sen NISSAN PATROL 1998 Y61 / 5.G Electrical System Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PATROL, Model: NISSAN PATROL 1998 Y61 / 5.GPages: 326, PDF Size: 11.36 MB

Page 3 of 326

Wiring Diagram Ð P/ANT Ð/LHD Models..............181

Wiring Diagram Ð P/ANT Ð/RHD Models .............182

Trouble Diagnoses...................................................183

Location of Antenna .................................................183

Antenna Rod Replacement .....................................183

Window Antenna Repair ..........................................184

ELECTRIC SUNROOF................................................186

Wiring Diagram Ð SROOF Ð ................................186

POWER DOOR MIRROR............................................188

Wiring Diagram Ð MIRROR Ð/LHD Models..........188

Wiring Diagram Ð MIRROR Ð/RHD Models .........189

POWER SEAT.............................................................190

Wiring Diagram Ð SEAT Ð/LHD Models ...............190

Wiring Diagram Ð SEAT Ð/RHD Models...............192

HEATED SEAT............................................................194

Wiring Diagram Ð HSEAT Ð..................................194

POWER WINDOW.......................................................196

System Description ..................................................196

Schematic ................................................................197

Wiring Diagram Ð WINDOW Ð .............................198

Trouble Diagnoses...................................................203

POWER DOOR LOCK.................................................204

System Description ..................................................204

Wiring Diagram Ð D/LOCK Ð ................................205

Trouble Diagnosis ....................................................207

POWER DOOR LOCK Ð Super Lock Ð.................. 211

Component Parts and Harness Connector

Location ................................................................... 211

System Description ..................................................212

Schematic ................................................................214

Wiring Diagram Ð S/LOCK Ð/LHD Models ...........215

Wiring Diagram Ð S/LOCK Ð/RHD Models ..........219

Trouble Diagnoses...................................................223

MULTI-REMOTE CONTROL SYSTEM.......................234

System Description ..................................................234

Wiring Diagram Ð MULTI Ð/LHD Models..............235

Trouble Diagnoses...................................................237

ID Code Entry Procedure ........................................239

NATS (Nissan Anti-Theft System)/LHD MODELS....240System Description ..................................................240

System Composition ................................................240

Wiring Diagram Ð NATS Ð ....................................241

CONSULT ................................................................242

Trouble Diagnoses...................................................244

How to Replace NATS IMMU ..................................253

NATS (Nissan Anti-Theft System)/RHD MODELS...254

Component Parts and Harness Connector

Location ...................................................................254

System Description ..................................................255

System Composition ................................................255

Wiring Diagram Ð NATS Ð ....................................256

CONSULT ................................................................257

Trouble Diagnoses...................................................259

LOCATION OF ELECTRICAL UNITS.........................269

Engine Compartment ...............................................269

Passenger Compartment Ð LHD Models ...............270

Passenger Compartment Ð RHD Models ..............272

HARNESS LAYOUT....................................................275

How to Read Harness Layout .................................275

Outline/LHD Models.................................................276

Outline/RHD Models ................................................277

Main Harness/LHD Models......................................278

Main Harness/RHD Models .....................................282

Engine Room Harness/LHD Models .......................286

Engine Room Harness/RHD Models .......................290

Engine Harness .......................................................294

Engine Control Harness and Alternator Harness ....295

Body Harness/LHD Models .....................................296

Body Harness/RHD Models.....................................300

Body No. 2 Harness/LHD Models ...........................304

Body No. 2 Harness/RHD Models...........................306

Chassis Harness......................................................308

Room Lamp Harness...............................................309

Front Door Harness (Driver side) ............................310

Front Door Harness (Passenger side) .................... 311

Rear Door Harness..................................................312

Back Door Harness and Rear Window Defogger

Harness....................................................................313

Page 5 of 326

Supplemental Restraint System (SRS) ``AIR

BAG'' and ``SEAT BELT PRE-TENSIONER''

The Supplemental Restraint System such as ``AIR BAG'' and ``SEAT BELT PRE-TENSIONER'' used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger in a frontal collision.

The SRS system composition which is available to NISSAN MODEL Y61 is as follows (The composition var-

ies according to the destination.):

Driver air bag module (located in the center of the steering wheel), front passenger air bag module (located

on the instrument panel on passenger side), seat belt pre-tensioner, a diagnosis sensor unit, warning lamp,

wiring harness and spiral cable.

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

+To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag in¯ation, all maintenance must be performed

by an authorized NISSAN dealer.

+Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the RS section.

+Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation either just before

the harness connectors or for the complete harness are related to the SRS.

PRECAUTIONS

EL-1

Page 6 of 326

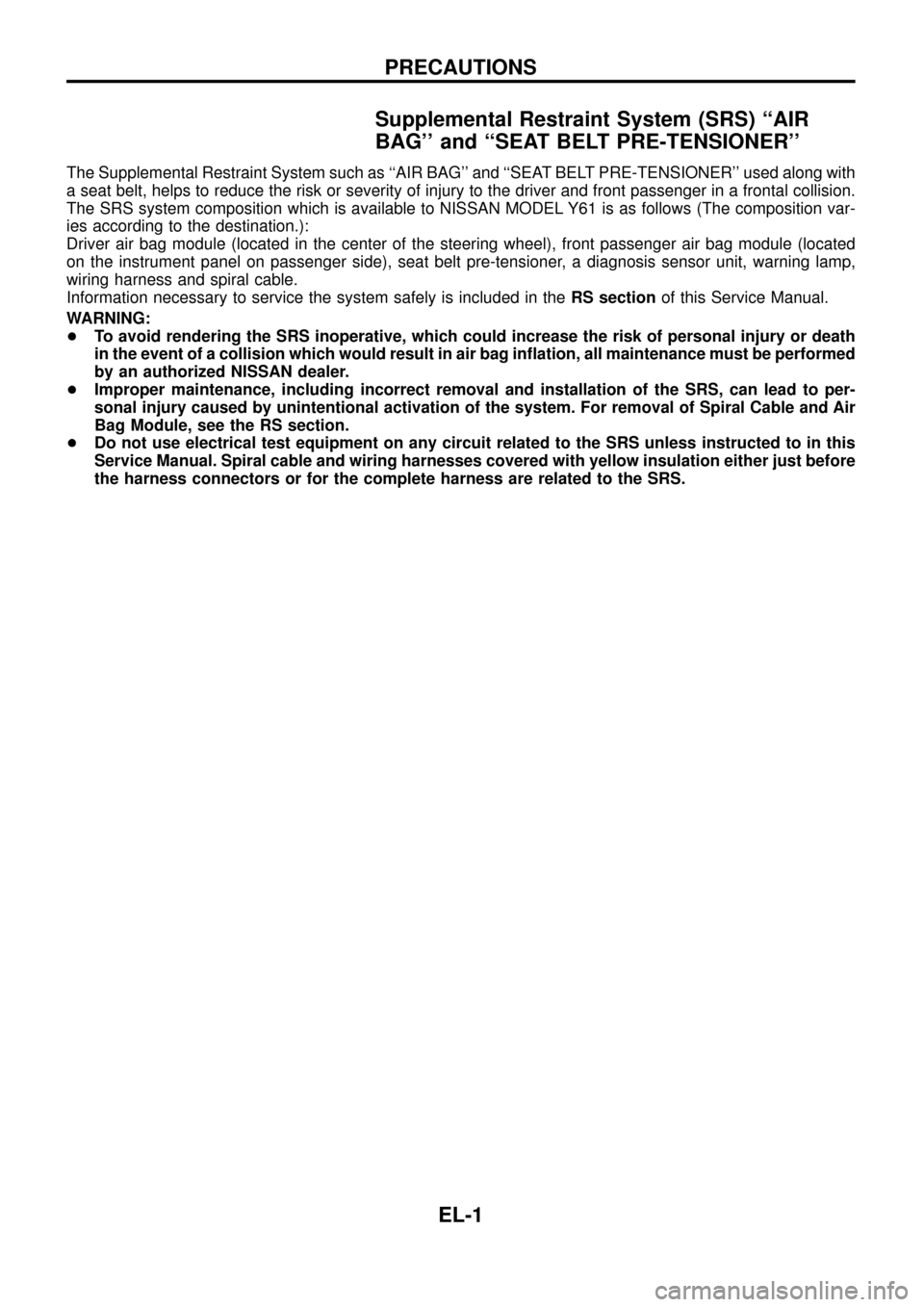

Description

HARNESS CONNECTOR

+All harness connectors have been modi®ed to prevent accidental looseness or disconnection.

+The connector can be disconnected by pushing or lifting the locking section.

CAUTION:

Do not pull the harness when disconnecting the connector.

[Example]

SEL769D

HARNESS CONNECTOR

EL-2

Page 66 of 326

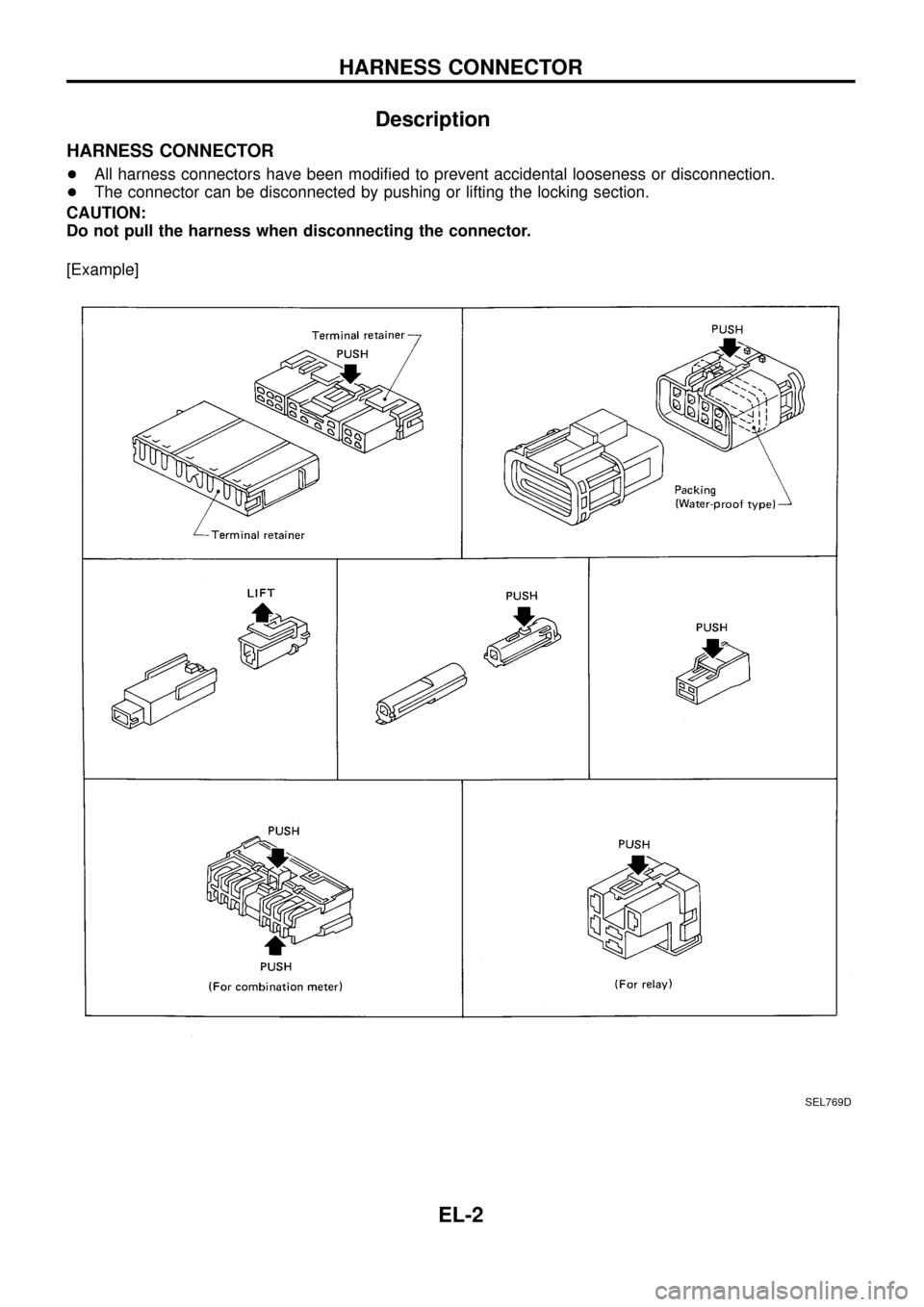

Trouble Diagnoses

Symptom Possible cause Repair order

LH headlamps do not operate. 1. Bulb

2. Grounds

E25andE40

3. 15A fuse

4. Lighting switch1. Check bulb.

2. Check grounds

E25andE40.

3. Check 15A fuse (No.

51, located in fuse and fusible

link box). Verify battery positive voltage is present at

terminalj

8of lighting switch.

4. Check lighting switch.

RH headlamps do not operate. 1. Bulb

2. Grounds

E25andE40

3. 15A fuse

4. Lighting switch1. Check bulb.

2. Check grounds

E25andE40.

3. Check 15A fuse (No.

52, located in fuse and fusible

link box). Verify battery positive voltage is present at

terminalj

5of lighting switch.

4. Check lighting switch.

LH high beams do not operate, but

LH low beam operates.1. Bulbs

2. Open in LH high beams circuit

3. Lighting switch1. Check bulbs.

2. Check R/L wire between lighting switch and LH head-

lamps for an open circuit.

3. Check lighting switch.

LH low beam does not operate, but

LH high beam operates.1. Bulb

2. Open in LH low beam circuit

3. Lighting switch1. Check bulb.

2. Check R/G wire between lighting switch and LH head-

lamp for an open circuit.

3. Check lighting switch.

RH high beams do not operate, but

RH low beam operates.1. Bulbs

2. Open in RH high beams circuit

3. Lighting switch1. Check bulbs.

2. Check R/Y wire between lighting switch and RH head-

lamps for an open circuit.

3. Check lighting switch.

RH low beam does not operate, but

RH high beam operates.1. Bulb

2. Open in RH low beam circuit

3. Lighting switch1. Check bulb.

2. Check R/B wire between lighting switch and RH head-

lamp for an open circuit.

3. Check lighting switch.

High beam indicator does not work. 1. Bulb

2. Grounds

M30andM98

3. Open in high beam circuit1. Check bulb in combination meter.

2. Check grounds

M30andM98.

3. Check R/L wire between lighting switch and combina-

tion meter for an open circuit.

HEADLAMP Ð Conventional Type Ð

EL-62

Page 68 of 326

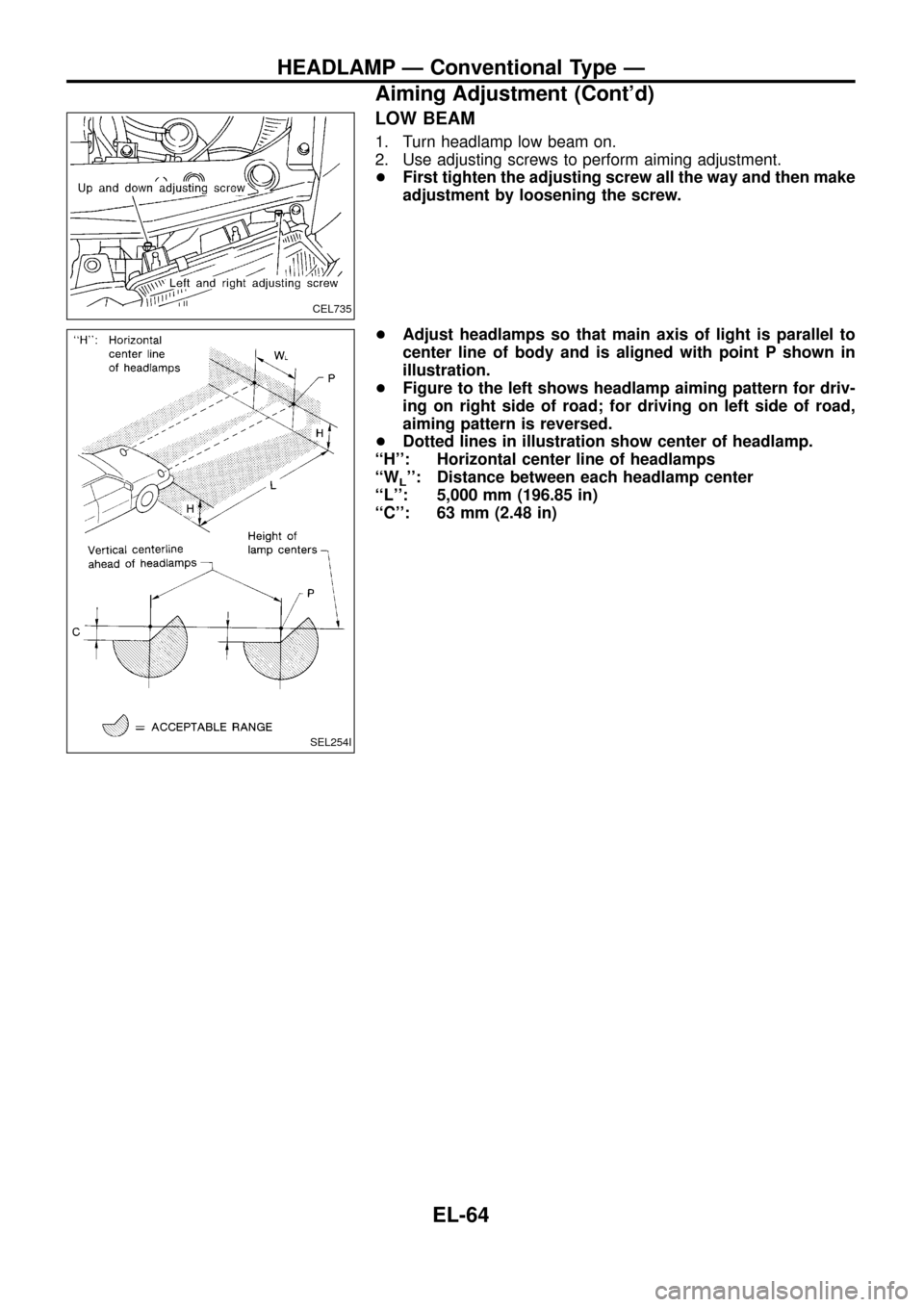

LOW BEAM

1. Turn headlamp low beam on.

2. Use adjusting screws to perform aiming adjustment.

+First tighten the adjusting screw all the way and then make

adjustment by loosening the screw.

+Adjust headlamps so that main axis of light is parallel to

center line of body and is aligned with point P shown in

illustration.

+Figure to the left shows headlamp aiming pattern for driv-

ing on right side of road; for driving on left side of road,

aiming pattern is reversed.

+Dotted lines in illustration show center of headlamp.

``H'': Horizontal center line of headlamps

``W

L'': Distance between each headlamp center

``L'': 5,000 mm (196.85 in)

``C'': 63 mm (2.48 in)

CEL735

SEL254I

HEADLAMP Ð Conventional Type Ð

Aiming Adjustment (Cont'd)

EL-64

Page 74 of 326

![NISSAN PATROL 1998 Y61 / 5.G Electrical System Workshop Manual System Description

CIRCUIT OPERATION

[Example]

Aiming switch ``0

+When the aiming switch is set to ``0, the motor will not start.

This is because the power terminals are positioned at the non-

con NISSAN PATROL 1998 Y61 / 5.G Electrical System Workshop Manual System Description

CIRCUIT OPERATION

[Example]

Aiming switch ``0

+When the aiming switch is set to ``0, the motor will not start.

This is because the power terminals are positioned at the non-

con](/img/5/616/w960_616-73.png)

System Description

CIRCUIT OPERATION

[Example]

Aiming switch ``0''

+When the aiming switch is set to ``0'', the motor will not start.

This is because the power terminals are positioned at the non-

conductive section of the sensor's rotary unit.

Aiming switch ``0''®``1''

+When the aiming switch is moved from ``0'' to ``1'', the sensor's

conductive section activates the relay. Power is supplied

through the relay to the motor. The headlamps will then move

in the ``DOWN'' direction.

+The motor continues to rotate while the rotary unit of the sen-

sor moves from point A to point B.

+The power terminals will then be positioned at the nonconduc-

tive section, disconnecting the power to the motor. The motor

will then stop.

Aiming switch ``1''®``0''

+When the aiming switch is moved from ``1'' to ``0'', the sensor's

conductive section activates the relay. Power is supplied

through the relay to the motor. The motor will rotate to move the

headlamps in the ``UP'' direction.

+When the rotary unit of the sensor moves from point B to point

A, the motor will stop.

SEL465M

SEL364P

SEL365P

HEADLAMP Ð Headlamp Aiming Control Ð

EL-70

Page 89 of 326

Trouble Diagnoses

Symptom Possible cause Repair order

Turn signal and hazard warning

lamps do not operate.1. Hazard switch

2. Combination ¯asher unit

3. Open in combination ¯asher unit

circuit1. Check hazard switch.

2. Refer to combination ¯asher unit check.

3. Check wiring to combination ¯asher unit for open cir-

cuit.

Turn signal lamps do not operate

but hazard warning lamps operate.1. 7.5A fuse

2. Hazard switch

3. Turn signal switch

4. Open in turn signal switch circuit1. Check 7.5A fuse [No.

11, located in fuse block

(J/B)]. Turn ignition switch ON and verify battery

positive voltage is present at terminalj

2of hazard

switch.

2. Check hazard switch.

3. Check turn signal switch.

4. Check harness between combination ¯asher unit and

turn signal switch for open circuit.

Hazard warning lamps do not oper-

ate but turn signal lamps operate.1. 15A fuse

2. Hazard switch

3. Open in hazard switch circuit1. Check 10A fuse (No.

48, located in fuse and fusible

link box). Verify battery positive voltage is present at

terminalj

3of hazard switch.

2. Check hazard switch.

3. Check harness between combination ¯asher unit and

hazard switch for open circuit.

Front turn signal lamp LH or RH

does not operate.1. Bulb

2. Grounds

E25andE40

1. Check bulb.

2. Check grounds

E25andE40.

Rear turn signal lamp LH or RH

does not operate.1. Bulb

2. Grounds

B23andD83or

B112andD106

1. Check bulb.

2. Check grounds

B23andD83orB112andD106.

LH and RH turn indicators do not

operate.1. Ground 1. Check grounds

M30andM98.

LH or RH turn indicator does not

operate.1. Bulb 1. Check bulb in combination meter.

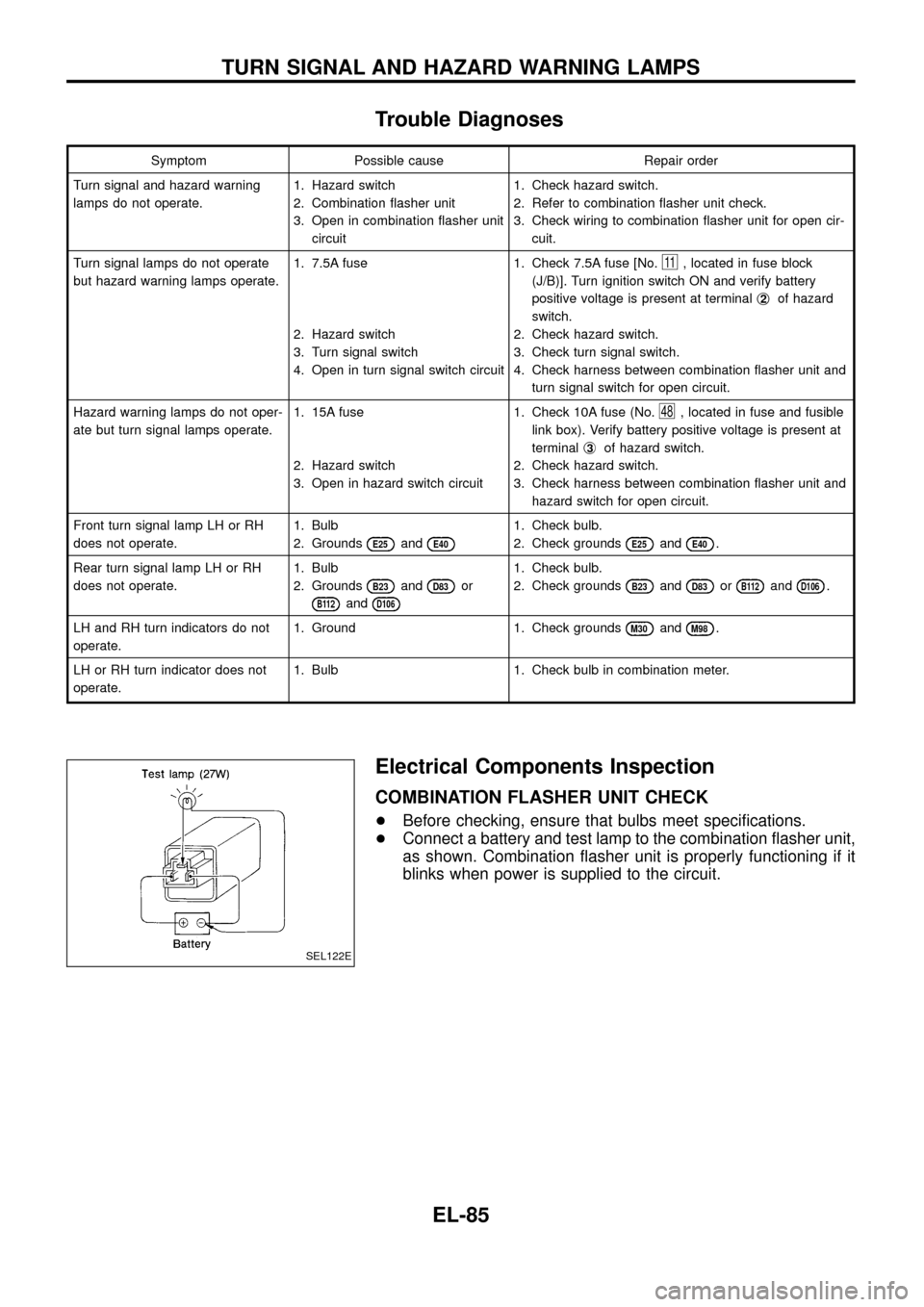

Electrical Components Inspection

COMBINATION FLASHER UNIT CHECK

+Before checking, ensure that bulbs meet speci®cations.

+Connect a battery and test lamp to the combination ¯asher unit,

as shown. Combination ¯asher unit is properly functioning if it

blinks when power is supplied to the circuit.

SEL122E

TURN SIGNAL AND HAZARD WARNING LAMPS

EL-85

Page 97 of 326

System Description

Front interior room lamp timer is controlled by smart entrance control unit while interior room lamp switch is

in the ``DOOR'' position.

Smart entrance control unit does not control rear interior room lamp.

TIMER OPERATION

Interior room lamp timer keeps interior room lamp illuminated for about 15 seconds when:

+driver's door is unlocked while key is out of ignition key cylinder,

+key is withdrawn from ignition key cylinder while driver's door is closed, and

+driver's door is opened and then closed while ignition switch is not in the ``ON'' position.

The timer is cancelled, and interior room lamp turns off when:

+driver's door is locked, or

+ignition switch is turned ``ON''.

ON-OFF CONTROL

When the front driver side door, front passenger side door, rear LH door, rear RH door or back door is opened,

interior room lamp turns on.

When driver side door is opened and then closed while ignition switch is not in the ON position, interior room

lamp timer operates. (Timer does not operate when doors other than the driver side door is opened and

closed.)

INTERIOR ROOM LAMP Ð With Timer Ð

EL-93

Page 115 of 326

SYMPTOM CHART

Symptom chart 1 (Malfunction is indicated in Diagnosis mode)

Symptom Possible causes Repair order

Speedometer and/or odo/trip

meter indicate(s) malfunction

in Diagnosis mode.+Speedometer (Uni®ed meter control unit)+Replace speedometer (uni®ed meter control unit).

Multiple meter/gauge indicate

malfunction in Diagnosis

mode.

One of tachometer/fuel gauge/

water temp. gauge indicates

malfunction in Diagnosis

mode.+Meter/Gauge

+Speedometer (Uni®ed meter control unit)1. Check resistance of meter/gauge indicating malfunction. If

the resistance is NG, replace the meter/gauge. Refer to

``METER/GAUGE RESISTANCE CHECK'', EL-114.

2. If the resistance is OK, replace speedometer (uni®ed meter

control unit).

Symptom chart 2 (No malfunction is indicated in Diagnosis mode)

Symptom Possible causes Repair order

Speedometer and odo/trip

meter are malfunctioning.1. Sensor

- Speedometer, Odo/Trip meter

2. FPC connector

3. Speedometer (Uni®ed meter control unit)1. Check vehicle speed sensor.

INSPECTION/VEHICLE SPEED SENSOR (Refer to EL-112.)

2. Check FPC connector. Refer to ``Flexible Print Circuit

(FPC)'', EL-109.

3. Replace speedometer (uni®ed meter control unit).

Multiple meter/gauge are mal-

functioning. (except

speedometer, odo/trip meter)1. FPC connector

2. Speedometer (Uni®ed meter control unit)1. Check FPC connector. Refer to ``Flexible Print Circuit

(FPC)'', EL-109.

2. Replace speedometer (uni®ed meter control unit).

One of tachometer/fuel gauge/

water temp. gauge is malfunc-

tioning.1. Sensor/Engine revolution signal

- Tachometer

- Fuel gauge

- Water temp. gauge

2. FPC connector

3. Speedometer (Uni®ed meter control unit)1. Check the sensor for malfunctioning meter/gauge.

INSPECTION/ENGINE REVOLUTION SIGNAL (Refer to

EL-113.)

INSPECTION/FUEL TANK GAUGE (Refer to EL-113.)

INSPECTION/THERMAL TRANSMITTER (Refer to EL-114.)

2. Check FPC connector. Refer to ``Flexible Print Circuit

(FPC)'', EL-109.

3. Replace speedometer (uni®ed meter control unit).

Before starting trouble diagnoses above, perform PRELIMINARY CHECK, EL-110.

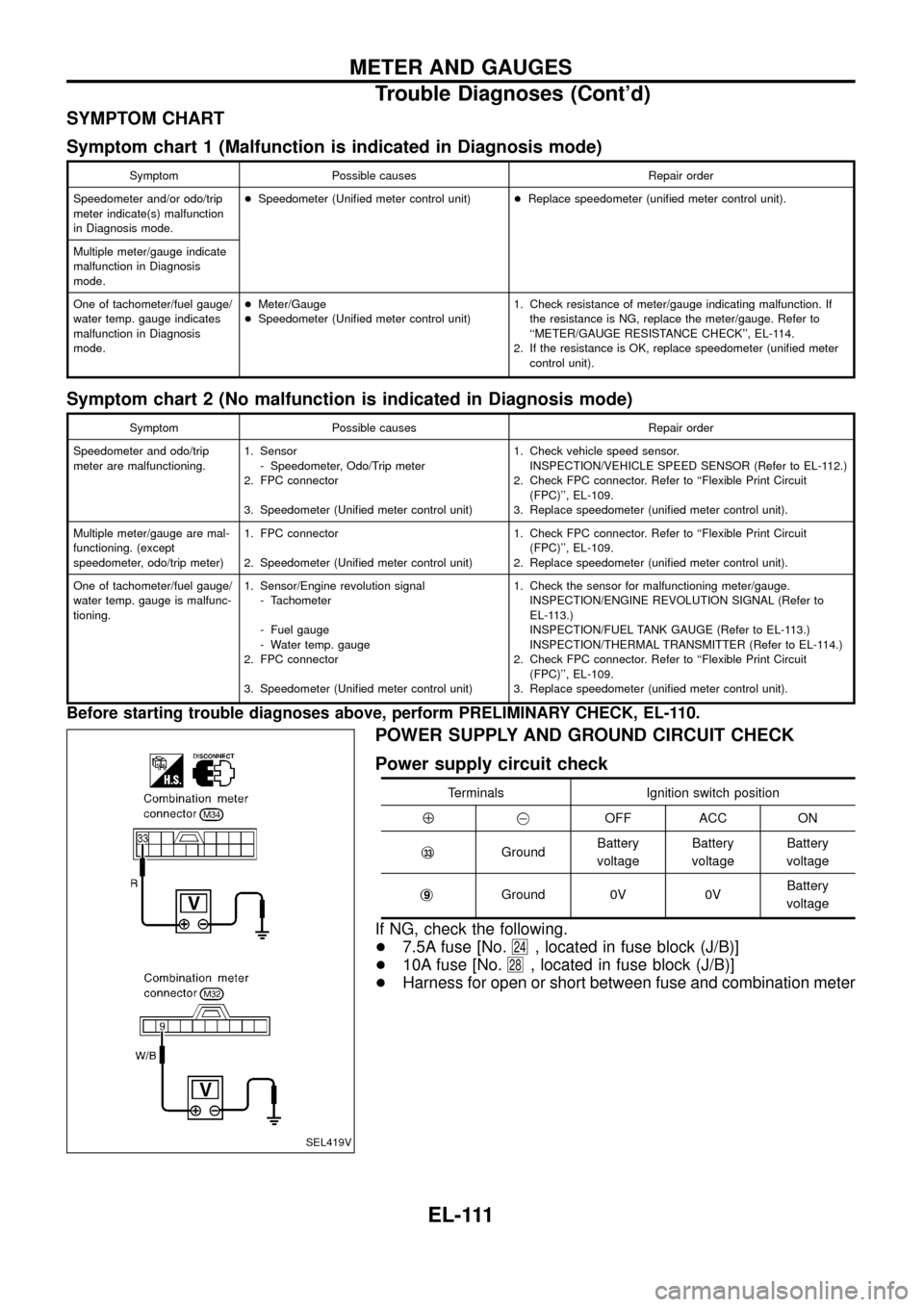

POWER SUPPLY AND GROUND CIRCUIT CHECK

Power supply circuit check

Terminals Ignition switch position

Å@OFF ACC ON

j

33GroundBattery

voltageBattery

voltageBattery

voltage

j

9Ground 0V 0VBattery

voltage

If NG, check the following.

+7.5A fuse [No.

24, located in fuse block (J/B)]

+10A fuse [No.

28, located in fuse block (J/B)]

+Harness for open or short between fuse and combination meter

SEL419V

METER AND GAUGES

Trouble Diagnoses (Cont'd)

EL-111

Page 116 of 326

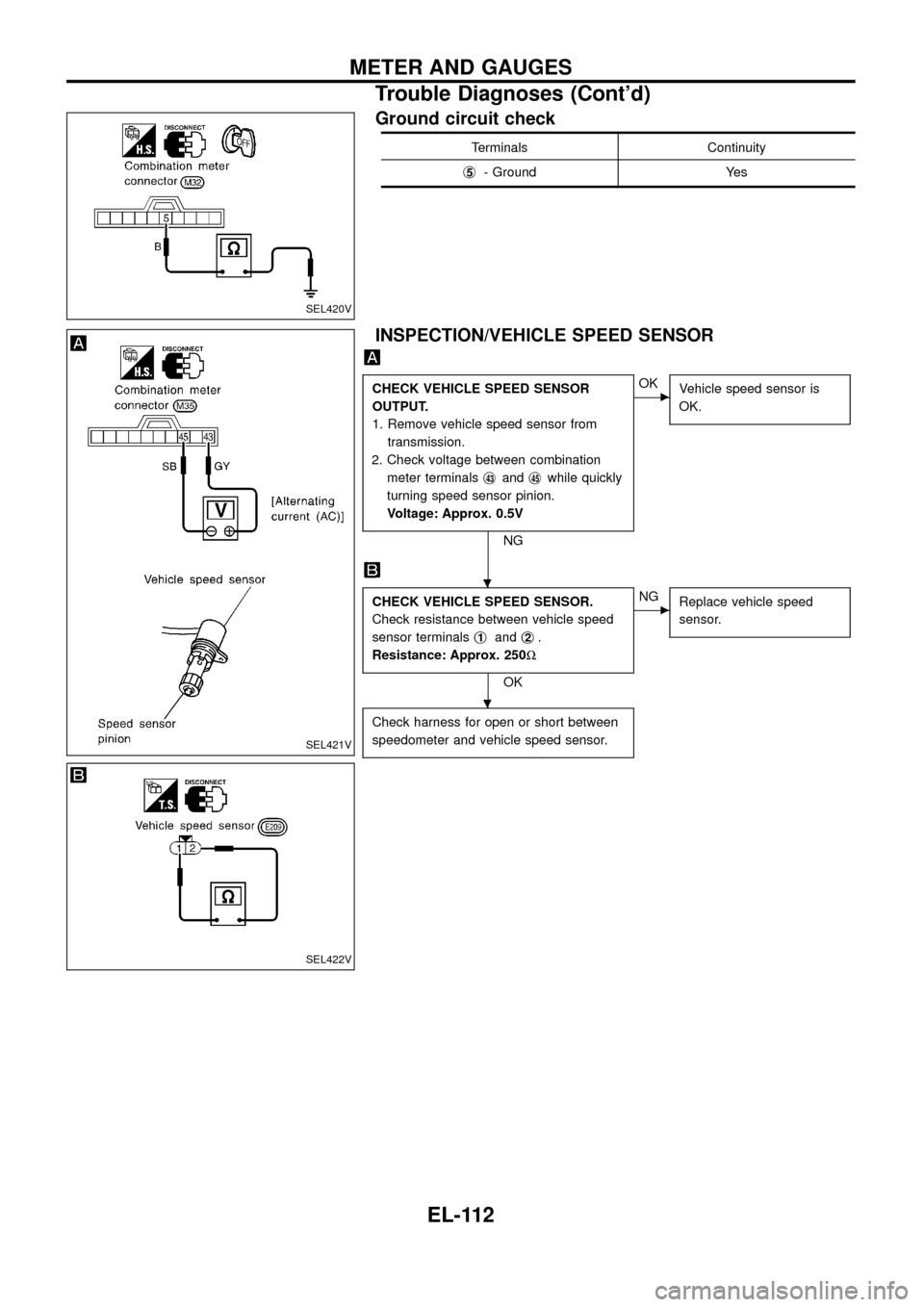

Ground circuit check

Terminals Continuity

j

5- Ground Yes

INSPECTION/VEHICLE SPEED SENSOR

CHECK VEHICLE SPEED SENSOR

OUTPUT.

1. Remove vehicle speed sensor from

transmission.

2. Check voltage between combination

meter terminalsj

43andj45while quickly

turning speed sensor pinion.

Voltage: Approx. 0.5V

NG

cOK

Vehicle speed sensor is

OK.

CHECK VEHICLE SPEED SENSOR.

Check resistance between vehicle speed

sensor terminalsj

1andj2.

Resistance: Approx. 250W

OK

cNG

Replace vehicle speed

sensor.

Check harness for open or short between

speedometer and vehicle speed sensor.

SEL420V

SEL421V

SEL422V

.

.

METER AND GAUGES

Trouble Diagnoses (Cont'd)

EL-112