NISSAN PATROL 2000 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 941 of 1033

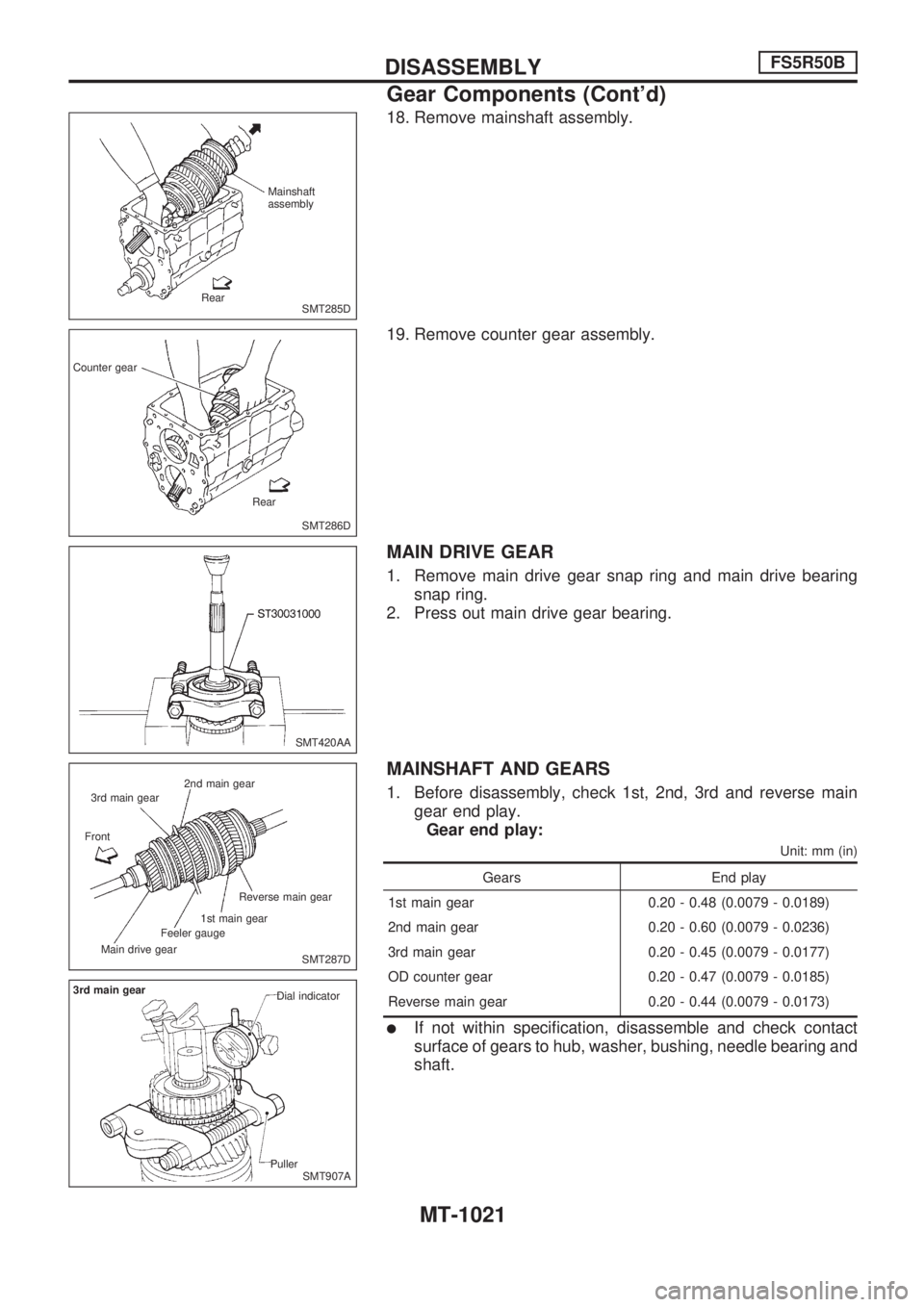

18. Remove mainshaft assembly.

19. Remove counter gear assembly.

MAIN DRIVE GEAR

1. Remove main drive gear snap ring and main drive bearing

snap ring.

2. Press out main drive gear bearing.

MAINSHAFT AND GEARS

1. Before disassembly, check 1st, 2nd, 3rd and reverse main

gear end play.

Gear end play:

Unit: mm (in)

Gears End play

1st main gear 0.20 - 0.48 (0.0079 - 0.0189)

2nd main gear 0.20 - 0.60 (0.0079 - 0.0236)

3rd main gear 0.20 - 0.45 (0.0079 - 0.0177)

OD counter gear 0.20 - 0.47 (0.0079 - 0.0185)

Reverse main gear 0.20 - 0.44 (0.0079 - 0.0173)

lIf not within specification, disassemble and check contact

surface of gears to hub, washer, bushing, needle bearing and

shaft.

SMT285D Mainshaft

assembly

Rear

SMT286D Counter gear

Rear

SMT420AA

SMT287D 2nd main gear

3rd main gear

Front

Main drive gearFeeler gauge1st main gearReverse main gear

SMT907A 3rd main gear

Dial indicator

Puller

DISASSEMBLYFS5R50B

Gear Components (Cont'd)

MT-1021

Page 942 of 1033

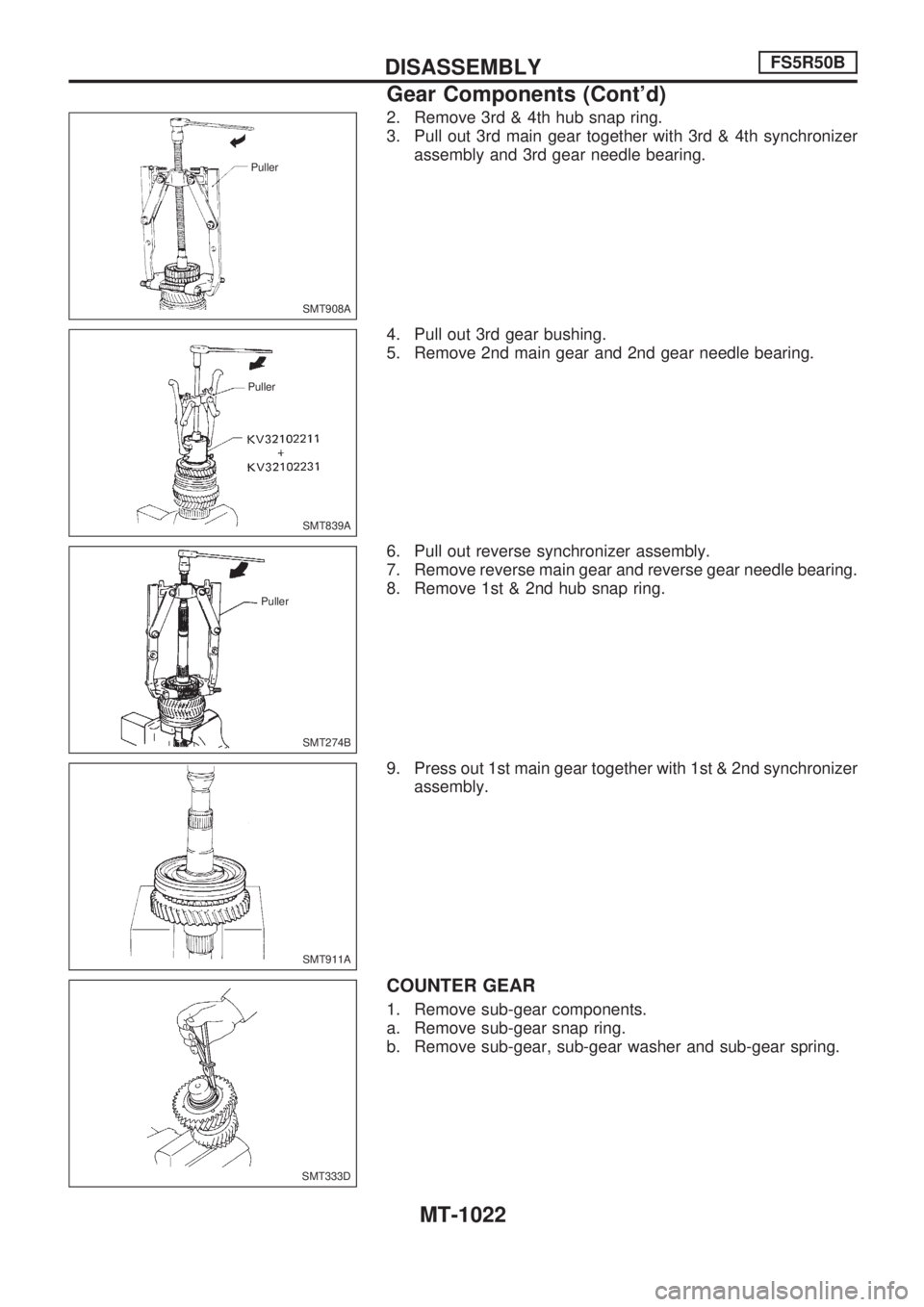

2. Remove 3rd & 4th hub snap ring.

3. Pull out 3rd main gear together with 3rd & 4th synchronizer

assembly and 3rd gear needle bearing.

4. Pull out 3rd gear bushing.

5. Remove 2nd main gear and 2nd gear needle bearing.

6. Pull out reverse synchronizer assembly.

7. Remove reverse main gear and reverse gear needle bearing.

8. Remove 1st & 2nd hub snap ring.

9. Press out 1st main gear together with 1st & 2nd synchronizer

assembly.

COUNTER GEAR

1. Remove sub-gear components.

a. Remove sub-gear snap ring.

b. Remove sub-gear, sub-gear washer and sub-gear spring.

SMT908A Puller

SMT839A Puller

SMT274B Puller

SMT911A

SMT333D

DISASSEMBLYFS5R50B

Gear Components (Cont'd)

MT-1022

Page 943 of 1033

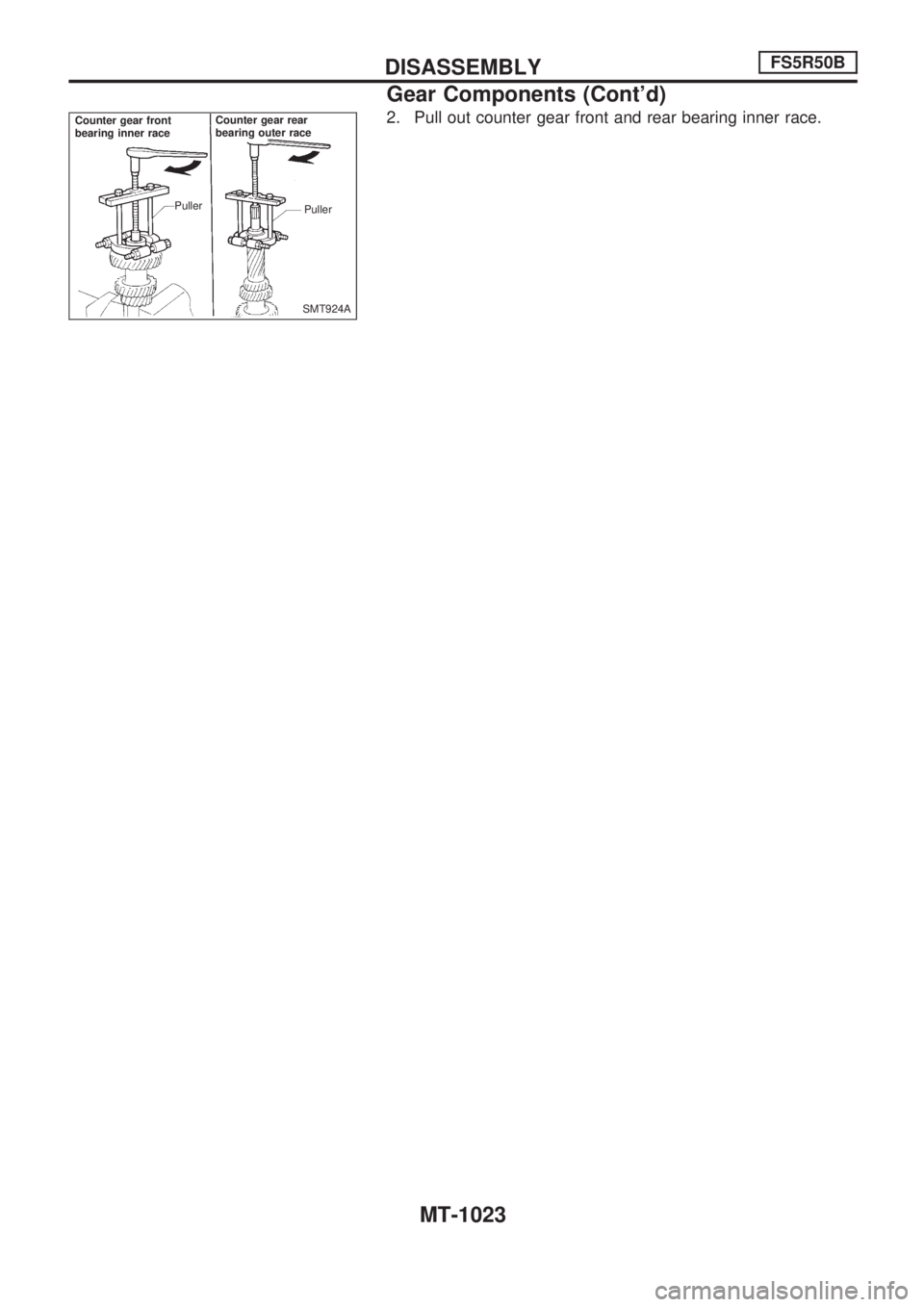

2. Pull out counter gear front and rear bearing inner race.

SMT924A Counter gear front

bearing inner raceCounter gear rear

bearing outer race

Puller

Puller

DISASSEMBLYFS5R50B

Gear Components (Cont'd)

MT-1023

Page 944 of 1033

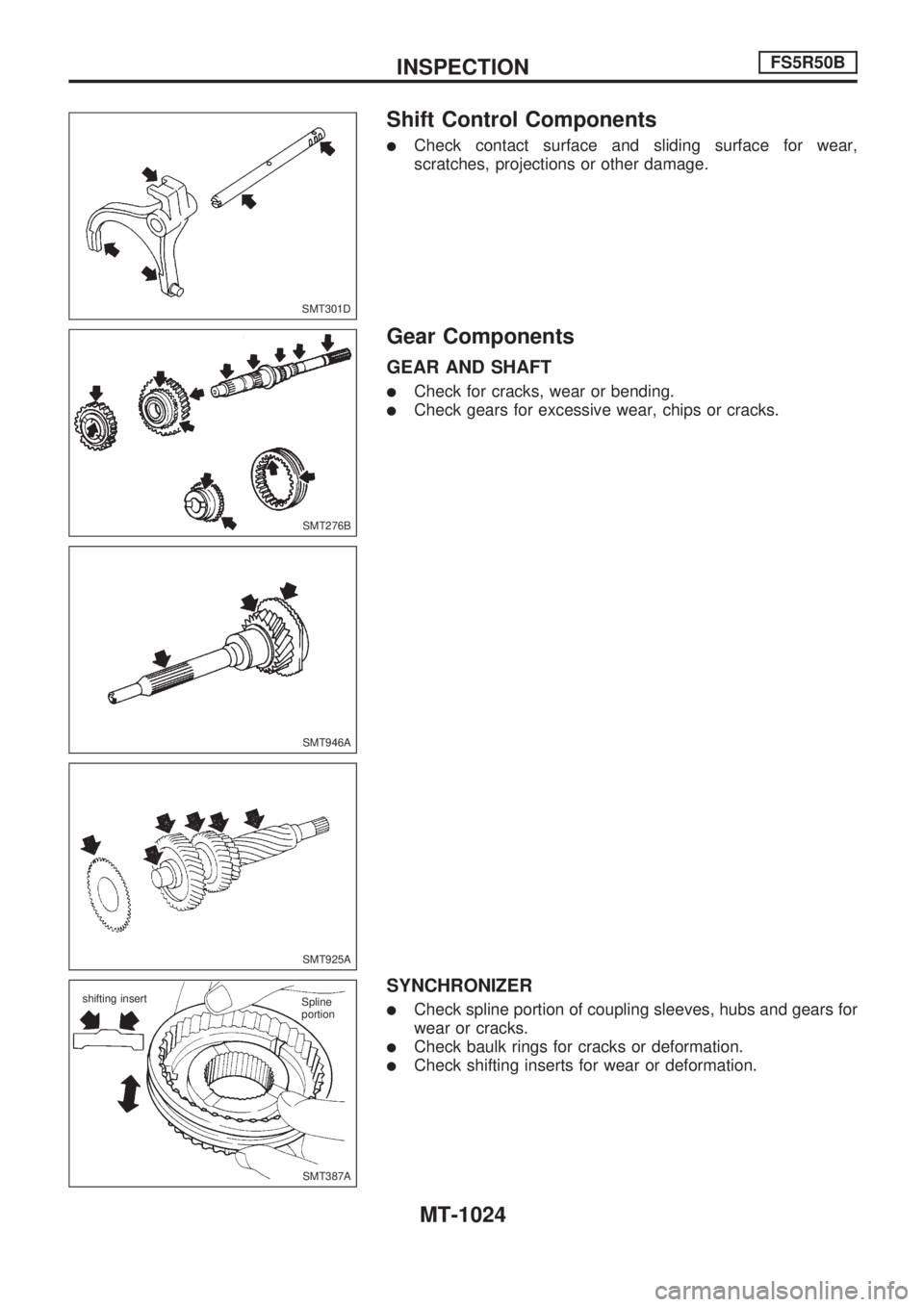

Shift Control Components

lCheck contact surface and sliding surface for wear,

scratches, projections or other damage.

Gear Components

GEAR AND SHAFT

lCheck for cracks, wear or bending.

lCheck gears for excessive wear, chips or cracks.

SYNCHRONIZER

lCheck spline portion of coupling sleeves, hubs and gears for

wear or cracks.

lCheck baulk rings for cracks or deformation.

lCheck shifting inserts for wear or deformation.

SMT301D

SMT276B

SMT946A

SMT925A

SMT387A shifting insert

Spline

portion

INSPECTIONFS5R50B

MT-1024

Page 945 of 1033

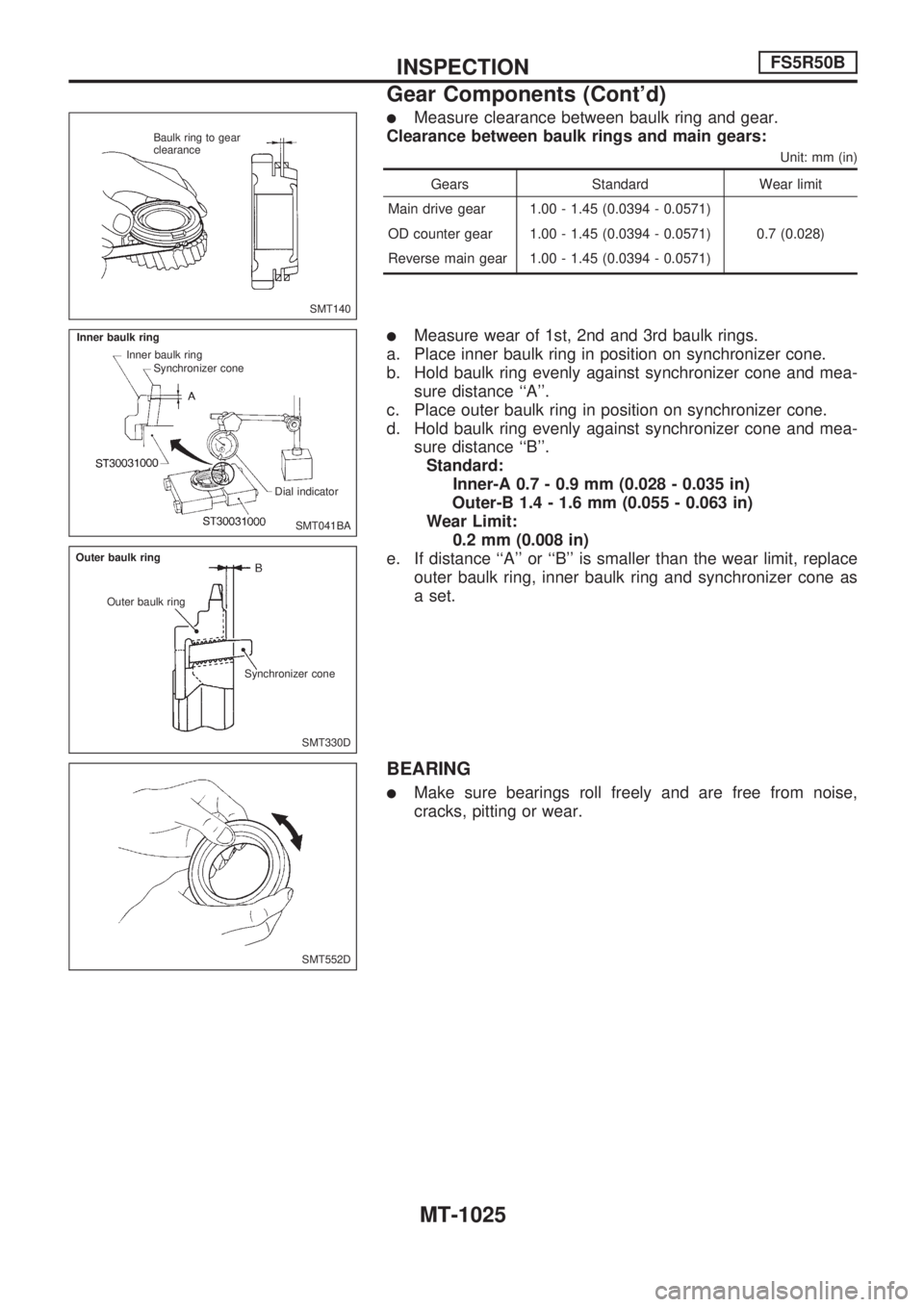

lMeasure clearance between baulk ring and gear.

Clearance between baulk rings and main gears:

Unit: mm (in)

Gears Standard Wear limit

Main drive gear 1.00 - 1.45 (0.0394 - 0.0571)

0.7 (0.028) OD counter gear 1.00 - 1.45 (0.0394 - 0.0571)

Reverse main gear 1.00 - 1.45 (0.0394 - 0.0571)

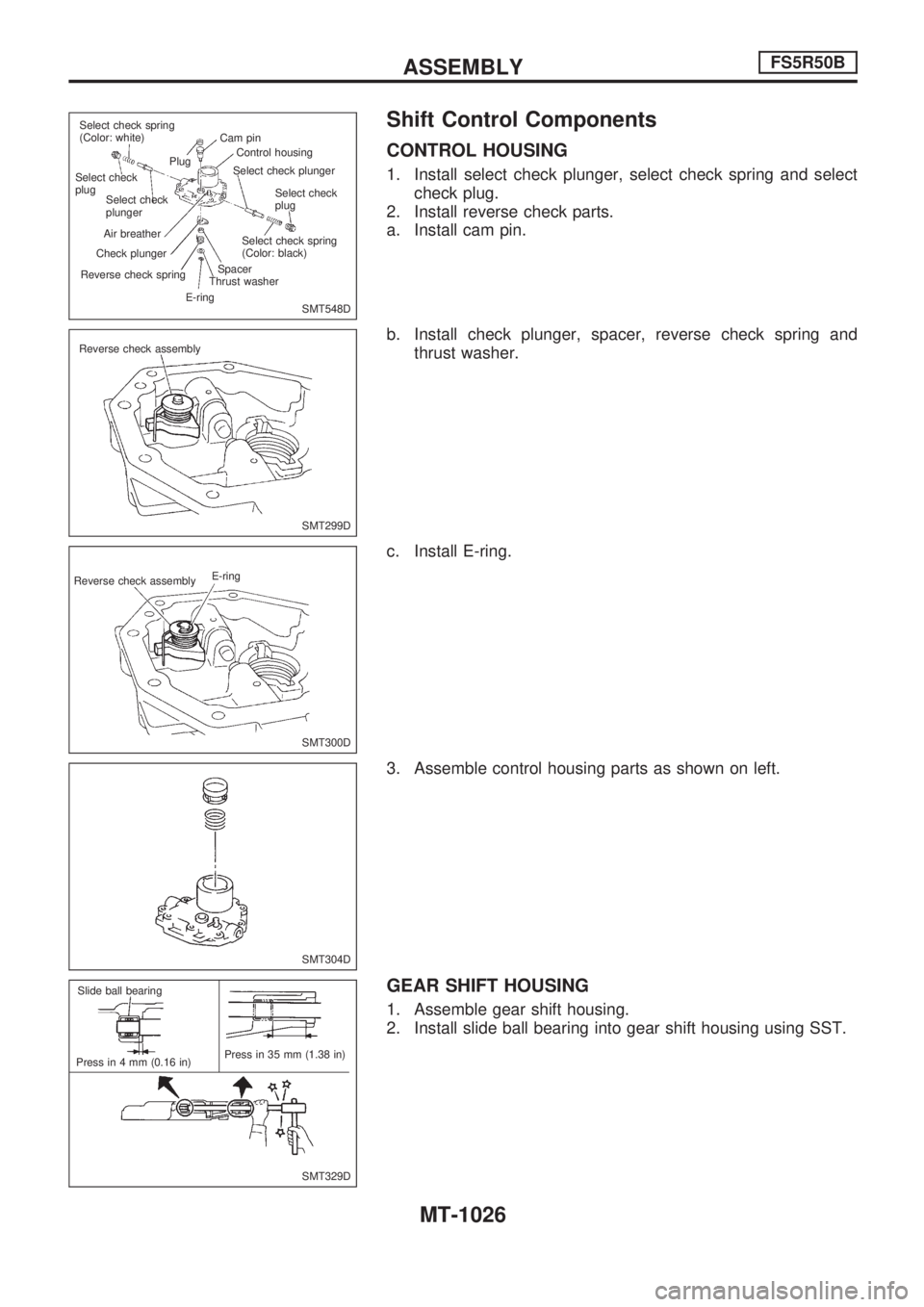

lMeasure wear of 1st, 2nd and 3rd baulk rings.

a. Place inner baulk ring in position on synchronizer cone.

b. Hold baulk ring evenly against synchronizer cone and mea-

sure distance ``A''.

c. Place outer baulk ring in position on synchronizer cone.

d. Hold baulk ring evenly against synchronizer cone and mea-

sure distance ``B''.

Standard:

Inner-A 0.7 - 0.9 mm (0.028 - 0.035 in)

Outer-B 1.4 - 1.6 mm (0.055 - 0.063 in)

Wear Limit:

0.2 mm (0.008 in)

e. If distance ``A'' or ``B'' is smaller than the wear limit, replace

outer baulk ring, inner baulk ring and synchronizer cone as

a set.

BEARING

lMake sure bearings roll freely and are free from noise,

cracks, pitting or wear.

SMT140 Baulk ring to gear

clearance

SMT041BA Inner baulk ring

Inner baulk ring

Synchronizer cone

Dial indicator

SMT330D Outer baulk ring

Outer baulk ring

Synchronizer cone

SMT552D

INSPECTIONFS5R50B

Gear Components (Cont'd)

MT-1025

Page 946 of 1033

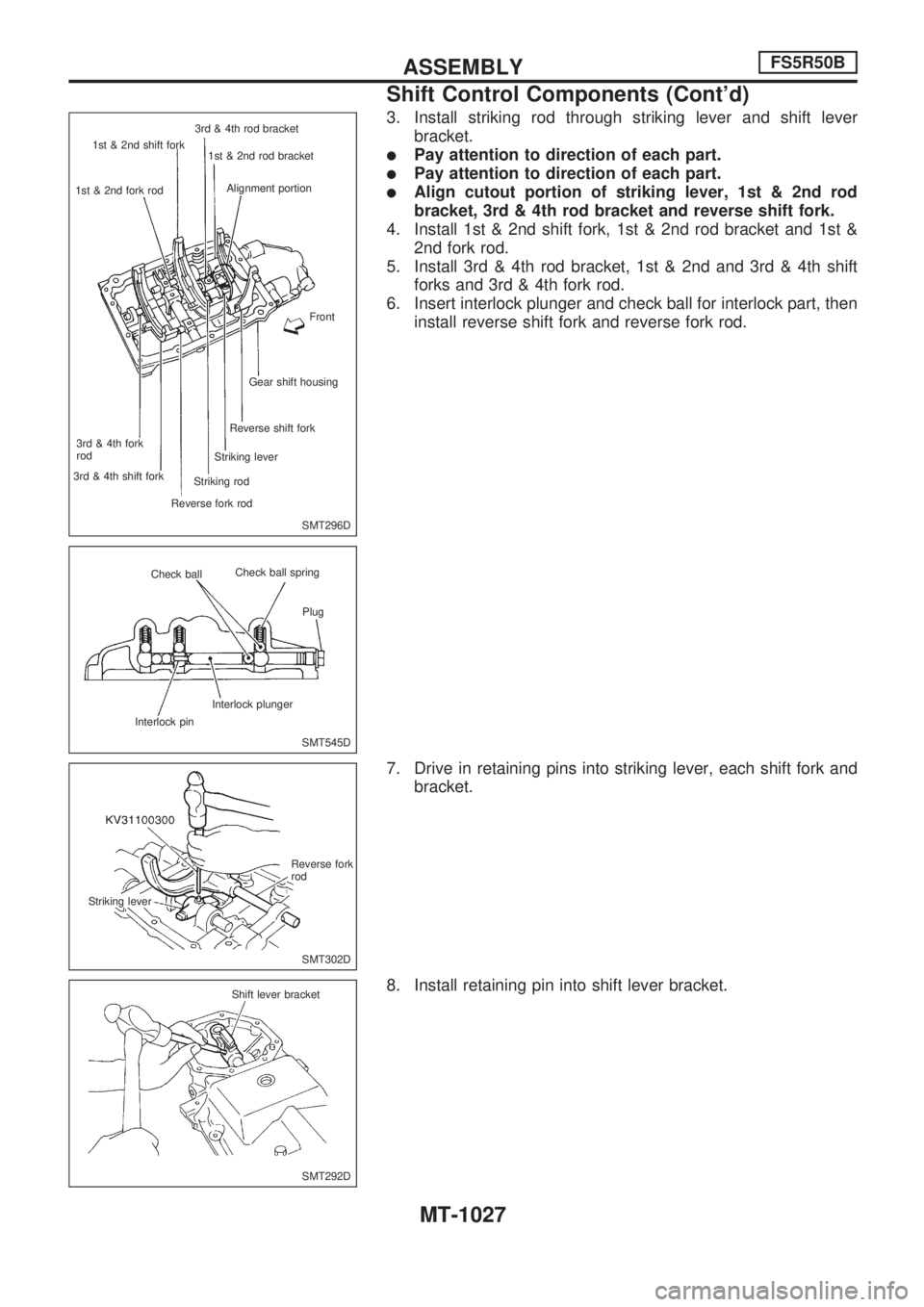

Shift Control Components

CONTROL HOUSING

1. Install select check plunger, select check spring and select

check plug.

2. Install reverse check parts.

a. Install cam pin.

b. Install check plunger, spacer, reverse check spring and

thrust washer.

c. Install E-ring.

3. Assemble control housing parts as shown on left.

GEAR SHIFT HOUSING

1. Assemble gear shift housing.

2. Install slide ball bearing into gear shift housing using SST.

SMT548D Select check spring

(Color: white)

Select check

plug

Select check

plunger

Air breather

Check plunger

Reverse check spring

E-ringThrust washerSpacerSelect check spring

(Color: black)Select check

plug Select check plungerControl housing Cam pin

Plug

SMT299D Reverse check assembly

SMT300D Reverse check assemblyE-ring

SMT304D

SMT329D Slide ball bearing

Press in 4 mm (0.16 in)Press in 35 mm (1.38 in)

ASSEMBLYFS5R50B

MT-1026

Page 947 of 1033

3. Install striking rod through striking lever and shift lever

bracket.

lPay attention to direction of each part.

lPay attention to direction of each part.

lAlign cutout portion of striking lever, 1st & 2nd rod

bracket, 3rd & 4th rod bracket and reverse shift fork.

4. Install 1st & 2nd shift fork, 1st & 2nd rod bracket and 1st &

2nd fork rod.

5. Install 3rd & 4th rod bracket, 1st & 2nd and 3rd & 4th shift

forks and 3rd & 4th fork rod.

6. Insert interlock plunger and check ball for interlock part, then

install reverse shift fork and reverse fork rod.

7. Drive in retaining pins into striking lever, each shift fork and

bracket.

8. Install retaining pin into shift lever bracket.

SMT296D 1st & 2nd fork rod1st & 2nd shift fork3rd & 4th rod bracket

1st & 2nd rod bracket

Alignment portion

Front

Gear shift housing

Reverse shift fork

Striking lever

Striking rod

Reverse fork rod 3rd & 4th shift fork3rd & 4th fork

rod

SMT545D Interlock plungerPlug

Interlock pinCheck ballCheck ball spring

SMT302D Striking leverReverse fork

rod

SMT292D Shift lever bracket

ASSEMBLYFS5R50B

Shift Control Components (Cont'd)

MT-1027

Page 948 of 1033

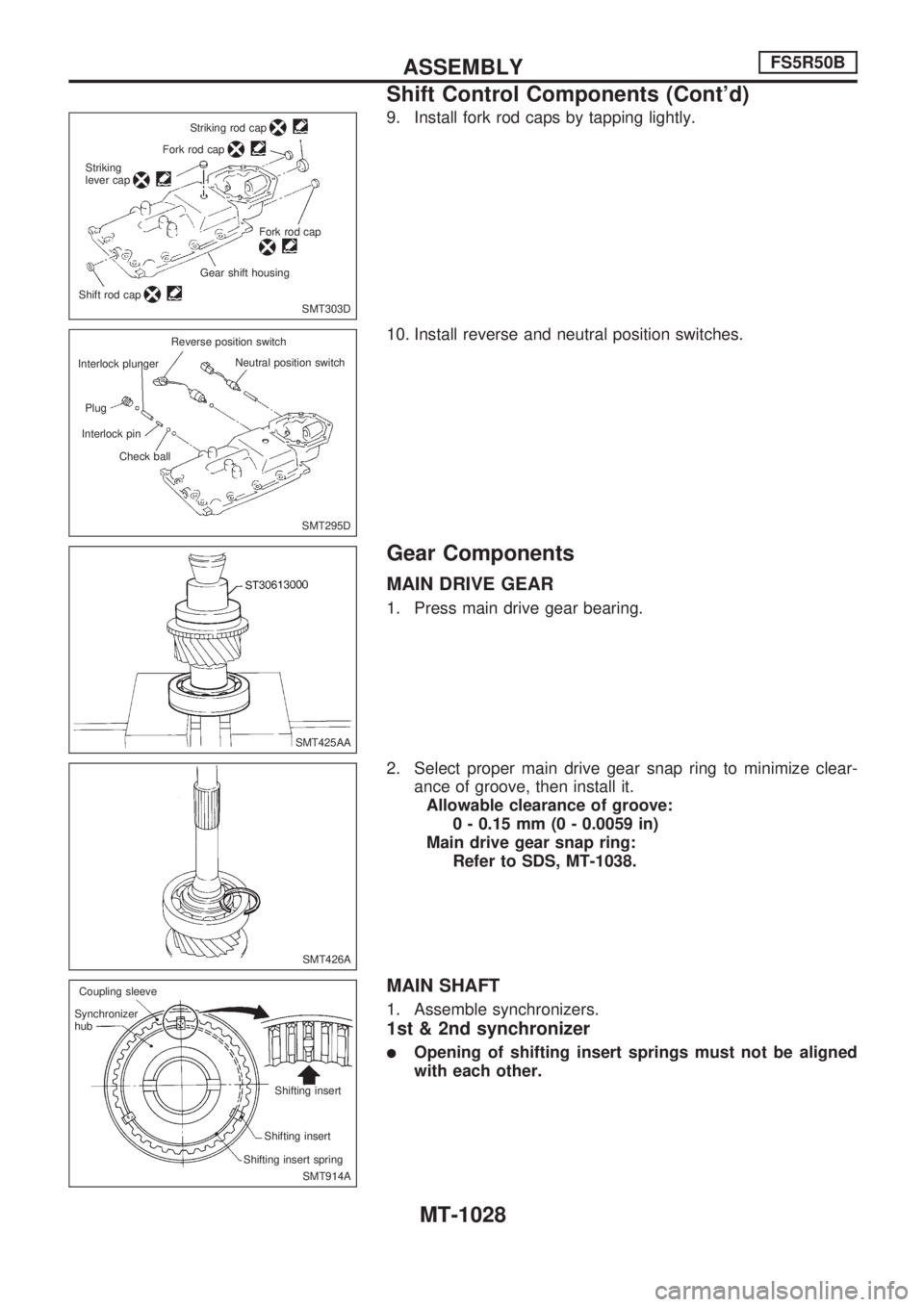

9. Install fork rod caps by tapping lightly.

10. Install reverse and neutral position switches.

Gear Components

MAIN DRIVE GEAR

1. Press main drive gear bearing.

2. Select proper main drive gear snap ring to minimize clear-

ance of groove, then install it.

Allowable clearance of groove:

0 - 0.15 mm (0 - 0.0059 in)

Main drive gear snap ring:

Refer to SDS, MT-1038.

MAIN SHAFT

1. Assemble synchronizers.

1st & 2nd synchronizer

lOpening of shifting insert springs must not be aligned

with each other.

SMT303D Striking rod cap

Fork rod cap

Striking

lever cap

Fork rod cap

Gear shift housing

Shift rod cap

SMT295D Interlock plunger

Plug

Interlock pin

Check ballNeutral position switch Reverse position switch

SMT425AA

SMT426A

SMT914A Synchronizer

hubCoupling sleeve

Shifting insert

Shifting insert

Shifting insert spring

ASSEMBLYFS5R50B

Shift Control Components (Cont'd)

MT-1028

Page 949 of 1033

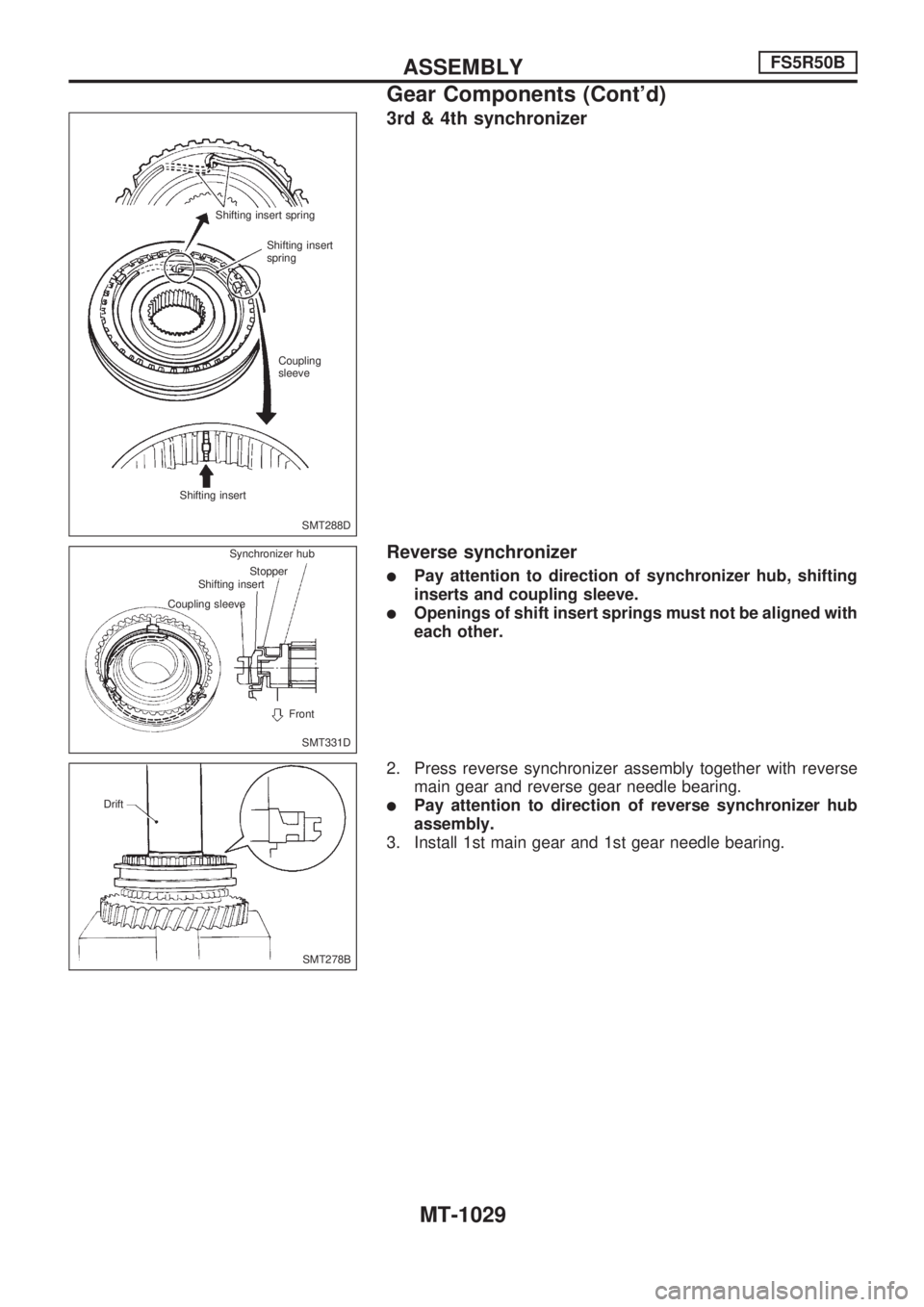

3rd & 4th synchronizer

Reverse synchronizer

lPay attention to direction of synchronizer hub, shifting

inserts and coupling sleeve.

lOpenings of shift insert springs must not be aligned with

each other.

2. Press reverse synchronizer assembly together with reverse

main gear and reverse gear needle bearing.

lPay attention to direction of reverse synchronizer hub

assembly.

3. Install 1st main gear and 1st gear needle bearing.

SMT288D Shifting insert spring

Shifting insert

spring

Coupling

sleeve

Shifting insert

SMT331D Synchronizer hub

Stopper

Shifting insert

Coupling sleeve

Front

SMT278B Drift

ASSEMBLYFS5R50B

Gear Components (Cont'd)

MT-1029

Page 950 of 1033

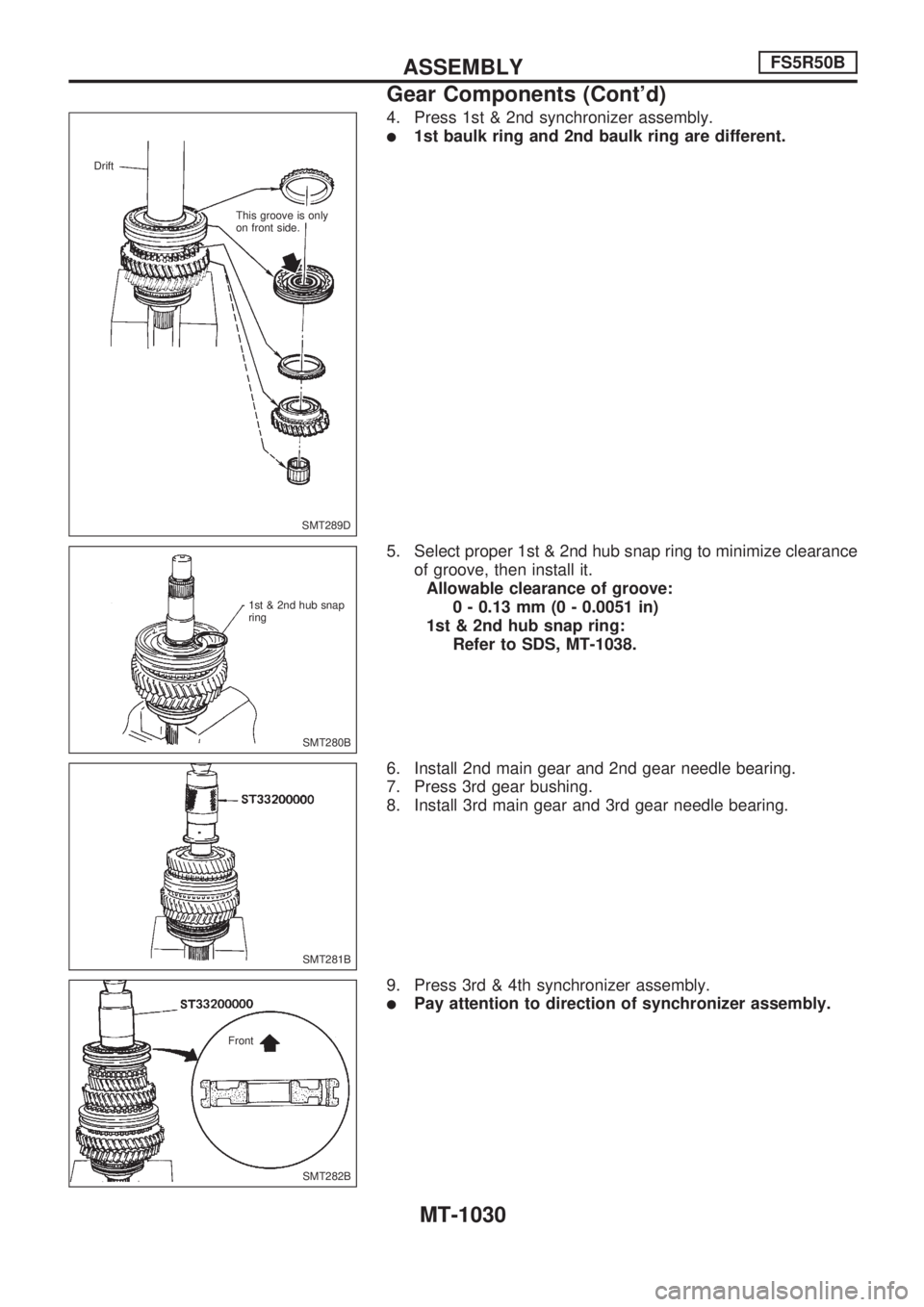

4. Press 1st & 2nd synchronizer assembly.

l1st baulk ring and 2nd baulk ring are different.

5. Select proper 1st & 2nd hub snap ring to minimize clearance

of groove, then install it.

Allowable clearance of groove:

0 - 0.13 mm (0 - 0.0051 in)

1st & 2nd hub snap ring:

Refer to SDS, MT-1038.

6. Install 2nd main gear and 2nd gear needle bearing.

7. Press 3rd gear bushing.

8. Install 3rd main gear and 3rd gear needle bearing.

9. Press 3rd & 4th synchronizer assembly.

lPay attention to direction of synchronizer assembly.

SMT289D Drift

This groove is only

on front side.

SMT280B 1st & 2nd hub snap

ring

SMT281B

SMT282B Front

ASSEMBLYFS5R50B

Gear Components (Cont'd)

MT-1030