height adjustment NISSAN PATROL 1998 Y61 / 5.G Propeller Shaft And Differential Carrier Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PATROL, Model: NISSAN PATROL 1998 Y61 / 5.GPages: 54, PDF Size: 1.85 MB

Page 1 of 54

PROPELLER SHAFT &

DIFFERENTIAL CARRIER

SECTION

PD

CONTENTS

PREPARATION................................................................1

Special Service Tools ..................................................1

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING.....................................................4

NVH Troubleshooting Chart.........................................4

PROPELLER SHAFT......................................................5

Front Propeller Shaft ...................................................5

Rear Propeller Shaft ....................................................5

On-vehicle Service.......................................................6

Removal and Installation .............................................7

Inspection.....................................................................7

Disassembly.................................................................7

Assembly .....................................................................8

ON-VEHICLE SERVICE (Final Drive)..........................10

Front Oil Seal Replacement ......................................10

REMOVAL AND INSTALLATION.................................. 11

Removal ..................................................................... 11

Installation .................................................................. 11

FRONT FINAL DRIVE...................................................12

REAR FINAL DRIVE.....................................................13

DISASSEMBLY..............................................................14

Pre-inspection ............................................................14

Differential Carrier......................................................15

Differential Case ........................................................17

INSPECTION..................................................................19

Ring Gear and Drive Pinion ......................................19

Differential Case Assembly........................................19Bearing.......................................................................19

LIMITED SLIP DIFFERENTIAL.....................................20

Preparation for Disassembly .....................................20

Disassembly...............................................................21

Inspection...................................................................21

Adjustment .................................................................23

Assembly ...................................................................24

ADJUSTMENT...............................................................27

Drive Pinion Height ....................................................27

Tooth Contact.............................................................29

ASSEMBLY....................................................................31

Differential Case Ð 4-pinion type Ð.........................31

Differential Case Ð 2-pinion type Ð.........................32

Differential Carrier......................................................33

DIFFERENTIAL LOCK..................................................37

Actuator and Fork ......................................................37

Disassembly...............................................................38

Inspection...................................................................39

Assembly ...................................................................40

System Description ....................................................43

Component Parts Location ........................................44

Wiring Diagram Ð DIFF/L Ð/LHD Models ...............45

Wiring Diagram Ð DIFF/L Ð/RHD Models ...............47

Electrical Components Inspection .............................49

SERVICE DATA AND SPECIFICATIONS (SDS)..........51

Propeller Shaft ...........................................................51

Final Drive..................................................................52

PD

Page 28 of 54

To avoid confusion while calculating bearing shims, it is absolutely

necessary to stay with the metric system. If you measure anything

in inches,the results must be converted to the metric system.

Drive Pinion Height

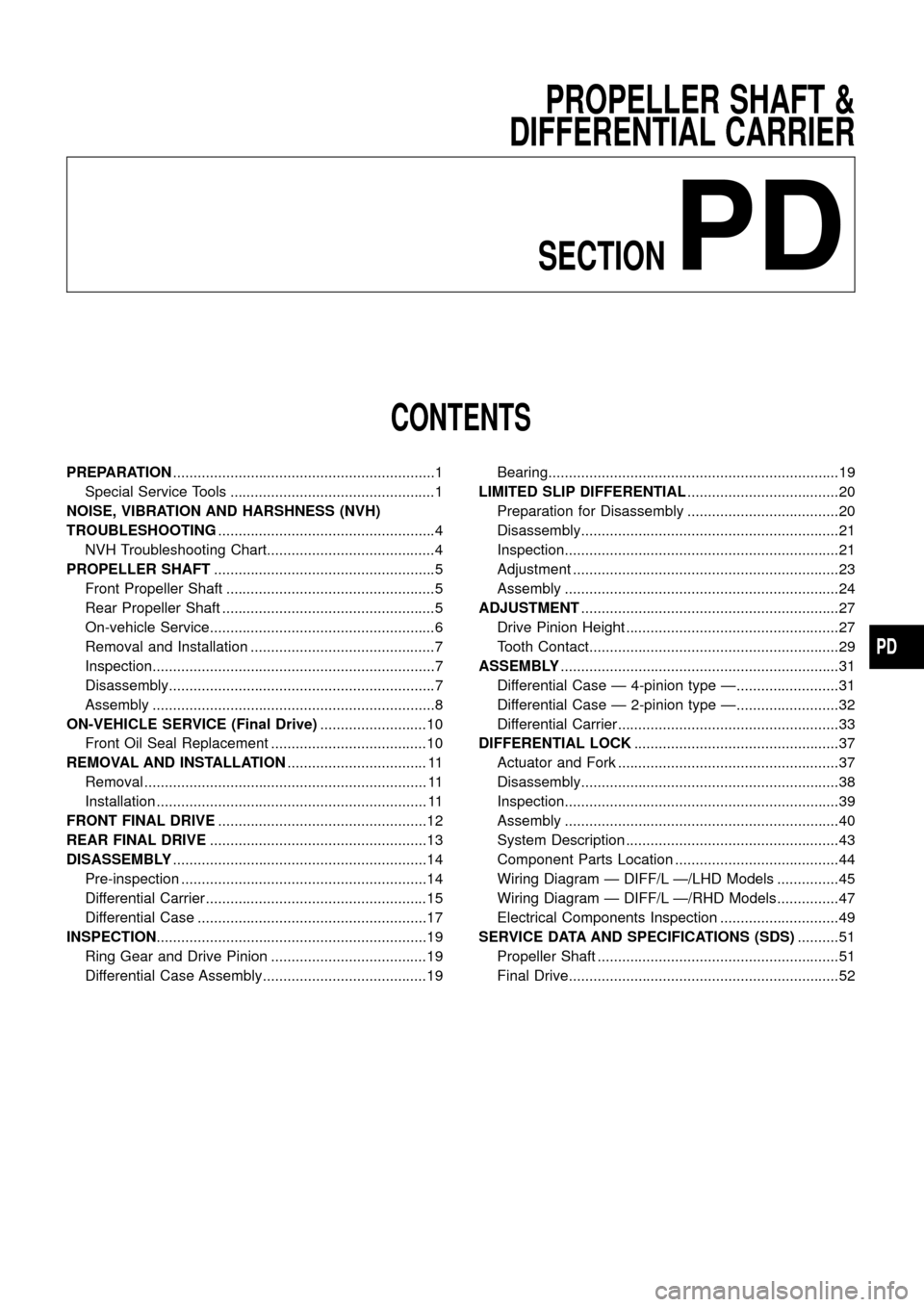

1. First prepare Tools for pinion height adjustment.

:

V1Height gauge (ST31251000)

V2Dummy shaft (ST31181001)

V3Spacer [thickness: 2.50 mm (0.0984 in)]

V4Feeler gauge

2. To simplify the job, make a chart, like the one below, to orga-

nize your calculations.

LETTERSHUNDREDTHS OF

A MILLIMETER

H: Head number

D¢: Figure marked on dummy shaft

S: Figure marked on height gauge

N: Measuring clearance

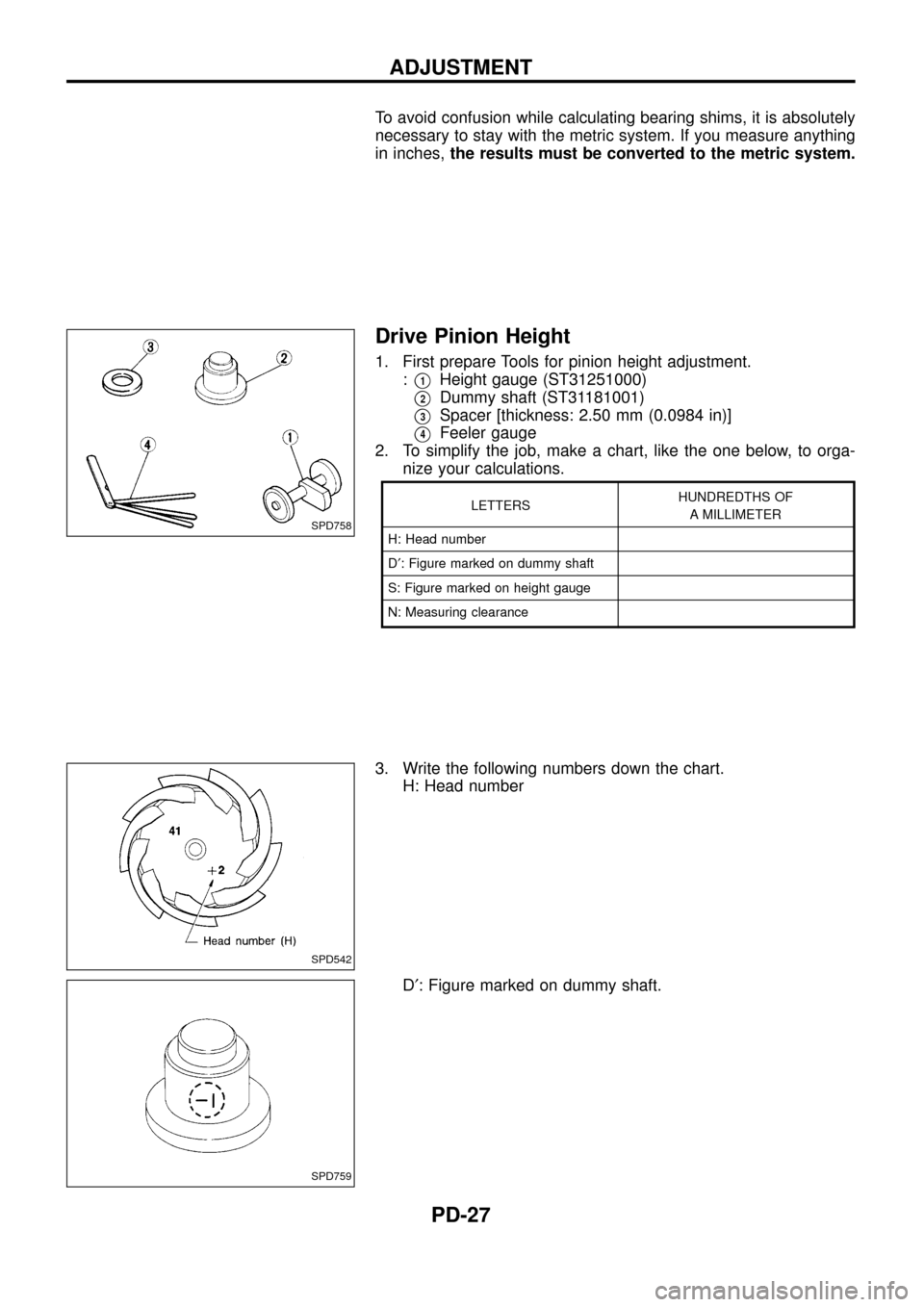

3. Write the following numbers down the chart.

H: Head number

D¢: Figure marked on dummy shaft.

SPD758

SPD542

SPD759

ADJUSTMENT

PD-27

Page 29 of 54

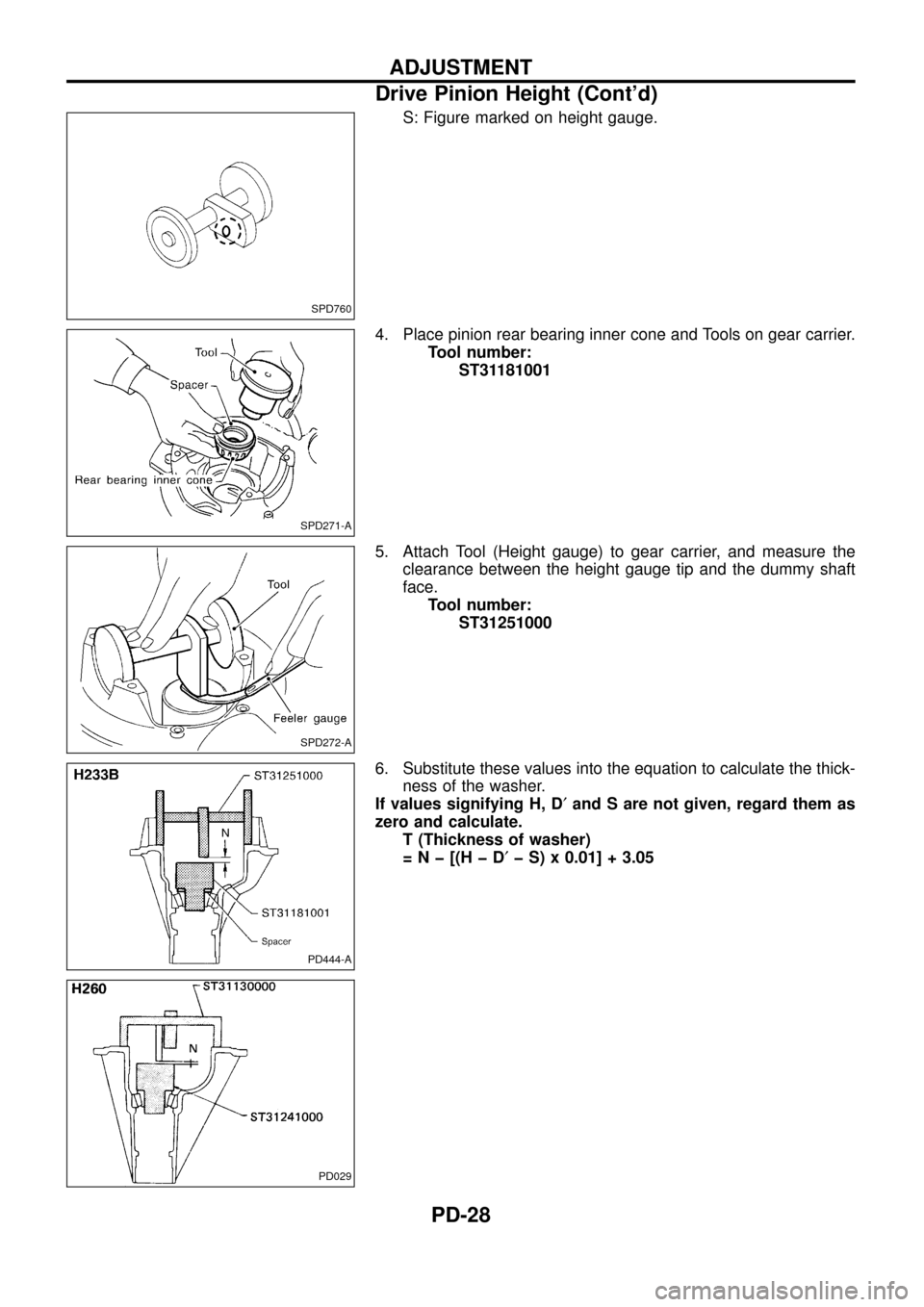

S: Figure marked on height gauge.

4. Place pinion rear bearing inner cone and Tools on gear carrier.

Tool number:

ST31181001

5. Attach Tool (Height gauge) to gear carrier, and measure the

clearance between the height gauge tip and the dummy shaft

face.

Tool number:

ST31251000

6. Substitute these values into the equation to calculate the thick-

ness of the washer.

If values signifying H, D¢and S are not given, regard them as

zero and calculate.

T (Thickness of washer)

=Nþ[(HþD¢þ S) x 0.01] + 3.05

SPD760

SPD271-A

SPD272-A

PD444-A

PD029

ADJUSTMENT

Drive Pinion Height (Cont'd)

PD-28

Page 30 of 54

![NISSAN PATROL 1998 Y61 / 5.G Propeller Shaft And Differential Carrier Workshop Manual Example (H233B):

N = 0.30

H=2

D¢=þ1

S=0

T=Nþ[(HþD¢þ S) x 0.01] + 3.05

= 0.30 þ [{2 þ (þ1) þ 0} x 0.01] + 3.05

(1) H ........................................................................ 2 NISSAN PATROL 1998 Y61 / 5.G Propeller Shaft And Differential Carrier Workshop Manual Example (H233B):

N = 0.30

H=2

D¢=þ1

S=0

T=Nþ[(HþD¢þ S) x 0.01] + 3.05

= 0.30 þ [{2 þ (þ1) þ 0} x 0.01] + 3.05

(1) H ........................................................................ 2](/img/5/625/w960_625-29.png)

Example (H233B):

N = 0.30

H=2

D¢=þ1

S=0

T=Nþ[(HþD¢þ S) x 0.01] + 3.05

= 0.30 þ [{2 þ (þ1) þ 0} x 0.01] + 3.05

(1) H ........................................................................ 2

þD¢................................................................. þ(þ1)

3

þS ...................................................................... þ0

3

(2) 3

x 0.01

0.03

(3) N ................................................................... 0.30

þ0.03

0.27

(4) 0.27

+3.05

3.32

\T = 3.32

7. Select the proper pinion height washer.

Drive pinion height adjusting washer:

Refer to SDS (PD-0, 53).

If you cannot ®nd the desired thickness of washer, use washer

with thickness closest to the calculated value.

Example (H233B):

Calculated value ... T = 3.32 mm

Used washer ... T = 3.33 mm

Tooth Contact

Gear tooth contact pattern check is necessary to verify correct

relationship between ring gear and drive pinion.

Hypoid gear sets which are not positioned properly in relation to

one another may be noisy, or have short life or both. With a pat-

tern check, the most desirable contact for low noise level and long

life can be assured.

1. Thoroughly clean ring gear and drive pinion teeth.

2. Sparingly apply a mixture of powdered ferric oxide and oil or

equivalent to 3 or 4 teeth of ring gear drive side.

SPD005

ADJUSTMENT

Drive Pinion Height (Cont'd)

PD-29

Page 54 of 54

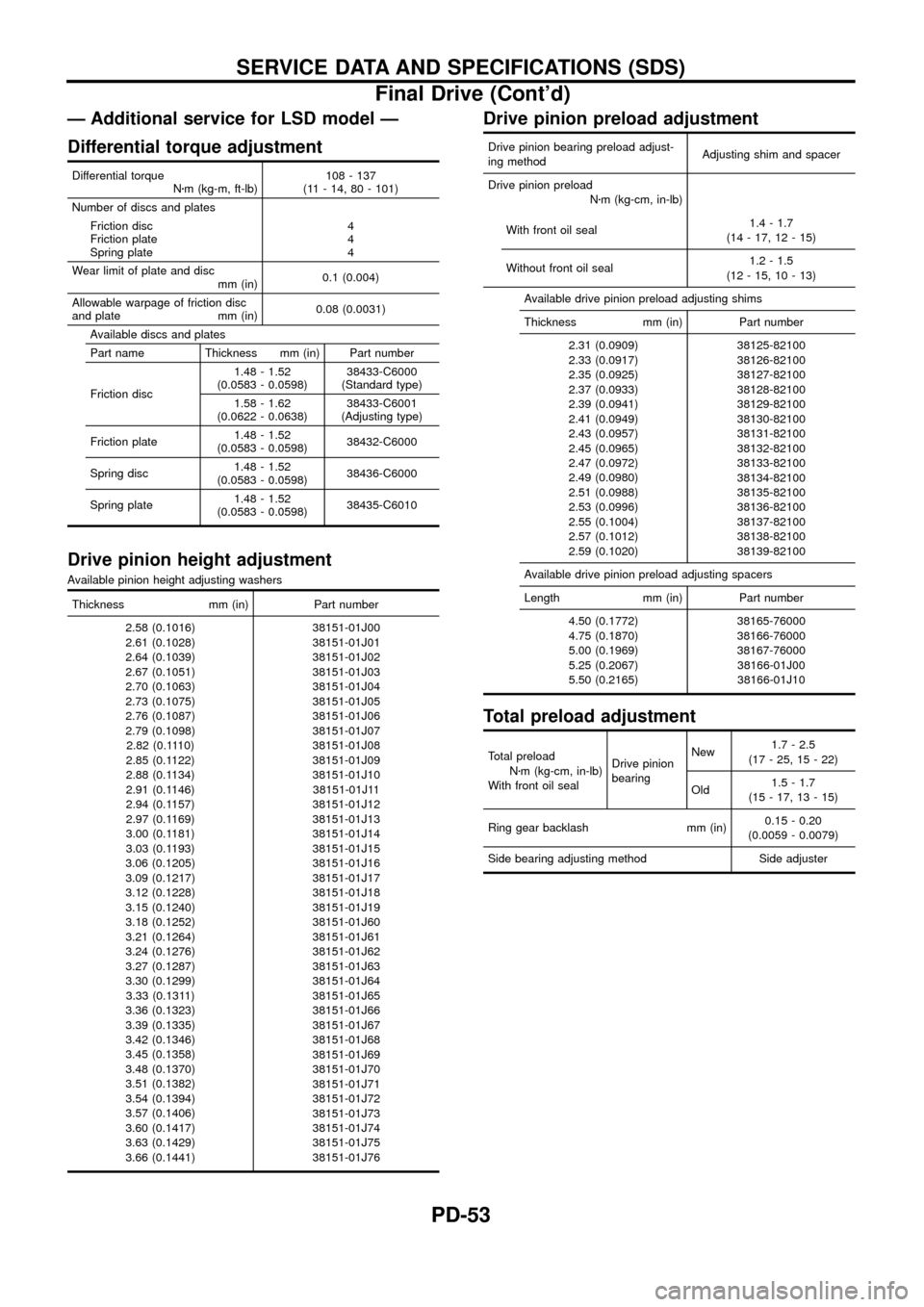

Ð Additional service for LSD model Ð

Differential torque adjustment

Differential torque

Nzm (kg-m, ft-lb)108 - 137

(11 - 14, 80 - 101)

Number of discs and plates

Friction disc

Friction plate

Spring plate4

4

4

Wear limit of plate and disc

mm (in)0.1 (0.004)

Allowable warpage of friction disc

and plate mm (in)0.08 (0.0031)

Available discs and plates

Part name Thickness mm (in) Part number

Friction disc1.48 - 1.52

(0.0583 - 0.0598)38433-C6000

(Standard type)

1.58 - 1.62

(0.0622 - 0.0638)38433-C6001

(Adjusting type)

Friction plate1.48 - 1.52

(0.0583 - 0.0598)38432-C6000

Spring disc1.48 - 1.52

(0.0583 - 0.0598)38436-C6000

Spring plate1.48 - 1.52

(0.0583 - 0.0598)38435-C6010

Drive pinion height adjustment

Available pinion height adjusting washers

Thickness mm (in) Part number

2.58 (0.1016)

2.61 (0.1028)

2.64 (0.1039)

2.67 (0.1051)

2.70 (0.1063)

2.73 (0.1075)

2.76 (0.1087)

2.79 (0.1098)

2.82 (0.1110)

2.85 (0.1122)

2.88 (0.1134)

2.91 (0.1146)

2.94 (0.1157)

2.97 (0.1169)

3.00 (0.1181)

3.03 (0.1193)

3.06 (0.1205)

3.09 (0.1217)

3.12 (0.1228)

3.15 (0.1240)

3.18 (0.1252)

3.21 (0.1264)

3.24 (0.1276)

3.27 (0.1287)

3.30 (0.1299)

3.33 (0.1311)

3.36 (0.1323)

3.39 (0.1335)

3.42 (0.1346)

3.45 (0.1358)

3.48 (0.1370)

3.51 (0.1382)

3.54 (0.1394)

3.57 (0.1406)

3.60 (0.1417)

3.63 (0.1429)

3.66 (0.1441)38151-01J00

38151-01J01

38151-01J02

38151-01J03

38151-01J04

38151-01J05

38151-01J06

38151-01J07

38151-01J08

38151-01J09

38151-01J10

38151-01J11

38151-01J12

38151-01J13

38151-01J14

38151-01J15

38151-01J16

38151-01J17

38151-01J18

38151-01J19

38151-01J60

38151-01J61

38151-01J62

38151-01J63

38151-01J64

38151-01J65

38151-01J66

38151-01J67

38151-01J68

38151-01J69

38151-01J70

38151-01J71

38151-01J72

38151-01J73

38151-01J74

38151-01J75

38151-01J76

Drive pinion preload adjustment

Drive pinion bearing preload adjust-

ing methodAdjusting shim and spacer

Drive pinion preload

Nzm (kg-cm, in-lb)

With front oil seal1.4 - 1.7

(14 - 17, 12 - 15)

Without front oil seal1.2 - 1.5

(12 - 15, 10 - 13)

Available drive pinion preload adjusting shims

Thickness mm (in) Part number

2.31 (0.0909)

2.33 (0.0917)

2.35 (0.0925)

2.37 (0.0933)

2.39 (0.0941)

2.41 (0.0949)

2.43 (0.0957)

2.45 (0.0965)

2.47 (0.0972)

2.49 (0.0980)

2.51 (0.0988)

2.53 (0.0996)

2.55 (0.1004)

2.57 (0.1012)

2.59 (0.1020)38125-82100

38126-82100

38127-82100

38128-82100

38129-82100

38130-82100

38131-82100

38132-82100

38133-82100

38134-82100

38135-82100

38136-82100

38137-82100

38138-82100

38139-82100

Available drive pinion preload adjusting spacers

Length mm (in) Part number

4.50 (0.1772)

4.75 (0.1870)

5.00 (0.1969)

5.25 (0.2067)

5.50 (0.2165)38165-76000

38166-76000

38167-76000

38166-01J00

38166-01J10

Total preload adjustment

Total preload

Nzm (kg-cm, in-lb)

With front oil sealDrive pinion

bearingNew1.7 - 2.5

(17 - 25, 15 - 22)

Old1.5 - 1.7

(15 - 17, 13 - 15)

Ring gear backlash mm (in)0.15 - 0.20

(0.0059 - 0.0079)

Side bearing adjusting method Side adjuster

SERVICE DATA AND SPECIFICATIONS (SDS)

Final Drive (Cont'd)

PD-53