NISSAN PATROL 2000 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 951 of 1033

10. Select proper 3rd & 4th hub snap ring to minimize clearance

of groove, then install it.

Allowable clearance of groove:

0 - 0.1 mm (0 - 0.004 in)

3rd & 4th hub snap ring:

Refer to SDS, MT-1038.

11. Measure 1st, 2nd, 3rd and reverse main gear end plays as

the final check. Ð Refer to ``Disassembly''.

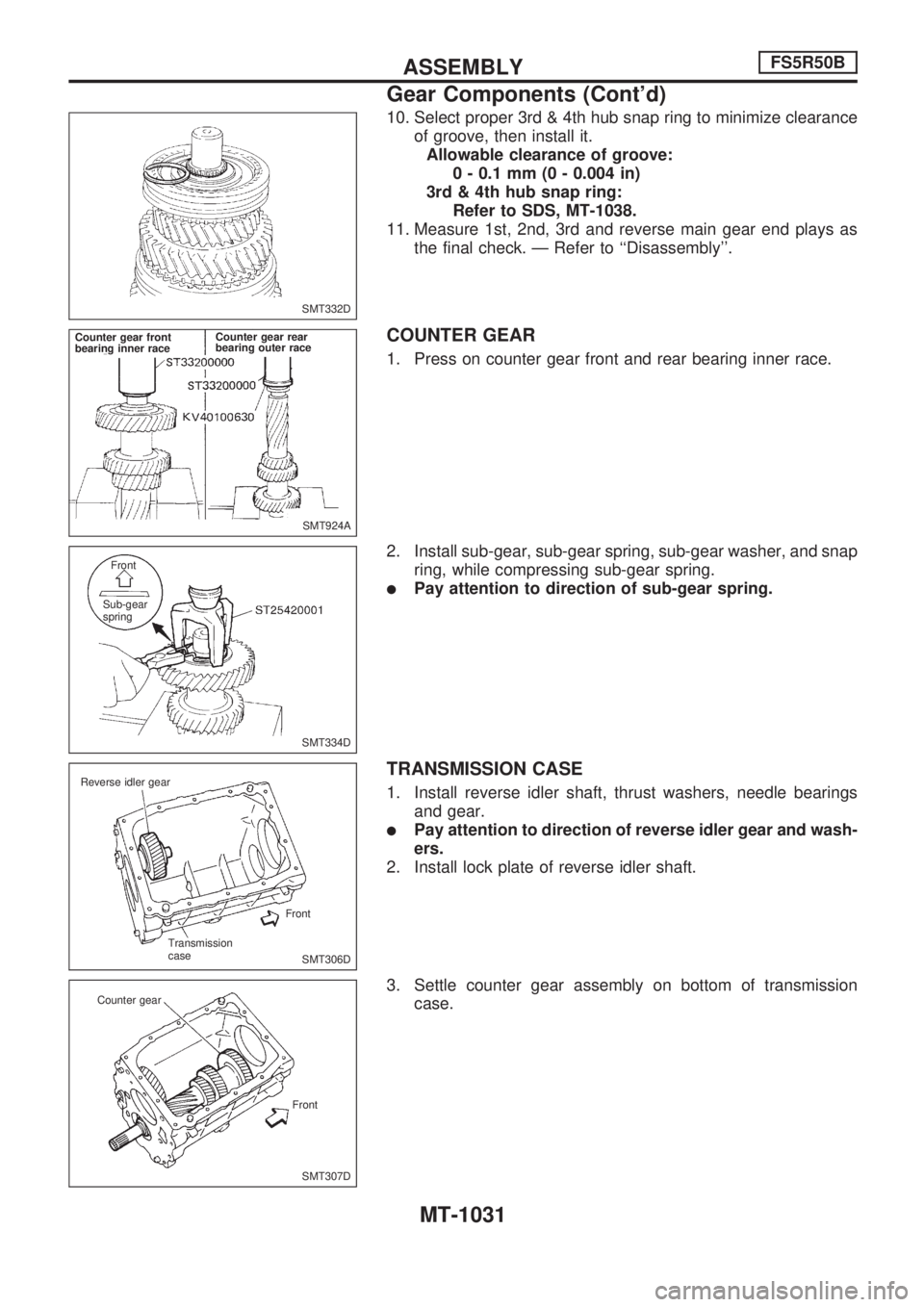

COUNTER GEAR

1. Press on counter gear front and rear bearing inner race.

2. Install sub-gear, sub-gear spring, sub-gear washer, and snap

ring, while compressing sub-gear spring.

lPay attention to direction of sub-gear spring.

TRANSMISSION CASE

1. Install reverse idler shaft, thrust washers, needle bearings

and gear.

lPay attention to direction of reverse idler gear and wash-

ers.

2. Install lock plate of reverse idler shaft.

3. Settle counter gear assembly on bottom of transmission

case.

SMT332D

SMT924A Counter gear front

bearing inner raceCounter gear rear

bearing outer race

SMT334D Front

Sub-gear

spring

SMT306D Reverse idler gear

Front

Transmission

case

SMT307D Counter gear

Front

ASSEMBLYFS5R50B

Gear Components (Cont'd)

MT-1031

Page 952 of 1033

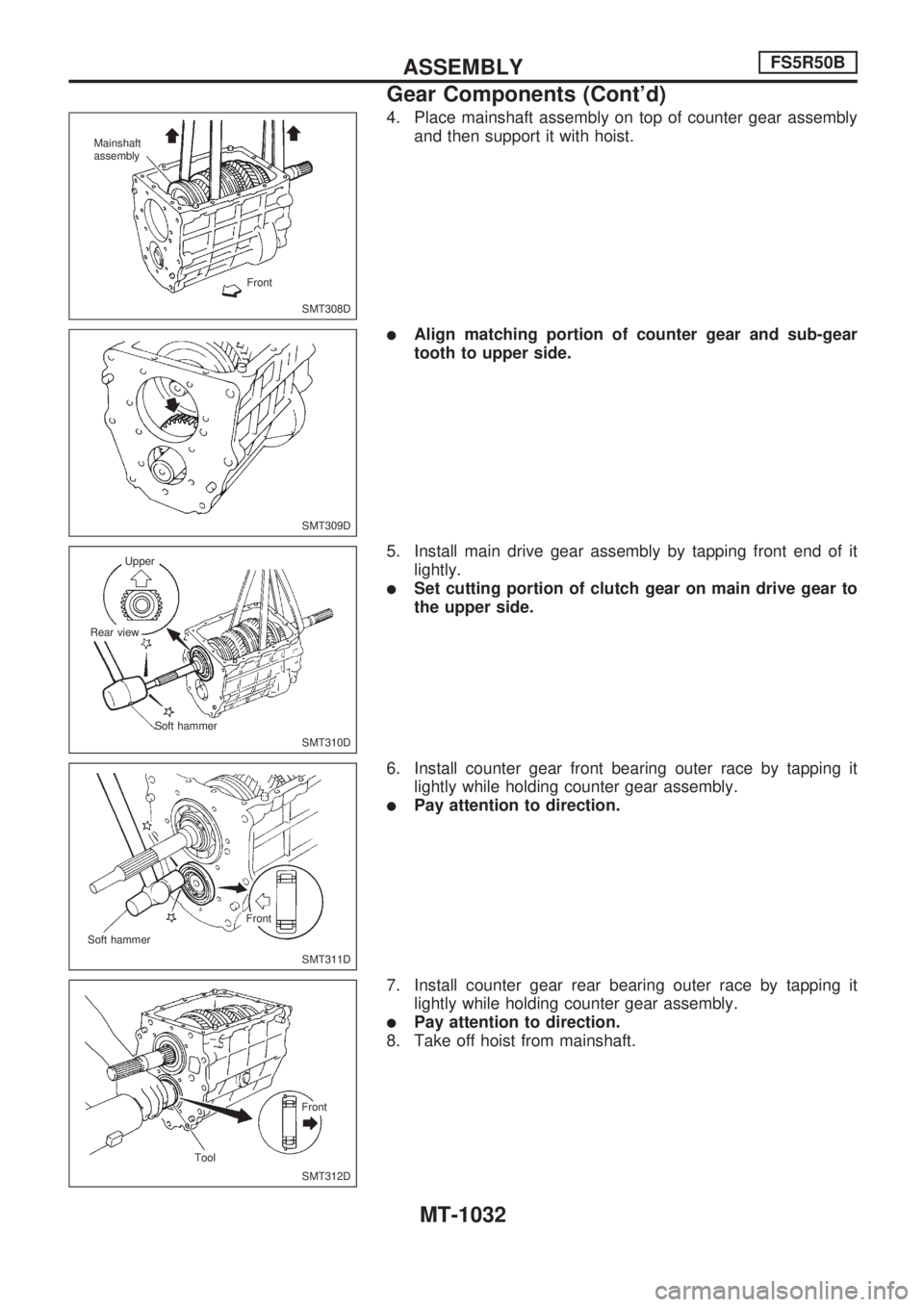

4. Place mainshaft assembly on top of counter gear assembly

and then support it with hoist.

lAlign matching portion of counter gear and sub-gear

tooth to upper side.

5. Install main drive gear assembly by tapping front end of it

lightly.

lSet cutting portion of clutch gear on main drive gear to

the upper side.

6. Install counter gear front bearing outer race by tapping it

lightly while holding counter gear assembly.

lPay attention to direction.

7. Install counter gear rear bearing outer race by tapping it

lightly while holding counter gear assembly.

lPay attention to direction.

8. Take off hoist from mainshaft.

SMT308D Mainshaft

assembly

Front

SMT309D

SMT310D Upper

Rear view

Soft hammer

SMT311D Front

Soft hammer

SMT312D Front

Tool

ASSEMBLYFS5R50B

Gear Components (Cont'd)

MT-1032

Page 953 of 1033

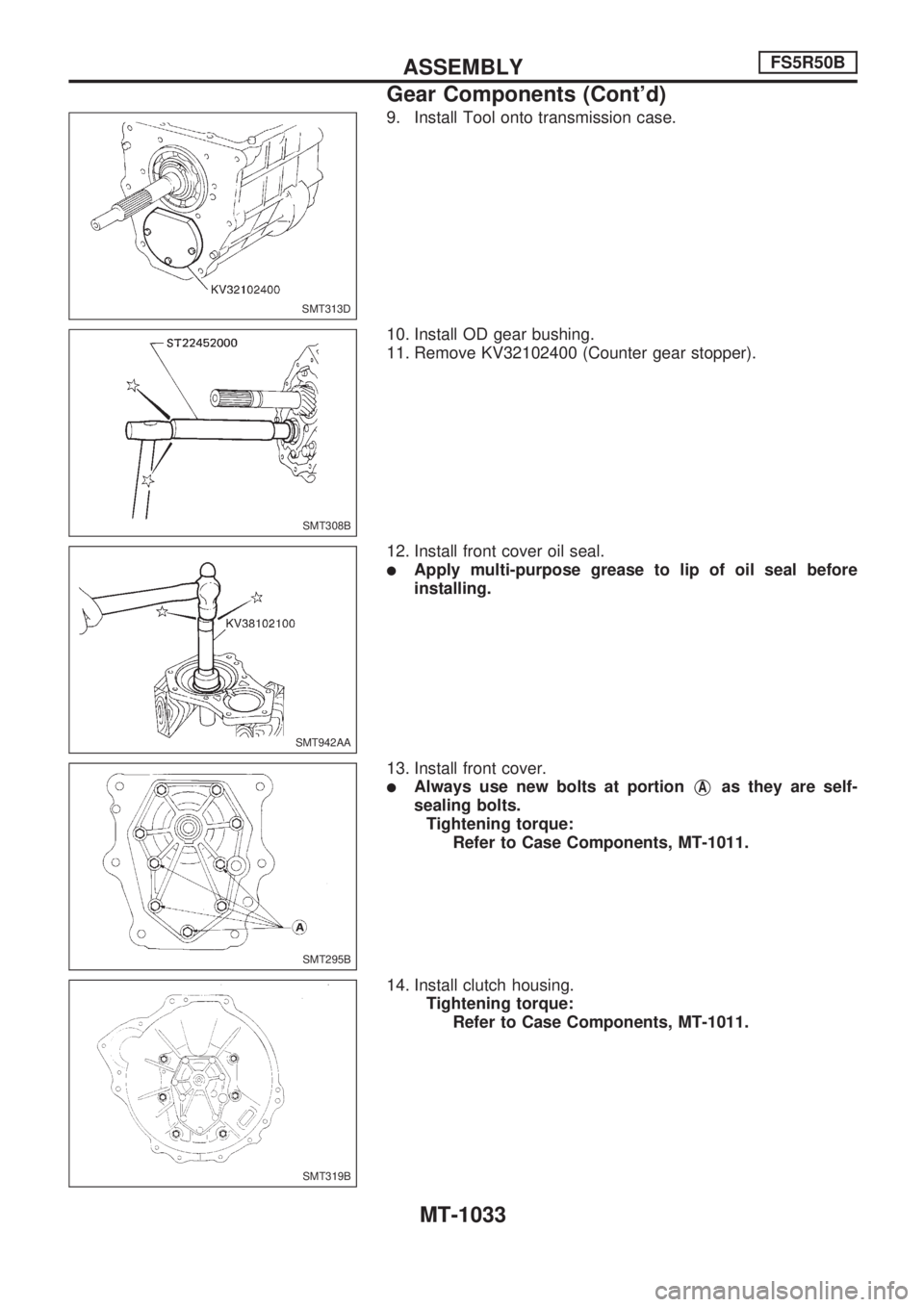

9. Install Tool onto transmission case.

10. Install OD gear bushing.

11. Remove KV32102400 (Counter gear stopper).

12. Install front cover oil seal.

lApply multi-purpose grease to lip of oil seal before

installing.

13. Install front cover.

lAlways use new bolts at portionVAas they are self-

sealing bolts.

Tightening torque:

Refer to Case Components, MT-1011.

14. Install clutch housing.

Tightening torque:

Refer to Case Components, MT-1011.

SMT313D

SMT308B

SMT942AA

SMT295B

SMT319B

ASSEMBLYFS5R50B

Gear Components (Cont'd)

MT-1033

Page 954 of 1033

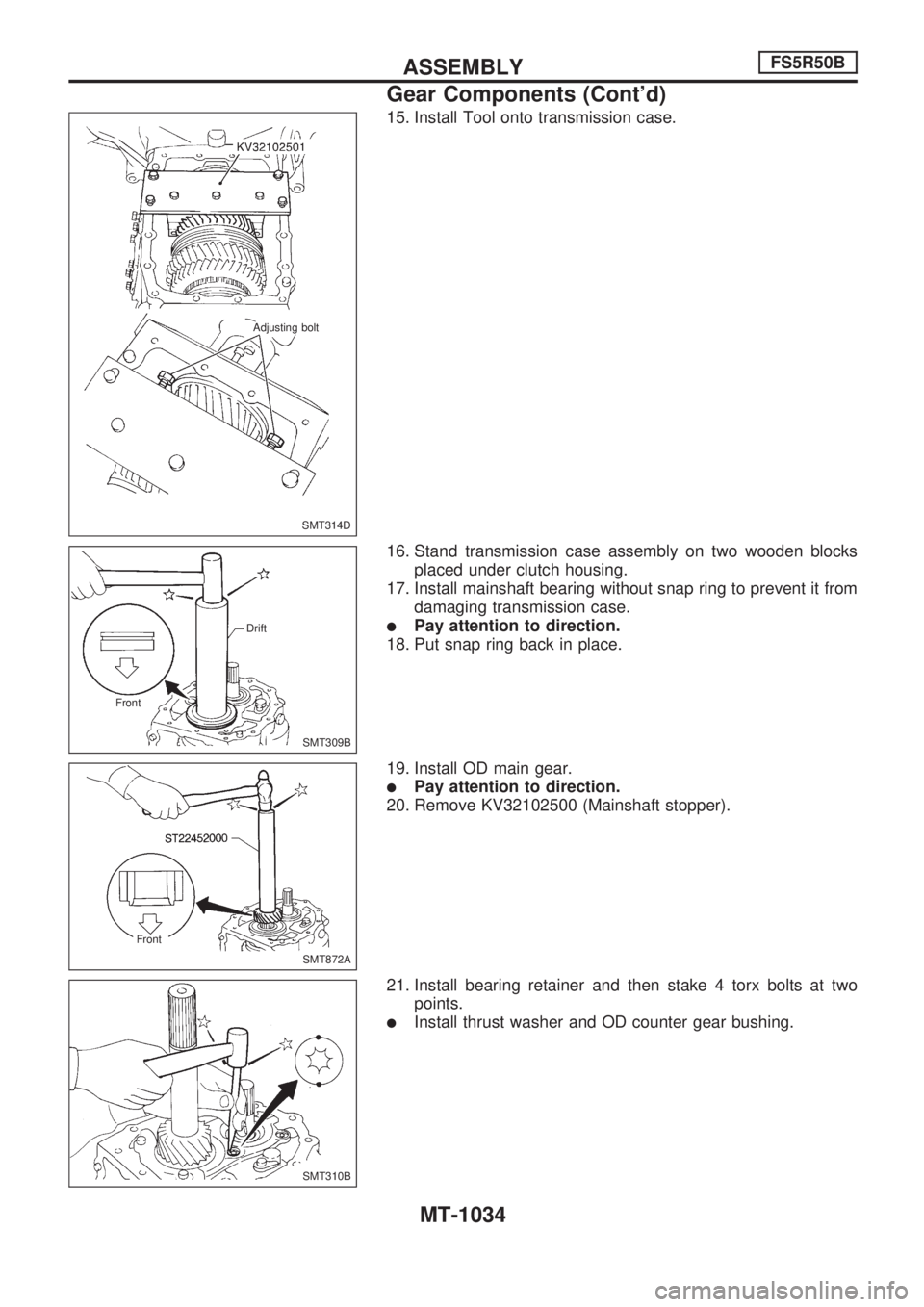

15. Install Tool onto transmission case.

16. Stand transmission case assembly on two wooden blocks

placed under clutch housing.

17. Install mainshaft bearing without snap ring to prevent it from

damaging transmission case.

lPay attention to direction.

18. Put snap ring back in place.

19. Install OD main gear.

lPay attention to direction.

20. Remove KV32102500 (Mainshaft stopper).

21. Install bearing retainer and then stake 4 torx bolts at two

points.

lInstall thrust washer and OD counter gear bushing.

SMT314D Adjusting bolt

SMT309B Drift

Front

SMT872A Front

SMT310B

ASSEMBLYFS5R50B

Gear Components (Cont'd)

MT-1034

Page 955 of 1033

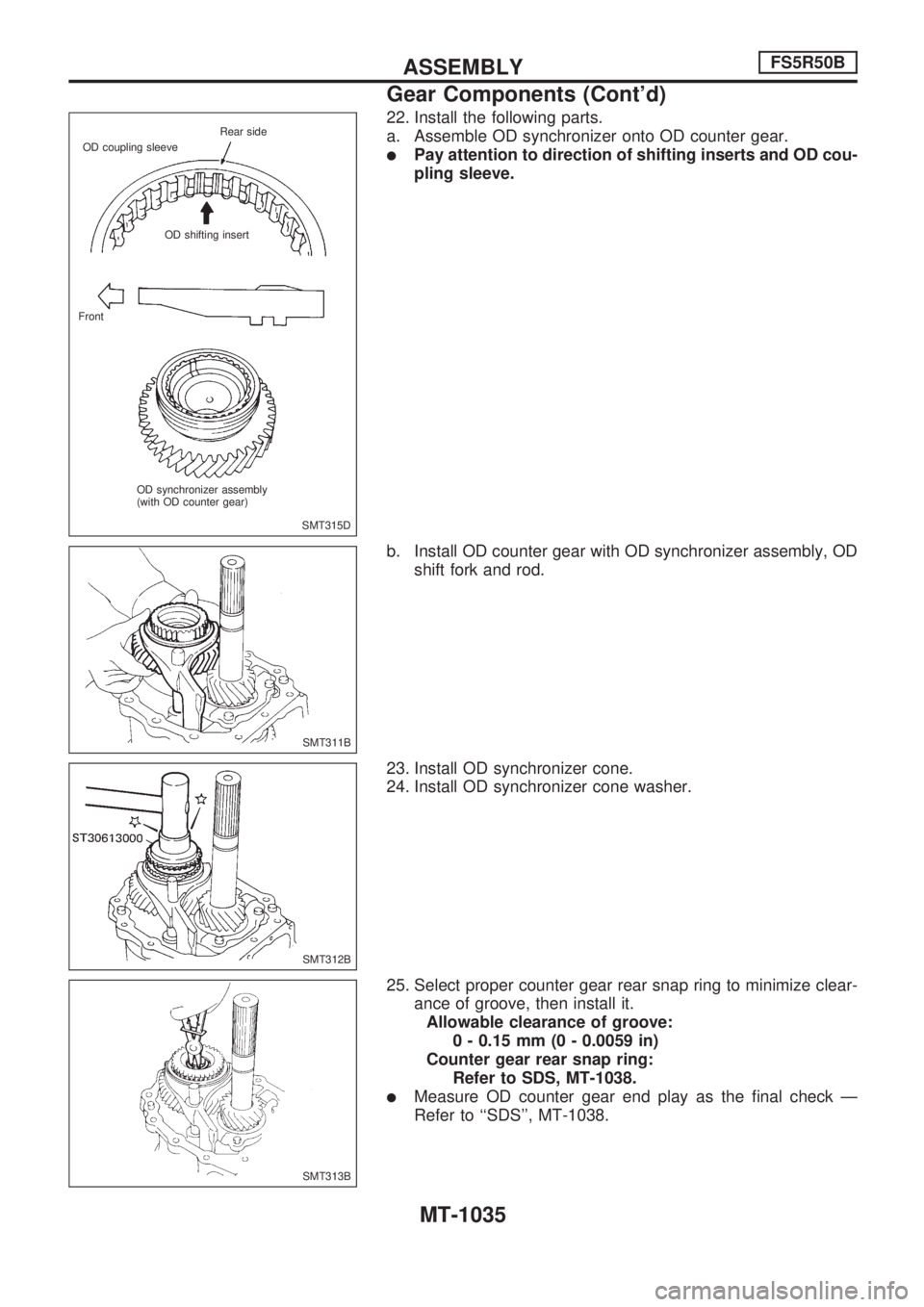

22. Install the following parts.

a. Assemble OD synchronizer onto OD counter gear.

lPay attention to direction of shifting inserts and OD cou-

pling sleeve.

b. Install OD counter gear with OD synchronizer assembly, OD

shift fork and rod.

23. Install OD synchronizer cone.

24. Install OD synchronizer cone washer.

25. Select proper counter gear rear snap ring to minimize clear-

ance of groove, then install it.

Allowable clearance of groove:

0 - 0.15 mm (0 - 0.0059 in)

Counter gear rear snap ring:

Refer to SDS, MT-1038.

lMeasure OD counter gear end play as the final check Ð

Refer to ``SDS'', MT-1038.

SMT315D Rear side

OD coupling sleeve

OD shifting insert

Front

OD synchronizer assembly

(with OD counter gear)

SMT311B

SMT312B

SMT313B

ASSEMBLYFS5R50B

Gear Components (Cont'd)

MT-1035

Page 956 of 1033

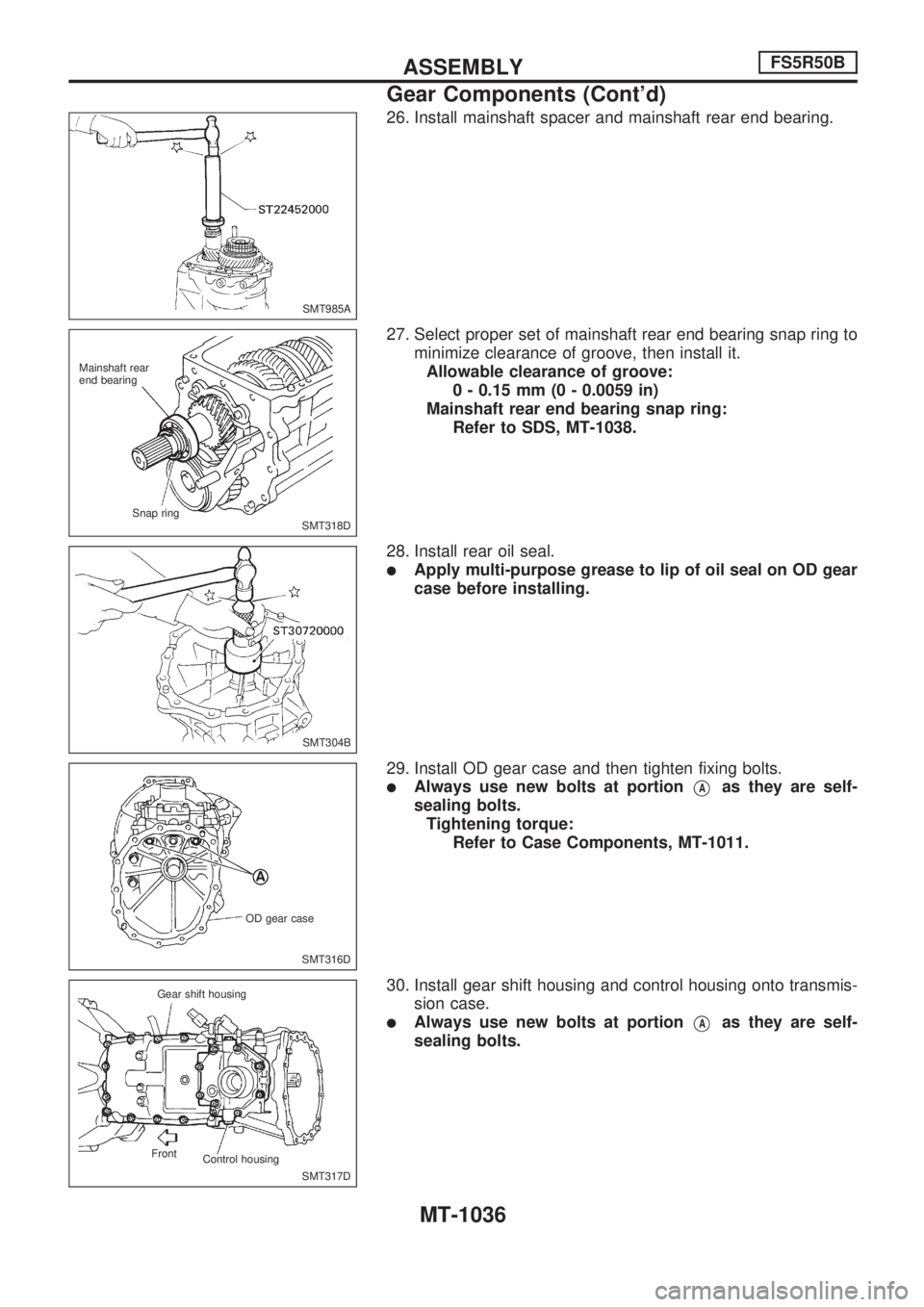

26. Install mainshaft spacer and mainshaft rear end bearing.

27. Select proper set of mainshaft rear end bearing snap ring to

minimize clearance of groove, then install it.

Allowable clearance of groove:

0 - 0.15 mm (0 - 0.0059 in)

Mainshaft rear end bearing snap ring:

Refer to SDS, MT-1038.

28. Install rear oil seal.

lApply multi-purpose grease to lip of oil seal on OD gear

case before installing.

29. Install OD gear case and then tighten fixing bolts.

lAlways use new bolts at portionVAas they are self-

sealing bolts.

Tightening torque:

Refer to Case Components, MT-1011.

30. Install gear shift housing and control housing onto transmis-

sion case.

lAlways use new bolts at portionVAas they are self-

sealing bolts.

SMT985A

SMT318D Mainshaft rear

end bearing

Snap ring

SMT304B

SMT316D OD gear case

SMT317D Gear shift housing

Control housing Front

ASSEMBLYFS5R50B

Gear Components (Cont'd)

MT-1036

Page 957 of 1033

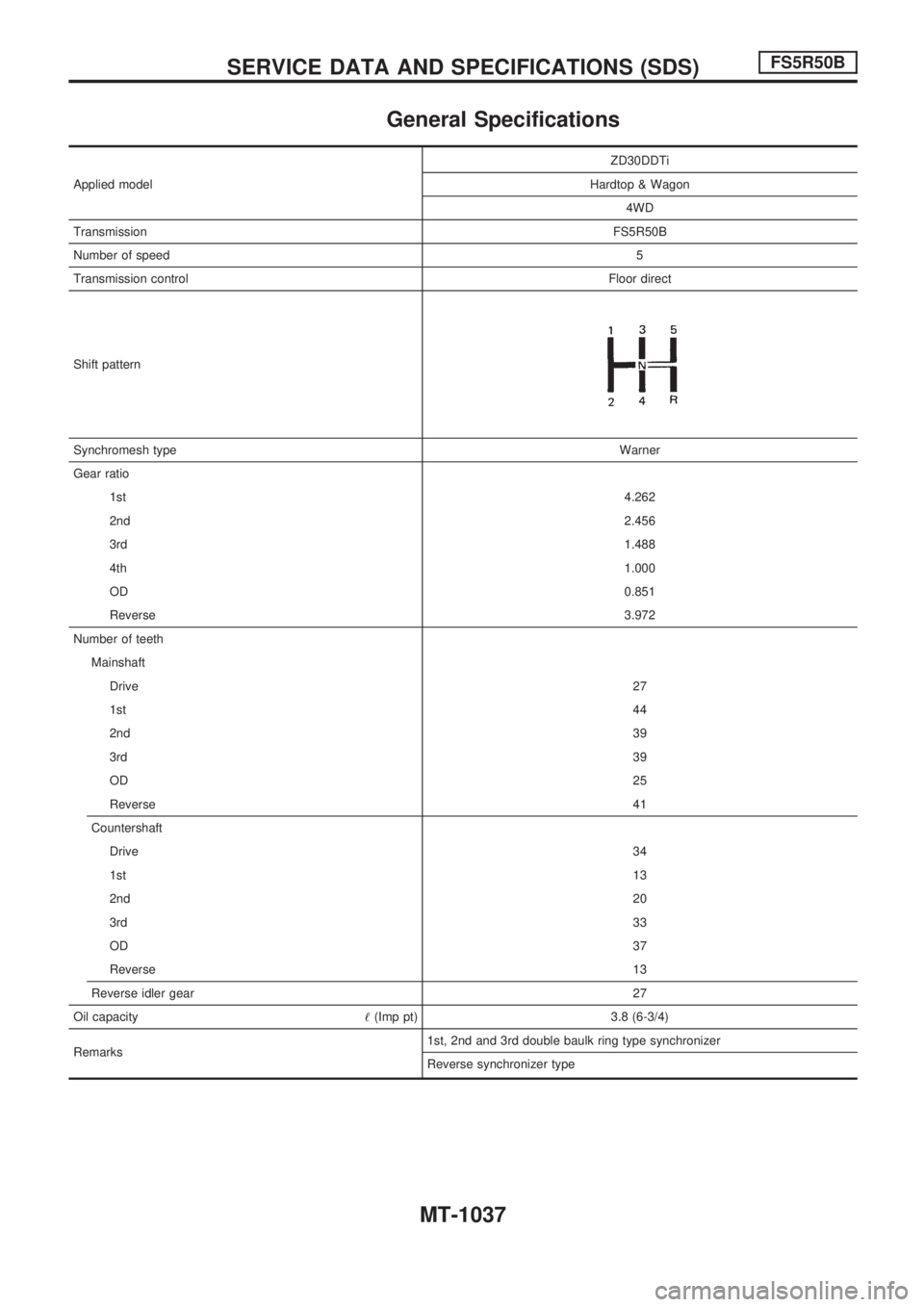

General Specifications

Applied modelZD30DDTi

Hardtop & Wagon

4WD

TransmissionFS5R50B

Number of speed5

Transmission controlFloor direct

Shift pattern

Synchromesh typeWarner

Gear ratio

1st4.262

2nd2.456

3rd1.488

4th1.000

OD0.851

Reverse3.972

Number of teeth

Mainshaft

Drive27

1st44

2nd39

3rd39

OD25

Reverse41

Countershaft

Drive34

1st13

2nd20

3rd33

OD37

Reverse13

Reverse idler gear27

Oil capacity!(Imp pt) 3.8 (6-3/4)

Remarks1st, 2nd and 3rd double baulk ring type synchronizer

Reverse synchronizer type

SERVICE DATA AND SPECIFICATIONS (SDS)FS5R50B

MT-1037

Page 958 of 1033

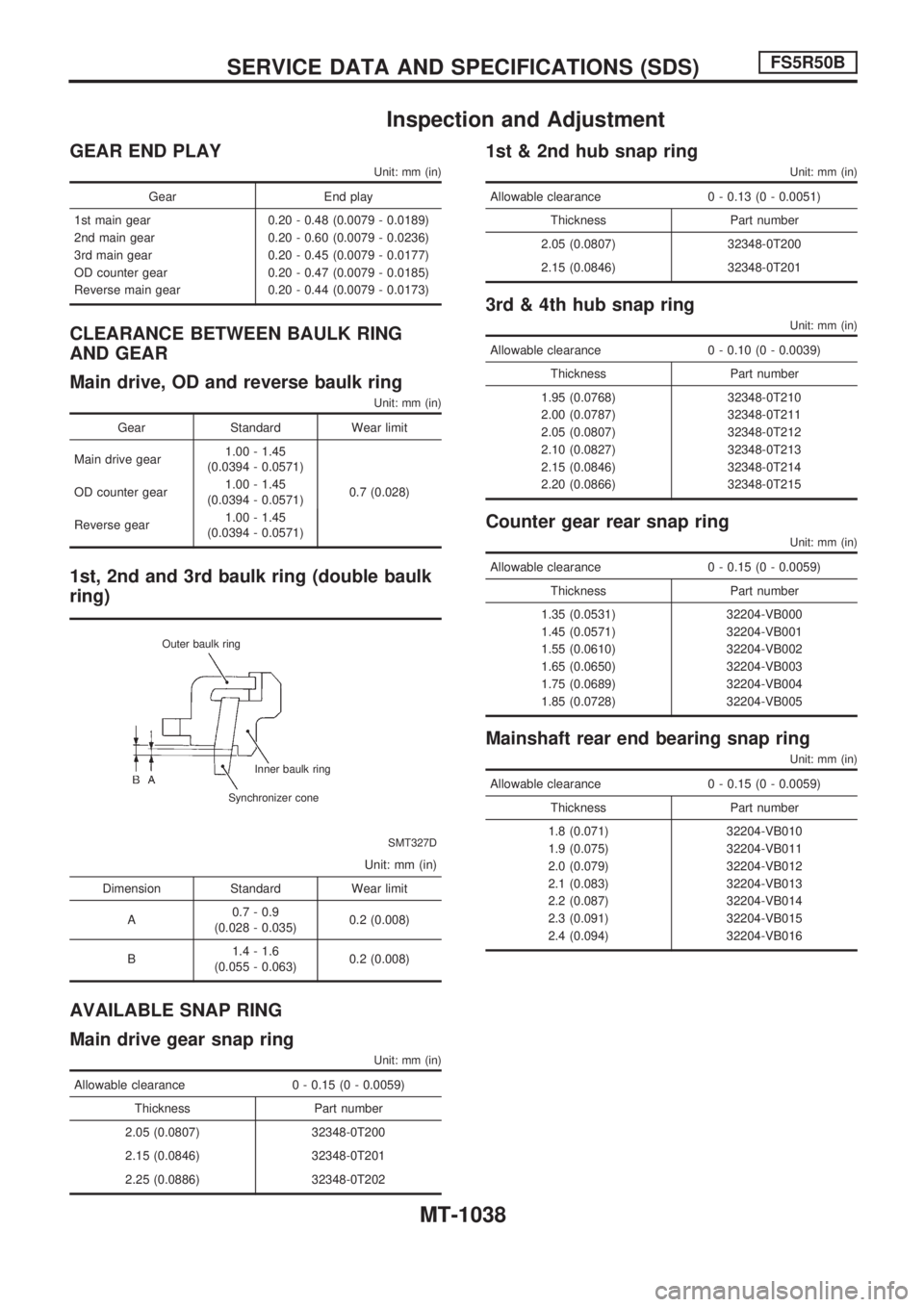

Inspection and Adjustment

GEAR END PLAY

Unit: mm (in)

Gear End play

1st main gear 0.20 - 0.48 (0.0079 - 0.0189)

2nd main gear 0.20 - 0.60 (0.0079 - 0.0236)

3rd main gear 0.20 - 0.45 (0.0079 - 0.0177)

OD counter gear 0.20 - 0.47 (0.0079 - 0.0185)

Reverse main gear 0.20 - 0.44 (0.0079 - 0.0173)

CLEARANCE BETWEEN BAULK RING

AND GEAR

Main drive, OD and reverse baulk ring

Unit: mm (in)

Gear Standard Wear limit

Main drive gear1.00 - 1.45

(0.0394 - 0.0571)

0.7 (0.028) OD counter gear1.00 - 1.45

(0.0394 - 0.0571)

Reverse gear1.00 - 1.45

(0.0394 - 0.0571)

1st, 2nd and 3rd baulk ring (double baulk

ring)

SMT327D Outer baulk ring

Inner baulk ring

Synchronizer cone

Unit: mm (in)

Dimension Standard Wear limit

A0.7 - 0.9

(0.028 - 0.035)0.2 (0.008)

B1.4 - 1.6

(0.055 - 0.063)0.2 (0.008)

AVAILABLE SNAP RING

Main drive gear snap ring

Unit: mm (in)

Allowable clearance 0 - 0.15 (0 - 0.0059)

Thickness Part number

2.05 (0.0807) 32348-0T200

2.15 (0.0846) 32348-0T201

2.25 (0.0886) 32348-0T202

1st & 2nd hub snap ring

Unit: mm (in)

Allowable clearance 0 - 0.13 (0 - 0.0051)

Thickness Part number

2.05 (0.0807) 32348-0T200

2.15 (0.0846) 32348-0T201

3rd & 4th hub snap ring

Unit: mm (in)

Allowable clearance 0 - 0.10 (0 - 0.0039)

Thickness Part number

1.95 (0.0768) 32348-0T210

2.00 (0.0787) 32348-0T211

2.05 (0.0807) 32348-0T212

2.10 (0.0827) 32348-0T213

2.15 (0.0846) 32348-0T214

2.20 (0.0866) 32348-0T215

Counter gear rear snap ring

Unit: mm (in)

Allowable clearance 0 - 0.15 (0 - 0.0059)

Thickness Part number

1.35 (0.0531) 32204-VB000

1.45 (0.0571) 32204-VB001

1.55 (0.0610) 32204-VB002

1.65 (0.0650) 32204-VB003

1.75 (0.0689) 32204-VB004

1.85 (0.0728) 32204-VB005

Mainshaft rear end bearing snap ring

Unit: mm (in)

Allowable clearance 0 - 0.15 (0 - 0.0059)

Thickness Part number

1.8 (0.071) 32204-VB010

1.9 (0.075) 32204-VB011

2.0 (0.079) 32204-VB012

2.1 (0.083) 32204-VB013

2.2 (0.087) 32204-VB014

2.3 (0.091) 32204-VB015

2.4 (0.094) 32204-VB016

SERVICE DATA AND SPECIFICATIONS (SDS)FS5R50B

MT-1038

Page 959 of 1033

PROPELLER SHAFT &

DIFFERENTIAL CARRIER

SECTION

PD

MODIFICATION NOTICE:

+ ZD30ETi engine has been adopted.

CONTENTS

PROPELLER SHAFT .......................................... 1002

On-vehicle Service ........................................... 1003

FRONT FINAL DRIVE ......................................... 1004

REAR FINAL DRIVE ........................................... 1005

DIFFERENTIAL LOCK ........................................ 1006

Wiring Diagram Ð DIFF/L Ð/LHD Models ..... 1006 Wiring Diagram Ð DIFF/L Ð/RHD Models ..... 1008

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................... 1010

Propeller Shaft ................................................. 1010

Final Drive ........................................................ 1011

PD

Page 960 of 1033

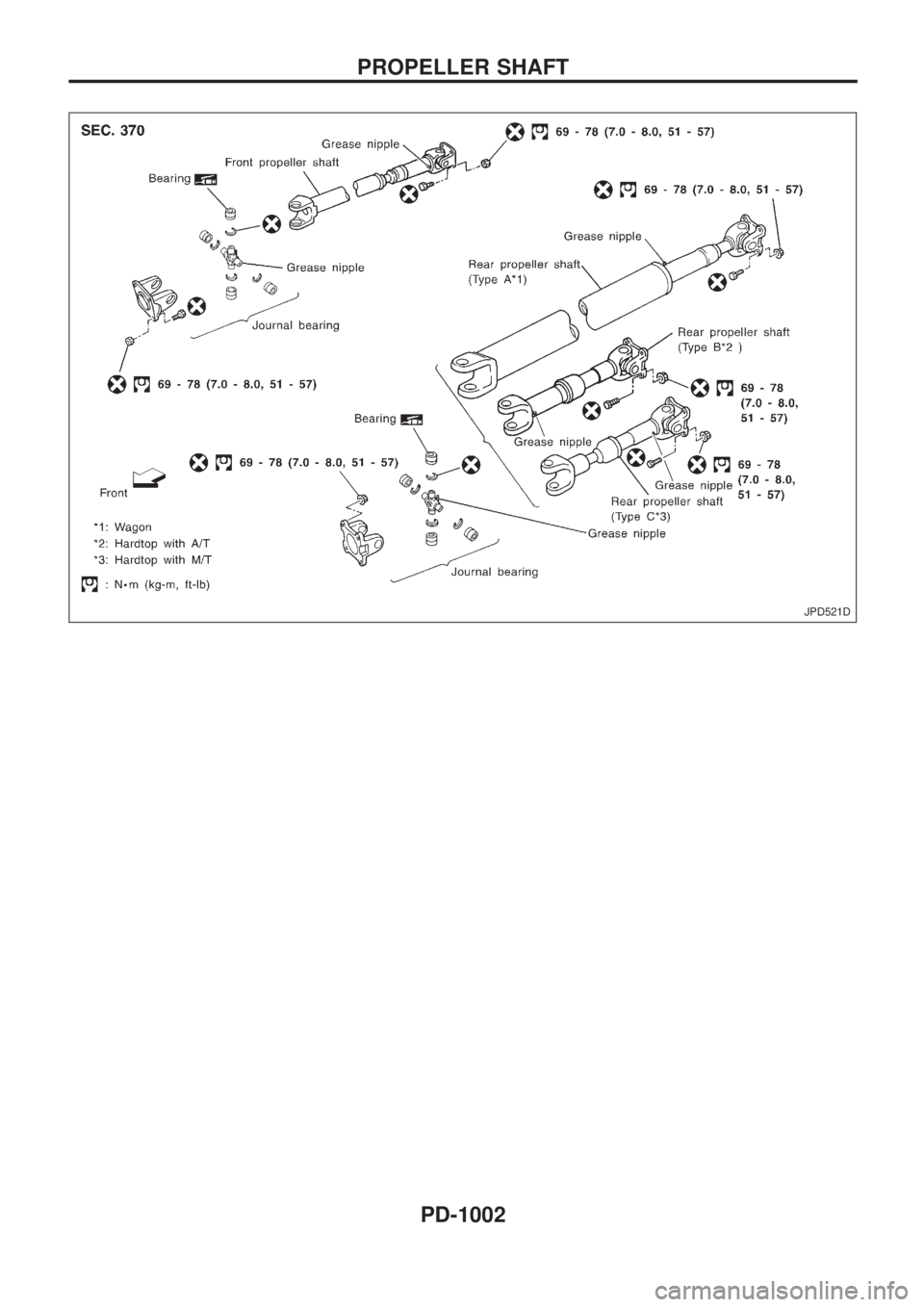

JPD521D

PROPELLER SHAFT

PD-1002