clock NISSAN NOTE 2016 Service Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 1766 of 3641

EXL-114

< UNIT DISASSEMBLY AND ASSEMBLY >

REAR COMBINATION LAMP

REAR COMBINATION LAMP

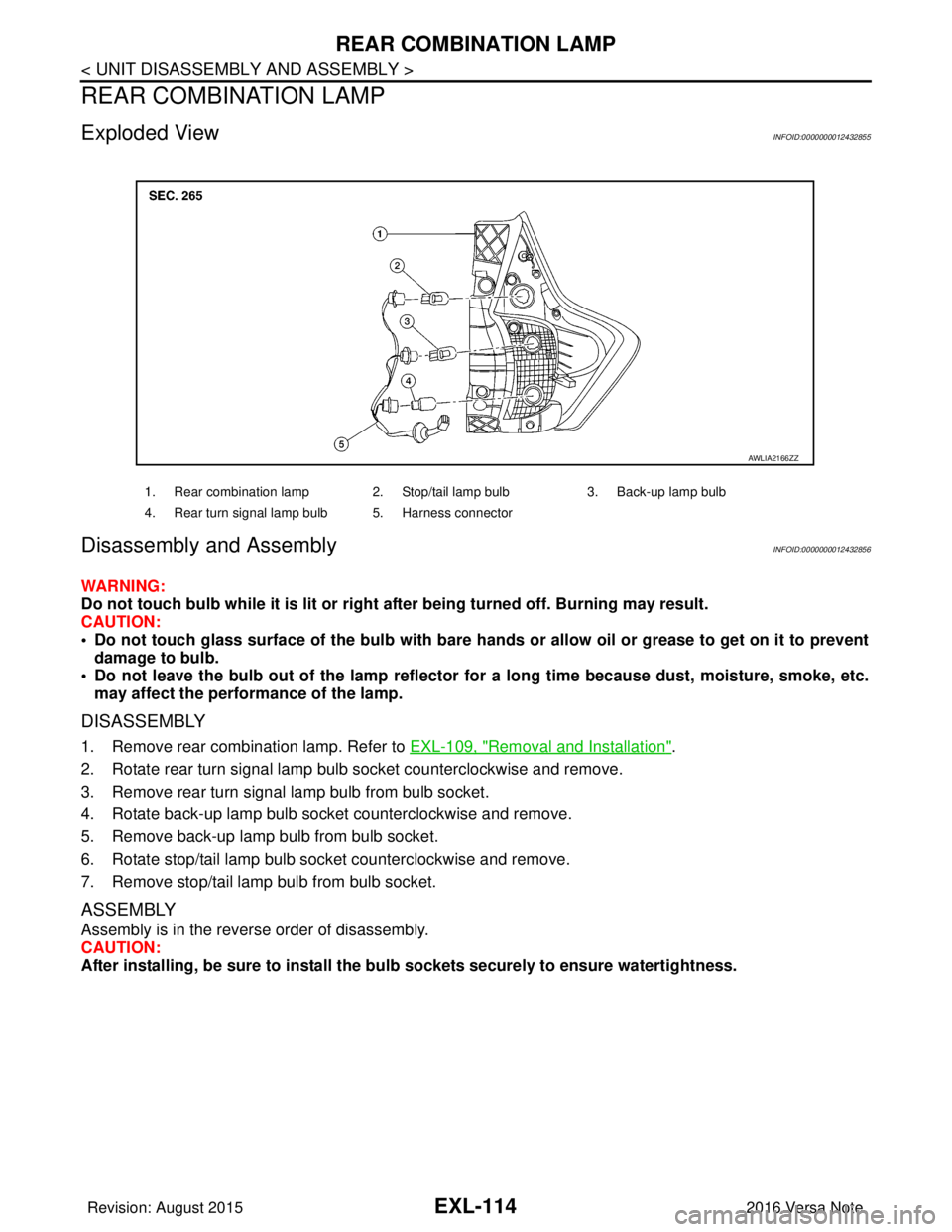

Exploded ViewINFOID:0000000012432855

Disassembly and Assembly INFOID:0000000012432856

WARNING:

Do not touch bulb while it is lit or right after being turned off. Burning may result.

CAUTION:

• Do not touch glass surface of the bulb with bare hands or allow oil or grease to get on it to preventdamage to bulb.

• Do not leave the bulb out of the lamp reflector fo r a long time because dust, moisture, smoke, etc.

may affect the performance of the lamp.

DISASSEMBLY

1. Remove rear combination lamp. Refer to EXL-109, "Removal and Installation".

2. Rotate rear turn signal lamp bulb socket counterclockwise and remove.

3. Remove rear turn signal lamp bulb from bulb socket.

4. Rotate back-up lamp bulb socket counterclockwise and remove.

5. Remove back-up lamp bulb from bulb socket.

6. Rotate stop/tail lamp bulb socket counterclockwise and remove.

7. Remove stop/tail lamp bulb from bulb socket.

ASSEMBLY

Assembly is in the reverse order of disassembly.

CAUTION:

After installing, be sure to install the bu lb sockets securely to ensure watertightness.

1. Rear combination lamp 2. Stop/tail lamp bulb 3. Back-up lamp bulb

4. Rear turn signal lamp bulb 5. Harness connector

AWLIA2166ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1784 of 3641

SQUEAK AND RATTLE TROUBLE DIAGNOSESEXT-17

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

I

J

L

M A

B

EXT

N

O P

SYMPTOM DIAGNOSIS

SQUEAK AND RATTLE TROUBLE DIAGNOSES

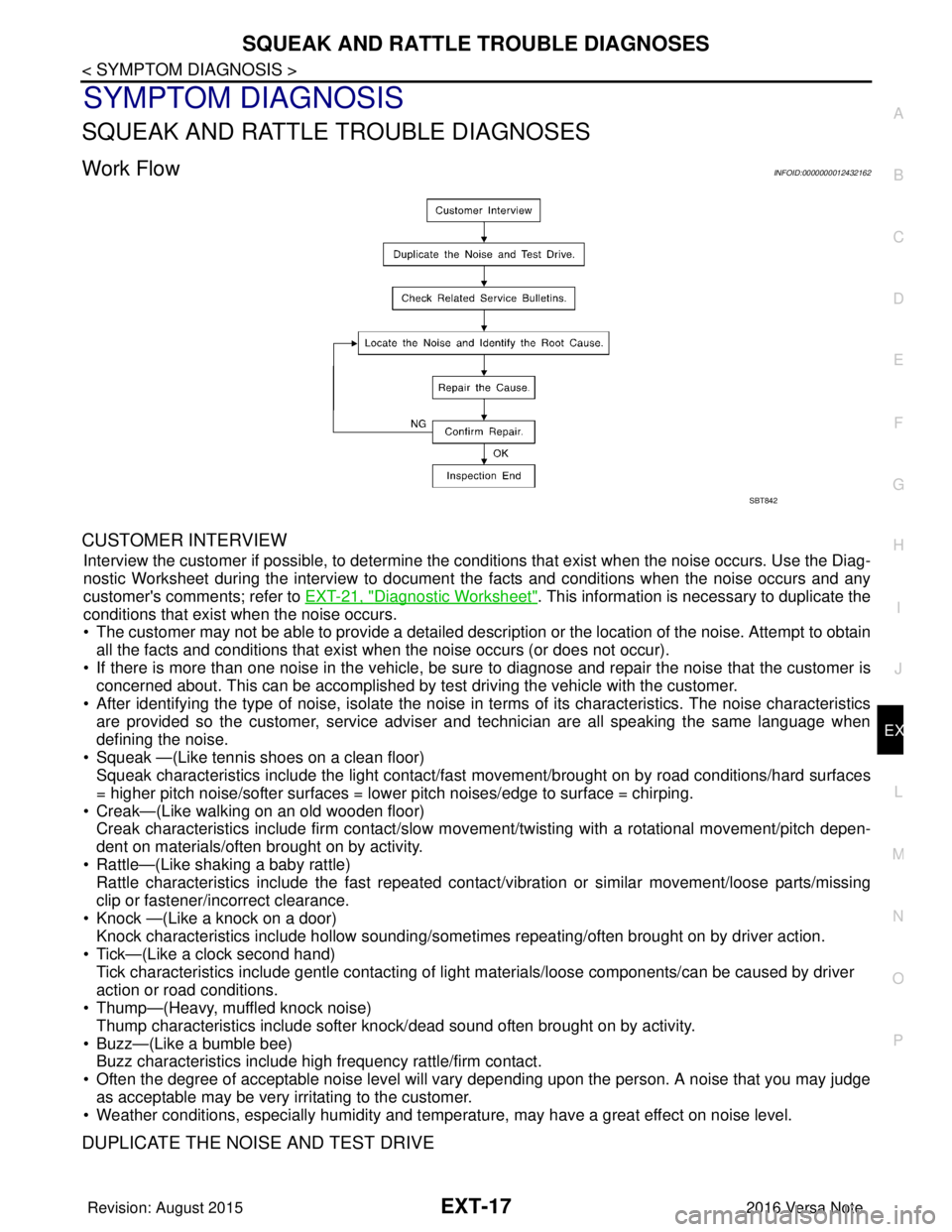

Work FlowINFOID:0000000012432162

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the conditions that exist when the noise occurs. Use the Diag-

nostic Worksheet during the interv iew to document the facts and conditions when the noise occurs and any

customer's comments; refer to EXT-21, "

Diagnostic Worksheet". This information is necessary to duplicate the

conditions that exist when the noise occurs.

• The customer may not be able to provide a detailed descr iption or the location of the noise. Attempt to obtain

all the facts and conditions that exist when the noise occurs (or does not occur).

• If there is more than one noise in the vehicle, be sure to diagnose and repair the noise that the customer is

concerned about. This can be accomplished by test driving the vehicle with the customer.

• After identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics are provided so the customer, service adviser and technician are all speaking the same language when

defining the noise.

• Squeak —(Like tennis shoes on a clean floor) Squeak characteristics include the light contact/fast movement/brought on by road conditions/hard surfaces

= higher pitch noise/softer surfaces = lower pitch noises/edge to surface = chirping.

• Creak—(Like walking on an old wooden floor) Creak characteristics include firm contact/slow mo vement/twisting with a rotational movement/pitch depen-

dent on materials/often brought on by activity.

• Rattle—(Like shaking a baby rattle) Rattle characteristics include the fast repeated contac t/vibration or similar movement/loose parts/missing

clip or fastener/incorrect clearance.

• Knock —(Like a knock on a door) Knock characteristics include hollow sounding/someti mes repeating/often brought on by driver action.

• Tick—(Like a clock second hand) Tick characteristics include gentle contacting of li ght materials/loose components/can be caused by driver

action or road conditions.

• Thump—(Heavy, muffled knock noise)

Thump characteristics include softer k nock/dead sound often brought on by activity.

• Buzz—(Like a bumble bee) Buzz characteristics include high frequency rattle/firm contact.

• Often the degree of acceptable noise level will vary depending upon the person. A noise that you may judge as acceptable may be very irritating to the customer.

• Weather conditions, especially humidity and temperature, may have a great effect on noise level.

DUPLICATE THE NOISE AND TEST DRIVE

SBT842

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1830 of 3641

FRONT WHEEL HUB AND KNUCKLEFAX-13

< REMOVAL AND INSTALLATION >

CEF

G H

I

J

K L

M A

B

FA X

N

O P

5. Perform inspection after assembly. Refer to FAX-13, "Inspection".

InspectionINFOID:0000000012431893

INSPECTION AFTER REMOVAL

Check the following items, and replace the part if necessary.

• Check components for deformation, cracks, and other damage.

• Check boots of transverse link and steering outer so cket ball joint for breakage, axial end play, and swing

torque. Refer to FSU-10, "

Inspection" and FSU-20, "Ball Joint".

INSPECTION AFTER DISASSEMBLY

Wheel Hub

• Check wheel hub for cracks (with magnetic exploration or dye testing). Replace if necessary.

Steering Knuckle

• Check steering knuckle for deformation, cracks, and other damage. Replace if any non-standard conditions

are found.

Snap Rings

• Check snap ring for wear or cracks. Replace if necessary.

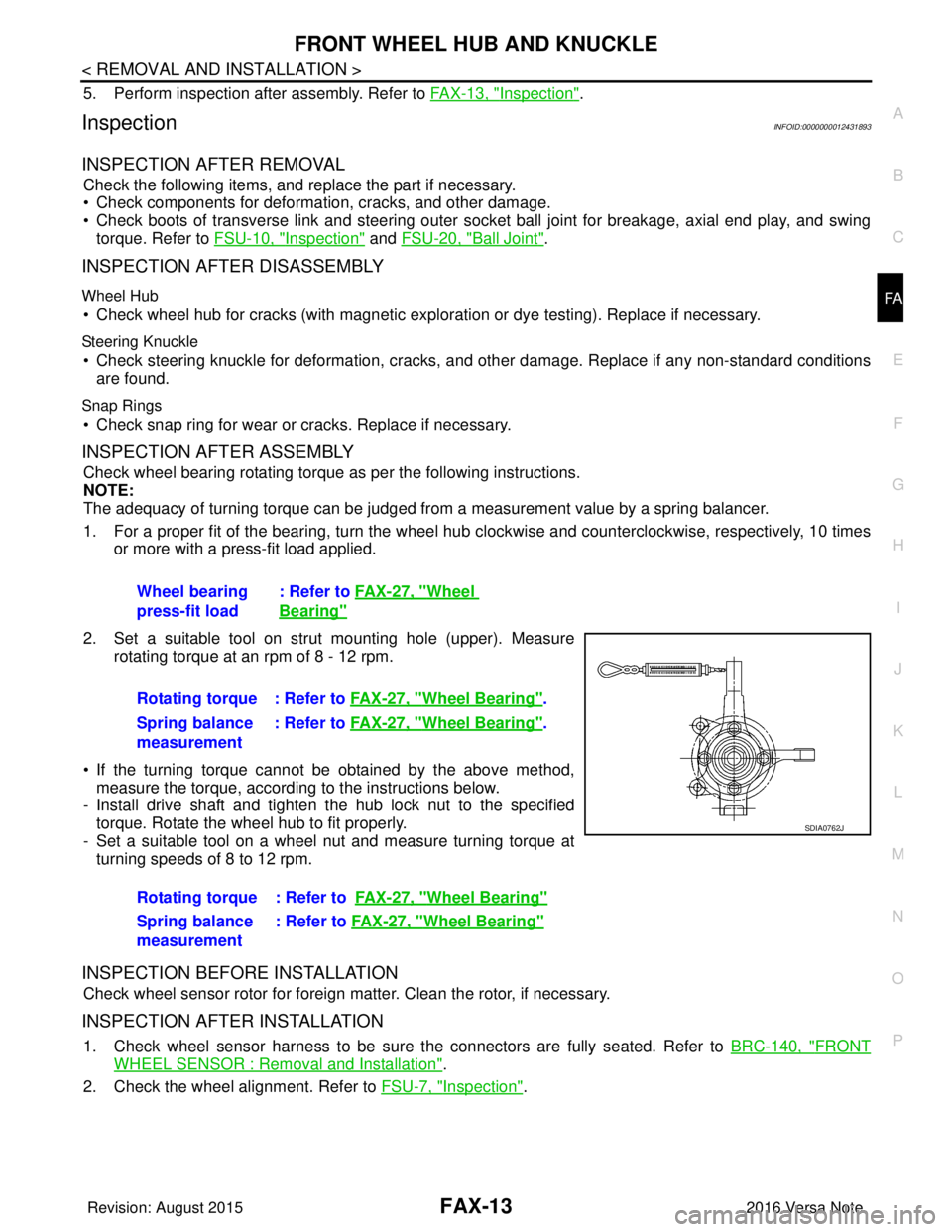

INSPECTION AFTER ASSEMBLY

Check wheel bearing rotating torque as per the following instructions.

NOTE:

The adequacy of turning torque can be judged from a measurement value by a spring balancer.

1. For a proper fit of the bearing, turn the wheel hub clockwise and counterclockwise, respectively, 10 times

or more with a press-fit load applied.

2. Set a suitable tool on strut mounting hole (upper). Measure rotating torque at an rpm of 8 - 12 rpm.

• If the turning torque cannot be obtained by the above method, measure the torque, according to the instructions below.

- Install drive shaft and tighten the hub lock nut to the specified

torque. Rotate the wheel hub to fit properly.

- Set a suitable tool on a wheel nut and measure turning torque at turning speeds of 8 to 12 rpm.

INSPECTION BEFORE INSTALLATION

Check wheel sensor rotor for foreign matter. Clean the rotor, if necessary.

INSPECTION AFTER INSTALLATION

1. Check wheel sensor harness to be sure the connectors are fully seated. Refer to BRC-140, "FRONT

WHEEL SENSOR : Removal and Installation".

2. Check the wheel alignment. Refer to FSU-7, "

Inspection".

Wheel bearing

press-fit load

: Refer to

FAX-27, "

Wheel

Bearing"

Rotating torque : Refer to FAX-27, "Wheel Bearing".

Spring balance

measurement : Refer to

FAX-27, "

Wheel Bearing".

Rotating torque : Refer to FAX-27, "

Wheel Bearing"

Spring balance

measurement: Refer to

FAX-27, "Wheel Bearing"

SDIA0762J

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1874 of 3641

FL -8

< REMOVAL AND INSTALLATION >

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

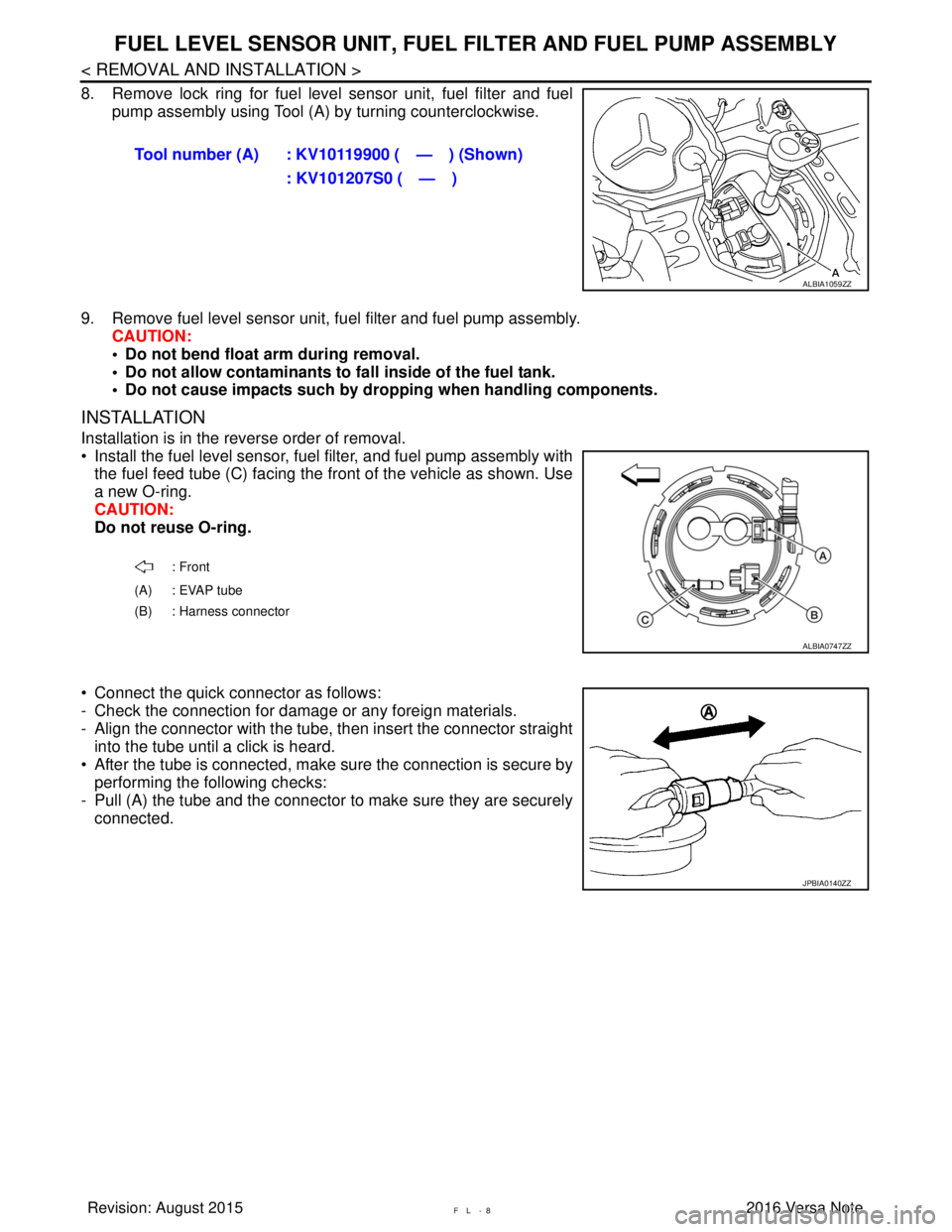

8. Remove lock ring for fuel level sensor unit, fuel filter and fuel

pump assembly using Tool (A) by turning counterclockwise.

9. Remove fuel level sensor unit, fuel filter and fuel pump assembly. CAUTION:

• Do not bend float arm during removal.

• Do not allow contaminants to fa ll inside of the fuel tank.

• Do not cause impacts such by dro pping when handling components.

INSTALLATION

Installation is in the reverse order of removal.

• Install the fuel level sensor, fuel filter, and fuel pump assembly with

the fuel feed tube (C) facing the front of the vehicle as shown. Use

a new O-ring.

CAUTION:

Do not reuse O-ring.

• Connect the quick connector as follows:

- Check the connection for damage or any foreign materials.

- Align the connector with the tube, then insert the connector straight into the tube until a click is heard.

• After the tube is connected, make sure the connection is secure by performing the following checks:

- Pull (A) the tube and the connector to make sure they are securely

connected. Tool number (A) : KV10119900 ( — ) (Shown)

: KV101207S0 ( — )

ALBIA1059ZZ

: Front

(A) : EVAP tube

(B) : Harness connector

ALBIA0747ZZ

JPBIA0140ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1884 of 3641

FL-18

< REMOVAL AND INSTALLATION >

EVAP CANISTER VENT CONTROL VALVE

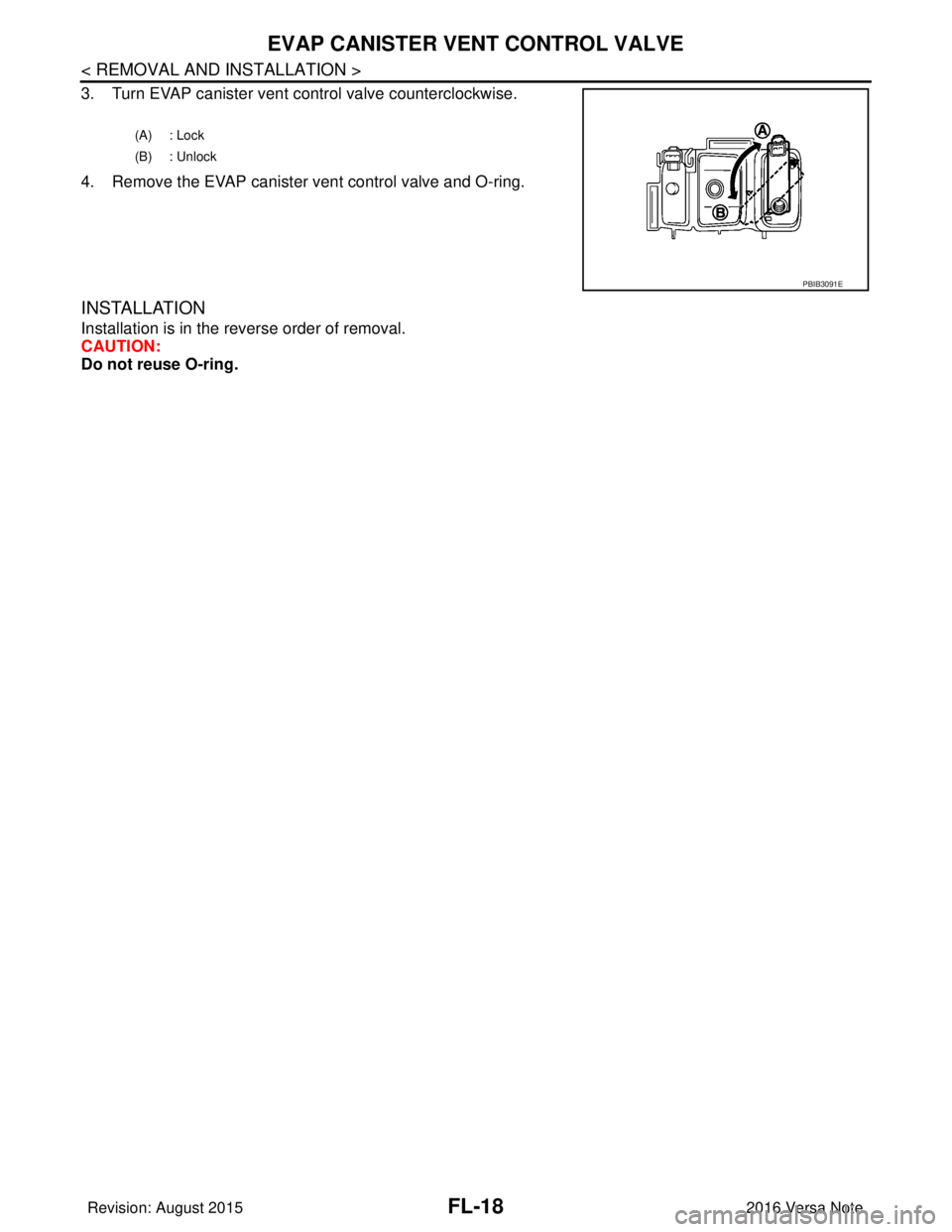

3. Turn EVAP canister vent control valve counterclockwise.

4. Remove the EVAP canister vent control valve and O-ring.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Do not reuse O-ring.

(A) : Lock

(B) : Unlock

PBIB3091E

Revision: August 20152016 Versa Note

cardiagn.com

Page 1905 of 3641

ABBREVIATIONSGI-17

< HOW TO USE THIS MANUAL >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

O

P

R

S

T

ABBREVIATION DESCRIPTION

O2 Oxygen

O2S Oxygen sensor

OBD On board diagnostic

OC Oxidation catalytic converter

OD Overdrive

OL Open loop

OSS Output shaft speed

ABBREVIATION DESCRIPTION

P/S Power steering

PBR Potentio balance resistor

PCV Positive crankcase ventilation

PNP Park/Neutral position

PSP Power steering pressure

PTC Positive temperature coefficient

PTO Power takeoff

PWM Pulse width modulation

ABBREVIATION DESCRIPTION

RAM Random access memory

RAS Rear active steer

RH Right-hand

RHD Right-hand drive

ROM Read only memory

RPM Engine speed

RR Rear

ABBREVIATION DESCRIPTION

SAE Society of Automoti ve Engineers, Inc.

SCK Serial clock

SDS Service Data and Specifications

SRT System readiness test

SST Special Service Tools

ABBREVIATION DESCRIPTION

TC Turbocharger

TCM Transmission control module

TCS Traction control system

TCU Telematics communication unit

TP Throttle position

TPMS Tire pressure monitoring system TSS Turbine shaft speed

TWC Three way catalytic converter

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1945 of 3641

SQUEAK AND RATTLE TROUBLE DIAGNOSESGW-5

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

I

J

L

M A

B

GW

N

O P

SYMPTOM DIAGNOSIS

SQUEAK AND RATTLE TROUBLE DIAGNOSES

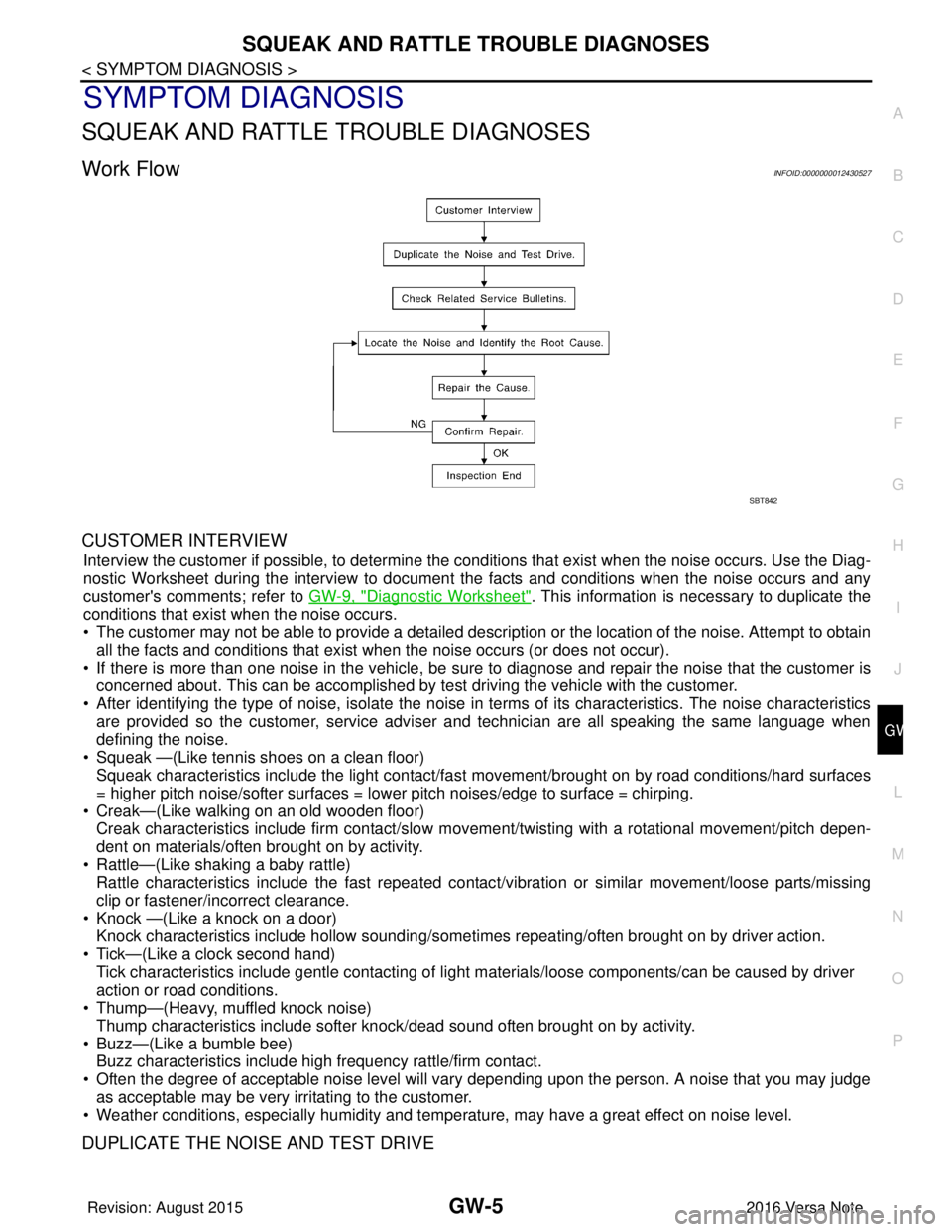

Work FlowINFOID:0000000012430527

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the conditions that exist when the noise occurs. Use the Diag-

nostic Worksheet during the interv iew to document the facts and conditions when the noise occurs and any

customer's comments; refer to GW-9, "

Diagnostic Worksheet". This information is necessary to duplicate the

conditions that exist when the noise occurs.

• The customer may not be able to provide a detailed descr iption or the location of the noise. Attempt to obtain

all the facts and conditions that exist when the noise occurs (or does not occur).

• If there is more than one noise in the vehicle, be sure to diagnose and repair the noise that the customer is

concerned about. This can be accomplished by test driving the vehicle with the customer.

• After identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics are provided so the customer, service adviser and technician are all speaking the same language when

defining the noise.

• Squeak —(Like tennis shoes on a clean floor) Squeak characteristics include the light contact/fast movement/brought on by road conditions/hard surfaces

= higher pitch noise/softer surfaces = lower pitch noises/edge to surface = chirping.

• Creak—(Like walking on an old wooden floor) Creak characteristics include firm contact/slow mo vement/twisting with a rotational movement/pitch depen-

dent on materials/often brought on by activity.

• Rattle—(Like shaking a baby rattle) Rattle characteristics include the fast repeated contac t/vibration or similar movement/loose parts/missing

clip or fastener/incorrect clearance.

• Knock —(Like a knock on a door) Knock characteristics include hollow sounding/someti mes repeating/often brought on by driver action.

• Tick—(Like a clock second hand) Tick characteristics include gentle contacting of li ght materials/loose components/can be caused by driver

action or road conditions.

• Thump—(Heavy, muffled knock noise)

Thump characteristics include softer k nock/dead sound often brought on by activity.

• Buzz—(Like a bumble bee) Buzz characteristics include high frequency rattle/firm contact.

• Often the degree of acceptable noise level will vary depending upon the person. A noise that you may judge as acceptable may be very irritating to the customer.

• Weather conditions, especially humidity and temperature, may have a great effect on noise level.

DUPLICATE THE NOISE AND TEST DRIVE

SBT842

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1975 of 3641

![NISSAN NOTE 2016 Service Owners Guide PRECAUTIONSHAC-7

< PRECAUTION > [MANUAL AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

Be certain that the gauge face indicates HFC-134a or R-134a. Be

sure the gauge set has 1/2 ″-16 ACME threa NISSAN NOTE 2016 Service Owners Guide PRECAUTIONSHAC-7

< PRECAUTION > [MANUAL AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

Be certain that the gauge face indicates HFC-134a or R-134a. Be

sure the gauge set has 1/2 ″-16 ACME threa](/img/5/57363/w960_57363-1974.png)

PRECAUTIONSHAC-7

< PRECAUTION > [MANUAL AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

Be certain that the gauge face indicates HFC-134a or R-134a. Be

sure the gauge set has 1/2 ″-16 ACME threaded connections for ser-

vice hoses. Confirm the set has been used only with refrigerant

HFC-134a (R-134a) and specified oils.

SERVICE HOSES

Be certain that the service hoses display the markings described

(colored hose with black stripe) . All hoses must be equipped with

positive shut-off devices (either manual or automatic) near the end of

the hoses opposite to the manifold gauge.

SERVICE COUPLERS

Do not attempt to connect HFC-134a (R-134a) service couplers to

the CFC-12 (R-12) A/C system. The HFC-134a (R-134a) couplers

do not properly connect to the CFC-12 (R-12) system. However, if an

improper connection is attempted, discharging and contamination

may occur.

REFRIGERANT WEIGHT SCALE

Verify that no refrigerant other than HFC-134a (R-134a) and speci-

fied oils have been used with the scale. The hose fitting must be 1/

2 ″-16 ACME if the scale controls refrigerant flow electronically.

CHARGING CYLINDER

Using a charging cylinder is not re commended. Refrigerant may be vented into air from cylinder’s top valve

when filling the cylinder with refrigerant. Also, the accura cy of the cylinder is generally less than that of an

electronic scale or of quality recycle/recharge equipment.

SHA533D

RHA272D

Shut-off valve rotati on A/C service valve

Clockwise Open

Counterclockwise Close

RHA273D

RHA274D

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2033 of 3641

HA-8

< PRECAUTION >

PRECAUTIONS

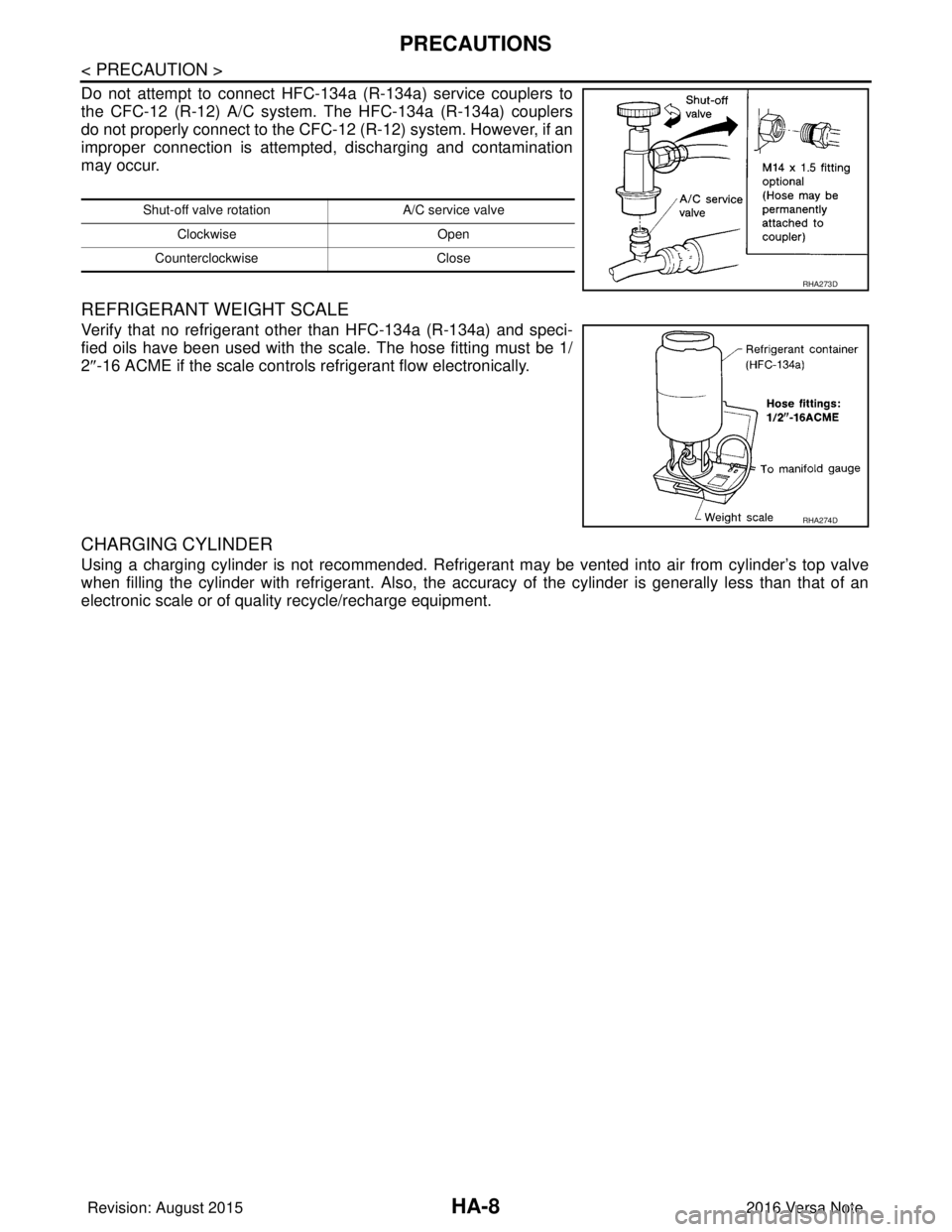

Do not attempt to connect HFC-134a (R-134a) service couplers to

the CFC-12 (R-12) A/C system. The HFC-134a (R-134a) couplers

do not properly connect to the CFC-12 (R-12) system. However, if an

improper connection is attempted, discharging and contamination

may occur.

REFRIGERANT WEIGHT SCALE

Verify that no refrigerant other than HFC-134a (R-134a) and speci-

fied oils have been used with the scale. The hose fitting must be 1/

2 ″-16 ACME if the scale controls refrigerant flow electronically.

CHARGING CYLINDER

Using a charging cylinder is not recommended. Refrigerant may be vented into air from cylinder’s top valve

when filling the cylinder with refrigerant. Also, the accuracy of the cylinder is generally less than that of an

electronic scale or of quality recycle/recharge equipment.

Shut-off valve rotati on A/C service valve

Clockwise Open

Counterclockwise Close

RHA273D

RHA274D

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2062 of 3641

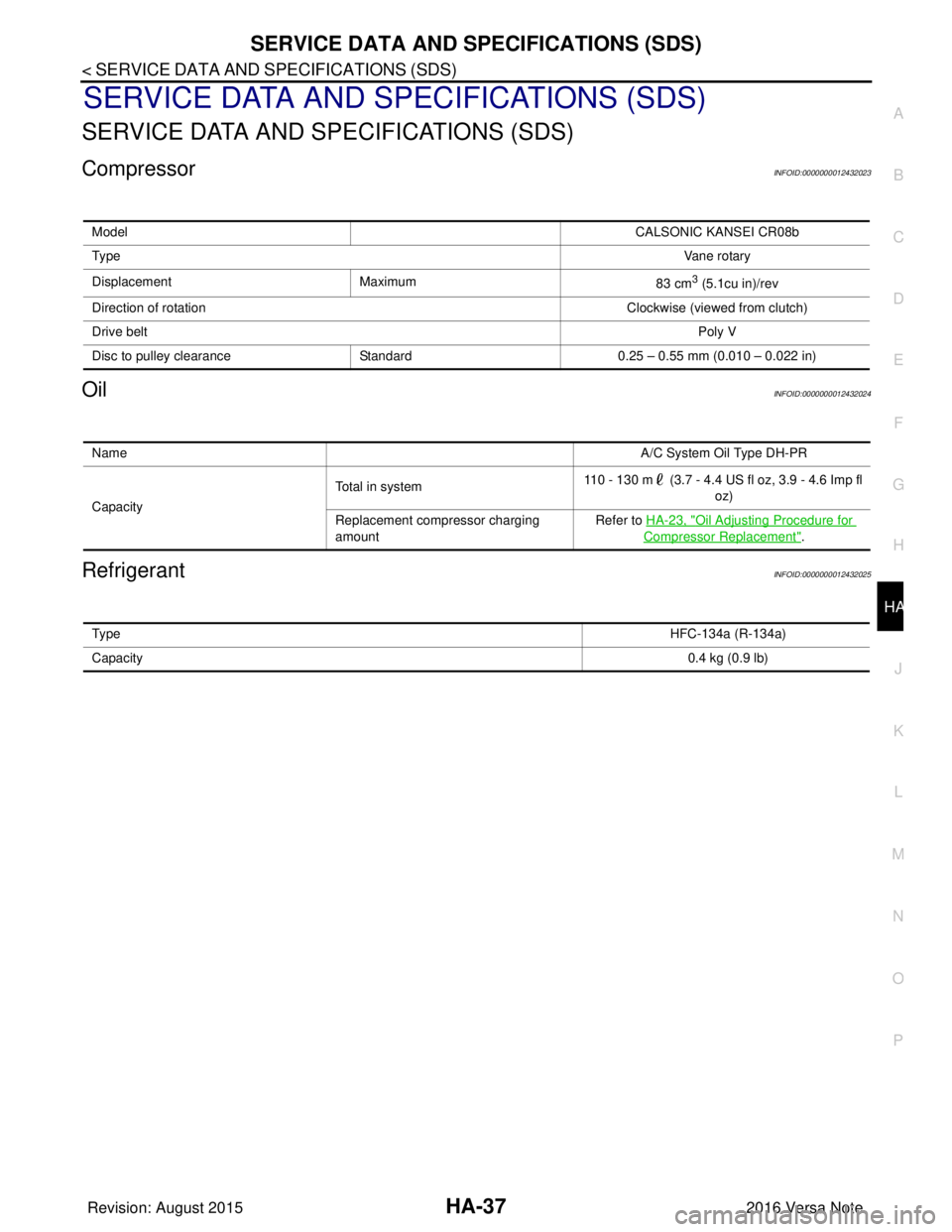

SERVICE DATA AND SPECIFICATIONS (SDS)HA-37

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

DE

F

G H

J

K L

M A

B

HA

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

CompressorINFOID:0000000012432023

OilINFOID:0000000012432024

RefrigerantINFOID:0000000012432025

Model CALSONIC KANSEI CR08b

Ty p e Vane rotary

Displacement Maximum 83 cm

3 (5.1cu in)/rev

Direction of rotation Clockwise (viewed from clutch)

Drive belt Poly V

Disc to pulley clearance Standard0.25 – 0.55 mm (0.010 – 0.022 in)

Name A/C System Oil Type DH-PR

Capacity Total in system

110 - 130 m (3.7 - 4.4 US fl oz, 3.9 - 4.6 Imp fl

oz)

Replacement compressor charging

amount Refer to

HA-23, "

Oil Adjusting Procedure for

Compressor Replacement".

Ty p e HFC-134a (R-134a)

Capacity 0.4 kg (0.9 lb)

Revision: August 20152016 Versa Note

cardiagn.com