rear NISSAN PATROL 1998 Y61 / 5.G Electrical System Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PATROL, Model: NISSAN PATROL 1998 Y61 / 5.GPages: 326, PDF Size: 11.36 MB

Page 167 of 326

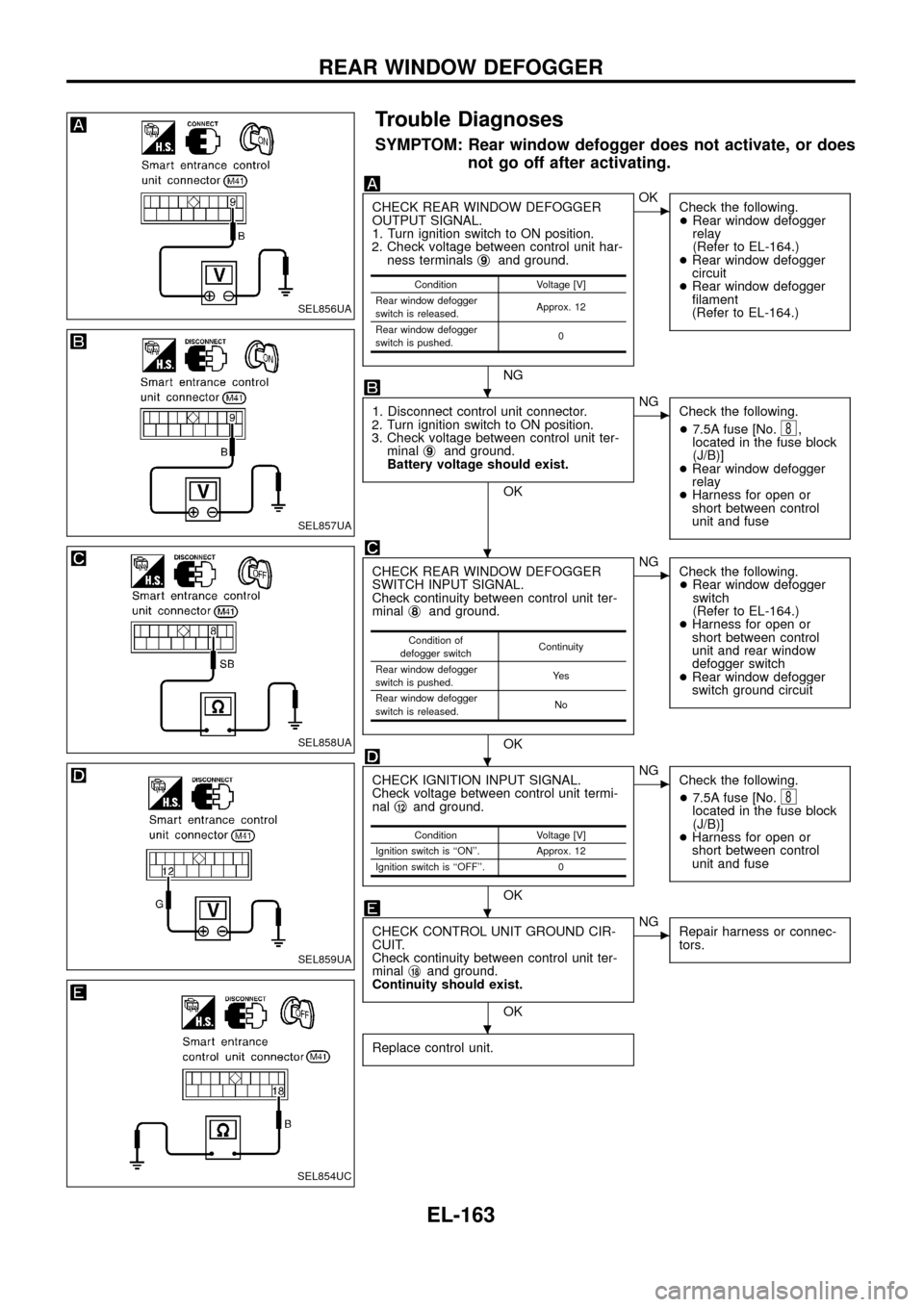

Trouble Diagnoses

SYMPTOM: Rear window defogger does not activate, or does

not go off after activating.

CHECK REAR WINDOW DEFOGGER

OUTPUT SIGNAL.

1. Turn ignition switch to ON position.

2. Check voltage between control unit har-

ness terminalsj

9and ground.

NG

cOK

Check the following.

+Rear window defogger

relay

(Refer to EL-164.)

+Rear window defogger

circuit

+Rear window defogger

®lament

(Refer to EL-164.)

1. Disconnect control unit connector.

2. Turn ignition switch to ON position.

3. Check voltage between control unit ter-

minalj

9and ground.

Battery voltage should exist.

OK

cNG

Check the following.

+7.5A fuse [No.

8,

located in the fuse block

(J/B)]

+Rear window defogger

relay

+Harness for open or

short between control

unit and fuse

CHECK REAR WINDOW DEFOGGER

SWITCH INPUT SIGNAL.

Check continuity between control unit ter-

minalj

8and ground.

OK

cNG

Check the following.

+Rear window defogger

switch

(Refer to EL-164.)

+Harness for open or

short between control

unit and rear window

defogger switch

+Rear window defogger

switch ground circuit

CHECK IGNITION INPUT SIGNAL.

Check voltage between control unit termi-

nalj

12and ground.

OK

cNG

Check the following.

+7.5A fuse [No.

8located in the fuse block

(J/B)]

+Harness for open or

short between control

unit and fuse

CHECK CONTROL UNIT GROUND CIR-

CUIT.

Check continuity between control unit ter-

minalj

18and ground.

Continuity should exist.

OK

cNG

Repair harness or connec-

tors.

Replace control unit.

Condition Voltage [V]

Rear window defogger

switch is released.Approx. 12

Rear window defogger

switch is pushed.0

Condition of

defogger switchContinuity

Rear window defogger

switch is pushed.Ye s

Rear window defogger

switch is released.No

Condition Voltage [V]

Ignition switch is ``ON''. Approx. 12

Ignition switch is ``OFF''. 0

SEL856UA

SEL857UA

SEL858UA

SEL859UA

SEL854UC

.

.

.

.

.

REAR WINDOW DEFOGGER

EL-163

Page 168 of 326

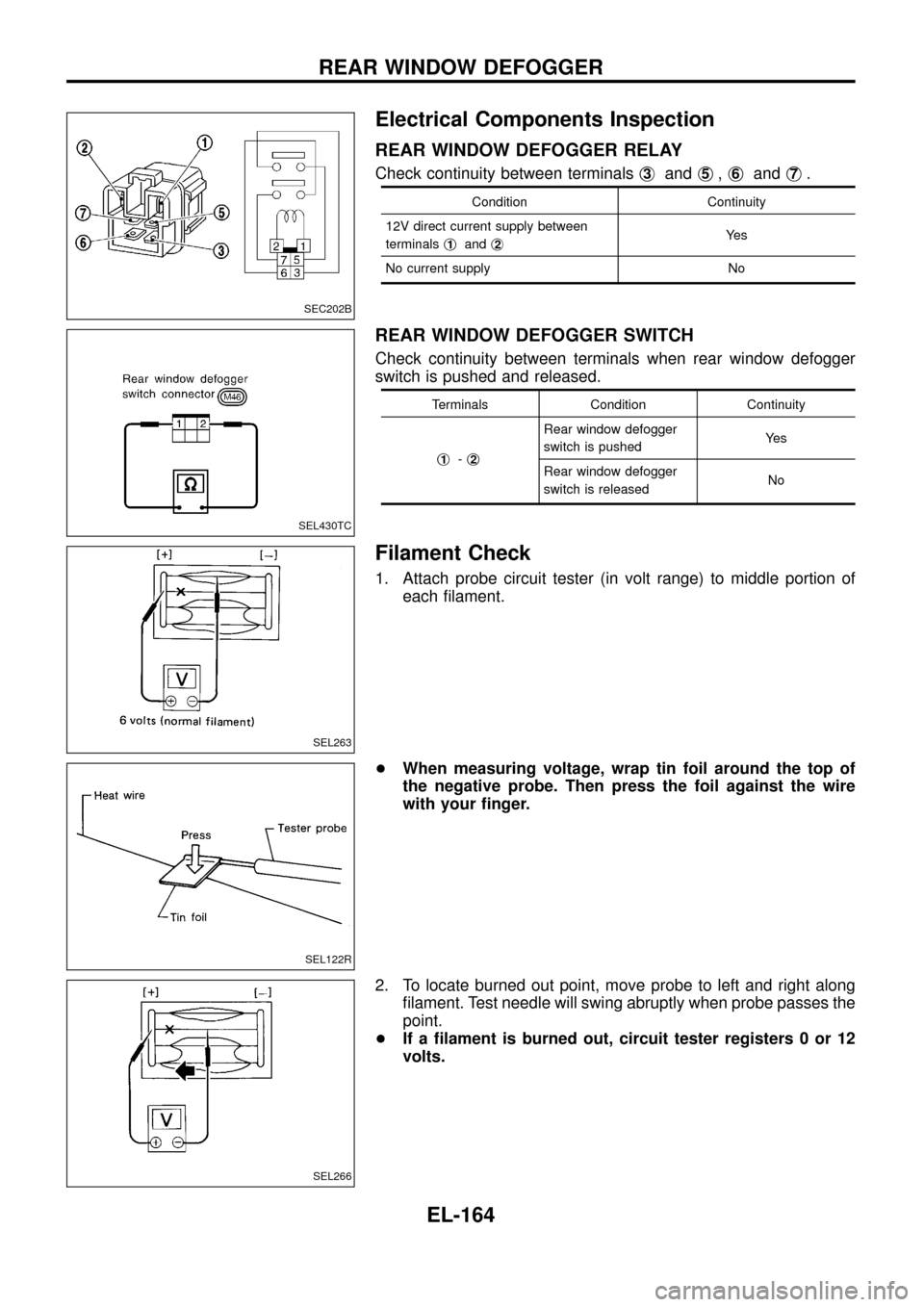

Electrical Components Inspection

REAR WINDOW DEFOGGER RELAY

Check continuity between terminalsj3andj5,j6andj7.

Condition Continuity

12V direct current supply between

terminalsj

1andj2Ye s

No current supply No

REAR WINDOW DEFOGGER SWITCH

Check continuity between terminals when rear window defogger

switch is pushed and released.

Terminals Condition Continuity

j

1-j2

Rear window defogger

switch is pushedYe s

Rear window defogger

switch is releasedNo

Filament Check

1. Attach probe circuit tester (in volt range) to middle portion of

each ®lament.

+When measuring voltage, wrap tin foil around the top of

the negative probe. Then press the foil against the wire

with your ®nger.

2. To locate burned out point, move probe to left and right along

®lament. Test needle will swing abruptly when probe passes the

point.

+If a ®lament is burned out, circuit tester registers 0 or 12

volts.

SEC202B

SEL430TC

SEL263

SEL122R

SEL266

REAR WINDOW DEFOGGER

EL-164

Page 169 of 326

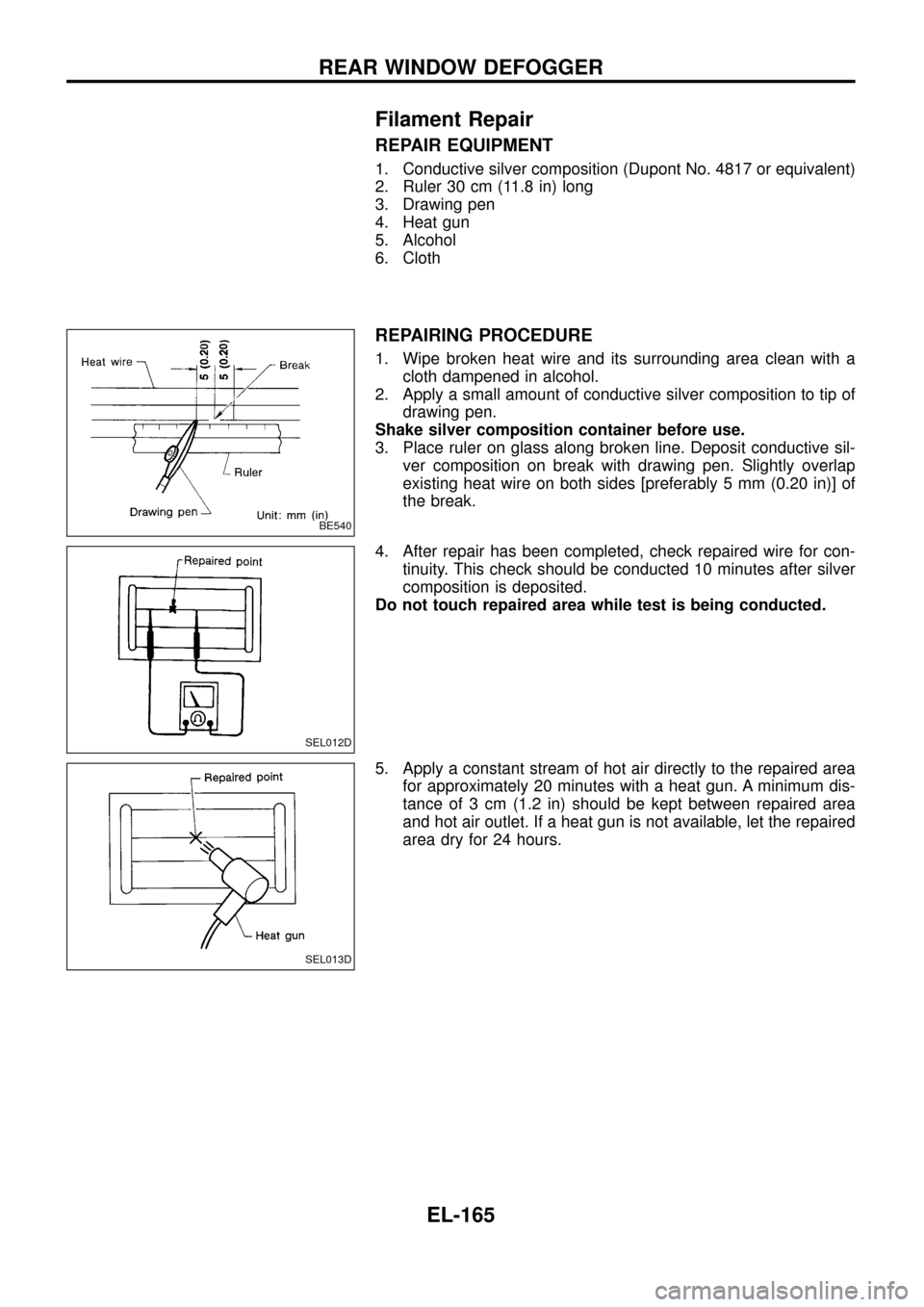

Filament Repair

REPAIR EQUIPMENT

1. Conductive silver composition (Dupont No. 4817 or equivalent)

2. Ruler 30 cm (11.8 in) long

3. Drawing pen

4. Heat gun

5. Alcohol

6. Cloth

REPAIRING PROCEDURE

1. Wipe broken heat wire and its surrounding area clean with a

cloth dampened in alcohol.

2. Apply a small amount of conductive silver composition to tip of

drawing pen.

Shake silver composition container before use.

3. Place ruler on glass along broken line. Deposit conductive sil-

ver composition on break with drawing pen. Slightly overlap

existing heat wire on both sides [preferably 5 mm (0.20 in)] of

the break.

4. After repair has been completed, check repaired wire for con-

tinuity. This check should be conducted 10 minutes after silver

composition is deposited.

Do not touch repaired area while test is being conducted.

5. Apply a constant stream of hot air directly to the repaired area

for approximately 20 minutes with a heat gun. A minimum dis-

tance of 3 cm (1.2 in) should be kept between repaired area

and hot air outlet. If a heat gun is not available, let the repaired

area dry for 24 hours.

BE540

SEL012D

SEL013D

REAR WINDOW DEFOGGER

EL-165

Page 176 of 326

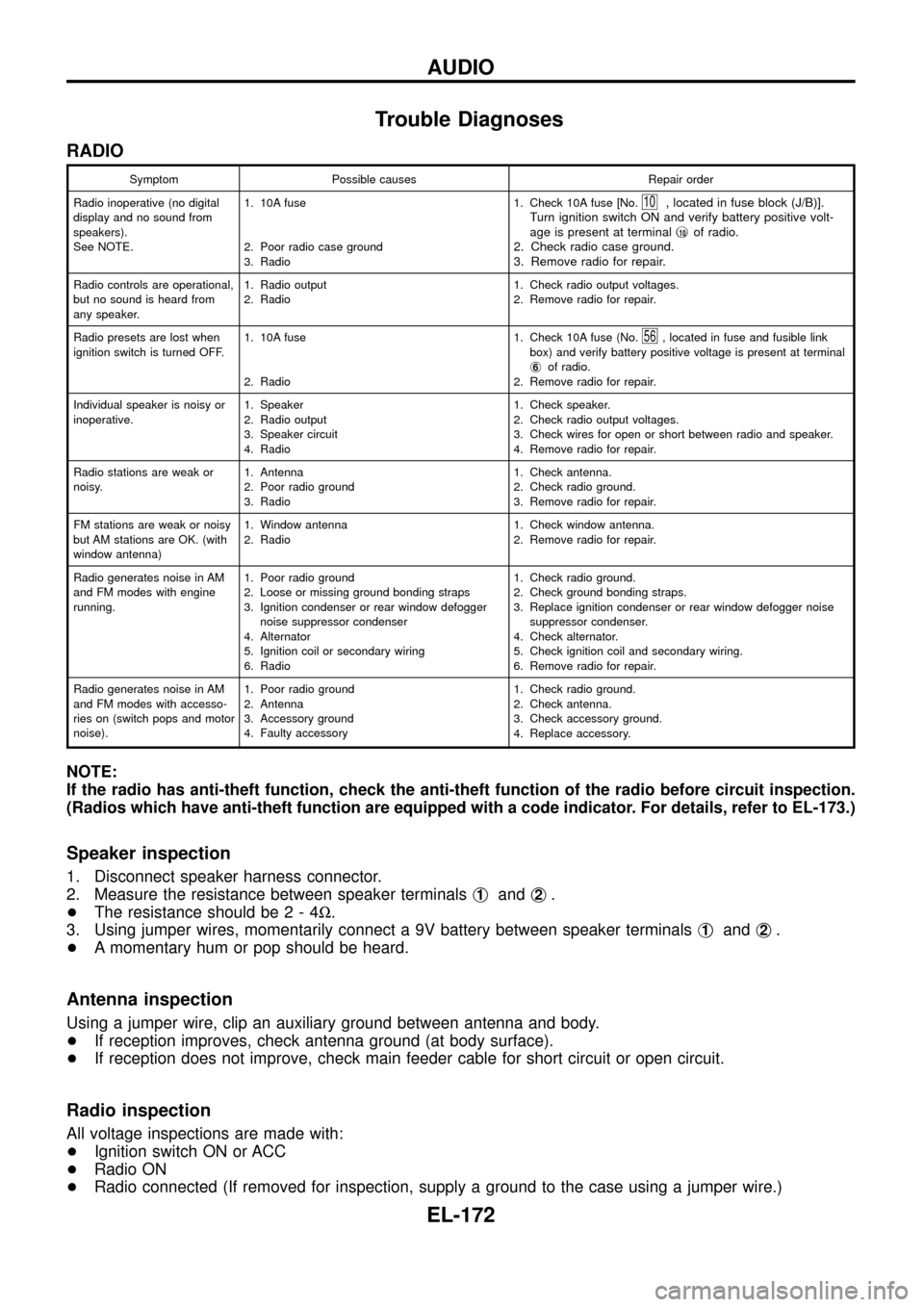

Trouble Diagnoses

RADIO

Symptom Possible causes Repair order

Radio inoperative (no digital

display and no sound from

speakers).

See NOTE.1. 10A fuse

2. Poor radio case ground

3. Radio1. Check 10A fuse [No.

10, located in fuse block (J/B)].

Turn ignition switch ON and verify battery positive volt-

age is present at terminalj

10of radio.

2. Check radio case ground.

3. Remove radio for repair.

Radio controls are operational,

but no sound is heard from

any speaker.1. Radio output

2. Radio1. Check radio output voltages.

2. Remove radio for repair.

Radio presets are lost when

ignition switch is turned OFF.1. 10A fuse

2. Radio1. Check 10A fuse (No.

56, located in fuse and fusible link

box) and verify battery positive voltage is present at terminal

j

6of radio.

2. Remove radio for repair.

Individual speaker is noisy or

inoperative.1. Speaker

2. Radio output

3. Speaker circuit

4. Radio1. Check speaker.

2. Check radio output voltages.

3. Check wires for open or short between radio and speaker.

4. Remove radio for repair.

Radio stations are weak or

noisy.1. Antenna

2. Poor radio ground

3. Radio1. Check antenna.

2. Check radio ground.

3. Remove radio for repair.

FM stations are weak or noisy

but AM stations are OK. (with

window antenna)1. Window antenna

2. Radio1. Check window antenna.

2. Remove radio for repair.

Radio generates noise in AM

and FM modes with engine

running.1. Poor radio ground

2. Loose or missing ground bonding straps

3. Ignition condenser or rear window defogger

noise suppressor condenser

4. Alternator

5. Ignition coil or secondary wiring

6. Radio1. Check radio ground.

2. Check ground bonding straps.

3. Replace ignition condenser or rear window defogger noise

suppressor condenser.

4. Check alternator.

5. Check ignition coil and secondary wiring.

6. Remove radio for repair.

Radio generates noise in AM

and FM modes with accesso-

ries on (switch pops and motor

noise).1. Poor radio ground

2. Antenna

3. Accessory ground

4. Faulty accessory1. Check radio ground.

2. Check antenna.

3. Check accessory ground.

4. Replace accessory.

NOTE:

If the radio has anti-theft function, check the anti-theft function of the radio before circuit inspection.

(Radios which have anti-theft function are equipped with a code indicator. For details, refer to EL-173.)

Speaker inspection

1. Disconnect speaker harness connector.

2. Measure the resistance between speaker terminalsj

1andj2.

+The resistance should be2-4W.

3. Using jumper wires, momentarily connect a 9V battery between speaker terminalsj

1andj2.

+A momentary hum or pop should be heard.

Antenna inspection

Using a jumper wire, clip an auxiliary ground between antenna and body.

+If reception improves, check antenna ground (at body surface).

+If reception does not improve, check main feeder cable for short circuit or open circuit.

Radio inspection

All voltage inspections are made with:

+Ignition switch ON or ACC

+Radio ON

+Radio connected (If removed for inspection, supply a ground to the case using a jumper wire.)

AUDIO

EL-172

Page 189 of 326

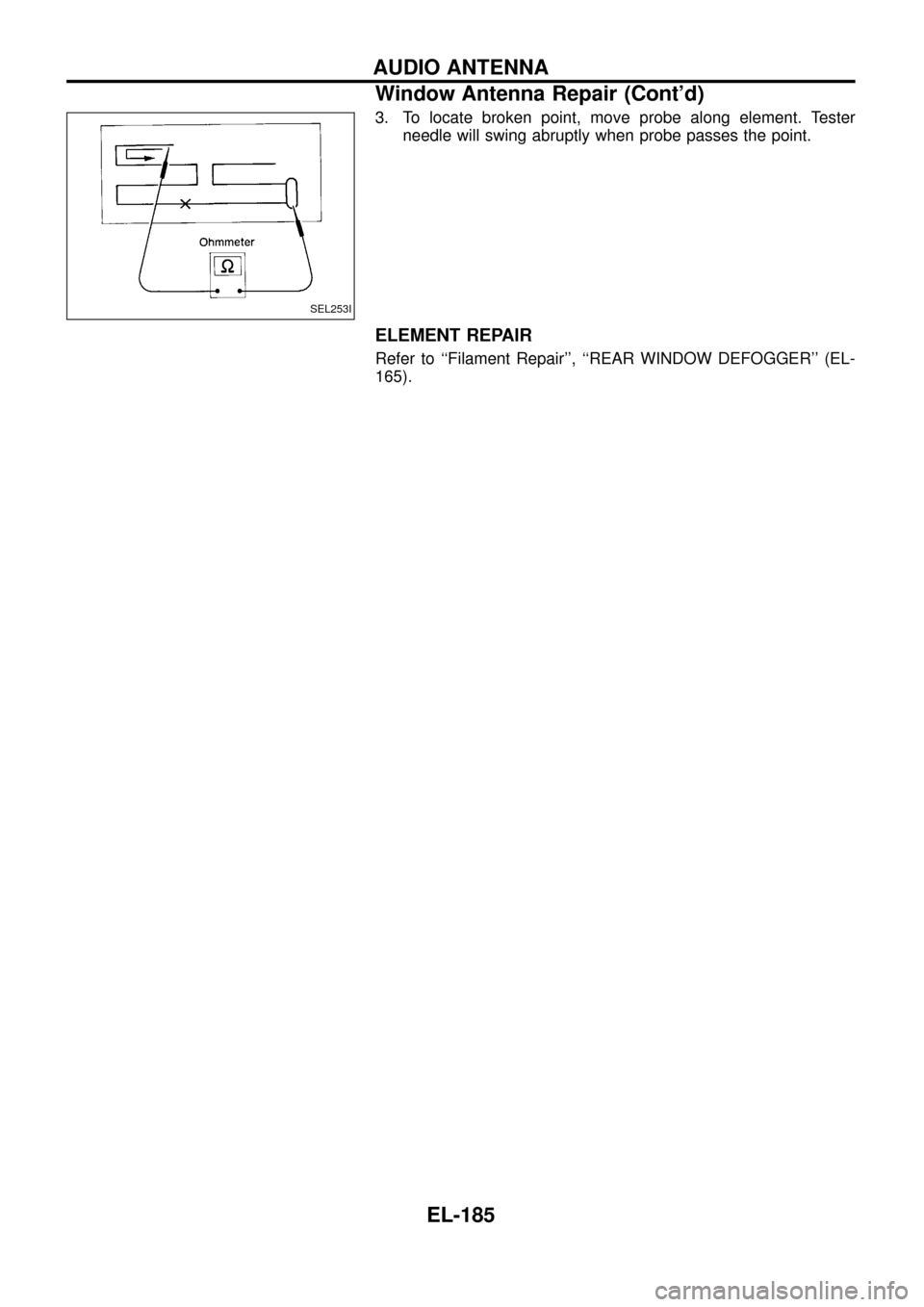

3. To locate broken point, move probe along element. Tester

needle will swing abruptly when probe passes the point.

ELEMENT REPAIR

Refer to ``Filament Repair'', ``REAR WINDOW DEFOGGER'' (EL-

165).

SEL253I

AUDIO ANTENNA

Window Antenna Repair (Cont'd)

EL-185

Page 200 of 326

![NISSAN PATROL 1998 Y61 / 5.G Electrical System Owners Guide System Description

With ignition switch in ON or START position, power is supplied

+through 7.5A fuse [No.

8, located in the fuse block (J/B)]

+to power window relay terminalj

1.

The power window rela NISSAN PATROL 1998 Y61 / 5.G Electrical System Owners Guide System Description

With ignition switch in ON or START position, power is supplied

+through 7.5A fuse [No.

8, located in the fuse block (J/B)]

+to power window relay terminalj

1.

The power window rela](/img/5/616/w960_616-199.png)

System Description

With ignition switch in ON or START position, power is supplied

+through 7.5A fuse [No.

8, located in the fuse block (J/B)]

+to power window relay terminalj

1.

The power window relay is energized and power is supplied

+through power window relay terminalj

5

+to power window main switch terminalj1,

+to power window sub switch terminalj

5.

MANUAL OPERATION

NOTE:

Numbers in parentheses are terminal numbers, when power window switch is pressed in the UP and DOWN

positions respectively.

Driver side

When the driver side switch in the power window main switch is pressed in the up position, power is supplied

+to driver side power window regulator terminal (j

2,j1)

+through power window main switch terminal (j

9,j8).

Ground is supplied

+to driver side power window regulator terminal (j

1,j2)

+through power window main switch terminal (j

8,j9).

Then, the motor raises or lowers the window until the switch is released.

Passenger side

MAIN SWITCH OPERATION

Power is supplied

+through power window main switch (j

5,j6)

+to front power window sub-switch (j

3,j4).

The subsequent operation is the same as the sub-switch operation.

SUB-SWITCH OPERATION

Power is supplied

+through front power window sub-switch (j

1,j2)

+to passenger side power window regulator (j

2,j1).

Ground is supplied

+to passenger side power window regulator (j

1,j2)

+through front power window sub-switch (j

2,j1)

+to front power window sub-switch (j

4,j3)

+through power window main switch (j

6,j5).

Then, the motor raises or lowers the window until the switch is released.

Rear door

Rear door windows will raise and lower in the same manner as passenger side door window.

AUTO OPERATION

The power window AUTO feature enables the driver to open or close the driver's window without holding the

window switch in the respective position.

When the AUTO switch in the main switch is pressed and released, the driver's window will travel to the fully

open or closed position.

POWER WINDOW LOCK

The power window lock is designed to lock operation of all windows except for driver's door window.

When the lock switch is pressed to lock position, ground of the sub-switches in the power window main switch

is disconnected. This prevents the power window motors from operating.

POWER WINDOW

EL-196

Page 208 of 326

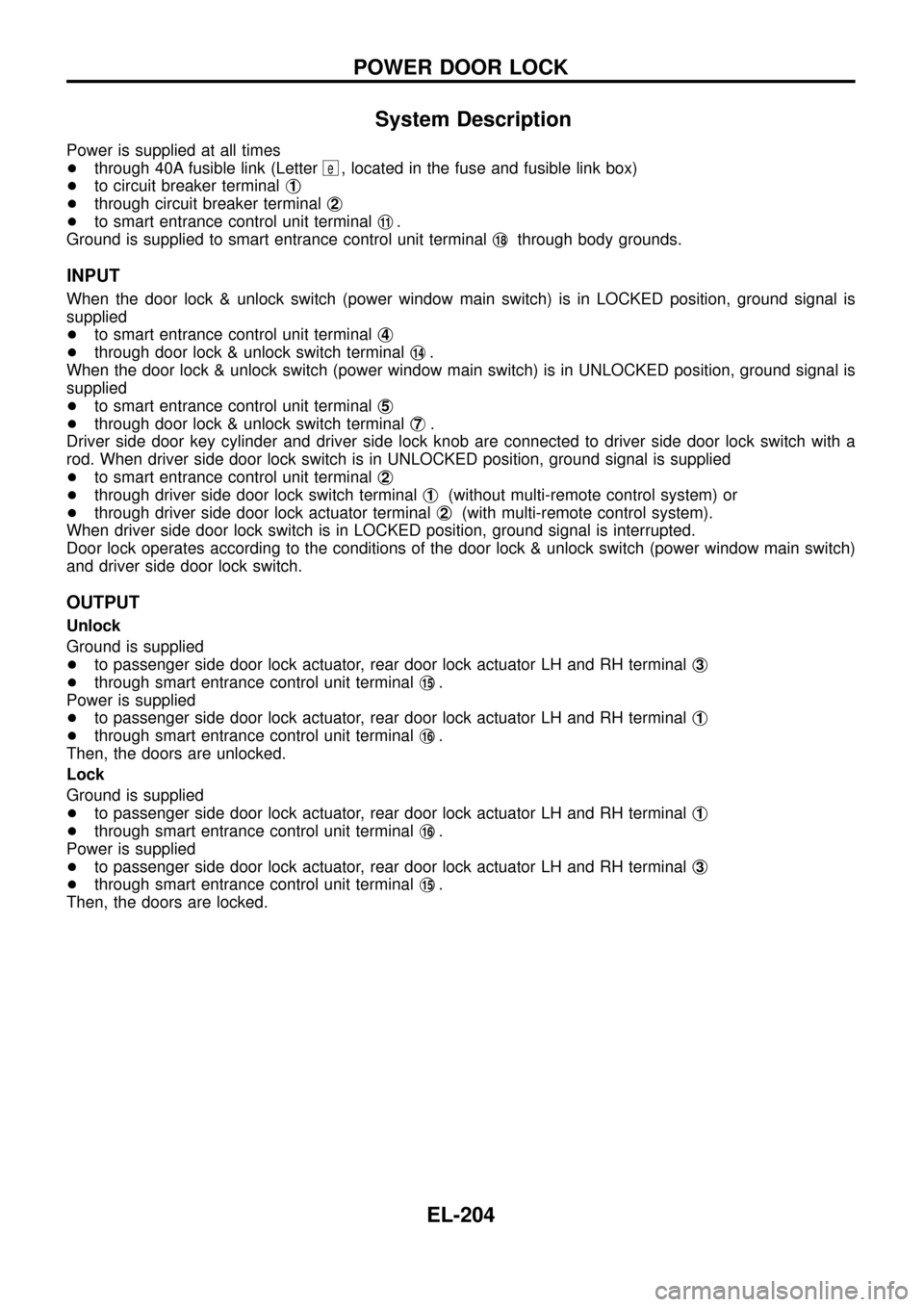

System Description

Power is supplied at all times

+through 40A fusible link (Letter

e, located in the fuse and fusible link box)

+to circuit breaker terminalj

1

+through circuit breaker terminalj2

+to smart entrance control unit terminalj11.

Ground is supplied to smart entrance control unit terminalj

18through body grounds.

INPUT

When the door lock & unlock switch (power window main switch) is in LOCKED position, ground signal is

supplied

+to smart entrance control unit terminalj

4

+through door lock & unlock switch terminalj14.

When the door lock & unlock switch (power window main switch) is in UNLOCKED position, ground signal is

supplied

+to smart entrance control unit terminalj

5

+through door lock & unlock switch terminalj7.

Driver side door key cylinder and driver side lock knob are connected to driver side door lock switch with a

rod. When driver side door lock switch is in UNLOCKED position, ground signal is supplied

+to smart entrance control unit terminalj

2

+through driver side door lock switch terminalj1(without multi-remote control system) or

+through driver side door lock actuator terminalj

2(with multi-remote control system).

When driver side door lock switch is in LOCKED position, ground signal is interrupted.

Door lock operates according to the conditions of the door lock & unlock switch (power window main switch)

and driver side door lock switch.

OUTPUT

Unlock

Ground is supplied

+to passenger side door lock actuator, rear door lock actuator LH and RH terminalj

3

+through smart entrance control unit terminalj15.

Power is supplied

+to passenger side door lock actuator, rear door lock actuator LH and RH terminalj

1

+through smart entrance control unit terminalj16.

Then, the doors are unlocked.

Lock

Ground is supplied

+to passenger side door lock actuator, rear door lock actuator LH and RH terminalj

1

+through smart entrance control unit terminalj16.

Power is supplied

+to passenger side door lock actuator, rear door lock actuator LH and RH terminalj

3

+through smart entrance control unit terminalj15.

Then, the doors are locked.

POWER DOOR LOCK

EL-204

Page 316 of 326

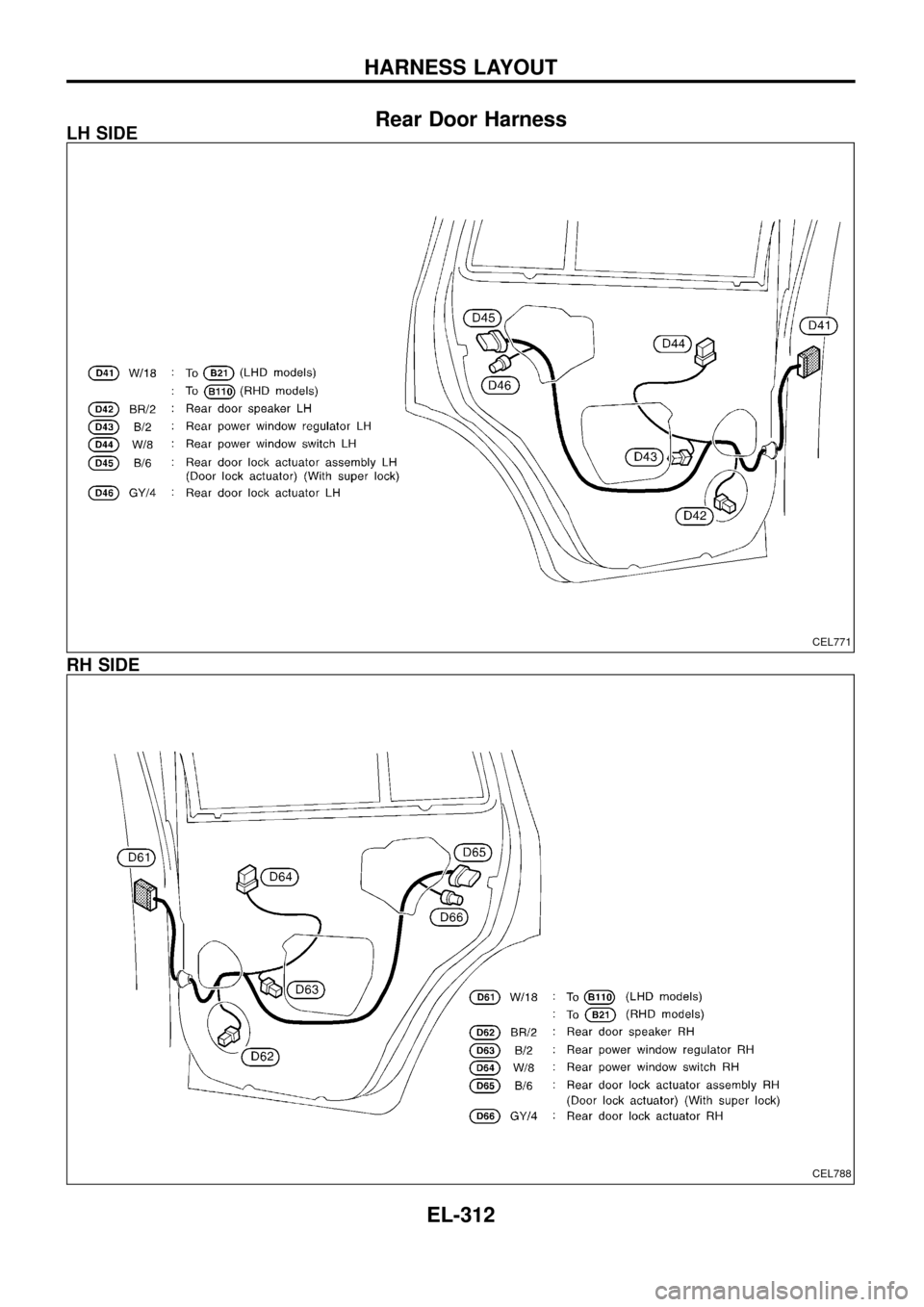

Rear Door HarnessLH SIDE

RH SIDE

CEL771

CEL788

HARNESS LAYOUT

EL-312

Page 317 of 326

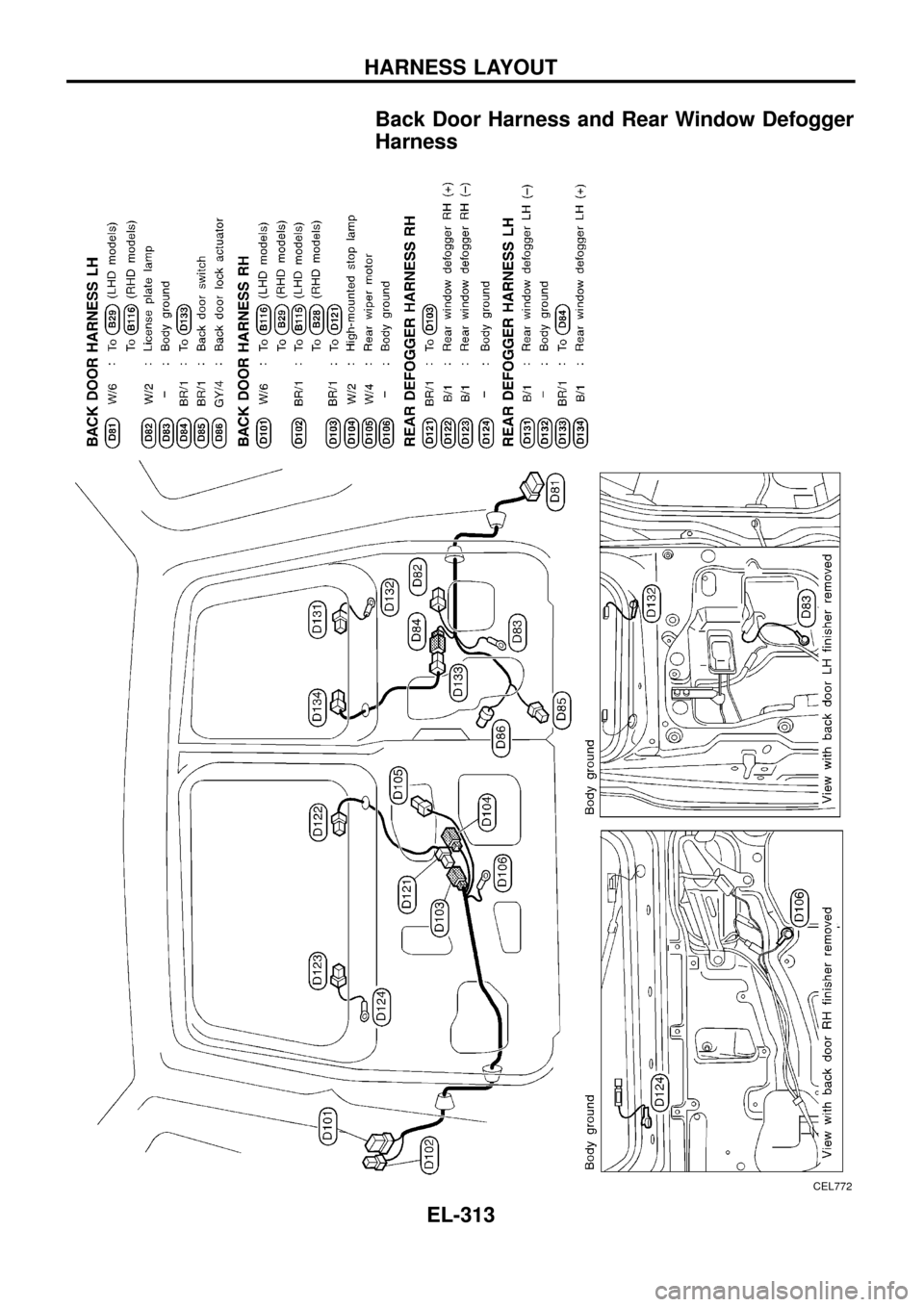

Back Door Harness and Rear Window Defogger

Harness

CEL772

HARNESS LAYOUT

EL-313

Page 318 of 326

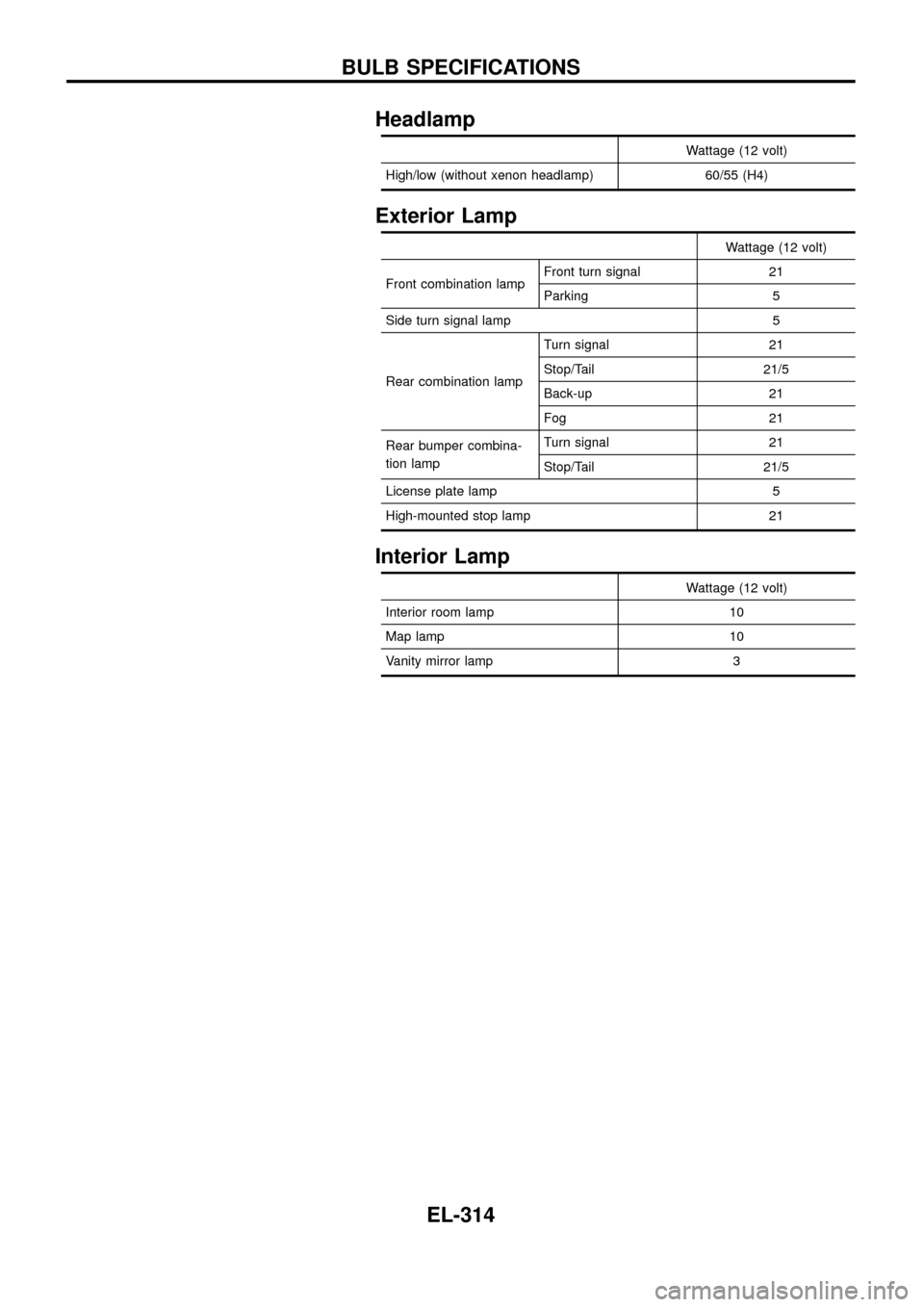

Headlamp

Wattage (12 volt)

High/low (without xenon headlamp) 60/55 (H4)

Exterior Lamp

Wattage (12 volt)

Front combination lampFront turn signal 21

Parking 5

Side turn signal lamp 5

Rear combination lampTurn signal 21

Stop/Tail 21/5

Back-up 21

Fog 21

Rear bumper combina-

tion lampTurn signal 21

Stop/Tail 21/5

License plate lamp 5

High-mounted stop lamp 21

Interior Lamp

Wattage (12 volt)

Interior room lamp 10

Map lamp 10

Vanity mirror lamp 3

BULB SPECIFICATIONS

EL-314