TDC NISSAN PATROL 1998 Y61 / 5.G Engine Control User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PATROL, Model: NISSAN PATROL 1998 Y61 / 5.GPages: 192, PDF Size: 4.28 MB

Page 39 of 192

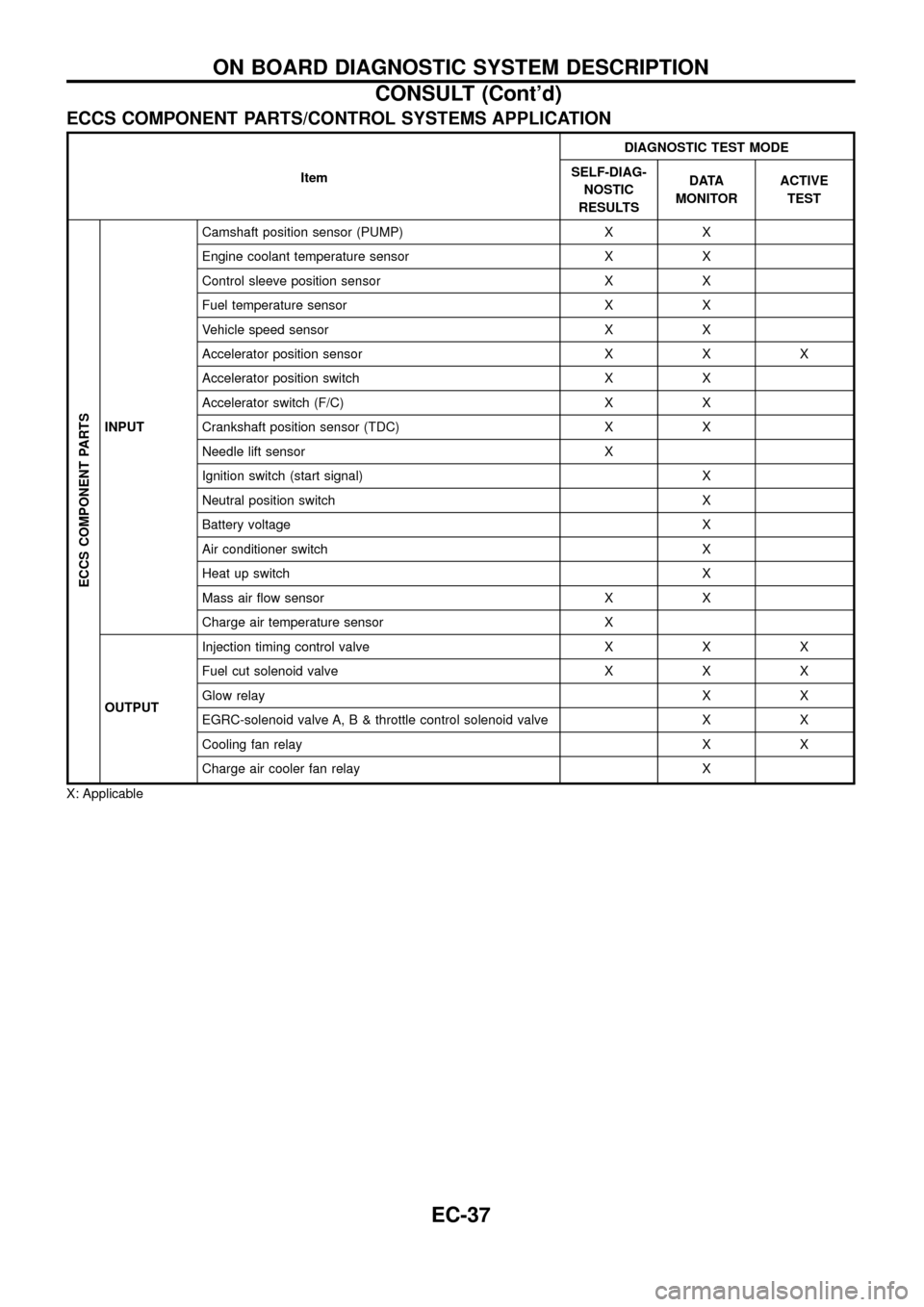

ECCS COMPONENT PARTS/CONTROL SYSTEMS APPLICATION

ItemDIAGNOSTIC TEST MODE

SELF-DIAG-

NOSTIC

RESULTSDATA

MONITORACTIVE

TEST

ECCS COMPONENT PARTS

INPUTCamshaft position sensor (PUMP) X X

Engine coolant temperature sensor X X

Control sleeve position sensor X X

Fuel temperature sensor X X

Vehicle speed sensor X X

Accelerator position sensor X X X

Accelerator position switch X X

Accelerator switch (F/C) X X

Crankshaft position sensor (TDC) X X

Needle lift sensor X

Ignition switch (start signal) X

Neutral position switch X

Battery voltage X

Air conditioner switch X

Heat up switch X

Mass air ¯ow sensor X X

Charge air temperature sensor X

OUTPUTInjection timing control valve X X X

Fuel cut solenoid valve X X X

Glow relayXX

EGRC-solenoid valve A, B & throttle control solenoid valve X X

Cooling fan relay X X

Charge air cooler fan relay X

X: Applicable

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

CONSULT (Cont'd)

EC-37

Page 40 of 192

![NISSAN PATROL 1998 Y61 / 5.G Engine Control User Guide SELF-DIAGNOSTIC MODE

Regarding items detected in ``SELF-DIAG RESULTS mode, refer to ``DIAGNOSTIC TROUBLE CODE

INDEX, EC-1.

DATA MONITOR MODE

Monitored item

[Unit]ECM

input

signalsMain

signalsDescr NISSAN PATROL 1998 Y61 / 5.G Engine Control User Guide SELF-DIAGNOSTIC MODE

Regarding items detected in ``SELF-DIAG RESULTS mode, refer to ``DIAGNOSTIC TROUBLE CODE

INDEX, EC-1.

DATA MONITOR MODE

Monitored item

[Unit]ECM

input

signalsMain

signalsDescr](/img/5/617/w960_617-39.png)

SELF-DIAGNOSTIC MODE

Regarding items detected in ``SELF-DIAG RESULTS'' mode, refer to ``DIAGNOSTIC TROUBLE CODE

INDEX'', EC-1.

DATA MONITOR MODE

Monitored item

[Unit]ECM

input

signalsMain

signalsDescription Remarks

CKPSzRPM

(TDC) [rpm]

jj

+The engine speed computed from the

crankshaft position sensor (TDC) signal

is displayed.

CKPSzRPM

(REF) [rpm]

jj

+The engine speed [determined by the

time between pulses from the crankshaft

position sensor (TDC) signal] is dis-

played.

CMPSzRPM -

PUMP [rpm]

jj

+The engine speed computed from the

camshaft position sensor (PUMP) signal

is displayed.

COOLAN TEMP/S

[ÉC] or [ÉF]

jj

+The engine coolant temperature (deter-

mined by the signal voltage of the engine

coolant temperature sensor) is displayed.+When the engine coolant temperature

sensor is open or short-circuited, ECM

enters fail-safe mode. The engine cool-

ant temperature determined by the ECM

is displayed.

VHCL SPEED SE

[km/h] or [mph]

jj+The vehicle speed computed from the

vehicle speed sensor signal is displayed.

FUEL TEMP SEN

[ÉC] or [ÉF]

jj

+The fuel temperature (determined by the

signal voltage of the fuel temperature

sensor) is displayed.

ACCEL POS SEN [V]

jj+The accelerator position sensor signal

voltage is displayed.

FULL ACCEL SW

[ON/OFF]

jj+Indicates [ON/OFF] condition from the

accelerator position switch signal.

ACCEL SW (FC)

[OPEN/CLOSE]

jj+Indicates [OPEN/CLOSE] condition from

the accelerator switch (FC) signal.

OFF ACCEL SW

[ON/OFF]

jj+Indicates [ON/OFF] condition from the

accelerator position switch signal.

C/SLEEV POS/S [V]

jj+The control sleeve position sensor signal

voltage is displayed.

BATTERY VOLT [V]

jj+The power supply voltage of ECM is dis-

played.

P/N POSI SW

[ON/OFF]

jj+Indicates [ON/OFF] condition from the

park/neutral position switch signal.

START SIGNAL

[ON/OFF]

jj+Indicates [ON/OFF] condition from the

starter signal.+After starting the engine, [OFF] is dis-

played regardless of the starter signal.

NOTE:

Any monitored item that does not match the vehicle being diagnosed is deleted from the display automatically.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

CONSULT (Cont'd)

EC-38

Page 41 of 192

![NISSAN PATROL 1998 Y61 / 5.G Engine Control User Guide Monitored item

[Unit]ECM

input

signalsMain

signalsDescription Remarks

AIR COND SIG

[ON/OFF]

jj

+Indicates [ON/OFF] condition of the air

conditioner switch as determined by the

air conditioner signal.

NISSAN PATROL 1998 Y61 / 5.G Engine Control User Guide Monitored item

[Unit]ECM

input

signalsMain

signalsDescription Remarks

AIR COND SIG

[ON/OFF]

jj

+Indicates [ON/OFF] condition of the air

conditioner switch as determined by the

air conditioner signal.](/img/5/617/w960_617-40.png)

Monitored item

[Unit]ECM

input

signalsMain

signalsDescription Remarks

AIR COND SIG

[ON/OFF]

jj

+Indicates [ON/OFF] condition of the air

conditioner switch as determined by the

air conditioner signal.

IGN SW

[ON/OFF]

jj+Indicates [ON/OFF] condition from igni-

tion switch signal.

MAS AIR/FL SE [V]

jj+The signal voltage of the mass air ¯ow

sensor is displayed.+When the engine is stopped, a certain

value is indicated.

ACT INJ TIMG [É]

jj

+The actual injection timing angle deter-

mined by the ECM (an approximate

average angle between injection start

and end from TDC) is displayed.

INJ TIMG C/V [%]+Indicates the duty ratio of fuel injection

timing control valve.

DECELER F/CUT

[ON/OFF]

j

+Indicates [ON/OFF] condition from decel-

eration fuel cut signal.+When the accelerator pedal is released

quickly with engine speed at 3,000 rpm

or more, ``ON'' is displayed.

FUEL CUT S/V

[ON/OFF]

j

+The control condition of the fuel cut sole-

noid valve (determined by ECM accord-

ing to the input signal) is indicted.

+OFF ... Fuel cut solenoid valve is not

operating.

ON ... Fuel cut solenoid valve is operat-

ing.+When the fuel cut solenoid valve is not

operating, fuel is not supplied to injection

nozzles.

GLOW RLY [ON/OFF]

j

+The glow relay control condition (deter-

mined by ECM according to the input

signal) is displayed.

COOLING FAN

[LOW/HI/OFF]

j

+Indicates the control condition of the

cooling fans (determined by ECM

according to the input signal).

+LOW ... Operates at low speed.

HI ... Operates at high speed.

OFF ... Stopped.

I/C FAN RLY

[ON/OFF]

j

+Indicates the control condition of the

charge air cooler fan (determined by

ECM according to the input signals).

EGRC SOL/V A

[ON/OFF]+The control condition of the EGRC-sole-

noid valve A (determined by ECM

according to the input signal) is indi-

cated.

+OFF ... EGRC-solenoid valve A is not

operating.

ON ... EGRC-solenoid valve A is operat-

ing.

EGRC SOL/V B

[ON/OFF]+The control condition of the EGRC-sole-

noid valve B (determined by ECM

according to the input signal) is indi-

cated.

+OFF ... EGRC-solenoid valve B is not

operating.

ON ... EGRC-solenoid valve B is operat-

ing.

THROT RLY

[ON/OFF]+The control condition of the throttle con-

trol solenoid valve (determined by ECM

according to the input signal) is indi-

cated.

+OFF ... Throttle control solenoid valve is

not operating.

ON ... Throttle control solenoid valve is

operating.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

CONSULT (Cont'd)

EC-39

Page 49 of 192

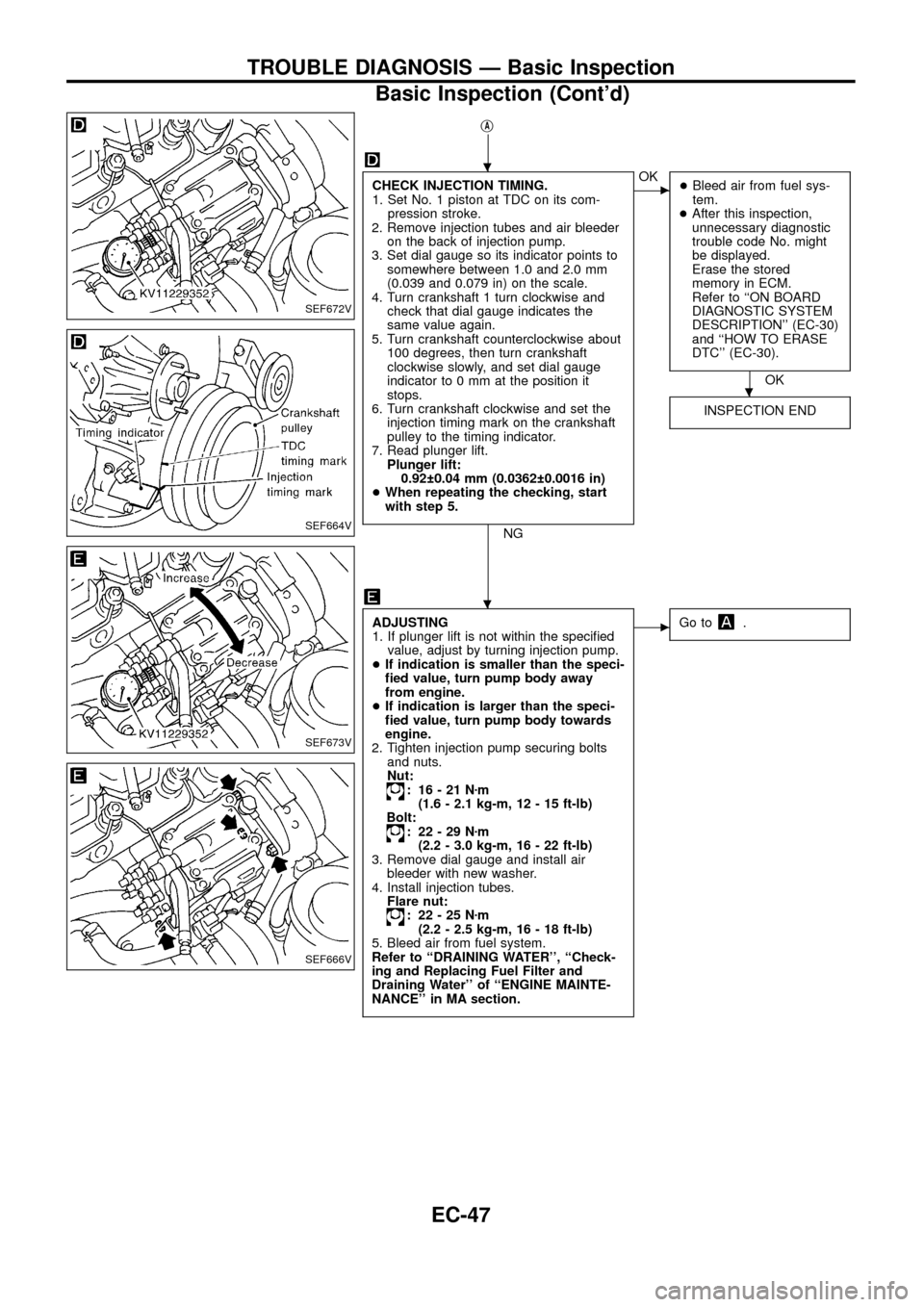

jA

CHECK INJECTION TIMING.

1. Set No. 1 piston at TDC on its com-

pression stroke.

2. Remove injection tubes and air bleeder

on the back of injection pump.

3. Set dial gauge so its indicator points to

somewhere between 1.0 and 2.0 mm

(0.039 and 0.079 in) on the scale.

4. Turn crankshaft 1 turn clockwise and

check that dial gauge indicates the

same value again.

5. Turn crankshaft counterclockwise about

100 degrees, then turn crankshaft

clockwise slowly, and set dial gauge

indicator to 0 mm at the position it

stops.

6. Turn crankshaft clockwise and set the

injection timing mark on the crankshaft

pulley to the timing indicator.

7. Read plunger lift.

Plunger lift:

0.92 0.04 mm (0.0362 0.0016 in)

+When repeating the checking, start

with step 5.

NG

cOK

+Bleed air from fuel sys-

tem.

+After this inspection,

unnecessary diagnostic

trouble code No. might

be displayed.

Erase the stored

memory in ECM.

Refer to ``ON BOARD

DIAGNOSTIC SYSTEM

DESCRIPTION'' (EC-30)

and ``HOW TO ERASE

DTC'' (EC-30).

OK

INSPECTION END

ADJUSTING

1. If plunger lift is not within the speci®ed

value, adjust by turning injection pump.

+If indication is smaller than the speci-

®ed value, turn pump body away

from engine.

+If indication is larger than the speci-

®ed value, turn pump body towards

engine.

2. Tighten injection pump securing bolts

and nuts.

Nut:

: 16-21Nzm

(1.6 - 2.1 kg-m, 12 - 15 ft-lb)

Bolt:

: 22-29Nzm

(2.2 - 3.0 kg-m, 16 - 22 ft-lb)

3. Remove dial gauge and install air

bleeder with new washer.

4. Install injection tubes.

Flare nut:

: 22-25Nzm

(2.2 - 2.5 kg-m, 16 - 18 ft-lb)

5. Bleed air from fuel system.

Refer to ``DRAINING WATER'', ``Check-

ing and Replacing Fuel Filter and

Draining Water'' of ``ENGINE MAINTE-

NANCE'' in MA section.

cGo to.

SEF672V

SEF664V

SEF673V

SEF666V

.

.

.

TROUBLE DIAGNOSIS Ð Basic Inspection

Basic Inspection (Cont'd)

EC-47

Page 51 of 192

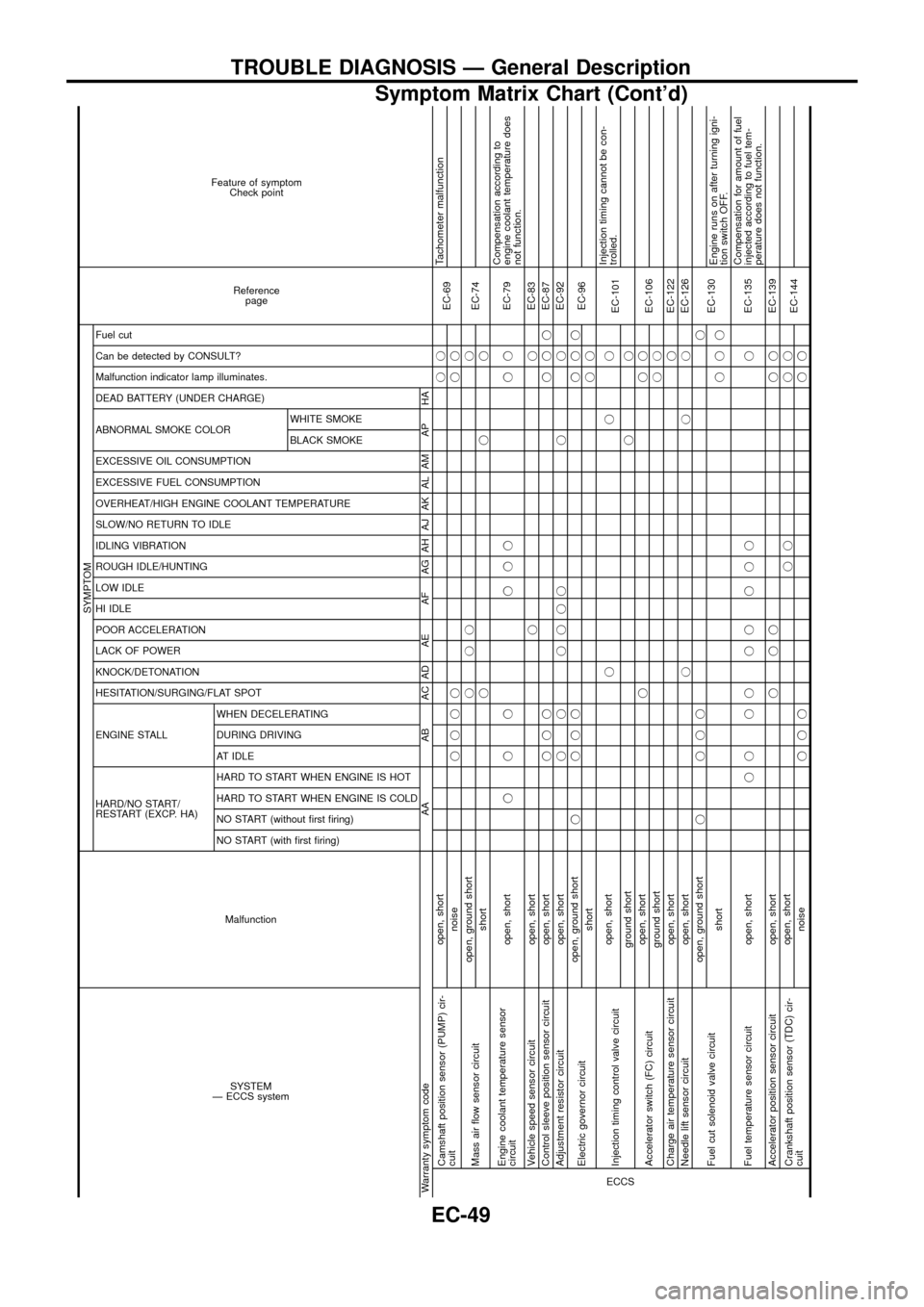

SYSTEM

Ð ECCS systemMalfunction

SYMPTOM

Reference

page Feature of symptom

Check point

HARD/NO START/

RESTART (EXCP. HA) ENGINE STALL HESITATION/SURGING/FLAT SPOT KNOCK/DETONATION

LACK OF POWER

POOR ACCELERATION

HI IDLE

LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEAT/HIGH ENGINE COOLANT TEMPERATURE

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION ABNORMAL SMOKE COLOR

DEAD BATTERY (UNDER CHARGE) Malfunction indicator lamp illuminates.

Can be detected by CONSULT?

Fuel cut

NO START (with ®rst ®ring) NO START (without ®rst ®ring)

HARD TO START WHEN ENGINE IS COLD

HARD TO START WHEN ENGINE IS HOT

AT IDLE

DURING DRIVING

WHEN DECELERATINGBLACK SMOKE WHITE SMOKE

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM AP HAECCS

Camshaft position sensor (PUMP) cir-

cuitopen, shortjj

EC-69Tachometer malfunction

noisejjjj jj

Mass air ¯ow sensor circuitopen, ground shortjjj j

EC-74

shortjjj

Engine coolant temperature sensor

circuitopen, shortjjj jjj jjEC-79Compensation according to

engine coolant temperature does

not function.

Vehicle speed sensor circuit open, shortjjEC-83

Control sleeve position sensor circuit open, shortjjjjjjEC-87

Adjustment resistor circuit open, shortj j jjjj j jEC-92

Electric governor circuitopen, ground shortj jjjjjj

EC-96

shortjj

Injection timing control valve circuitopen, shortjjj

EC-101Injection timing cannot be con-

trolled.

ground shortjj

Accelerator switch (FC) circuitopen, shortjjj

EC-106

ground shortjj

Charge air temperature sensor circuit open, shortjEC-122

Needle lift sensor circuit open, shortjjjEC-126

Fuel cut solenoid valve circuitopen, ground shortj jjjj

EC-130

shortjjjEngine runs on after turning igni-

tion switch OFF.

Fuel temperature sensor circuit open, shortjj jj jj j jj jEC-135Compensation for amount of fuel

injected according to fuel tem-

perature does not function.

Accelerator position sensor circuit open, shortjjj jjEC-139

Crankshaft position sensor (TDC) cir-

cuitopen, shortjj jj

EC-144

noisejjjjj

TROUBLE DIAGNOSIS Ð General Description

Symptom Matrix Chart (Cont'd)

EC-49

Page 53 of 192

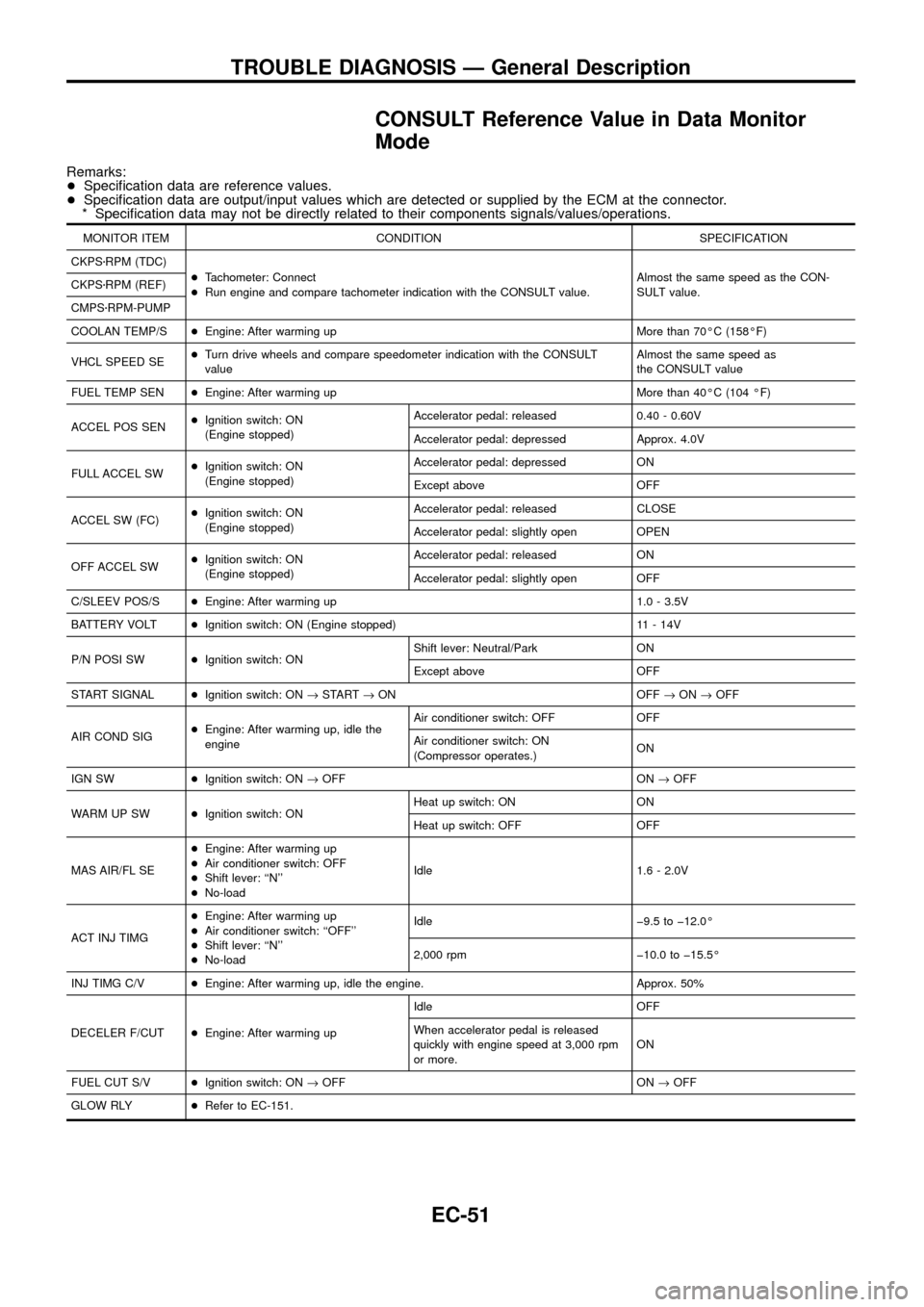

CONSULT Reference Value in Data Monitor

Mode

Remarks:

+Speci®cation data are reference values.

+Speci®cation data are output/input values which are detected or supplied by the ECM at the connector.

* Speci®cation data may not be directly related to their components signals/values/operations.

MONITOR ITEM CONDITION SPECIFICATION

CKPSzRPM (TDC)

+Tachometer: Connect

+Run engine and compare tachometer indication with the CONSULT value.Almost the same speed as the CON-

SULT value. CKPSzRPM (REF)

CMPSzRPM-PUMP

COOLAN TEMP/S+Engine: After warming up More than 70ÉC (158ÉF)

VHCL SPEED SE+Turn drive wheels and compare speedometer indication with the CONSULT

valueAlmost the same speed as

the CONSULT value

FUEL TEMP SEN+Engine: After warming up More than 40ÉC (104 ÉF)

ACCEL POS SEN+Ignition switch: ON

(Engine stopped)Accelerator pedal: released 0.40 - 0.60V

Accelerator pedal: depressed Approx. 4.0V

FULL ACCEL SW+Ignition switch: ON

(Engine stopped)Accelerator pedal: depressed ON

Except above OFF

ACCEL SW (FC)+Ignition switch: ON

(Engine stopped)Accelerator pedal: released CLOSE

Accelerator pedal: slightly open OPEN

OFF ACCEL SW+Ignition switch: ON

(Engine stopped)Accelerator pedal: released ON

Accelerator pedal: slightly open OFF

C/SLEEV POS/S+Engine: After warming up 1.0 - 3.5V

BATTERY VOLT+Ignition switch: ON (Engine stopped) 11 - 14V

P/N POSI SW+Ignition switch: ONShift lever: Neutral/Park ON

Except above OFF

START SIGNAL+Ignition switch: ON®START®ON OFF®ON®OFF

AIR COND SIG+Engine: After warming up, idle the

engineAir conditioner switch: OFF OFF

Air conditioner switch: ON

(Compressor operates.)ON

IGN SW+Ignition switch: ON®OFF ON®OFF

WARM UP SW+Ignition switch: ONHeat up switch: ON ON

Heat up switch: OFF OFF

MAS AIR/FL SE+Engine: After warming up

+Air conditioner switch: OFF

+Shift lever: ``N''

+No-loadIdle 1.6 - 2.0V

ACT INJ TIMG+Engine: After warming up

+Air conditioner switch: ``OFF''

+Shift lever: ``N''

+No-loadIdle þ9.5 to þ12.0É

2,000 rpm þ10.0 to þ15.5É

INJ TIMG C/V+Engine: After warming up, idle the engine. Approx. 50%

DECELER F/CUT+Engine: After warming upIdle OFF

When accelerator pedal is released

quickly with engine speed at 3,000 rpm

or more.ON

FUEL CUT S/V+Ignition switch: ON®OFF ON®OFF

GLOW RLY+Refer to EC-151.

TROUBLE DIAGNOSIS Ð General Description

EC-51

Page 61 of 192

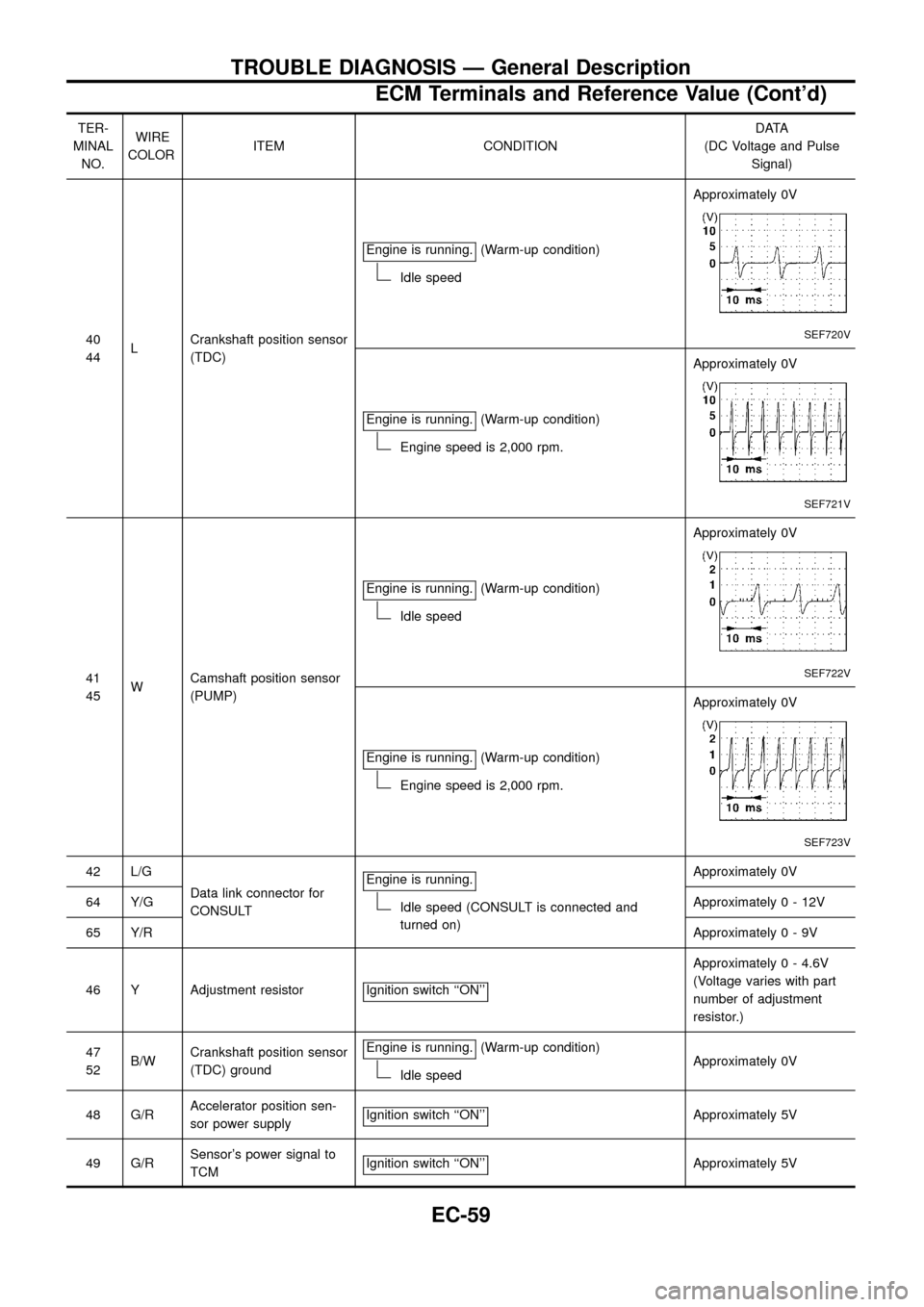

TER-

MINAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage and Pulse

Signal)

40

44LCrankshaft position sensor

(TDC)Engine is running.

(Warm-up condition)

Idle speedApproximately 0V

SEF720V

Engine is running.(Warm-up condition)

Engine speed is 2,000 rpm.Approximately 0V

SEF721V

41

45WCamshaft position sensor

(PUMP)Engine is running.

(Warm-up condition)

Idle speedApproximately 0V

SEF722V

Engine is running.(Warm-up condition)

Engine speed is 2,000 rpm.Approximately 0V

SEF723V

42 L/G

Data link connector for

CONSULTEngine is running.

Idle speed (CONSULT is connected and

turned on)Approximately 0V

64 Y/GApproximately0-12V

65 Y/RApproximately0-9V

46 Y Adjustment resistor Ignition switch ``ON''

Approximately 0 - 4.6V

(Voltage varies with part

number of adjustment

resistor.)

47

52B/WCrankshaft position sensor

(TDC) groundEngine is running.

(Warm-up condition)

Idle speedApproximately 0V

48 G/RAccelerator position sen-

sor power supplyIgnition switch ``ON''

Approximately 5V

49 G/RSensor's power signal to

TCMIgnition switch ``ON''

Approximately 5V

TROUBLE DIAGNOSIS Ð General Description

ECM Terminals and Reference Value (Cont'd)

EC-59

Page 104 of 192

ON BOARD DIAGNOSIS LOGIC

Diagnostic

Trouble Code

No.Malfunction is detected when ....Check Items

(Possible cause)

21+Injection timing feedback system does not operate

properly. (This system consists essentially of ECM,

injection timing control valve and needle lift sensor.)+Harness or connectors

[Injection timing control valve, needle lift sensor,

crankshaft position sensor (TDC) circuits]

+Injection timing control valve

+Needle lift sensor

+Crankshaft position sensor (TDC)

+Air in fuel line

DIAGNOSTIC TROUBLE CODE CONFIRMATION

PROCEDURE

Note: If both DTC 21 and 34 or 47 are displayed, perform

TROUBLE DIAGNOSIS FOR DTC 34 or 47. (See EC-126

or EC-144.)

1) Turn ignition switch ``ON'' and select ``DATA MONITOR''

mode with CONSULT.

2) Start engine and warm it up to normal operating tem-

perature.

3) Run engine for 2 seconds at 3,000 rpm. Return engine

speed to idle, then increase to 3,000 rpm under no load.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------OR-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1) Start engine and warm it up to normal operating tem-

perature.

2) Run engine for 2 seconds at 3,000 rpm. Return engine

speed to idle, then increase to 3,000 rpm under no load.

3) Turn ignition switch ``OFF'', wait at least 5 seconds and

then turn ``ON''.

4) Perform ``Diagnostic Test Mode II (Self-diagnostic

results)'' with ECM.

Note: If a malfunction occurs intermittently, conduct suitable

driving pattern for 10 minutes. This makes it possible to

determine DTC.

SEF751V

TROUBLE DIAGNOSIS FOR ``F/INJ TIMG F/B'' (DTC 21)

Injection Timing Control Valve (Cont'd)

EC-102

Page 146 of 192

Crankshaft Position Sensor (TDC)

The crankshaft position sensor (TDC) monitors engine speed by

means of signals from the sensing plate (with two protrusions)

installed to the crankshaft pulley. The datum signal output is

detected at ATDC 70É and sent to the ECM. The sensor signal is

used for fuel injection control and fuel injection timing control.

CONSULT REFERENCE VALUE IN DATA MONITOR MODE

Remarks: Speci®cation data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

CKPSzRPM (TDC)+Tachometer: Connect

+Run engine and compare tachometer indication with the CONSULT

value.Almost the same speed as the

CONSULT value.

ECM TERMINALS AND REFERENCE VALUE

Remarks: Speci®cation data are reference values and are measured between each terminal andV43(ECCS

ground) with a voltmeter.

TER-

MINAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage and Pulse

Signal)

40

44LCrankshaft position sensor

(TDC)Engine is running.

(Warm-up condition)

Idle speedApproximately 0V

SEF720V

Engine is running.(Warm-up condition)

Engine speed is 2,000 rpm.Approximately 0V

SEF721V

47

52B/WCrankshaft position sensor

(TDC) groundEngine is running.(Warm-up condition)

Idle speedApproximately 0V

ON BOARD DIAGNOSIS LOGIC

Diagnostic

Trouble Code

No.Malfunction is detected when ....Check Items

(Possible Cause)

47+An improper signal from the sensor is detected by

ECM during engine running and cranking.+Harness or connectors

(The sensor circuit is open.)

+Crankshaft position sensor (TDC)

SEF615S

TROUBLE DIAGNOSIS FOR ``CRANK POS SEN (TDC)'' (DTC 47)

EC-144

Page 147 of 192

DIAGNOSTIC TROUBLE CODE CONFIRMATION

PROCEDURE

Before performing the following procedure, con®rm that bat-

tery voltage is more than 10V.

1) Turn ignition switch ``ON'' and select ``DATA MONITOR''

mode with CONSULT.

2) Crank engine for at least 1 second.

3) Start engine and run it for at least 2 seconds at idle

speed.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------OR-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1) Crank engine for at least 1 second.

2) Start engine and run it for at least 2 seconds at idle

speed.

3) Turn ignition switch ``OFF'', wait at least 5 seconds and

then turn ``ON''.

4) Perform ``Diagnostic Test Mode II (Self-diagnostic

results)'' with ECM.SEF714V

TROUBLE DIAGNOSIS FOR ``CRANK POS SEN (TDC)'' (DTC 47)

Crankshaft Position Sensor (TDC) (Cont'd)

EC-145