battery NISSAN NOTE 2016 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 2633 of 3641

PG-46

< WIRING DIAGRAM >

HARNESS

D3 E4 Y/2 : Crash zone sensorE1 E42 B/2: IPDM E/R (Intelligent power distribution

module engine room)

E4 E5 B/2 : Cooling fan motor (With CVT)E2 E43 B/6: IPDM E/R (Intelligent power distribution

module engine room)

E2 E8 W/24 : To F8 F2 E44 BR/8: IPDM E/R (Intelligent power distribution

module engine room)

E3 E9 BR/2 : Fusible link b o x ( B a t t e r y )E 1 E 4 5 B R / 1 2: IPDM E/R (Intelligent power distribution

module engine room)

E2 E10 GR/2 : Fusible link box (Battery) F2 E46 W/24: IPDM E/R (Intelligent power distribution

module engine room)

G 2 E 1 5 — : B o d y g r o u n d F 2 E 4 7 W / 1 6: IPDM E/R (Intelligent power distribution

module engine room)

F 2 E 1 6 B / 3 2 : E C M B 3 E 5 0 B R / 2 : W a s h e r f l u i d l e v e l s w i t c h

F4 E17 B/3 : Refrigerant pressure sensor E3 E51 B/2 : Front wheel sensor LH

C4 E18 BR/1 : Horn C4 E52 B/2 : Front wheel sensor RH

E 2 E 1 9 W / 6 : To F 3 3 G 4 E 5 3 B / 2 : F r o n t f o g l a m p L H

C 4 E 2 0 B / 1 : H o r n B 5 E 5 4 B / 2 : F r o n t f o g l a m p R H

A2 E24 — : Body ground E2 E55 GR/12 : To F55

G3 E25 B/3 : Front combination lamp LH G3 E62 L/4 : Cooling fan relay

A3 E26 B/3 : Front combination lamp RH C3 E63 GR/4 : Heated oxygen sensor 2

G2 E27 B/2 : Front combination lamp LH C4 E64 L/4 : Heated seat relay

A2 E28 B/2 : Front combinati on lamp RHG5 E69 B/2 : Ambient sensor

F4 E29 GR/3 : Front combination lamp LH E5 E70 BR/3 : Intelligent Key warning buzzer

B3 E30 GR/3 : Front combination lamp RH F5 E71 B/4 : Front camera

E3 E31 GR/4 : Cooling fan motor (With CVT) G3 E72 L/4 : Active grille shutter relay

E4 E32 W/2 : Cooling fan motor (With CVT) Front fog lamp sub harness

B2 E33 B/38 : ABS actuator and electric unit (Control

unit) E5 E302 B/4 : To E35

E5 E35 B/4 : To E302 F5 E303 B/4 : Active grille shutter

E1 E39 W/3 : Horn relay F5 E303 B/4 : Active grille shutter

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2636 of 3641

PG

HARNESSPG-49

< WIRING DIAGRAM >

C

DE

F

G H

I

J

K L

B A

O P

N

B3 F1 B/3 : Generator

D4 F28 — : Starter motor

B3 F2 — : Generator D3 F29 B/2 : Fuel injector no. 3 (Rear)

B4 F3 B/1 : A/C compressor D3 F30 B/2 : Fuel injector no. 4 (Rear)

B4 F4 — : Generator D1 F31 B/6 : Mass air flow sensor

B4 F5 — : Engine ground E1 F32 GR/2: Exhaust valve timing control solenoid

valve

E2 F6 GR/2 : Engine coolant temperature sensor F1 F33 W/6 : To E19

D1 F7 B/6 : Electric throttle control actuator B1 F34 GR/3: Ignition coil no.1 (With power

transistor)

E 1 F 8 W / 2 4 : To E 8 C 1 F 3 5 G R / 3: Ignition coil no.2 (With power

transistor)

F2 F9 GR/4 : Battery current sensor C1 F36 GR/3: Ignition coil no.3 (With power

transistor)

G 2 F 1 0 G R / 3 2 : E C M D 2 F 3 7 G R / 3: Ignition coil no.4 (With power

transistor)

G1 F11 BR/48 : ECM C4 F38 B/3 : Engine oil pressure sensor

D1 F12 BR/4 : Air fuel ratio (A/F) sensor 1 G3 F39 — : Fusible link box (Battery)

C3 F14 GR/2 : Knock sensor G3 F40 — : Fusible link box (Battery)

E1 F15 B/3 : Crankshaft position sensor (POS) G4 F41 B/3 : Output speed sensor

D4 F16 — : Engine ground F2 F42 W/12: IPDM E/R (Intelligent power distribution

module engine room)

B3 F17 B/2 : Fuel injector no. 1 (Front) F2 F43 W/12: IPDM E/R (Intelligent power distribution

module engine room)

C3 F18 B/2 : Fuel injector no. 2 (Front) F2 F44 B/48 : TCM (Transmission control module)

C3 F19 B/2 : Fuel injector no. 3 (Front) F4 F46 GR/22 : CVT unit

D3 F20 B/2 : Fuel injector no. 4 (Front) G4 F48 B/3 : Secondary speed sensor

D2 F21 B/3 : Camshaft position sensor G4 F50 B/3 : Primary speed sensor

C 1 F 2 2 G R / 2 : Evap canister purge volume control

solenoid valve F3 F52 B/10 : Transmission range switch

B 3 F 2 3 G R / 2 : Intake valve timing control solenoid

valve

B3 F53 B/2 : Fuel injector no. 1 (Rear)

E4 F24 G/3 : Park/neutral position (PNP) switch C3 F54 B/2 : Fuel injector no. 2 (Rear)

C4 F25 GR/2 : Engine oil temperature sensor G1 F55 GR/12 : To E55

C 3 F 2 6 W / 2 : C o n d e n s e r D 2 F 5 6 B / 3: Exhaust valve timing control position

sensor

D 3 F 2 7 — : S t a r t e r m o t o r D 3 F 5 9 — : E n g i n e g r o u n d

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2648 of 3641

PG

BATTERYPG-61

< BASIC INSPECTION >

C

DE

F

G H

I

J

K L

B A

O P

N

BASIC INSPECTION

BATTERY

How to Handle BatteryINFOID:0000000012433127

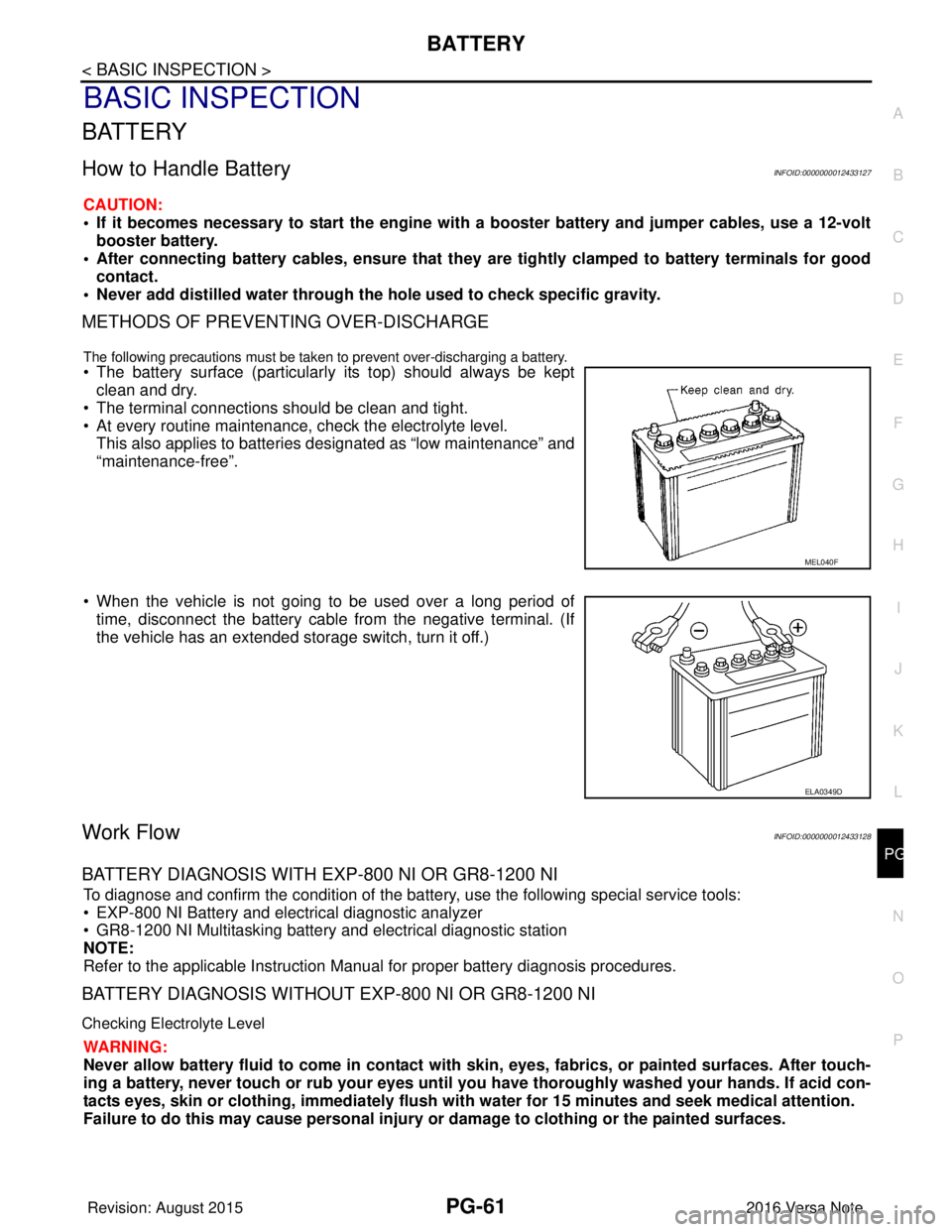

CAUTION:

• If it becomes necessary to start the engine with

a booster battery and jumper cables, use a 12-volt

booster battery.

• After connecting battery cables, ensure that they are tightly clamped to battery terminals for good

contact.

• Never add distilled water through the hole used to check specific gravity.

METHODS OF PREVENTING OVER-DISCHARGE

The following precautions must be taken to prevent over-discharging a battery.

• The battery surface (particularly its top) should always be kept

clean and dry.

• The terminal connections should be clean and tight.

• At every routine maintenance, check the electrolyte level. This also applies to batteries designated as “low maintenance” and

“maintenance-free”.

• When the vehicle is not going to be used over a long period of time, disconnect the battery cable from the negative terminal. (If

the vehicle has an extended storage switch, turn it off.)

Work FlowINFOID:0000000012433128

BATTERY DIAGNOSIS WITH EXP-800 NI OR GR8-1200 NI

To diagnose and confirm the condition of the batte ry, use the following special service tools:

• EXP-800 NI Battery and electrical diagnostic analyzer

• GR8-1200 NI Multitasking battery and electrical diagnostic station

NOTE:

Refer to the applicable Instruction Manual for proper battery diagnosis procedures.

BATTERY DIAGNOSIS WITHOUT EXP-800 NI OR GR8-1200 NI

Checking Electrolyte Level

WARNING:

Never allow battery fluid to come in contact with skin, eyes, fabrics, or painted surfaces. After touch-

ing a battery, never touch or rub your eyes until you have thoroughly washed your hands. If acid con-

tacts eyes, skin or clothing, imme diately flush with water for 15 minutes and seek medical attention.

Failure to do this may cause personal injury or damage to clothing or the painted surfaces.

MEL040F

ELA0349D

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2649 of 3641

PG-62

< BASIC INSPECTION >

BATTERY

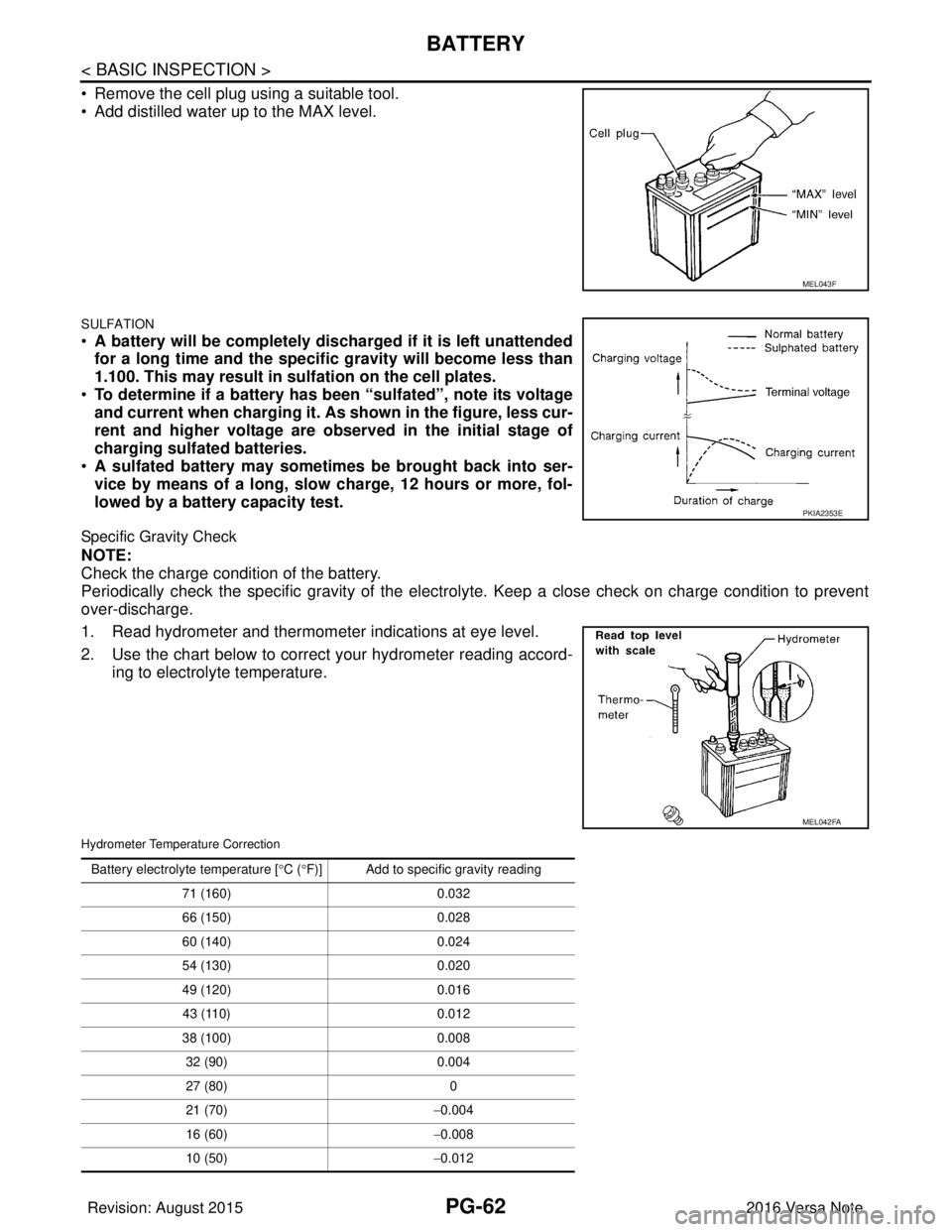

• Remove the cell plug using a suitable tool.

• Add distilled water up to the MAX level.

SULFATION

•A battery will be completely discharged if it is left unattended

for a long time and the specific gravity will become less than

1.100. This may result in su lfation on the cell plates.

• To determine if a battery has been “sulfated”, note its voltage

and current when charging it. As shown in the figure, less cur-

rent and higher voltage are ob served in the initial stage of

charging sulfated batteries.

• A sulfated battery may someti mes be brought back into ser-

vice by means of a long, slow charge, 12 hours or more, fol-

lowed by a battery capacity test.

Specific Gravity Check

NOTE:

Check the charge condition of the battery.

Periodically check the specific gravity of the electr olyte. Keep a close check on charge condition to prevent

over-discharge.

1. Read hydrometer and thermometer indications at eye level.

2. Use the chart below to correct your hydrometer reading accord- ing to electrolyte temperature.

Hydrometer Temperature Correction

MEL043F

PKIA2353E

MEL042FA

Battery electrolyte temperature [° C (°F)] Add to specific gravity reading

71 (160) 0.032

66 (150) 0.028

60 (140) 0.024

54 (130) 0.020

49 (120) 0.016

43 (110) 0.012

38 (100) 0.008

32 (90) 0.004

27 (80) 0

21 (70) −0.004

16 (60) −0.008

10 (50) −0.012

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2650 of 3641

PG

BATTERYPG-63

< BASIC INSPECTION >

C

DE

F

G H

I

J

K L

B A

O P

N

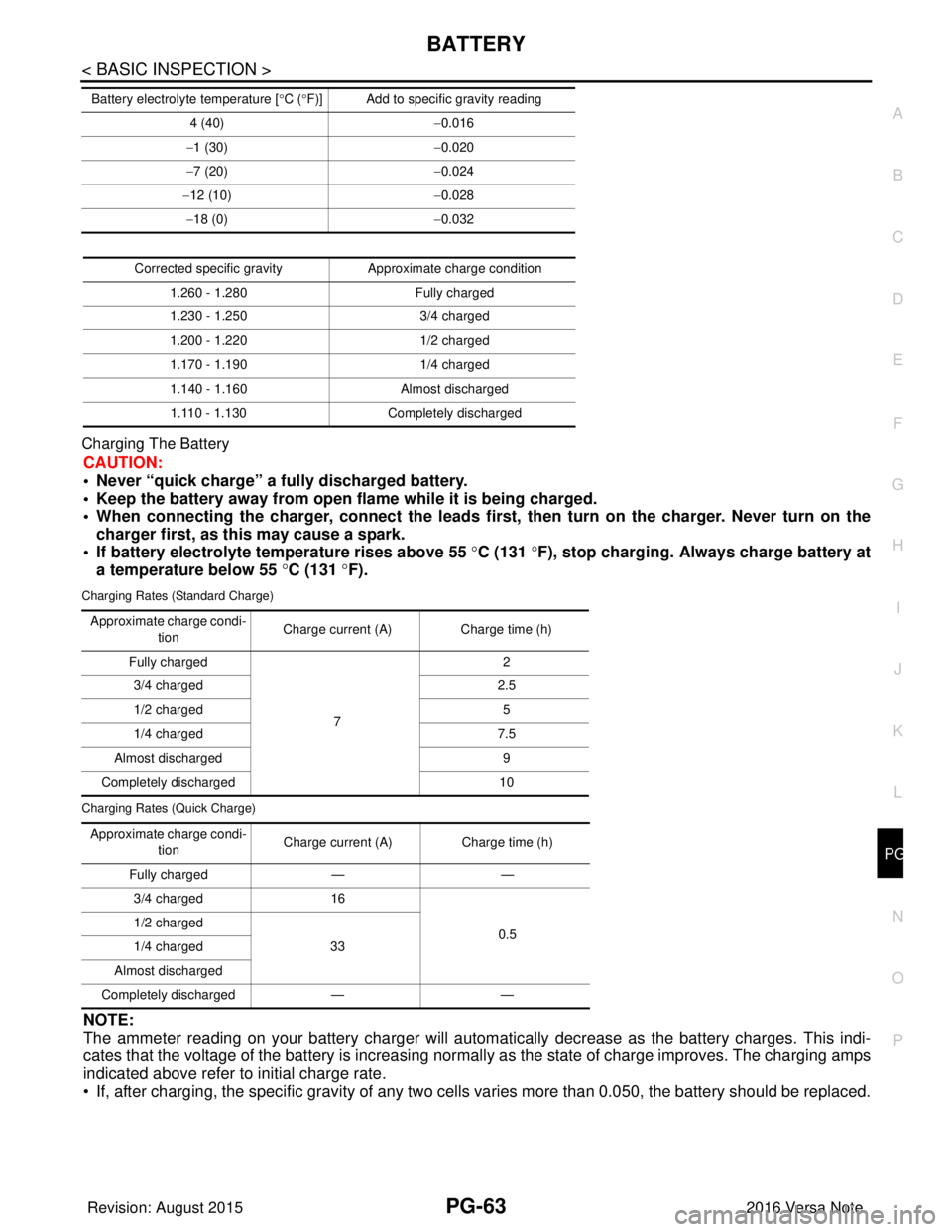

Charging The Battery

CAUTION:

• Never “quick charge” a fully discharged battery.

• Keep the battery away from open flame while it is being charged.

• When connecting the charger, connect

the leads first, then turn on the charger. Never turn on the

charger first, as this may cause a spark.

• If battery electrolyte temperature rises above 55 °C (131 °F), stop charging. Always charge battery at

a temperature below 55 °C (131 °F).

Charging Rates (Standard Charge)

Charging Rates (Quick Charge)

NOTE:

The ammeter reading on your battery charger will automatically decrease as the battery charges. This indi-

cates that the voltage of the battery is increasing norma lly as the state of charge improves. The charging amps

indicated above refer to initial charge rate.

• If, after charging, the specific gravity of any two cells varies more than 0.050, the battery should be replaced.

4 (40) −0.016

− 1 (30) −0.020

− 7 (20) −0.024

− 12 (10) −0.028

− 18 (0) −0.032

Battery electrolyte temperature [

°C ( °F)] Add to specific gravity reading

Corrected specific gravity Approximate charge condition

1.260 - 1.280 Fully charged

1.230 - 1.250 3/4 charged

1.200 - 1.220 1/2 charged

1.170 - 1.190 1/4 charged

1.140 - 1.160 Almost discharged

1.110 - 1.130 Completely discharged

Approximate charge condi-

tion Charge current (A)

Charge time (h)

Fully charged

72

3/4 charged 2.5

1/2 charged 5

1/4 charged 7.5

Almost discharged 9

Completely discharged 10

Approximate charge condi- tion Charge current (A)

Charge time (h)

Fully charged ——

3/4 charged 16

0.5

1/2 charged

33

1/4 charged

Almost discharged

Completely discharged ——

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2651 of 3641

PG-64

< BASIC INSPECTION >

INSPECTION AND ADJUSTMENT

INSPECTION AND ADJUSTMENT

ADDITIONAL SERVICE WHEN REMOVING BATTERY NEGATIVE TERMINAL

ADDITIONAL SERVICE WHEN REMOVING BATTERY NEGATIVE TERMINAL : Spe-

cial Repair Requirement

INFOID:0000000012433129

Required Procedure After Battery Disconnection

System ItemReference

Engine Control System Idle Air Volume Learning EC-130

Audio, Visual & Navigation SystemAudio (Radio Preset) Refer to Owner's Manual.

Navigation System

Refer to Owner's Manual.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2657 of 3641

PG-70

< REMOVAL AND INSTALLATION >

BATTERY

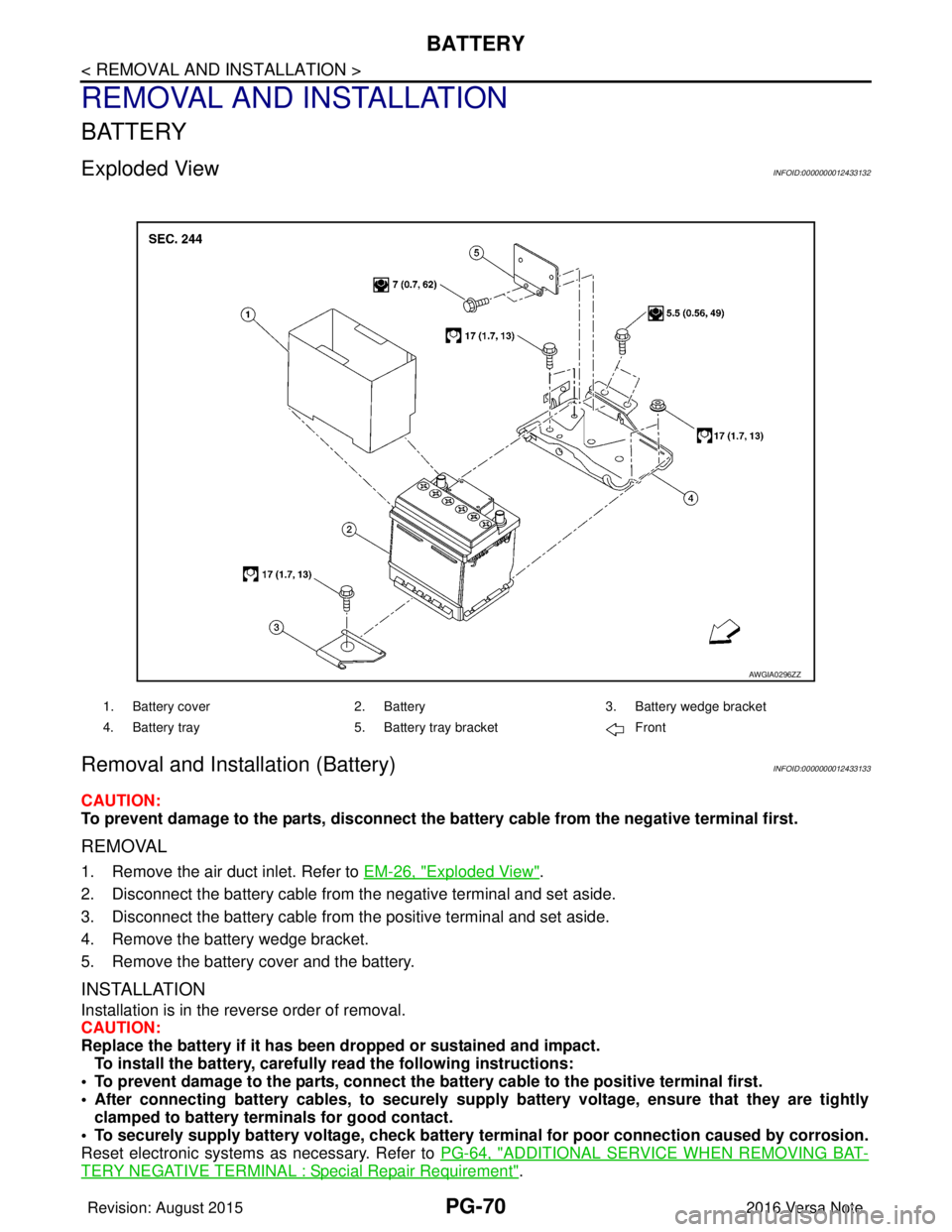

REMOVAL AND INSTALLATION

BATTERY

Exploded ViewINFOID:0000000012433132

Removal and Installation (Battery)INFOID:0000000012433133

CAUTION:

To prevent damage to the parts, disconnect the battery cable from the negative terminal first.

REMOVAL

1. Remove the air duct inlet. Refer to EM-26, "Exploded View".

2. Disconnect the battery cable from the negative terminal and set aside.

3. Disconnect the battery cable from the positive terminal and set aside.

4. Remove the battery wedge bracket.

5. Remove the battery cover and the battery.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Replace the battery if it has been dropped or sustained and impact. To install the battery, carefully read the following instructions:

• To prevent damage to the parts, connect the battery cable to the positive terminal first.

• After connecting battery cables, to securely supply battery voltage, ensure that they are tightly

clamped to battery term inals for good contact.

• To securely supply battery voltage, check battery terminal for poor connection caused by corrosion.

Reset electronic systems as necessary. Refer to PG-64, "

ADDITIONAL SERVICE WHEN REMOVING BAT-

TERY NEGATIVE TERMINAL : Special Repair Requirement".

AWGIA0296ZZ

1. Battery cover2. Battery3. Battery wedge bracket

4. Battery tray 5. Battery tray bracket Front

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2658 of 3641

PG

BATTERYPG-71

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

B A

O P

N

Removal and Installation (Battery Tray)INFOID:0000000012433134

CAUTION:

To prevent damage to the parts, disconnect the battery cable from the negative terminal first.

REMOVAL

1. Remove the battery. Refer to

PG-70, "Removal and Installation (Battery)".

2. Remove the battery tray bracket. Refer to PG-70, "

Exploded View".

3. Remove the IPDM E/R. Refer to PCS-30, "

Removal and Installation".

4. Disconnect the harness from the TCM and remove the TCM bracket. Refer to TM-239, "

Removal and

Installation" (FOR CVT MODEL).

5. Disconnect the harness fr om the battery tray.

6. Remove the nuts and bolts and remove the battery tray. Refer to PG-70, "

Exploded View".

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Replace electrical components as necessary, if any have been dropped or sustained and impact.

To install the battery, carefully read the following instructions:

• To prevent damage to the parts, connect the battery cable to the positive terminal first.

• After connecting battery cables, to securely supp ly battery voltage, ensure that they are tightly

clamped to battery terminals for good contact.

• To securely supply battery voltage, check battery terminal for poor connection caused by corrosion.

Reset electronic systems as necessary. Refer to PG-64, "

ADDITIONAL SERVICE WHEN REMOVING BAT-

TERY NEGATIVE TERMINAL : Special Repair Requirement".

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2659 of 3641

PG-72

< REMOVAL AND INSTALLATION >

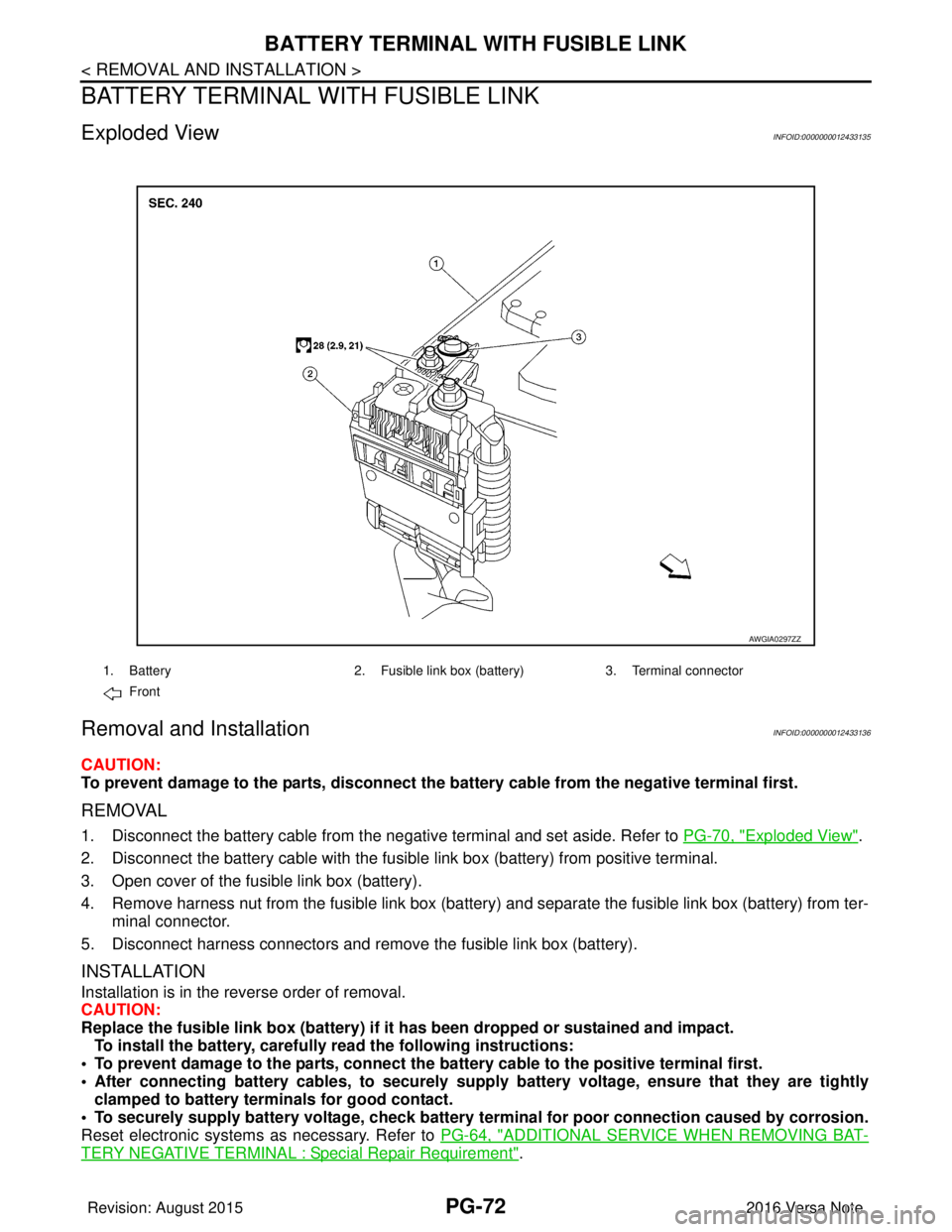

BATTERY TERMINAL WITH FUSIBLE LINK

BATTERY TERMINAL WITH FUSIBLE LINK

Exploded ViewINFOID:0000000012433135

Removal and InstallationINFOID:0000000012433136

CAUTION:

To prevent damage to the parts, disconnect the battery cable from the negative terminal first.

REMOVAL

1. Disconnect the battery cable from the negative terminal and set aside. Refer to PG-70, "Exploded View".

2. Disconnect the battery cable with the fusibl e link box (battery) from positive terminal.

3. Open cover of the fusible link box (battery).

4. Remove harness nut from the fusible link box (battery ) and separate the fusible link box (battery) from ter-

minal connector.

5. Disconnect harness connectors and remove the fusible link box (battery).

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Replace the fusible link box (battery) if it has been dropped or sustained and impact.

To install the battery, carefully read the following instructions:

• To prevent damage to the parts, connect the battery cable to the positive terminal first.

• After connecting battery cables, to securely supply battery voltage, ensure that they are tightly

clamped to battery term inals for good contact.

• To securely supply battery voltage, check battery terminal for poor connection caused by corrosion.

Reset electronic systems as necessary. Refer to PG-64, "

ADDITIONAL SERVICE WHEN REMOVING BAT-

TERY NEGATIVE TERMINAL : Special Repair Requirement".

AWGIA0297ZZ

1. Battery2. Fusible link box (battery) 3. Terminal connector

Front

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2660 of 3641

PG

BATTERY CURRENT SENSORPG-73

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

B A

O P

N

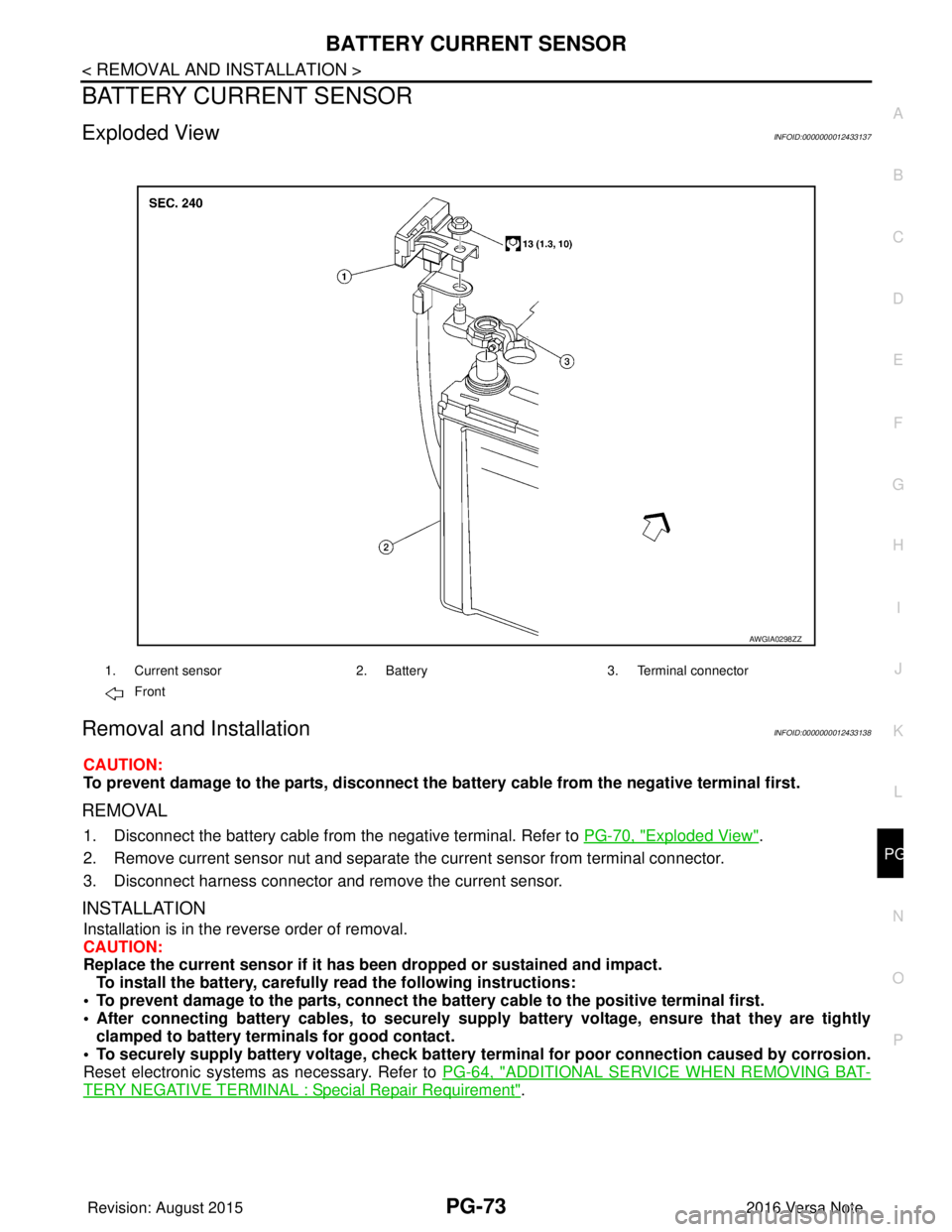

BATTERY CURRENT SENSOR

Exploded ViewINFOID:0000000012433137

Removal and InstallationINFOID:0000000012433138

CAUTION:

To prevent damage to the parts, disconnect the battery cable from the negative terminal first.

REMOVAL

1. Disconnect the battery cable from

the negative terminal. Refer to PG-70, "Exploded View".

2. Remove current sensor nut and separate the current sensor from terminal connector.

3. Disconnect harness connector and remove the current sensor.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Replace the current sensor if it has b een dropped or sustained and impact.

To install the battery, carefully read the following instructions:

• To prevent damage to the parts, connect the battery cable to the positive terminal first.

• After connecting battery cables, to securely supp ly battery voltage, ensure that they are tightly

clamped to battery terminals for good contact.

• To securely supply battery voltage, check battery terminal for poor connection caused by corrosion.

Reset electronic systems as necessary. Refer to PG-64, "

ADDITIONAL SERVICE WHEN REMOVING BAT-

TERY NEGATIVE TERMINAL : Special Repair Requirement".

AWGIA0298ZZ

1. Current sensor2. Battery3. Terminal connector

Front

Revision: August 2015 2016 Versa Note

cardiagn.com