NISSAN PATROL 2000 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 921 of 1033

MANUAL TRANSAXLE

SECTION

MT

CONTENTS

PREPARATION................................................... 1002

Special Service Tools ...................................... 1002

Commercial Service Tools ............................... 1004

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING......................................... 1005

NVH Troubleshooting Chart............................. 1005

ON-VEHICLE SERVICE...................................... 1006

Replacing Rear Oil Seal .................................. 1006

Position Switch Check ..................................... 1006

REMOVAL AND INSTALLATION....................... 1007

Removal ........................................................... 1007

Installation ........................................................ 1008

DESCRIPTION..................................................... 1009

Cross-sectional View ....................................... 1009

AIR BREATHER.................................................. 1010

Air Breather Piping........................................... 1010

MAJOR OVERHAUL........................................... 1011

Case Components ........................................... 1011Gear Components............................................ 1012

Shift Control Components................................ 1014

DISASSEMBLY.................................................... 1015

Case Components ........................................... 1015

Shift Control Components................................ 1015

Gear Components............................................ 1018

INSPECTION........................................................ 1024

Shift Control Components................................ 1024

Gear Components............................................ 1024

ASSEMBLY.......................................................... 1026

Shift Control Components................................ 1026

Gear Components............................................ 1028

SERVICE DATA AND SPECIFICATIONS

(SDS).................................................................... 1037

General Specifications ..................................... 1037

Inspection and Adjustment .............................. 1038

Page 922 of 1033

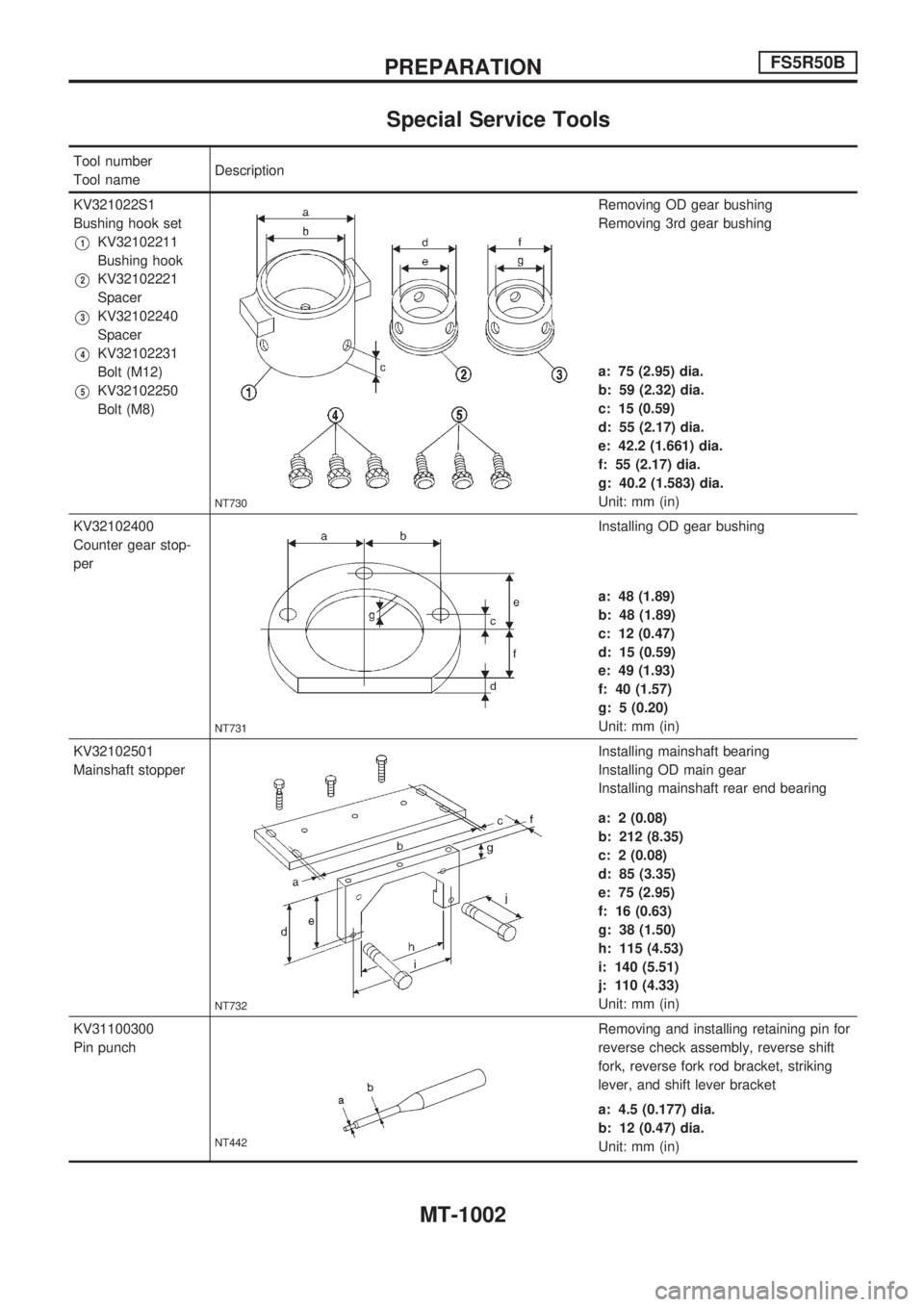

Special Service Tools

Tool number

Tool nameDescription

KV321022S1

Bushing hook set

V1KV32102211

Bushing hook

V2KV32102221

Spacer

V3KV32102240

Spacer

V4KV32102231

Bolt (M12)

V5KV32102250

Bolt (M8)

NT730

Removing OD gear bushing

Removing 3rd gear bushing

a: 75 (2.95) dia.

b: 59 (2.32) dia.

c: 15 (0.59)

d: 55 (2.17) dia.

e: 42.2 (1.661) dia.

f: 55 (2.17) dia.

g: 40.2 (1.583) dia.

Unit: mm (in)

KV32102400

Counter gear stop-

per

NT731

Installing OD gear bushing

a: 48 (1.89)

b: 48 (1.89)

c: 12 (0.47)

d: 15 (0.59)

e: 49 (1.93)

f: 40 (1.57)

g: 5 (0.20)

Unit: mm (in)

KV32102501

Mainshaft stopper

NT732

Installing mainshaft bearing

Installing OD main gear

Installing mainshaft rear end bearing

a: 2 (0.08)

b: 212 (8.35)

c: 2 (0.08)

d: 85 (3.35)

e: 75 (2.95)

f: 16 (0.63)

g: 38 (1.50)

h: 115 (4.53)

i: 140 (5.51)

j: 110 (4.33)

Unit: mm (in)

KV31100300

Pin punch

NT442

Removing and installing retaining pin for

reverse check assembly, reverse shift

fork, reverse fork rod bracket, striking

lever, and shift lever bracket

a: 4.5 (0.177) dia.

b: 12 (0.47) dia.

Unit: mm (in)

PREPARATIONFS5R50B

MT-1002

Page 923 of 1033

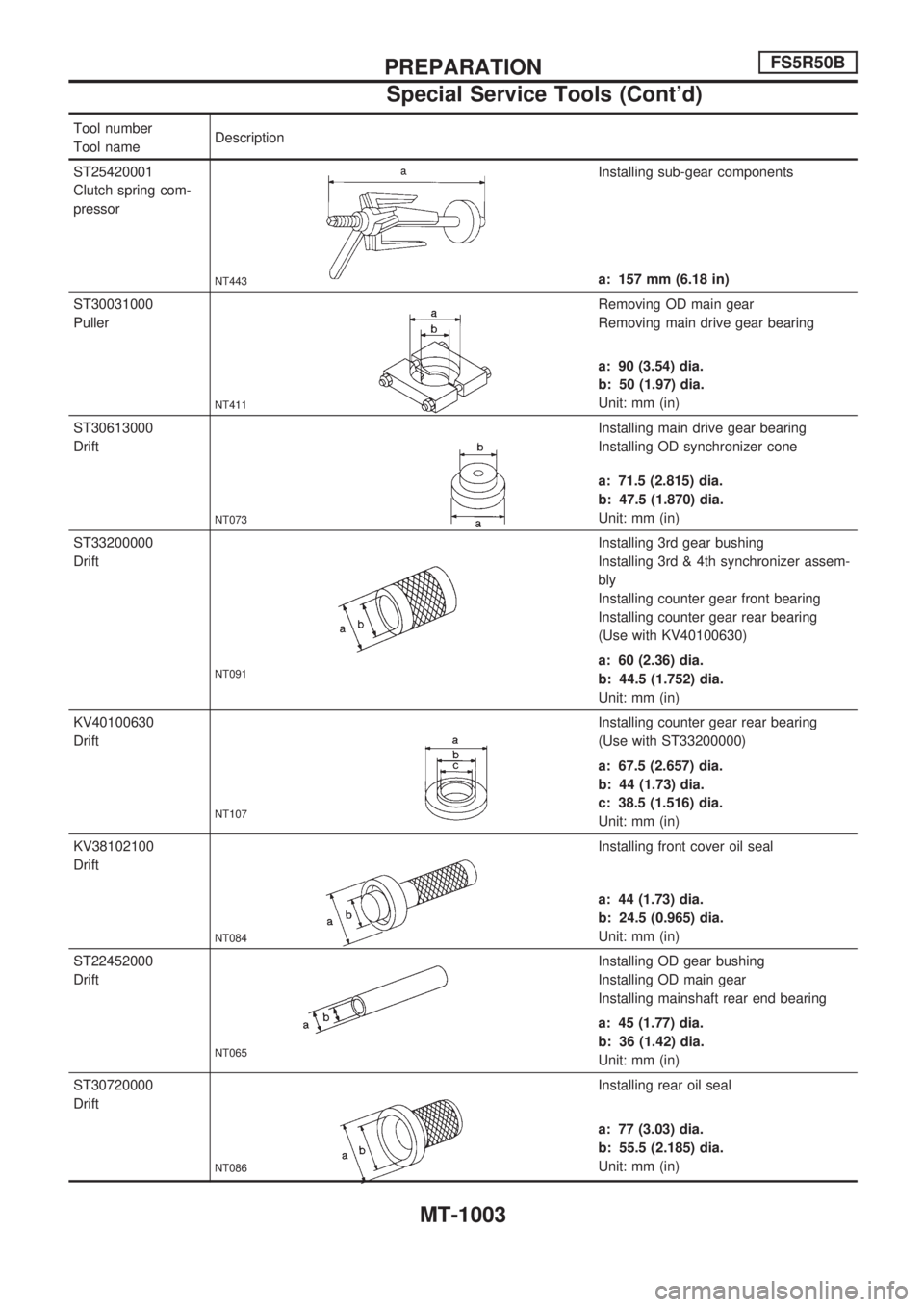

Tool number

Tool nameDescription

ST25420001

Clutch spring com-

pressor

NT443

Installing sub-gear components

a: 157 mm (6.18 in)

ST30031000

Puller

NT411

Removing OD main gear

Removing main drive gear bearing

a: 90 (3.54) dia.

b: 50 (1.97) dia.

Unit: mm (in)

ST30613000

Drift

NT073

Installing main drive gear bearing

Installing OD synchronizer cone

a: 71.5 (2.815) dia.

b: 47.5 (1.870) dia.

Unit: mm (in)

ST33200000

Drift

NT091

Installing 3rd gear bushing

Installing 3rd & 4th synchronizer assem-

bly

Installing counter gear front bearing

Installing counter gear rear bearing

(Use with KV40100630)

a: 60 (2.36) dia.

b: 44.5 (1.752) dia.

Unit: mm (in)

KV40100630

Drift

NT107

Installing counter gear rear bearing

(Use with ST33200000)

a: 67.5 (2.657) dia.

b: 44 (1.73) dia.

c: 38.5 (1.516) dia.

Unit: mm (in)

KV38102100

Drift

NT084

Installing front cover oil seal

a: 44 (1.73) dia.

b: 24.5 (0.965) dia.

Unit: mm (in)

ST22452000

Drift

NT065

Installing OD gear bushing

Installing OD main gear

Installing mainshaft rear end bearing

a: 45 (1.77) dia.

b: 36 (1.42) dia.

Unit: mm (in)

ST30720000

Drift

NT086

Installing rear oil seal

a: 77 (3.03) dia.

b: 55.5 (2.185) dia.

Unit: mm (in)

PREPARATIONFS5R50B

Special Service Tools (Cont'd)

MT-1003

Page 924 of 1033

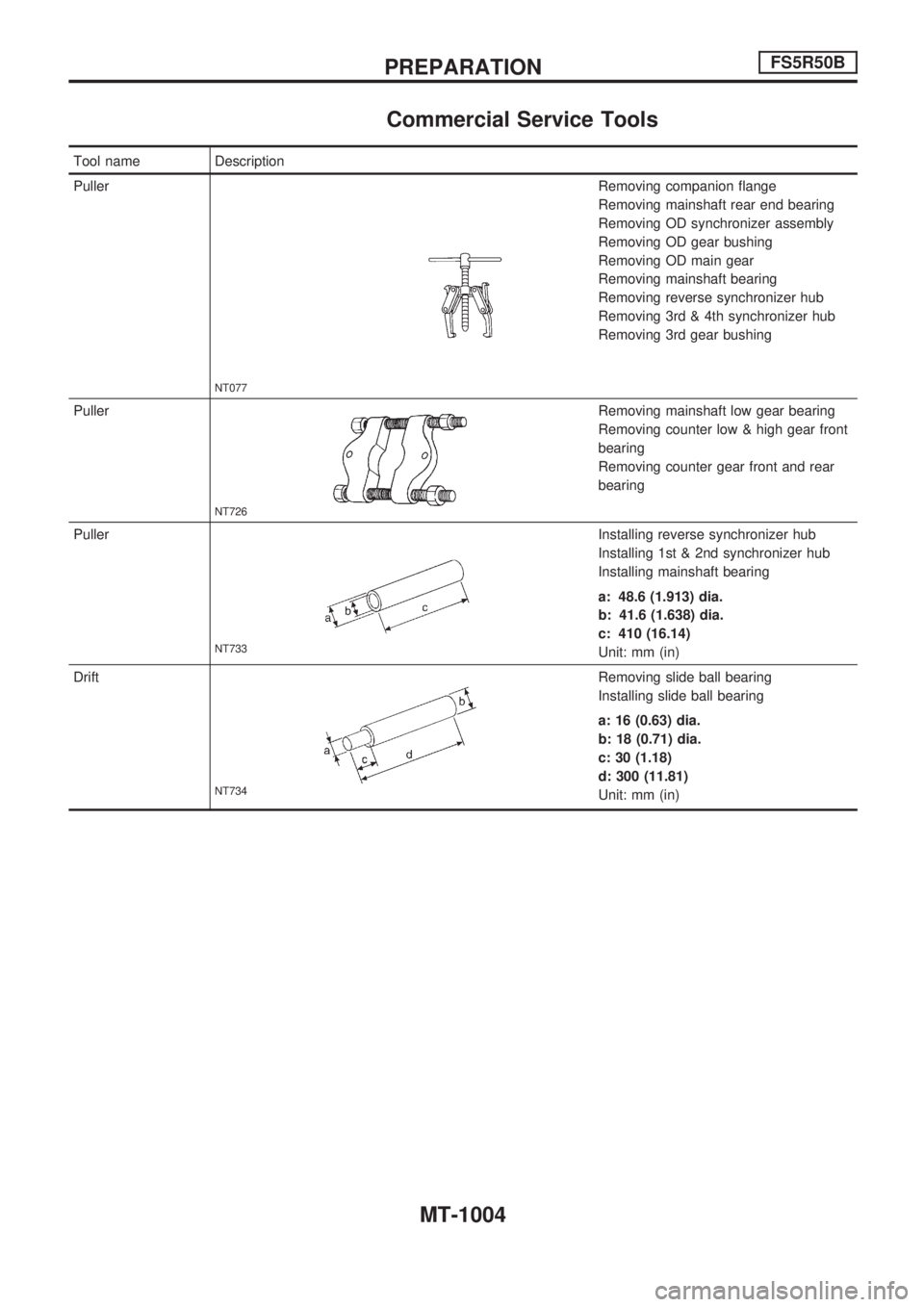

Commercial Service Tools

Tool name Description

Puller

NT077

Removing companion flange

Removing mainshaft rear end bearing

Removing OD synchronizer assembly

Removing OD gear bushing

Removing OD main gear

Removing mainshaft bearing

Removing reverse synchronizer hub

Removing 3rd & 4th synchronizer hub

Removing 3rd gear bushing

Puller

NT726

Removing mainshaft low gear bearing

Removing counter low & high gear front

bearing

Removing counter gear front and rear

bearing

Puller

NT733

Installing reverse synchronizer hub

Installing 1st & 2nd synchronizer hub

Installing mainshaft bearing

a: 48.6 (1.913) dia.

b: 41.6 (1.638) dia.

c: 410 (16.14)

Unit: mm (in)

Drift

NT734

Removing slide ball bearing

Installing slide ball bearing

a: 16 (0.63) dia.

b: 18 (0.71) dia.

c: 30 (1.18)

d: 300 (11.81)

Unit: mm (in)

PREPARATIONFS5R50B

MT-1004

Page 925 of 1033

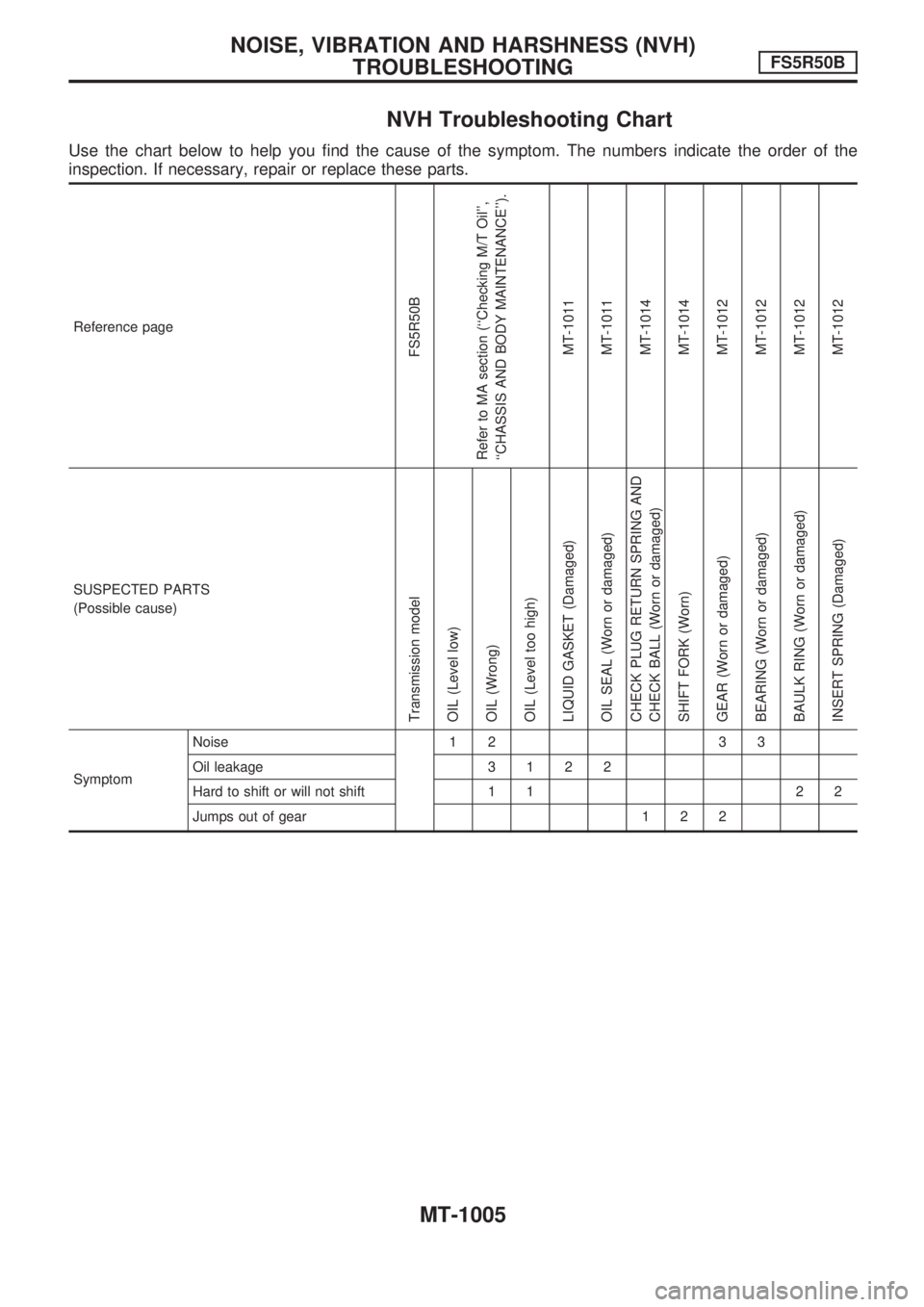

NVH Troubleshooting Chart

Use the chart below to help you find the cause of the symptom. The numbers indicate the order of the

inspection. If necessary, repair or replace these parts.

Reference page

FS5R50B

Refer to MA section (``Checking M/T Oil'',

``CHASSIS AND BODY MAINTENANCE'').

MT-1011

MT-1011

MT-1014

MT-1014

MT-1012

MT-1012

MT-1012

MT-1012

SUSPECTED PARTS

(Possible cause)

Transmission model

OIL (Level low)

OIL (Wrong)

OIL (Level too high)

LIQUID GASKET (Damaged)

OIL SEAL (Worn or damaged)

CHECK PLUG RETURN SPRING AND

CHECK BALL (Worn or damaged)

SHIFT FORK (Worn)

GEAR (Worn or damaged)

BEARING (Worn or damaged)

BAULK RING (Worn or damaged)

INSERT SPRING (Damaged)

SymptomNoise 1 2 3 3

Oil leakage3122

Hard to shift or will not shift 1 1 2 2

Jumps out of gear 1 2 2

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTINGFS5R50B

MT-1005

Page 926 of 1033

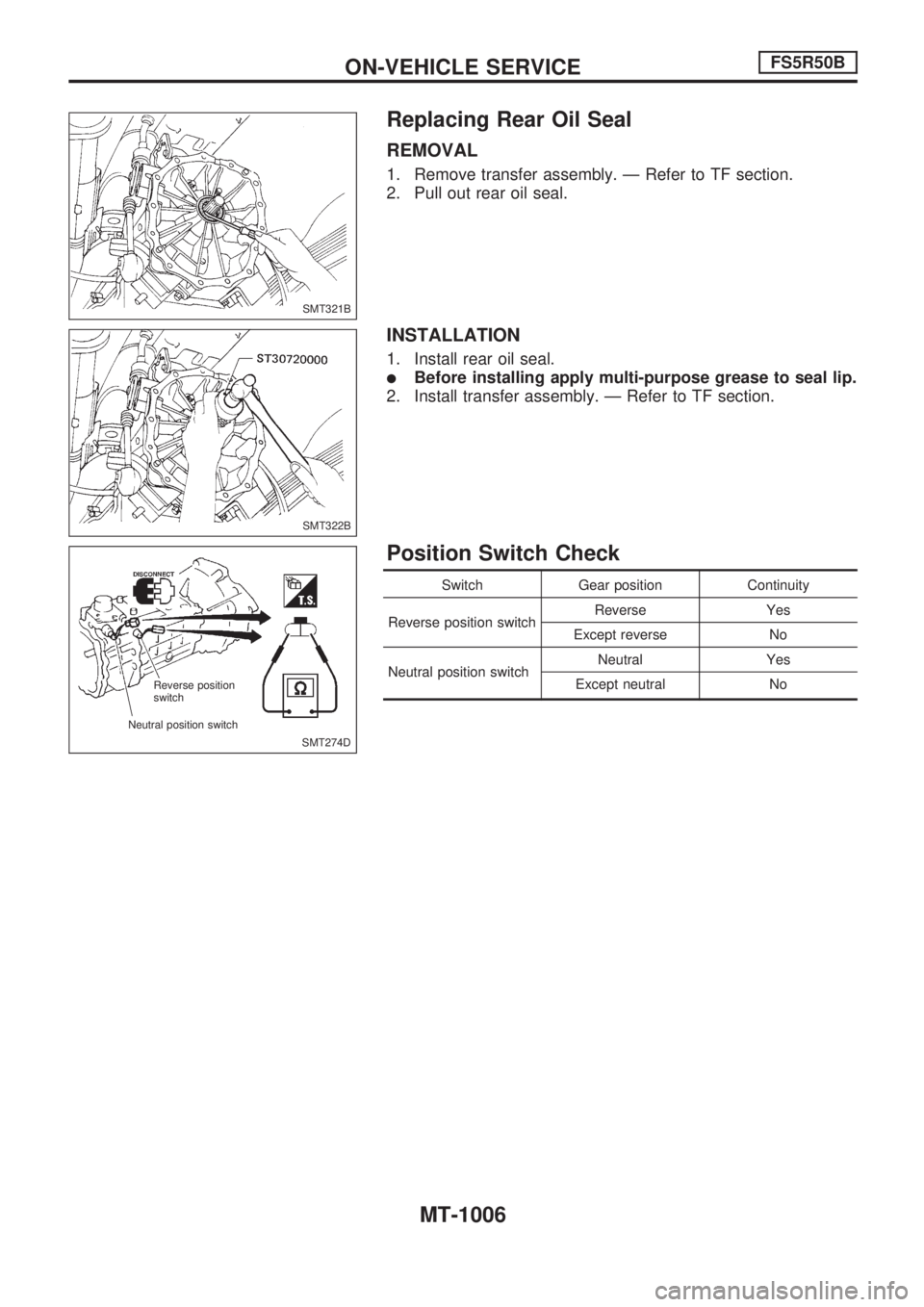

Replacing Rear Oil Seal

REMOVAL

1. Remove transfer assembly. Ð Refer to TF section.

2. Pull out rear oil seal.

INSTALLATION

1. Install rear oil seal.

lBefore installing apply multi-purpose grease to seal lip.

2. Install transfer assembly. Ð Refer to TF section.

Position Switch Check

Switch Gear position Continuity

Reverse position switchReverse Yes

Except reverse No

Neutral position switchNeutral Yes

Except neutral No

SMT321B

SMT322B

SMT274D Reverse position

switch

Neutral position switch

ON-VEHICLE SERVICEFS5R50B

MT-1006

Page 927 of 1033

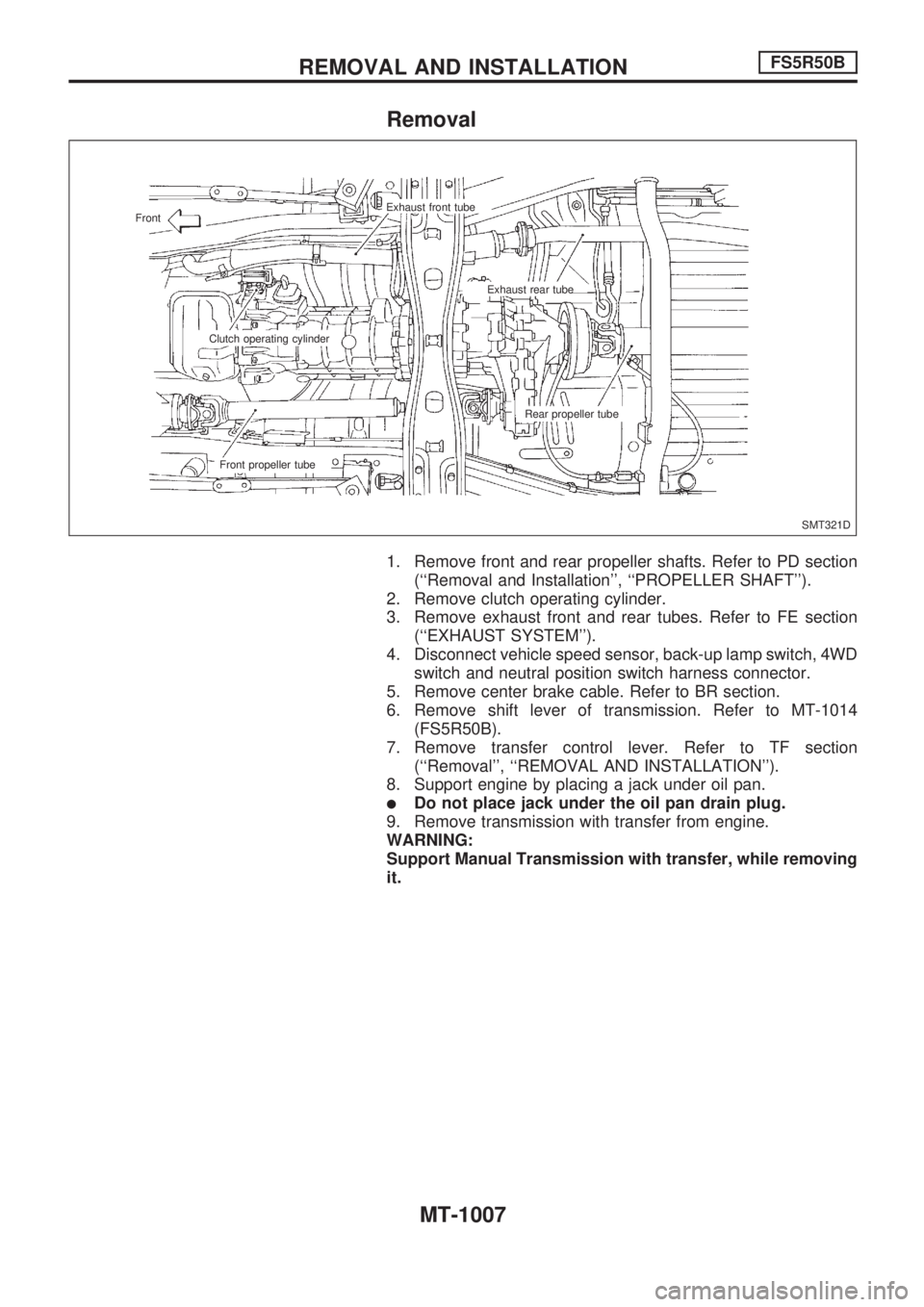

Removal

1. Remove front and rear propeller shafts. Refer to PD section

(``Removal and Installation'', ``PROPELLER SHAFT'').

2. Remove clutch operating cylinder.

3. Remove exhaust front and rear tubes. Refer to FE section

(``EXHAUST SYSTEM'').

4. Disconnect vehicle speed sensor, back-up lamp switch, 4WD

switch and neutral position switch harness connector.

5. Remove center brake cable. Refer to BR section.

6. Remove shift lever of transmission. Refer to MT-1014

(FS5R50B).

7. Remove transfer control lever. Refer to TF section

(``Removal'', ``REMOVAL AND INSTALLATION'').

8. Support engine by placing a jack under oil pan.

lDo not place jack under the oil pan drain plug.

9. Remove transmission with transfer from engine.

WARNING:

Support Manual Transmission with transfer, while removing

it.

SMT321D Exhaust front tube

Front

Exhaust rear tube

Clutch operating cylinder

Rear propeller tube

Front propeller tube

REMOVAL AND INSTALLATIONFS5R50B

MT-1007

Page 928 of 1033

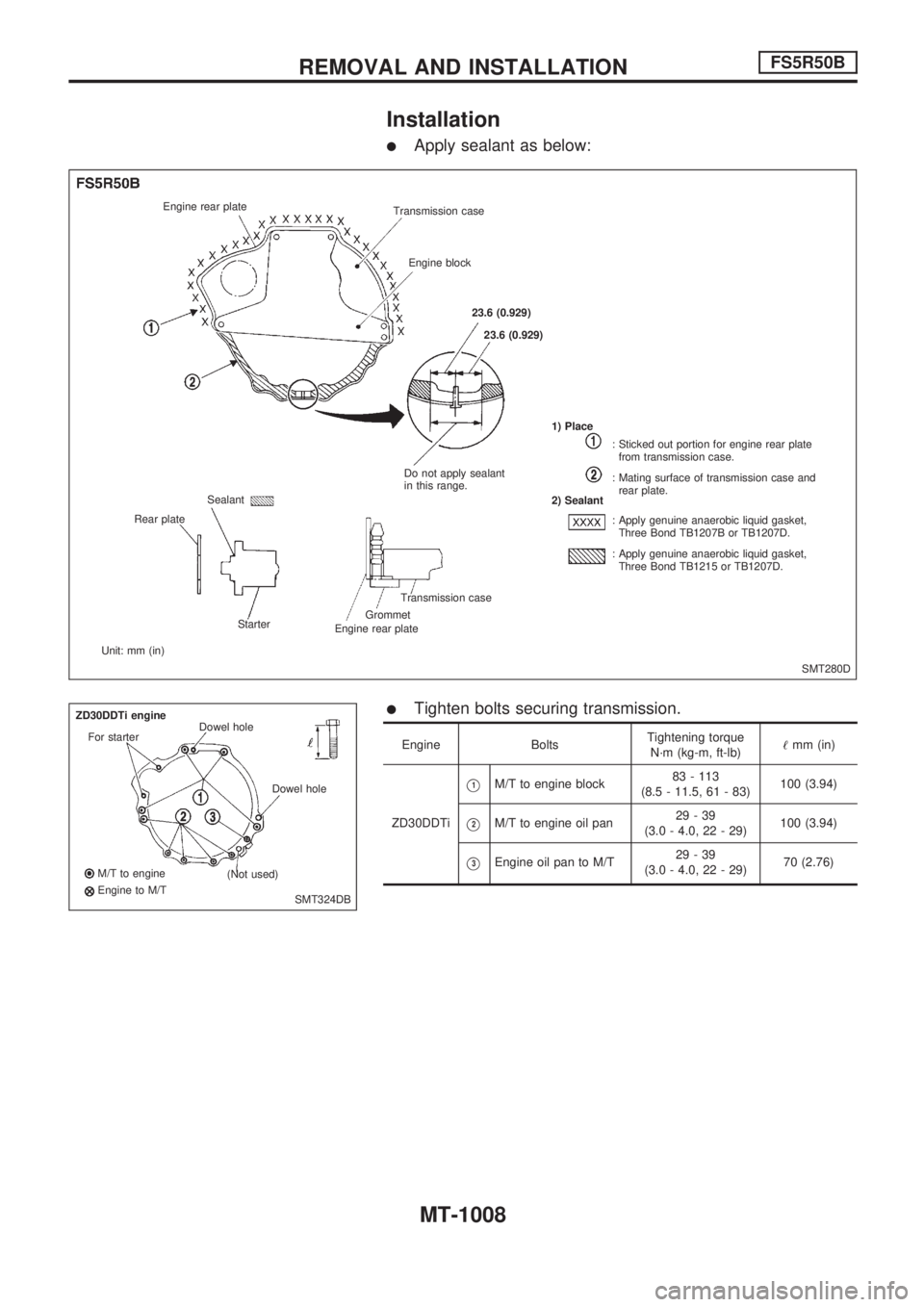

Installation

lApply sealant as below:

lTighten bolts securing transmission.

Engine BoltsTightening torque

N´m (kg-m, ft-lb)!mm (in)

ZD30DDTi

V1M/T to engine block83 - 113

(8.5 - 11.5, 61 - 83)100 (3.94)

V2M/T to engine oil pan29-39

(3.0 - 4.0, 22 - 29)100 (3.94)

V3Engine oil pan to M/T29-39

(3.0 - 4.0, 22 - 29)70 (2.76)

SMT280D Engine rear plate

Transmission case

Engine block

23.6 (0.929)

23.6 (0.929)

Do not apply sealant

in this range.1) Place

2) Sealant

: Sticked out portion for engine rear plate

from transmission case.

: Mating surface of transmission case and

rear plate.

: Apply genuine anaerobic liquid gasket,

Three Bond TB1207B or TB1207D.

: Apply genuine anaerobic liquid gasket,

Three Bond TB1215 or TB1207D.

Transmission case

Grommet

Engine rear plate Starter Sealant

Rear plate

Unit: mm (in)

SMT324DB ZD30DDTi engine

For starterDowel hole

Dowel hole

(Not used) M/T to engine

Engine to M/T

REMOVAL AND INSTALLATIONFS5R50B

MT-1008

Page 929 of 1033

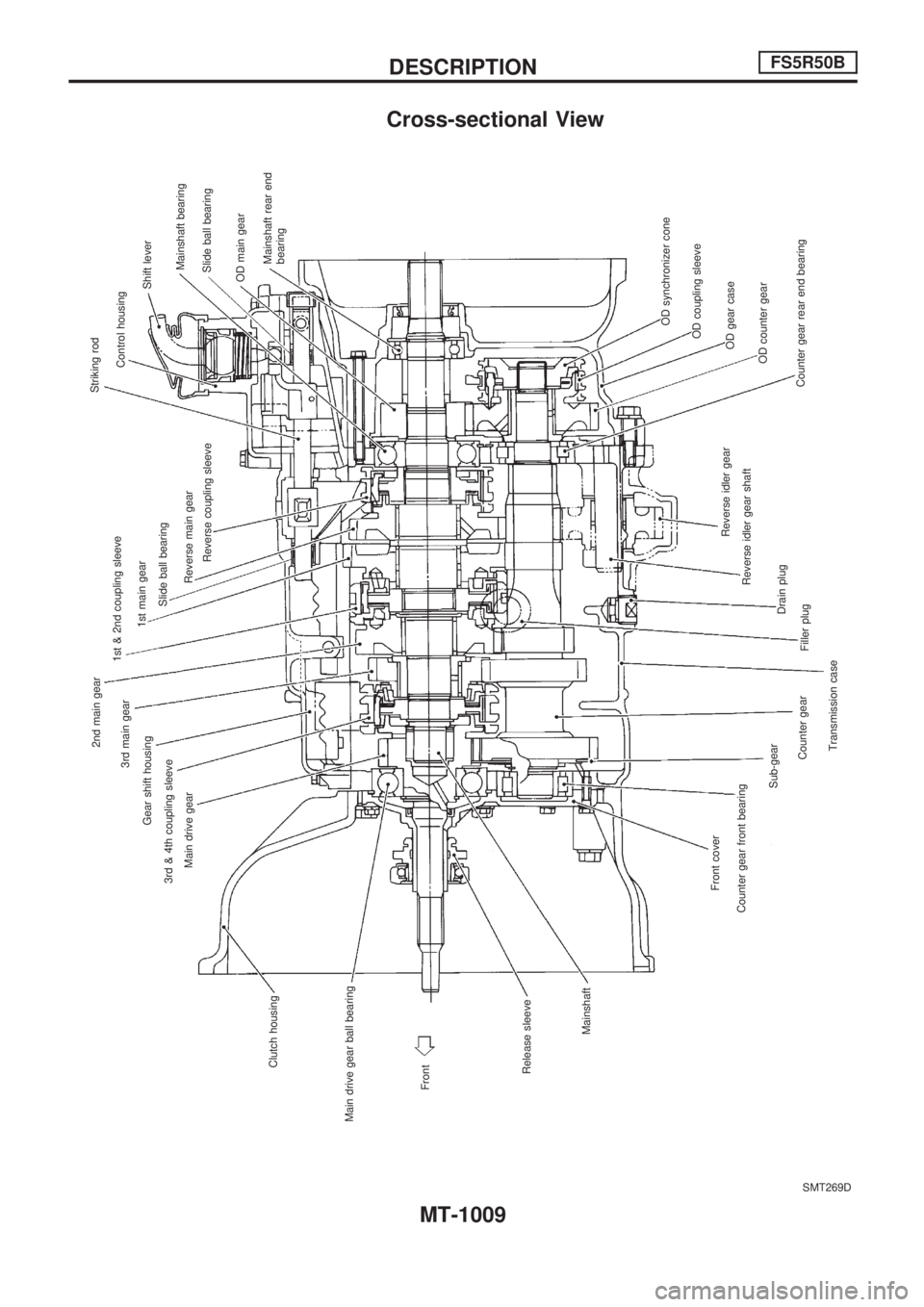

Cross-sectional View

SMT269D

Front Main drive gear ball bearingClutch housingMain drive gear 3rd & 4th coupling sleeveGear shift housing3rd main gear2nd main gear

1st & 2nd coupling sleeve

1st main gear

Slide ball bearing

Reverse main gear

Reverse coupling sleeveStriking rod

Control housing

Shift lever

Mainshaft bearing

Slide ball bearing

OD main gear

Mainshaft rear end

bearing

OD synchronizer cone

OD coupling sleeve

OD gear case

OD counter gear

Counter gear rear end bearing Reverse idler gear

Reverse idler gear shaft

Drain plug

Filler plug

Transmission case Counter gear Sub-gear Counter gear front bearingFront cover Mainshaft Release sleeve

DESCRIPTIONFS5R50B

MT-1009

Page 930 of 1033

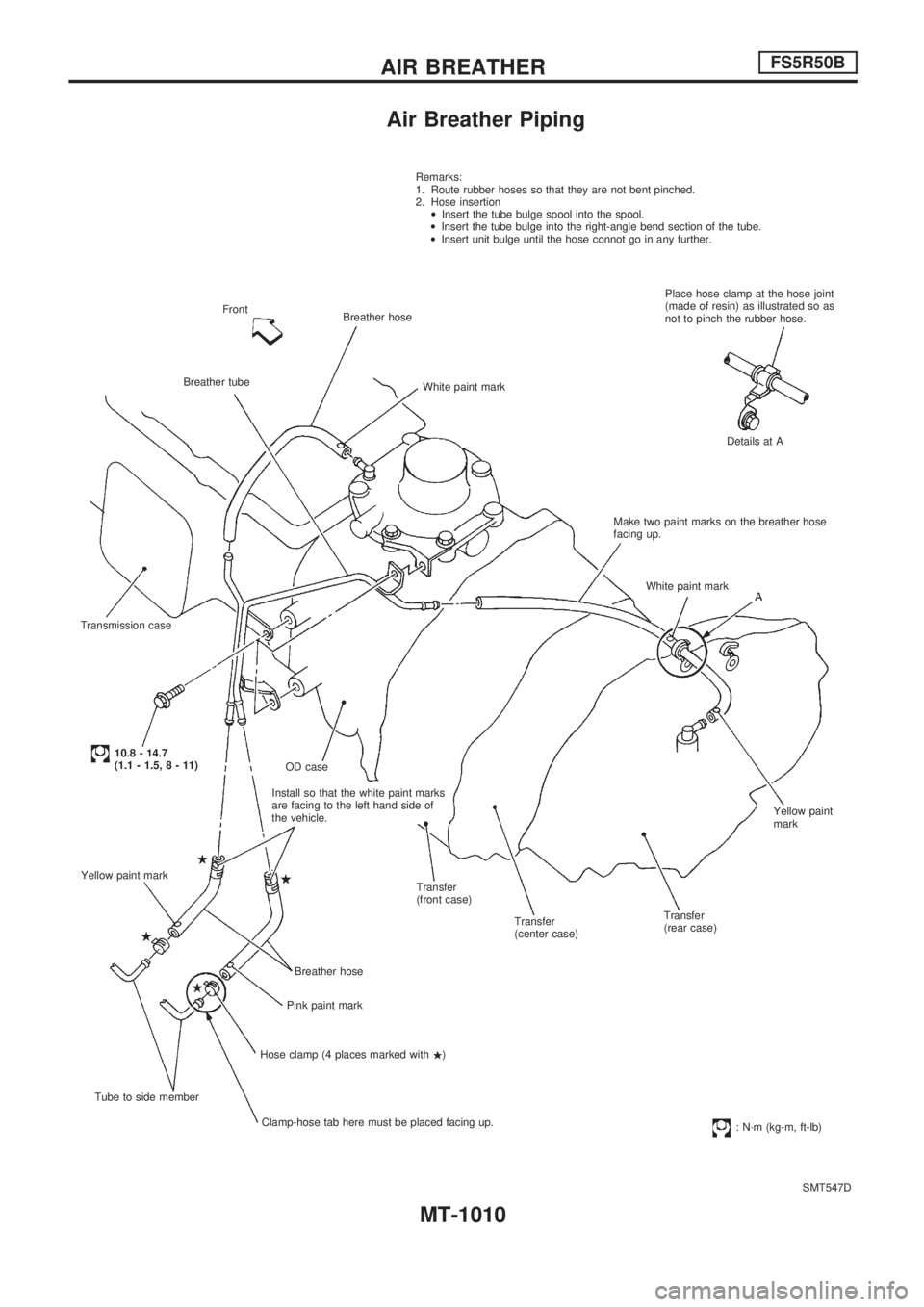

Air Breather Piping

SMT547D Remarks:

1. Route rubber hoses so that they are not bent pinched.

2. Hose insertion

·Insert the tube bulge spool into the spool.

·Insert the tube bulge into the right-angle bend section of the tube.

·Insert unit bulge until the hose connot go in any further.

Place hose clamp at the hose joint

(made of resin) as illustrated so as

not to pinch the rubber hose.

Details at A

Make two paint marks on the breather hose

facing up.

White paint mark

Yellow paint

mark

Transfer

(rear case) Transfer

(center case) Transfer

(front case) Install so that the white paint marks

are facing to the left hand side of

the vehicle.OD case

Breather hose

Pink paint mark

Hose clamp (4 places marked with.)

Clamp-hose tab here must be placed facing up. Tube to side member Yellow paint mark

10.8 - 14.7

(1.1 - 1.5, 8 - 11) Transmission caseBreather tubeFront

Breather hose

White paint mark

: N´m (kg-m, ft-lb)

AIR BREATHERFS5R50B

MT-1010