NISSAN PATROL 2000 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 321 of 1033

Wiring Diagram

TEC098M

DTC 0102 MASS AIR FLOW SENZD30DDTi

EC-1088

Page 322 of 1033

Diagnostic Procedure

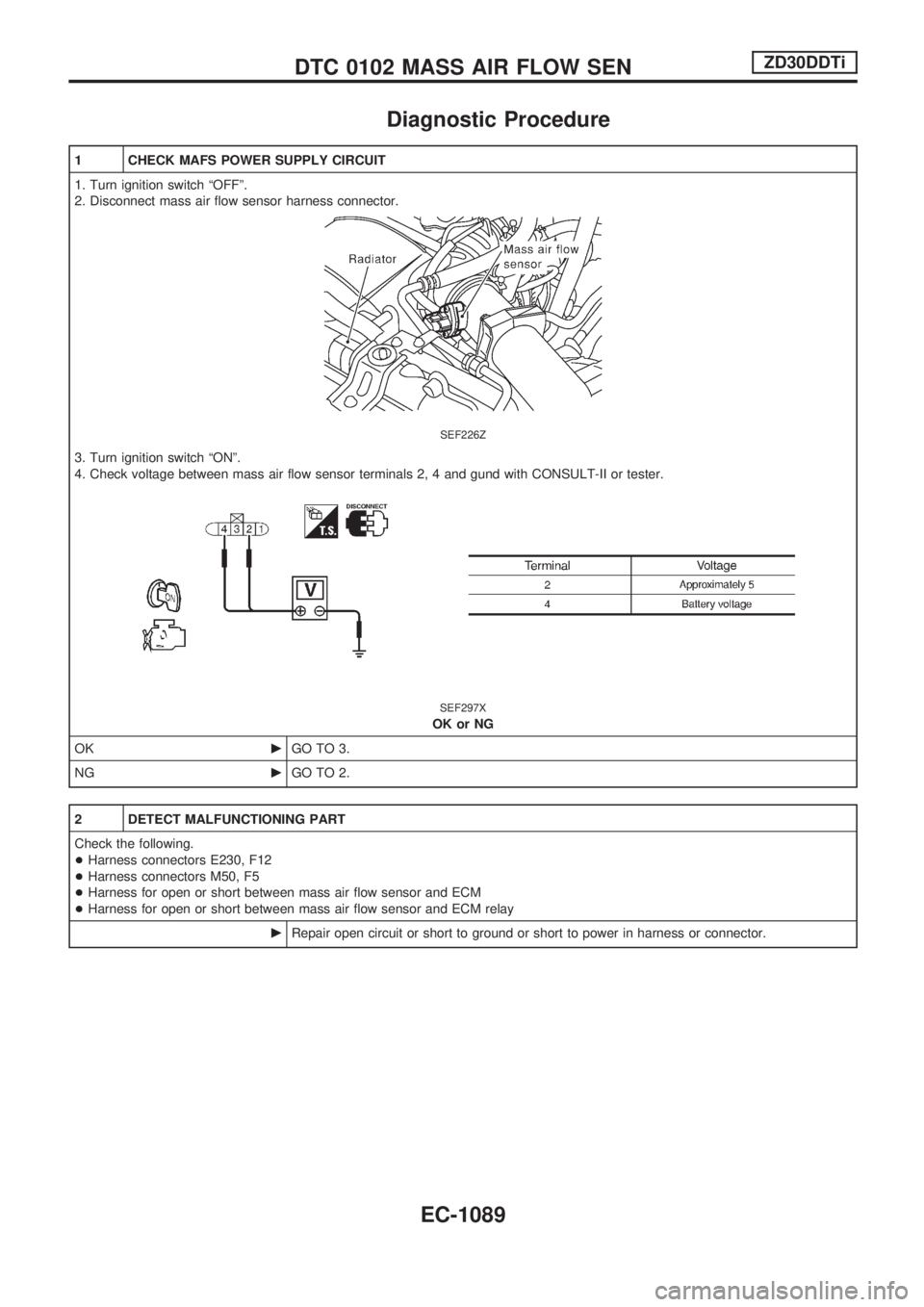

1 CHECK MAFS POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect mass air flow sensor harness connector.

SEF226Z

3. Turn ignition switch ªONº.

4. Check voltage between mass air flow sensor terminals 2, 4 and gund with CONSULT-II or tester.

SEF297X

OK or NG

OKcGO TO 3.

NGcGO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E230, F12

+Harness connectors M50, F5

+Harness for open or short between mass air flow sensor and ECM

+Harness for open or short between mass air flow sensor and ECM relay

cRepair open circuit or short to ground or short to power in harness or connector.

DTC 0102 MASS AIR FLOW SENZD30DDTi

EC-1089

Page 323 of 1033

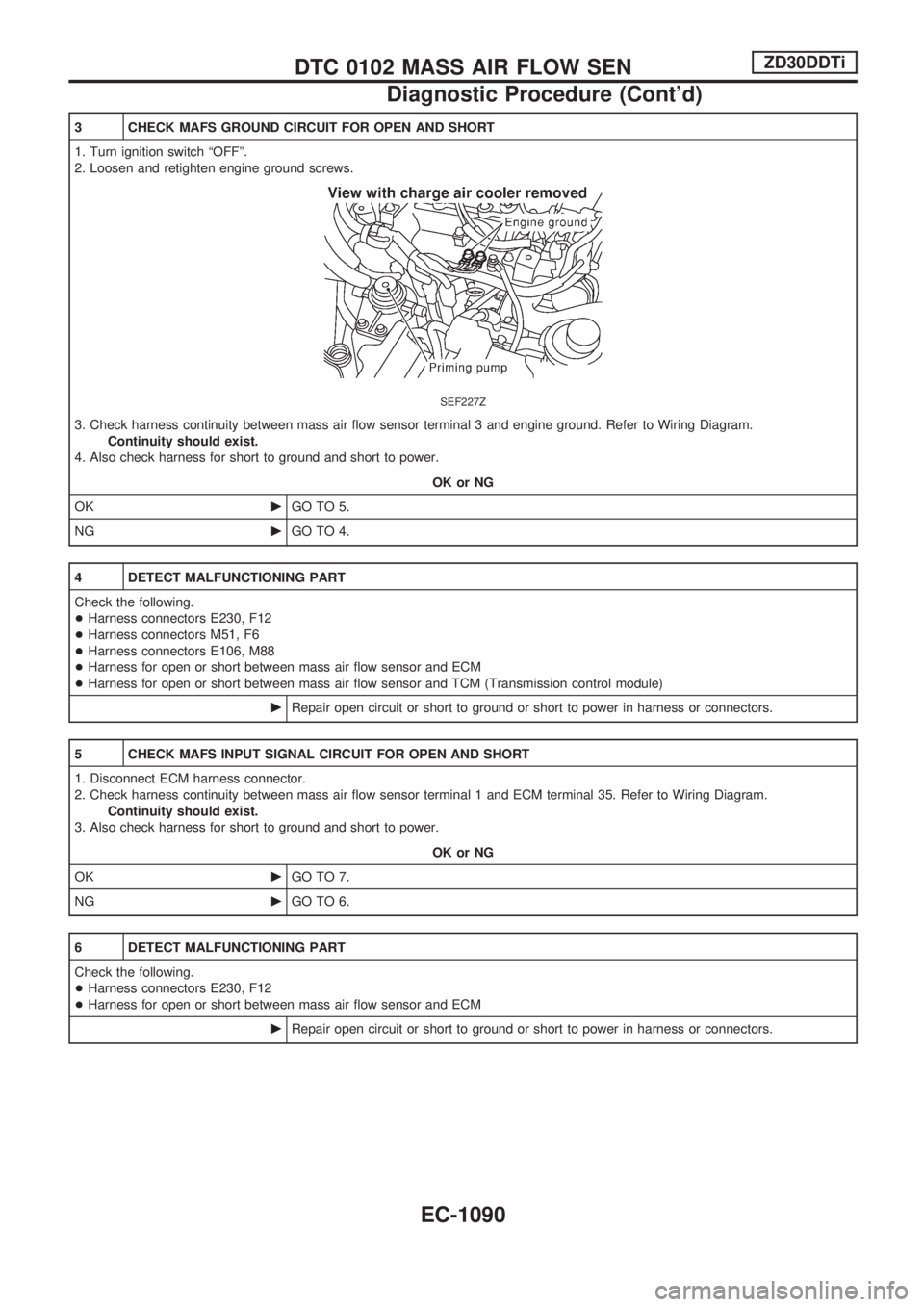

3 CHECK MAFS GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Loosen and retighten engine ground screws.

SEF227Z

3. Check harness continuity between mass air flow sensor terminal 3 and engine ground. Refer to Wiring Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 5.

NGcGO TO 4.

4 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E230, F12

+Harness connectors M51, F6

+Harness connectors E106, M88

+Harness for open or short between mass air flow sensor and ECM

+Harness for open or short between mass air flow sensor and TCM (Transmission control module)

cRepair open circuit or short to ground or short to power in harness or connectors.

5 CHECK MAFS INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between mass air flow sensor terminal 1 and ECM terminal 35. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 7.

NGcGO TO 6.

6 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E230, F12

+Harness for open or short between mass air flow sensor and ECM

cRepair open circuit or short to ground or short to power in harness or connectors.

DTC 0102 MASS AIR FLOW SENZD30DDTi

Diagnostic Procedure (Cont'd)

EC-1090

Page 324 of 1033

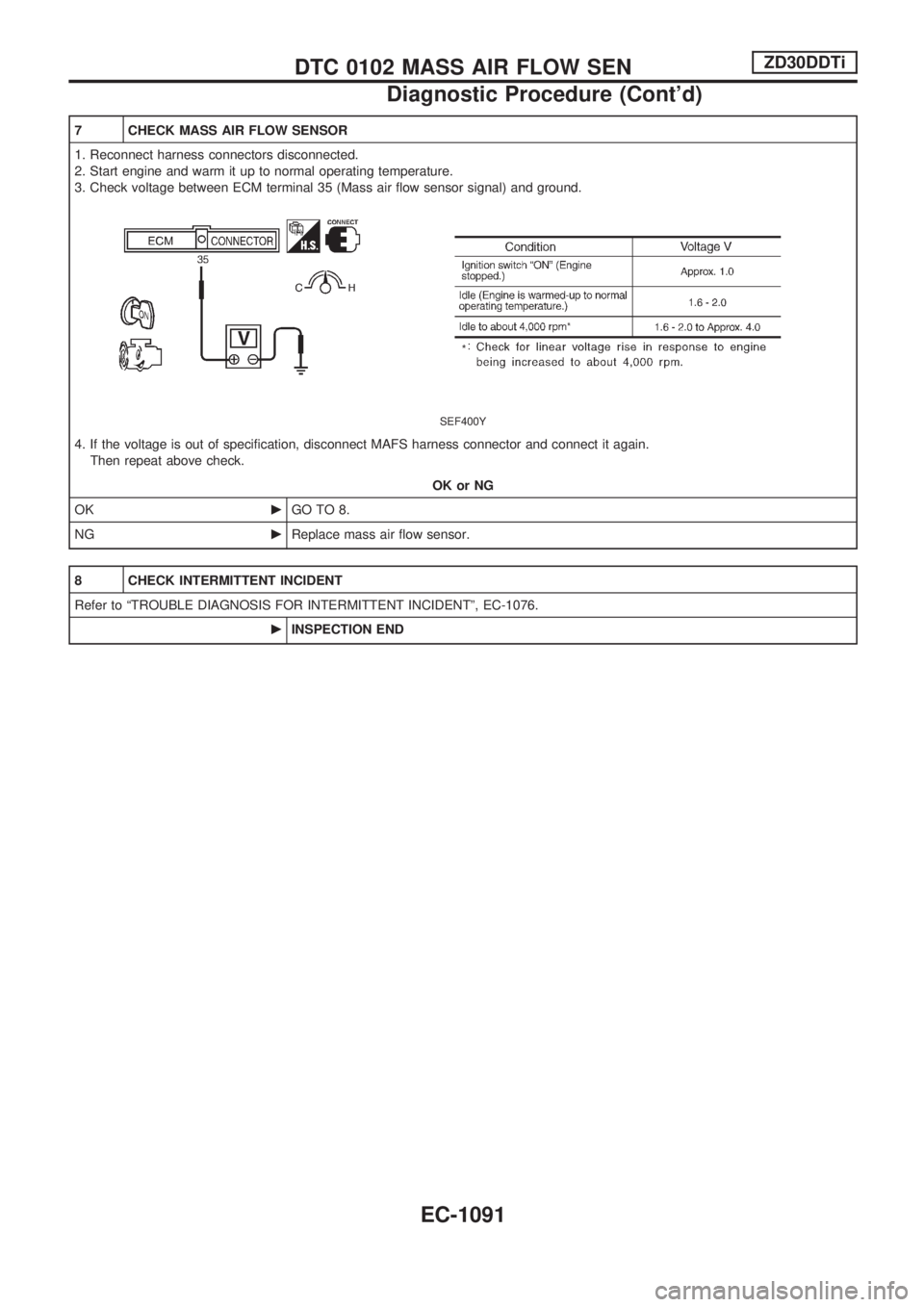

7 CHECK MASS AIR FLOW SENSOR

1. Reconnect harness connectors disconnected.

2. Start engine and warm it up to normal operating temperature.

3. Check voltage between ECM terminal 35 (Mass air flow sensor signal) and ground.

SEF400Y

4. If the voltage is out of specification, disconnect MAFS harness connector and connect it again.

Then repeat above check.

OK or NG

OKcGO TO 8.

NGcReplace mass air flow sensor.

8 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-1076.

cINSPECTION END

DTC 0102 MASS AIR FLOW SENZD30DDTi

Diagnostic Procedure (Cont'd)

EC-1091

Page 325 of 1033

Description

The engine coolant temperature sensor is used to detect the

engine coolant temperature. The sensor modifies a voltage sig-

nal from the ECM. The modified signal returns to the ECM as the

engine coolant temperature input. The sensor uses a thermistor

which is sensitive to the change in temperature. The electrical

resistance of the thermistor decreases as temperature

increases.

Engine coolant tempera-

ture ÉC (ÉF)Voltage* (V) Resistance (kW)

þ10 (14) 4.4 7.0 - 11.4

20 (68) 3.5 2.1 - 2.9

50 (122) 2.3 0.68 - 1.00

90 (194) 1.0 0.236 - 0.260

*: These data are reference values and measured between ECM terminal 19

(Engine coolant temperature sensor) and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/

output voltage. Doing so may damage the ECM's transistor.

Use a ground other than ECM terminals, such as the ground.

On Board Diagnosis Logic

Malfunction is detected when ... Check Items (Possible Cause)

+An excessively high or low voltage from the sensor is entered

to ECM.+Harness or connectors (The sensor circuit is open or shorted.)

+Engine coolant temperature sensor

DTC Confirmation Procedure

WITH CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Wait at least 5 seconds.

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-1094.

WITHOUT CONSULT-II

1) Turn ignition switch ªONº and wait at least 5 seconds.

2) Turn ignition switch ªOFFº, wait at least 5 seconds and then

turn ªONº.

3) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º

with ECM.

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-1094.

SEF594K

SEF012P

SEF817Y

DTC 0103 COOLANT TEMP SENZD30DDTi

EC-1092

Page 326 of 1033

Wiring Diagram

TEC099M

DTC 0103 COOLANT TEMP SENZD30DDTi

EC-1093

Page 327 of 1033

Diagnostic Procedure

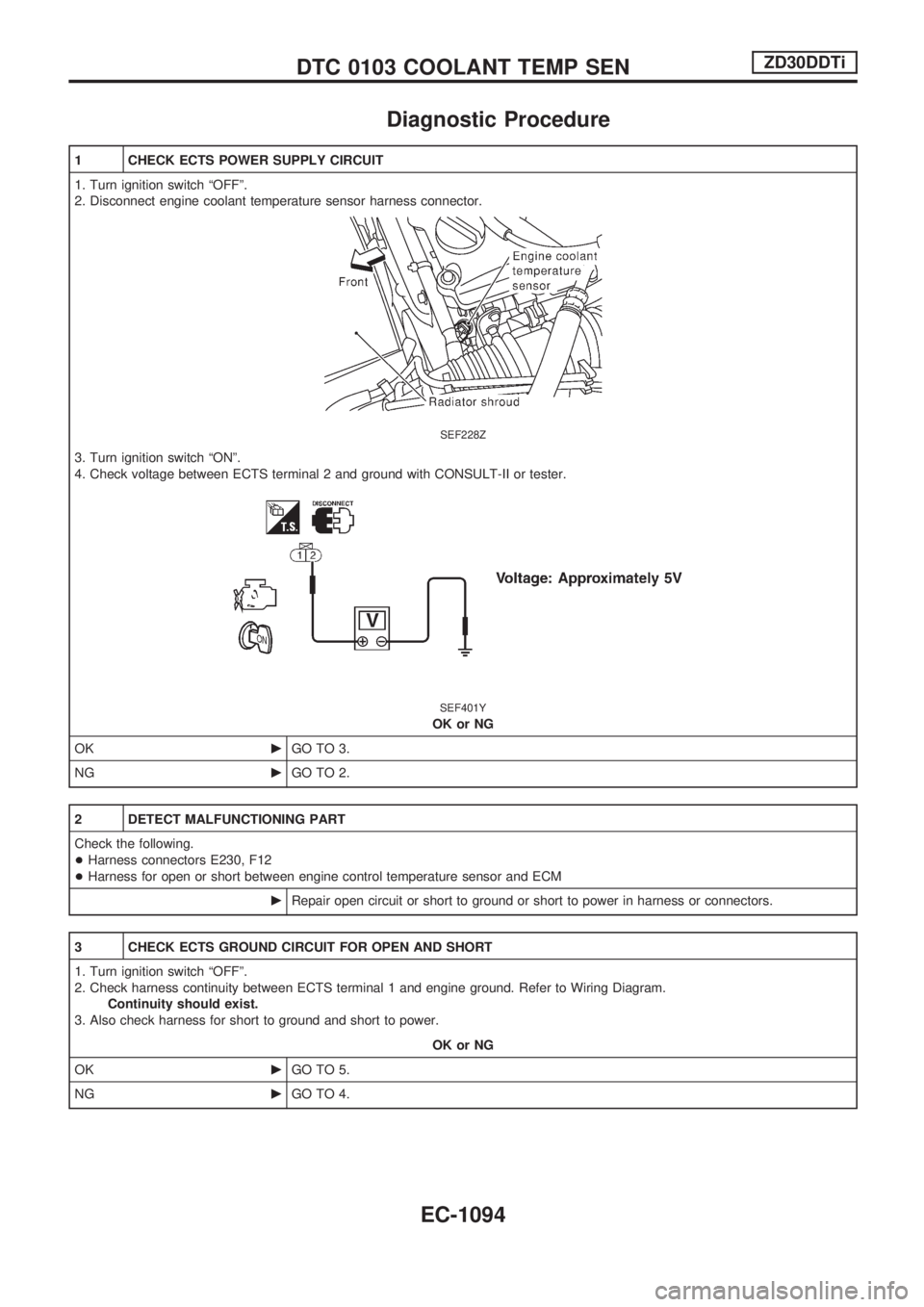

1 CHECK ECTS POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect engine coolant temperature sensor harness connector.

SEF228Z

3. Turn ignition switch ªONº.

4. Check voltage between ECTS terminal 2 and ground with CONSULT-II or tester.

SEF401Y

OK or NG

OKcGO TO 3.

NGcGO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E230, F12

+Harness for open or short between engine control temperature sensor and ECM

cRepair open circuit or short to ground or short to power in harness or connectors.

3 CHECK ECTS GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Check harness continuity between ECTS terminal 1 and engine ground. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 5.

NGcGO TO 4.

DTC 0103 COOLANT TEMP SENZD30DDTi

EC-1094

Page 328 of 1033

4 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E230, F12

+Harness connectors F6, M51

+Harness connectors M88, E106

+Harness for open or short between engine coolant temperature sensor and ECM

+Harness for open or short between engine coolant temperature sensor and TCM (Transmission control module)

cRepair open circuit or short to ground or short to power in harness or connectors.

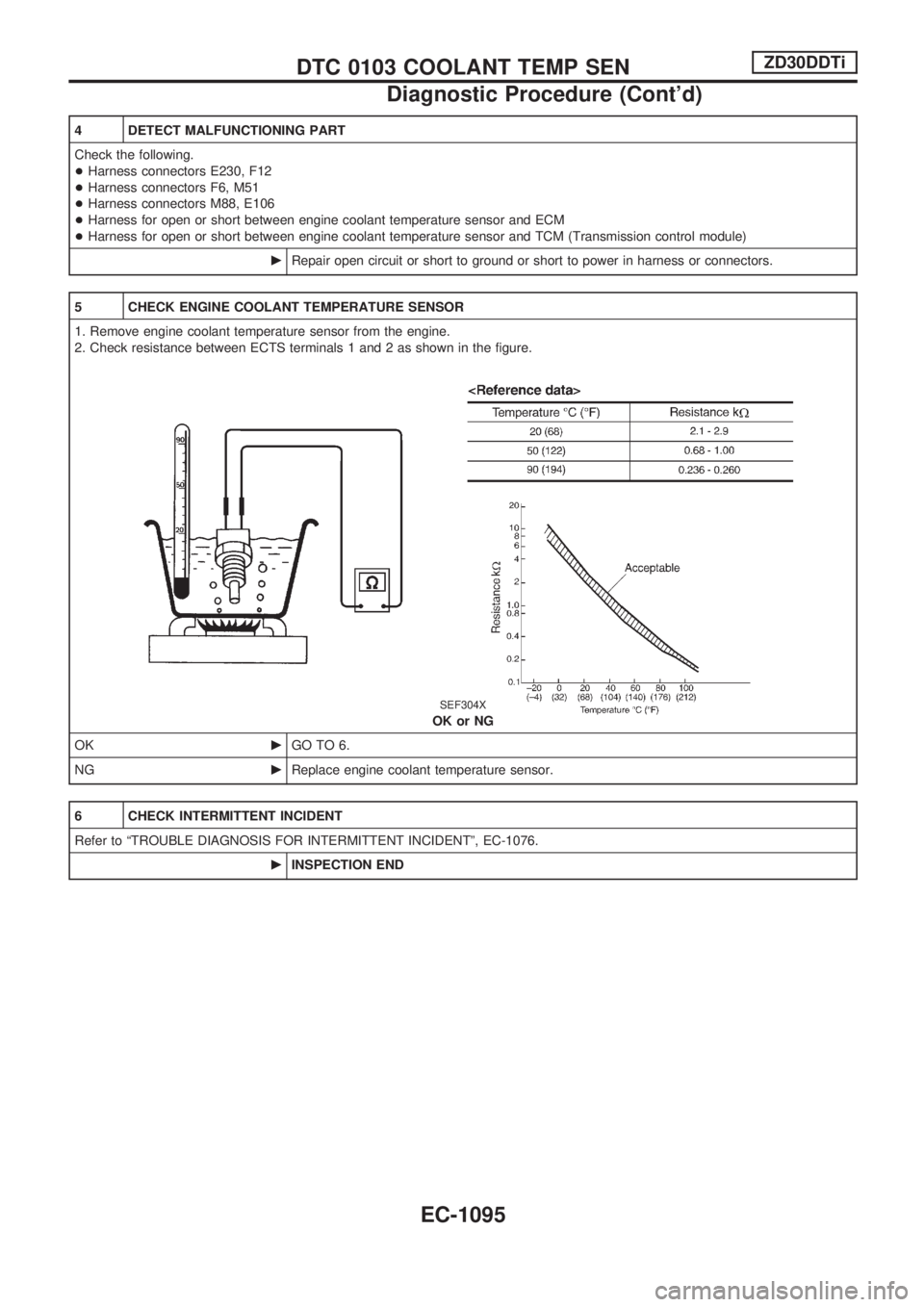

5 CHECK ENGINE COOLANT TEMPERATURE SENSOR

1. Remove engine coolant temperature sensor from the engine.

2. Check resistance between ECTS terminals 1 and 2 as shown in the figure.

SEF304X

OK or NG

OKcGO TO 6.

NGcReplace engine coolant temperature sensor.

6 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-1076.

cINSPECTION END

DTC 0103 COOLANT TEMP SENZD30DDTi

Diagnostic Procedure (Cont'd)

EC-1095

Page 329 of 1033

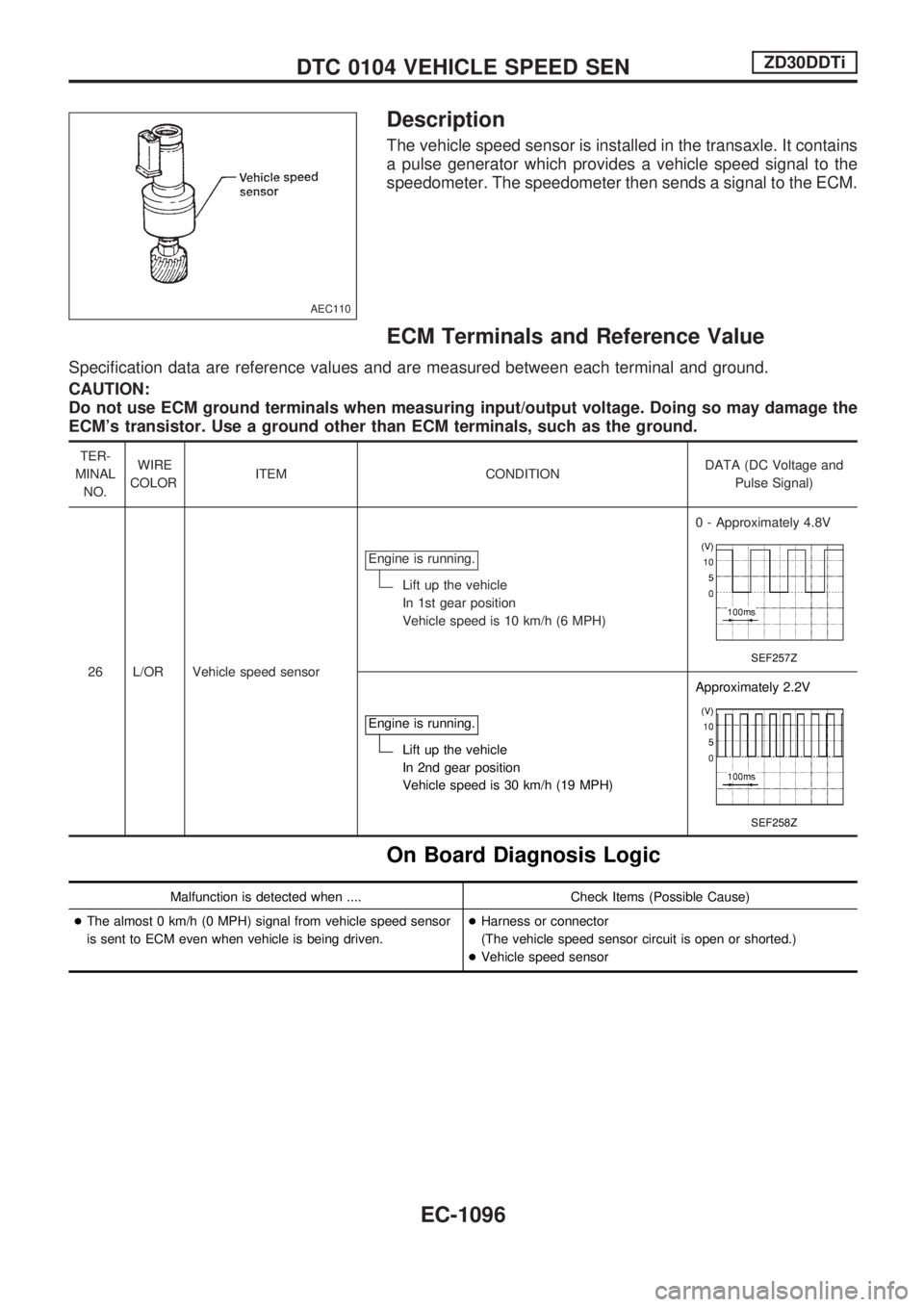

Description

The vehicle speed sensor is installed in the transaxle. It contains

a pulse generator which provides a vehicle speed signal to the

speedometer. The speedometer then sends a signal to the ECM.

ECM Terminals and Reference Value

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may damage the

ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL

NO.WIRE

COLORITEM CONDITIONDATA (DC Voltage and

Pulse Signal)

26 L/OR Vehicle speed sensorEngine is running.

Lift up the vehicle

In 1st gear position

Vehicle speed is 10 km/h (6 MPH)0 - Approximately 4.8V

SEF257Z

Engine is running.

Lift up the vehicle

In 2nd gear position

Vehicle speed is 30 km/h (19 MPH)Approximately 2.2V

SEF258Z

On Board Diagnosis Logic

Malfunction is detected when .... Check Items (Possible Cause)

+The almost 0 km/h (0 MPH) signal from vehicle speed sensor

is sent to ECM even when vehicle is being driven.+Harness or connector

(The vehicle speed sensor circuit is open or shorted.)

+Vehicle speed sensor

AEC110

DTC 0104 VEHICLE SPEED SENZD30DDTi

EC-1096

Page 330 of 1033

Overall Function Check

Use this procedure to check the overall function of the vehicle

speed sensor circuit. During this check, a DTC might not be

confirmed.

WITH CONSULT-II

1) Lift up the vehicle.

2) Start engine.

3) Read vehicle speed sensor signal in ªDATA MONITORº

mode with CONSULT-II.

The vehicle speed on CONSULT-II should be able to

exceed 10 km/h (6 MPH) when rotating wheels with suit-

able gear position.

4) If NG, go to ªDiagnostic Procedureº, EC-1099.

WITHOUT CONSULT-II

1) Lift up the vehicle.

2) Start engine.

3) Rotate drive wheel by hand.

4) Check voltage between ECM terminal 26 and ground with

tester.

Voltage should vary between 0 - 4.8V.

5) If NG, go to ªDiagnostic Procedureº, EC-1099.

SEF864Y

SEF811R

DTC 0104 VEHICLE SPEED SENZD30DDTi

EC-1097