NISSAN PATROL 2000 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 911 of 1033

3. Drain oil and fill with new engine oil.

Oil grade: API CF4 or ACEA B3-96.98 or ACEA B3/E3-

96.98

Viscosity:

See ªRECOMMENDED FLUIDS AND

LUBRICANTSº, MA-1009.

Refill oil capacity (approximate):

Without oil filter change

5.2!(4-5/8 Imp qt)

With oil filter change

5.7!(5 Imp qt)

CAUTION:

+Be sure to clean and install oil pan drain plug with

washer.

Drain plug:

:54-58Nzm (5.5 - 6.0 kg-m, 40 - 43 ft-lb)

+The refill capacity changes depending on the oil tem-

perature and drain time; use these valves as a reference

and be certain to check with the dipstick when changing

the oil.

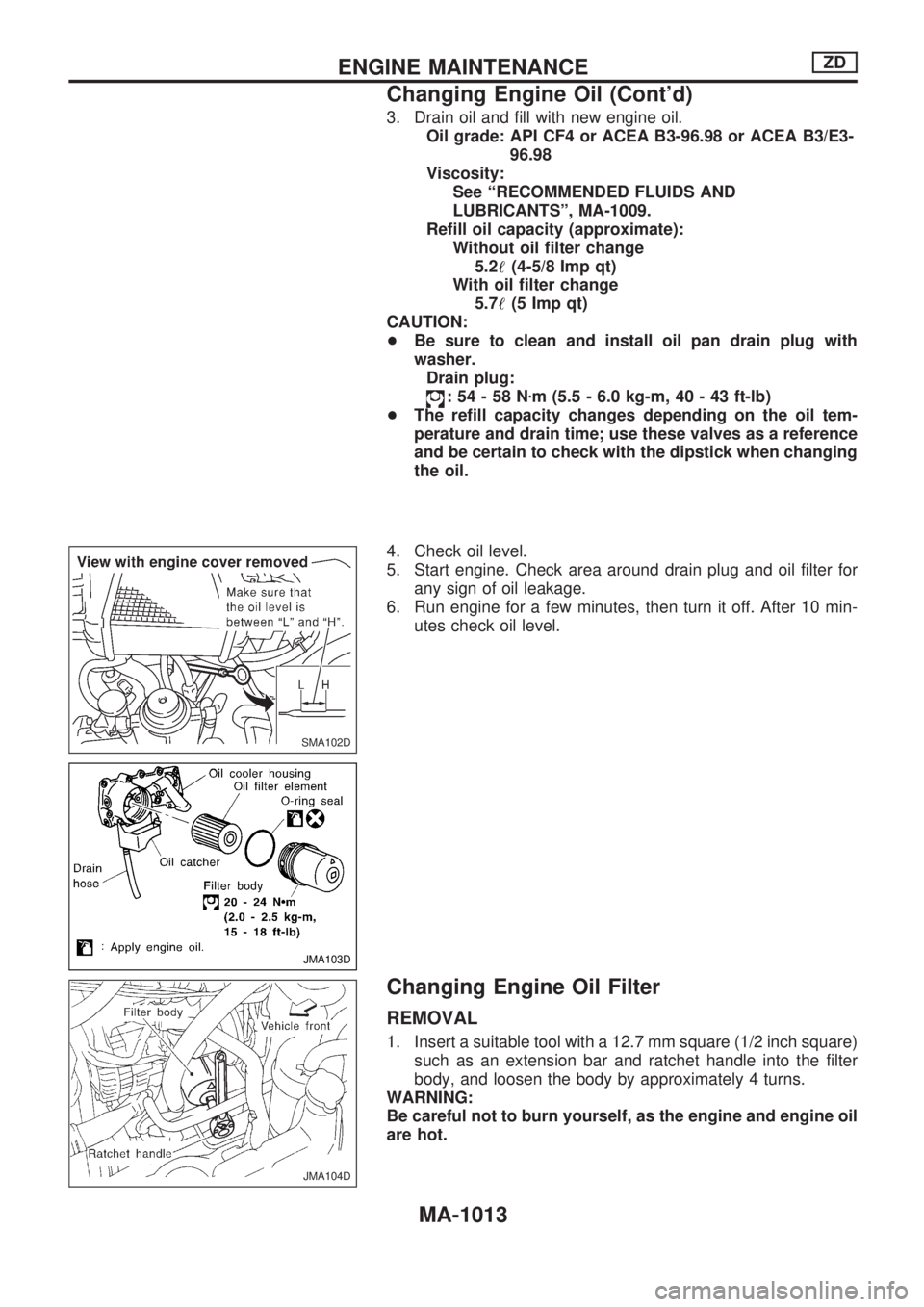

4. Check oil level.

5. Start engine. Check area around drain plug and oil filter for

any sign of oil leakage.

6. Run engine for a few minutes, then turn it off. After 10 min-

utes check oil level.

Changing Engine Oil Filter

REMOVAL

1. Insert a suitable tool with a 12.7 mm square (1/2 inch square)

such as an extension bar and ratchet handle into the filter

body, and loosen the body by approximately 4 turns.

WARNING:

Be careful not to burn yourself, as the engine and engine oil

are hot.

SMA102D

JMA103D

JMA104D

ENGINE MAINTENANCEZD

Changing Engine Oil (Cont'd)

MA-1013

Page 912 of 1033

2. Set themmark of the filter body to the top position and dis-

charge the oil.

+Receive the oil discharged from the drain hose in a tray.

+About 500 cc (17.6 Imp fl oz) of oil will be discharged in about

3 minutes.

+The oil is discharged from the oil catcher to under the vehicle

through the drain hose.

3. Remove the filter body, and then remove the oil filter ele-

ment.

CAUTION:

+If the engine oil gets on the engine or vehicle, thoroughly

wipe it off.

+Thoroughly wipe off the oil remaining in the oil catcher.

(This is to prevent misidentifying oil leaking from the oil

catcher as oil leaking from the engine.)

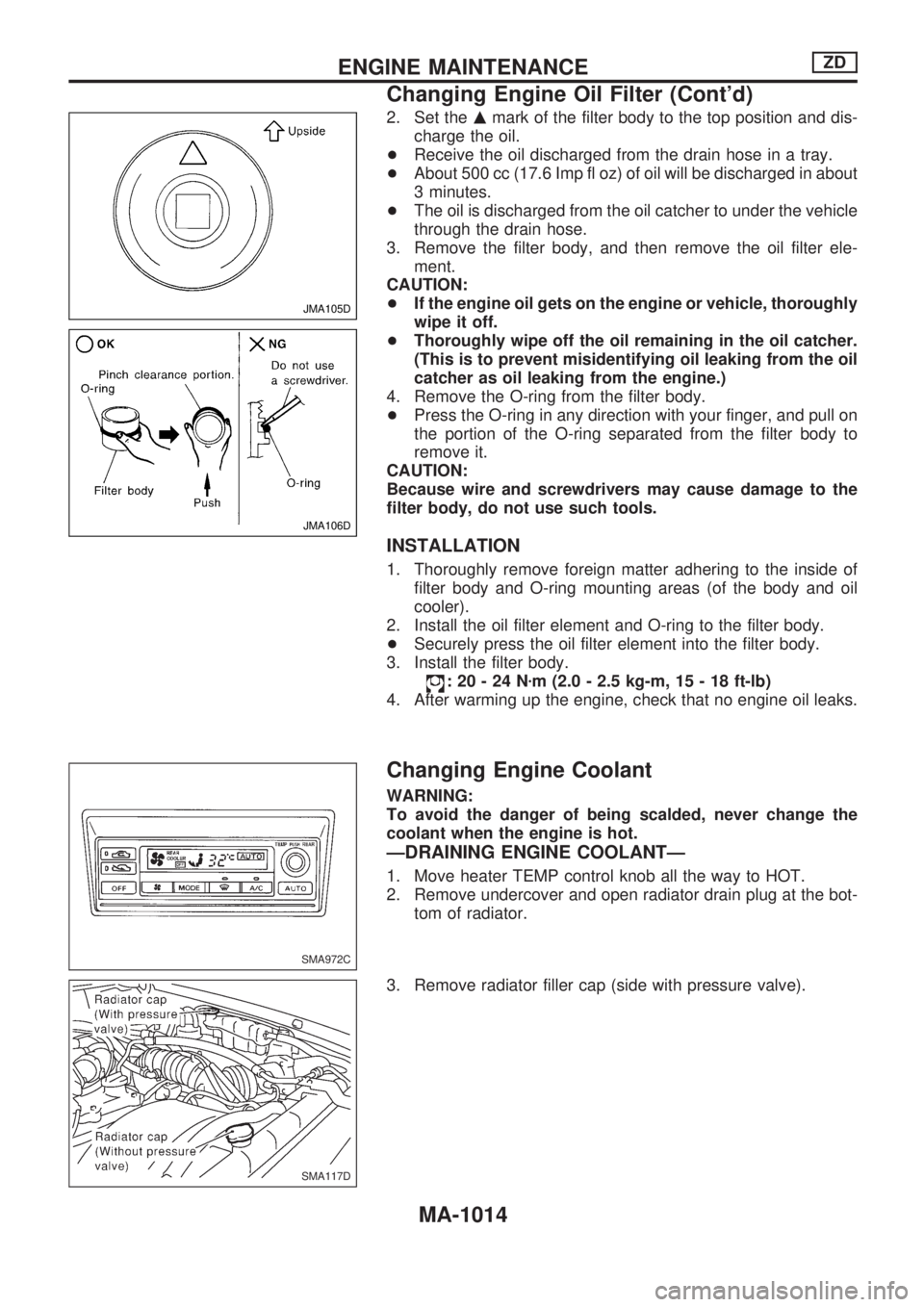

4. Remove the O-ring from the filter body.

+Press the O-ring in any direction with your finger, and pull on

the portion of the O-ring separated from the filter body to

remove it.

CAUTION:

Because wire and screwdrivers may cause damage to the

filter body, do not use such tools.

INSTALLATION

1. Thoroughly remove foreign matter adhering to the inside of

filter body and O-ring mounting areas (of the body and oil

cooler).

2. Install the oil filter element and O-ring to the filter body.

+Securely press the oil filter element into the filter body.

3. Install the filter body.

:20-24Nzm (2.0 - 2.5 kg-m, 15 - 18 ft-lb)

4. After warming up the engine, check that no engine oil leaks.

Changing Engine Coolant

WARNING:

To avoid the danger of being scalded, never change the

coolant when the engine is hot.

ÐDRAINING ENGINE COOLANTÐ

1. Move heater TEMP control knob all the way to HOT.

2. Remove undercover and open radiator drain plug at the bot-

tom of radiator.

3. Remove radiator filler cap (side with pressure valve).

JMA105D

JMA106D

SMA972C

SMA117D

ENGINE MAINTENANCEZD

Changing Engine Oil Filter (Cont'd)

MA-1014

Page 913 of 1033

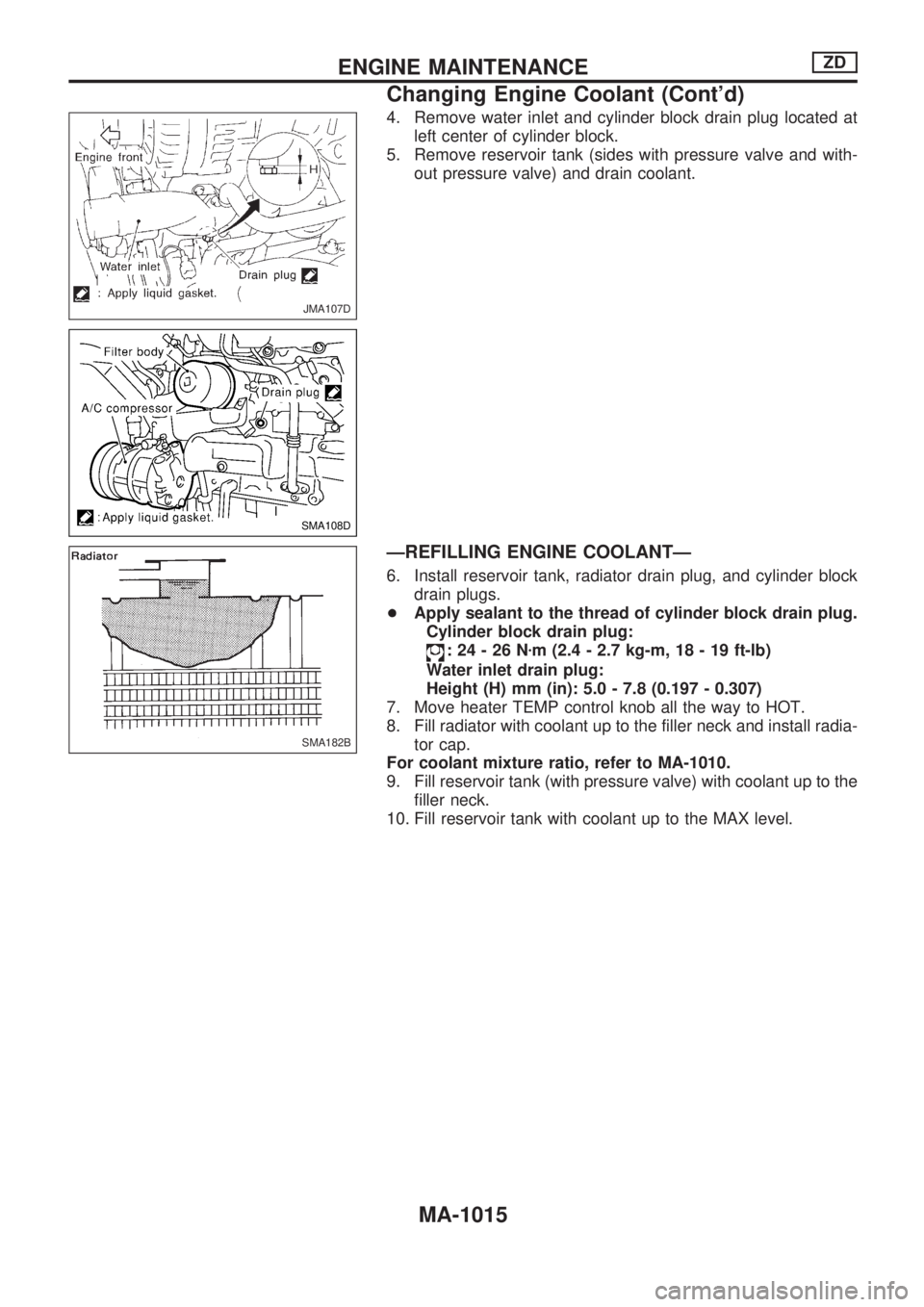

4. Remove water inlet and cylinder block drain plug located at

left center of cylinder block.

5. Remove reservoir tank (sides with pressure valve and with-

out pressure valve) and drain coolant.

ÐREFILLING ENGINE COOLANTÐ

6. Install reservoir tank, radiator drain plug, and cylinder block

drain plugs.

+Apply sealant to the thread of cylinder block drain plug.

Cylinder block drain plug:

:24-26Nzm (2.4 - 2.7 kg-m, 18 - 19 ft-lb)

Water inlet drain plug:

Height (H) mm (in): 5.0 - 7.8 (0.197 - 0.307)

7. Move heater TEMP control knob all the way to HOT.

8. Fill radiator with coolant up to the filler neck and install radia-

tor cap.

For coolant mixture ratio, refer to MA-1010.

9. Fill reservoir tank (with pressure valve) with coolant up to the

filler neck.

10. Fill reservoir tank with coolant up to the MAX level.

JMA107D

SMA108D

SMA182B

ENGINE MAINTENANCEZD

Changing Engine Coolant (Cont'd)

MA-1015

Page 914 of 1033

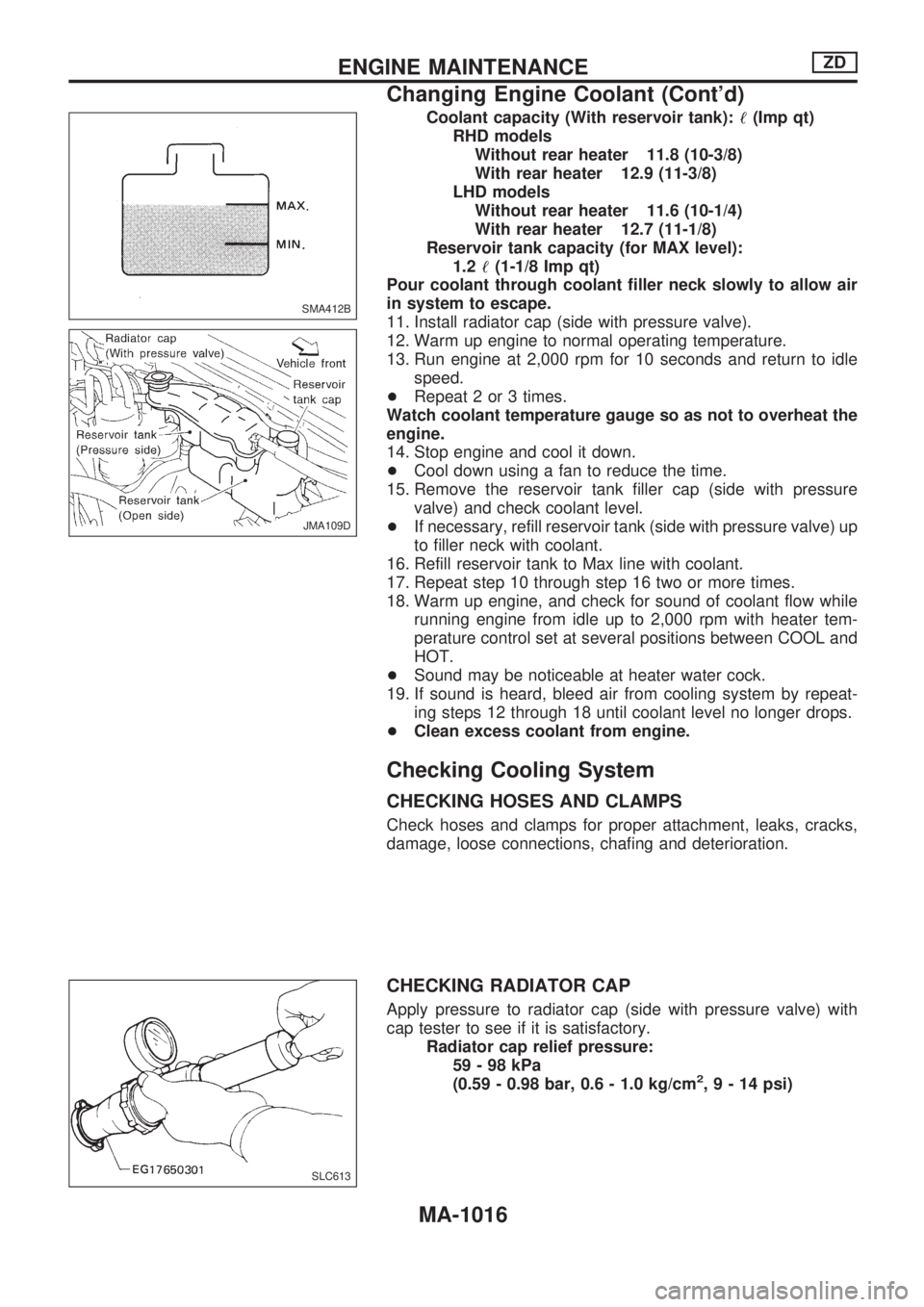

Coolant capacity (With reservoir tank):!(Imp qt)

RHD models

Without rear heater 11.8 (10-3/8)

With rear heater 12.9 (11-3/8)

LHD models

Without rear heater 11.6 (10-1/4)

With rear heater 12.7 (11-1/8)

Reservoir tank capacity (for MAX level):

1.2!(1-1/8 Imp qt)

Pour coolant through coolant filler neck slowly to allow air

in system to escape.

11. Install radiator cap (side with pressure valve).

12. Warm up engine to normal operating temperature.

13. Run engine at 2,000 rpm for 10 seconds and return to idle

speed.

+Repeat 2 or 3 times.

Watch coolant temperature gauge so as not to overheat the

engine.

14. Stop engine and cool it down.

+Cool down using a fan to reduce the time.

15. Remove the reservoir tank filler cap (side with pressure

valve) and check coolant level.

+If necessary, refill reservoir tank (side with pressure valve) up

to filler neck with coolant.

16. Refill reservoir tank to Max line with coolant.

17. Repeat step 10 through step 16 two or more times.

18. Warm up engine, and check for sound of coolant flow while

running engine from idle up to 2,000 rpm with heater tem-

perature control set at several positions between COOL and

HOT.

+Sound may be noticeable at heater water cock.

19. If sound is heard, bleed air from cooling system by repeat-

ing steps 12 through 18 until coolant level no longer drops.

+Clean excess coolant from engine.

Checking Cooling System

CHECKING HOSES AND CLAMPS

Check hoses and clamps for proper attachment, leaks, cracks,

damage, loose connections, chafing and deterioration.

CHECKING RADIATOR CAP

Apply pressure to radiator cap (side with pressure valve) with

cap tester to see if it is satisfactory.

Radiator cap relief pressure:

59-98kPa

(0.59 - 0.98 bar, 0.6 - 1.0 kg/cm

2,9-14psi)

SMA412B

JMA109D

SLC613

ENGINE MAINTENANCEZD

Changing Engine Coolant (Cont'd)

MA-1016

Page 915 of 1033

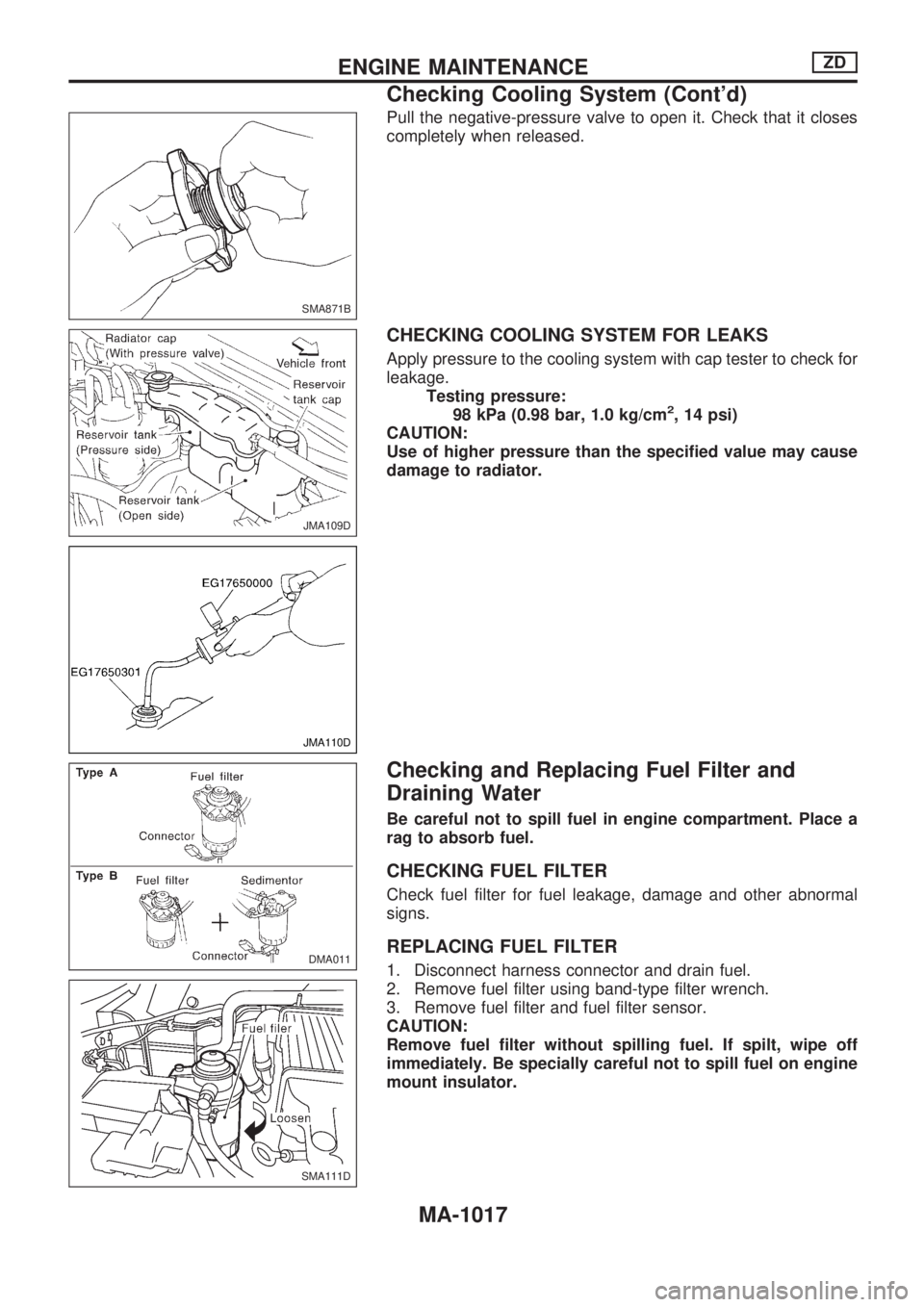

Pull the negative-pressure valve to open it. Check that it closes

completely when released.

CHECKING COOLING SYSTEM FOR LEAKS

Apply pressure to the cooling system with cap tester to check for

leakage.

Testing pressure:

98 kPa (0.98 bar, 1.0 kg/cm

2, 14 psi)

CAUTION:

Use of higher pressure than the specified value may cause

damage to radiator.

Checking and Replacing Fuel Filter and

Draining Water

Be careful not to spill fuel in engine compartment. Place a

rag to absorb fuel.

CHECKING FUEL FILTER

Check fuel filter for fuel leakage, damage and other abnormal

signs.

REPLACING FUEL FILTER

1. Disconnect harness connector and drain fuel.

2. Remove fuel filter using band-type filter wrench.

3. Remove fuel filter and fuel filter sensor.

CAUTION:

Remove fuel filter without spilling fuel. If spilt, wipe off

immediately. Be specially careful not to spill fuel on engine

mount insulator.

SMA871B

JMA109D

JMA110D

DMA011

SMA111D

ENGINE MAINTENANCEZD

Checking Cooling System (Cont'd)

MA-1017

Page 916 of 1033

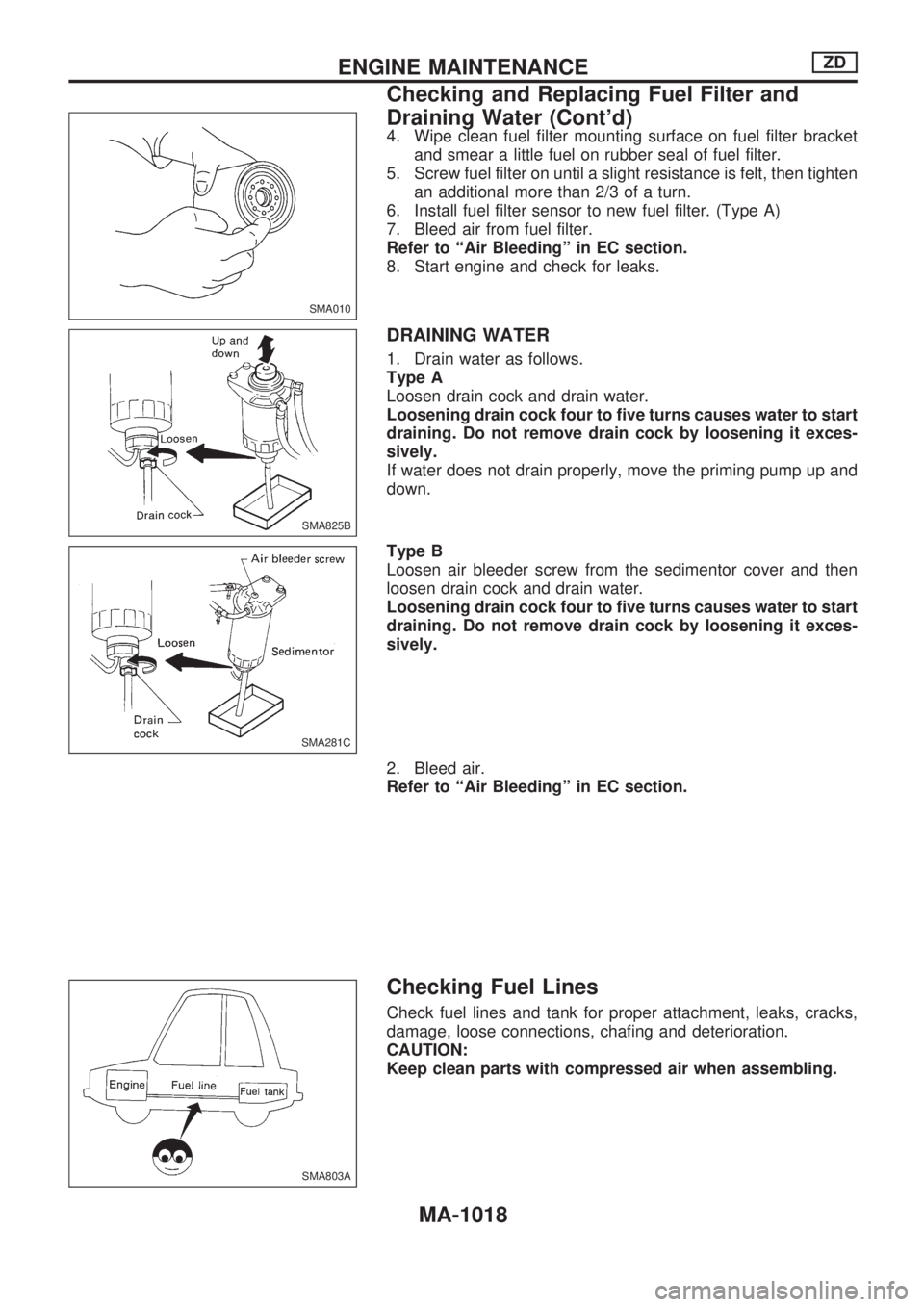

4. Wipe clean fuel filter mounting surface on fuel filter bracket

and smear a little fuel on rubber seal of fuel filter.

5. Screw fuel filter on until a slight resistance is felt, then tighten

an additional more than 2/3 of a turn.

6. Install fuel filter sensor to new fuel filter. (Type A)

7. Bleed air from fuel filter.

Refer to ªAir Bleedingº in EC section.

8. Start engine and check for leaks.

DRAINING WATER

1. Drain water as follows.

Type A

Loosen drain cock and drain water.

Loosening drain cock four to five turns causes water to start

draining. Do not remove drain cock by loosening it exces-

sively.

If water does not drain properly, move the priming pump up and

down.

Type B

Loosen air bleeder screw from the sedimentor cover and then

loosen drain cock and drain water.

Loosening drain cock four to five turns causes water to start

draining. Do not remove drain cock by loosening it exces-

sively.

2. Bleed air.

Refer to ªAir Bleedingº in EC section.

Checking Fuel Lines

Check fuel lines and tank for proper attachment, leaks, cracks,

damage, loose connections, chafing and deterioration.

CAUTION:

Keep clean parts with compressed air when assembling.

SMA010

SMA825B

SMA281C

SMA803A

ENGINE MAINTENANCEZD

Checking and Replacing Fuel Filter and

Draining Water (Cont'd)

MA-1018

Page 917 of 1033

Cleaning and Replacing Air Cleaner Filter

VISCOUS PAPER TYPE

The viscous paper type air cleaner filter does not require any

cleaning operation between renewal.

SMA114D

ENGINE MAINTENANCEZD

MA-1019

Page 918 of 1033

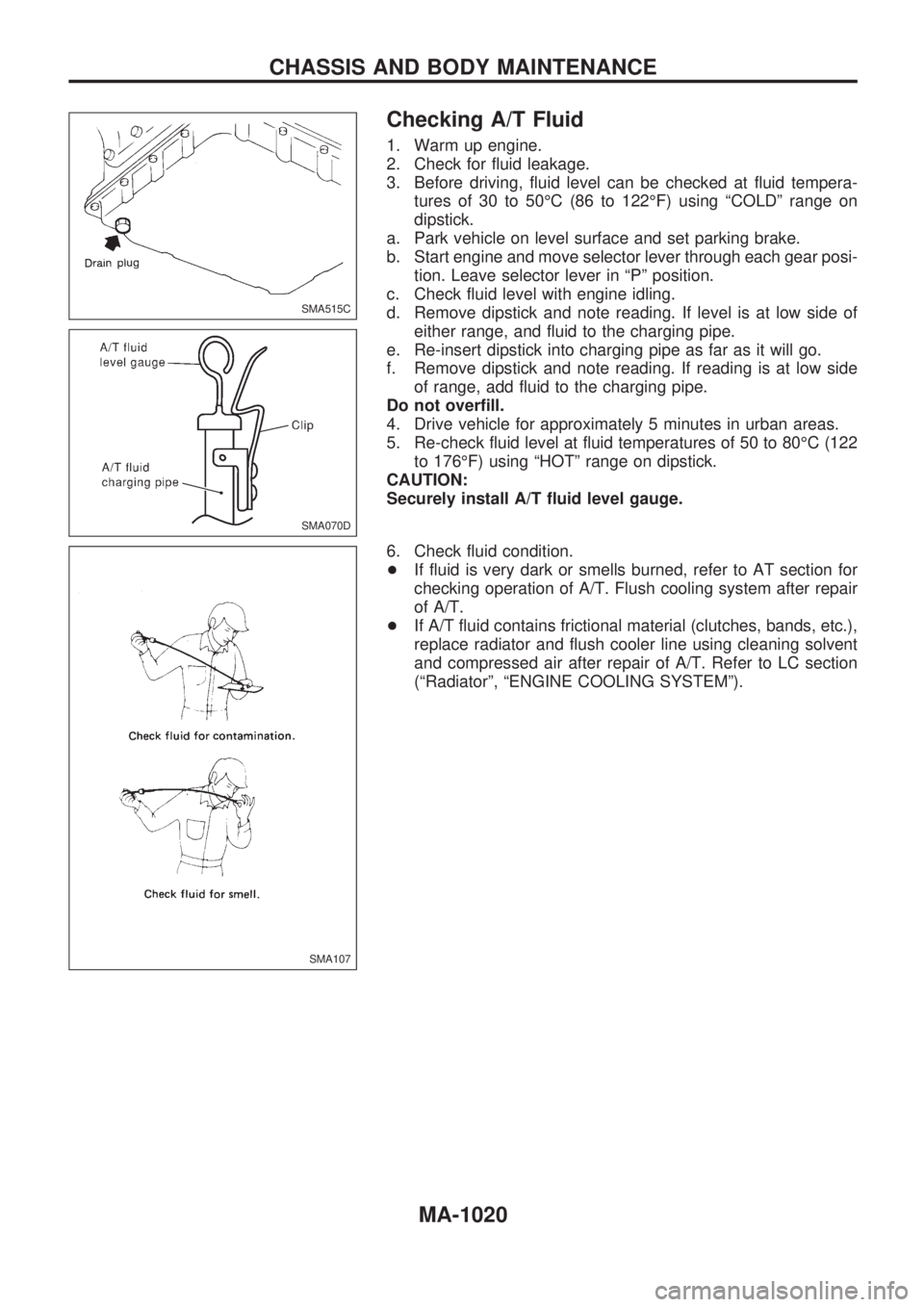

Checking A/T Fluid

1. Warm up engine.

2. Check for fluid leakage.

3. Before driving, fluid level can be checked at fluid tempera-

tures of 30 to 50ÉC (86 to 122ÉF) using ªCOLDº range on

dipstick.

a. Park vehicle on level surface and set parking brake.

b. Start engine and move selector lever through each gear posi-

tion. Leave selector lever in ªPº position.

c. Check fluid level with engine idling.

d. Remove dipstick and note reading. If level is at low side of

either range, and fluid to the charging pipe.

e. Re-insert dipstick into charging pipe as far as it will go.

f. Remove dipstick and note reading. If reading is at low side

of range, add fluid to the charging pipe.

Do not overfill.

4. Drive vehicle for approximately 5 minutes in urban areas.

5. Re-check fluid level at fluid temperatures of 50 to 80ÉC (122

to 176ÉF) using ªHOTº range on dipstick.

CAUTION:

Securely install A/T fluid level gauge.

6. Check fluid condition.

+If fluid is very dark or smells burned, refer to AT section for

checking operation of A/T. Flush cooling system after repair

of A/T.

+If A/T fluid contains frictional material (clutches, bands, etc.),

replace radiator and flush cooler line using cleaning solvent

and compressed air after repair of A/T. Refer to LC section

(ªRadiatorº, ªENGINE COOLING SYSTEMº).

SMA515C

SMA070D

SMA107

CHASSIS AND BODY MAINTENANCE

MA-1020

Page 919 of 1033

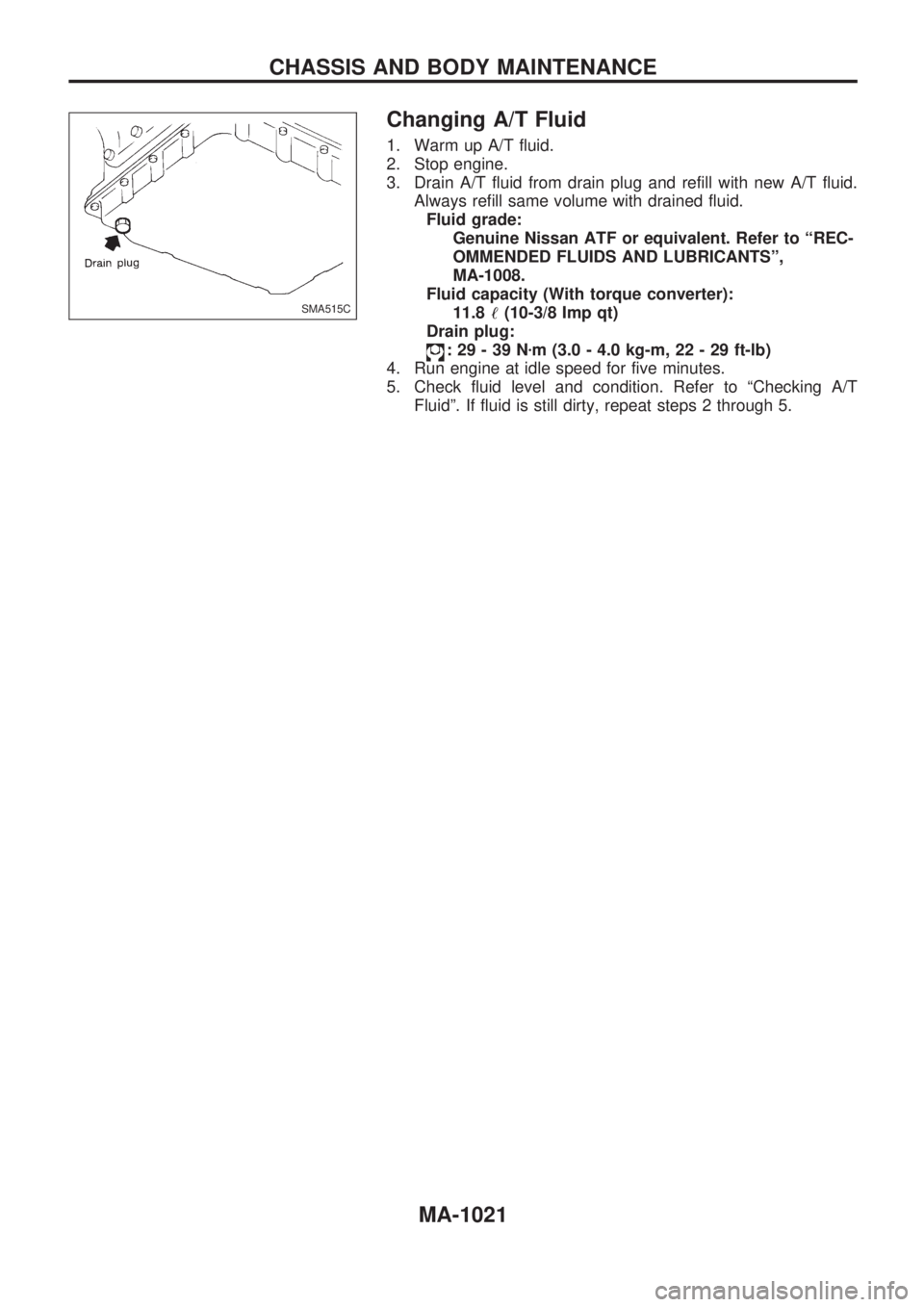

Changing A/T Fluid

1. Warm up A/T fluid.

2. Stop engine.

3. Drain A/T fluid from drain plug and refill with new A/T fluid.

Always refill same volume with drained fluid.

Fluid grade:

Genuine Nissan ATF or equivalent. Refer to ªREC-

OMMENDED FLUIDS AND LUBRICANTSº,

MA-1008.

Fluid capacity (With torque converter):

11.8!(10-3/8 Imp qt)

Drain plug:

:29-39Nzm (3.0 - 4.0 kg-m, 22 - 29 ft-lb)

4. Run engine at idle speed for five minutes.

5. Check fluid level and condition. Refer to ªChecking A/T

Fluidº. If fluid is still dirty, repeat steps 2 through 5.

SMA515C

CHASSIS AND BODY MAINTENANCE

MA-1021

Page 920 of 1033

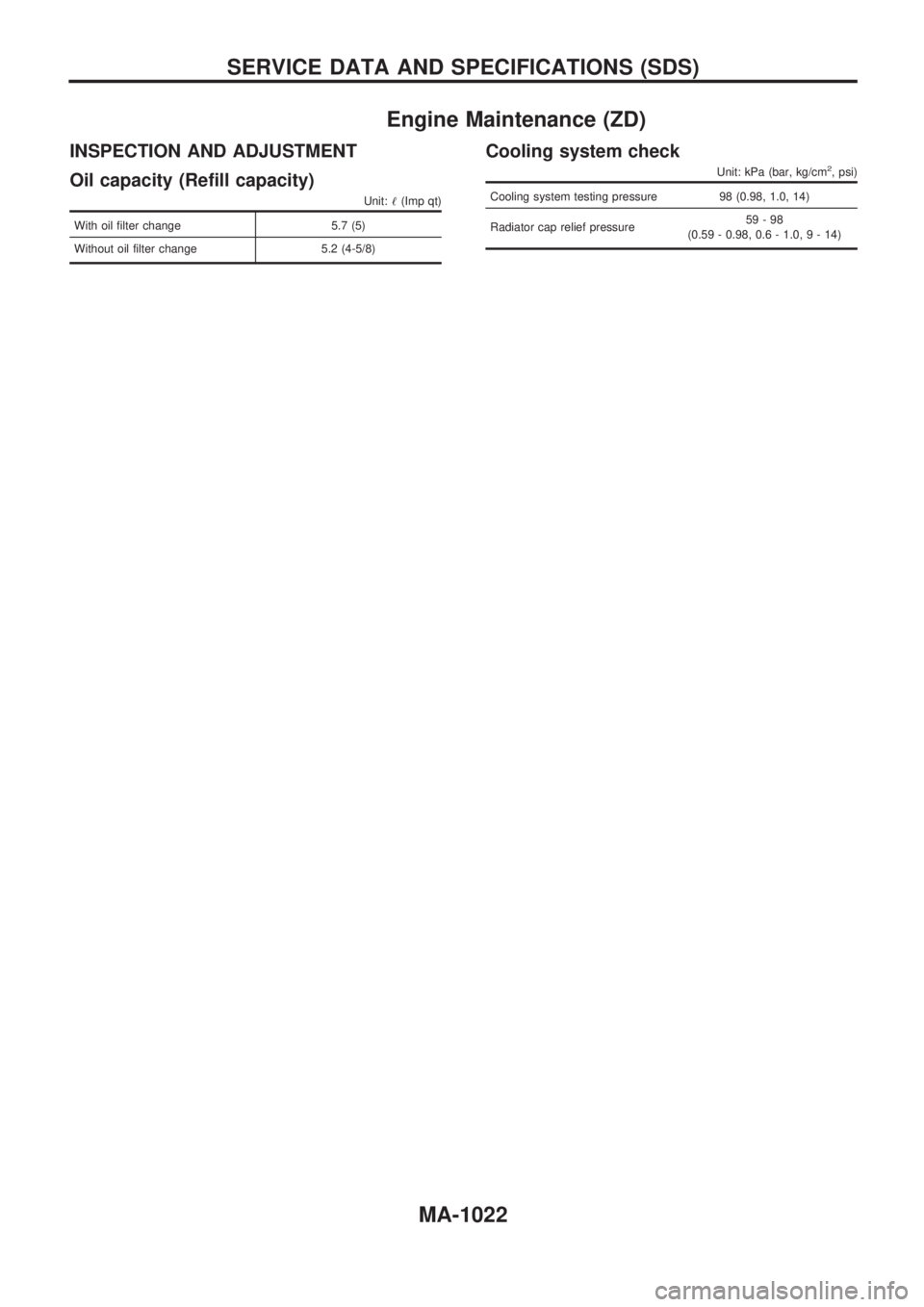

Engine Maintenance (ZD)

INSPECTION AND ADJUSTMENT

Oil capacity (Refill capacity)

Unit:!(Imp qt)

With oil filter change 5.7 (5)

Without oil filter change 5.2 (4-5/8)

Cooling system check

Unit: kPa (bar, kg/cm2, psi)

Cooling system testing pressure 98 (0.98, 1.0, 14)

Radiator cap relief pressure59-98

(0.59 - 0.98, 0.6 - 1.0,9-14)

SERVICE DATA AND SPECIFICATIONS (SDS)

MA-1022