NISSAN PICK-UP 1998 Repair Manual

Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 1631 of 1659

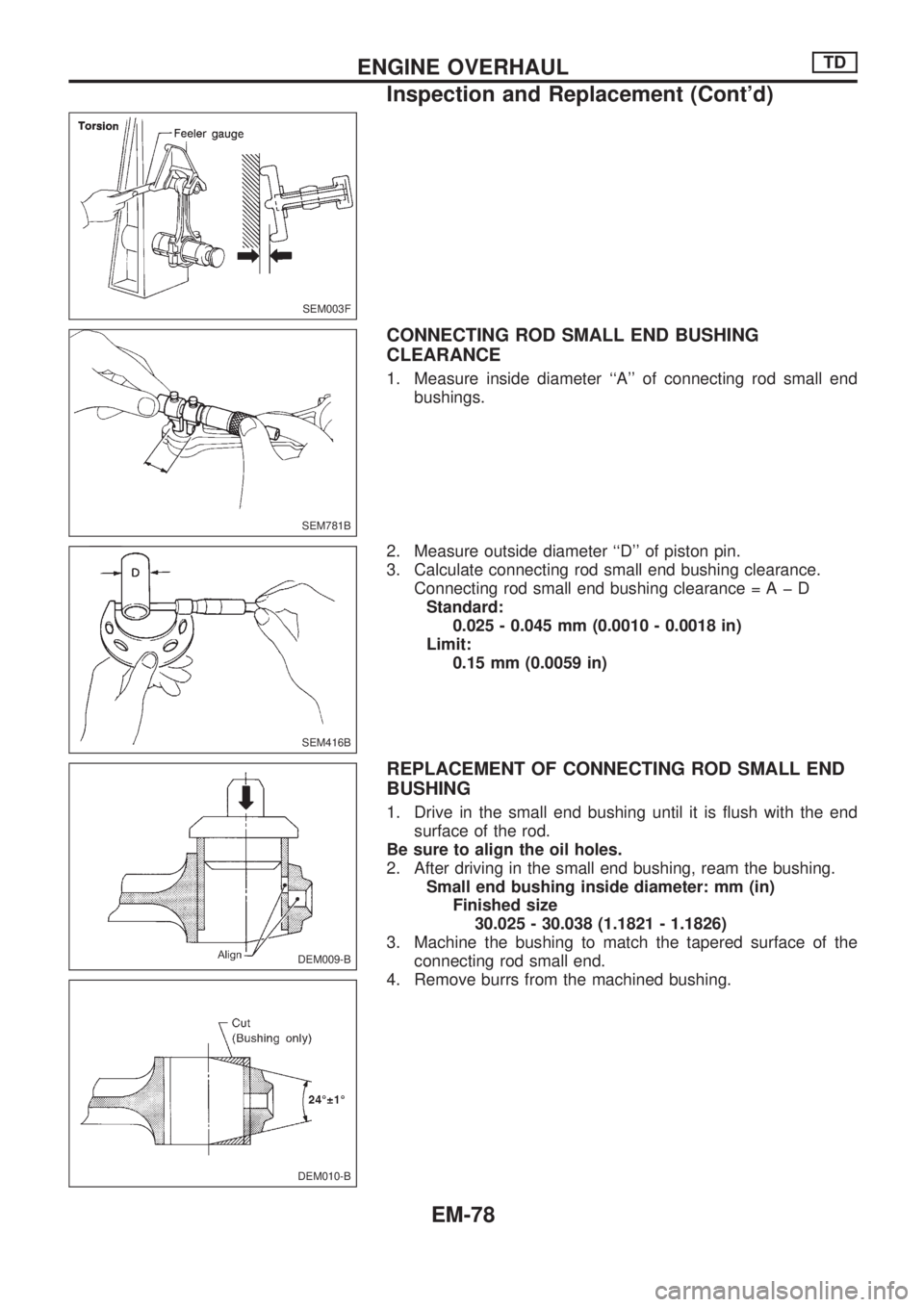

CONNECTING ROD SMALL END BUSHING

CLEARANCE

1. Measure inside diameter ``A'' of connecting rod small end

bushings.

2. Measure outside diameter ``D'' of piston pin.

3. Calculate connecting rod small end bushing clearance.

Connecting rod small end bushing clearance=AþD

Standard:

0.025 - 0.045 mm (0.0010 - 0.0018 in)

Limit:

0.15 mm (0.0059 in)

REPLACEMENT OF CONNECTING ROD SMALL END

BUSHING

1. Drive in the small end bushing until it is flush with the end

surface of the rod.

Be sure to align the oil holes.

2. After driving in the small end bushing, ream the bushing.

Small end bushing inside diameter: mm (in)

Finished size

30.025 - 30.038 (1.1821 - 1.1826)

3. Machine the bushing to match the tapered surface of the

connecting rod small end.

4. Remove burrs from the machined bushing.

SEM003F

SEM781B

SEM416B

DEM009-B

DEM010-B

ENGINE OVERHAULTD

Inspection and Replacement (Cont'd)

EM-78

Page 1632 of 1659

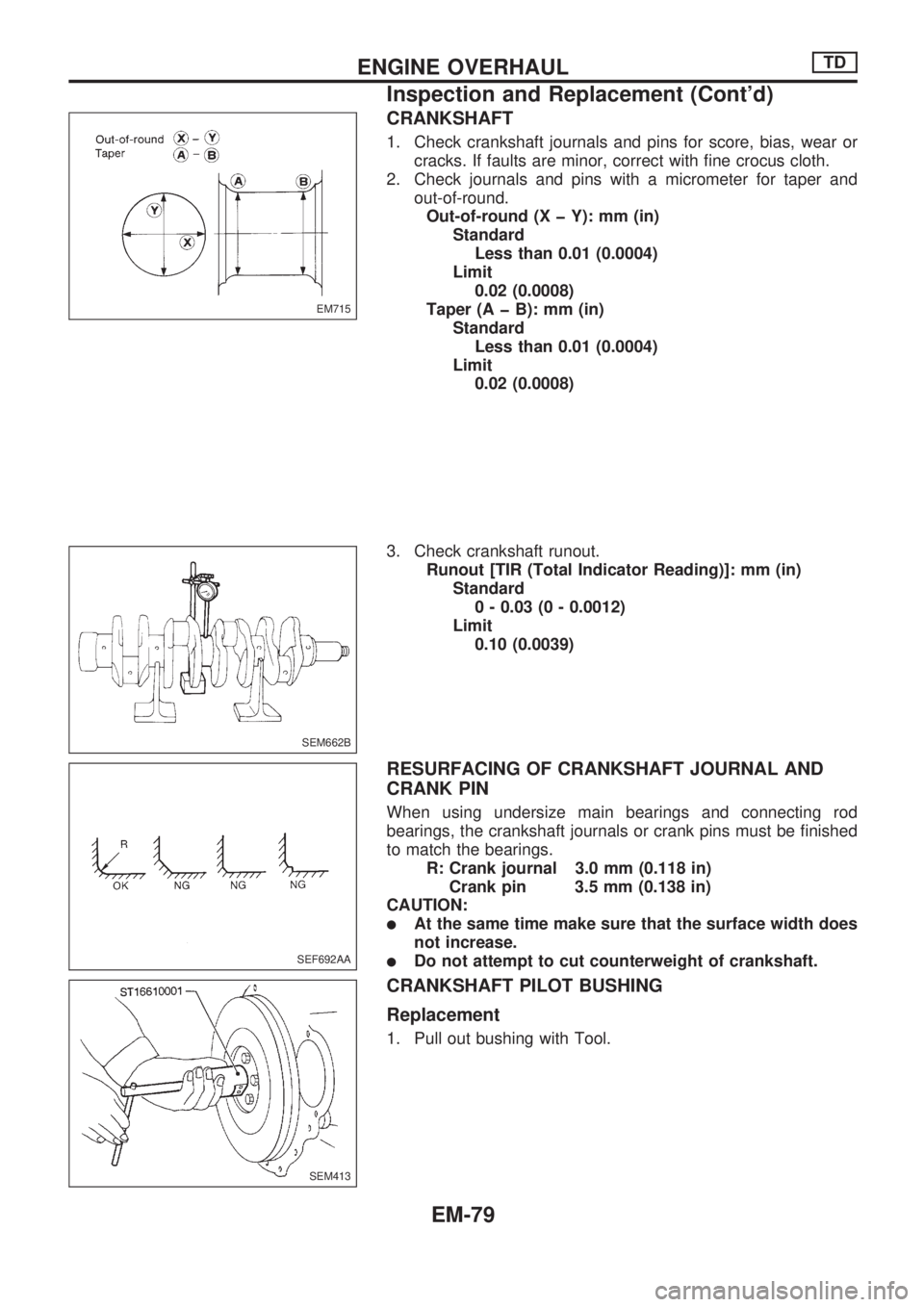

CRANKSHAFT

1. Check crankshaft journals and pins for score, bias, wear or

cracks. If faults are minor, correct with fine crocus cloth.

2. Check journals and pins with a micrometer for taper and

out-of-round.

Out-of-round (X þ Y): mm (in)

Standard

Less than 0.01 (0.0004)

Limit

0.02 (0.0008)

Taper (A þ B): mm (in)

Standard

Less than 0.01 (0.0004)

Limit

0.02 (0.0008)

3. Check crankshaft runout.

Runout [TIR (Total Indicator Reading)]: mm (in)

Standard

0 - 0.03 (0 - 0.0012)

Limit

0.10 (0.0039)

RESURFACING OF CRANKSHAFT JOURNAL AND

CRANK PIN

When using undersize main bearings and connecting rod

bearings, the crankshaft journals or crank pins must be finished

to match the bearings.

R: Crank journal 3.0 mm (0.118 in)

Crank pin 3.5 mm (0.138 in)

CAUTION:

lAt the same time make sure that the surface width does

not increase.

lDo not attempt to cut counterweight of crankshaft.

CRANKSHAFT PILOT BUSHING

Replacement

1. Pull out bushing with Tool.

EM715

SEM662B

SEF692AA

SEM413

ENGINE OVERHAULTD

Inspection and Replacement (Cont'd)

EM-79

Page 1633 of 1659

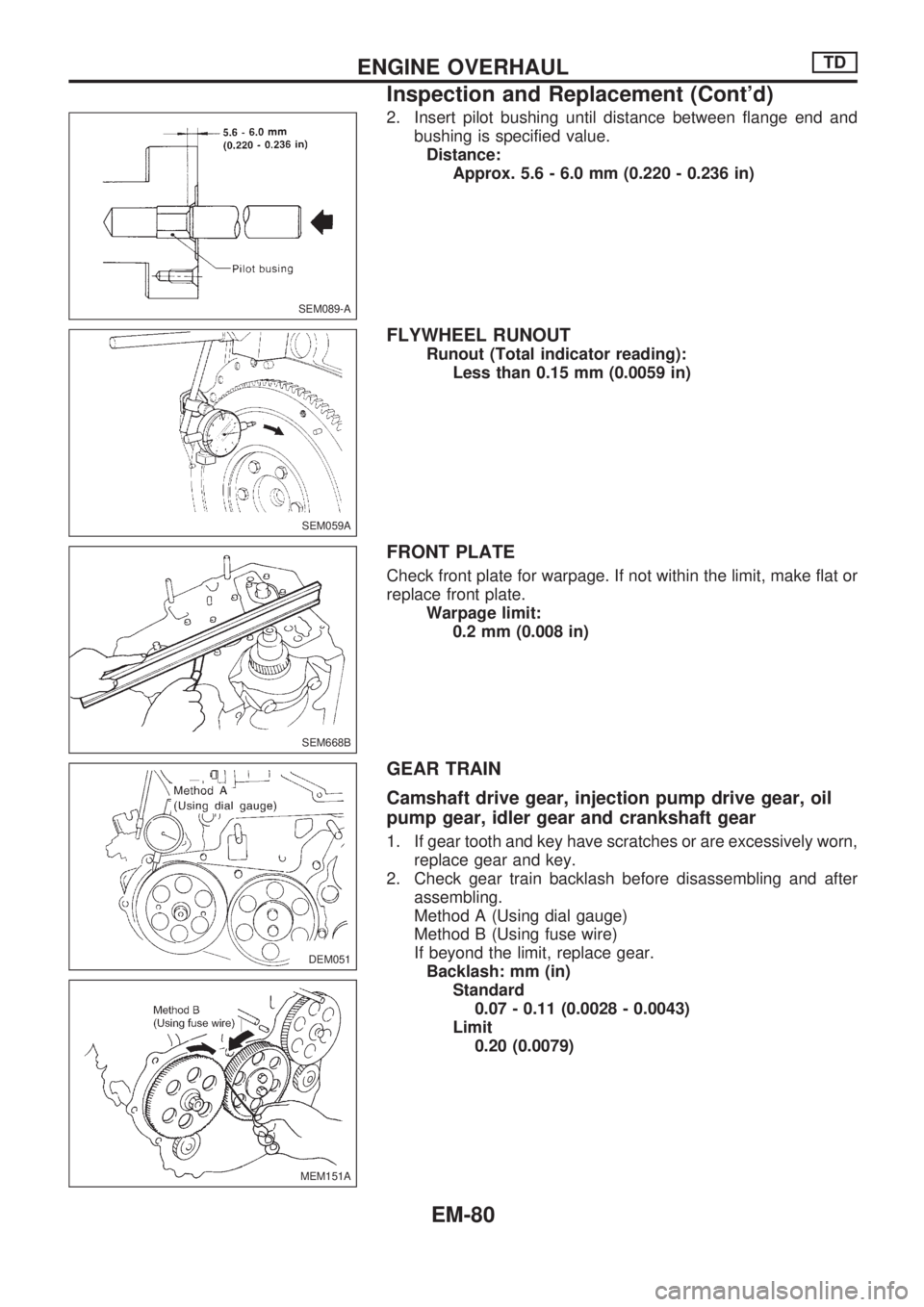

2. Insert pilot bushing until distance between flange end and

bushing is specified value.

Distance:

Approx. 5.6 - 6.0 mm (0.220 - 0.236 in)

FLYWHEEL RUNOUT

Runout (Total indicator reading):

Less than 0.15 mm (0.0059 in)

FRONT PLATE

Check front plate for warpage. If not within the limit, make flat or

replace front plate.

Warpage limit:

0.2 mm (0.008 in)

GEAR TRAIN

Camshaft drive gear, injection pump drive gear, oil

pump gear, idler gear and crankshaft gear

1. If gear tooth and key have scratches or are excessively worn,

replace gear and key.

2. Check gear train backlash before disassembling and after

assembling.

Method A (Using dial gauge)

Method B (Using fuse wire)

If beyond the limit, replace gear.

Backlash: mm (in)

Standard

0.07 - 0.11 (0.0028 - 0.0043)

Limit

0.20 (0.0079)

SEM089-A

SEM059A

SEM668B

DEM051

MEM151A

ENGINE OVERHAULTD

Inspection and Replacement (Cont'd)

EM-80

Page 1634 of 1659

IDLER GEAR BUSHING CLEARANCE

1. Measure idler gear shaft outer diameter.

2. Measure idler gear bushing inner diameter.

3. Calculate idler gear bushing clearance.

Bushing clearance: mm (in)

Standard

0.025 - 0.061 (0.0010 - 0.0024)

Limit

0.20 (0.0079)

IDLER GEAR END PLAY

Measure idler gear end play between gear plate and gear.

Idler gear end play: mm (in)

Standard

0.03 - 0.14 (0.0012 - 0.0055)

Limit

Less than 0.3 (0.012)

REPLACEMENT OF IDLER GEAR BUSHING

1. Use a suitable tool to replace bushing.

2. Ream idler gear bushing.

Finished size:

42.00 - 42.02 mm (1.6535 - 1.6543 in)

Idler gear shaft

Install idler gear shaft so that oil hole of shaft faces upward.

CAMSHAFT AND CAMSHAFT BUSHING

Camshaft bushing clearance

Measure inside diameter of camshaft bushing and outside diam-

eter of camshaft journal with a suitable gauge.

Clearance between camshaft and bushing

(A þ B): mm (in)

Standard

0.020 - 0.109 (0.0008 - 0.0043)

Limit

Less than 0.15 (0.0059)

SEM666B

SEM705

DEM052

SEM706

SEM669B

ENGINE OVERHAULTD

Inspection and Replacement (Cont'd)

EM-81

Page 1635 of 1659

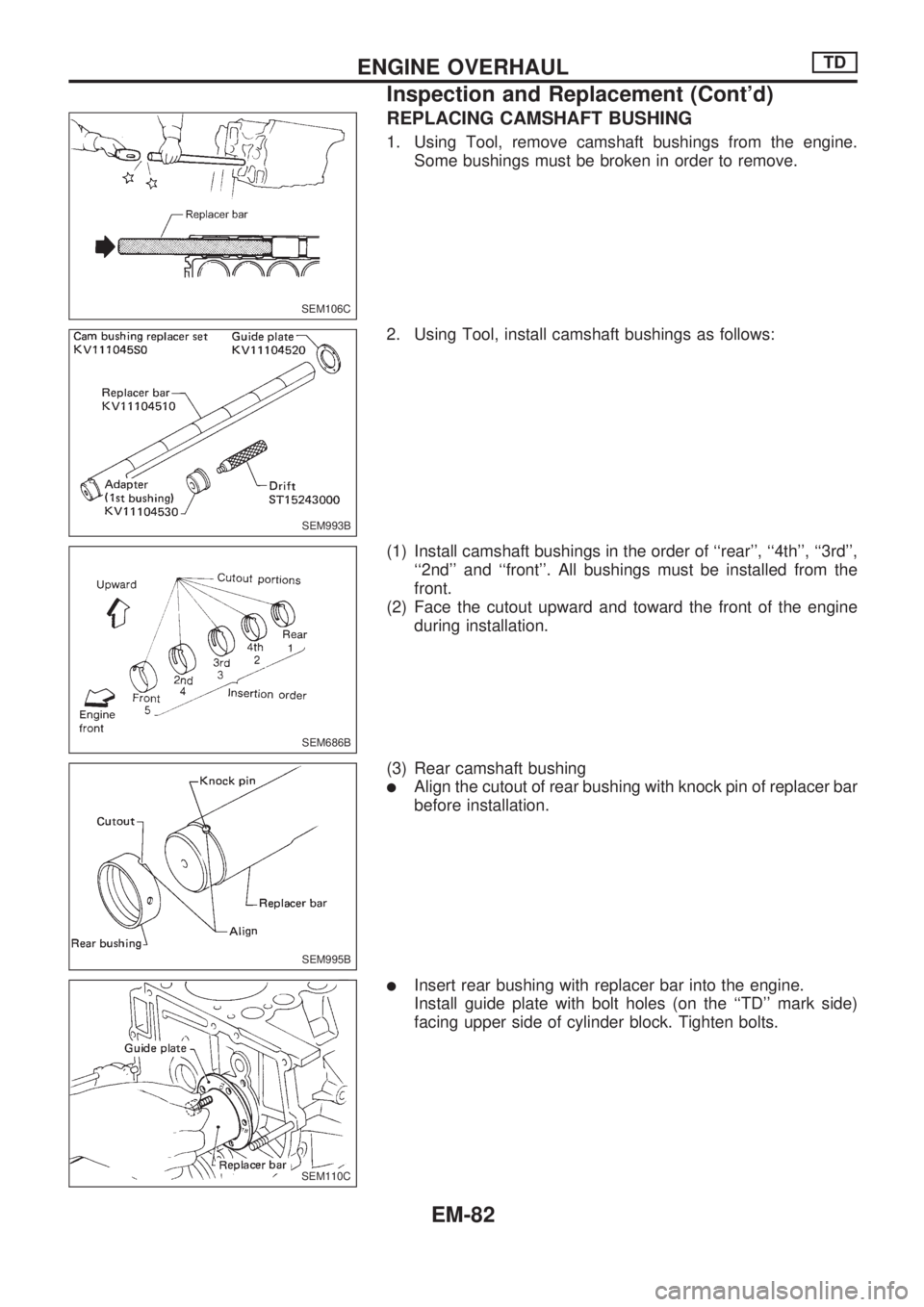

REPLACING CAMSHAFT BUSHING

1. Using Tool, remove camshaft bushings from the engine.

Some bushings must be broken in order to remove.

2. Using Tool, install camshaft bushings as follows:

(1) Install camshaft bushings in the order of ``rear'', ``4th'', ``3rd'',

``2nd'' and ``front''. All bushings must be installed from the

front.

(2) Face the cutout upward and toward the front of the engine

during installation.

(3) Rear camshaft bushing

lAlign the cutout of rear bushing with knock pin of replacer bar

before installation.

lInsert rear bushing with replacer bar into the engine.

Install guide plate with bolt holes (on the ``TD'' mark side)

facing upper side of cylinder block. Tighten bolts.

SEM106C

SEM993B

SEM686B

SEM995B

SEM110C

ENGINE OVERHAULTD

Inspection and Replacement (Cont'd)

EM-82

Page 1636 of 1659

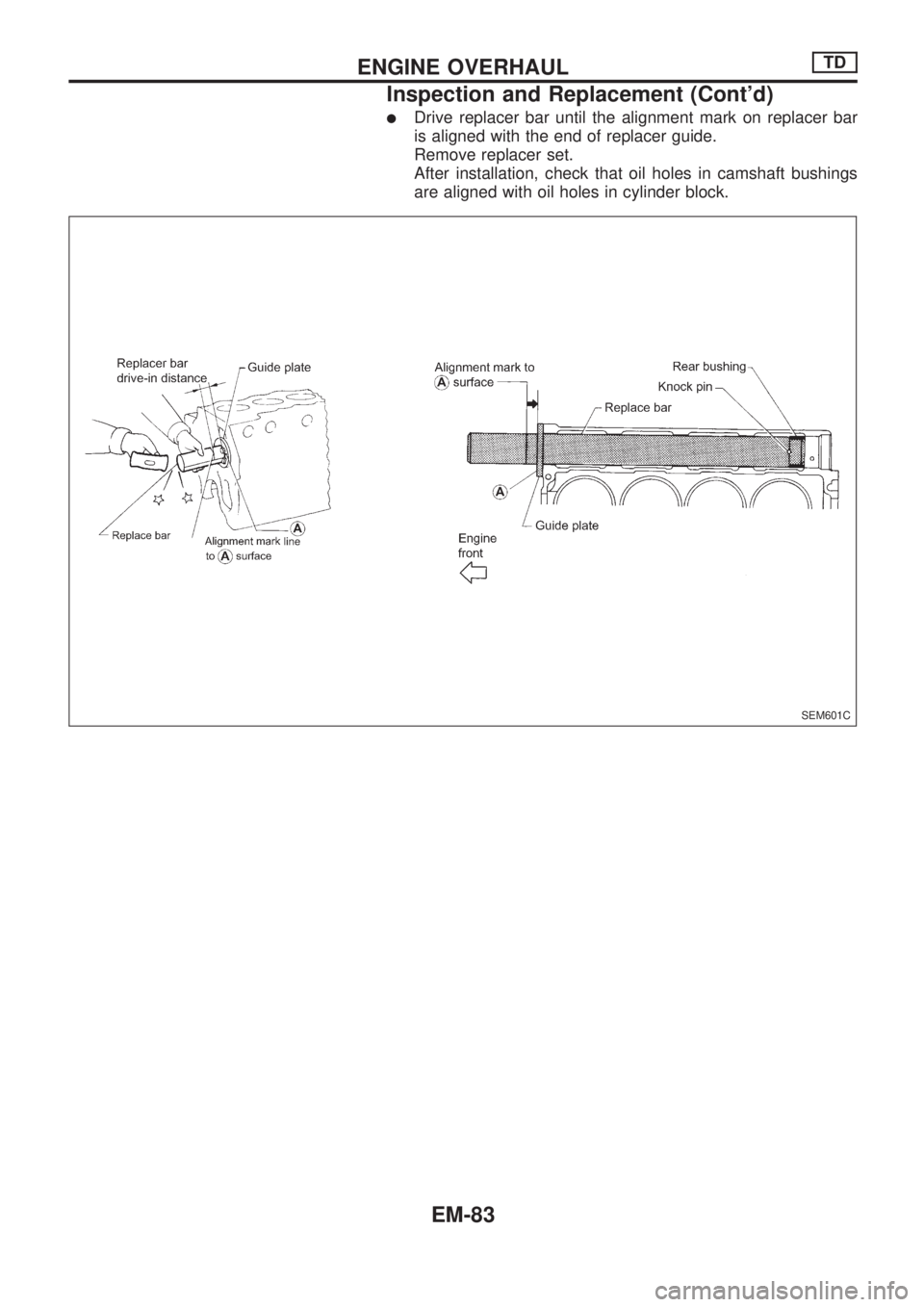

lDrive replacer bar until the alignment mark on replacer bar

is aligned with the end of replacer guide.

Remove replacer set.

After installation, check that oil holes in camshaft bushings

are aligned with oil holes in cylinder block.

SEM601C

ENGINE OVERHAULTD

Inspection and Replacement (Cont'd)

EM-83

Page 1637 of 1659

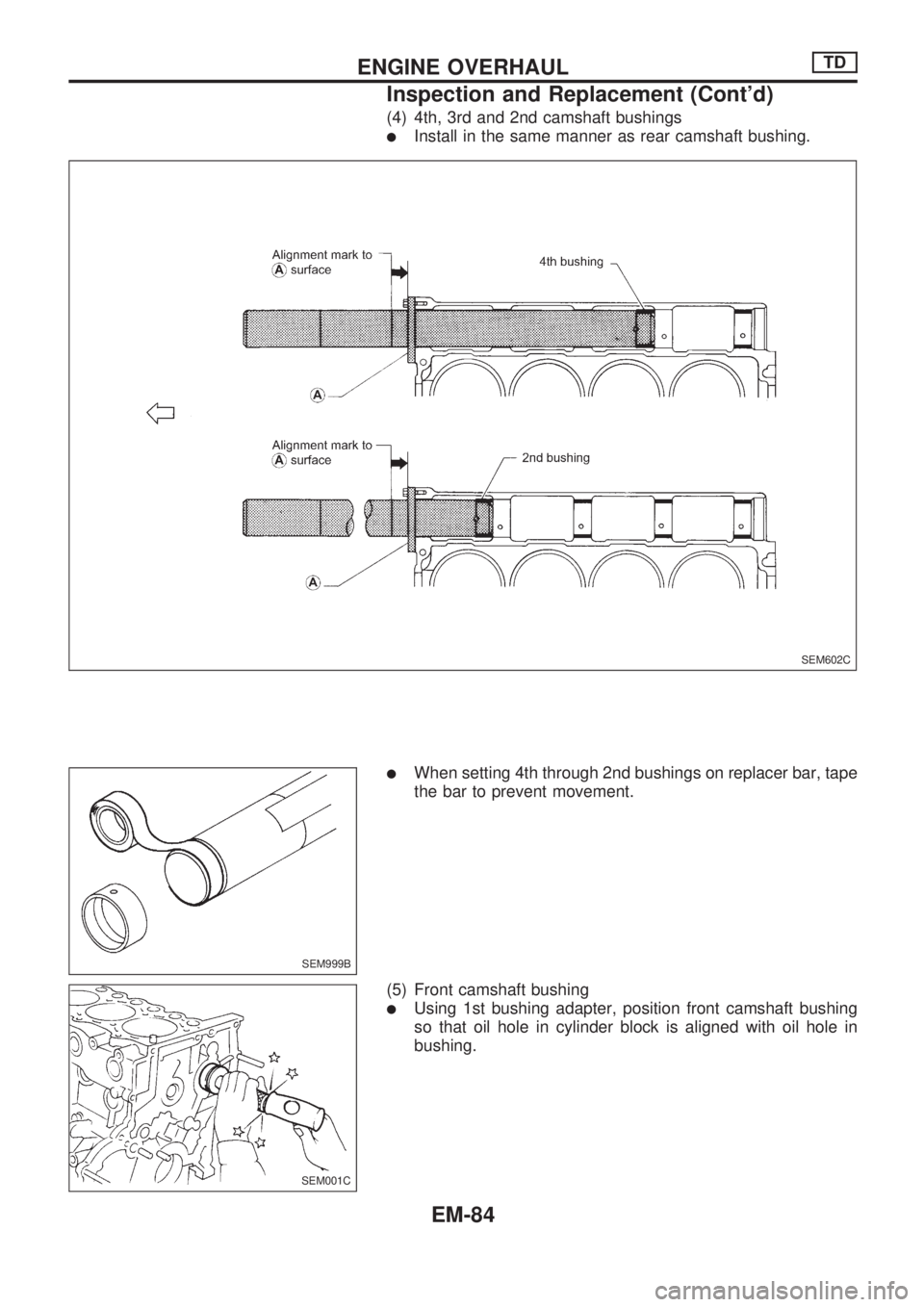

(4) 4th, 3rd and 2nd camshaft bushings

lInstall in the same manner as rear camshaft bushing.

lWhen setting 4th through 2nd bushings on replacer bar, tape

the bar to prevent movement.

(5) Front camshaft bushing

lUsing 1st bushing adapter, position front camshaft bushing

so that oil hole in cylinder block is aligned with oil hole in

bushing.

SEM602C

SEM999B

SEM001C

ENGINE OVERHAULTD

Inspection and Replacement (Cont'd)

EM-84

Page 1638 of 1659

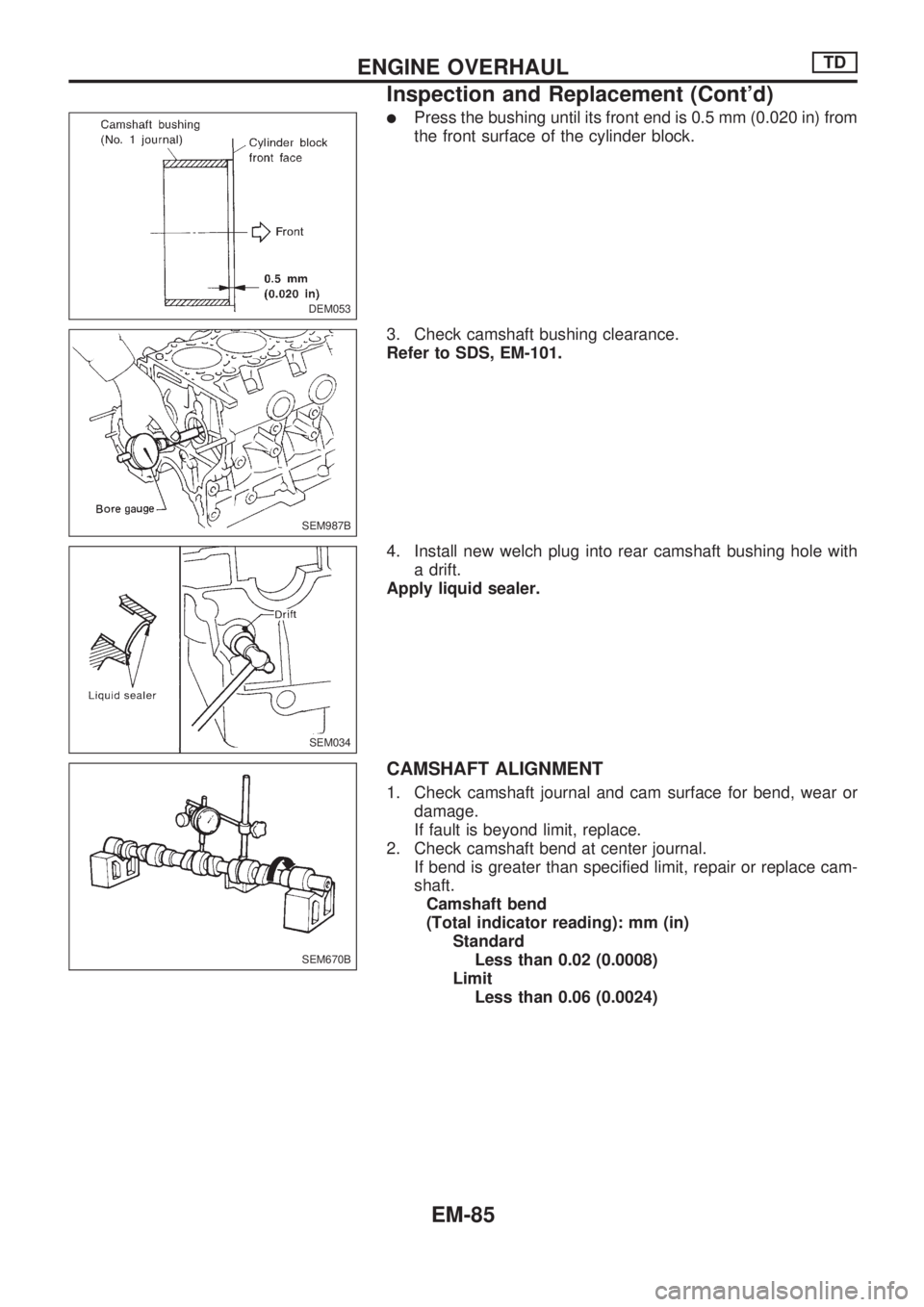

lPress the bushing until its front end is 0.5 mm (0.020 in) from

the front surface of the cylinder block.

3. Check camshaft bushing clearance.

Refer to SDS, EM-101.

4. Install new welch plug into rear camshaft bushing hole with

a drift.

Apply liquid sealer.

CAMSHAFT ALIGNMENT

1. Check camshaft journal and cam surface for bend, wear or

damage.

If fault is beyond limit, replace.

2. Check camshaft bend at center journal.

If bend is greater than specified limit, repair or replace cam-

shaft.

Camshaft bend

(Total indicator reading): mm (in)

Standard

Less than 0.02 (0.0008)

Limit

Less than 0.06 (0.0024)

DEM053

SEM987B

SEM034

SEM670B

ENGINE OVERHAULTD

Inspection and Replacement (Cont'd)

EM-85

Page 1639 of 1659

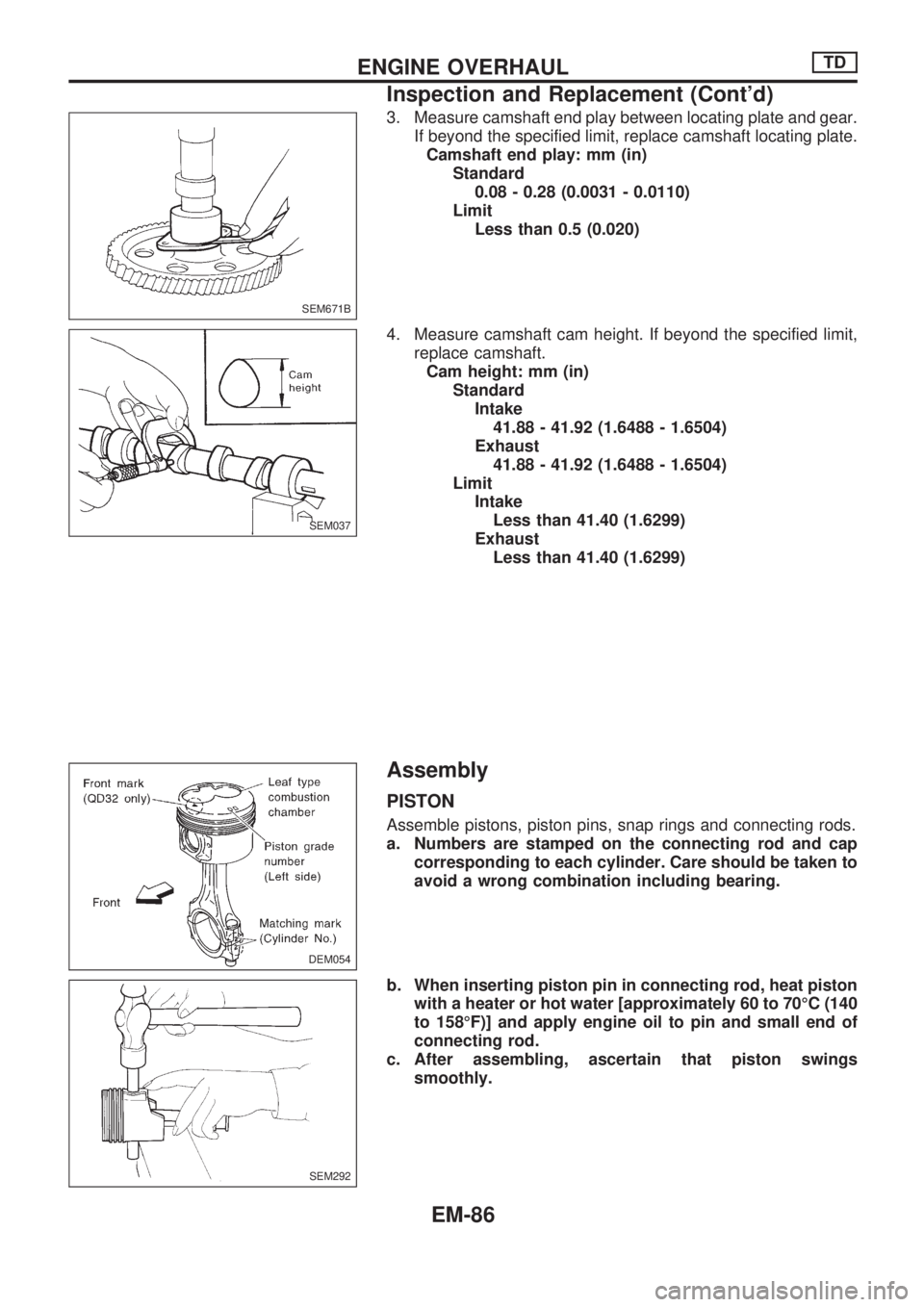

3. Measure camshaft end play between locating plate and gear.

If beyond the specified limit, replace camshaft locating plate.

Camshaft end play: mm (in)

Standard

0.08 - 0.28 (0.0031 - 0.0110)

Limit

Less than 0.5 (0.020)

4. Measure camshaft cam height. If beyond the specified limit,

replace camshaft.

Cam height: mm (in)

Standard

Intake

41.88 - 41.92 (1.6488 - 1.6504)

Exhaust

41.88 - 41.92 (1.6488 - 1.6504)

Limit

Intake

Less than 41.40 (1.6299)

Exhaust

Less than 41.40 (1.6299)

Assembly

PISTON

Assemble pistons, piston pins, snap rings and connecting rods.

a. Numbers are stamped on the connecting rod and cap

corresponding to each cylinder. Care should be taken to

avoid a wrong combination including bearing.

b. When inserting piston pin in connecting rod, heat piston

with a heater or hot water [approximately 60 to 70ÉC (140

to 158ÉF)] and apply engine oil to pin and small end of

connecting rod.

c. After assembling, ascertain that piston swings

smoothly.

SEM671B

SEM037

DEM054

SEM292

ENGINE OVERHAULTD

Inspection and Replacement (Cont'd)

EM-86

Page 1640 of 1659

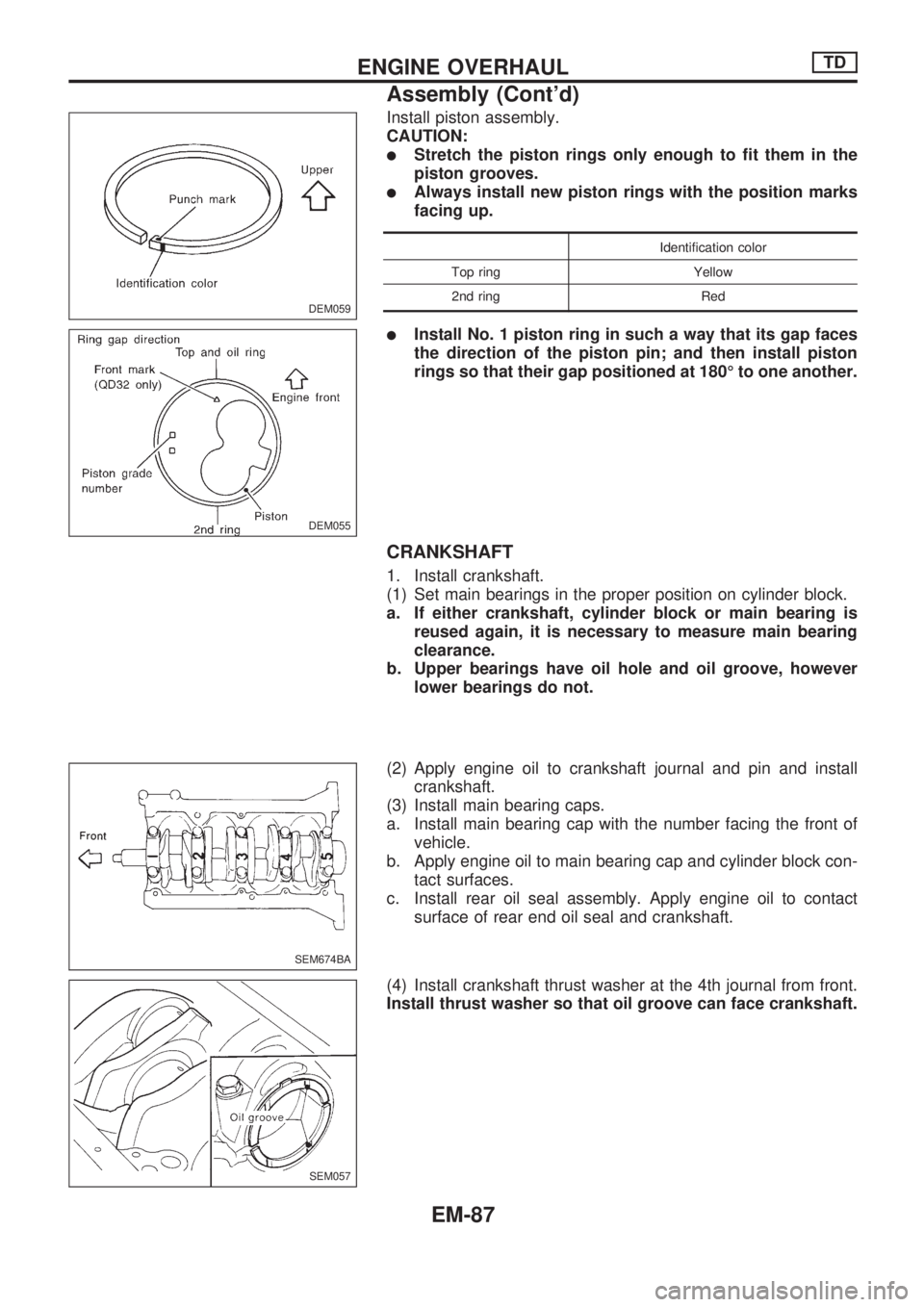

Install piston assembly.

CAUTION:

lStretch the piston rings only enough to fit them in the

piston grooves.

lAlways install new piston rings with the position marks

facing up.

Identification color

Top ring Yellow

2nd ring Red

lInstall No. 1 piston ring in such a way that its gap faces

the direction of the piston pin; and then install piston

rings so that their gap positioned at 180É to one another.

CRANKSHAFT

1. Install crankshaft.

(1) Set main bearings in the proper position on cylinder block.

a. If either crankshaft, cylinder block or main bearing is

reused again, it is necessary to measure main bearing

clearance.

b. Upper bearings have oil hole and oil groove, however

lower bearings do not.

(2) Apply engine oil to crankshaft journal and pin and install

crankshaft.

(3) Install main bearing caps.

a. Install main bearing cap with the number facing the front of

vehicle.

b. Apply engine oil to main bearing cap and cylinder block con-

tact surfaces.

c. Install rear oil seal assembly. Apply engine oil to contact

surface of rear end oil seal and crankshaft.

(4) Install crankshaft thrust washer at the 4th journal from front.

Install thrust washer so that oil groove can face crankshaft.

DEM059

DEM055

SEM674BA

SEM057

ENGINE OVERHAULTD

Assembly (Cont'd)

EM-87