NISSAN PATROL 1998 Y61 / 5.G Propeller Shaft And Differential Carrier User Guide

PATROL 1998 Y61 / 5.G

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/625/w960_625-0.png

NISSAN PATROL 1998 Y61 / 5.G Propeller Shaft And Differential Carrier User Guide

Trending: sensor, engine, Front bearing, oil, steering, transmission oil, check oil

Page 11 of 54

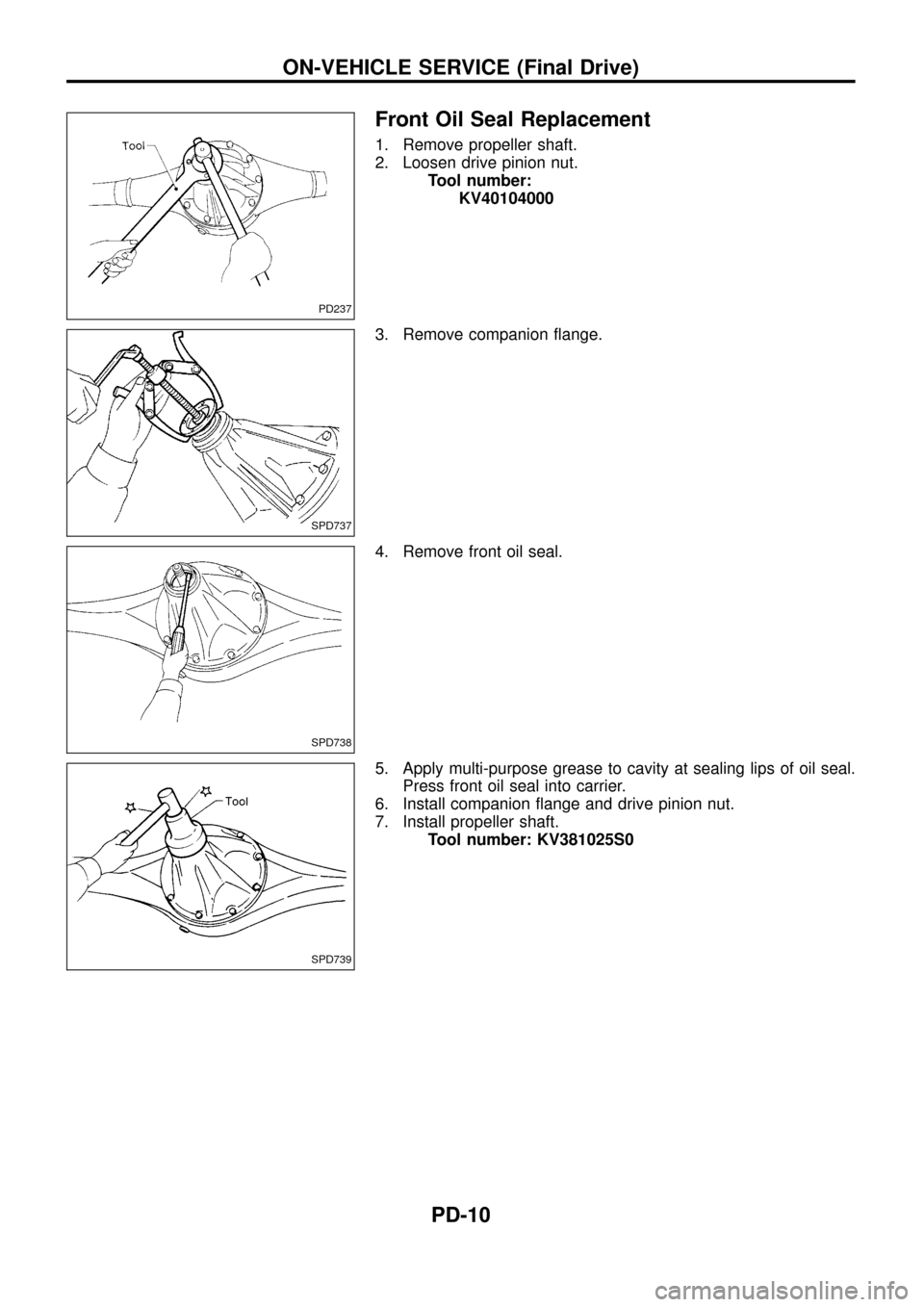

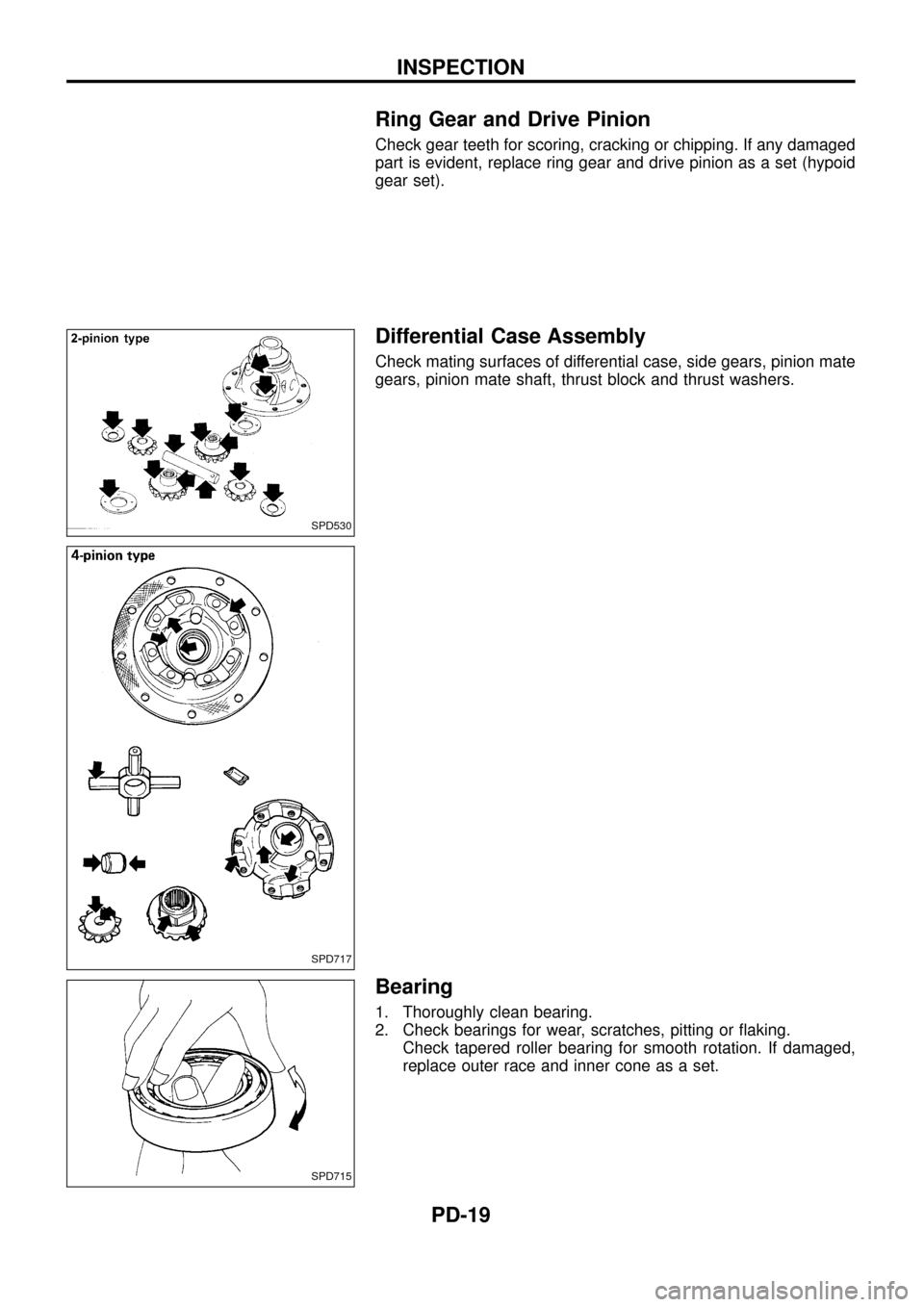

Front Oil Seal Replacement

1. Remove propeller shaft.

2. Loosen drive pinion nut.

Tool number:

KV40104000

3. Remove companion ¯ange.

4. Remove front oil seal.

5. Apply multi-purpose grease to cavity at sealing lips of oil seal.

Press front oil seal into carrier.

6. Install companion ¯ange and drive pinion nut.

7. Install propeller shaft.

Tool number: KV381025S0

PD237

SPD737

SPD738

SPD739

ON-VEHICLE SERVICE (Final Drive)

PD-10

Page 12 of 54

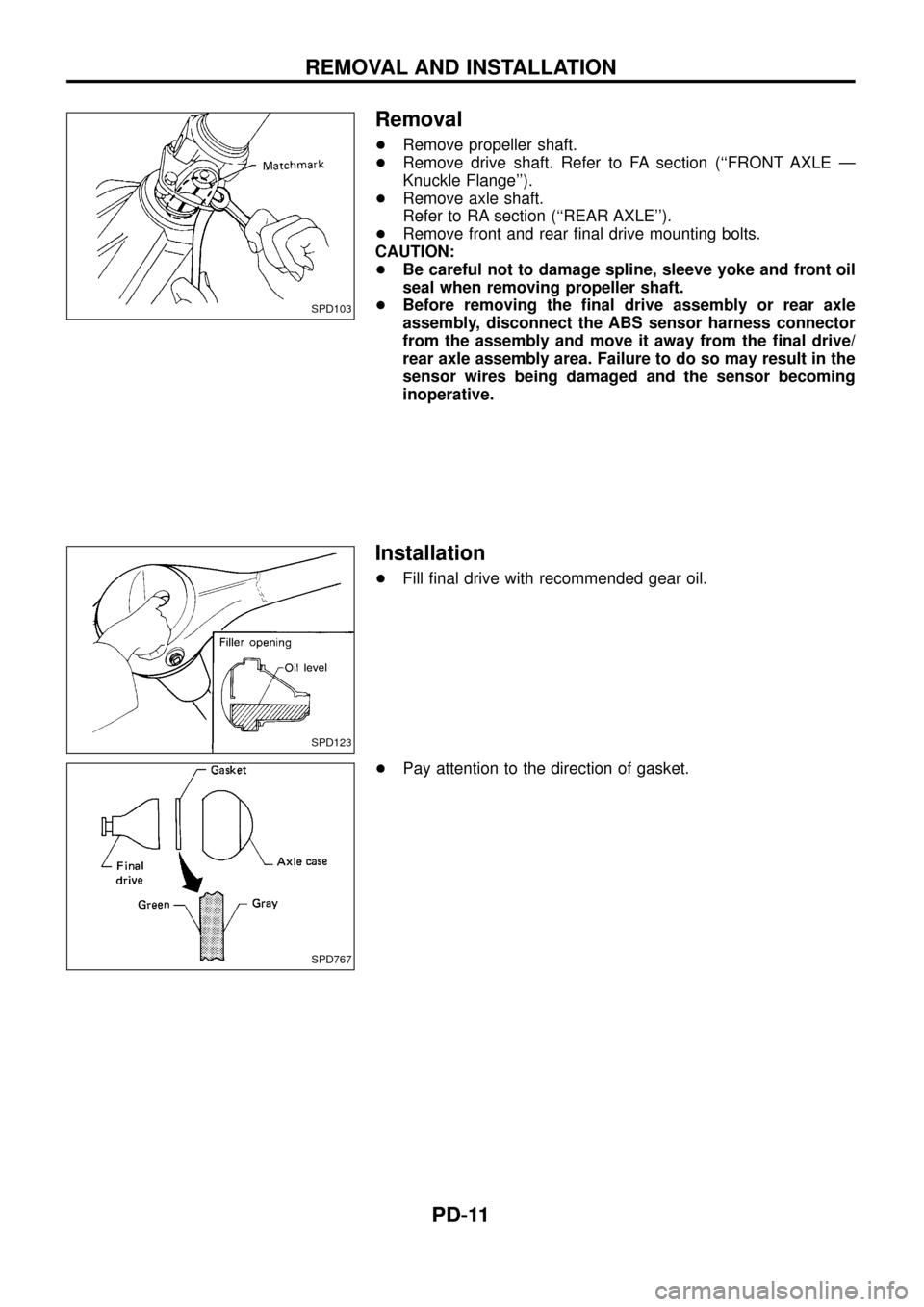

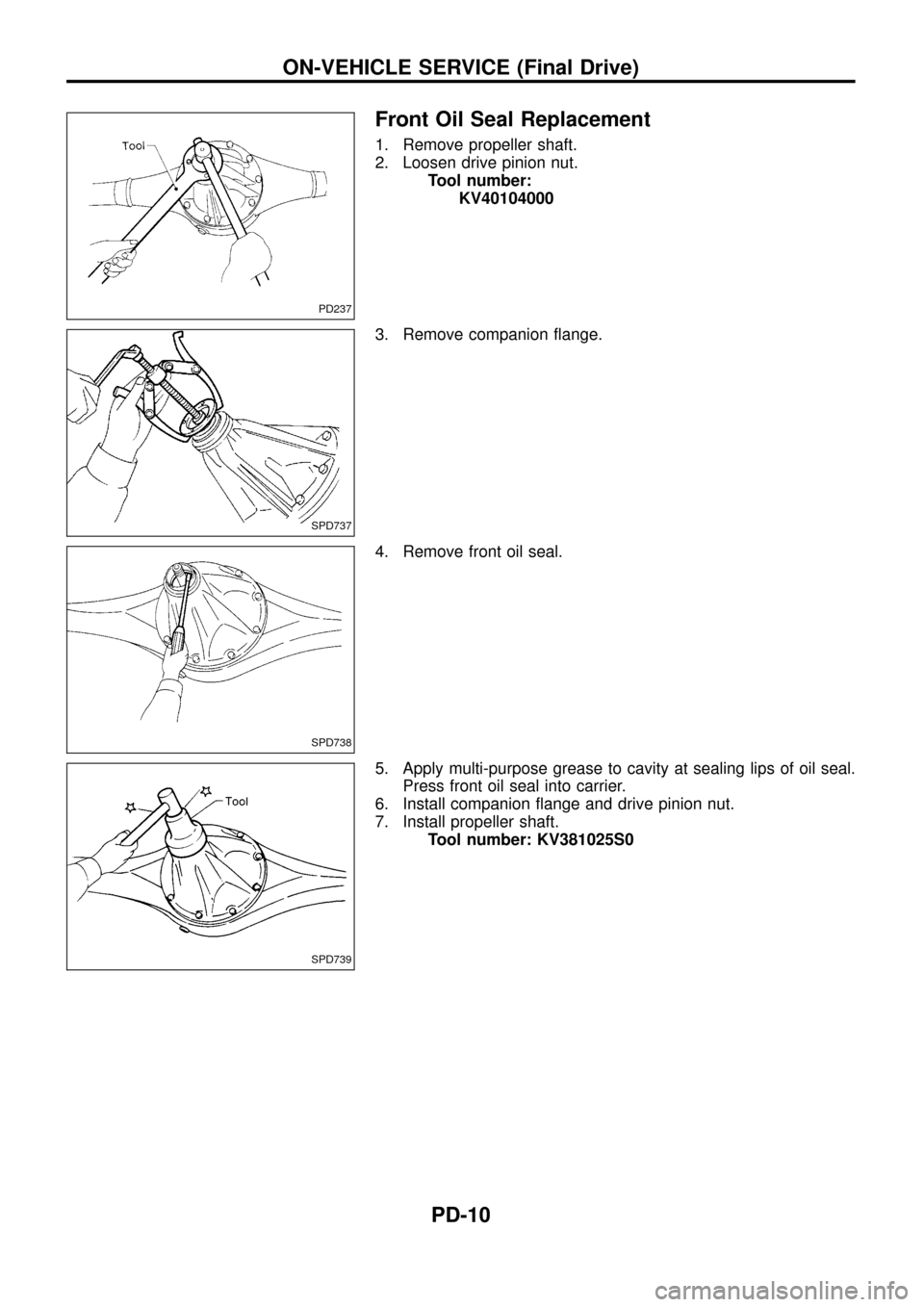

Removal

+Remove propeller shaft.

+Remove drive shaft. Refer to FA section (``FRONT AXLE Ð

Knuckle Flange'').

+Remove axle shaft.

Refer to RA section (``REAR AXLE'').

+Remove front and rear ®nal drive mounting bolts.

CAUTION:

+Be careful not to damage spline, sleeve yoke and front oil

seal when removing propeller shaft.

+Before removing the ®nal drive assembly or rear axle

assembly, disconnect the ABS sensor harness connector

from the assembly and move it away from the ®nal drive/

rear axle assembly area. Failure to do so may result in the

sensor wires being damaged and the sensor becoming

inoperative.

Installation

+Fill ®nal drive with recommended gear oil.

+Pay attention to the direction of gasket.

SPD103

SPD123

SPD767

REMOVAL AND INSTALLATION

PD-11

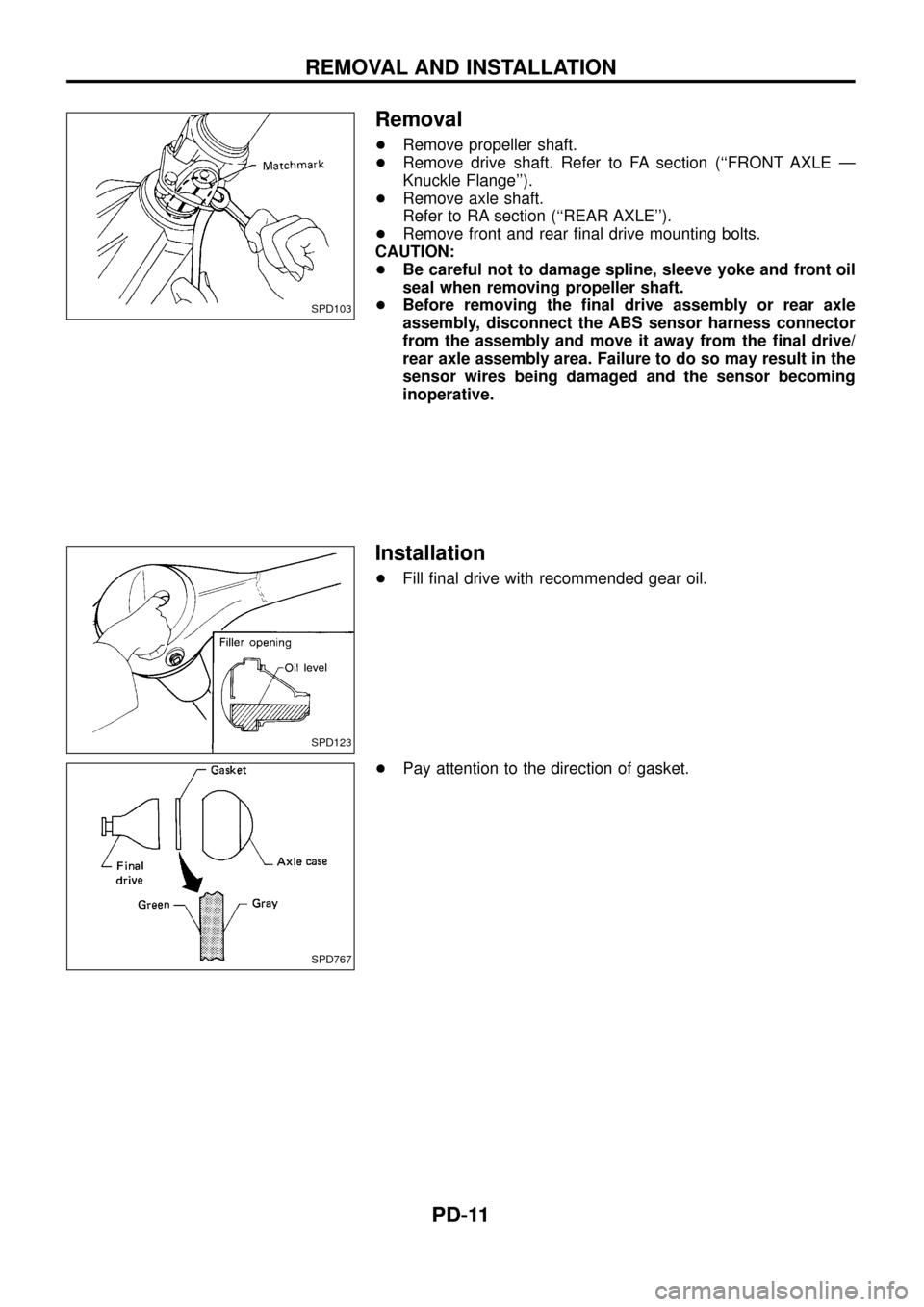

Page 13 of 54

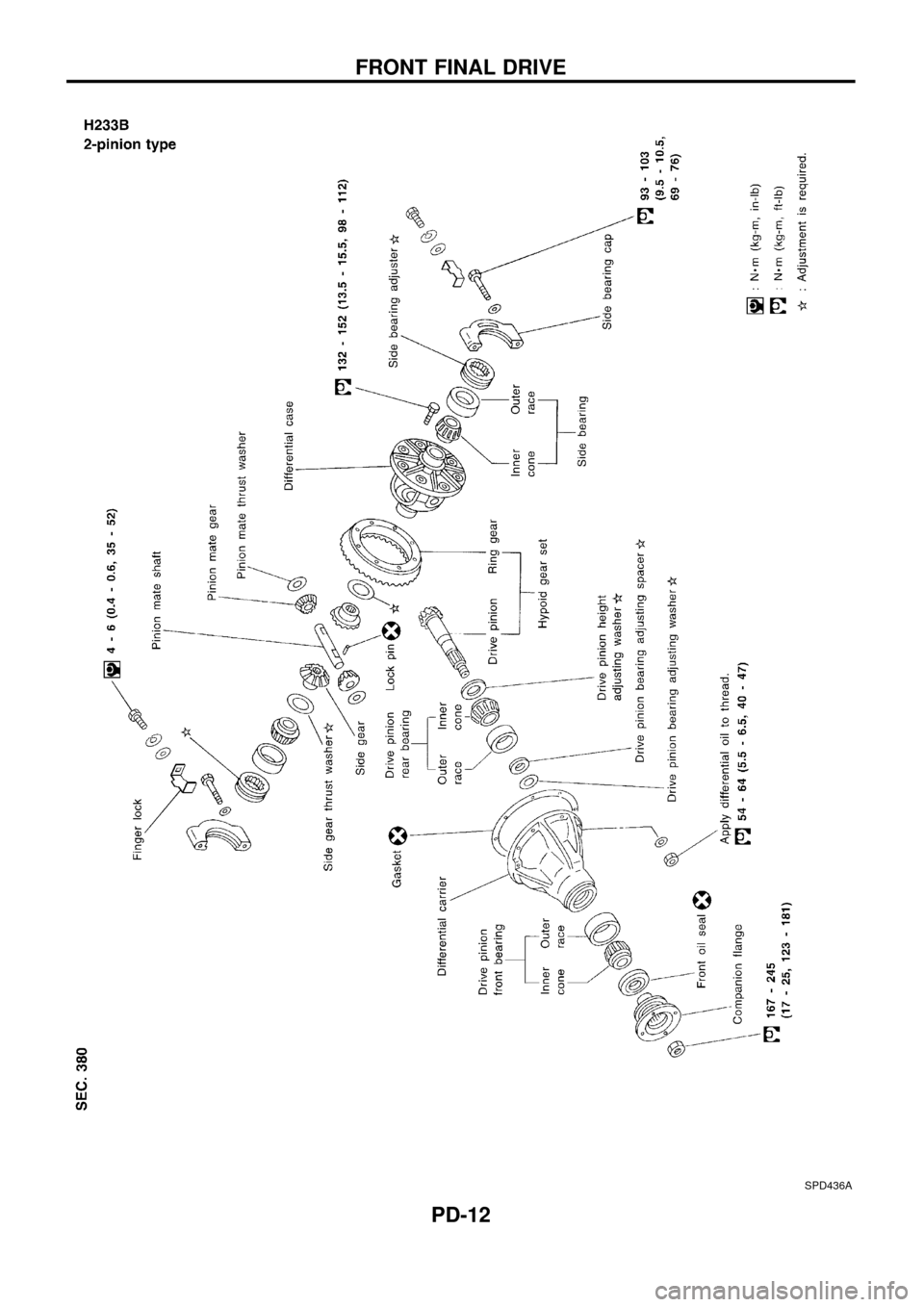

SPD436A

FRONT FINAL DRIVE

PD-12

Page 14 of 54

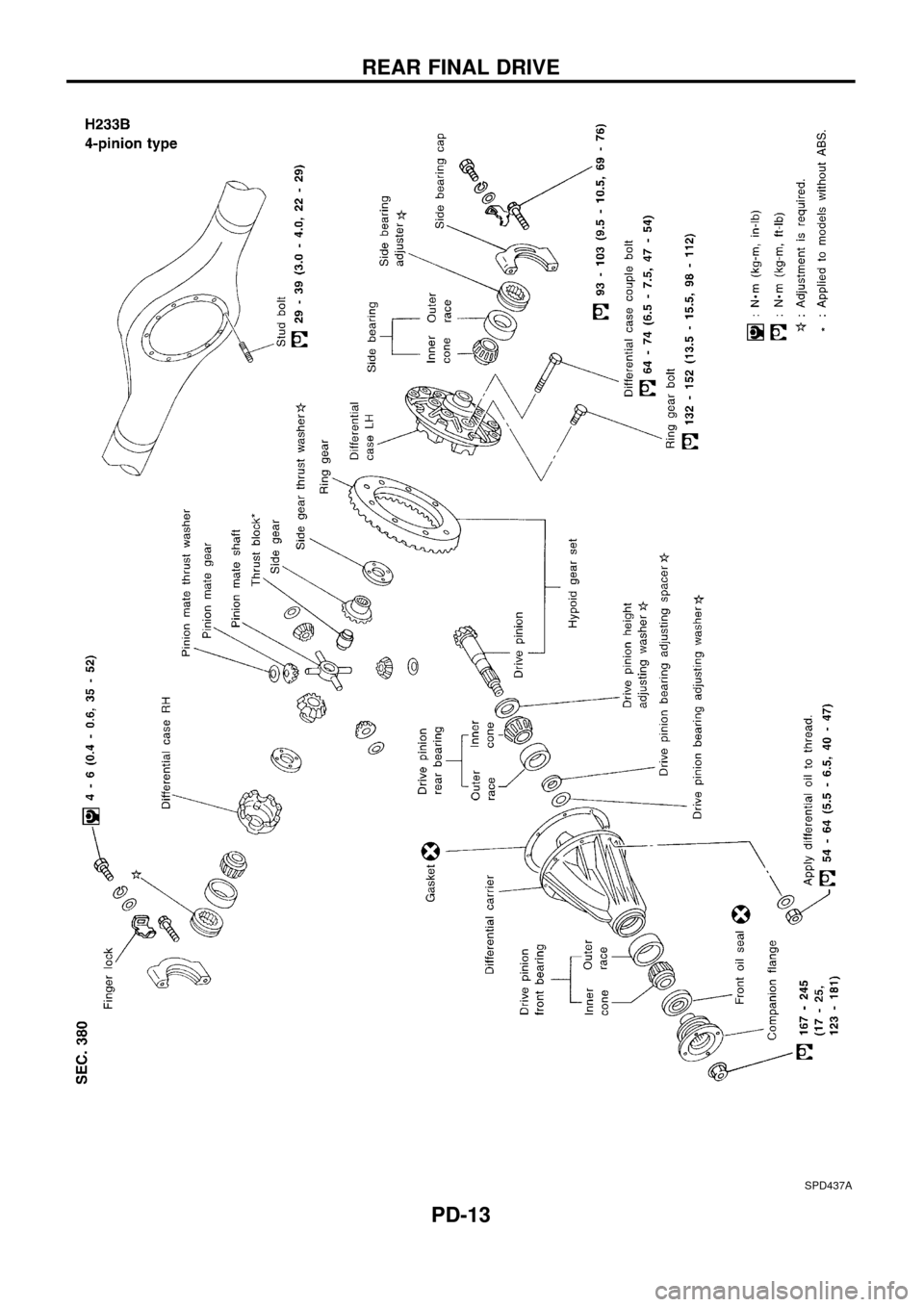

SPD437A

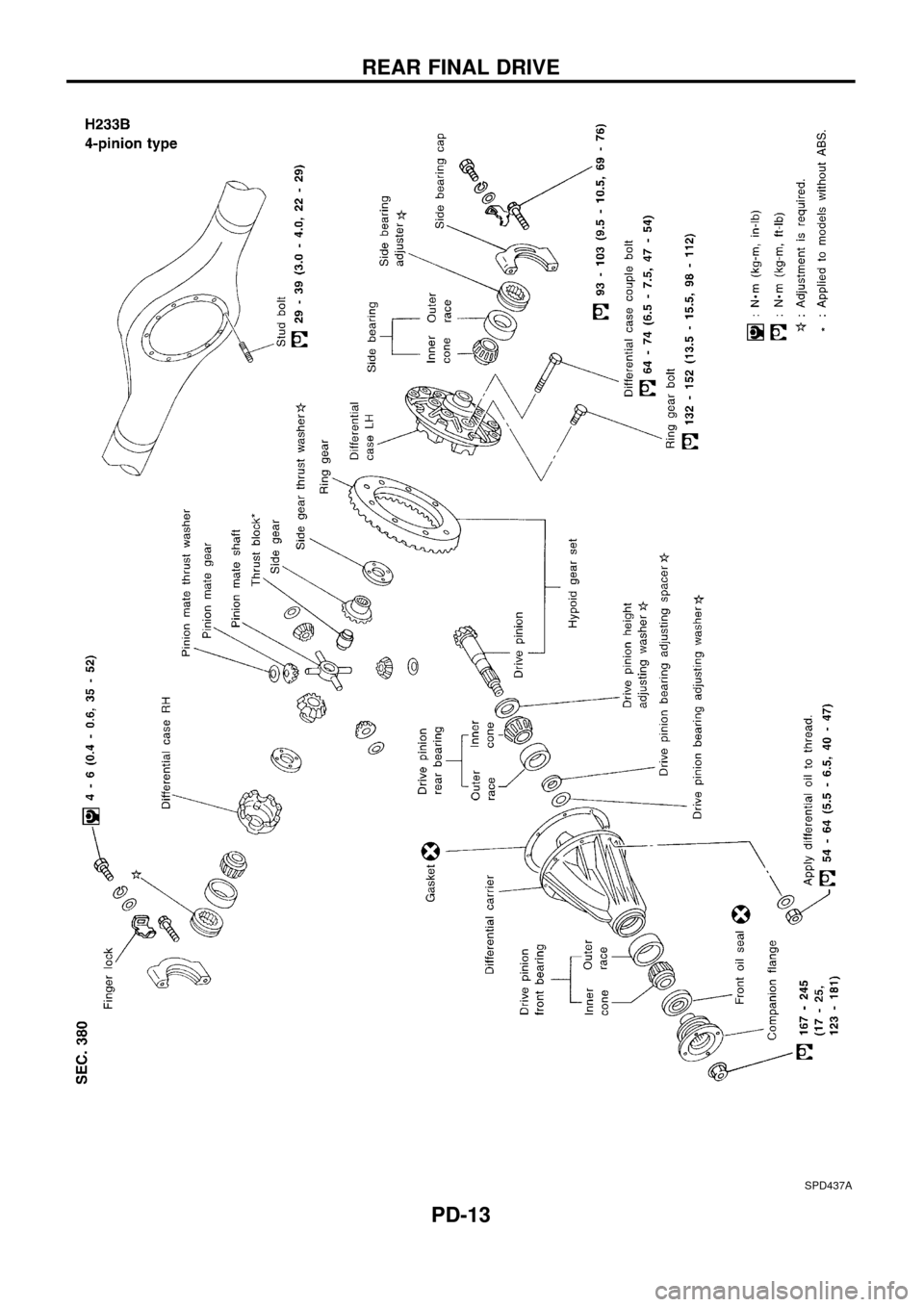

REAR FINAL DRIVE

PD-13

Page 15 of 54

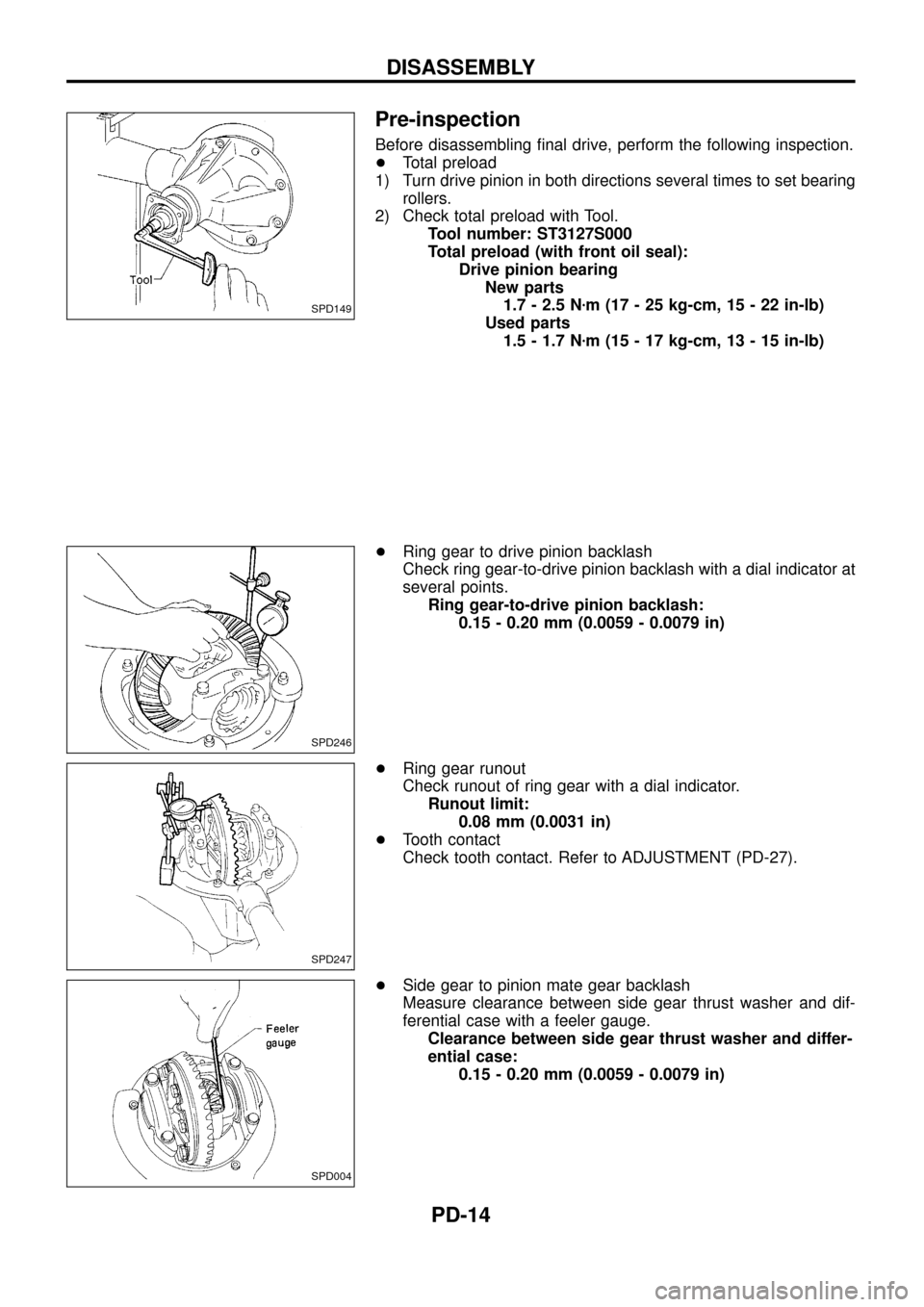

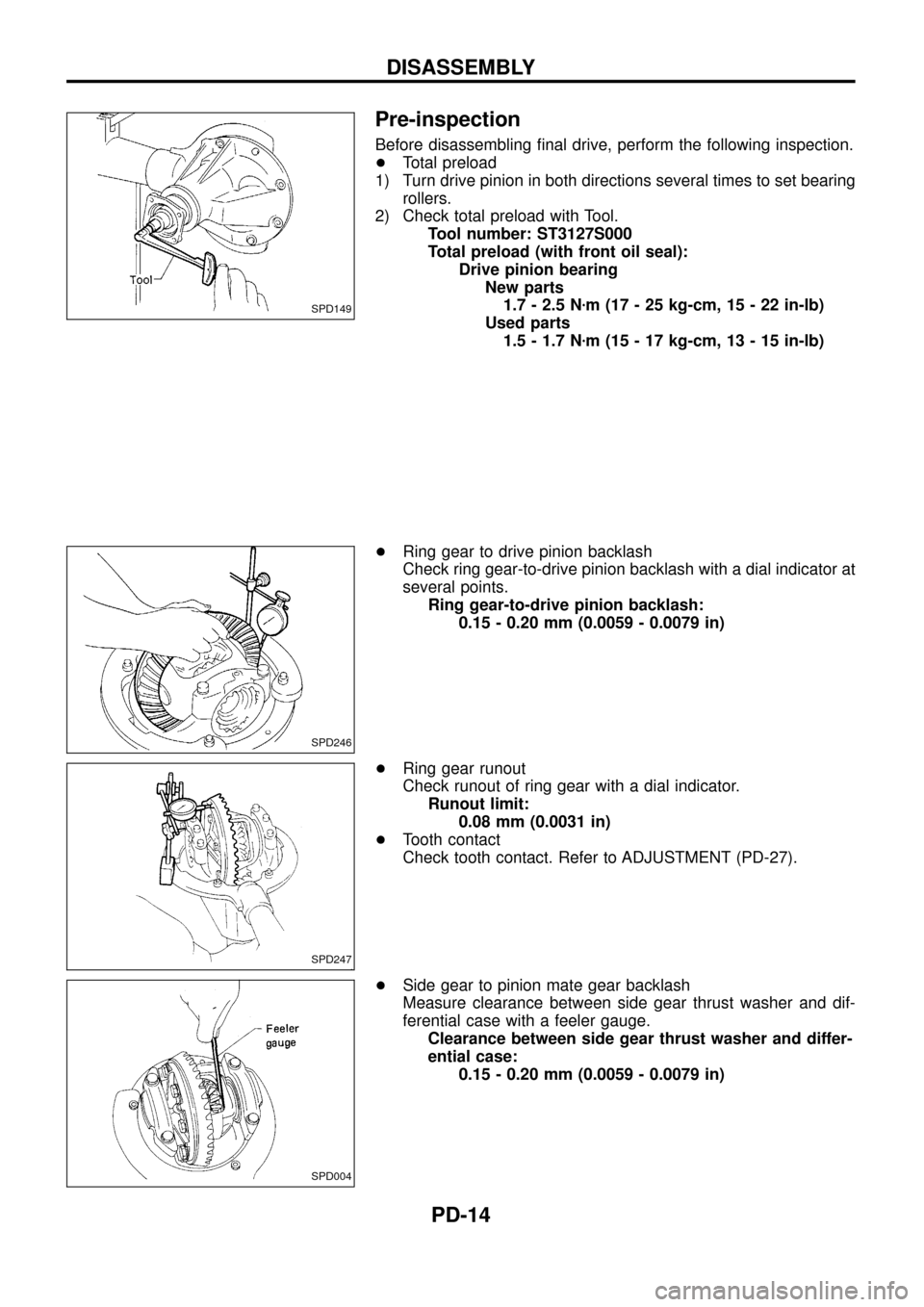

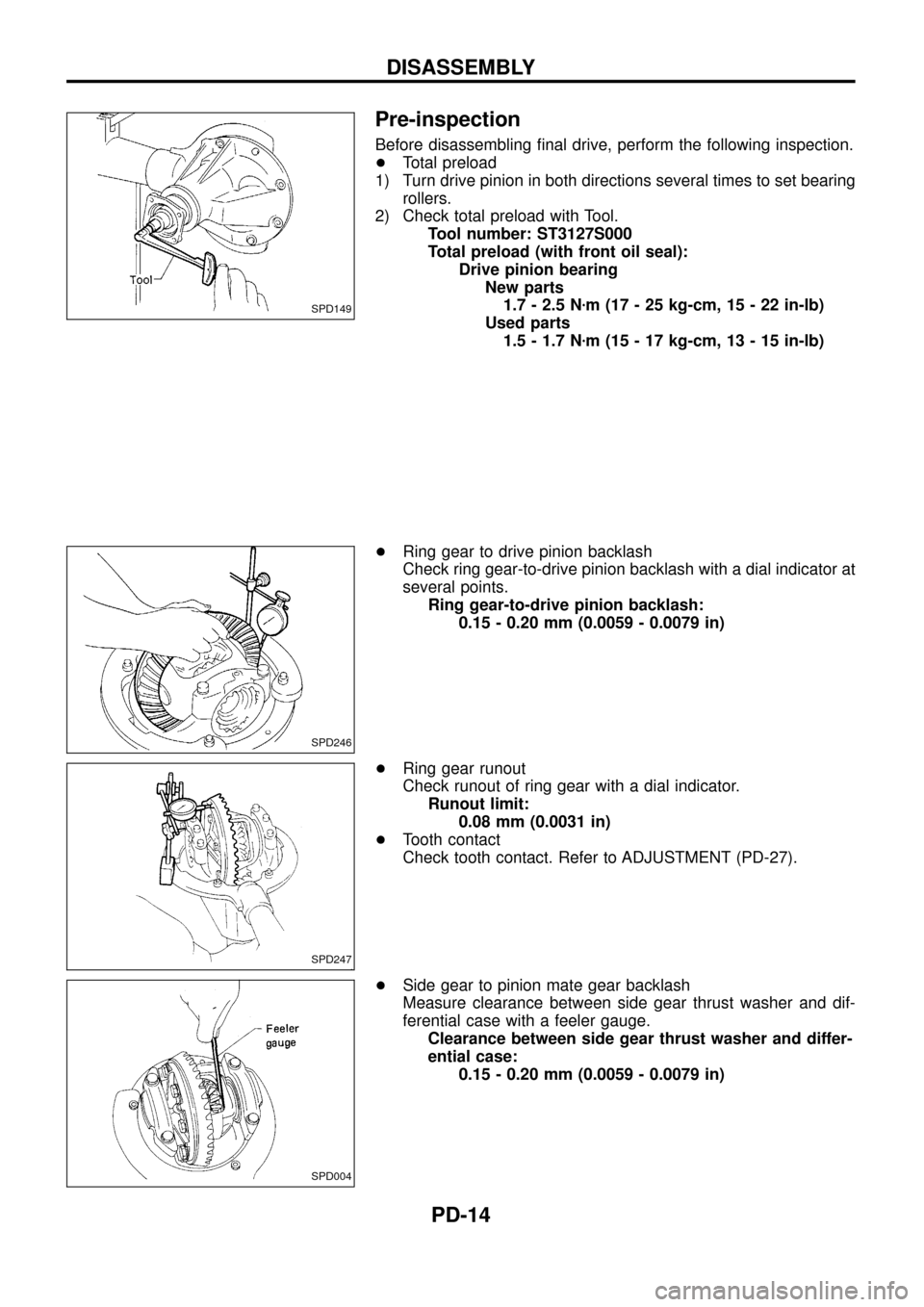

Pre-inspection

Before disassembling ®nal drive, perform the following inspection.

+Total preload

1) Turn drive pinion in both directions several times to set bearing

rollers.

2) Check total preload with Tool.

Tool number: ST3127S000

Total preload (with front oil seal):

Drive pinion bearing

New parts

1.7 - 2.5 Nzm (17 - 25 kg-cm, 15 - 22 in-lb)

Used parts

1.5 - 1.7 Nzm (15 - 17 kg-cm, 13 - 15 in-lb)

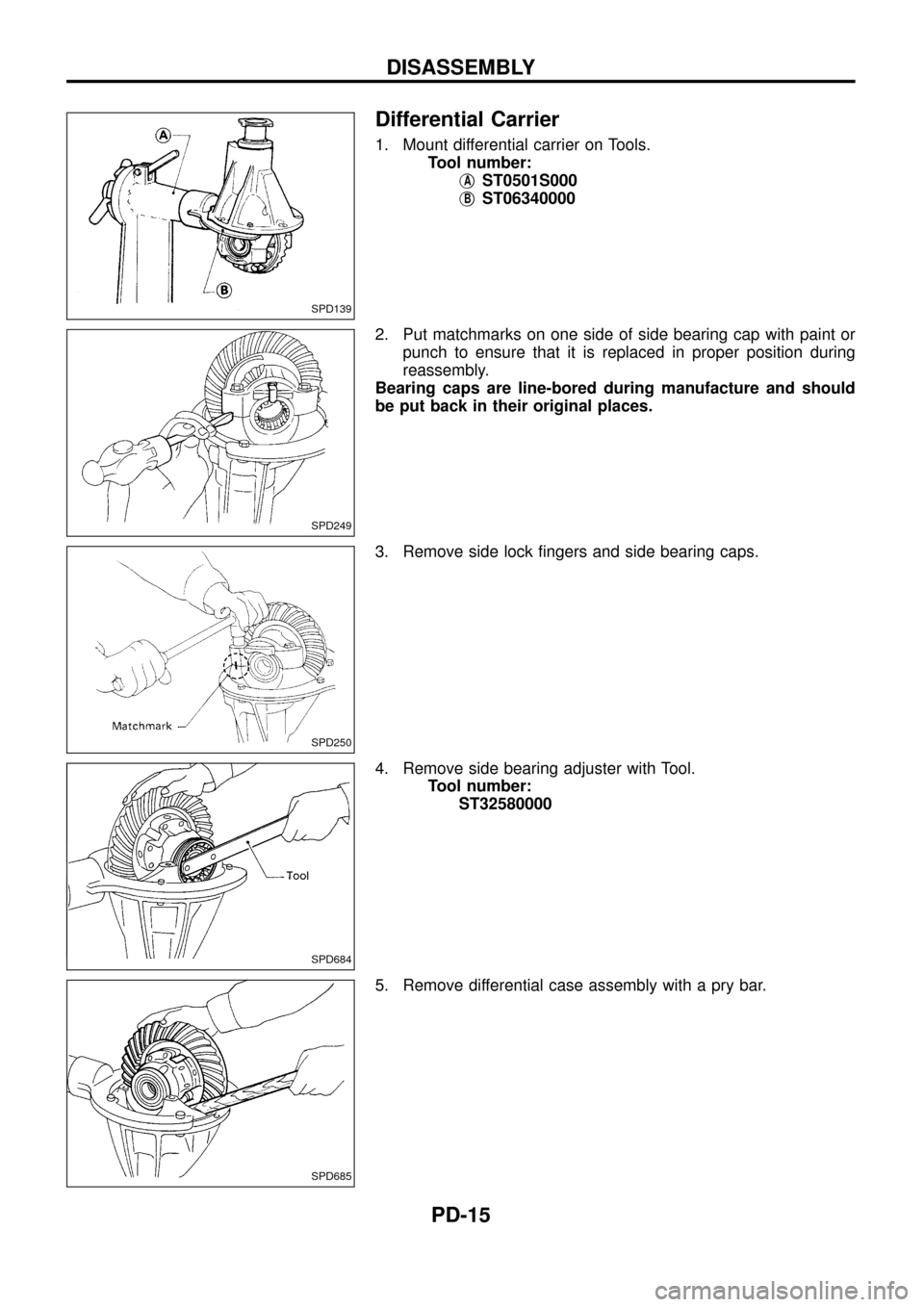

+Ring gear to drive pinion backlash

Check ring gear-to-drive pinion backlash with a dial indicator at

several points.

Ring gear-to-drive pinion backlash:

0.15 - 0.20 mm (0.0059 - 0.0079 in)

+Ring gear runout

Check runout of ring gear with a dial indicator.

Runout limit:

0.08 mm (0.0031 in)

+Tooth contact

Check tooth contact. Refer to ADJUSTMENT (PD-27).

+Side gear to pinion mate gear backlash

Measure clearance between side gear thrust washer and dif-

ferential case with a feeler gauge.

Clearance between side gear thrust washer and differ-

ential case:

0.15 - 0.20 mm (0.0059 - 0.0079 in)

SPD149

SPD246

SPD247

SPD004

DISASSEMBLY

PD-14

Page 16 of 54

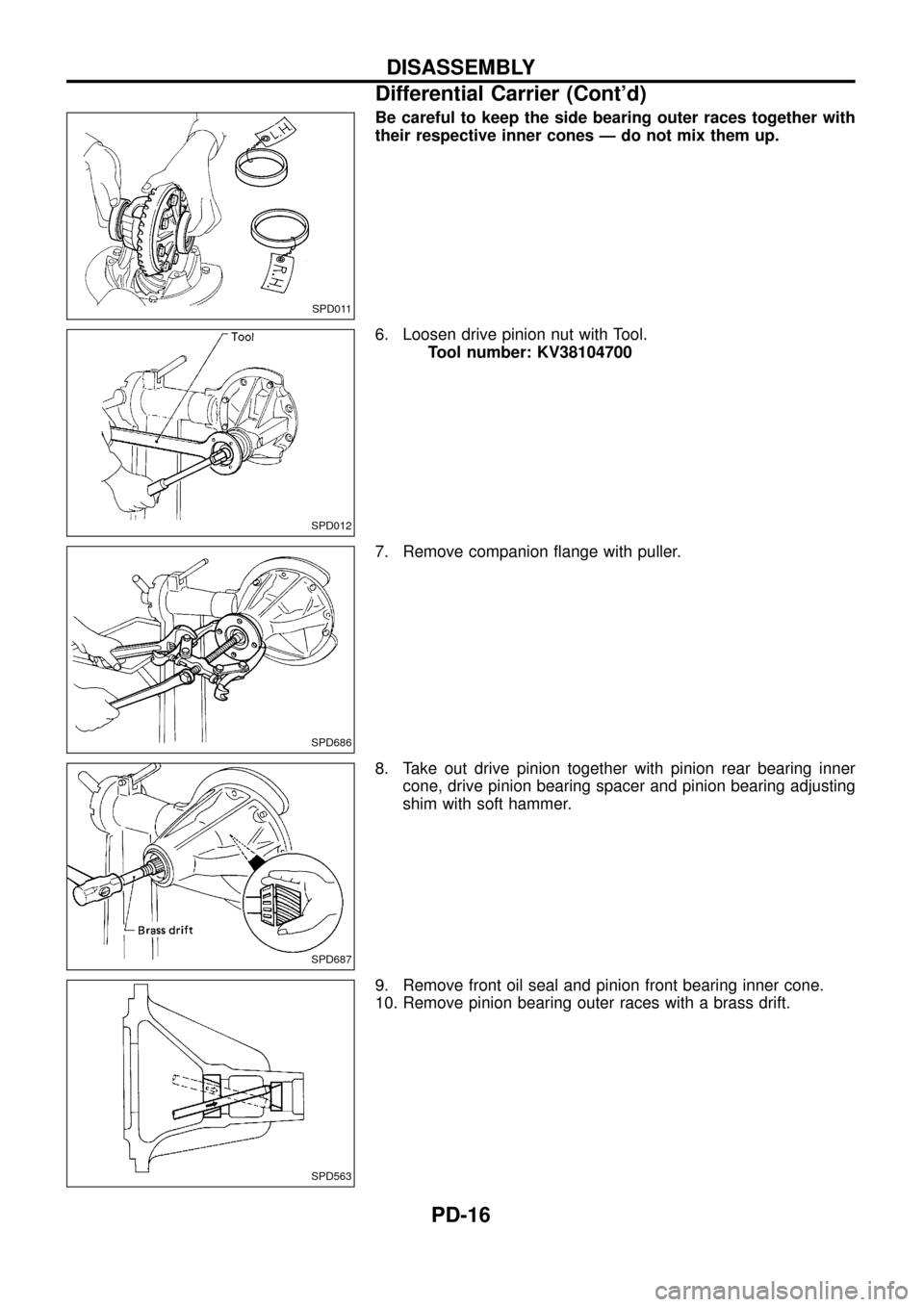

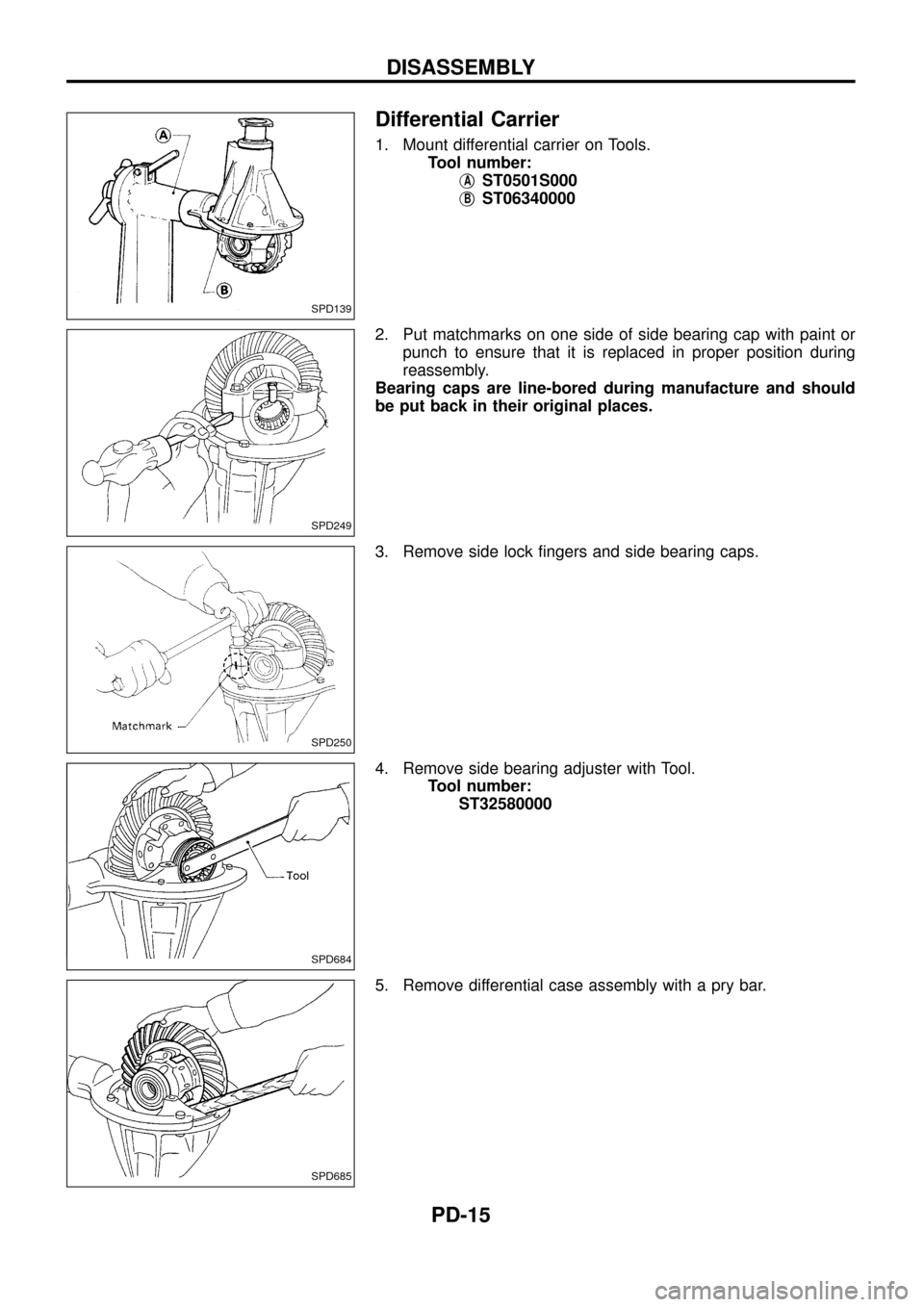

Differential Carrier

1. Mount differential carrier on Tools.

Tool number:

j

AST0501S000

j

BST06340000

2. Put matchmarks on one side of side bearing cap with paint or

punch to ensure that it is replaced in proper position during

reassembly.

Bearing caps are line-bored during manufacture and should

be put back in their original places.

3. Remove side lock ®ngers and side bearing caps.

4. Remove side bearing adjuster with Tool.

Tool number:

ST32580000

5. Remove differential case assembly with a pry bar.

SPD139

SPD249

SPD250

SPD684

SPD685

DISASSEMBLY

PD-15

Page 17 of 54

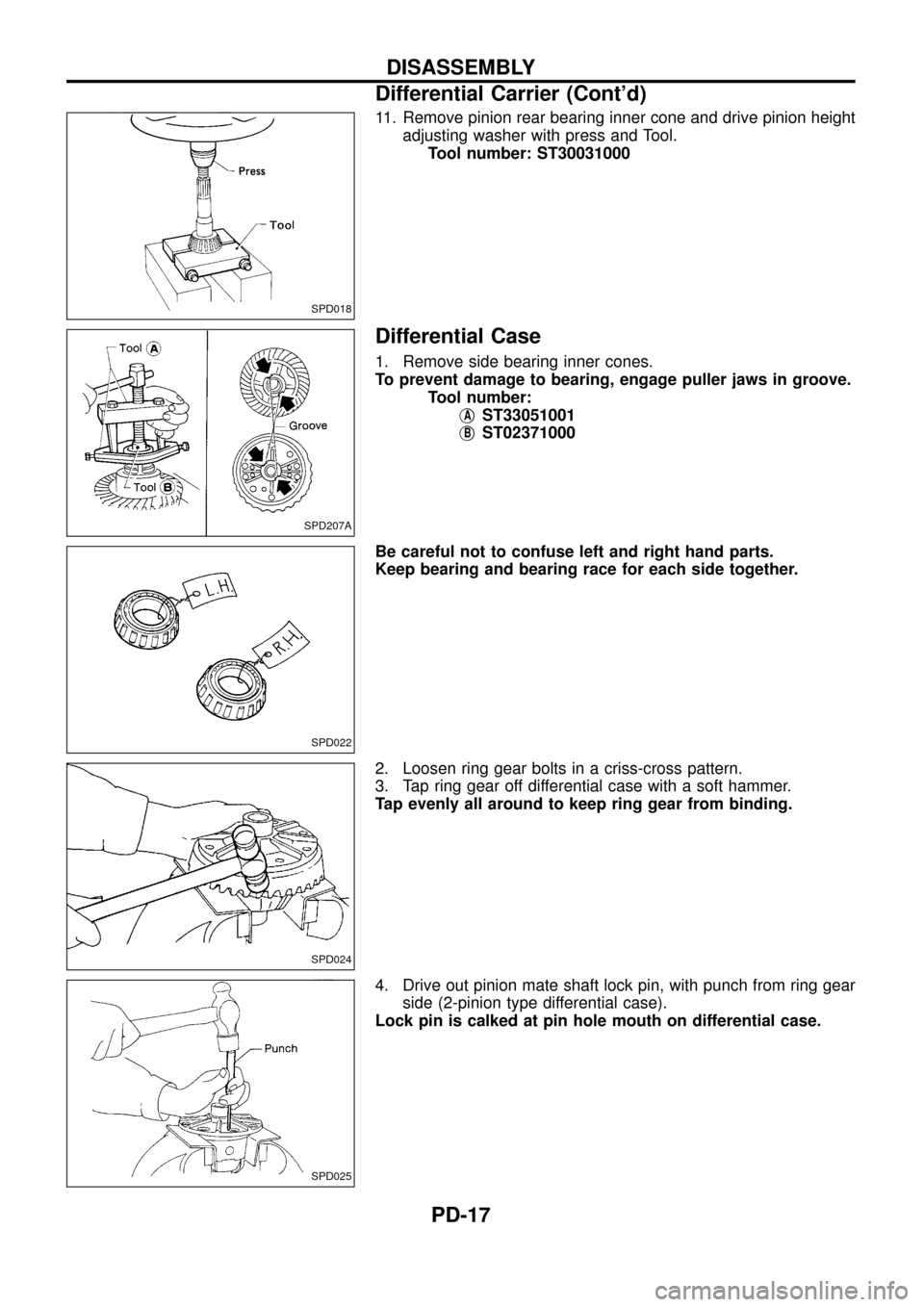

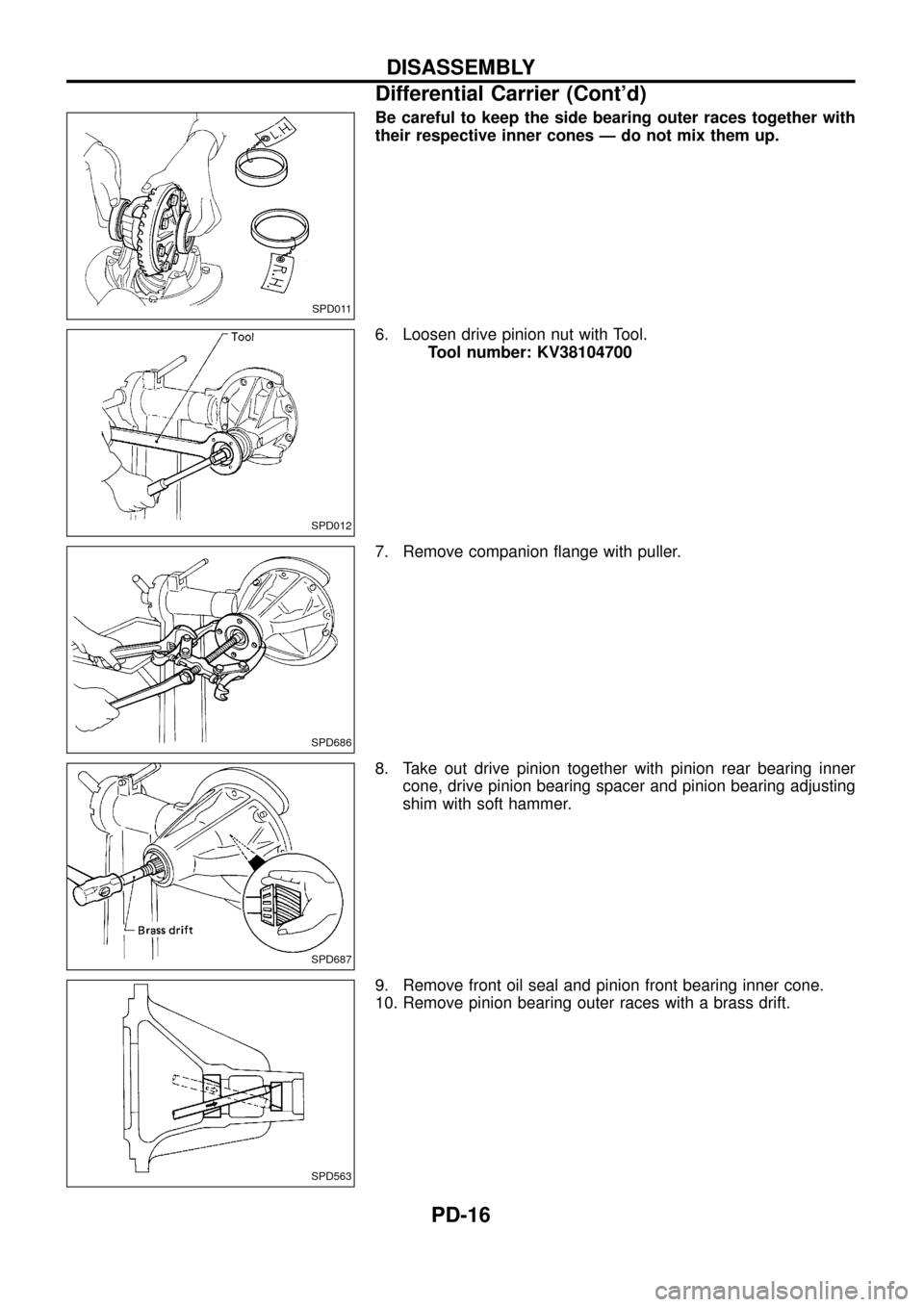

Be careful to keep the side bearing outer races together with

their respective inner cones Ð do not mix them up.

6. Loosen drive pinion nut with Tool.

Tool number: KV38104700

7. Remove companion ¯ange with puller.

8. Take out drive pinion together with pinion rear bearing inner

cone, drive pinion bearing spacer and pinion bearing adjusting

shim with soft hammer.

9. Remove front oil seal and pinion front bearing inner cone.

10. Remove pinion bearing outer races with a brass drift.

SPD011

SPD012

SPD686

SPD687

SPD563

DISASSEMBLY

Differential Carrier (Cont'd)

PD-16

Page 18 of 54

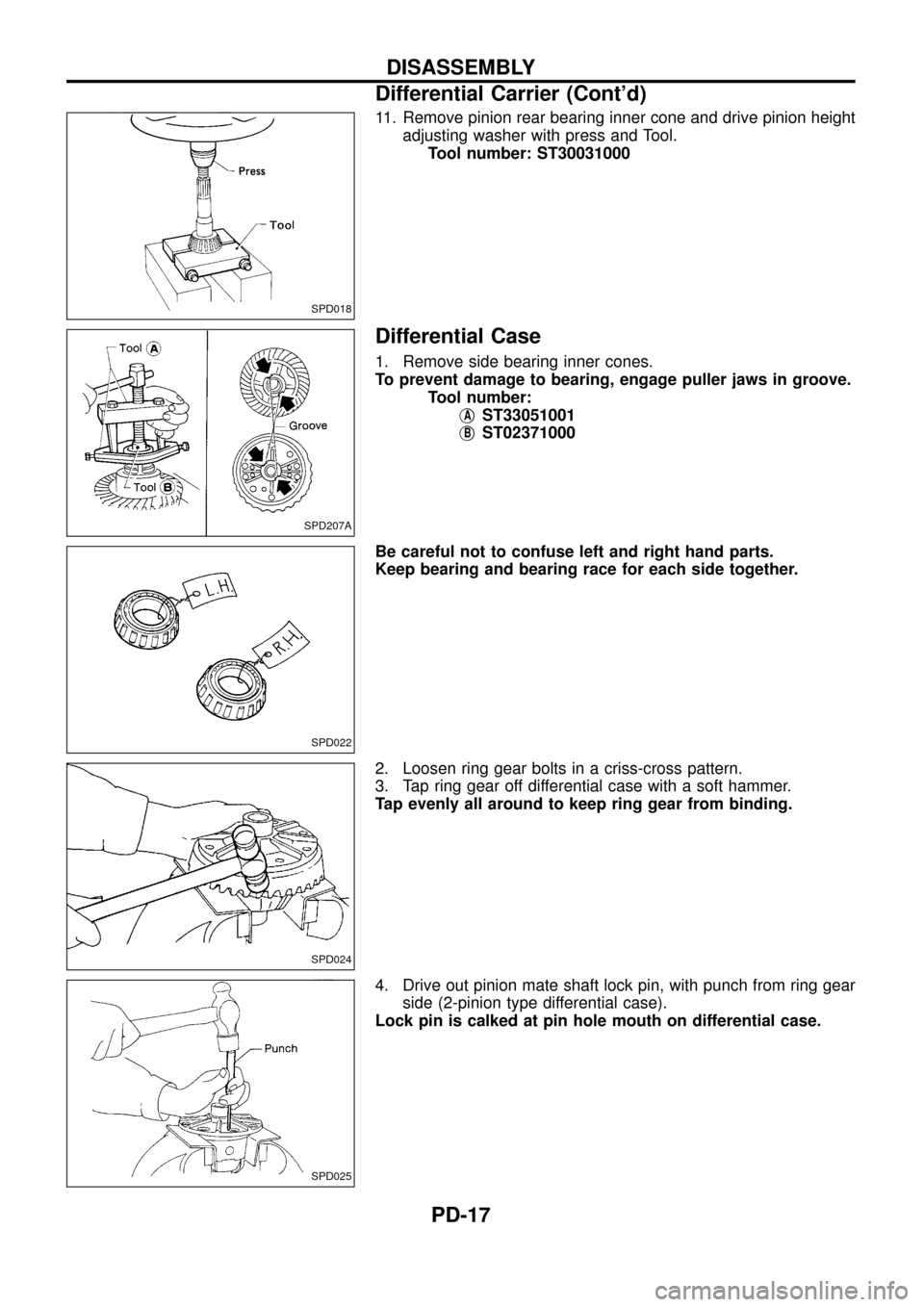

11. Remove pinion rear bearing inner cone and drive pinion height

adjusting washer with press and Tool.

Tool number: ST30031000

Differential Case

1. Remove side bearing inner cones.

To prevent damage to bearing, engage puller jaws in groove.

Tool number:

j

AST33051001

j

BST02371000

Be careful not to confuse left and right hand parts.

Keep bearing and bearing race for each side together.

2. Loosen ring gear bolts in a criss-cross pattern.

3. Tap ring gear off differential case with a soft hammer.

Tap evenly all around to keep ring gear from binding.

4. Drive out pinion mate shaft lock pin, with punch from ring gear

side (2-pinion type differential case).

Lock pin is calked at pin hole mouth on differential case.

SPD018

SPD207A

SPD022

SPD024

SPD025

DISASSEMBLY

Differential Carrier (Cont'd)

PD-17

Page 19 of 54

5. Separate differential case LH and RH (4-pinion type differential

case).

Put matchmarks on both differential case LH and RH sides

prior to separating them.

SPD716

DISASSEMBLY

Differential Case (Cont'd)

PD-18

Page 20 of 54

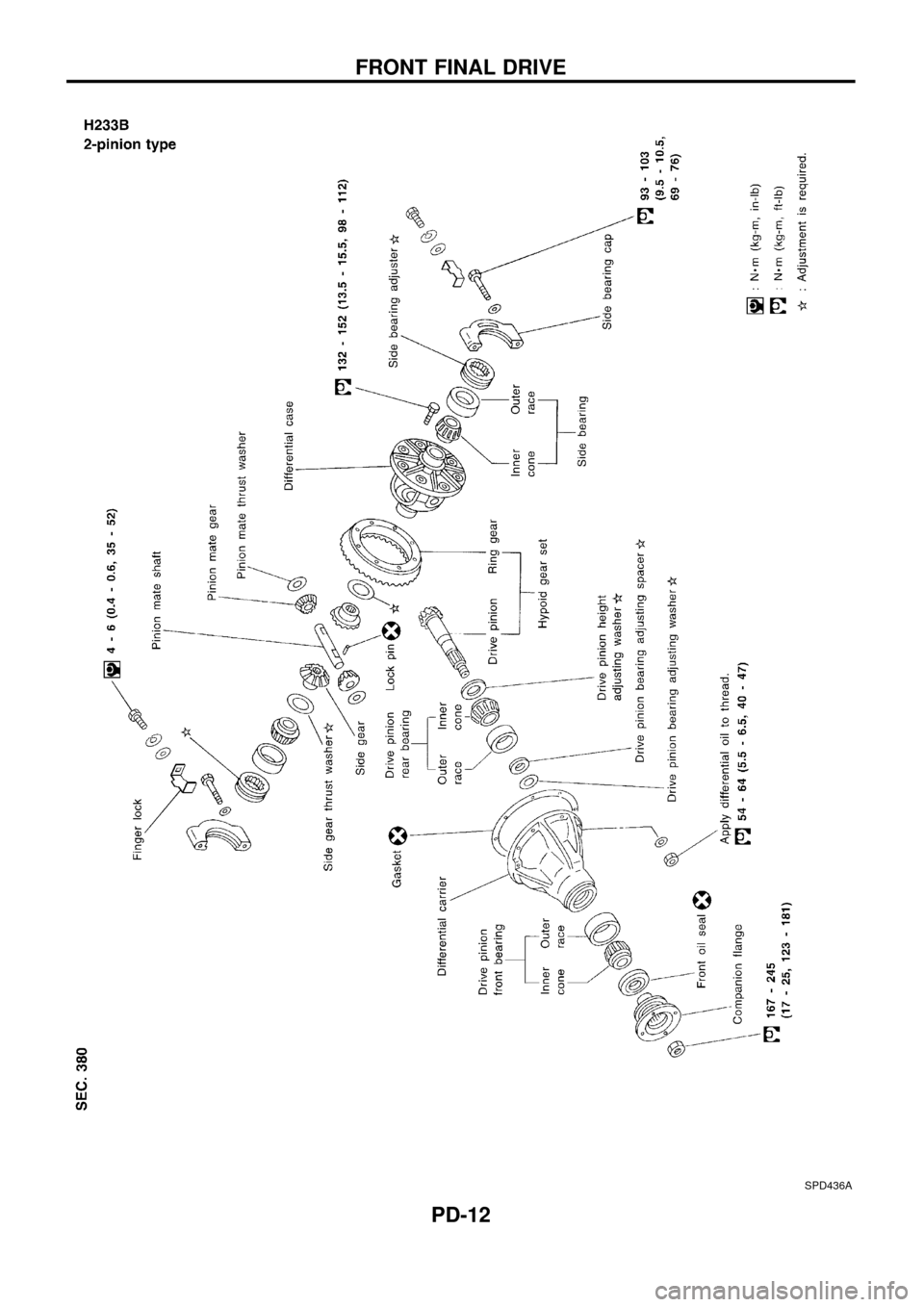

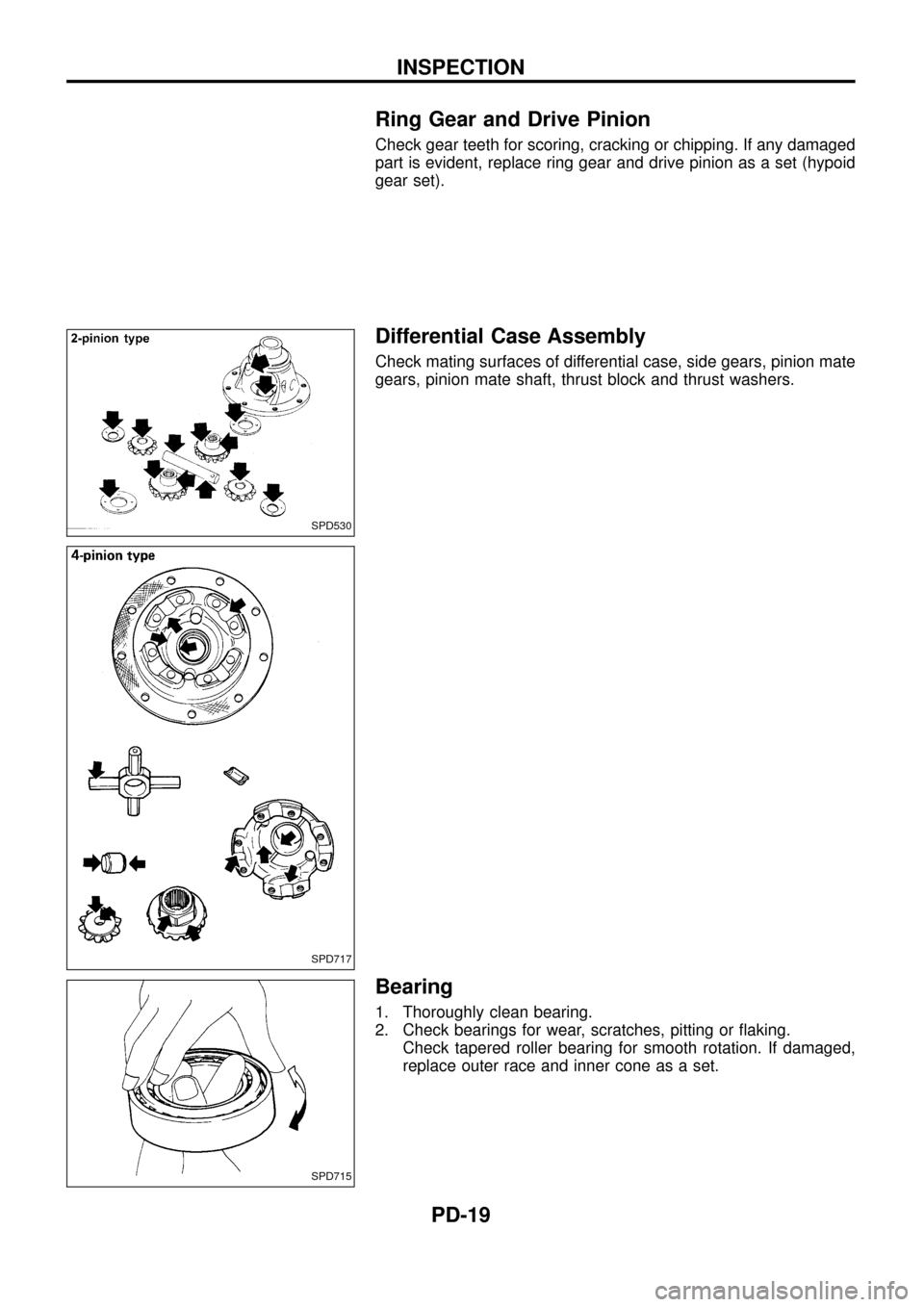

Ring Gear and Drive Pinion

Check gear teeth for scoring, cracking or chipping. If any damaged

part is evident, replace ring gear and drive pinion as a set (hypoid

gear set).

Differential Case Assembly

Check mating surfaces of differential case, side gears, pinion mate

gears, pinion mate shaft, thrust block and thrust washers.

Bearing

1. Thoroughly clean bearing.

2. Check bearings for wear, scratches, pitting or ¯aking.

Check tapered roller bearing for smooth rotation. If damaged,

replace outer race and inner cone as a set.

SPD530

SPD717

SPD715

INSPECTION

PD-19

Trending: steering wheel, engine, oil level, bolt pattern, ESP, transmission, lock