battery NISSAN PATROL 1998 Y61 / 5.G Engine Control Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PATROL, Model: NISSAN PATROL 1998 Y61 / 5.GPages: 192, PDF Size: 4.28 MB

Page 111 of 192

DIAGNOSTIC PROCEDURE

INSPECTION START

CHECK OVERALL FUNCTION.1. Turn ignition switch ``ON''.

2. Check ``ACCEL SW (F/C)'' in

``DATA MONITOR'' mode with

CONSULT.

Accelerator pedal released:

OFF

Accelerator pedal depressed:

ON

--------------------------------------------------------------------------------------------------------------------------------------OR--------------------------------------------------------------------------------------------------------------------------------------

1. Turn ignition switch ``ON''.

2. Check voltage between ECM

terminal

V29and ground.

Voltage:

Accelerator pedal released

Battery voltage

Accelerator pedal depressed

Approximately 0V

NG

cOK

INSPECTION END

CHECK GROUND CIRCUIT.

1. Turn ignition switch ``OFF''.

2. Loosen and retighten engine ground

screws.

3. Disconnect accelerator switch (F/C) har-

ness connector.

4. Check harness continuity between termi-

nal

V3and engine ground.

Continuity should exist.

If OK, check harness for short to ground

and short to power.

OK

cNG

Check the following.

+Harness connectors

M51,F6(RHD mod-

els)

+Joint connector

F18+Harness for open or

short between accelera-

tor switch (F/C) and

engine ground

If NG, repair open circuit or

short to ground or short to

power in harness or con-

nectors.

CHECK INPUT SIGNAL CIRCUIT.

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM

terminal

V29and terminalV1.

Continuity should exist.

If OK, check harness for short to ground

and short to power.

OK

cNG

Check the following.

+Harness connectors

F6,M51(RHD mod-

els)

+Harness for open or short

between ECM and accel-

erator switch (F/C)

If NG, repair open circuit or

short to ground or short to

power in harness or con-

nectors.

CHECK COMPONENT

[Accelerator switch (F/C)].

Refer to ``COMPONENT INSPECTION''

on next page.

OK

cNG

Replace accelerator pedal

assembly.

Disconnect and reconnect harness connec-

tors in the circuit. Then retest.

Trouble is not ®xed.

Check ECM pin terminals for damage and

check the connection of ECM harness con-

nector. Reconnect ECM harness connector

and retest.

INSPECTION END

SEF688V

SEF589S

SEF590S

SEF591S

SEF592S

.

.

.

.

.

.

.

TROUBLE DIAGNOSIS FOR ``ACCEL POS SW (F/C)'' (DTC 23)

Accelerator Switch (F/C) (Cont'd)

EC-109

Page 115 of 192

Cooling Fan (Overheat)

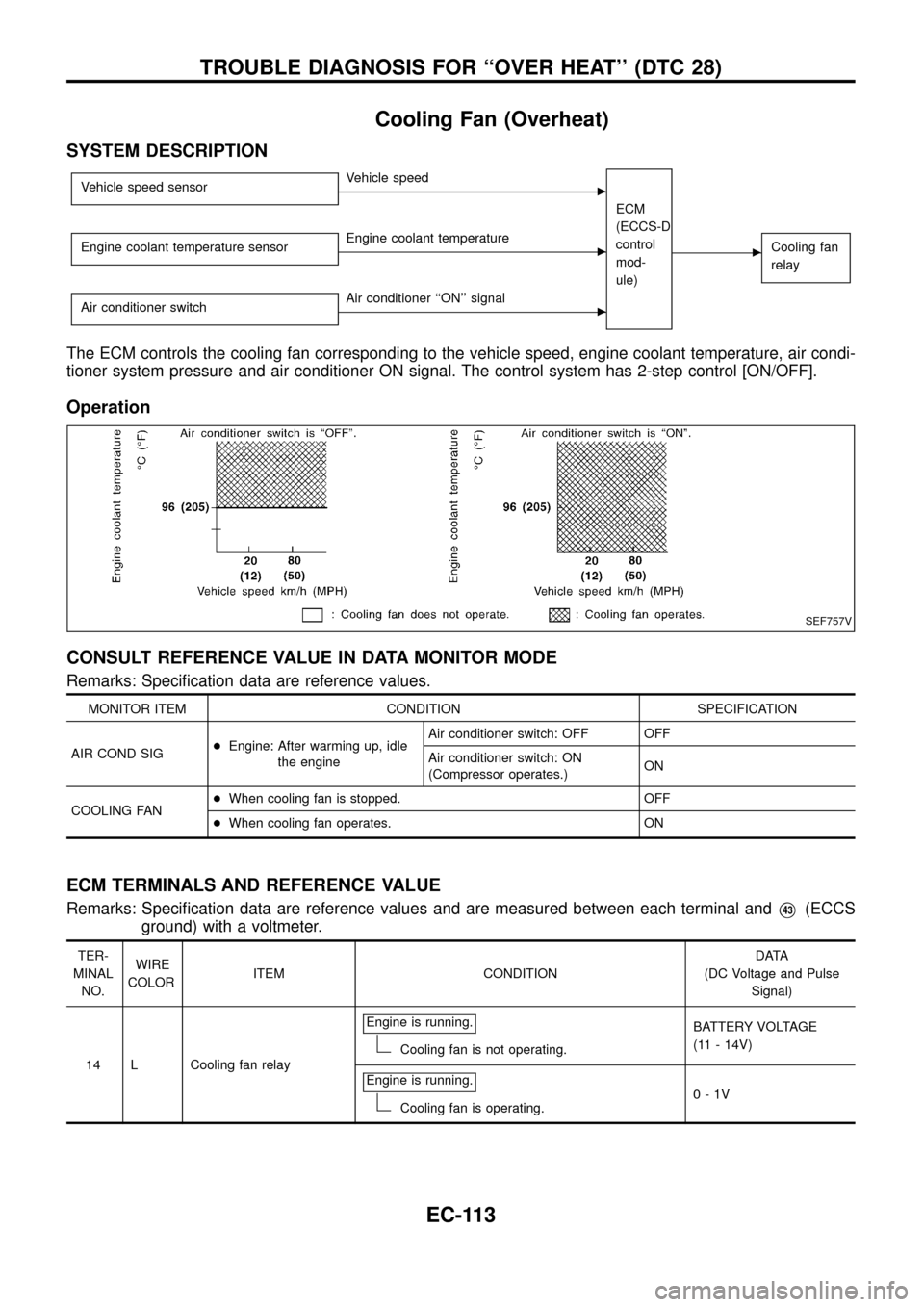

SYSTEM DESCRIPTION

Vehicle speed sensorcVehicle speed

ECM

(ECCS-D

control

mod-

ule)

cCooling fan

relayEngine coolant temperature sensorcEngine coolant temperature

Air conditioner switch

cAir conditioner ``ON'' signal

The ECM controls the cooling fan corresponding to the vehicle speed, engine coolant temperature, air condi-

tioner system pressure and air conditioner ON signal. The control system has 2-step control [ON/OFF].

Operation

CONSULT REFERENCE VALUE IN DATA MONITOR MODE

Remarks: Speci®cation data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

AIR COND SIG+Engine: After warming up, idle

the engineAir conditioner switch: OFF OFF

Air conditioner switch: ON

(Compressor operates.)ON

COOLING FAN+When cooling fan is stopped. OFF

+When cooling fan operates. ON

ECM TERMINALS AND REFERENCE VALUE

Remarks: Speci®cation data are reference values and are measured between each terminal andV43(ECCS

ground) with a voltmeter.

TER-

MINAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage and Pulse

Signal)

14 L Cooling fan relayEngine is running.

Cooling fan is not operating.BATTERY VOLTAGE

(11 - 14V)

Engine is running.

Cooling fan is operating.0-1V

SEF757V

TROUBLE DIAGNOSIS FOR ``OVER HEAT'' (DTC 28)

EC-113

Page 116 of 192

TER-

MINAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage and Pulse

Signal)

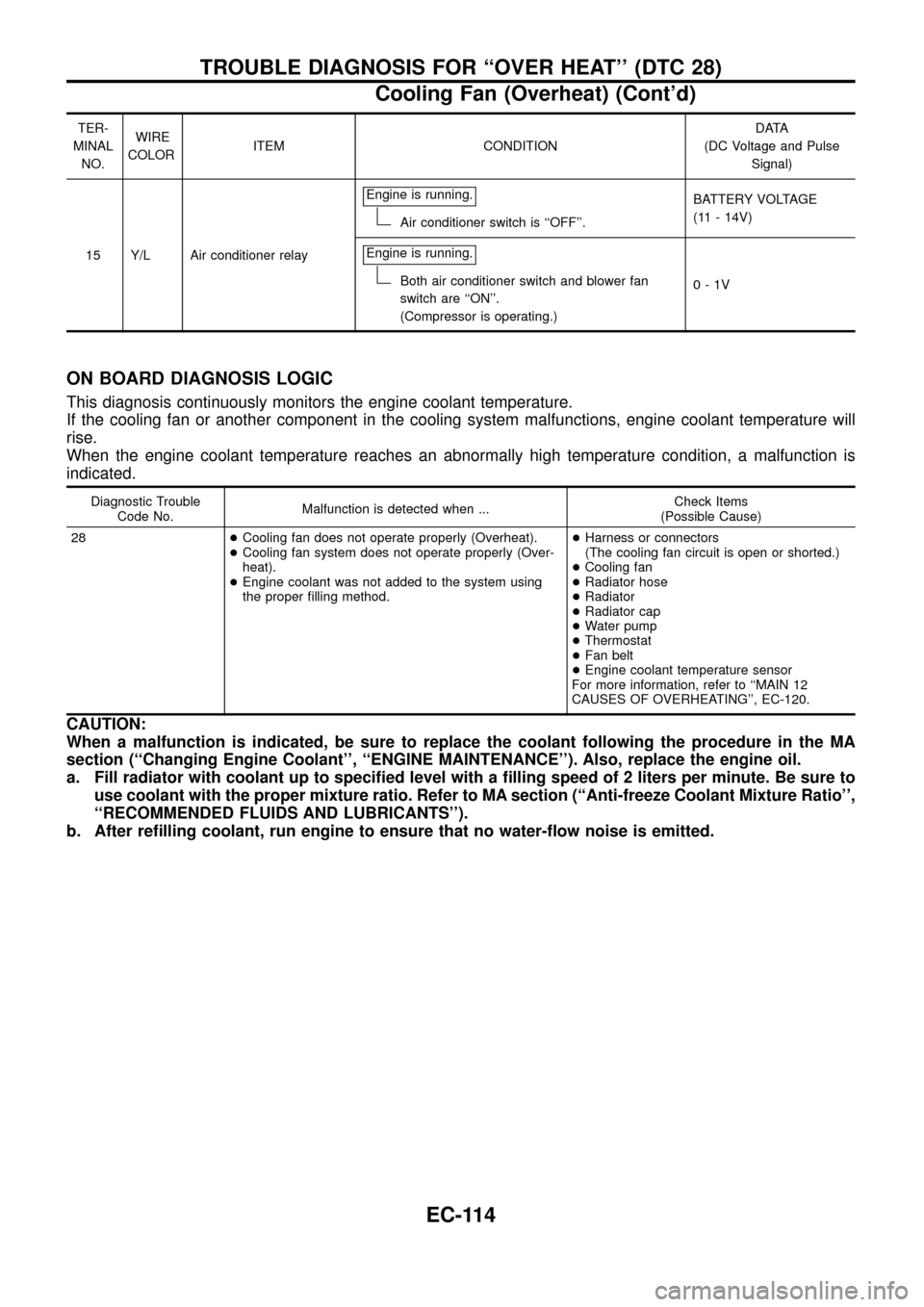

15 Y/L Air conditioner relayEngine is running.

Air conditioner switch is ``OFF''.BATTERY VOLTAGE

(11 - 14V)

Engine is running.

Both air conditioner switch and blower fan

switch are ``ON''.

(Compressor is operating.)0-1V

ON BOARD DIAGNOSIS LOGIC

This diagnosis continuously monitors the engine coolant temperature.

If the cooling fan or another component in the cooling system malfunctions, engine coolant temperature will

rise.

When the engine coolant temperature reaches an abnormally high temperature condition, a malfunction is

indicated.

Diagnostic Trouble

Code No.Malfunction is detected when ...Check Items

(Possible Cause)

28+Cooling fan does not operate properly (Overheat).

+Cooling fan system does not operate properly (Over-

heat).

+Engine coolant was not added to the system using

the proper ®lling method.+Harness or connectors

(The cooling fan circuit is open or shorted.)

+Cooling fan

+Radiator hose

+Radiator

+Radiator cap

+Water pump

+Thermostat

+Fan belt

+Engine coolant temperature sensor

For more information, refer to ``MAIN 12

CAUSES OF OVERHEATING'', EC-120.

CAUTION:

When a malfunction is indicated, be sure to replace the coolant following the procedure in the MA

section (``Changing Engine Coolant'', ``ENGINE MAINTENANCE''). Also, replace the engine oil.

a. Fill radiator with coolant up to speci®ed level with a ®lling speed of 2 liters per minute. Be sure to

use coolant with the proper mixture ratio. Refer to MA section (``Anti-freeze Coolant Mixture Ratio'',

``RECOMMENDED FLUIDS AND LUBRICANTS'').

b. After re®lling coolant, run engine to ensure that no water-¯ow noise is emitted.

TROUBLE DIAGNOSIS FOR ``OVER HEAT'' (DTC 28)

Cooling Fan (Overheat) (Cont'd)

EC-114

Page 119 of 192

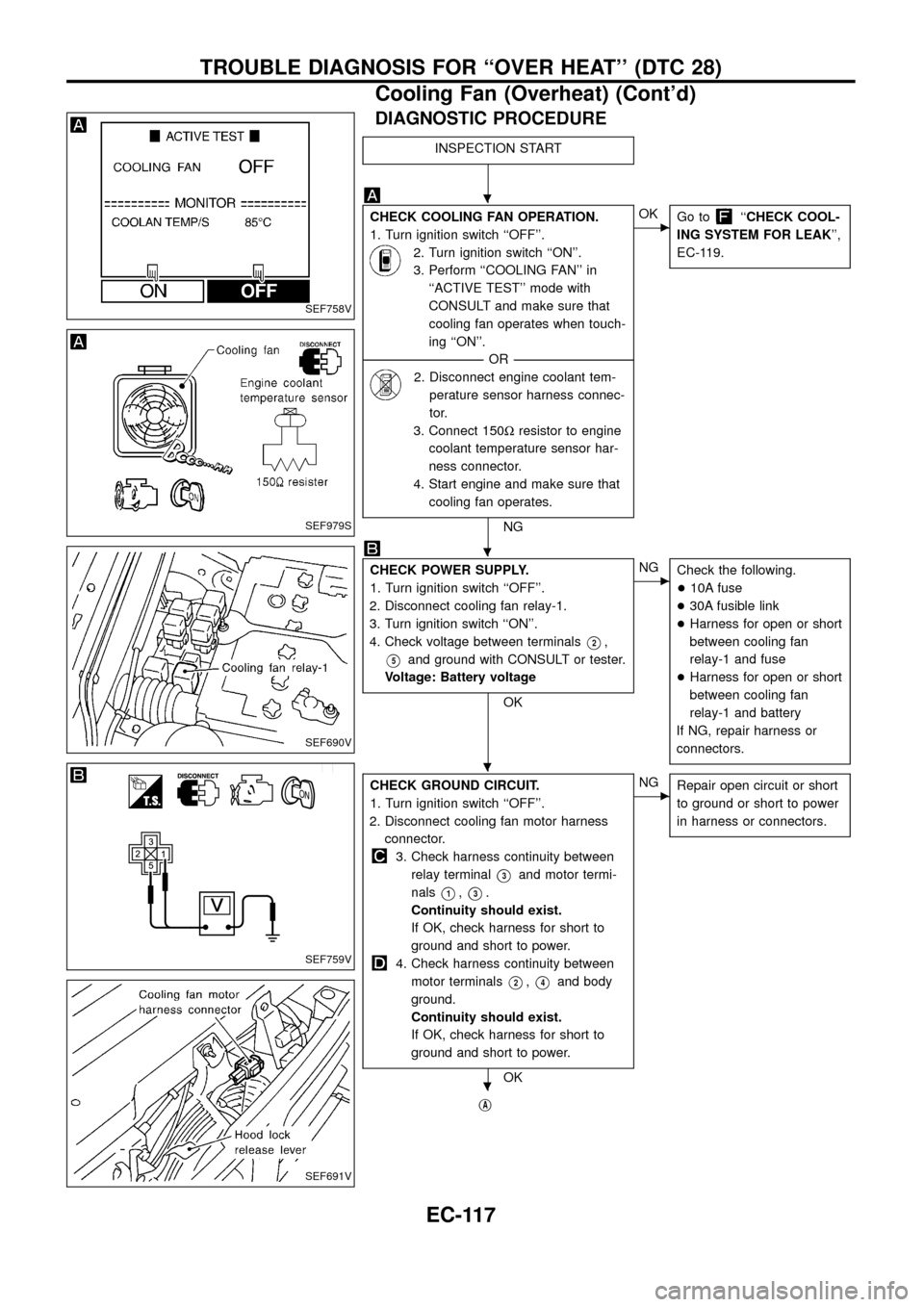

DIAGNOSTIC PROCEDURE

INSPECTION START

CHECK COOLING FAN OPERATION.

1. Turn ignition switch ``OFF''.

2. Turn ignition switch ``ON''.

3. Perform ``COOLING FAN'' in

``ACTIVE TEST'' mode with

CONSULT and make sure that

cooling fan operates when touch-

ing ``ON''.

--------------------------------------------------------------------------------------------------------------------------------------OR--------------------------------------------------------------------------------------------------------------------------------------

2. Disconnect engine coolant tem-

perature sensor harness connec-

tor.

3. Connect 150Wresistor to engine

coolant temperature sensor har-

ness connector.

4. Start engine and make sure that

cooling fan operates.

NG

cOK

Go to``CHECK COOL-

ING SYSTEM FOR LEAK'',

EC-119.

CHECK POWER SUPPLY.

1. Turn ignition switch ``OFF''.

2. Disconnect cooling fan relay-1.

3. Turn ignition switch ``ON''.

4. Check voltage between terminals

V2,

V5and ground with CONSULT or tester.

Voltage: Battery voltage

OK

cNG

Check the following.

+10A fuse

+30A fusible link

+Harness for open or short

between cooling fan

relay-1 and fuse

+Harness for open or short

between cooling fan

relay-1 and battery

If NG, repair harness or

connectors.

CHECK GROUND CIRCUIT.

1. Turn ignition switch ``OFF''.

2. Disconnect cooling fan motor harness

connector.

3. Check harness continuity between

relay terminal

V3and motor termi-

nals

V1,V3.

Continuity should exist.

If OK, check harness for short to

ground and short to power.

4. Check harness continuity between

motor terminals

V2,V4and body

ground.

Continuity should exist.

If OK, check harness for short to

ground and short to power.

OK

cNG

Repair open circuit or short

to ground or short to power

in harness or connectors.

jA

SEF758V

SEF979S

SEF690V

SEF759V

SEF691V

.

.

.

.

TROUBLE DIAGNOSIS FOR ``OVER HEAT'' (DTC 28)

Cooling Fan (Overheat) (Cont'd)

EC-117

Page 123 of 192

COMPONENT INSPECTION

Cooling fan relay-1

Check continuity between terminalsV3andV5.

Conditions Continuity

12V direct current supply between

terminals

V1andV2Ye s

No current supply No

If NG, replace relay.

Cooling fan motor-1

1. Disconnect cooling fan motor harness connector.

2. Supply cooling fan motor terminals with battery voltage and

check operation.

Terminals

(Å)(@)

Cooling fan motor

V1,V3V2,V4

Cooling fan motor should operate.

If NG, replace cooling fan motor.

SEF511P

SEF763V

TROUBLE DIAGNOSIS FOR ``OVER HEAT'' (DTC 28)

Cooling Fan (Overheat) (Cont'd)

EC-121

Page 132 of 192

Fuel Cut Solenoid Valve

When the ignition switch is OFF, the ECM turns the fuel cut sole-

noid valve OFF (under this condition, no current ¯ows through the

fuel cut solenoid valve), shutting off fuel supply.

When the engine is not operating due to trouble, the fuel cut sole-

noid valve may or may not be OFF even when the ignition switch

is ON.

CONSULT REFERENCE VALUE IN DATA MONITOR MODE

Remarks: Speci®cation data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

DECELER F/CUT+Engine: After warming upIdle OFF

When accelerator pedal is released

quickly with engine speed at 3,000

rpm or more.ON

FUEL CUT S/V+Ignition switch: ON®OFF ON®OFF

ECM TERMINALS AND REFERENCE VALUE

Remarks: Speci®cation data are reference values and are measured between each terminal andV43(ECCS

ground) with a voltmeter.

TER-

MINAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage and Pulse

Signal)

4 B/Y ECCS relay (Self-shutoff)Ignition switch ``ON''

Ignition switch ``OFF''

For a few seconds after turning ignition switch

``OFF''0 - 1.5V

Ignition switch ``OFF''

A few seconds passed after turning ignition

switch ``OFF''BATTERY VOLTAGE

(11 - 14V)

56

61W Power supply for ECM Ignition switch ``ON''

BATTERY VOLTAGE

(11 - 14V)

11 3

11 5R/W Fuel cut solenoid valveIgnition switch ``OFF''

Approximately 0V

Ignition switch ``ON''

BATTERY VOLTAGE

(11 - 14V)

11 6

11 7W Power supply for ECM Ignition switch ``ON''

BATTERY VOLTAGE

(11 - 14V)

SEF667S

TROUBLE DIAGNOSIS FOR ``FUEL CUT S/V 1'' (DTC 36),

``FCV SHORT'' (DTC 37), ``FUEL CUT S/V 2'' (DTC 38)

EC-130

Page 153 of 192

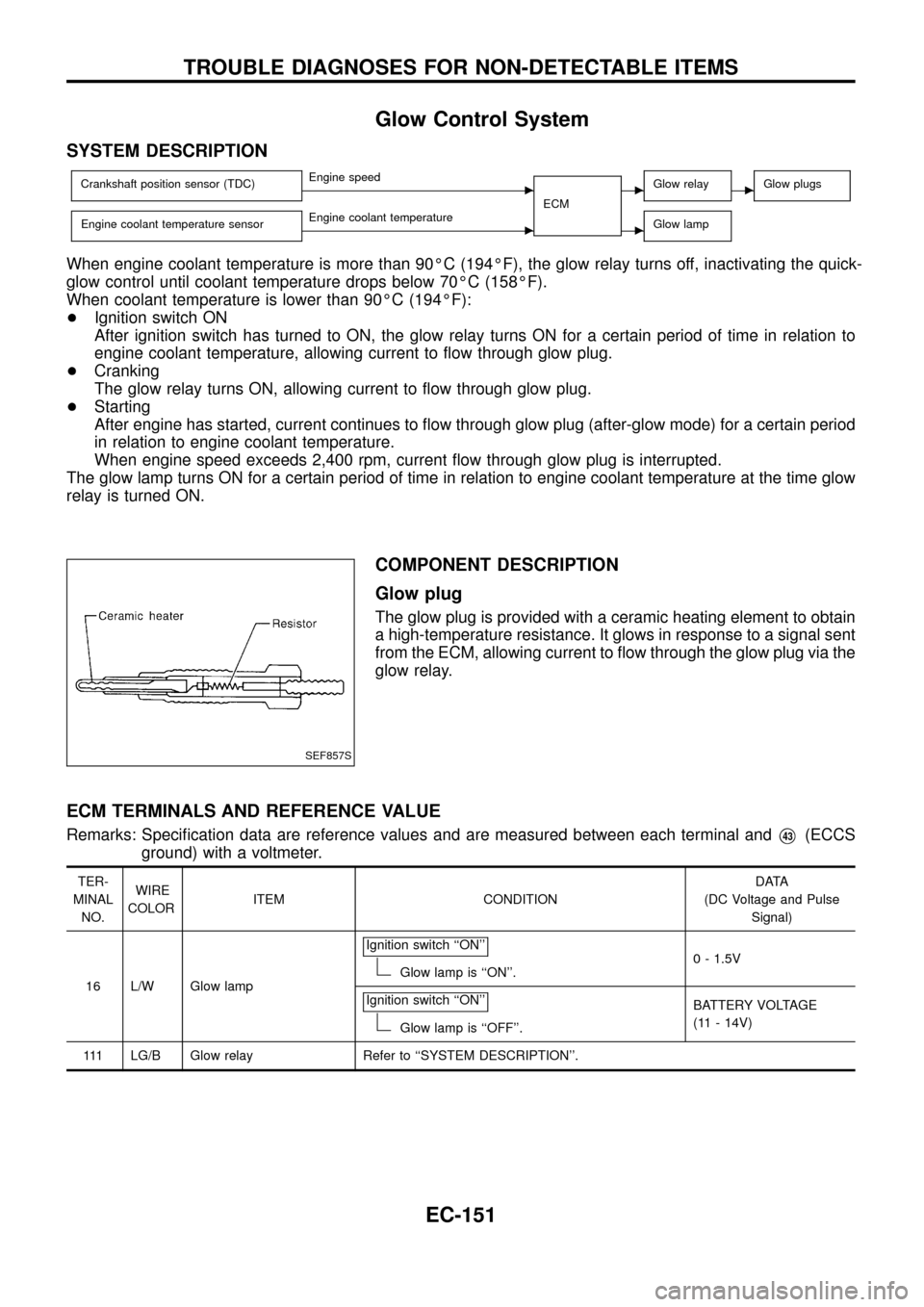

Glow Control System

SYSTEM DESCRIPTION

Crankshaft position sensor (TDC)cEngine speed

ECMcGlow relaycGlow plugs

Engine coolant temperature sensorcEngine coolant temperaturecGlow lamp

When engine coolant temperature is more than 90ÉC (194ÉF), the glow relay turns off, inactivating the quick-

glow control until coolant temperature drops below 70ÉC (158ÉF).

When coolant temperature is lower than 90ÉC (194ÉF):

+Ignition switch ON

After ignition switch has turned to ON, the glow relay turns ON for a certain period of time in relation to

engine coolant temperature, allowing current to ¯ow through glow plug.

+Cranking

The glow relay turns ON, allowing current to ¯ow through glow plug.

+Starting

After engine has started, current continues to ¯ow through glow plug (after-glow mode) for a certain period

in relation to engine coolant temperature.

When engine speed exceeds 2,400 rpm, current ¯ow through glow plug is interrupted.

The glow lamp turns ON for a certain period of time in relation to engine coolant temperature at the time glow

relay is turned ON.

COMPONENT DESCRIPTION

Glow plug

The glow plug is provided with a ceramic heating element to obtain

a high-temperature resistance. It glows in response to a signal sent

from the ECM, allowing current to ¯ow through the glow plug via the

glow relay.

ECM TERMINALS AND REFERENCE VALUE

Remarks: Speci®cation data are reference values and are measured between each terminal andV43(ECCS

ground) with a voltmeter.

TER-

MINAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage and Pulse

Signal)

16 L/W Glow lampIgnition switch ``ON''

Glow lamp is ``ON''.0 - 1.5V

Ignition switch ``ON''

Glow lamp is ``OFF''.BATTERY VOLTAGE

(11 - 14V)

111 LG/B Glow relay Refer to ``SYSTEM DESCRIPTION''.

SEF857S

TROUBLE DIAGNOSES FOR NON-DETECTABLE ITEMS

EC-151

Page 155 of 192

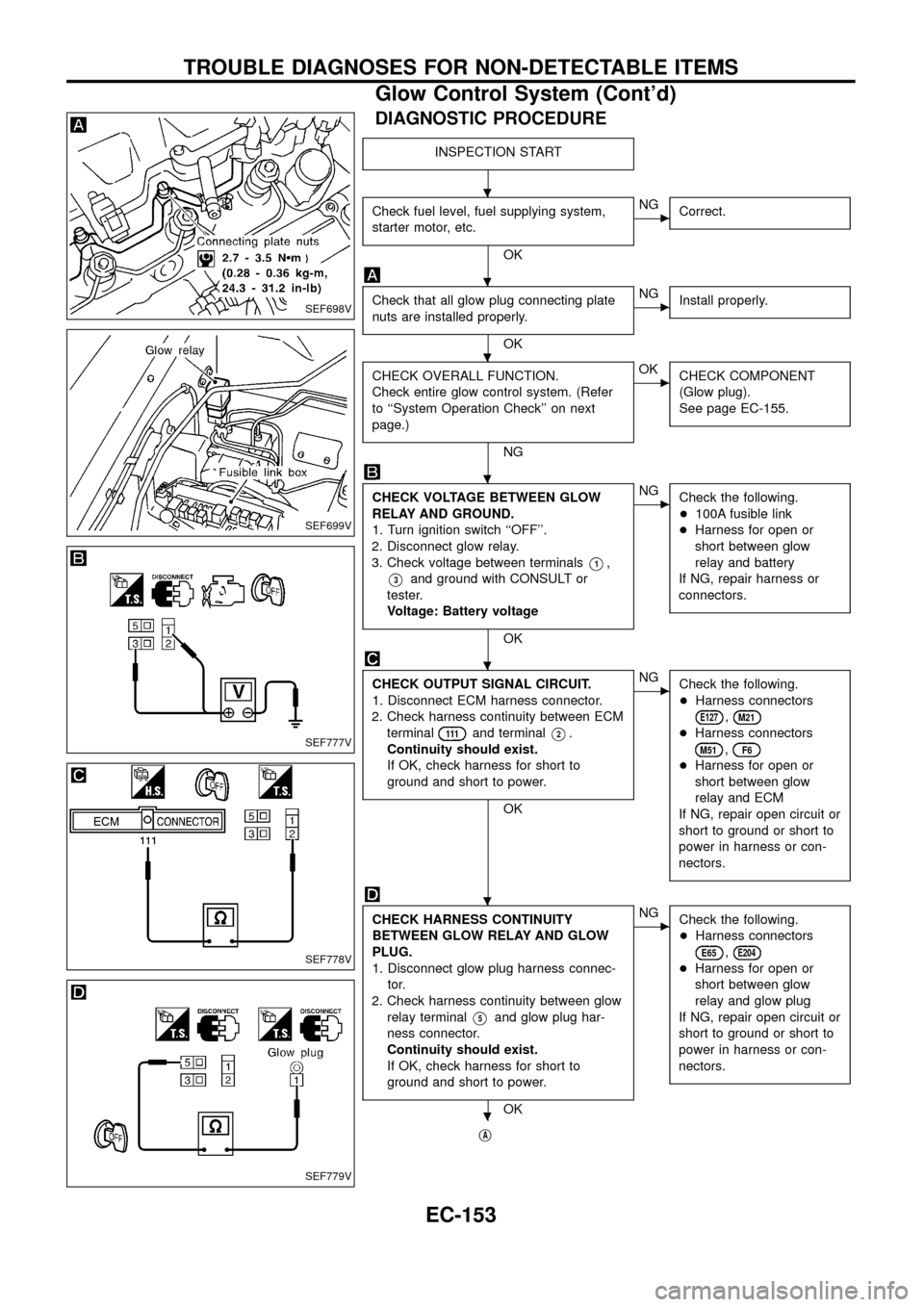

DIAGNOSTIC PROCEDURE

INSPECTION START

Check fuel level, fuel supplying system,

starter motor, etc.

OK

cNG

Correct.

Check that all glow plug connecting plate

nuts are installed properly.

OK

cNG

Install properly.

CHECK OVERALL FUNCTION.

Check entire glow control system. (Refer

to ``System Operation Check'' on next

page.)

NG

cOK

CHECK COMPONENT

(Glow plug).

See page EC-155.

CHECK VOLTAGE BETWEEN GLOW

RELAY AND GROUND.

1. Turn ignition switch ``OFF''.

2. Disconnect glow relay.

3. Check voltage between terminals

V1,

V3and ground with CONSULT or

tester.

Voltage: Battery voltage

OK

cNG

Check the following.

+100A fusible link

+Harness for open or

short between glow

relay and battery

If NG, repair harness or

connectors.

CHECK OUTPUT SIGNAL CIRCUIT.

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM

terminal

111and terminalV2.

Continuity should exist.

If OK, check harness for short to

ground and short to power.

OK

cNG

Check the following.

+Harness connectors

E127,M21

+Harness connectors

M51,F6

+Harness for open or

short between glow

relay and ECM

If NG, repair open circuit or

short to ground or short to

power in harness or con-

nectors.

CHECK HARNESS CONTINUITY

BETWEEN GLOW RELAY AND GLOW

PLUG.

1. Disconnect glow plug harness connec-

tor.

2. Check harness continuity between glow

relay terminal

V5and glow plug har-

ness connector.

Continuity should exist.

If OK, check harness for short to

ground and short to power.

OK

cNG

Check the following.

+Harness connectors

E65,E204

+Harness for open or

short between glow

relay and glow plug

If NG, repair open circuit or

short to ground or short to

power in harness or con-

nectors.

jA

SEF698V

SEF699V

SEF777V

SEF778V

SEF779V

.

.

.

.

.

.

.

TROUBLE DIAGNOSES FOR NON-DETECTABLE ITEMS

Glow Control System (Cont'd)

EC-153

Page 156 of 192

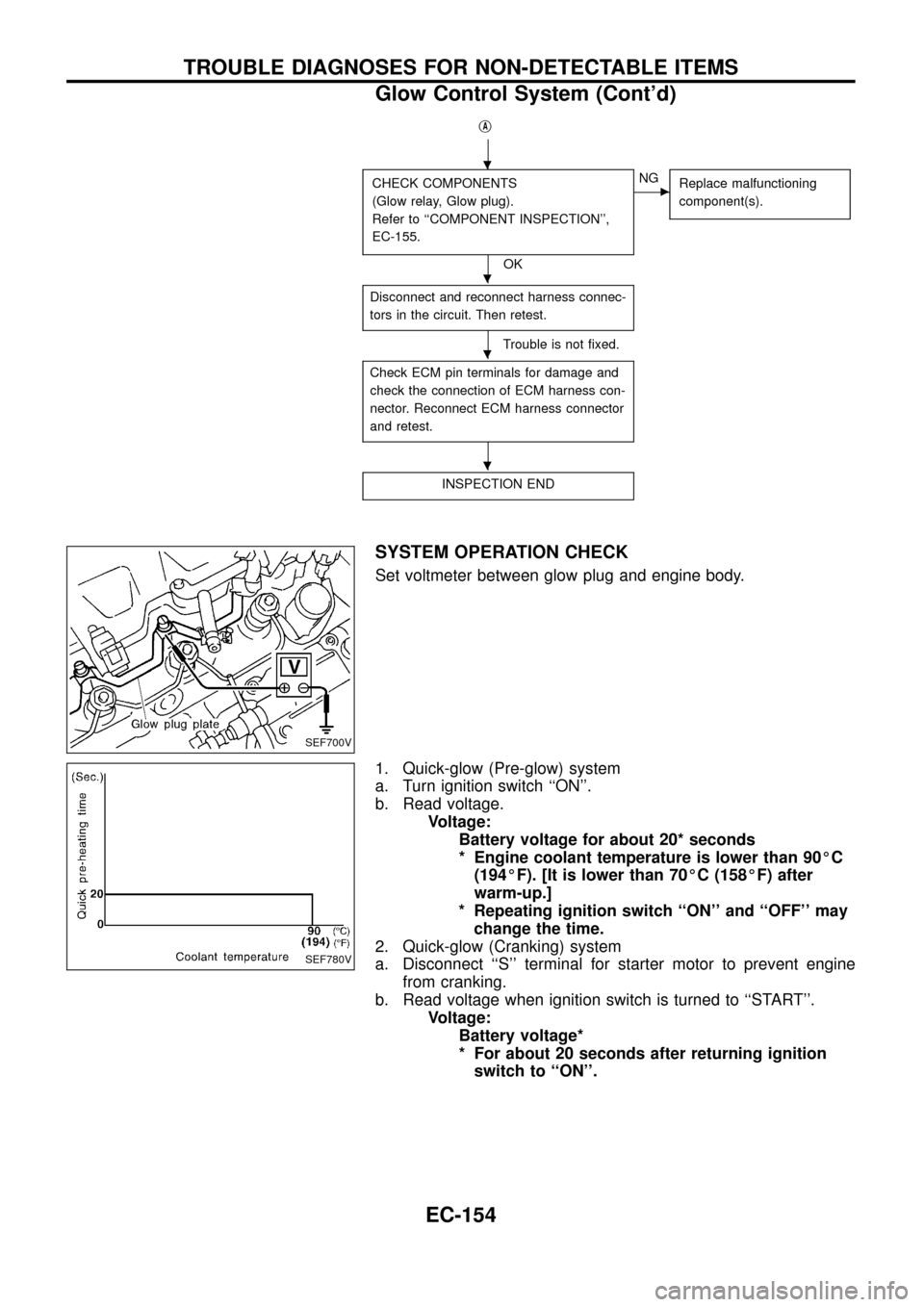

jA

CHECK COMPONENTS

(Glow relay, Glow plug).

Refer to ``COMPONENT INSPECTION'',

EC-155.

OK

cNG

Replace malfunctioning

component(s).

Disconnect and reconnect harness connec-

tors in the circuit. Then retest.

Trouble is not ®xed.

Check ECM pin terminals for damage and

check the connection of ECM harness con-

nector. Reconnect ECM harness connector

and retest.

INSPECTION END

SYSTEM OPERATION CHECK

Set voltmeter between glow plug and engine body.

1. Quick-glow (Pre-glow) system

a. Turn ignition switch ``ON''.

b. Read voltage.

Voltage:

Battery voltage for about 20* seconds

* Engine coolant temperature is lower than 90ÉC

(194ÉF). [It is lower than 70ÉC (158ÉF) after

warm-up.]

* Repeating ignition switch ``ON'' and ``OFF'' may

change the time.

2. Quick-glow (Cranking) system

a. Disconnect ``S'' terminal for starter motor to prevent engine

from cranking.

b. Read voltage when ignition switch is turned to ``START''.

Voltage:

Battery voltage*

* For about 20 seconds after returning ignition

switch to ``ON''.

SEF700V

SEF780V

.

.

.

.

TROUBLE DIAGNOSES FOR NON-DETECTABLE ITEMS

Glow Control System (Cont'd)

EC-154

Page 157 of 192

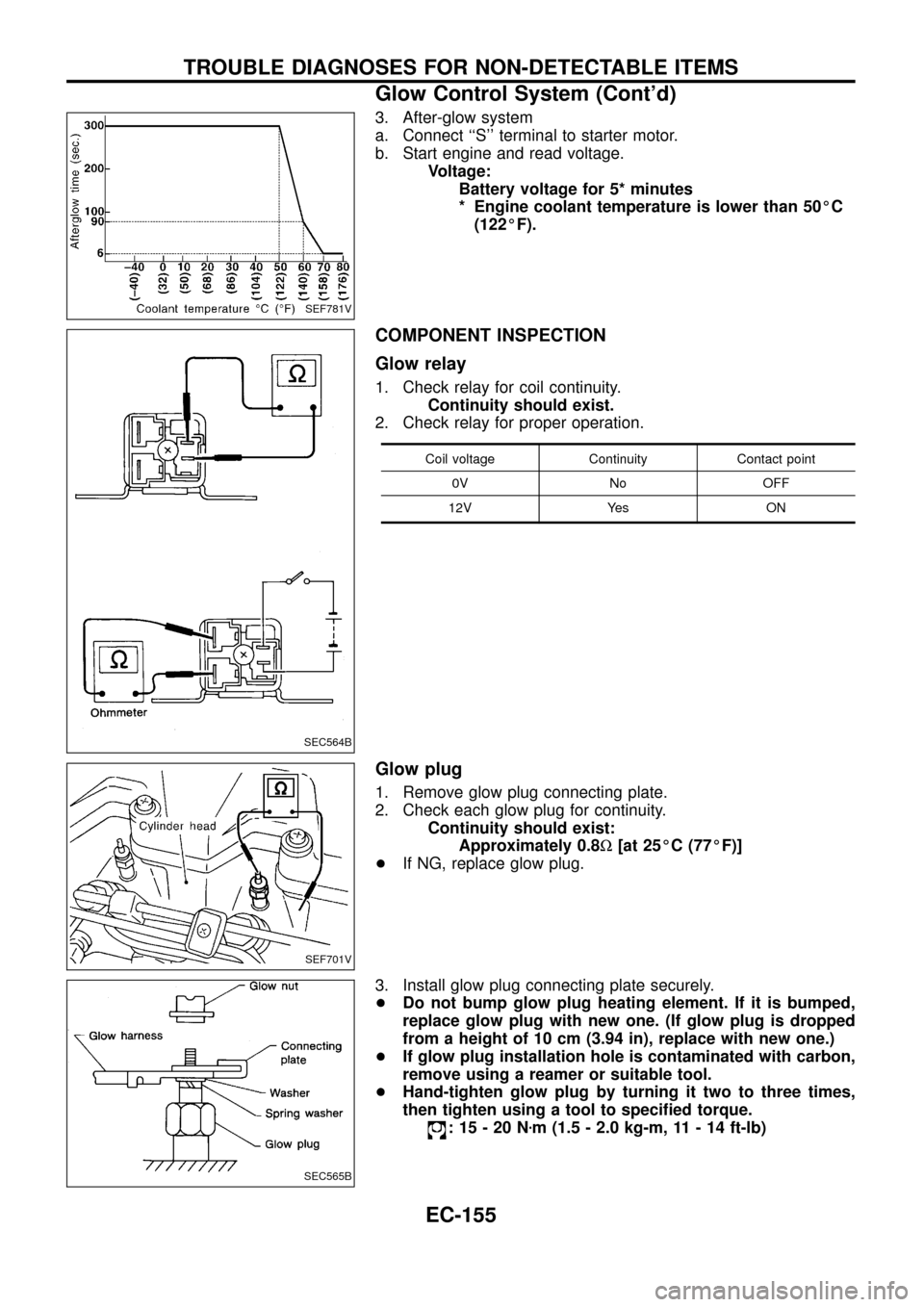

3. After-glow system

a. Connect ``S'' terminal to starter motor.

b. Start engine and read voltage.

Voltage:

Battery voltage for 5* minutes

* Engine coolant temperature is lower than 50ÉC

(122ÉF).

COMPONENT INSPECTION

Glow relay

1. Check relay for coil continuity.

Continuity should exist.

2. Check relay for proper operation.

Coil voltage Continuity Contact point

0V No OFF

12V Yes ON

Glow plug

1. Remove glow plug connecting plate.

2. Check each glow plug for continuity.

Continuity should exist:

Approximately 0.8W[at 25ÉC (77ÉF)]

+If NG, replace glow plug.

3. Install glow plug connecting plate securely.

+Do not bump glow plug heating element. If it is bumped,

replace glow plug with new one. (If glow plug is dropped

from a height of 10 cm (3.94 in), replace with new one.)

+If glow plug installation hole is contaminated with carbon,

remove using a reamer or suitable tool.

+Hand-tighten glow plug by turning it two to three times,

then tighten using a tool to speci®ed torque.

:15-20Nzm (1.5 - 2.0 kg-m, 11 - 14 ft-lb)

SEF781V

SEC564B

SEF701V

SEC565B

TROUBLE DIAGNOSES FOR NON-DETECTABLE ITEMS

Glow Control System (Cont'd)

EC-155