clock NISSAN NOTE 2016 Service Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 1099 of 3641

![NISSAN NOTE 2016 Service Owners Manual EM-98

< UNIT DISASSEMBLY AND ASSEMBLY >[HR16DE]

CYLINDER BLOCK

• Install the main bearing cap while referring to the front mark

(B) and the journal number stamp (A).

NOTE:

Main bearing cap cannot be NISSAN NOTE 2016 Service Owners Manual EM-98

< UNIT DISASSEMBLY AND ASSEMBLY >[HR16DE]

CYLINDER BLOCK

• Install the main bearing cap while referring to the front mark

(B) and the journal number stamp (A).

NOTE:

Main bearing cap cannot be](/img/5/57363/w960_57363-1098.png)

EM-98

< UNIT DISASSEMBLY AND ASSEMBLY >[HR16DE]

CYLINDER BLOCK

• Install the main bearing cap while referring to the front mark

(B) and the journal number stamp (A).

NOTE:

Main bearing cap cannot be replaced as a single part,

because it is machined together with cylinder block.

8. Tighten main bearing cap bolts in numerical order as shown with the following steps:

a. Apply new engine oil to threads and seat surfaces of the bolts.

b. Tighten main bearing cap bolts in numerical order.

c. Turn main bearing cap bolts 60 degrees clockwise (angle tight- ening) in numerical order as shown.

CAUTION:

Check and confirm the tightening angle by using the Tool

(A) or protractor. Do not judge by visual inspection without

the Tool (A).

• After installing the main bearing cap bolts, check that crankshaft can be rotated smoothly by hand.

• Check crankshaft end play. Refer to EM-102, "

Inspection".

9. Install piston to connecting rod with the following procedure:

a. Using a heat gun, heat the piston until the pist on pin can be pushed in by hand without excess force

[approximately 60 to 70 °C (140 to 158 °F)]. From the front to the rear, insert piston pin into piston and con-

necting rod.

b. Set so that the front mark (A) on the piston head and the cylin- der number (C) are in the position as shown.

NOTE:

The symbols without notes are for manufacturing.

CAUTION:

Press-fit the piston so as not to damage it.

NOTE:

The joint between the connecting rod and the piston pin is a

press fit.

: Engine front

JPBIA4204ZZ

: Engine front

Step 1 : 32.4 N·m (3.3 kg-m, 24 ft-lb)

Step 2 : 60° clockwise

JPBIA4203ZZ

Tool number (A) : KV10112100 (BT-8653-A)

PBIC3750E

(B) : Oil hole

(D) : Connecting rod big end grade

PBIC3766E

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1101 of 3641

![NISSAN NOTE 2016 Service Owners Manual EM-100

< UNIT DISASSEMBLY AND ASSEMBLY >[HR16DE]

CYLINDER BLOCK

12. Install piston and connecting rod assembly to crankshaft.

• Position crankshaft pin corresponding to connecting rod to be install NISSAN NOTE 2016 Service Owners Manual EM-100

< UNIT DISASSEMBLY AND ASSEMBLY >[HR16DE]

CYLINDER BLOCK

12. Install piston and connecting rod assembly to crankshaft.

• Position crankshaft pin corresponding to connecting rod to be install](/img/5/57363/w960_57363-1100.png)

EM-100

< UNIT DISASSEMBLY AND ASSEMBLY >[HR16DE]

CYLINDER BLOCK

12. Install piston and connecting rod assembly to crankshaft.

• Position crankshaft pin corresponding to connecting rod to be installed onto the bottom dead center.

• Apply new engine oil sufficiently to the cylinder bore, piston and crankshaft pin.

• Match the cylinder position with the cyli nder number on connecting rod to install.

• Using Tool (A) or suitable tool, install piston with the front mark on the piston head facing the front of the engine.

CAUTION:

• Do not damage mating surface with connecting rod cap.

• Do not damage the cylinder wall or crankshaft pin.

13. Install connecting rod cap. • Match the stamped cylinder number marks (C) on connectingrod with those on connecting rod cap to install.

14. Inspect outer diameter of connecting rod bolts. Refer to EM-102, "

Inspection".

15. Tighten connecting rod bolt:

a. Apply new engine oil to the threads and seats of connecting rod bolts.

b. Install connecting rod bolts in several steps.

c. Then turn all connecting rod bolts 60 degrees clockwise (angle tightening). CAUTION:

Check and confirm the tight ening angle by using the Tool (A) or protractor. Avoid judgement by

visual inspection without the Tool (A).

• After tightening connecting rod bolt, che ck that crankshaft rotates smoothly.

• Check the connecting rod side clearance. Refer to EM-102, "

Inspection".

16. Install oil pan (upper). Refer to EM-37, "

Removal and Installation (Upper Oil Pan)".

NOTE: Tool number (A) : EM03470000 (J-8037)

PBIC3765E

(A) : Front mark

(B) : Oil hole

(D) : Connecting rod big end grade

PBIC3766E

Step 1 Tighten to

: 27.4 N·m (2.8 kg-m, 20 ft-lb)

Step 2 Completely loosen : 0 N·m (0 kg-m, 0 ft-lb)

Step 3 Tighten to : 19.6 N·m (2.0 kg-m, 14 ft-lb)

Tool number (A) : KV10112100 (BT-8653-A)

PBIC3753E

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1185 of 3641

![NISSAN NOTE 2016 Service Owners Manual EC-58

< SYSTEM DESCRIPTION >[HR16DE]

DIAGNOSIS SYSTEM (ECM)

• ECM blinks MIL for about 10 seconds if all SRT codes are not set.

MALFUNCTION WARNING MODE

Description

In this function ECM turns on or NISSAN NOTE 2016 Service Owners Manual EC-58

< SYSTEM DESCRIPTION >[HR16DE]

DIAGNOSIS SYSTEM (ECM)

• ECM blinks MIL for about 10 seconds if all SRT codes are not set.

MALFUNCTION WARNING MODE

Description

In this function ECM turns on or](/img/5/57363/w960_57363-1184.png)

EC-58

< SYSTEM DESCRIPTION >[HR16DE]

DIAGNOSIS SYSTEM (ECM)

• ECM blinks MIL for about 10 seconds if all SRT codes are not set.

MALFUNCTION WARNING MODE

Description

In this function ECM turns on or blinks MIL when it detects a malfunction in the emission control system com-

ponents and/or the powertrain control components (which affe

ct vehicle emissions) to inform the driver that a

malfunction has been detected.

Operation Procedure

1. Turn ignition switch ON.

2. Check that MIL illuminates. If it remains OFF, check MIL circuit. Refer to EC-456, "

Diagnosis Procedure".

3. Start engine and let it idle. • For two trip detection logic diagnoses, ECM turns on MIL when it detects the same malfunction twice inthe two consecutive driving cycles.

• For 1st trip detection logic diagnoses, ECM turns on MIL when it detects a malfunction in one driving cycle.

• ECM blinks MIL when it detects a malfunction t hat may damage the three way catalyst (misfire).

SELF-DIAGNOSTIC RESULTS MODE

Description

This function allows to indicate DTCs or 1st trip DT Cs stored in ECM according to the number of times MIL is

blinking.

How to Set Self-diagnostic Results Mode

NOTE:

• It is better to count the time accurately with a clock.

• It is impossible to switch the diagnostic mode when an accelerator pedal position sensor circuit has a mal-

function.

• After ignition switch is turned off, ECM is always released from the “self-diagnostic results” mode.

1. Confirm that accelerator pedal is fully releas ed, turn ignition switch ON and wait 3 seconds.

2. Repeat the following procedure quickly five times within 5 seconds. • Fully depress the accelerator pedal.

• Fully release the accelerator pedal.

3. Wait 7 seconds, fully depress the accelerator pedal and keep it depressed for approx. 10 seconds until the MIL starts blinking.

NOTE:

Do not release the accelerator pedal for 10 seconds if MIL starts blinking during this period. This blinking

is displaying SRT status and is continued for another 10 seconds.

4. Fully release the accelerator pedal. ECM has entered to “Self-diagnostic results” mode.

JMBIA1515GB

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1257 of 3641

![NISSAN NOTE 2016 Service Owners Manual EC-130

< BASIC INSPECTION >[HR16DE]

IDLE AIR VOLUME LEARNING

IDLE AIR VOLUME LEARNING

DescriptionINFOID:0000000012431358

Idle Air Volume Learning is a function of ECM to learn the idle air volume that NISSAN NOTE 2016 Service Owners Manual EC-130

< BASIC INSPECTION >[HR16DE]

IDLE AIR VOLUME LEARNING

IDLE AIR VOLUME LEARNING

DescriptionINFOID:0000000012431358

Idle Air Volume Learning is a function of ECM to learn the idle air volume that](/img/5/57363/w960_57363-1256.png)

EC-130

< BASIC INSPECTION >[HR16DE]

IDLE AIR VOLUME LEARNING

IDLE AIR VOLUME LEARNING

DescriptionINFOID:0000000012431358

Idle Air Volume Learning is a function of ECM to learn the idle air volume that keeps each engine idle speed

within the specific range. It must be performed under any of the following conditions:

• Each time electric throttle control actuator or ECM is replaced.

• Idle speed or ignition timing is out of specification.

Refer to

EC-130, "

Work Procedure".

Work ProcedureINFOID:0000000012431359

1.PRECONDITIONING

Make sure that all of the following conditions are satisfied.

Learning will be cancelled if any of the follo wing conditions are missed for even a moment.

• Battery voltage: More than 12.9 V (At idle)

• Engine coolant temperature: 70 - 100 °C (158 - 212° F)

• Selector lever: P or N (CVT), Neutral (M/T)

• Electric load switch: OFF

(Air conditioner, headlamp, rear window defogger)

- For vehicles equipped with dayt ime light systems, perform one of the following procedures before

starting engine not to illuminate headlamps.

• Apply parking brake

• Set lighting switch to the 1st position

• Steering wheel: Neutral (Straight-ahead position) position

• Vehicle speed: Stopped

• Transmission: Warmed-up

- CVT models

• With CONSULT: Drive vehicle until “FLUID TEMP SE ” in “DATA MONITOR” mode of “TRANSMISSION” sys-

tem indicates less than 0.9 V.

• Without CONSULT: Drive vehicle for 10 minutes.

- M/T models

• Drive vehicle for 10 minutes.

Do you have CONSULT?

YES >> GO TO 2.

NO >> GO TO 3.

2.IDLE AIR VOLUME LEARNING

With CONSULT

1. Perform ACCELERATOR PEDAL RELEAS ED POSITION LEARNING. Refer to EC-128, "

Description".

2. Perform THROTTLE VALVE CLOSED POSITION LEARNING. Refer to EC-129, "

Description".

3. Start engine and warm it up to normal operating temperature.

4. Select “IDLE AIR VOL LEARN” in “WORK SUPPORT” mode with CONSULT.

5. Touch “START” and wait 20 seconds.

Is

“CMPLT” displayed on CONSULT screen?

YES >> GO TO 4.

NO >> GO TO 5.

3.IDLE AIR VOLUME LEARNING

Without CONSULT

NOTE:

• It is better to count the ti me accurately with a clock.

• It is impossible to switch the di agnostic mode when an accelerator pedal position sensor circuit has

a malfunction.

1. Perform ACCELERATOR PEDAL RELEAS ED POSITION LEARNING. Refer to EC-128, "

Description".

2. Perform THROTTLE VALVE CLOSED POSITION LEARNING. Refer to EC-129, "

Description".

3. Start engine and warm it up to normal operating temperature.

4. Turn ignition switch OFF and wait at least 10 seconds.

5. Confirm that accelerator pedal is fully releas ed, turn ignition switch ON and wait 3 seconds.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1451 of 3641

![NISSAN NOTE 2016 Service Owners Manual EC-324

< DTC/CIRCUIT DIAGNOSIS >[HR16DE]

P0456 EVAP CONTROL SYSTEM

2. Check for genuine NISSAN fuel filler cap design.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Replace with genuine NISSA NISSAN NOTE 2016 Service Owners Manual EC-324

< DTC/CIRCUIT DIAGNOSIS >[HR16DE]

P0456 EVAP CONTROL SYSTEM

2. Check for genuine NISSAN fuel filler cap design.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Replace with genuine NISSA](/img/5/57363/w960_57363-1450.png)

EC-324

< DTC/CIRCUIT DIAGNOSIS >[HR16DE]

P0456 EVAP CONTROL SYSTEM

2. Check for genuine NISSAN fuel filler cap design.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Replace with genuine NISSAN fuel filler cap.

2.CHECK FUEL FILLER CAP INSTALLATION

Check that the cap is tightened proper ly by rotating the cap clockwise.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Open fuel filler cap, then clean cap and fuel filler neck threads using air blower. Then retighten until reteaching sound is heard.

3.CHECK FUEL FILLER CAP FUNCTION

Check for air releasing sound while opening the fuel filler cap.

Is the inspection result normal?

YES >> GO TO 5.

NO >> GO TO 4.

4.CHECK FUEL TANK VACUUM RELIEF VALVE

Refer to EC-327, "

Component Inspection".

Is the inspection result normal?

YES >> GO TO 5.

NO >> Replace fuel filler cap with a genuine one.

5.CHECK FOR EVAP LEAK

Refer to EC-474, "

Inspection".

Is there any leak in EVAP line?

YES >> Repair or replace.

NO >> GO TO 6.

6.CHECK EVAP CANISTER VENT CONTROL VALVE

Check the following.

• EVAP canister vent control valve is installed properly. Refer to FL-17, "

Exploded View".

• EVAP canister vent control valve. Refer to EC-304, "

Component Inspection".

Is the inspection result normal?

YES >> GO TO 7.

NO >> Repair or replace EVAP canister vent control valve and O-ring. Refer to FL-17, "

Removal and

Installation".

7.CHECK IF EVAP CANISTER SATURATED WITH WATER

SEF915U

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1755 of 3641

FRONT COMBINATION LAMPEXL-103

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

Removal

1. Remove plastic cover.

2. Remove bulb from the front combination lamp.

Installation

Installation is in the reverse order of removal.

CAUTION:

After installing the bulb, install the bulb socket securely for watertightness.

SIDE MARKER LAMP BULB

Removal

1. Rotate bulb socket counterclockwise and remove.

2. Remove the bulb from bulb socket.

Installation

Installation is in the reverse order of removal.

CAUTION:

After installing the bulb, install the bulb socket securely for watertightness.

FRONT TURN SIGNAL/PARKING LAMP BULB

Removal

1. Rotate bulb socket counterclockwise and remove.

2. Remove the bulb from bulb socket.

Installation

Installation is in the reverse order of removal.

CAUTION:

After installing the bulb, install the bulb socket securely for watertightness.

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 1757 of 3641

FRONT FOG LAMPEXL-105

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

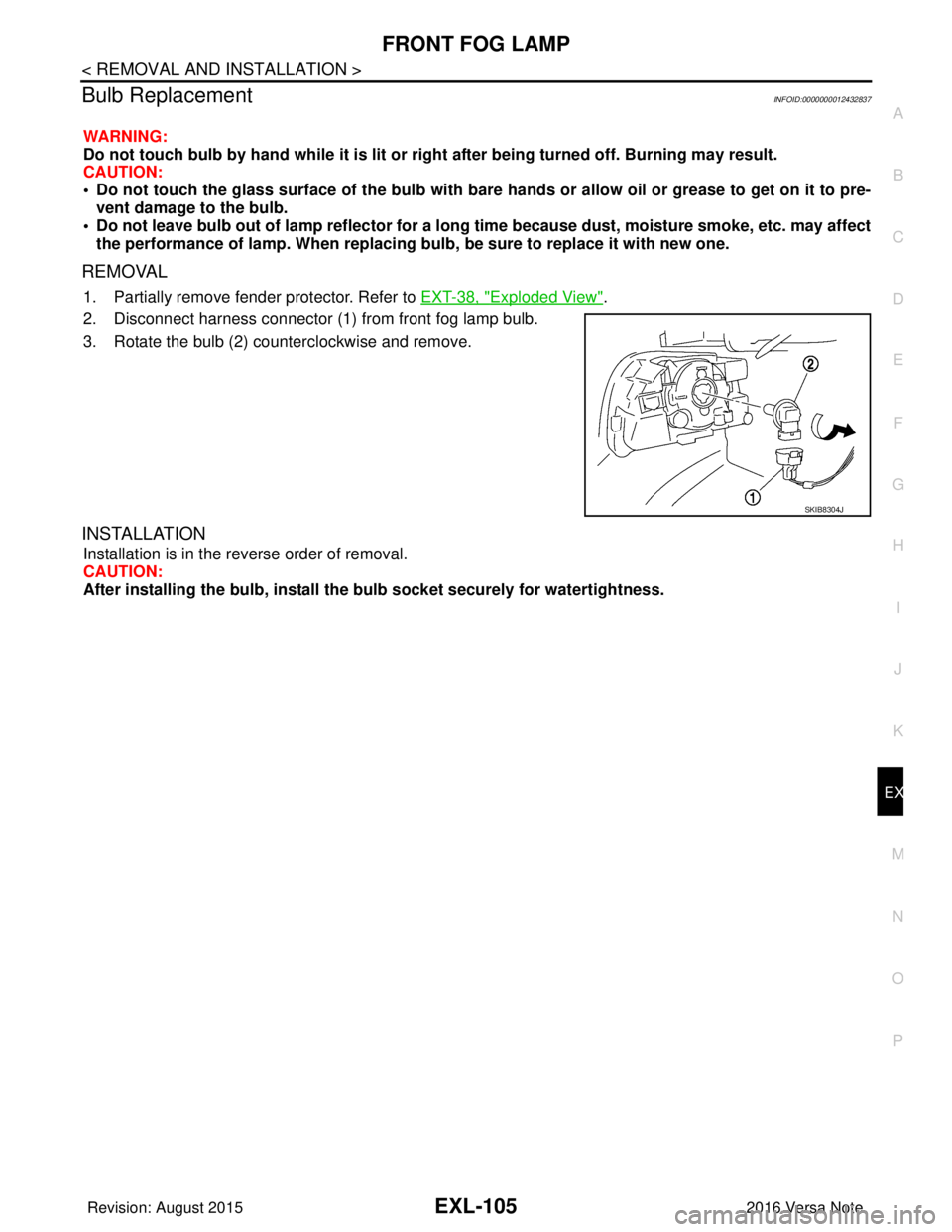

Bulb ReplacementINFOID:0000000012432837

WARNING:

Do not touch bulb by hand while it is lit or right after being turned off. Burning may result.

CAUTION:

• Do not touch the glass surface of the bulb with bare hands or allow oi l or grease to get on it to pre-

vent damage to the bulb.

• Do not leave bulb out of lamp reflector for a long time because dust, moisture smoke, etc. may affect

the performance of lamp. When replacing bulb, be sure to replace it with new one.

REMOVAL

1. Partially remove fender protector. Refer to EXT-38, "Exploded View".

2. Disconnect harness connector (1) from front fog lamp bulb.

3. Rotate the bulb (2) counterclockwise and remove.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

After installing the bulb, install the bulb socket securely for watertightness.

SKIB8304J

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1762 of 3641

EXL-110

< REMOVAL AND INSTALLATION >

REAR COMBINATION LAMP

2. Rotate stop/tail lamp bulb socket counterclockwise and remove.

3. Remove stop/tail lamp bulb from bulb socket.

Installation

Installation is in the reverse order of removal.

CAUTION:

After installing the bulb, install bulb socket securely for watertightness.

REAR TURN SIGNAL LAMP BULB

Removal

1. Remove rear combination lamp. Refer to EXL-109, "Removal and Installation".

2. Rotate rear turn signal lamp bulb socket counterclockwise and remove.

3. Remove rear turn signal lamp bulb from bulb socket.

Installation

Installation is in the reverse order of removal.

CAUTION:

After installing the bulb, install bu lb socket securely for watertightness.

BACK-UP LAMP BULB

Removal

1. Remove rear combination lamp. Refer to EXL-109, "Removal and Installation".

2. Rotate back-up lamp bulb socket counterclockwise and remove.

3. Remove back-up lamp bulb from bulb socket.

Installation

Installation is in the reverse order of removal.

CAUTION:

After installing the bulb, install bu lb socket securely for watertightness.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1764 of 3641

EXL-112

< REMOVAL AND INSTALLATION >

LICENSE PLATE LAMP

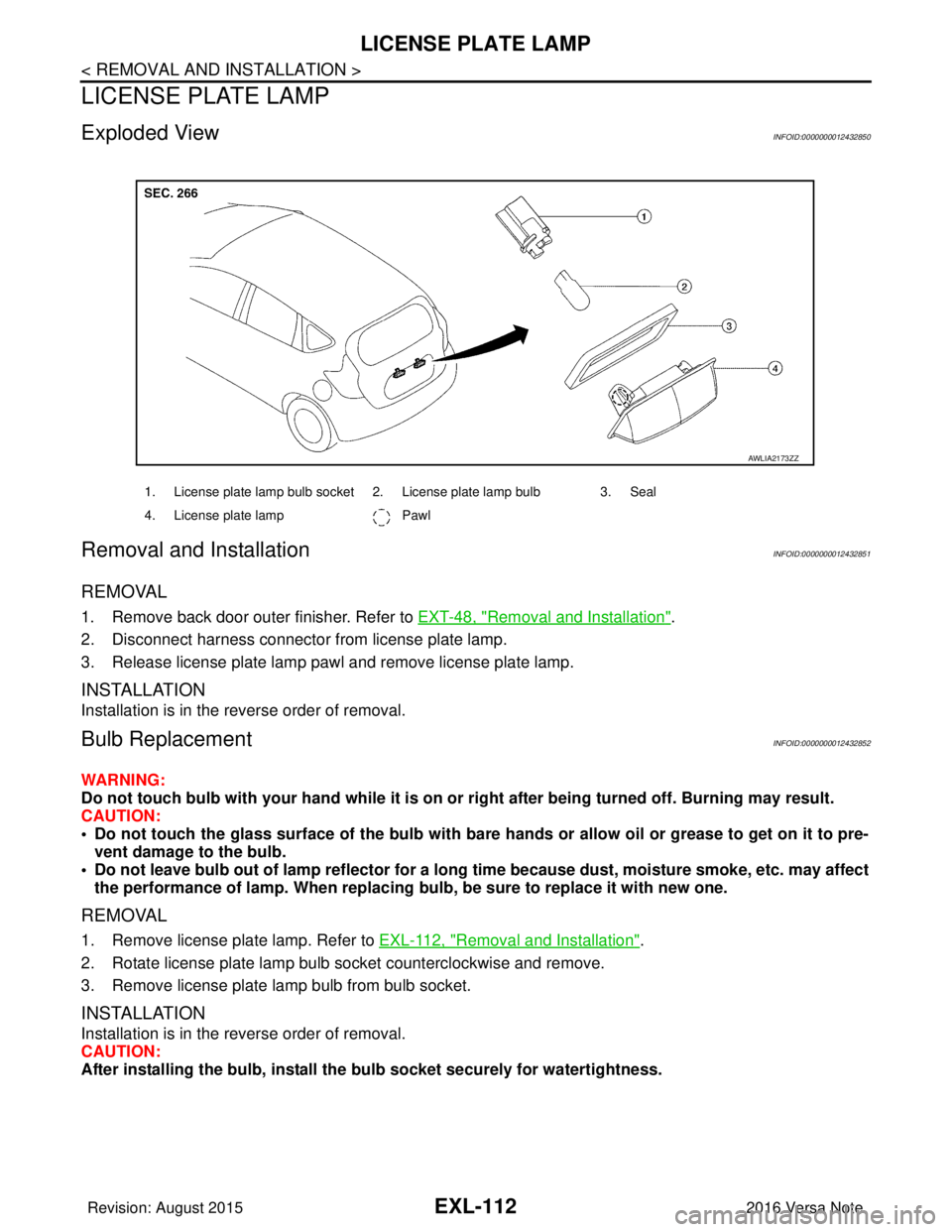

LICENSE PLATE LAMP

Exploded ViewINFOID:0000000012432850

Removal and InstallationINFOID:0000000012432851

REMOVAL

1. Remove back door outer finisher. Refer to EXT-48, "Removal and Installation".

2. Disconnect harness connector from license plate lamp.

3. Release license plate lamp pawl and remove license plate lamp.

INSTALLATION

Installation is in the reverse order of removal.

Bulb ReplacementINFOID:0000000012432852

WARNING:

Do not touch bulb with your hand while it is on or right after being turned off. Burning may result.

CAUTION:

• Do not touch the glass surface of the bulb with bare hands or allow oil or grease to get on it to pre- vent damage to the bulb.

• Do not leave bulb out of lamp reflector for a long time because dust, moisture smoke, etc. may affect

the performance of lamp. When replacing bulb, be sure to replace it with new one.

REMOVAL

1. Remove license plate lamp. Refer to EXL-112, "Removal and Installation".

2. Rotate license plate lamp bulb socket counterclockwise and remove.

3. Remove license plate lamp bulb from bulb socket.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

After installing the bulb, install the bulb socket securely for watertightness.

1. License plate lamp bulb socket 2. License plate lamp bulb 3. Seal

4. License plate lamp Pawl

AWLIA2173ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1765 of 3641

FRONT COMBINATION LAMPEXL-113

< UNIT DISASSEMBLY AND ASSEMBLY >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

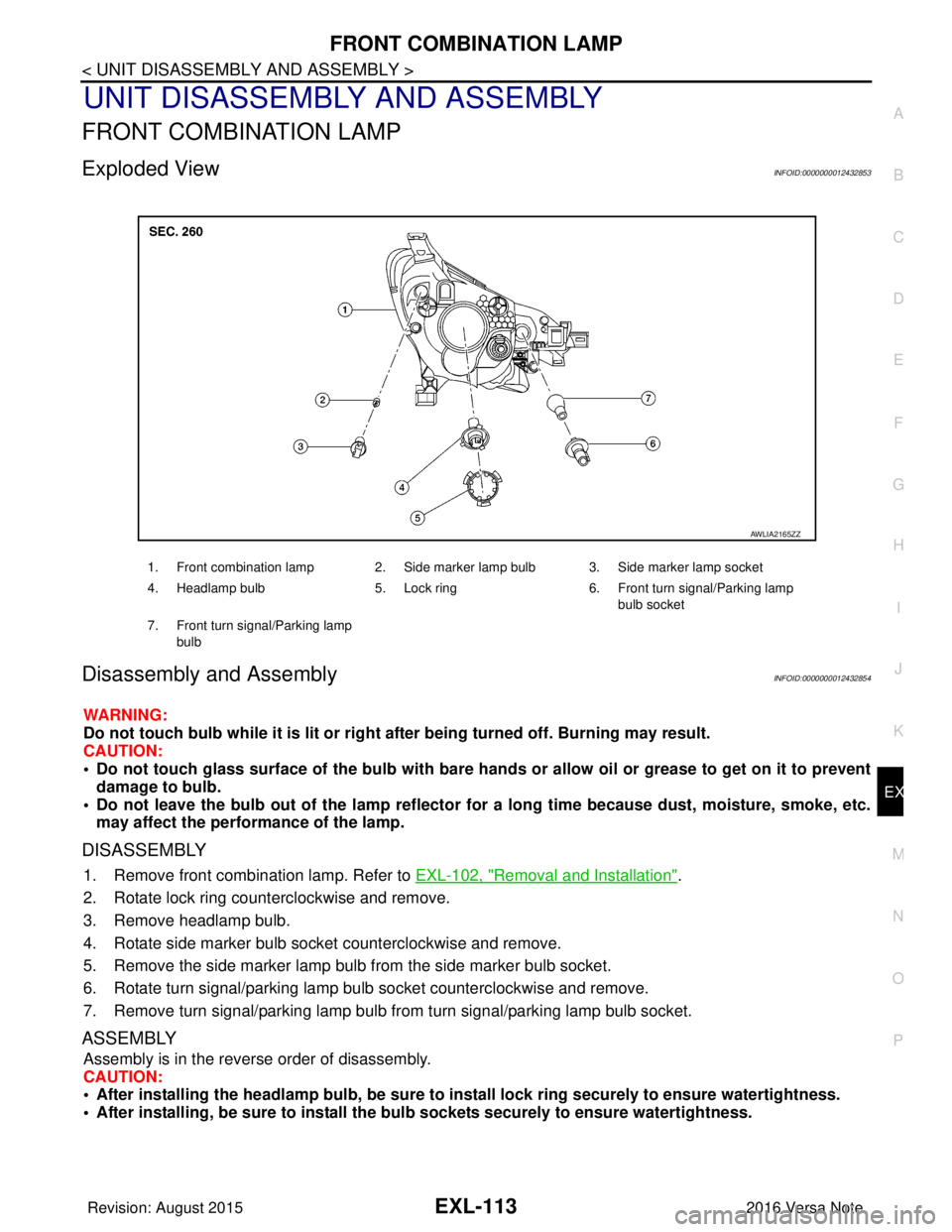

UNIT DISASSEMBLY AND ASSEMBLY

FRONT COMBINATION LAMP

Exploded ViewINFOID:0000000012432853

Disassembly and AssemblyINFOID:0000000012432854

WARNING:

Do not touch bulb while it is lit or right after being turned off. Burning may result.

CAUTION:

• Do not touch glass surface of the bulb with bare hands or allow oil or grease to get on it to prevent damage to bulb.

• Do not leave the bulb out of the lamp reflector for a long time because dust , moisture, smoke, etc.

may affect the performance of the lamp.

DISASSEMBLY

1. Remove front combination lamp. Refer to EXL-102, "Removal and Installation".

2. Rotate lock ring counterclockwise and remove.

3. Remove headlamp bulb.

4. Rotate side marker bulb socket counterclockwise and remove.

5. Remove the side marker lamp bulb from the side marker bulb socket.

6. Rotate turn signal/parking lamp bulb socket counterclockwise and remove.

7. Remove turn signal/parking lamp bulb from turn signal/parking lamp bulb socket.

ASSEMBLY

Assembly is in the reverse order of disassembly.

CAUTION:

• After installing the headlamp bulb, be sure to install lock ring securely to ensure watertightness.

• After installing, be sure to install the bulb sockets securely to ensure watertightness.

1. Front combination lamp 2. Side marker lamp bulb 3. Side marker lamp socket

4. Headlamp bulb 5. Lock ring 6. Front turn signal/Parking lamp

bulb socket

7. Front turn signal/Parking lamp bulb

AWLIA2165ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com