clock NISSAN NOTE 2016 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 640 of 3641

CL-14

< REMOVAL AND INSTALLATION >

CLUTCH MASTER CYLINDER

5. Remove master cylinder rod end ( ) from clutch pedal.

6. Use one of the following methods to remove reservoir hose frommaster cylinder.

• Drain clutch fluid from reservoir tank and remove reservoirhose. Refer to CL-7, "

Draining".

• Remove hose from master cylinder.

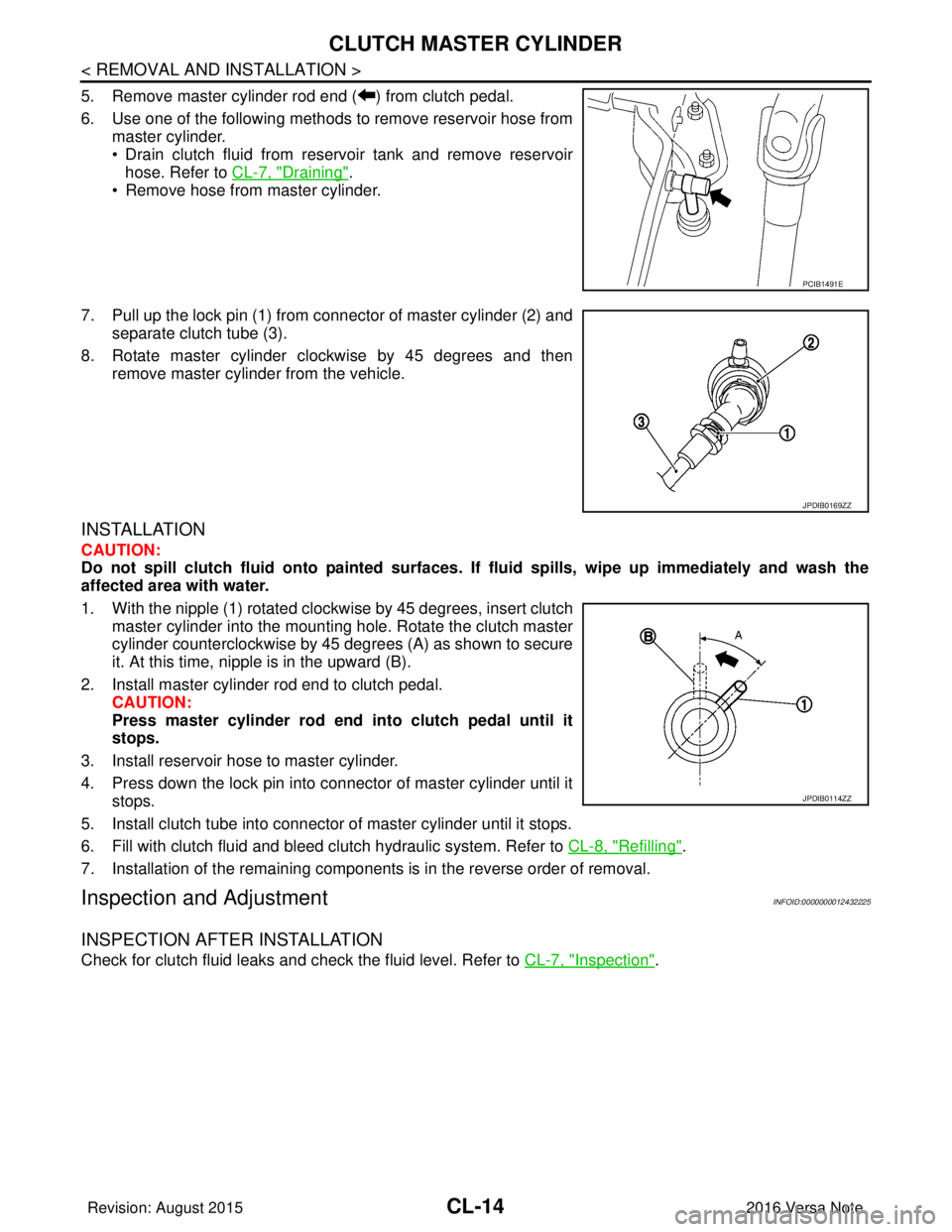

7. Pull up the lock pin (1) from connector of master cylinder (2) and separate clutch tube (3).

8. Rotate master cylinder clockwise by 45 degrees and then remove master cylinder from the vehicle.

INSTALLATION

CAUTION:

Do not spill clutch fluid onto pa inted surfaces. If fluid spills, wipe up imme diately and wash the

affected area with water.

1. With the nipple (1) rotated clockwise by 45 degrees, insert clutch master cylinder into the mounting hole. Rotate the clutch master

cylinder counterclockwise by 45 degrees (A) as shown to secure

it. At this time, nipple is in the upward (B).

2. Install master cylinder rod end to clutch pedal. CAUTION:

Press master cylinder rod end into clutch pedal until it

stops.

3. Install reservoir hose to master cylinder.

4. Press down the lock pin into connector of master cylinder until it stops.

5. Install clutch tube into connector of master cylinder until it stops.

6. Fill with clutch fluid and bleed clutch hydraulic system. Refer to CL-8, "

Refilling".

7. Installation of the remaining components is in the reverse order of removal.

Inspection and AdjustmentINFOID:0000000012432225

INSPECTION AFTER INSTALLATION

Check for clutch fluid leaks and check the fluid level. Refer to CL-7, "Inspection".

PCIB1491E

JPDIB0169ZZ

JPDIB0114ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 823 of 3641

![NISSAN NOTE 2016 Service User Guide DLK-134

< SYMPTOM DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

SQUEAK AND RATTLE TROUBLE DIAGNOSES

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Work FlowINFOID:0000000012430082

CUSTOMER INTERVIEW

Interview the cus NISSAN NOTE 2016 Service User Guide DLK-134

< SYMPTOM DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

SQUEAK AND RATTLE TROUBLE DIAGNOSES

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Work FlowINFOID:0000000012430082

CUSTOMER INTERVIEW

Interview the cus](/img/5/57363/w960_57363-822.png)

DLK-134

< SYMPTOM DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

SQUEAK AND RATTLE TROUBLE DIAGNOSES

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Work FlowINFOID:0000000012430082

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the conditions that exist when the noise occurs. Use the Diag-

nostic Worksheet during the interview to document the facts and conditions when the noise occurs and any

customer's comments; refer to

DLK-138, "

Diagnostic Worksheet". This information is necessary to duplicate

the conditions that exist when the noise occurs.

• The customer may not be able to provide a detailed description or the location of the noise. Attempt to obtain all the facts and conditions that exist w hen the noise occurs (or does not occur).

• If there is more than one noise in the vehicle, be sure to diagnose and repair the noise that the customer is

concerned about. This can be accomplished by test driving the vehicle with the customer.

• After identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics

are provided so the customer, service adviser and technician are all speaking the same language when

defining the noise.

• Squeak —(Like tennis shoes on a clean floor)

Squeak characteristics include the light contact/fast movement/brought on by road conditions/hard surfaces

= higher pitch noise/softer surfaces = lower pitch noises/edge to surface = chirping.

• Creak—(Like walking on an old wooden floor)

Creak characteristics include firm contact/slow mo vement/twisting with a rotational movement/pitch depen-

dent on materials/often brought on by activity.

• Rattle—(Like shaking a baby rattle)

Rattle characteristics include the fast repeated contac t/vibration or similar movement/loose parts/missing

clip or fastener/incorrect clearance.

• Knock —(Like a knock on a door)

Knock characteristics include hollow sounding/someti mes repeating/often brought on by driver action.

• Tick—(Like a clock second hand) Tick characteristics include gentle contacting of light materials/loose components/can be caused by driver

action or road conditions.

• Thump—(Heavy, muffled knock noise) Thump characteristics include softer k nock/dead sound often brought on by activity.

• Buzz—(Like a bumble bee)

Buzz characteristics include hi gh frequency rattle/firm contact.

• Often the degree of acceptable noise level will vary depending upon the person. A noise that you may judge as acceptable may be very irritating to the customer.

• Weather conditions, especially humidity and temperat ure, may have a great effect on noise level.

DUPLICATE THE NOISE AND TEST DRIVE

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or lo cation of the noise. This information can be used to

duplicate the same conditions when you confirm the repair.

SBT842

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 951 of 3641

![NISSAN NOTE 2016 Service User Guide DLK-262

< SYMPTOM DIAGNOSIS >[WITHOUT INTELLIGENT KEY SYSTEM]

SQUEAK AND RATTLE TROUBLE DIAGNOSES

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Work FlowINFOID:0000000012430228

CUSTOMER INTERVIEW

Interview the NISSAN NOTE 2016 Service User Guide DLK-262

< SYMPTOM DIAGNOSIS >[WITHOUT INTELLIGENT KEY SYSTEM]

SQUEAK AND RATTLE TROUBLE DIAGNOSES

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Work FlowINFOID:0000000012430228

CUSTOMER INTERVIEW

Interview the](/img/5/57363/w960_57363-950.png)

DLK-262

< SYMPTOM DIAGNOSIS >[WITHOUT INTELLIGENT KEY SYSTEM]

SQUEAK AND RATTLE TROUBLE DIAGNOSES

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Work FlowINFOID:0000000012430228

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the conditions that exist when the noise occurs. Use the Diag-

nostic Worksheet during the interview to document the facts and conditions when the noise occurs and any

customer's comments; refer to

DLK-266, "

Diagnostic Worksheet". This information is necessary to duplicate

the conditions that exist when the noise occurs.

• The customer may not be able to provide a detailed description or the location of the noise. Attempt to obtain all the facts and conditions that exist w hen the noise occurs (or does not occur).

• If there is more than one noise in the vehicle, be sure to diagnose and repair the noise that the customer is

concerned about. This can be accomplished by test driving the vehicle with the customer.

• After identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics

are provided so the customer, service adviser and technician are all speaking the same language when

defining the noise.

• Squeak —(Like tennis shoes on a clean floor)

Squeak characteristics include the light contact/fast movement/brought on by road conditions/hard surfaces

= higher pitch noise/softer surfaces = lower pitch noises/edge to surface = chirping.

• Creak—(Like walking on an old wooden floor)

Creak characteristics include firm contact/slow mo vement/twisting with a rotational movement/pitch depen-

dent on materials/often brought on by activity.

• Rattle—(Like shaking a baby rattle)

Rattle characteristics include the fast repeated contac t/vibration or similar movement/loose parts/missing

clip or fastener/incorrect clearance.

• Knock —(Like a knock on a door)

Knock characteristics include hollow sounding/someti mes repeating/often brought on by driver action.

• Tick—(Like a clock second hand) Tick characteristics include gentle contacting of light materials/loose components/can be caused by driver

action or road conditions.

• Thump—(Heavy, muffled knock noise) Thump characteristics include softer k nock/dead sound often brought on by activity.

• Buzz—(Like a bumble bee)

Buzz characteristics include hi gh frequency rattle/firm contact.

• Often the degree of acceptable noise level will vary depending upon the person. A noise that you may judge as acceptable may be very irritating to the customer.

• Weather conditions, especially humidity and temperat ure, may have a great effect on noise level.

DUPLICATE THE NOISE AND TEST DRIVE

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or lo cation of the noise. This information can be used to

duplicate the same conditions when you confirm the repair.

SBT842

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1011 of 3641

![NISSAN NOTE 2016 Service User Guide EM-10

< BASIC INSPECTION >[HR16DE]

CAMSHAFT VALVE CLEARANCE

BASIC INSPECTION

CAMSHAFT VALVE CLEARANCE

Inspection and AdjustmentINFOID:0000000012431690

INSPECTION

Perform inspection as follows after re NISSAN NOTE 2016 Service User Guide EM-10

< BASIC INSPECTION >[HR16DE]

CAMSHAFT VALVE CLEARANCE

BASIC INSPECTION

CAMSHAFT VALVE CLEARANCE

Inspection and AdjustmentINFOID:0000000012431690

INSPECTION

Perform inspection as follows after re](/img/5/57363/w960_57363-1010.png)

EM-10

< BASIC INSPECTION >[HR16DE]

CAMSHAFT VALVE CLEARANCE

BASIC INSPECTION

CAMSHAFT VALVE CLEARANCE

Inspection and AdjustmentINFOID:0000000012431690

INSPECTION

Perform inspection as follows after removal, replacement or installation of camshaft or valve-related parts, or if

there are unusual engine conditions regarding valve clearance.

1. Remove rocker cover. Refer to

EM-48, "

Removal and Installation".

2. Measure the valve clearance with the following procedure:

a. Set No. 1 cylinder at TDC of its compression stroke. • Rotate crankshaft pulley (2) clockwise and align TDC mark (no

paint) (A) to timing indicator (1) on front cover.

• At the same time, check that both intake and exhaust cam lobes of No. 1 cylinder face inside ( ) as shown.

• If the lobes do not face inside, rotate the crankshaft pulley 360 degrees to align as shown.

b. Using suitable tool (A) measure the clearance between the valve lifter and camshaft.

(B) : White paint mark (Not used for service)

PBIC3673E

(1) : Camshaft (INT)

(2) : Camshaft (EXH)

: Engine front

JPBIA4738ZZ

Valve clearance : Refer to EM-117, "Camshaft".

JPBIA4116ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1018 of 3641

![NISSAN NOTE 2016 Service User Guide DRIVE BELTEM-17

< PERIODIC MAINTENANCE > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

4. Tighten the lock nut to final tightening specification.

5. Check that belt tension is within the specification usin NISSAN NOTE 2016 Service User Guide DRIVE BELTEM-17

< PERIODIC MAINTENANCE > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

4. Tighten the lock nut to final tightening specification.

5. Check that belt tension is within the specification usin](/img/5/57363/w960_57363-1017.png)

DRIVE BELTEM-17

< PERIODIC MAINTENANCE > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

4. Tighten the lock nut to final tightening specification.

5. Check that belt tension is within the specification using suitable tool. Refer to

EM-116, "

Drive Belt".

InspectionINFOID:0000000012431695

• Inspection should be done only when engine is cold or over 30

minutes after the engine is stopped.

• Visually check belt for wear, damage, and cracks on inside and edges.

• Turn crankshaft pulley clockwise twice, and check that the tension on all pulleys equalizes before testing.

• When measuring deflection, apply 98.1 N (10 kg, 22 lb) at the ( ) marked point.

• Measure the belt tension and frequency using suitable tool at the ( ) marked point.

CAUTION:

• When checking immediately after installation, first ad just it to the specified value. Then, after turning

crankshaft two turns or more, readjust to the specified value to avoid varia tion in deflection between

pulleys.

AdjustmentINFOID:0000000012431696

CAUTION:

• When belt is replaced with new one, adjust belt te nsion to the value for “New belt,” because new belt

will not fully seat in the pulley groove.

• When tension of the belt being used exceeds “Limit,” adjust it to the value for “After adjusted.”

• When installing a belt, check it is correctly engaged with the pulley groove.

• Do not allow engine oil or engine coolant to get on the belt.

• Do not twist or bend the belt strongly.

1. Partially remove the fender protector (RH) front side clip. Refer to EXT-38, "

Removal and Installation".

2. Loosen lock nut (A) and temporarily set to the following torque.

3. Adjust the belt tension by turning the adjusting bolt. Refer to EM-116, "

Drive Belt".

CAUTION: Lock nut (Final tightening) :

34.8 N·m (3.5 kg-m, 26 ft-lb)

(1) : Generator

(2) : Water pump

(3) : Crankshaft pulley

(4) : A/C compressor

(5) : Idler pulley

(6) : Drive belt

Belt deflection/belt tension and frequency : Refer to EM-116, "Drive Belt".

PBIC3642E

LocationLocation of adjuster and tightening method

Drive belt Adjusting bolt on idler pulley

Lock nut (A)

(Temporary tightening): 4.4 N·m (0.45 kg-m, 39 in-lb)

(1) : Generator

(2) : Water pump

(3) : Crankshaft pulley

(4) : A/C compressor

(5) : Idler pulley

(6) : Drive belt

(B) : Adjusting bolt

PBIC3643E

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 1053 of 3641

![NISSAN NOTE 2016 Service User Guide EM-52

< REMOVAL AND INSTALLATION >[HR16DE]

TIMING CHAIN

1. Remove front wheel and tire (RH). Refer to

WT-48, "Removal and Installation".

2. Remove front fender protector (RH). Refer to EXT-38, "

Rem NISSAN NOTE 2016 Service User Guide EM-52

< REMOVAL AND INSTALLATION >[HR16DE]

TIMING CHAIN

1. Remove front wheel and tire (RH). Refer to

WT-48, "Removal and Installation".

2. Remove front fender protector (RH). Refer to EXT-38, "

Rem](/img/5/57363/w960_57363-1052.png)

EM-52

< REMOVAL AND INSTALLATION >[HR16DE]

TIMING CHAIN

1. Remove front wheel and tire (RH). Refer to

WT-48, "Removal and Installation".

2. Remove front fender protector (RH). Refer to EXT-38, "

Removal and Installation".

3. Drain engine oil. Refer to LU-8, "

Draining".

CAUTION:

• Perform this step when engine is cold.

• Do not spill engine oil on drive belt.

4. Drain coolant. Refer to CO-8, "

Draining Engine Coolant".

5. Remove the drive belt. Refer to EM-16, "

Removal and Installation".

6. Remove the rocker cover. Refer to EM-48, "

Removal and Installation".

7. Remove the water pump pulley. Refer to CO-18, "

Removal and Installation".

8. Support the bottom surface of engine (1) using a transmission jack (2), and then remove engine mounting insulator (RH). Refer

to EM-86, "

Exploded View".

CAUTION:

• Position a suitable jack under the engine and transaxle assembly as shown.

• Do not damage the front exhaust tube or transaxle oil pan with the jack.

9. Set No. 1 cylinder at TDC of its compression stroke:

a. Rotate crankshaft pulley (2) clockwise and align TDC mark (without paint mark) (A) to timing indicator (1) on front cover.

b. Check the matching marks on each camshaft sprocket are posi- tioned as shown.

• If not, rotate crankshaft pulley one more turn to align matchingmarks to the positions.

10. Remove crankshaft pulley:

ALBIA0894GB

(B) : White paint mark (Not use for service)

PBIC3673E

(1) : Timing chain

(2) : Camshaft sprocket (EXH)

(3) : Camshaft sprocket (INT)

(A) : Matching mark (Peripheral groove)

(B) : Pink link

(C) : Matching mark (Peripheral groove)

JPBIA4138ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1060 of 3641

![NISSAN NOTE 2016 Service User Guide TIMING CHAINEM-59

< REMOVAL AND INSTALLATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

• Secure crankshaft pulley with a suitable tool and tighten crankshaft pulley bolt.

a. Apply new engine oil to NISSAN NOTE 2016 Service User Guide TIMING CHAINEM-59

< REMOVAL AND INSTALLATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

• Secure crankshaft pulley with a suitable tool and tighten crankshaft pulley bolt.

a. Apply new engine oil to](/img/5/57363/w960_57363-1059.png)

TIMING CHAINEM-59

< REMOVAL AND INSTALLATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

• Secure crankshaft pulley with a suitable tool and tighten crankshaft pulley bolt.

a. Apply new engine oil to thread and seat surfaces of crankshaft pulley bolt.

b. Tighten crankshaft pulley bolt.

c. Put a paint mark (B) on crankshaft pulley, mating with any one of six easy to recognize angle marks (A) on crankshaft bolt flange

(1).

d. Turn another 60 degrees clockwise (angle tightening). • Check the tightening angle with movement of one angle mark.

10. Check that crankshaft turns smoothly by rotating by hand clockwise using suitable tool.

11. Installation of the remaining components is in the reverse order of removal.

INSPECTION AFTER INSTALLATION

• Before starting engine, check oil/fluid levels, includi ng engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to MA-11, "

Fluids and Lubricants".

• Use procedure below to check for fuel leaks.

• Turn ignition switch ON (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leaks at connection points.

• Start engine. With engine speed increased, check again for fuel leaks at connection points.

• Run engine to check for unusual noise and vibration. NOTE:

If hydraulic pressure inside timing chain tensioner drops after removal and installation, slack in the guide

may generate a pounding noise during and just after engine start. However, this is normal. Noise will stop

after hydraulic pressure rises.

• Warm up engine thoroughly to make sure there are no lea ks of fuel, exhaust gas, or any oils/fluids including

engine oil and engine coolant.

• Bleed air from passages in lines and hoses, such as in cooling system.

• After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to spec- ified level, if necessary.

• Summary of the inspection items:

*Power steering fluid, brake fluid, etc.

Crankshaft pulley bolt : 35.0 N·m (3.6 kg-m, 26 ft-lb)

PBIC3726E

ItemBefore starting engine Engine runningAfter engine stopped

Engine coolant LevelLeaks Level

Engine oil LevelLeaks Level

Transmission/

transaxle fluid CVT Models

LeaksLevel/Leaks Leaks

M/T Models Level/Leaks LeaksLevel/Leaks

Other oils and fluids* LevelLeaks Level

Fuel LeaksLeaks Leaks

Exhaust gas —Leaks —

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1063 of 3641

![NISSAN NOTE 2016 Service User Guide EM-62

< REMOVAL AND INSTALLATION >[HR16DE]

CAMSHAFT

• Be sure not to damage the oil pa

th with the tip of the air gun.

• Wipe all the oil off the air gun to prevent oil from being blown all over NISSAN NOTE 2016 Service User Guide EM-62

< REMOVAL AND INSTALLATION >[HR16DE]

CAMSHAFT

• Be sure not to damage the oil pa

th with the tip of the air gun.

• Wipe all the oil off the air gun to prevent oil from being blown all over](/img/5/57363/w960_57363-1062.png)

EM-62

< REMOVAL AND INSTALLATION >[HR16DE]

CAMSHAFT

• Be sure not to damage the oil pa

th with the tip of the air gun.

• Wipe all the oil off the air gun to prevent oil from being blown all over along with the air, and the

area around the air gun should be wipe d with a rag when applying air pressure.

NOTE:

The air pressure is used to move the lock pin into the disengage position.

c. Hold the camshaft sprocket (INT) with hands, and then apply the power counterclockwise/clockwise alter- nately.

• Finally rotate the sprocket of the camshaft sprocket (INT)

counterclockwise [the direction shown by the arrow ( )].

• Perform the work while continuously applying the air pressure to the oil hole.

• If the lock pin is not released, tap the camshaft sprocket (INT) lightly with a plastic hammer (A) using suitable tool.

• If the camshaft sprocket (INT) is not rotated counterclockwise

even if the above procedures are performed, check the air

pressure and the oil hole position.

d. While doing the above, once you hear a click (the sound of the internal lock pin disengaging) from inside the camshaft sprocket

(INT), start turning the camshaft sprocket (INT) in the counter-

clockwise direction in the most advanced angle position.

• Keep the air pressure on.

• If there is no click, as soon as the vane side (camshaft side)starts moving independently of the sprocket, the lock pin has

become disengaged.

• Check that it is in the most advanced angle positi on by seeing if the stopper pin groove (A) and the stop-

per pin hole (B) are matched up as shown.

e. Stop applying air pressure and release the camshaft (INT).

f. Insert the stopper pin (A) into the stopper pin holes in the cam- shaft sprocket (INT) and lock in the most advanced angle posi-

tion.

CAUTION:

No load is exerted on the stopper pin (spring reaction, etc.).

Since it comes out easily, secure it with tape (B) to prevent

it from falling out.

NOTE:

The stopper pin shows one example of a hexagonal wrench for

2.5 mm (0.098 in) [length of inse rted section: approximately15

mm (0.59 in)].

(A) : Air gun

(B) : Rubber nozzle

JPBIA4151ZZ

JPBIA4152ZZ

(A/B) : Lock pin recess

(C) : Lock pin engaged

(D) : Most advanced angle

PBIC3684E

JPBIA4153ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1068 of 3641

![NISSAN NOTE 2016 Service User Guide CAMSHAFTEM-67

< REMOVAL AND INSTALLATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

12. Pull out the stopper pin (A), and then apply the tension to the

timing chain by rotating the crankshaft pulley c NISSAN NOTE 2016 Service User Guide CAMSHAFTEM-67

< REMOVAL AND INSTALLATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

12. Pull out the stopper pin (A), and then apply the tension to the

timing chain by rotating the crankshaft pulley c](/img/5/57363/w960_57363-1067.png)

CAMSHAFTEM-67

< REMOVAL AND INSTALLATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

12. Pull out the stopper pin (A), and then apply the tension to the

timing chain by rotating the crankshaft pulley clockwise slightly.

13. Pull out the stopper pin of chain tensioner.

14. Install front cover.

15. Return the camshaft sprocket (INT) in the most retarded position:

a. Remove the stopper pin (A) from the camshaft sprocket (INT).

b. Turn the crankshaft pulley (1) slowly clockwise (A) and return the camshaft sprocket (INT) to the most retarded angle position.

• When first turning the crankshaft, the camshaft sprocket (INT)

will turn. Once it is turned more, and the vane (camshaft) also

turns, then it has reached t he most retarded angle position.

• The most retarded angle position can be checked by seeing if the stopper pin groove (A) is shifted clockwise.

• After spinning the crankshaft slightly in the counterclockwise direction, you can check the lock pin has joined by seeing if

the vane (camshaft) and the sprocket move together.

16. Install the camshaft position sensor (PHASE) to the rear end of cylinder head. • Tighten bolts with it completely inserted.

17. Check and adjust valve clearance. Refer to EM-10, "

Inspection and Adjustment".

18. Installation of the remaining components is in the reverse order of removal.

INSPECTION AFTER INSTALLATION

(1) : Plunger

(2) : Chain tensioner

(B) : Lever

(C) : Lever hole

(D) : Front cover has been removed for clarity.

PBIC3772E

(B) : Tape

PBIC3685E

PBIC3704E

(B) : Stopper pin hole

(C) : Most advanced angle

(D) : Lock pin engaged

PBIC3705E

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1078 of 3641

![NISSAN NOTE 2016 Service User Guide CYLINDER HEADEM-77

< REMOVAL AND INSTALLATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

1. Install new cylinder head gasket.

CAUTION:

Do not reuse cylinder head gasket.

2. Install cylinder head, and NISSAN NOTE 2016 Service User Guide CYLINDER HEADEM-77

< REMOVAL AND INSTALLATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

1. Install new cylinder head gasket.

CAUTION:

Do not reuse cylinder head gasket.

2. Install cylinder head, and](/img/5/57363/w960_57363-1077.png)

CYLINDER HEADEM-77

< REMOVAL AND INSTALLATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

1. Install new cylinder head gasket.

CAUTION:

Do not reuse cylinder head gasket.

2. Install cylinder head, and tighten cylinder head bolts in order as shown using Tool (A). • Clean threads and seating surfaces of bolts.

• Apply new engine oil to threads and seating surface of bolts.

CAUTION:

• If cylinder head bolts are reu sed, check their outer diameters before installation. Refer to EM-80,

"Inspection".

• Check and confirm the tighteni ng angle by using Tool (A).

Do not judge by visual insp ection without the Tool (A).

3. Installation of the remaining components is in the reverse order of removal. Tool number (A) : KV10112100 (BT-8653-A)

AWBIA1426ZZ

Step 1 : 40.0 N·m (4.1 kg-m, 30 ft-lb)

Step 2 : 60

° clockwise in order

Step 3 : 0 N·m (0 kg-m, 0 ft-lb)

Step 4 : 40.0 N·m (4.1 kg-m, 30 ft-lb)

Step 5 : 75 ° clockwise in order

Step 6 : 75 ° clockwise in order

: Engine frontAWBIA1425ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com