .............................................398

P2100, P2103 THROTTLE CONTROL MO-

TOR RELAY .....................................................

402

DTC Logic ............................................................ .402

Diagnosis Procedure .............................................402

P2101 ELECTRIC THROTTLE CONTROL

FUNCTION ........................................................

405

DTC Logic ............................................................ .405

Diagnosis Procedure .............................................405

Component Inspection ..........................................408

P2118 THROTTLE CONTROL MOTOR ..........409

DTC Logic ............................................................ .409

Diagnosis Procedure .............................................409

Component Inspection ..........................................410

P2119 ELECTRIC THROTTLE CONTROL

ACTUATOR ......................................................

411

DTC Logic ............................................................ .411

Diagnosis Procedure .............................................411

P2122, P2123 APP SENSOR ...........................413

DTC Logic ............................................................ .413

Diagnosis Procedure .............................................413

Component Inspection ..........................................414

P2127, P2128 APP SENSOR ...........................416

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1134 of 3641

EC-7

C

DE

F

G H

I

J

K L

M

EC A

N

O P

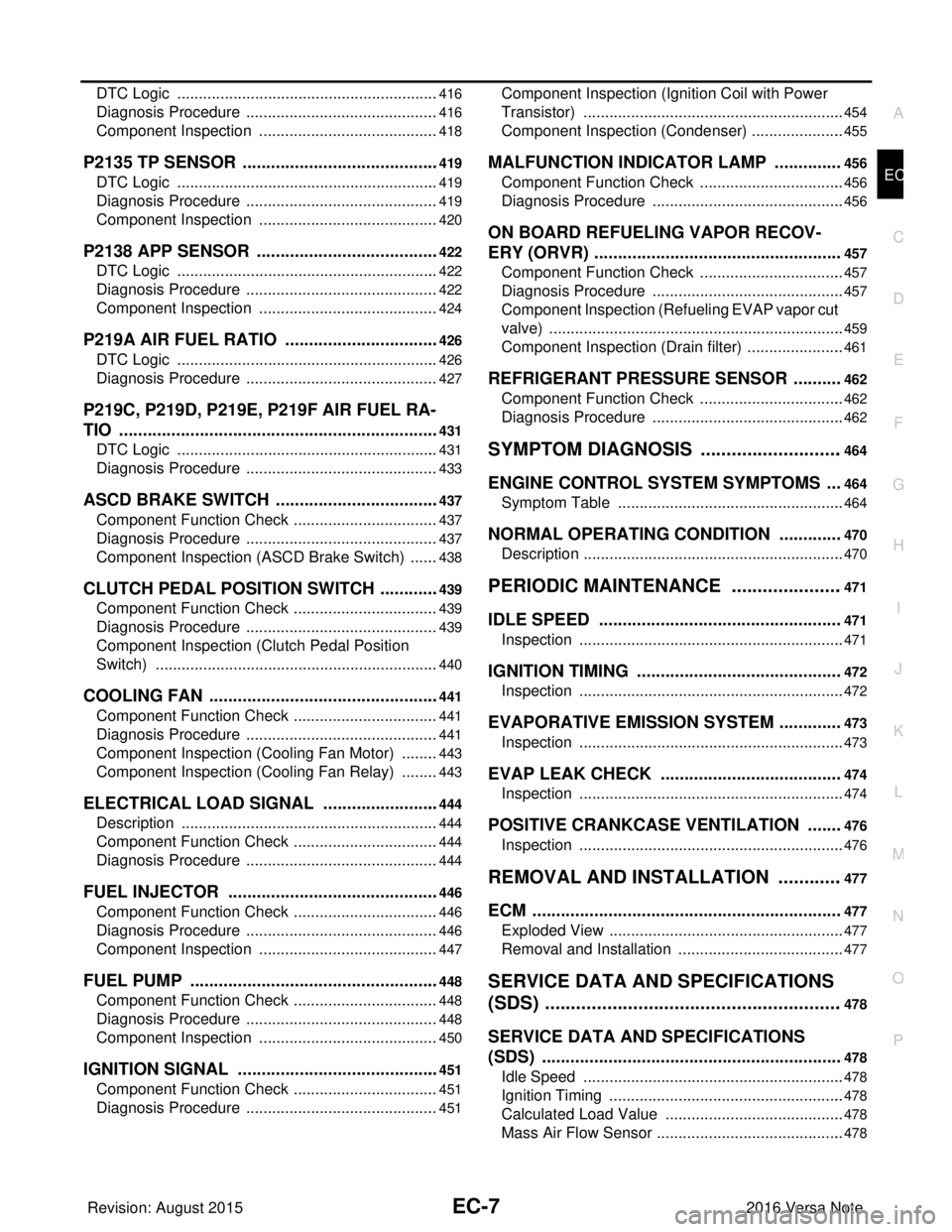

DTC Logic ...........................................................

..

416

Diagnosis Procedure .............................................416

Component Inspection ..........................................418

P2135 TP SENSOR ..........................................419

DTC Logic ........................................................... ..419

Diagnosis Procedure .............................................419

Component Inspection ..........................................420

P2138 APP SENSOR .......................................422

DTC Logic .............................................................422

Diagnosis Procedure .............................................422

Component Inspection ..........................................424

P219A AIR FUEL RATIO .................................426

DTC Logic ........................................................... ..426

Diagnosis Procedure .............................................427

P219C, P219D, P219E, P219F AIR FUEL RA-

TIO ....................................................................

431

DTC Logic ........................................................... ..431

Diagnosis Procedure .............................................433

ASCD BRAKE SWITCH ...................................437

Component Function Check ................................ ..437

Diagnosis Procedure .............................................437

Component Inspection (ASCD Brake Switch) .......438

CLUTCH PEDAL POSITION SWITCH .............439

Component Function Check ................................ ..439

Diagnosis Procedure .............................................439

Component Inspection (Clutch Pedal Position

Switch) ..................................................................

440

COOLING FAN .................................................441

Component Function Check ................................ ..441

Diagnosis Procedure .............................................441

Component Inspection (Cooling Fan Motor) .........443

Component Inspection (Cooling Fan Relay) .........443

ELECTRICAL LOAD SIGNAL .........................444

Description .......................................................... ..444

Component Function Check ..................................444

Diagnosis Procedure .............................................444

FUEL INJECTOR .............................................446

Component Function Check ................................ ..446

Diagnosis Procedure .............................................446

Component Inspection ..........................................447

FUEL PUMP .....................................................448

Component Function Check ................................ ..448

Diagnosis Procedure .............................................448

Component Inspection ..........................................450

IGNITION SIGNAL ...........................................451

Component Function Check ................................ ..451

Diagnosis Procedure .............................................451

Component Inspection (Ignition Coil with Power

Transistor) ........................................................... ..

454

Component Inspection (Condenser) ......................455

MALFUNCTION INDICATOR LAMP ..............456

Component Function Check ..................................456

Diagnosis Procedure .............................................456

ON BOARD REFUELING VAPOR RECOV-

ERY (ORVR) ....................................................

457

Component Function Check ..................................457

Diagnosis Procedure .............................................457

Component Inspection (Refueling EVAP vapor cut

valve) ................................................................... ..

459

Component Inspection (Drain filter) .......................461

REFRIGERANT PRESSURE SENSOR ..........462

Component Function Check ..................................462

Diagnosis Procedure .............................................462

SYMPTOM DIAGNOSIS ............................464

ENGINE CONTROL SYSTEM SYMPTOMS ...464

Symptom Table ................................................... ..464

NORMAL OPERATING CONDITION .............470

Description .............................................................470

PERIODIC MAINTENANCE ......................471

IDLE SPEED .... ...............................................471

Inspection ............................................................ ..471

IGNITION TIMING ...........................................472

Inspection ..............................................................472

EVAPORATIVE EMISSION SYSTEM .............473

Inspection ..............................................................473

EVAP LEAK CHECK ......................................474

Inspection ..............................................................474

POSITIVE CRANKCASE VENTILATION .......476

Inspection ..............................................................476

REMOVAL AND INSTALLATION .............477

ECM .................................................................477

Exploded View ..................................................... ..477

Removal and Installation .......................................477

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .......................................... .

478

SERVICE DATA AND SPECIFICATIONS

(SDS) ...............................................................

478

Idle Speed ........................................................... ..478

Ignition Timing .......................................................478

Calculated Load Value ..........................................478

Mass Air Flow Sensor ............................................478

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1135 of 3641

![NISSAN NOTE 2016 Service Repair Manual EC-8

< PRECAUTION >[HR16DE]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012431263

The Supplemental Res NISSAN NOTE 2016 Service Repair Manual EC-8

< PRECAUTION >[HR16DE]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012431263

The Supplemental Res](/img/5/57363/w960_57363-1134.png)

EC-8

< PRECAUTION >[HR16DE]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012431263

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

On Board Diagnosti c (OBD) System of Engine and CVTINFOID:0000000012431265

The ECM has an on board diagnostic system. It will light up the malfunction indicator lamp (MIL) to warn the

driver of a malfunction causing emission deterioration.

CAUTION:

• Be sure to turn the ignition switch OFF and disconnect the negative battery cable before any repair

or inspection work. The open/short circuit of re lated switches, sensors, solenoid valves, etc. will

cause the MIL to light up.

• Be sure to connect and lock the connectors secure ly after work. A loose (unlocked) connector will

cause the MIL to light up due to the open circuit. (Be sure the connector is free from water, grease,

dirt, bent terminals, etc.)

• Certain systems and components, especially those related to OBD, may use a new style slide-lock- ing type harness connector. For descripti on and how to disconnect, refer to PG-9, "

Harness Connec-

tor".

• Be sure to route and secure the harnesses properly after work. The interference of the harness with

a bracket, etc. may cause the MIL to li ght up due to the short circuit.

• Be sure to connect rubber tubes properly afte r work. A misconnected or disconnected rubber tube

may cause the MIL to light up due to the malfunction of the fuel injection system, etc.

• Be sure to erase the unnecessary malfunction info rmation (repairs completed) from the ECM and

TCM (Transmission control module) before returning the vehicle to the customer.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1136 of 3641

![NISSAN NOTE 2016 Service Repair Manual PRECAUTIONSEC-9

< PRECAUTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

General PrecautionsINFOID:0000000012431266

•

Always use a 12 volt battery as power source.

• Do not attempt to disconnect ba NISSAN NOTE 2016 Service Repair Manual PRECAUTIONSEC-9

< PRECAUTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

General PrecautionsINFOID:0000000012431266

•

Always use a 12 volt battery as power source.

• Do not attempt to disconnect ba](/img/5/57363/w960_57363-1135.png)

PRECAUTIONSEC-9

< PRECAUTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

General PrecautionsINFOID:0000000012431266

•

Always use a 12 volt battery as power source.

• Do not attempt to disconnect battery cables while engine is

running.

• Before connecting or disc onnecting the ECM harness con-

nector, turn ignition switch OFF and disconnect negative bat-

tery cable. Failure to do so may damage the ECM because

battery voltage is applied to ECM even if ignition switch is

turned OFF.

• Before removing parts, turn ig nition switch OFF and then dis-

connect battery ground cable.

• Do not disassemble ECM.

• If a battery cable is disconnected, the memory will return to

the ECM value.

The ECM will now start to self-c ontrol at its initial value. So,

engine operation can vary slight ly in this case. However, this

is not an indication of a malf unction. Do not replace parts

because of a slight variation.

• If the battery is disconnected, the following emission-related

diagnostic information will be lost within 24 hours.

- Diagnostic trouble codes

- 1st trip diagnostic trouble codes

- Freeze frame data

- 1st trip freeze frame data

- System readiness test (SRT) codes

- Test values

• When connecting or disconnecting pin connectors into or

from ECM, take care not to damage pin terminals (bend or

break).

Make sure that there are not any bends or breaks on ECM pin

terminal, when connecting pin connectors.

• Securely connect ECM harness connectors.

A poor connection can cause an extremely high (surge) volt-

age to develop in coil and cond enser, thus resulting in dam-

age to ICs.

• Keep engine control system harness at least 10 cm (4 in) away

from adjacent harness, to prevent engine control system mal-

functions due to receiving externa l noise, degraded operation

of ICs, etc.

• Keep engine control system parts and harness dry.

• Before replacing ECM, perform ECM Terminals and Reference

Value inspection and make sure ECM functions properly.

Refer to EC-71, "

Reference Value".

• Handle mass air flow sensor carefully to avoid damage.

• Do not clean mass air flow senso r with any type of detergent.

• Do not disassemble electric th rottle control actuator.

• Even a slight leak in the air intake system can cause serious

incidents.

• Do not shock or jar the camsh aft position sensor (PHASE),

crankshaft position sensor (POS).

SEF289H

PBIA9222J

PBIB0090E

MEF040D

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1137 of 3641

![NISSAN NOTE 2016 Service Repair Manual EC-10

< PRECAUTION >[HR16DE]

PRECAUTIONS

•

After performing each TROUBLE DIAGNOSIS, perform DTC

CONFIRMATION PROCEDURE or Component Function

Check. The DTC should not be displayed in the DTC Confir NISSAN NOTE 2016 Service Repair Manual EC-10

< PRECAUTION >[HR16DE]

PRECAUTIONS

•

After performing each TROUBLE DIAGNOSIS, perform DTC

CONFIRMATION PROCEDURE or Component Function

Check. The DTC should not be displayed in the DTC Confir](/img/5/57363/w960_57363-1136.png)

EC-10

< PRECAUTION >[HR16DE]

PRECAUTIONS

•

After performing each TROUBLE DIAGNOSIS, perform DTC

CONFIRMATION PROCEDURE or Component Function

Check. The DTC should not be displayed in the DTC Confir-

mation Procedure if the repair is completed. The Component

Function Check should be a good result if the repair is com-

pleted.

• When measuring ECM signals with a circuit tester, never allow

the two tester probes to contact.

Accidental contact of probes will cause a short circuit and

damage the ECM power transistor.

• Do not operate fuel pump when there is no fuel in lines.

• Tighten fuel hose clamps to the specified torque.

• Do not depress accelerator pedal when starting.

• Immediately after starting, do not rev up engine unnecessar-

ily.

• Do not rev up engine just prior to shutdown.

SAT652J

SEF348N

SEF709Y

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1140 of 3641

![NISSAN NOTE 2016 Service Repair Manual PREPARATIONEC-13

< PREPARATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Tool name

(TechMate No.)

Description

Leak detector

i.e.: (J-41416) Locates the EVAP leak

EVAP service port adapter

i.e.: (J-41 NISSAN NOTE 2016 Service Repair Manual PREPARATIONEC-13

< PREPARATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Tool name

(TechMate No.)

Description

Leak detector

i.e.: (J-41416) Locates the EVAP leak

EVAP service port adapter

i.e.: (J-41](/img/5/57363/w960_57363-1139.png)

PREPARATIONEC-13

< PREPARATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Tool name

(TechMate No.)

Description

Leak detector

i.e.: (J-41416) Locates the EVAP leak

EVAP service port adapter

i.e.: (J-41413-OBD) Applies positive pressure through EVAP service port

Fuel filler cap adapter

i.e.: (J-42909) Checks fuel tank vacuum relief valve opening pressure

Socket wrench

(—) Removes and installs engine coolant temperature sen-

sor

Oxygen sensor thread cleaner

i.e.: (J-43897-18), (J-43897-12) Reconditioning the exhaust system threads before in-

stalling a new oxygen sensor. Use with anti-seize lubri-

cant shown below.

a: 18 mm diameter with pitch 1.5 mm for Zirconia Ox-

ygen Sensor

b: 12 mm diameter with pitch 1.25 mm for Titania Ox-

ygen Sensor

Anti-seize lubricant

i.e.: (Permatex

TM 133AR or

equivalent meeting MIL specifica-

tion MIL-A-907) Lubricating oxygen sensor thread cleaning tool when re-

conditioning exhaust system threads.

S-NT703

S-NT704

ALBIA1353ZZ

S-NT705

AEM488

S-NT779

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 1141 of 3641

![NISSAN NOTE 2016 Service Repair Manual EC-14

< SYSTEM DESCRIPTION >[HR16DE]

COMPONENT PARTS

SYSTEM DESCRIPTION

COMPONENT PARTS

ENGINE CONTROL SYSTEM

ENGINE CONTROL SYSTEM : Component Parts LocationINFOID:0000000012431269

1. Battery current NISSAN NOTE 2016 Service Repair Manual EC-14

< SYSTEM DESCRIPTION >[HR16DE]

COMPONENT PARTS

SYSTEM DESCRIPTION

COMPONENT PARTS

ENGINE CONTROL SYSTEM

ENGINE CONTROL SYSTEM : Component Parts LocationINFOID:0000000012431269

1. Battery current](/img/5/57363/w960_57363-1140.png)

EC-14

< SYSTEM DESCRIPTION >[HR16DE]

COMPONENT PARTS

SYSTEM DESCRIPTION

COMPONENT PARTS

ENGINE CONTROL SYSTEM

ENGINE CONTROL SYSTEM : Component Parts LocationINFOID:0000000012431269

1. Battery current sensor

2. ECM3. IPDM E/R

Refer to PCS-4, "

Component Parts

Location"

4. Mass air flow sensor (with intake air temperature sensor) 5. Electric throttle control actuator

(with built in throttle position sensor

and throttle control motor) 6. EVAP canister purge volume control

solenoid valve

7. Cooling fan motor 8. Refrigerant pressure sensor

Refer to HA-12, "

Component Parts

Location"

ALBIA1071ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com