water pump NISSAN PATROL 1998 Y61 / 5.G Engine Lubrication And Cooling System Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PATROL, Model: NISSAN PATROL 1998 Y61 / 5.GPages: 22, PDF Size: 0.67 MB

Page 1 of 22

ENGINE LUBRICATION &

COOLING SYSTEMS

SECTION

LC

CONTENTS

PRECAUTIONS AND PREPARATION............................1

Liquid Gasket Application Procedure ..........................1

Special Service Tools ..................................................2

ENGINE LUBRICATION SYSTEM..................................3

Lubrication Circuit ........................................................3

Oil Pressure Check......................................................3

Oil Pump ......................................................................4

Oil Cooler .....................................................................7

Oil Jet...........................................................................7

Turbocharger ...............................................................8

ENGINE COOLING SYSTEM..........................................9

Cooling Circuit .............................................................9System Check..............................................................9

Water Pump ...............................................................10

Thermostat .................................................................12

Radiator .....................................................................14

Re®lling Engine Coolant ............................................14

Cooling Fan (Crankshaft driven) ...............................15

Cooling Fan (Motor driven)........................................15

Radiator (Aluminum type) ..........................................16

Overheating Cause Analysis .....................................20

SERVICE DATA AND SPECIFICATIONS (SDS)..........21

Engine Lubrication System ........................................21

Engine Cooling System .............................................21

LC

Page 11 of 22

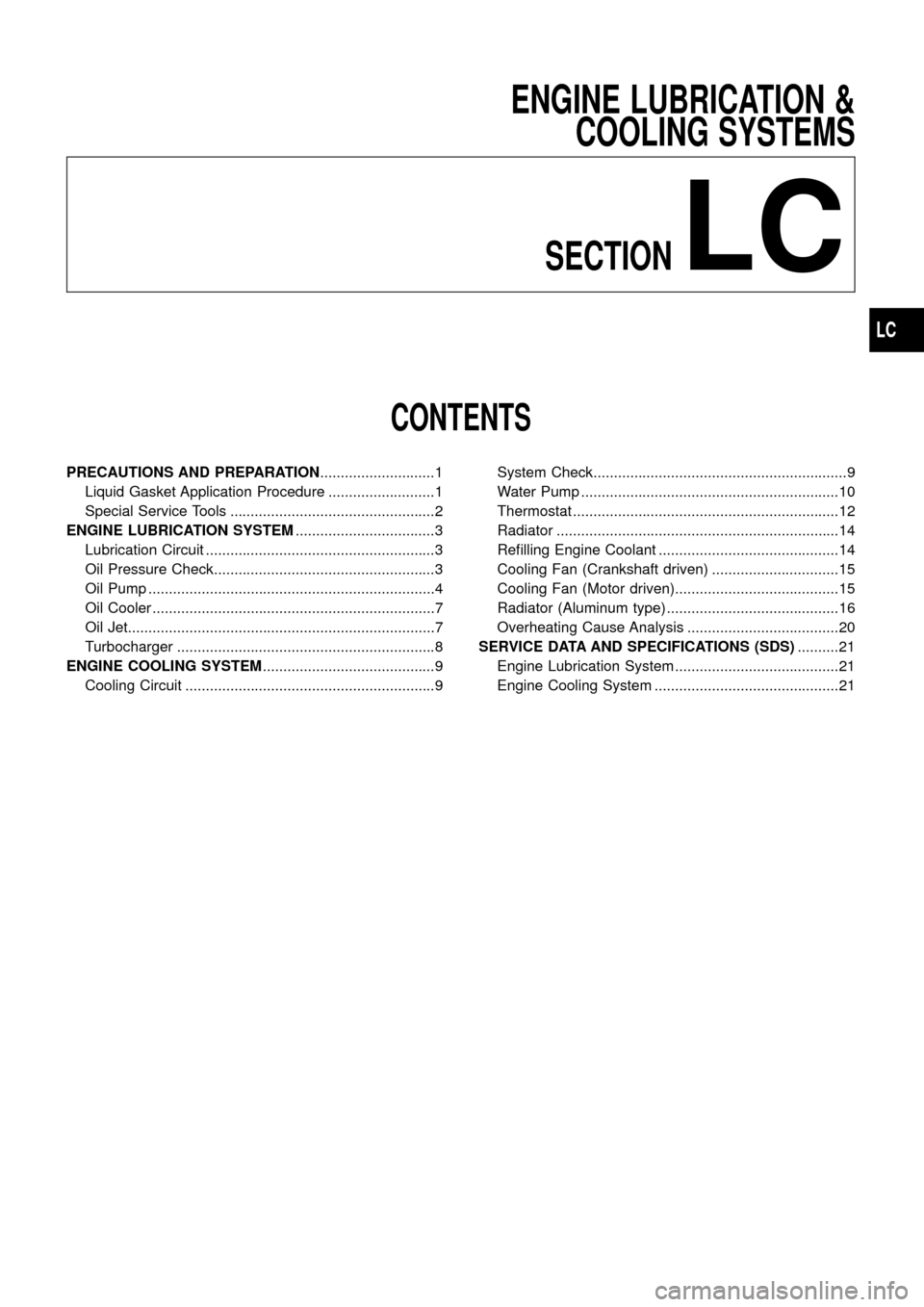

Pull the negative pressure valve to open it. Check that it closes

completely when released.

CHECKING COOLING SYSTEM FOR LEAKS

Apply pressure to the cooling system by means of a tester to check

for leakage.

Testing pressure:

98 kPa (0.98 bar, 1.0 kg/cm

2, 14 psi)

CAUTION:

Use of pressure higher than the speci®ed value may cause

damage to radiator.

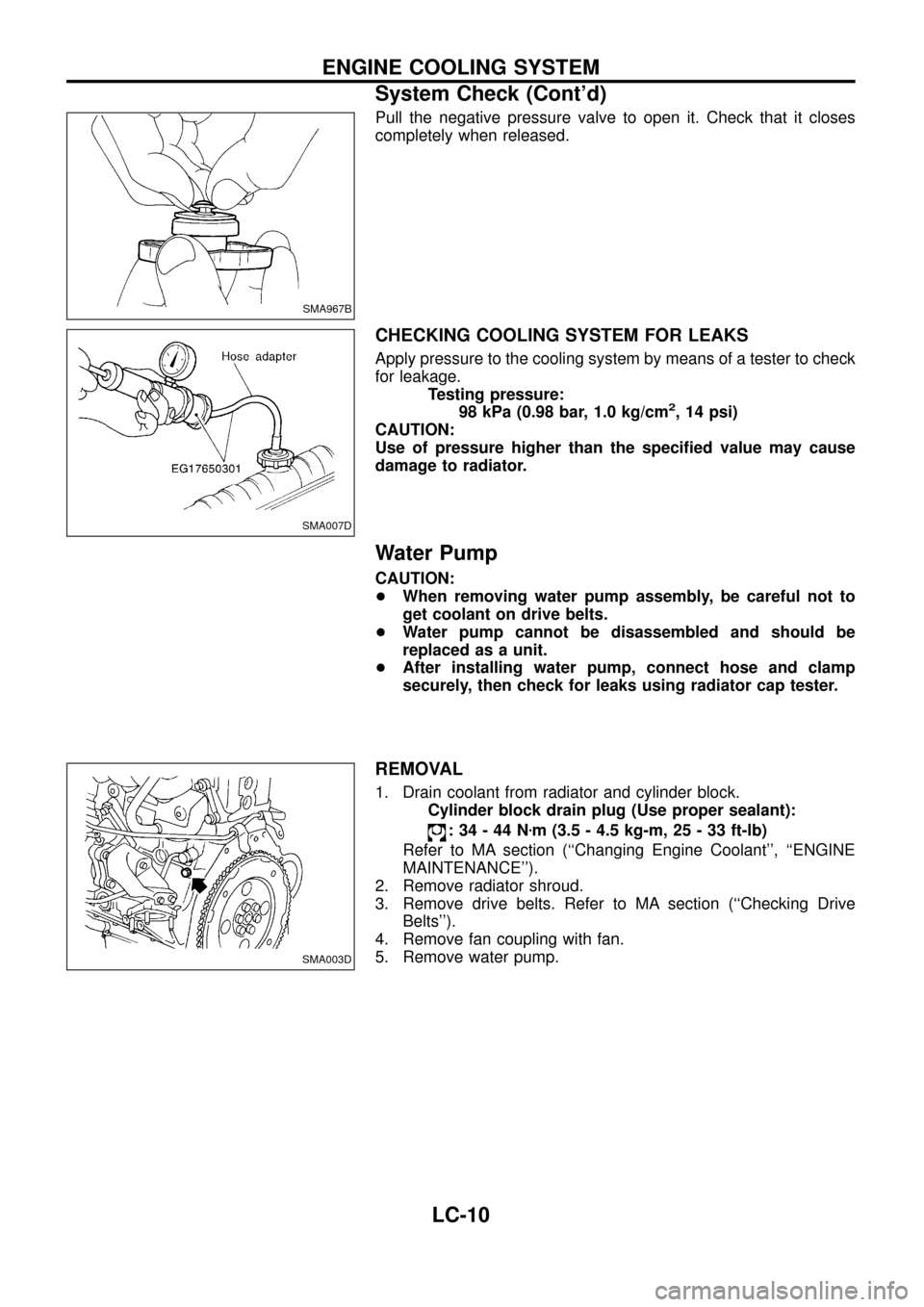

Water Pump

CAUTION:

+When removing water pump assembly, be careful not to

get coolant on drive belts.

+Water pump cannot be disassembled and should be

replaced as a unit.

+After installing water pump, connect hose and clamp

securely, then check for leaks using radiator cap tester.

REMOVAL

1. Drain coolant from radiator and cylinder block.

Cylinder block drain plug (Use proper sealant):

:34-44Nzm (3.5 - 4.5 kg-m, 25 - 33 ft-lb)

Refer to MA section (``Changing Engine Coolant'', ``ENGINE

MAINTENANCE'').

2. Remove radiator shroud.

3. Remove drive belts. Refer to MA section (``Checking Drive

Belts'').

4. Remove fan coupling with fan.

5. Remove water pump.

SMA967B

SMA007D

SMA003D

ENGINE COOLING SYSTEM

System Check (Cont'd)

LC-10

Page 12 of 22

INSPECTION

1. Check for rusted or corroded body assembly and vane.

2. Check for excessive end play and rough operation.

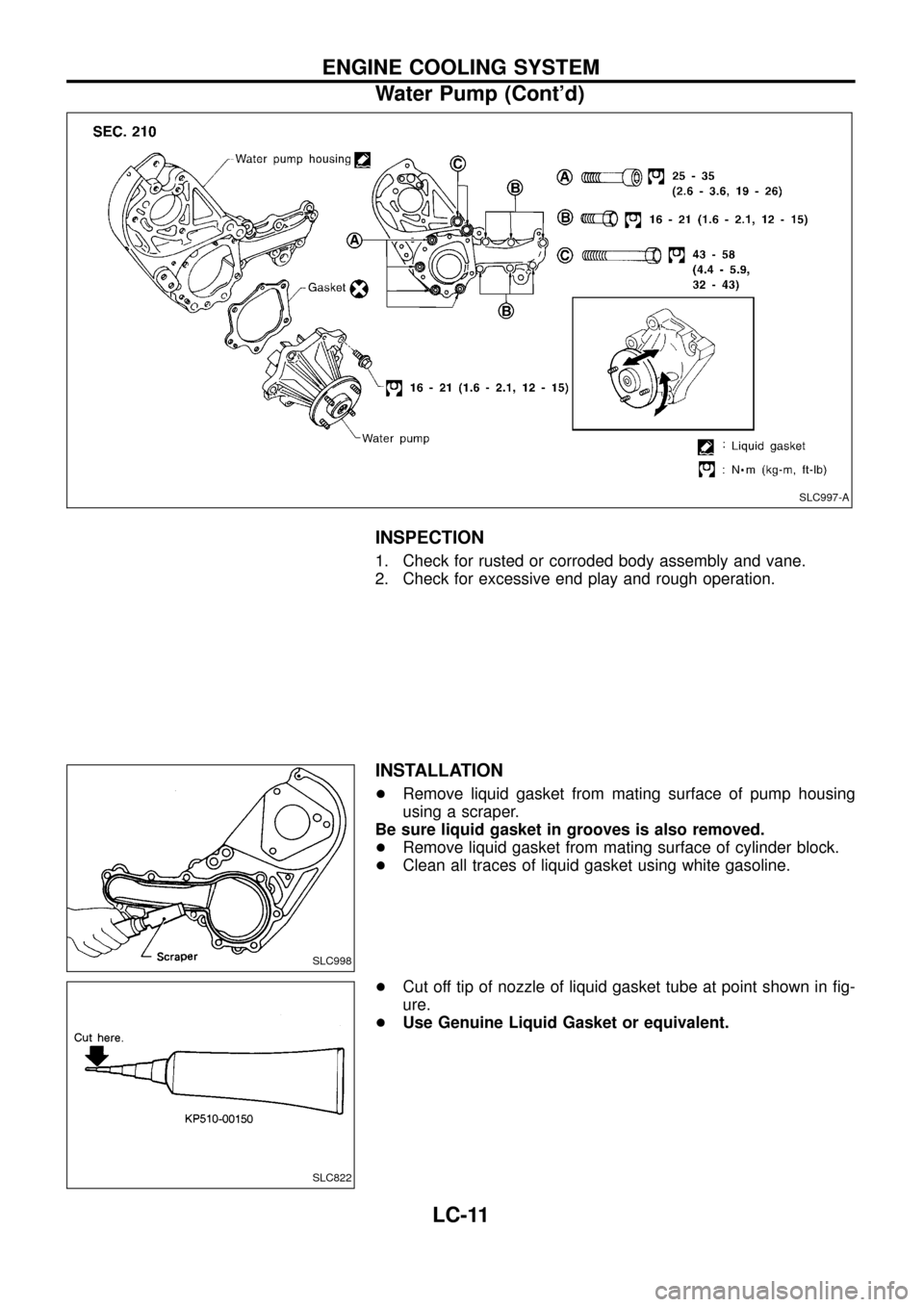

INSTALLATION

+Remove liquid gasket from mating surface of pump housing

using a scraper.

Be sure liquid gasket in grooves is also removed.

+Remove liquid gasket from mating surface of cylinder block.

+Clean all traces of liquid gasket using white gasoline.

+Cut off tip of nozzle of liquid gasket tube at point shown in ®g-

ure.

+Use Genuine Liquid Gasket or equivalent.

SLC997-A

SLC998

SLC822

ENGINE COOLING SYSTEM

Water Pump (Cont'd)

LC-11

Page 13 of 22

+Apply a continuous bead of liquid gasket to mating surface of

pump housing as shown.

a. Be sure diameter of liquid gasket is within 2.0 to 3.0 mm

(0.079 to 0.118 in) dia. range.

b. Attach pump housing to cylinder block within ®ve minutes

of applying liquid gasket.

c. After installing pump housing, wait at least 30 minutes

before starting engine.

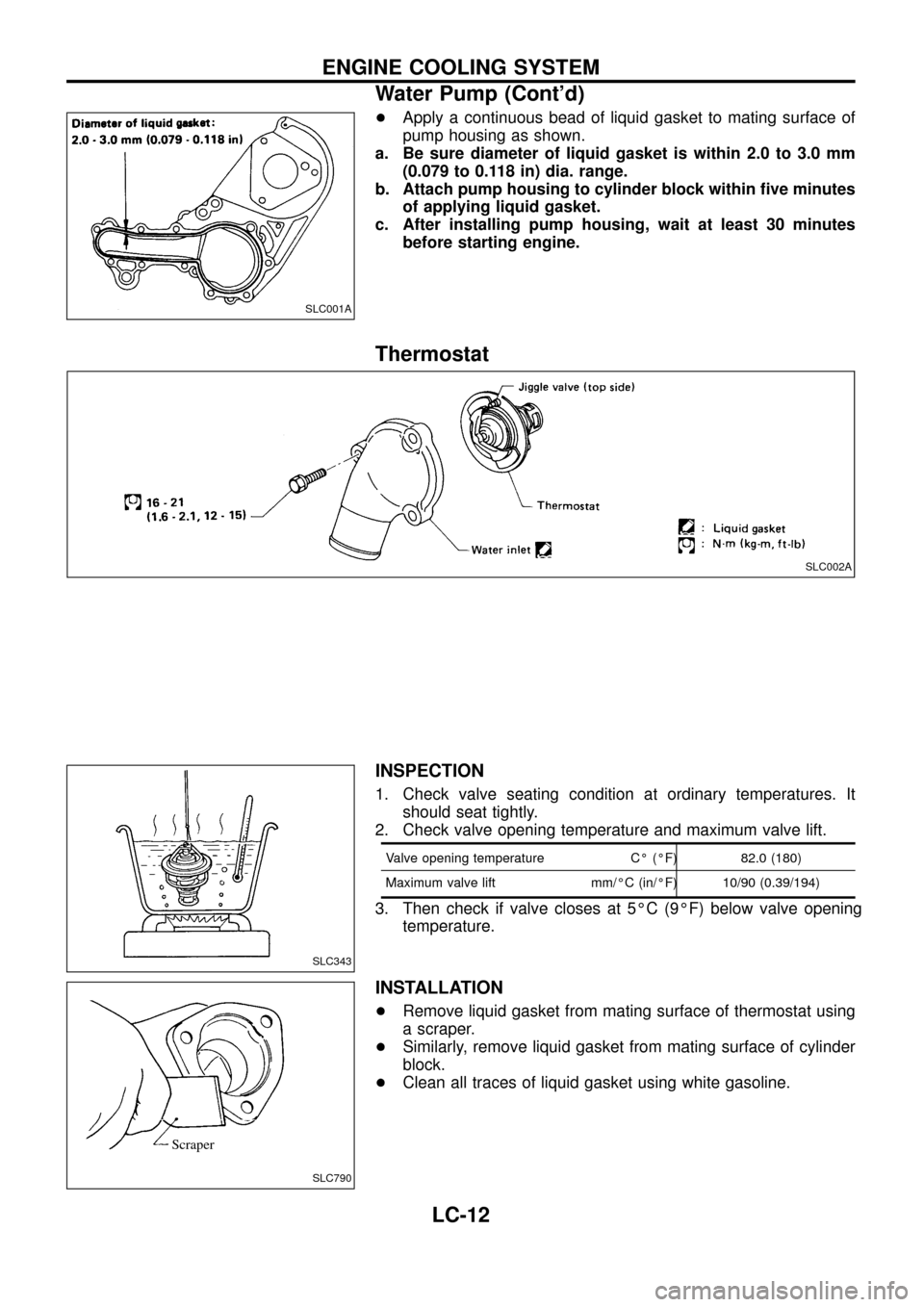

Thermostat

INSPECTION

1. Check valve seating condition at ordinary temperatures. It

should seat tightly.

2. Check valve opening temperature and maximum valve lift.

Valve opening temperature CÉ (ÉF) 82.0 (180)

Maximum valve lift mm/ÉC (in/ÉF) 10/90 (0.39/194)

3. Then check if valve closes at 5ÉC (9ÉF) below valve opening

temperature.

INSTALLATION

+Remove liquid gasket from mating surface of thermostat using

a scraper.

+Similarly, remove liquid gasket from mating surface of cylinder

block.

+Clean all traces of liquid gasket using white gasoline.

SLC001A

SLC002A

SLC343

SLC790

Scraper

ENGINE COOLING SYSTEM

Water Pump (Cont'd)

LC-12

Page 16 of 22

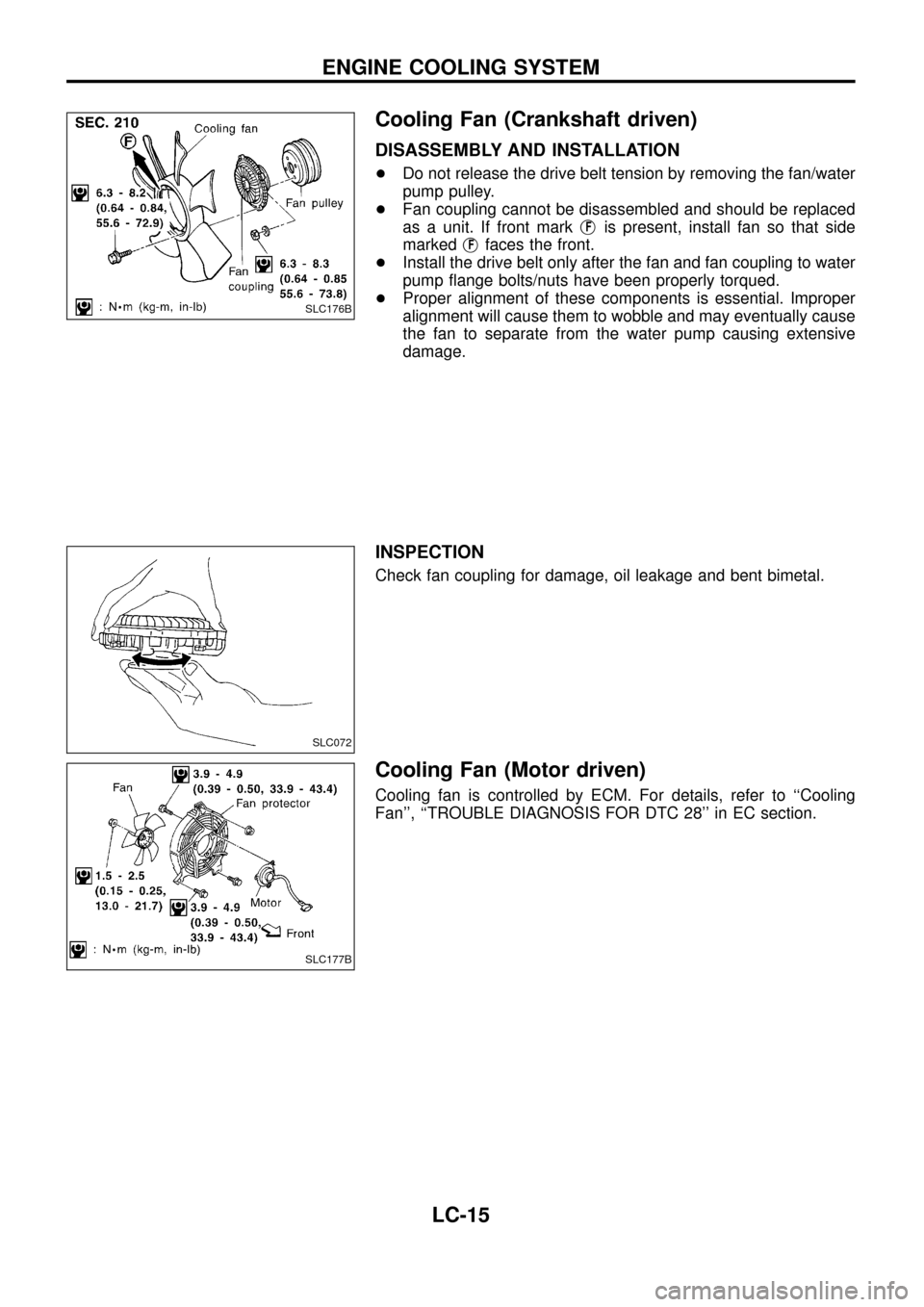

Cooling Fan (Crankshaft driven)

DISASSEMBLY AND INSTALLATION

+Do not release the drive belt tension by removing the fan/water

pump pulley.

+Fan coupling cannot be disassembled and should be replaced

as a unit. If front markj

Fis present, install fan so that side

markedj

Ffaces the front.

+Install the drive belt only after the fan and fan coupling to water

pump ¯ange bolts/nuts have been properly torqued.

+Proper alignment of these components is essential. Improper

alignment will cause them to wobble and may eventually cause

the fan to separate from the water pump causing extensive

damage.

INSPECTION

Check fan coupling for damage, oil leakage and bent bimetal.

Cooling Fan (Motor driven)

Cooling fan is controlled by ECM. For details, refer to ``Cooling

Fan'', ``TROUBLE DIAGNOSIS FOR DTC 28'' in EC section.

SLC176B

SLC072

SLC177B

ENGINE COOLING SYSTEM

LC-15

Page 21 of 22

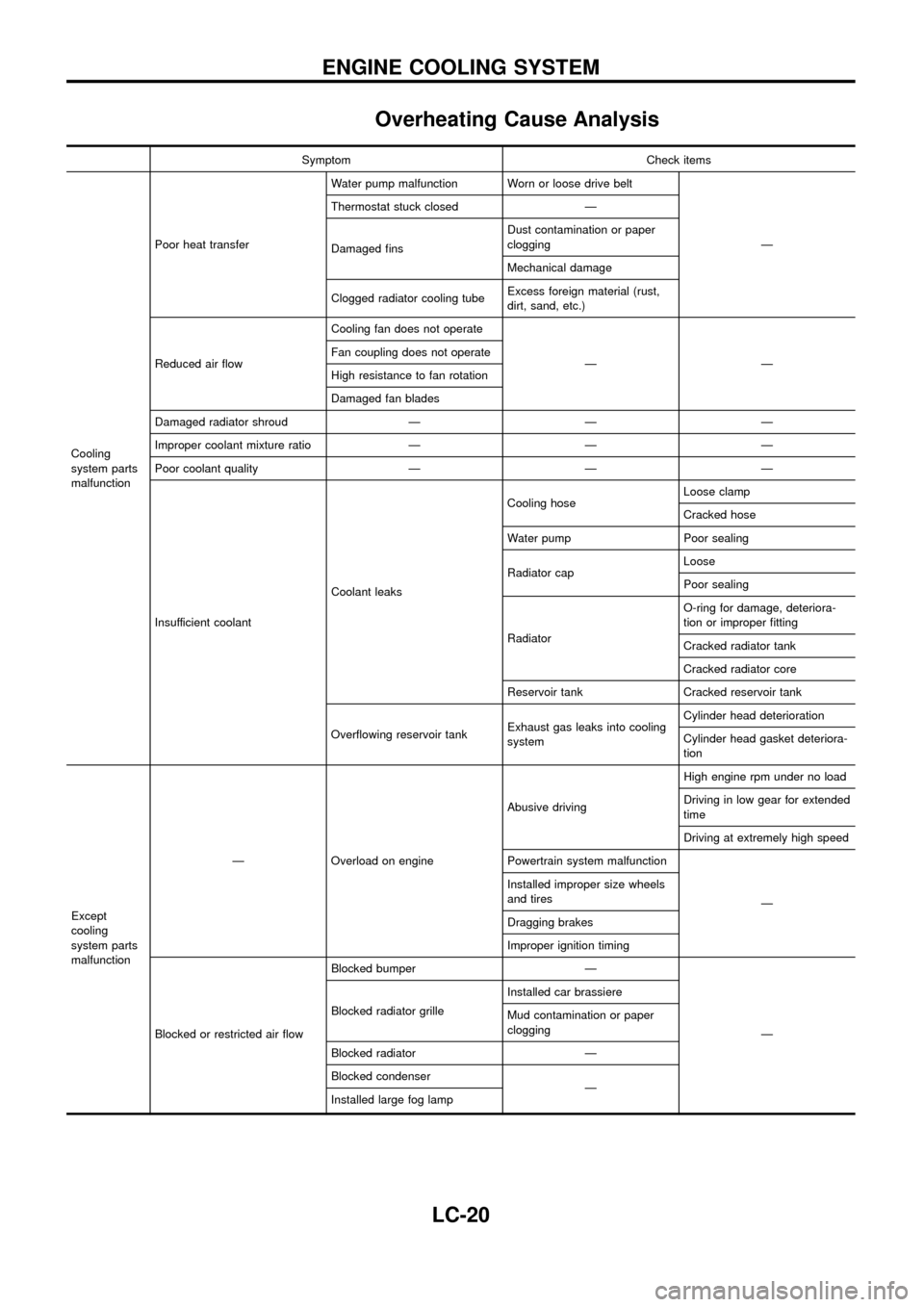

Overheating Cause Analysis

Symptom Check items

Cooling

system parts

malfunctionPoor heat transferWater pump malfunction Worn or loose drive belt

Ð Thermostat stuck closed Ð

Damaged ®nsDust contamination or paper

clogging

Mechanical damage

Clogged radiator cooling tubeExcess foreign material (rust,

dirt, sand, etc.)

Reduced air ¯owCooling fan does not operate

ÐÐ Fan coupling does not operate

High resistance to fan rotation

Damaged fan blades

Damaged radiator shroud Ð Ð Ð

Improper coolant mixture ratio Ð Ð Ð

Poor coolant quality Ð Ð Ð

Insufficient coolantCoolant leaksCooling hoseLoose clamp

Cracked hose

Water pump Poor sealing

Radiator capLoose

Poor sealing

RadiatorO-ring for damage, deteriora-

tion or improper ®tting

Cracked radiator tank

Cracked radiator core

Reservoir tank Cracked reservoir tank

Over¯owing reservoir tankExhaust gas leaks into cooling

systemCylinder head deterioration

Cylinder head gasket deteriora-

tion

Except

cooling

system parts

malfunctionÐ Overload on engineAbusive drivingHigh engine rpm under no load

Driving in low gear for extended

time

Driving at extremely high speed

Powertrain system malfunction

Ð Installed improper size wheels

and tires

Dragging brakes

Improper ignition timing

Blocked or restricted air ¯owBlocked bumper Ð

Ð Blocked radiator grilleInstalled car brassiere

Mud contamination or paper

clogging

Blocked radiator Ð

Blocked condenser

Ð

Installed large fog lamp

ENGINE COOLING SYSTEM

LC-20