clock NISSAN NOTE 2016 Service Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 2076 of 3641

IP-8

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

SYMPTOM DIAGNOSIS

SQUEAK AND RATTLE TROUBLE DIAGNOSES

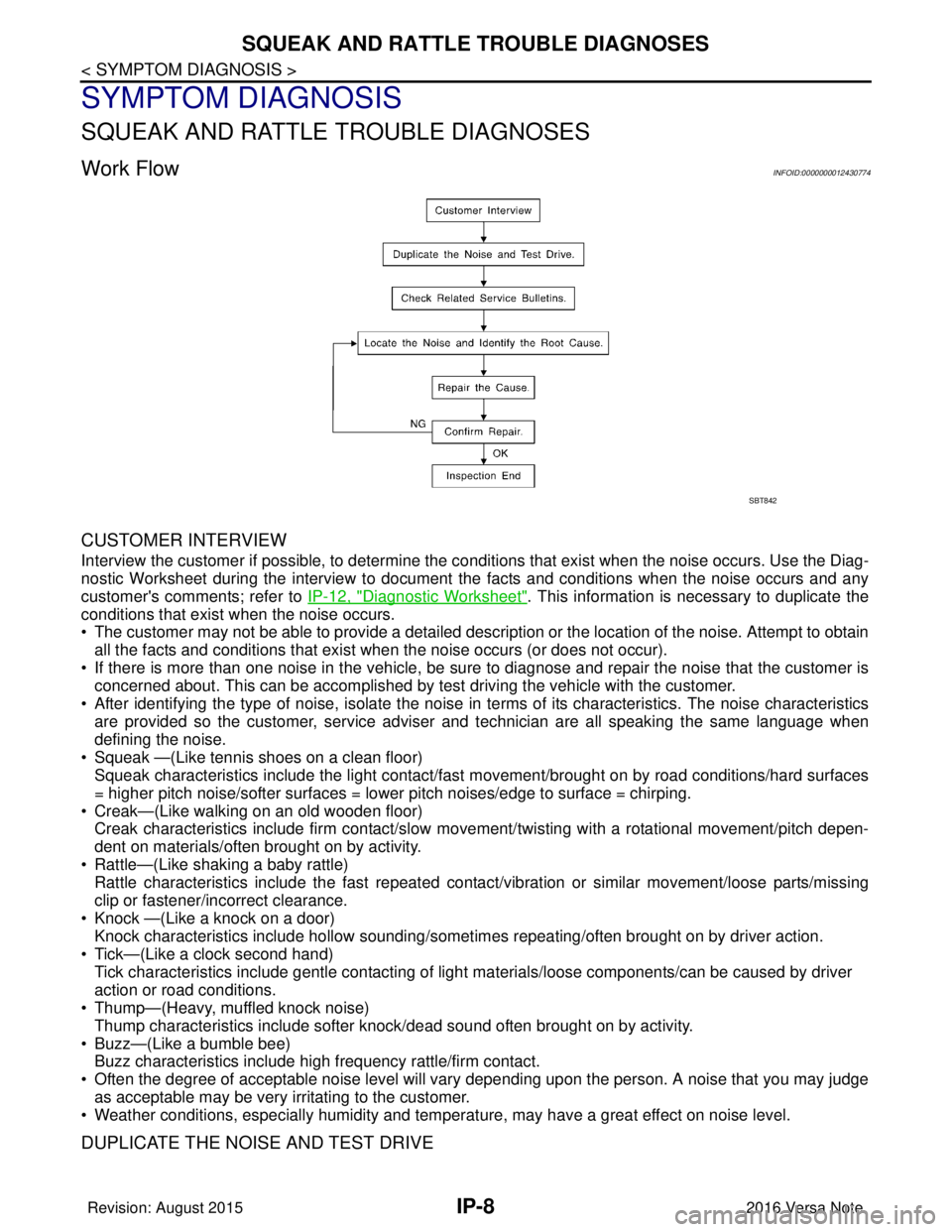

Work FlowINFOID:0000000012430774

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the conditions that exist when the noise occurs. Use the Diag-

nostic Worksheet during the interview to document the facts and conditions when the noise occurs and any

customer's comments; refer to IP-12, "

Diagnostic Worksheet". This information is necessary to duplicate the

conditions that exist when the noise occurs.

• The customer may not be able to provide a detailed description or the location of the noise. Attempt to obtain

all the facts and conditions that exist w hen the noise occurs (or does not occur).

• If there is more than one noise in the vehicle, be sure to diagnose and repair the noise that the customer is

concerned about. This can be accomplished by test driving the vehicle with the customer.

• After identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics

are provided so the customer, service adviser and technician are all speaking the same language when

defining the noise.

• Squeak —(Like tennis shoes on a clean floor) Squeak characteristics include the light contact/fast movement/brought on by road conditions/hard surfaces

= higher pitch noise/softer surfaces = lower pitch noises/edge to surface = chirping.

• Creak—(Like walking on an old wooden floor) Creak characteristics include firm contact/slow mo vement/twisting with a rotational movement/pitch depen-

dent on materials/often brought on by activity.

• Rattle—(Like shaking a baby rattle) Rattle characteristics include the fast repeated contac t/vibration or similar movement/loose parts/missing

clip or fastener/incorrect clearance.

• Knock —(Like a knock on a door) Knock characteristics include hollow sounding/someti mes repeating/often brought on by driver action.

• Tick—(Like a clock second hand) Tick characteristics include gentle contacting of light materials/loose components/can be caused by driver

action or road conditions.

• Thump—(Heavy, muffled knock noise)

Thump characteristics include softer k nock/dead sound often brought on by activity.

• Buzz—(Like a bumble bee) Buzz characteristics include hi gh frequency rattle/firm contact.

• Often the degree of acceptable noise level will vary depending upon the person. A noise that you may judge as acceptable may be very irritating to the customer.

• Weather conditions, especially humidity and temperat ure, may have a great effect on noise level.

DUPLICATE THE NOISE AND TEST DRIVE

SBT842

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2160 of 3641

SQUEAK AND RATTLE TROUBLE DIAGNOSESINT-9

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

I

K L

M A

B

INT

N

O P

SYMPTOM DIAGNOSIS

SQUEAK AND RATTLE TROUBLE DIAGNOSES

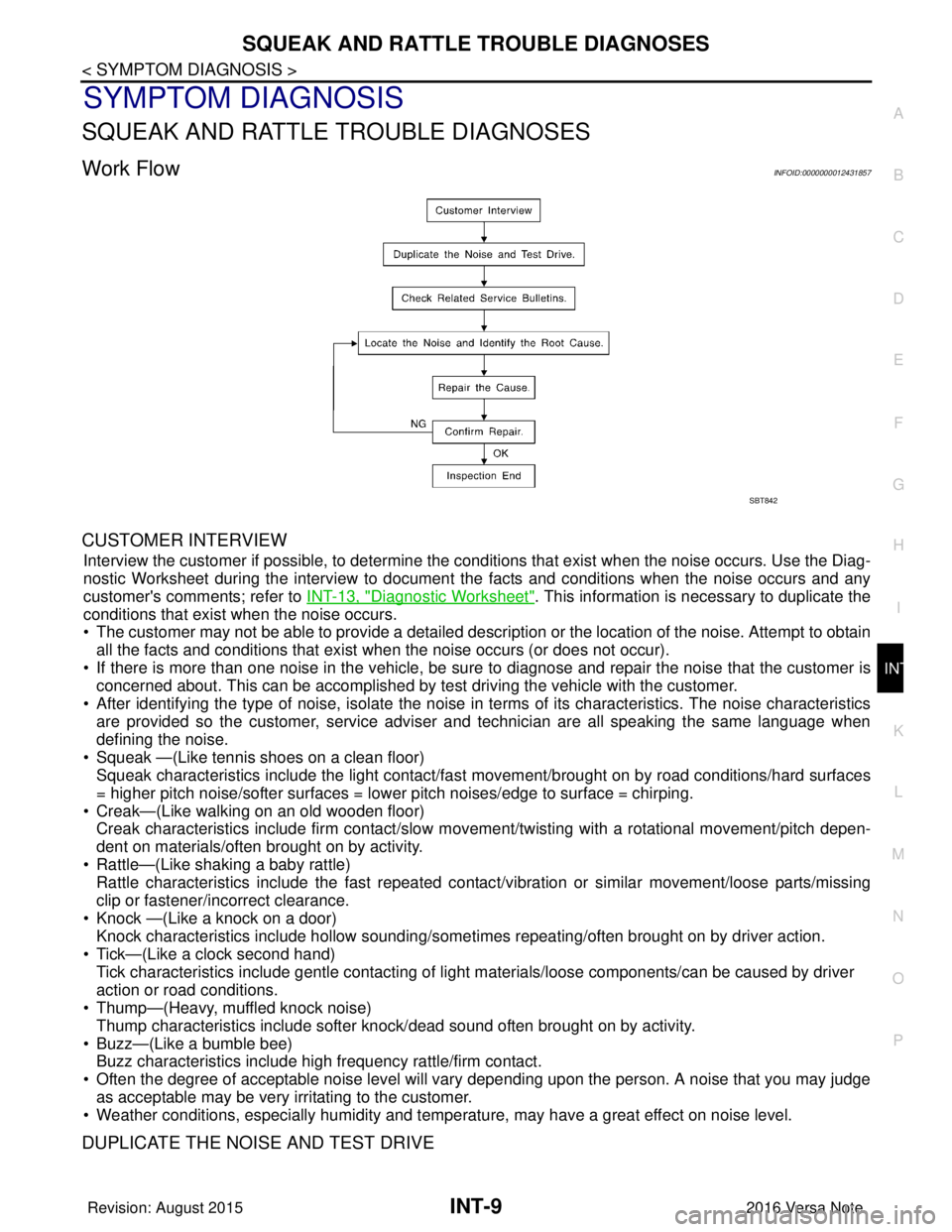

Work FlowINFOID:0000000012431857

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the conditions that exist when the noise occurs. Use the Diag-

nostic Worksheet during the interv iew to document the facts and conditions when the noise occurs and any

customer's comments; refer to INT-13, "

Diagnostic Worksheet". This information is necessary to duplicate the

conditions that exist when the noise occurs.

• The customer may not be able to provide a detailed descr iption or the location of the noise. Attempt to obtain

all the facts and conditions that exist when the noise occurs (or does not occur).

• If there is more than one noise in the vehicle, be sure to diagnose and repair the noise that the customer is

concerned about. This can be accomplished by test driving the vehicle with the customer.

• After identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics are provided so the customer, service adviser and technician are all speaking the same language when

defining the noise.

• Squeak —(Like tennis shoes on a clean floor) Squeak characteristics include the light contact/fast movement/brought on by road conditions/hard surfaces

= higher pitch noise/softer surfaces = lower pitch noises/edge to surface = chirping.

• Creak—(Like walking on an old wooden floor) Creak characteristics include firm contact/slow mo vement/twisting with a rotational movement/pitch depen-

dent on materials/often brought on by activity.

• Rattle—(Like shaking a baby rattle) Rattle characteristics include the fast repeated contac t/vibration or similar movement/loose parts/missing

clip or fastener/incorrect clearance.

• Knock —(Like a knock on a door) Knock characteristics include hollow sounding/someti mes repeating/often brought on by driver action.

• Tick—(Like a clock second hand) Tick characteristics include gentle contacting of li ght materials/loose components/can be caused by driver

action or road conditions.

• Thump—(Heavy, muffled knock noise)

Thump characteristics include softer k nock/dead sound often brought on by activity.

• Buzz—(Like a bumble bee) Buzz characteristics include high frequency rattle/firm contact.

• Often the degree of acceptable noise level will vary depending upon the person. A noise that you may judge as acceptable may be very irritating to the customer.

• Weather conditions, especially humidity and temperature, may have a great effect on noise level.

DUPLICATE THE NOISE AND TEST DRIVE

SBT842

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2329 of 3641

MA-14

< PERIODIC MAINTENANCE >

ENGINE MAINTENANCE

5. Check that belt tension is within the specification using suitable tool. Refer to EM-116, "Drive Belt".

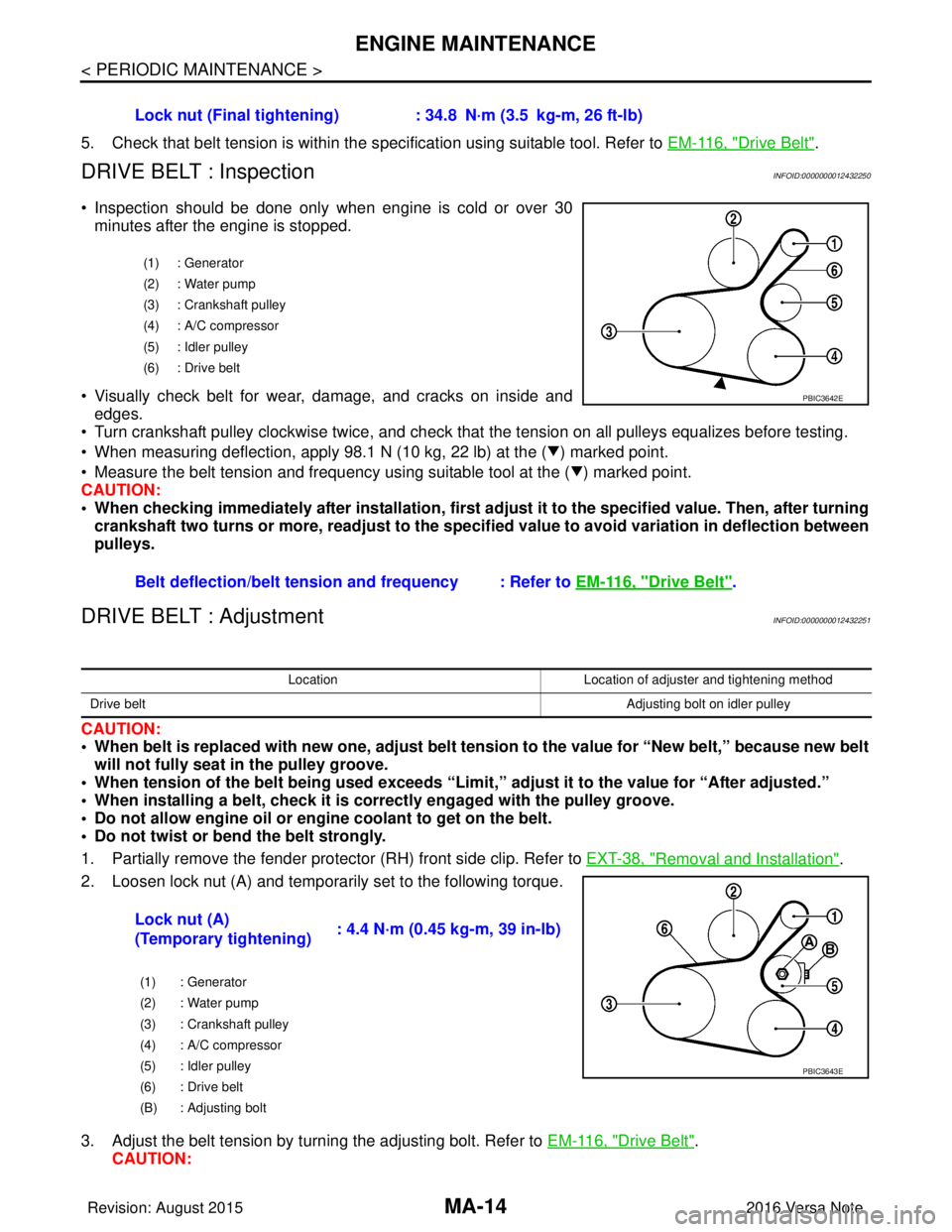

DRIVE BELT : InspectionINFOID:0000000012432250

• Inspection should be done only when engine is cold or over 30

minutes after the engine is stopped.

• Visually check belt for wear, damage, and cracks on inside and edges.

• Turn crankshaft pulley clockwise twice, and check that the tension on all pulleys equalizes before testing.

• When measuring deflection, apply 98.1 N (10 kg, 22 lb) at the ( ) marked point.

• Measure the belt tension and frequency using suitable tool at the ( ) marked point.

CAUTION:

• When checking immediately after installation, first ad just it to the specified value. Then, after turning

crankshaft two turns or more, readjust to the speci fied value to avoid variation in deflection between

pulleys.

DRIVE BELT : AdjustmentINFOID:0000000012432251

CAUTION:

• When belt is replaced with new one, adjust belt tension to the value for “New belt,” because new belt will not fully seat in the pulley groove.

• When tension of the belt being used exceeds “Limit,” adjust it to the value for “After adjusted.”

• When installing a belt, check it is co rrectly engaged with the pulley groove.

• Do not allow engine oil or engine coolant to get on the belt.

• Do not twist or bend the belt strongly.

1. Partially remove the fender protector (RH) front side clip. Refer to EXT-38, "

Removal and Installation".

2. Loosen lock nut (A) and temporarily set to the following torque.

3. Adjust the belt tension by turning the adjusting bolt. Refer to EM-116, "

Drive Belt".

CAUTION: Lock nut (Final tightening) :

34.8 N·m (3.5 kg-m, 26 ft-lb)

(1) : Generator

(2) : Water pump

(3) : Crankshaft pulley

(4) : A/C compressor

(5) : Idler pulley

(6) : Drive belt

Belt deflection/belt tension and frequency : Refer to EM-116, "Drive Belt".

PBIC3642E

LocationLocation of adjuster and tightening method

Drive belt Adjusting bolt on idler pulley

Lock nut (A)

(Temporary tightening): 4.4 N·m (0.45 kg-m, 39 in-lb)

(1) : Generator

(2) : Water pump

(3) : Crankshaft pulley

(4) : A/C compressor

(5) : Idler pulley

(6) : Drive belt

(B) : Adjusting bolt

PBIC3643E

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 2482 of 3641

MIR-8

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

SYMPTOM DIAGNOSIS

SQUEAK AND RATTLE TROUBLE DIAGNOSES

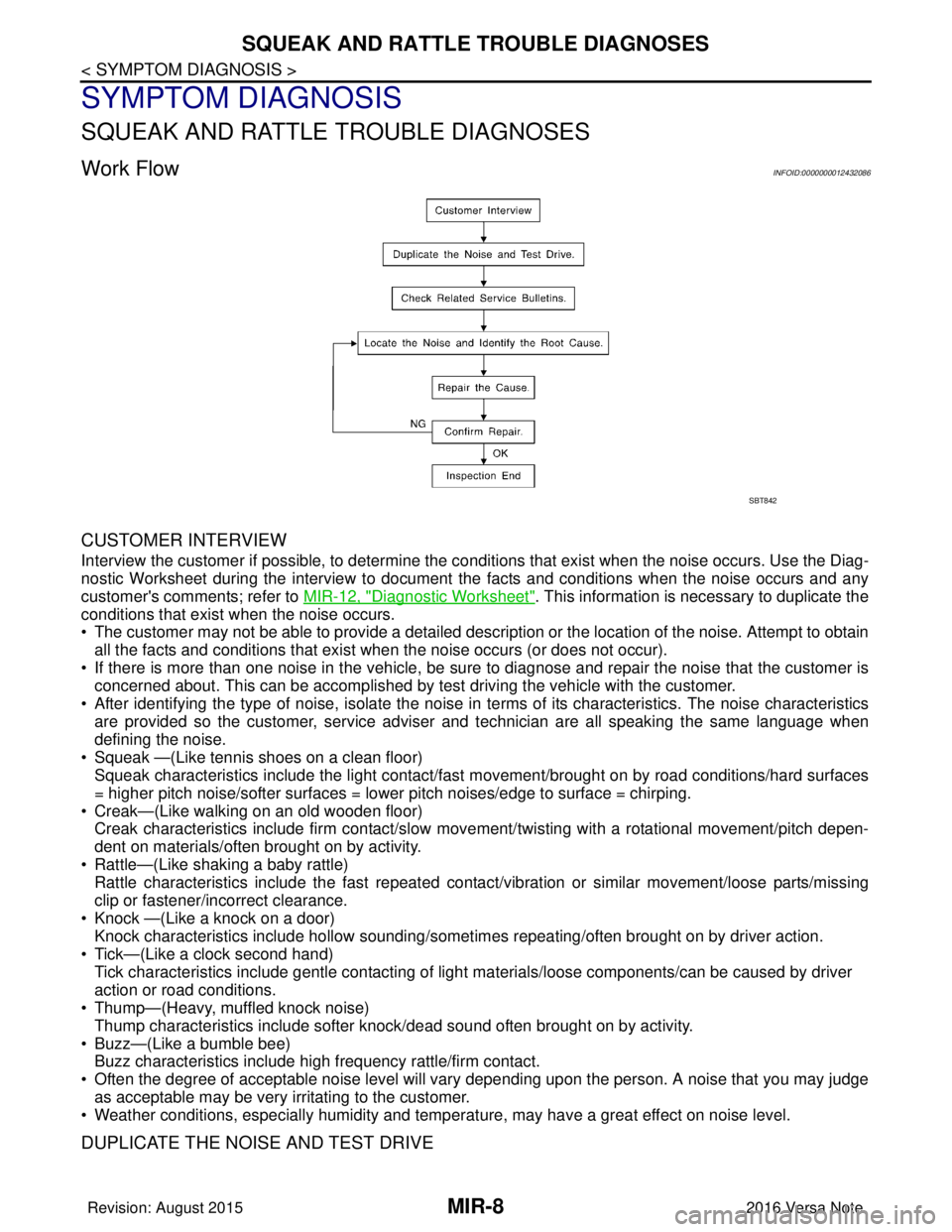

Work FlowINFOID:0000000012432086

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the conditions that exist when the noise occurs. Use the Diag-

nostic Worksheet during the interview to document the facts and conditions when the noise occurs and any

customer's comments; refer to MIR-12, "

Diagnostic Worksheet". This information is necessary to duplicate the

conditions that exist when the noise occurs.

• The customer may not be able to provide a detailed description or the location of the noise. Attempt to obtain

all the facts and conditions that exist w hen the noise occurs (or does not occur).

• If there is more than one noise in the vehicle, be sure to diagnose and repair the noise that the customer is

concerned about. This can be accomplished by test driving the vehicle with the customer.

• After identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics

are provided so the customer, service adviser and technician are all speaking the same language when

defining the noise.

• Squeak —(Like tennis shoes on a clean floor) Squeak characteristics include the light contact/fast movement/brought on by road conditions/hard surfaces

= higher pitch noise/softer surfaces = lower pitch noises/edge to surface = chirping.

• Creak—(Like walking on an old wooden floor) Creak characteristics include firm contact/slow mo vement/twisting with a rotational movement/pitch depen-

dent on materials/often brought on by activity.

• Rattle—(Like shaking a baby rattle) Rattle characteristics include the fast repeated contac t/vibration or similar movement/loose parts/missing

clip or fastener/incorrect clearance.

• Knock —(Like a knock on a door) Knock characteristics include hollow sounding/someti mes repeating/often brought on by driver action.

• Tick—(Like a clock second hand) Tick characteristics include gentle contacting of light materials/loose components/can be caused by driver

action or road conditions.

• Thump—(Heavy, muffled knock noise)

Thump characteristics include softer k nock/dead sound often brought on by activity.

• Buzz—(Like a bumble bee) Buzz characteristics include hi gh frequency rattle/firm contact.

• Often the degree of acceptable noise level will vary depending upon the person. A noise that you may judge as acceptable may be very irritating to the customer.

• Weather conditions, especially humidity and temperat ure, may have a great effect on noise level.

DUPLICATE THE NOISE AND TEST DRIVE

SBT842

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2727 of 3641

REAR WHEEL HUBRAX-9

< REMOVAL AND INSTALLATION >

CEF

G H

I

J

K L

M A

B

RAX

N

O P

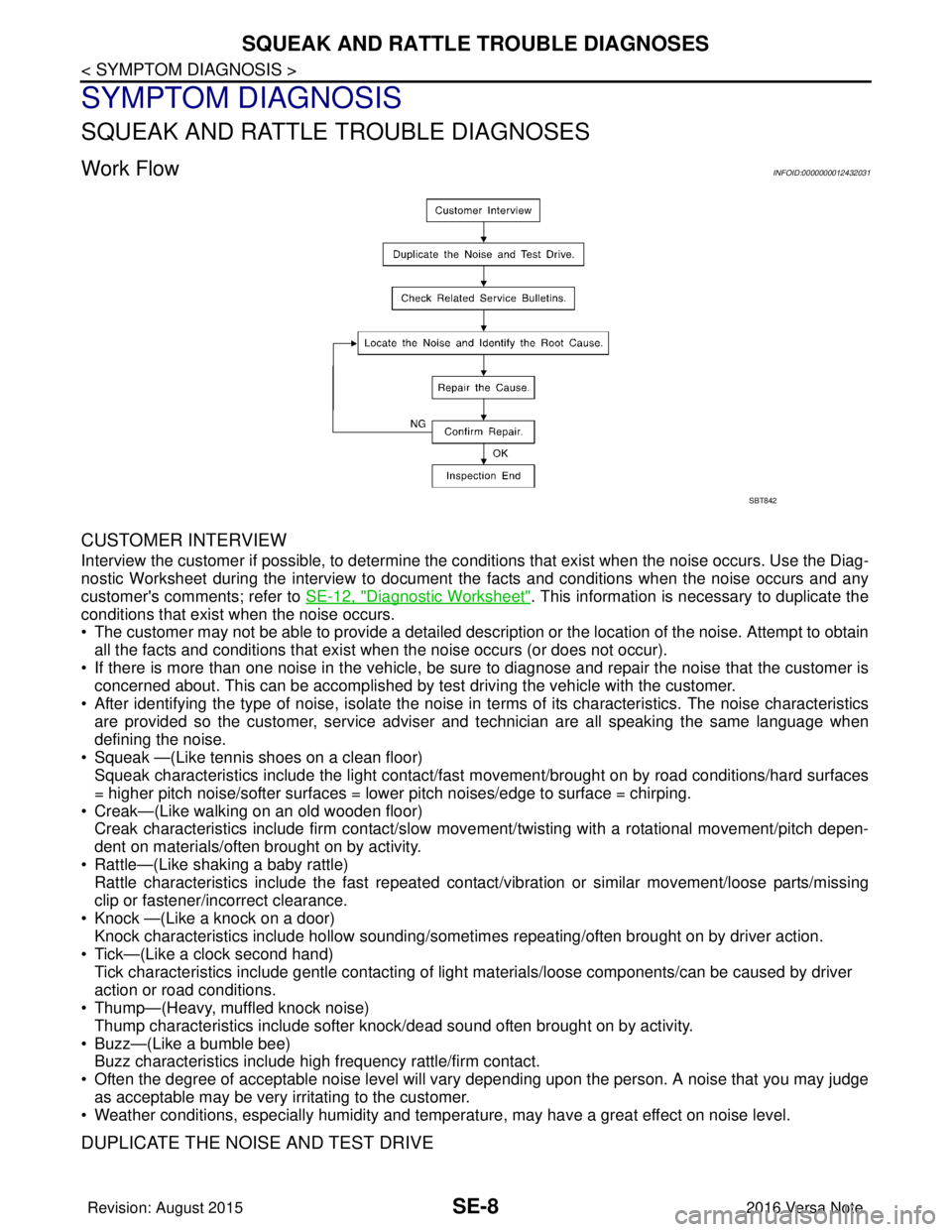

3. Install sensor rotor, using the Tool (A).

CAUTION:

Do not reuse sensor rotor.

InspectionINFOID:0000000012431913

INSPECTION AFTER REMOVAL

Check the brake drum and spindle for wear , cracks, and damage. Replace if necessary.

INSPECTION AFTER DISASSEMBLY

• Check brake drum for wear, cracks, or any other damage. Replace if necessary.

• Check snap ring for wear or cracks. Replace if necessary.

INSPECTION AFTER INSTALLATION

1. Check wheel bearing rotating torque per the following instructions. NOTE:

The adequacy of turning torque can be judged from a measurement value by a suitable tool.

a. Check the contact surface of the brake drum and spindle for foreign matter. If there is any foreign matter, clean the contact surface.

b. Check that the wheel hub lock nut is tightened to the specified torque.

c. Turn the brake drum 10 times or more bot h clockwise and counterclockwise for proper fit.

d. Set a suitable tool to the wheel nut and measure turning torque at turning speeds of 8 to 12 rpm.

2. Adjust parking brake operation (stroke). Refer to PB-4, "

Inspec-

tion and Adjustment".

Tool number (A) : ST30032000 ( — )

JPDIG0191ZZ

Wheel bearing rotat-

ing torque

: Refer to

RAX-10, "Wheel Bear-

ing".

MDIA0060E

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2821 of 3641

SE-8

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

SYMPTOM DIAGNOSIS

SQUEAK AND RATTLE TROUBLE DIAGNOSES

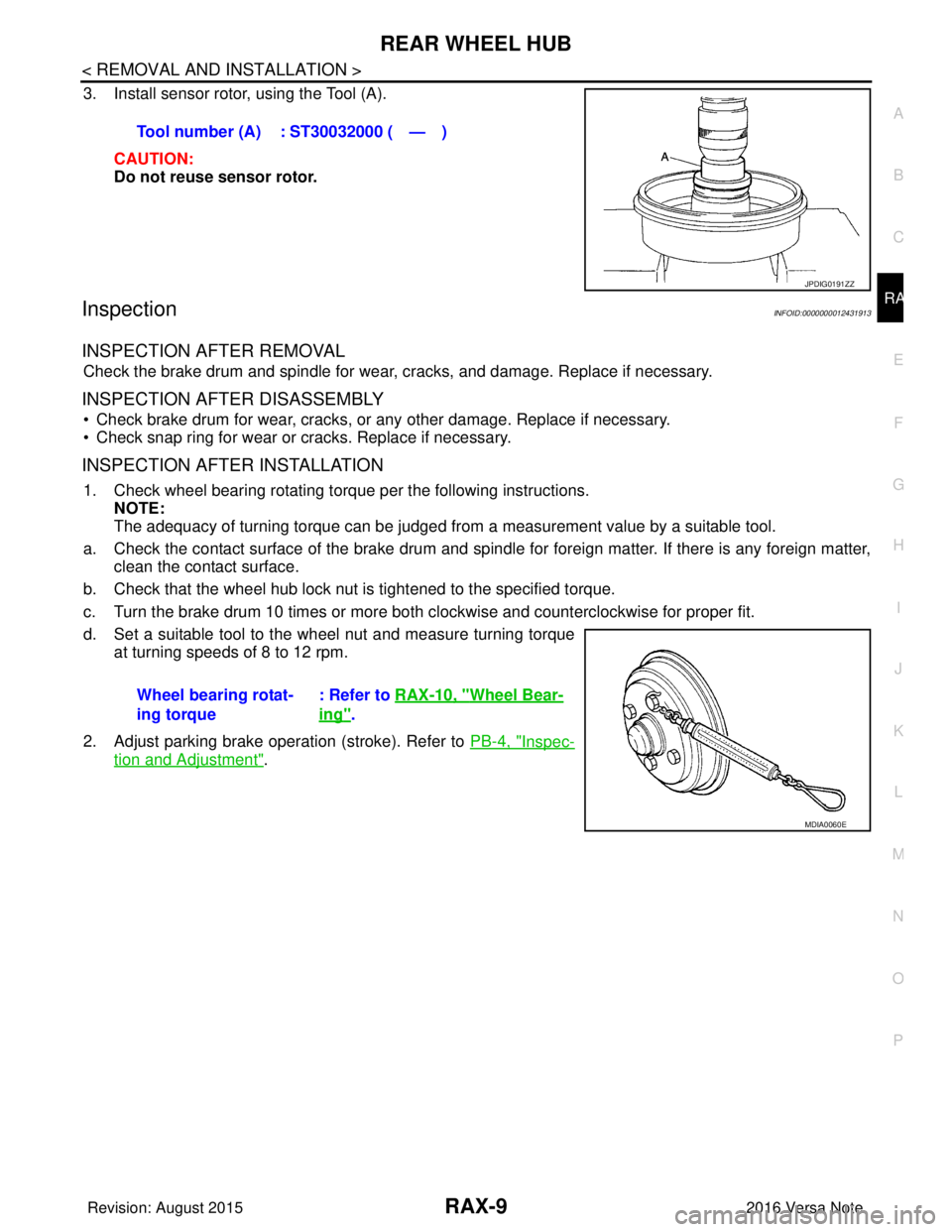

Work FlowINFOID:0000000012432031

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the conditions that exist when the noise occurs. Use the Diag-

nostic Worksheet during the interview to document the facts and conditions when the noise occurs and any

customer's comments; refer to SE-12, "

Diagnostic Worksheet". This information is necessary to duplicate the

conditions that exist when the noise occurs.

• The customer may not be able to provide a detailed description or the location of the noise. Attempt to obtain

all the facts and conditions that exist w hen the noise occurs (or does not occur).

• If there is more than one noise in the vehicle, be sure to diagnose and repair the noise that the customer is

concerned about. This can be accomplished by test driving the vehicle with the customer.

• After identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics

are provided so the customer, service adviser and technician are all speaking the same language when

defining the noise.

• Squeak —(Like tennis shoes on a clean floor) Squeak characteristics include the light contact/fast movement/brought on by road conditions/hard surfaces

= higher pitch noise/softer surfaces = lower pitch noises/edge to surface = chirping.

• Creak—(Like walking on an old wooden floor) Creak characteristics include firm contact/slow mo vement/twisting with a rotational movement/pitch depen-

dent on materials/often brought on by activity.

• Rattle—(Like shaking a baby rattle) Rattle characteristics include the fast repeated contac t/vibration or similar movement/loose parts/missing

clip or fastener/incorrect clearance.

• Knock —(Like a knock on a door) Knock characteristics include hollow sounding/someti mes repeating/often brought on by driver action.

• Tick—(Like a clock second hand) Tick characteristics include gentle contacting of light materials/loose components/can be caused by driver

action or road conditions.

• Thump—(Heavy, muffled knock noise)

Thump characteristics include softer k nock/dead sound often brought on by activity.

• Buzz—(Like a bumble bee) Buzz characteristics include hi gh frequency rattle/firm contact.

• Often the degree of acceptable noise level will vary depending upon the person. A noise that you may judge as acceptable may be very irritating to the customer.

• Weather conditions, especially humidity and temperat ure, may have a great effect on noise level.

DUPLICATE THE NOISE AND TEST DRIVE

SBT842

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2855 of 3641

SE-42

< UNIT DISASSEMBLY AND ASSEMBLY >

REAR SEAT

Seatback

INFOID:0000000012432056

DISASSEMBLY

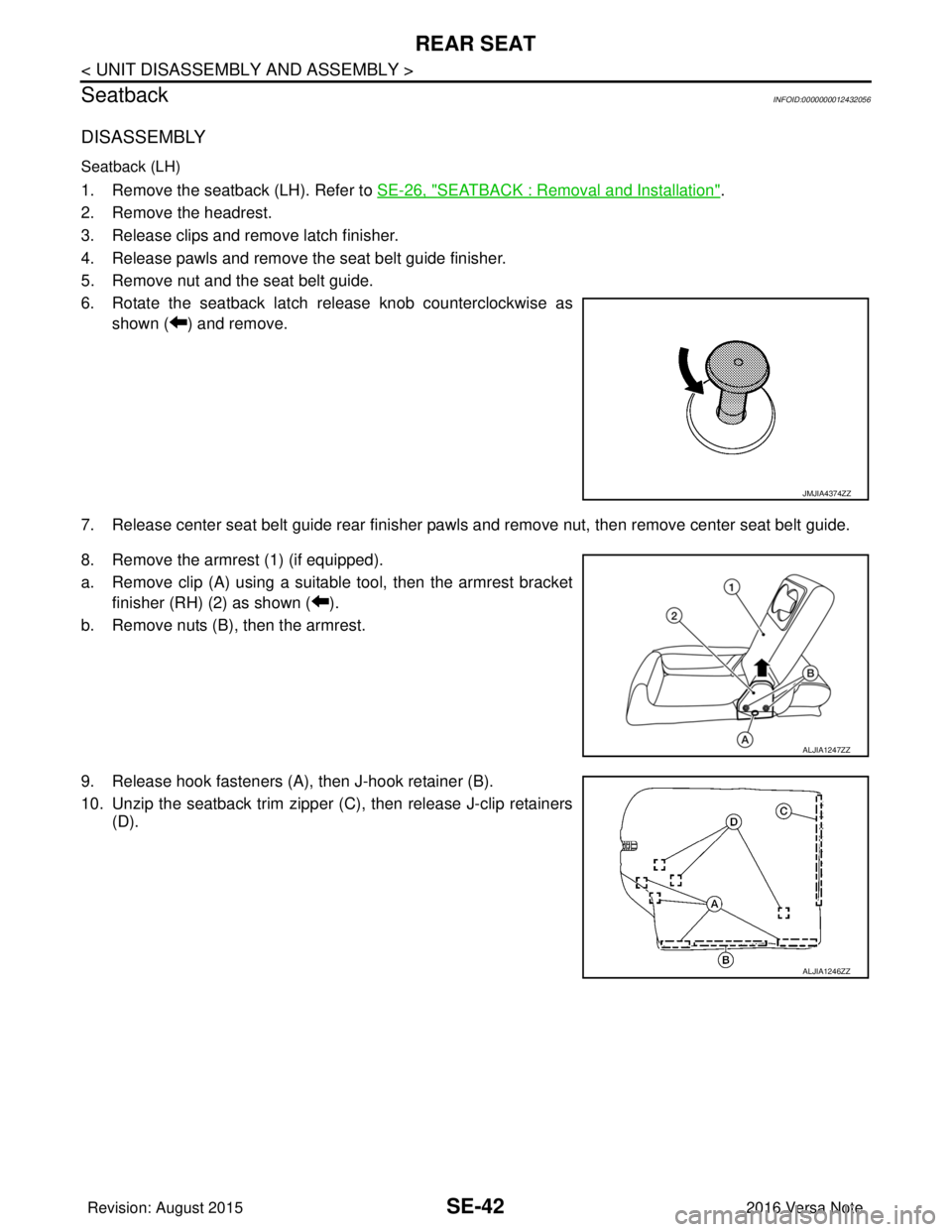

Seatback (LH)

1. Remove the seatback (LH). Refer to SE-26, "SEATBACK : Removal and Installation".

2. Remove the headrest.

3. Release clips and remove latch finisher.

4. Release pawls and remove the seat belt guide finisher.

5. Remove nut and the seat belt guide.

6. Rotate the seatback latch release knob counterclockwise as shown ( ) and remove.

7. Release center seat belt guide rear finisher pawls and remove nut, then remove center seat belt guide.

8. Remove the armrest (1) (if equipped).

a. Remove clip (A) using a suitable tool, then the armrest bracket finisher (RH) (2) as shown ( ).

b. Remove nuts (B), then the armrest.

9. Release hook fasteners (A), then J-hook retainer (B).

10. Unzip the seatback trim zipper (C), then release J-clip retainers (D).

JMJIA4374ZZ

ALJIA1247ZZ

ALJIA1246ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2856 of 3641

REAR SEATSE-43

< UNIT DISASSEMBLY AND ASSEMBLY >

C

DE

F

G H

I

K L

M A

B

SE

N

O P

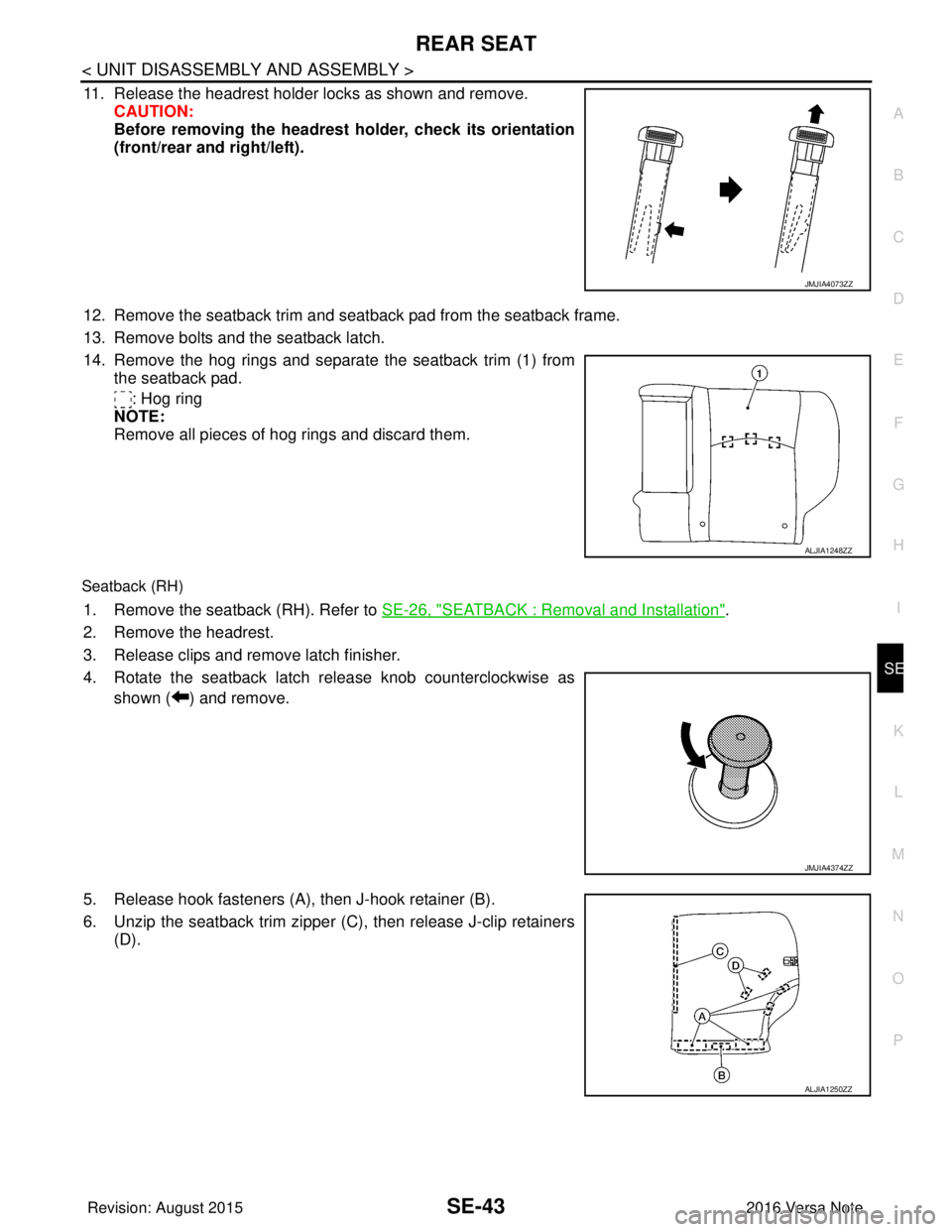

11. Release the headrest holder locks as shown and remove. CAUTION:

Before removing the headrest holder, check its orientation

(front/rear and right/left).

12. Remove the seatback trim and seatback pad from the seatback frame.

13. Remove bolts and the seatback latch.

14. Remove the hog rings and separate the seatback trim (1) from the seatback pad.

: Hog ring

NOTE:

Remove all pieces of hog rings and discard them.

Seatback (RH)

1. Remove the seatback (RH). Refer to SE-26, "SEATBACK : Removal and Installation".

2. Remove the headrest.

3. Release clips and remove latch finisher.

4. Rotate the seatback latch release knob counterclockwise as shown ( ) and remove.

5. Release hook fasteners (A), then J-hook retainer (B).

6. Unzip the seatback trim zipper (C), then release J-clip retainers (D).

JMJIA4073ZZ

ALJIA1248ZZ

JMJIA4374ZZ

ALJIA1250ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3134 of 3641

SR-18

< REMOVAL AND INSTALLATION >

SPIRAL CABLE

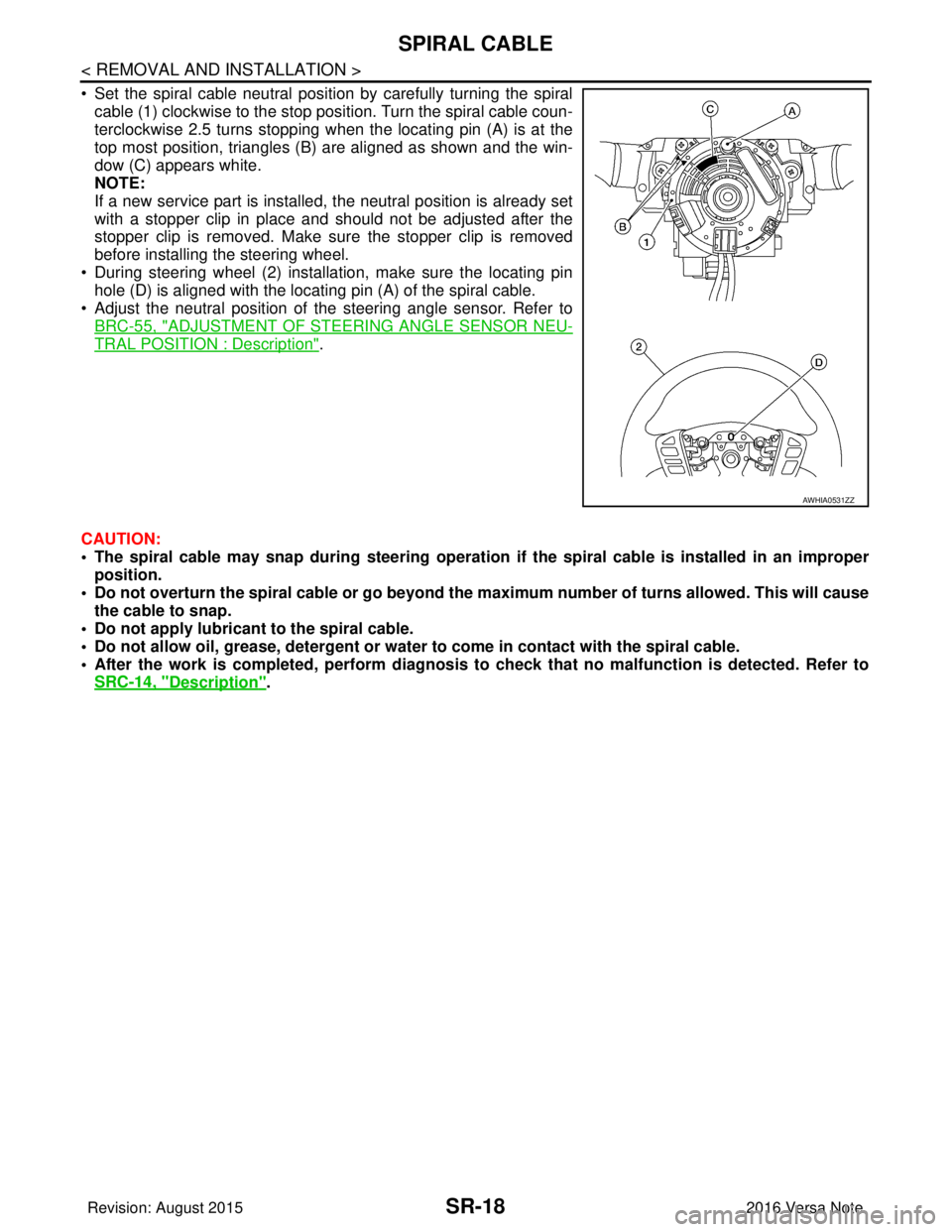

• Set the spiral cable neutral position by carefully turning the spiralcable (1) clockwise to the stop position. Turn the spiral cable coun-

terclockwise 2.5 turns stopping when the locating pin (A) is at the

top most position, triangles (B) are aligned as shown and the win-

dow (C) appears white.

NOTE:

If a new service part is installed, the neutral position is already set

with a stopper clip in place and should not be adjusted after the

stopper clip is removed. Make sure the stopper clip is removed

before installing the steering wheel.

• During steering wheel (2) installation, make sure the locating pin hole (D) is aligned with the locating pin (A) of the spiral cable.

• Adjust the neutral position of the steering angle sensor. Refer to

BRC-55, "

ADJUSTMENT OF STEERI NG ANGLE SENSOR NEU-

TRAL POSITION : Description".

CAUTION:

• The spiral cable may snap during steering operation if the spiral cable is installed in an improper

position.

• Do not overturn the spiral cable or go beyond the maximum number of turns allowed. This will cause

the cable to snap.

• Do not apply lubricant to the spiral cable.

• Do not allow oil, grease, detergent or water to come in contact with the spiral cable.

• After the work is completed, perform diagnosis to check that no malfunction is detected. Refer to

SRC-14, "

Description".

AWHIA0531ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3271 of 3641

![NISSAN NOTE 2016 Service Service Manual TM-30

< UNIT DISASSEMBLY AND ASSEMBLY >[5MT: RS5F91R]

TRANSAXLE ASSEMBLY

Disassembly

INFOID:0000000012430965

1. Remove drain plug and gasket from clutch housing using suitable tool, and drain gear oil NISSAN NOTE 2016 Service Service Manual TM-30

< UNIT DISASSEMBLY AND ASSEMBLY >[5MT: RS5F91R]

TRANSAXLE ASSEMBLY

Disassembly

INFOID:0000000012430965

1. Remove drain plug and gasket from clutch housing using suitable tool, and drain gear oil](/img/5/57363/w960_57363-3270.png)

TM-30

< UNIT DISASSEMBLY AND ASSEMBLY >[5MT: RS5F91R]

TRANSAXLE ASSEMBLY

Disassembly

INFOID:0000000012430965

1. Remove drain plug and gasket from clutch housing using suitable tool, and drain gear oil.

2. Remove filler plug and gasket from transaxle case.

3. Remove rear housing and O-ring. CAUTION:

Remove in direction of input shaft ( ) as shown. Rear

housing oil channel is inserte d to input shaft center hole.

4. Move the shifter lever A (1) to the 3rd gear position. NOTE:

• If it is not moved to the 3rd gear position, transaxle case can-

not be removed from clutch housing.

• The 3rd gear position means that shifter lever A is fully rotated

clockwise and it is returned approximately 10 degrees.

1. Differential side bearing outer race 2. Differential side bearing 3. Final drive

: Replace the parts as a set.

JPDIC0481ZZ

SCIA1709J

PCIB1524E

Revision: August 2015 2016 Versa Note

cardiagn.com