NISSAN PICK-UP 1999 Repair Manual

PICK-UP 1999

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57373/w960_57373-0.png

NISSAN PICK-UP 1999 Repair Manual

Trending: water pump, lock, alternator, compression ratio, window, charging, sensor

Page 431 of 666

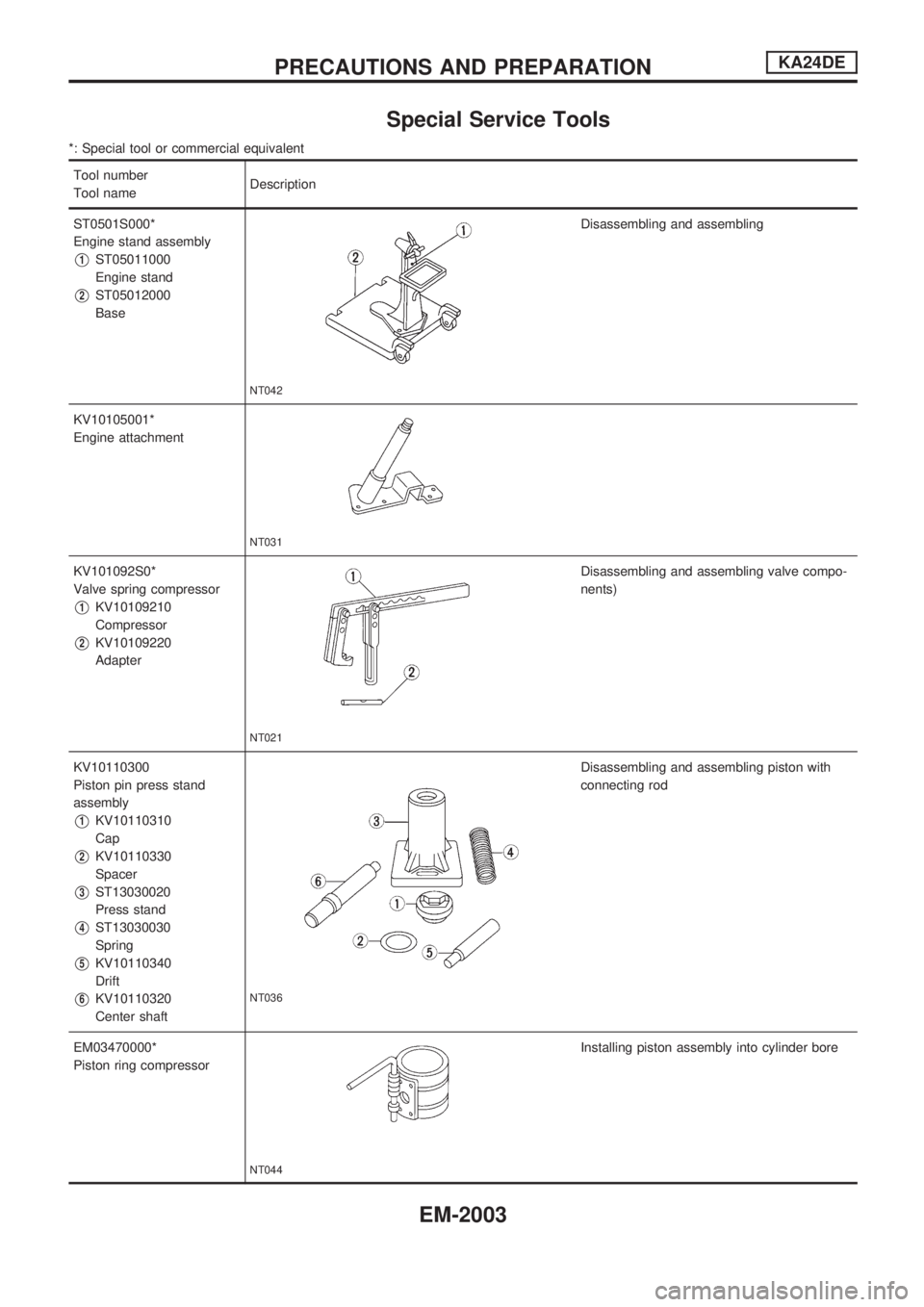

Special Service Tools

*: Special tool or commercial equivalent

Tool number

Tool nameDescription

ST0501S000*

Engine stand assembly

V1ST05011000

Engine stand

V2ST05012000

Base

NT042

Disassembling and assembling

KV10105001*

Engine attachment

NT031

KV101092S0*

Valve spring compressor

V1KV10109210

Compressor

V2KV10109220

Adapter

NT021

Disassembling and assembling valve compo-

nents)

KV10110300

Piston pin press stand

assembly

V1KV10110310

Cap

V2KV10110330

Spacer

V3ST13030020

Press stand

V4ST13030030

Spring

V5KV10110340

Drift

V6KV10110320

Center shaftNT036

Disassembling and assembling piston with

connecting rod

EM03470000*

Piston ring compressor

NT044

Installing piston assembly into cylinder bore

PRECAUTIONS AND PREPARATIONKA24DE

EM-2003

Page 432 of 666

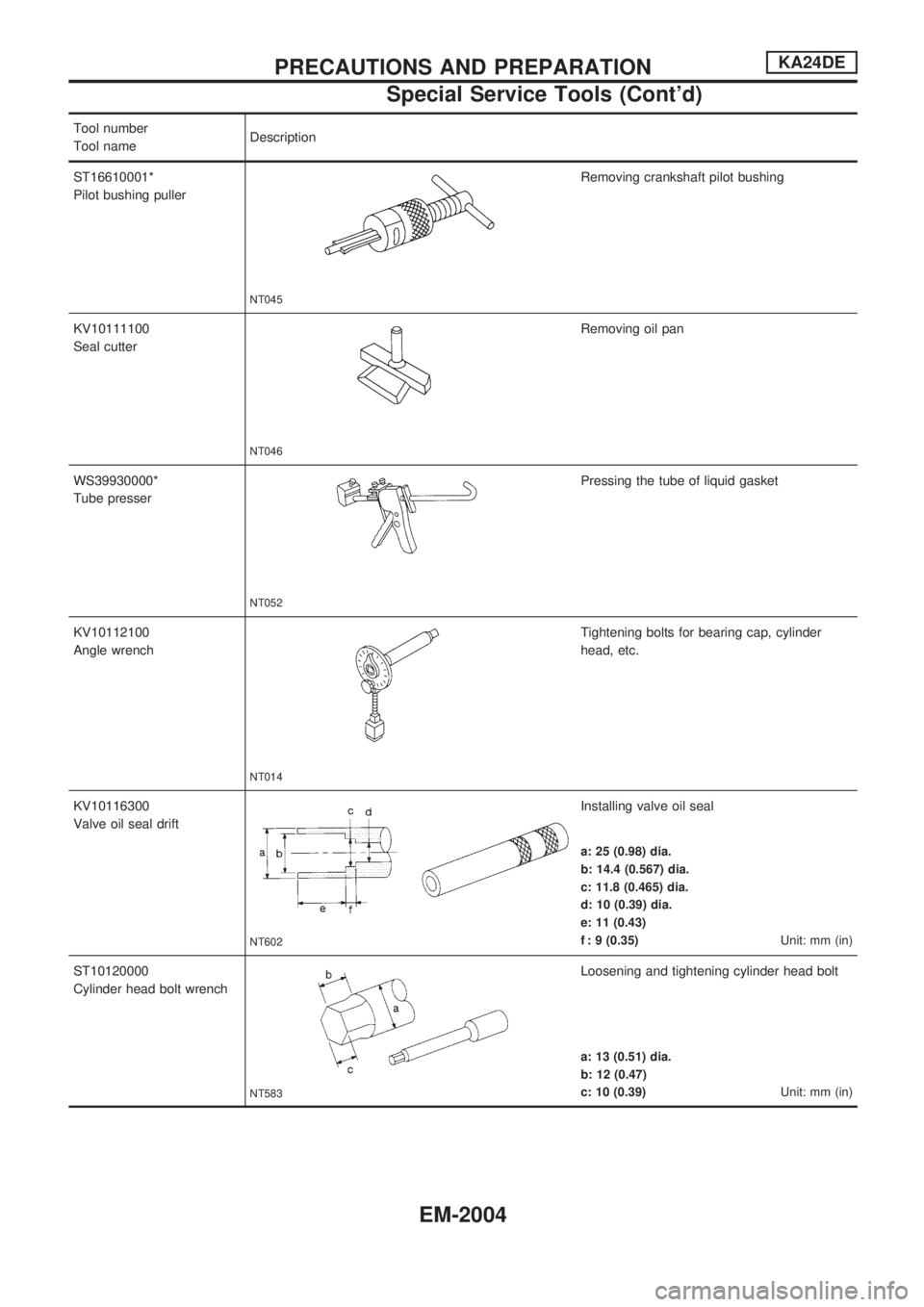

Tool number

Tool nameDescription

ST16610001*

Pilot bushing puller

NT045

Removing crankshaft pilot bushing

KV10111100

Seal cutter

NT046

Removing oil pan

WS39930000*

Tube presser

NT052

Pressing the tube of liquid gasket

KV10112100

Angle wrench

NT014

Tightening bolts for bearing cap, cylinder

head, etc.

KV10116300

Valve oil seal drift

NT602

Installing valve oil seal

a: 25 (0.98) dia.

b: 14.4 (0.567) dia.

c: 11.8 (0.465) dia.

d: 10 (0.39) dia.

e: 11 (0.43)

f : 9 (0.35)Unit: mm (in)

ST10120000

Cylinder head bolt wrench

NT583

Loosening and tightening cylinder head bolt

a: 13 (0.51) dia.

b: 12 (0.47)

c: 10 (0.39)Unit: mm (in)

PRECAUTIONS AND PREPARATIONKA24DE

Special Service Tools (Cont'd)

EM-2004

Page 433 of 666

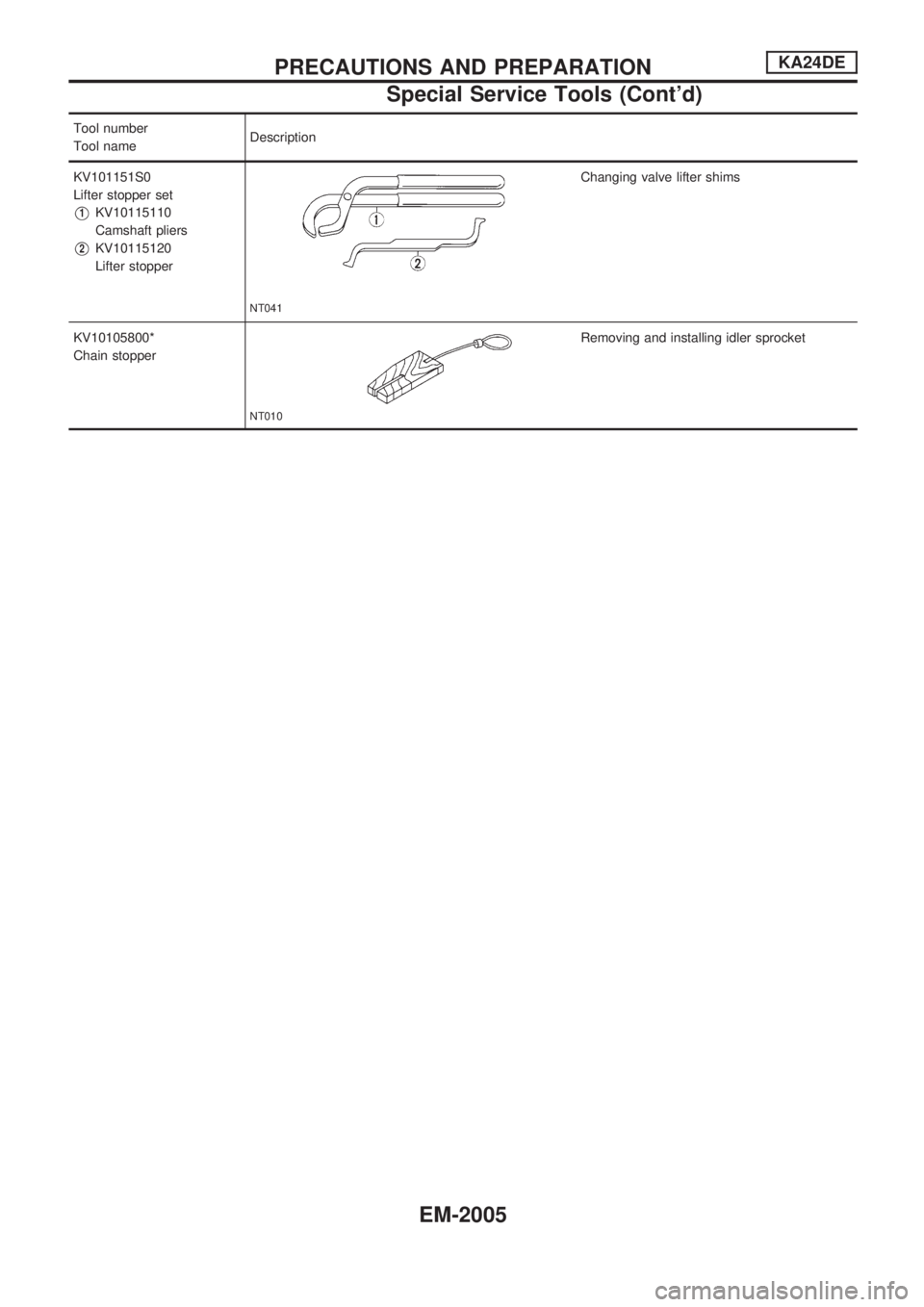

Tool number

Tool nameDescription

KV101151S0

Lifter stopper set

V1KV10115110

Camshaft pliers

V2KV10115120

Lifter stopper

NT041

Changing valve lifter shims

KV10105800*

Chain stopper

NT010

Removing and installing idler sprocket

PRECAUTIONS AND PREPARATIONKA24DE

Special Service Tools (Cont'd)

EM-2005

Page 434 of 666

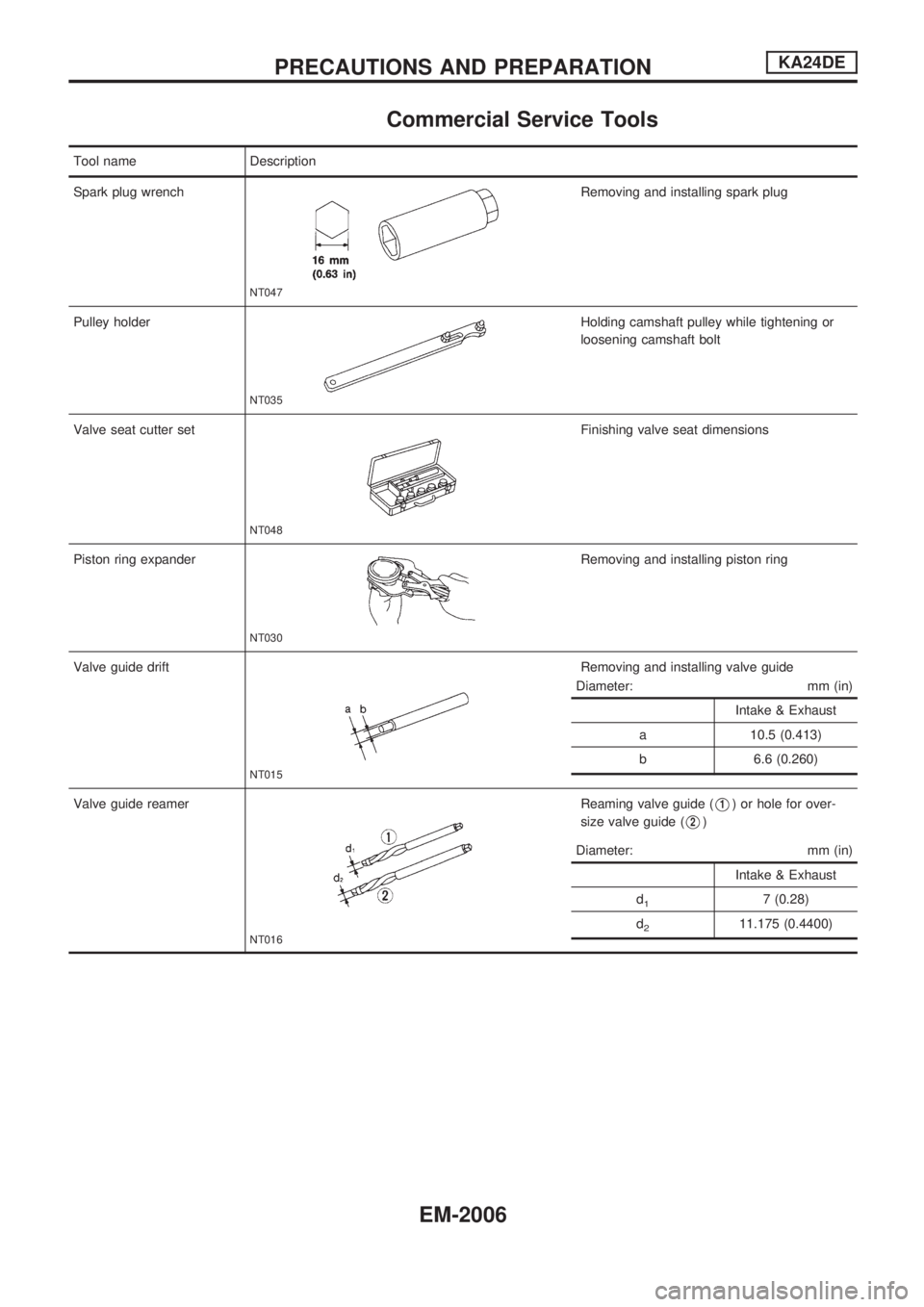

Commercial Service Tools

Tool name Description

Spark plug wrench

NT047

Removing and installing spark plug

Pulley holder

NT035

Holding camshaft pulley while tightening or

loosening camshaft bolt

Valve seat cutter set

NT048

Finishing valve seat dimensions

Piston ring expander

NT030

Removing and installing piston ring

Valve guide drift

NT015

Removing and installing valve guide

Valve guide reamer

NT016

Reaming valve guide (V1) or hole for over-

size valve guide (

V2)

Diameter: mm (in)

Intake & Exhaust

a 10.5 (0.413)

b 6.6 (0.260)

Diameter: mm (in)

Intake & Exhaust

d

17 (0.28)

d

211.175 (0.4400)

PRECAUTIONS AND PREPARATIONKA24DE

EM-2006

Page 435 of 666

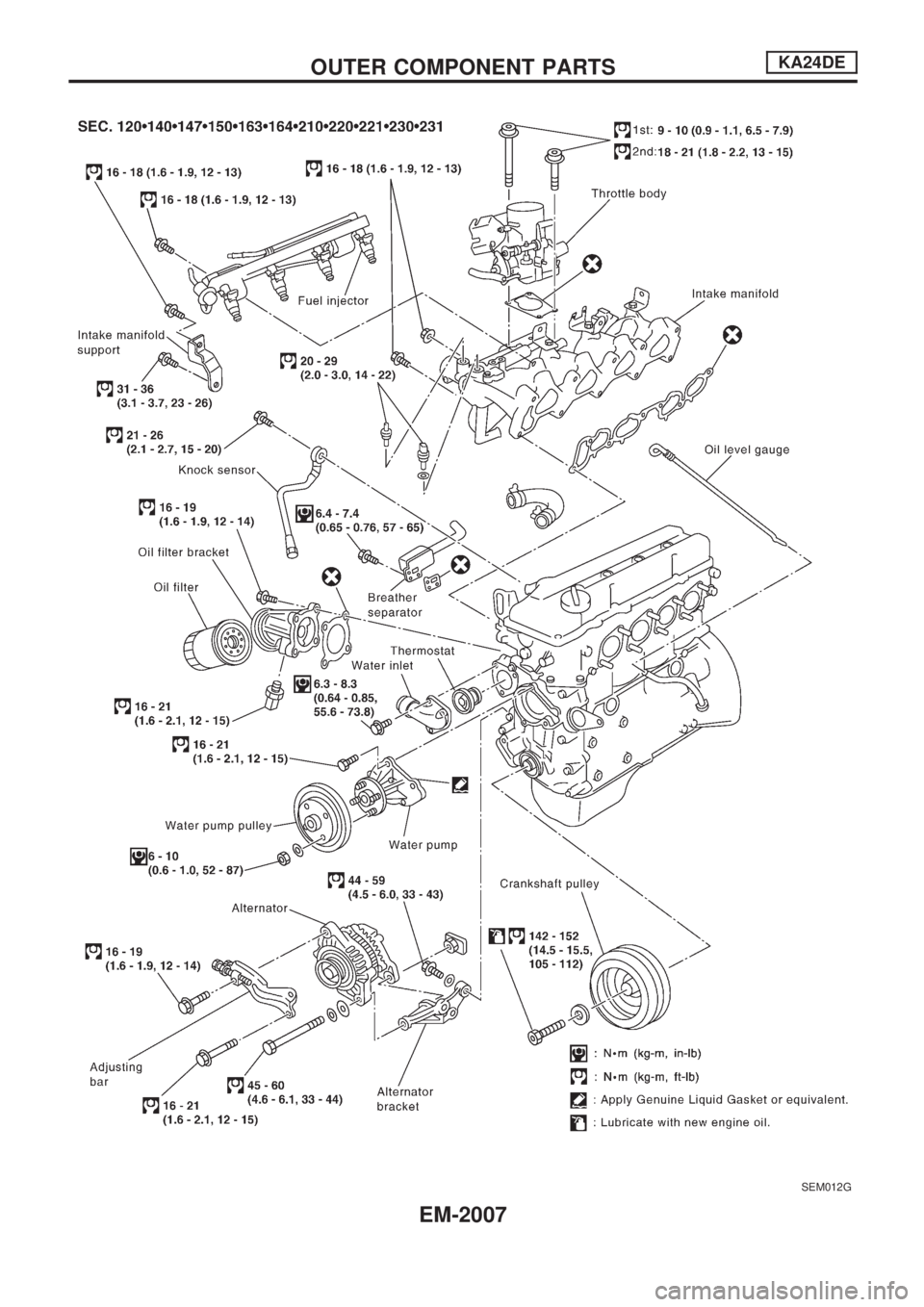

SEM012G

OUTER COMPONENT PARTSKA24DE

EM-2007

Page 436 of 666

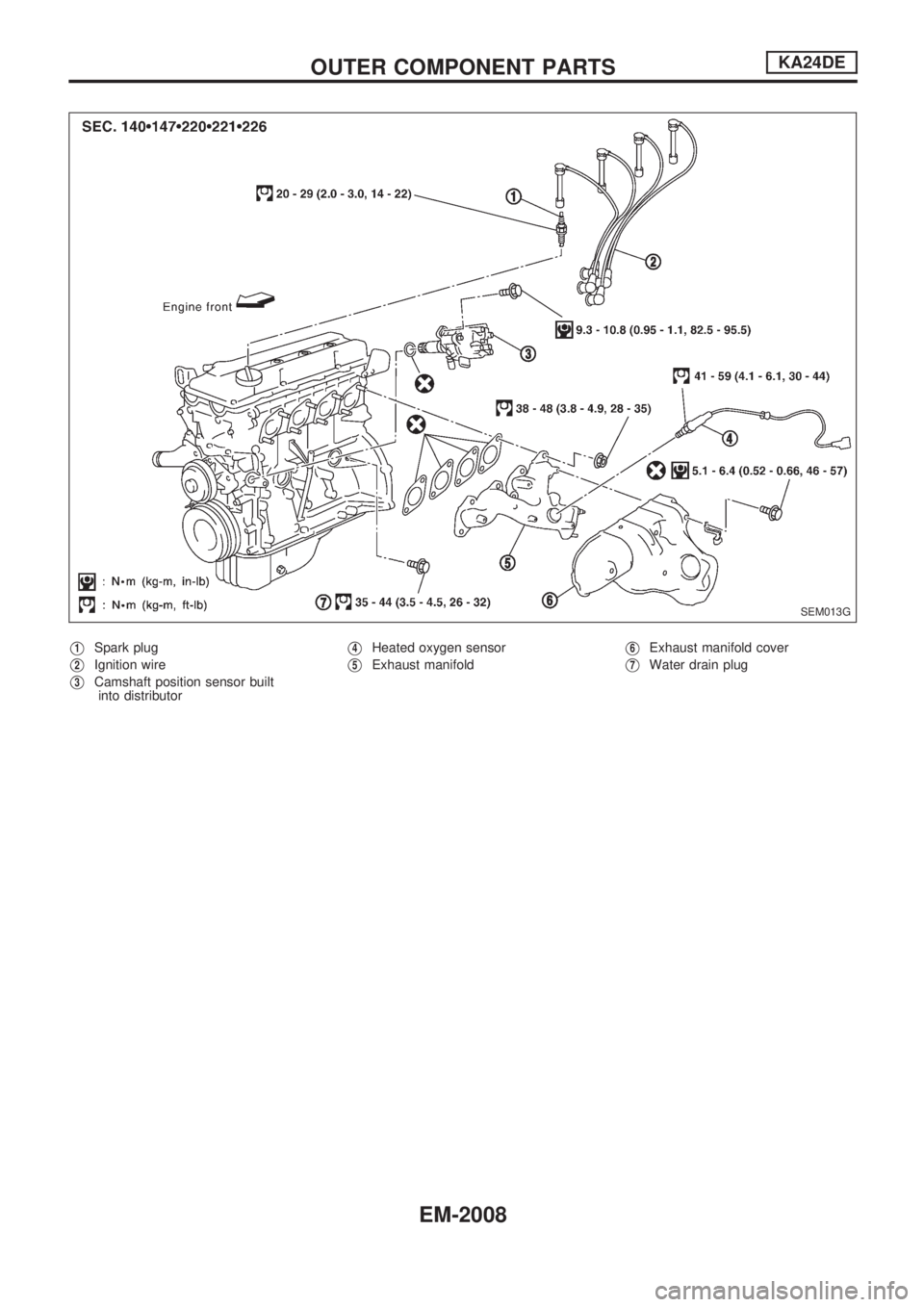

V1Spark plug

V2Ignition wire

V3Camshaft position sensor built

into distributor

V4Heated oxygen sensor

V5Exhaust manifoldV6Exhaust manifold cover

V7Water drain plug

SEM013G

OUTER COMPONENT PARTSKA24DE

EM-2008

Page 437 of 666

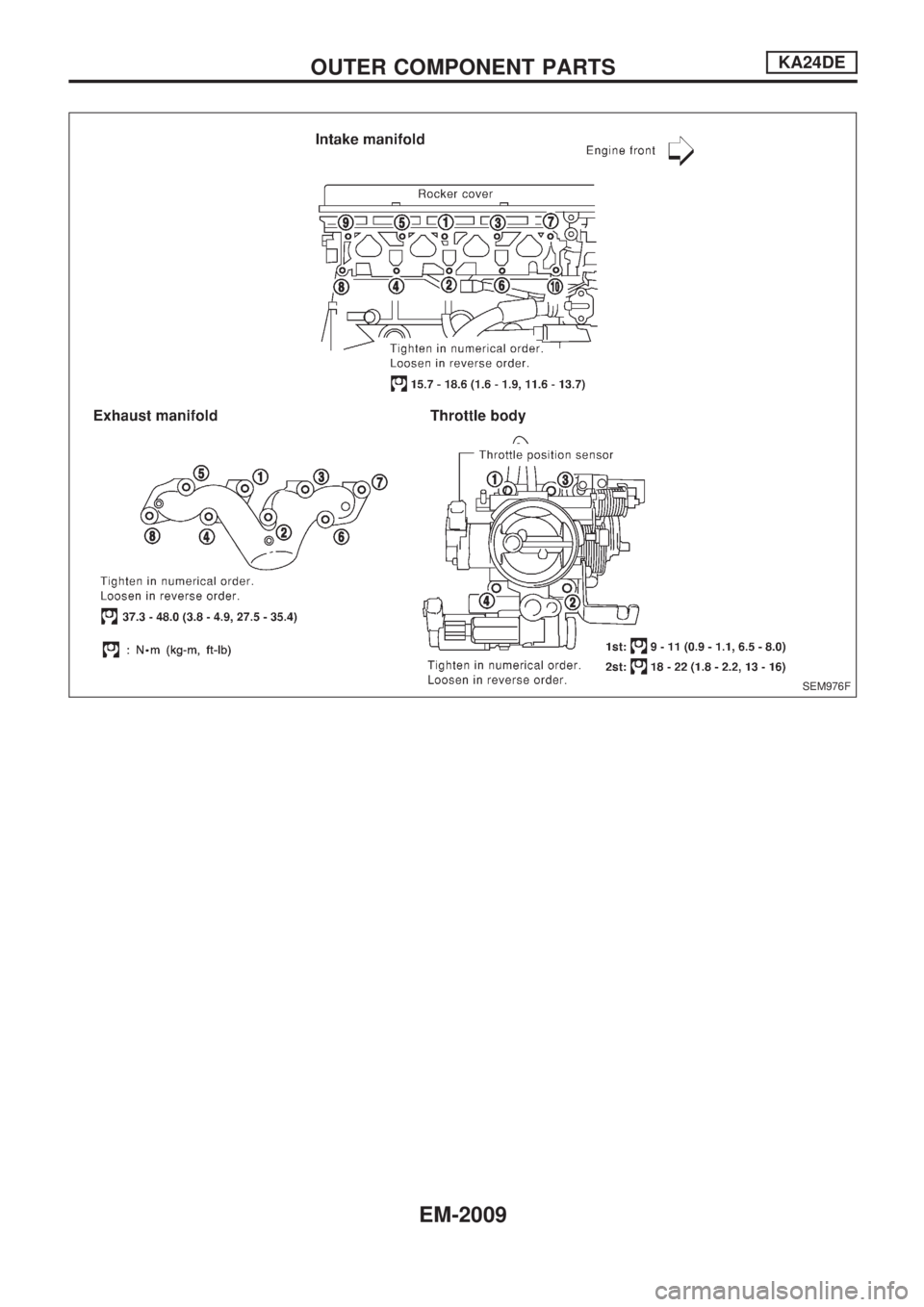

SEM976F

OUTER COMPONENT PARTSKA24DE

EM-2009

Page 438 of 666

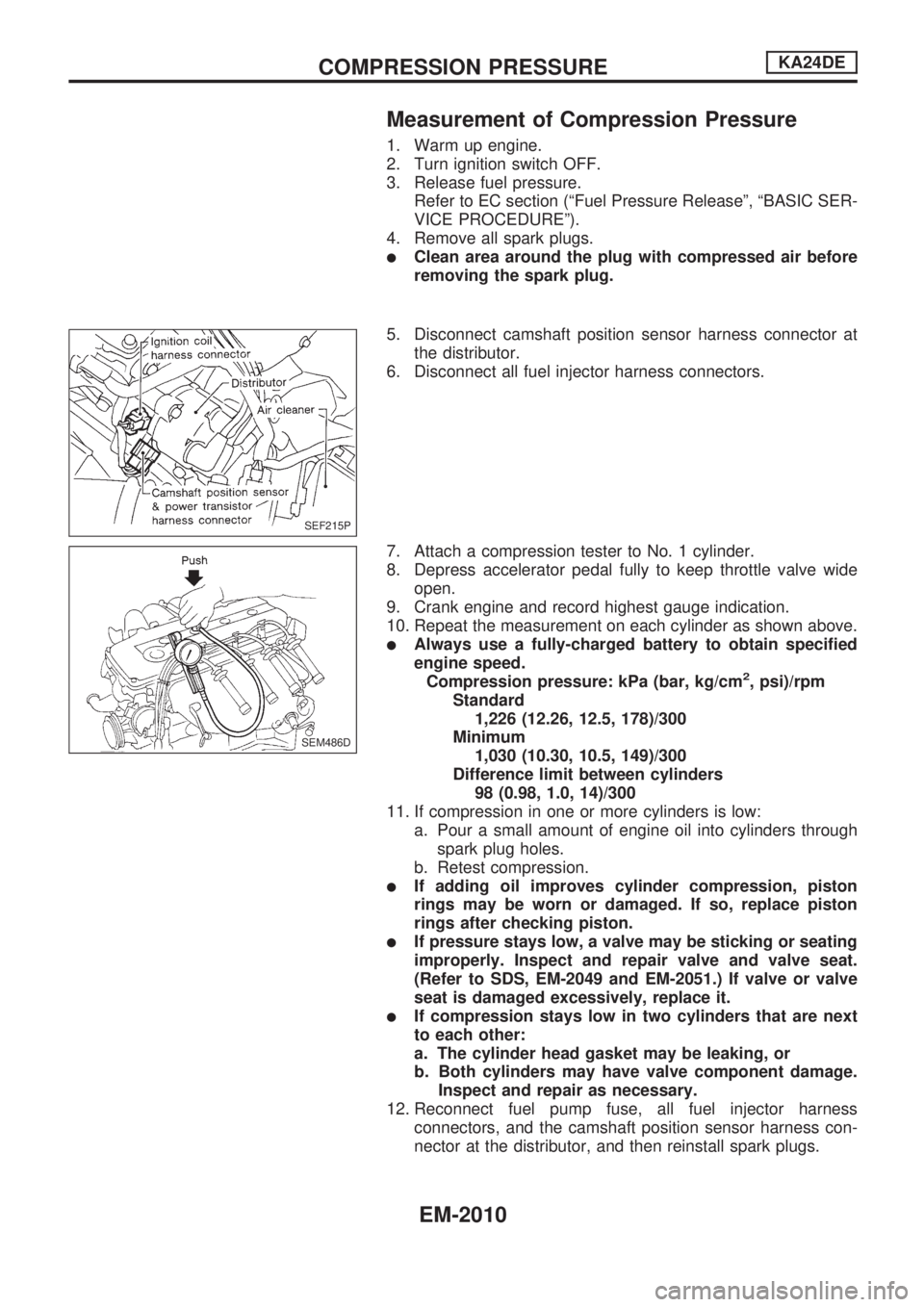

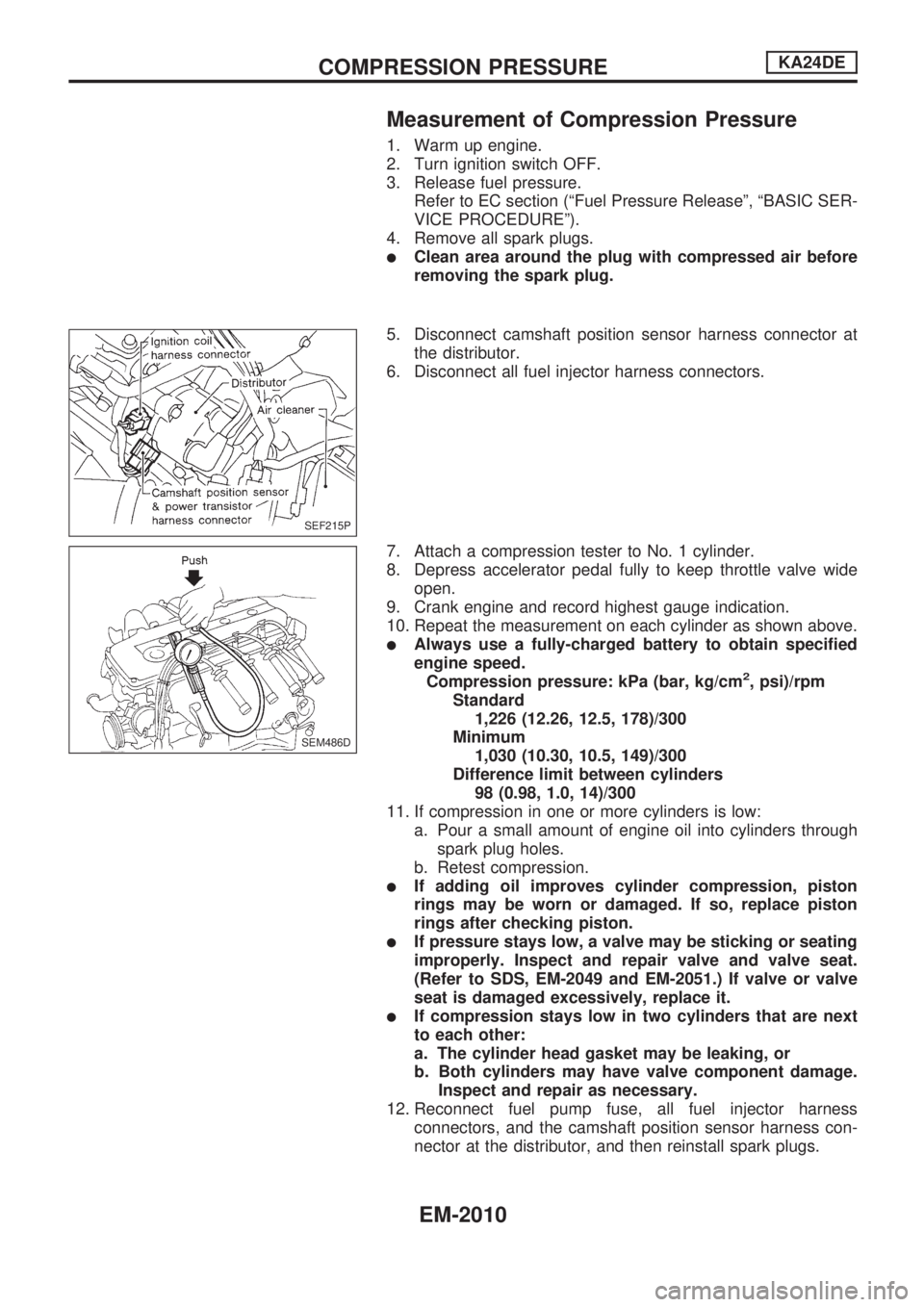

Measurement of Compression Pressure

1. Warm up engine.

2. Turn ignition switch OFF.

3. Release fuel pressure.

Refer to EC section (ªFuel Pressure Releaseº, ªBASIC SER-

VICE PROCEDUREº).

4. Remove all spark plugs.

lClean area around the plug with compressed air before

removing the spark plug.

5. Disconnect camshaft position sensor harness connector at

the distributor.

6. Disconnect all fuel injector harness connectors.

7. Attach a compression tester to No. 1 cylinder.

8. Depress accelerator pedal fully to keep throttle valve wide

open.

9. Crank engine and record highest gauge indication.

10. Repeat the measurement on each cylinder as shown above.

lAlways use a fully-charged battery to obtain specified

engine speed.

Compression pressure: kPa (bar, kg/cm

2, psi)/rpm

Standard

1,226 (12.26, 12.5, 178)/300

Minimum

1,030 (10.30, 10.5, 149)/300

Difference limit between cylinders

98 (0.98, 1.0, 14)/300

11. If compression in one or more cylinders is low:

a. Pour a small amount of engine oil into cylinders through

spark plug holes.

b. Retest compression.

lIf adding oil improves cylinder compression, piston

rings may be worn or damaged. If so, replace piston

rings after checking piston.

lIf pressure stays low, a valve may be sticking or seating

improperly. Inspect and repair valve and valve seat.

(Refer to SDS, EM-2049 and EM-2051.) If valve or valve

seat is damaged excessively, replace it.

lIf compression stays low in two cylinders that are next

to each other:

a. The cylinder head gasket may be leaking, or

b. Both cylinders may have valve component damage.

Inspect and repair as necessary.

12. Reconnect fuel pump fuse, all fuel injector harness

connectors, and the camshaft position sensor harness con-

nector at the distributor, and then reinstall spark plugs.

SEF215P

SEM486D

COMPRESSION PRESSUREKA24DE

EM-2010

Page 439 of 666

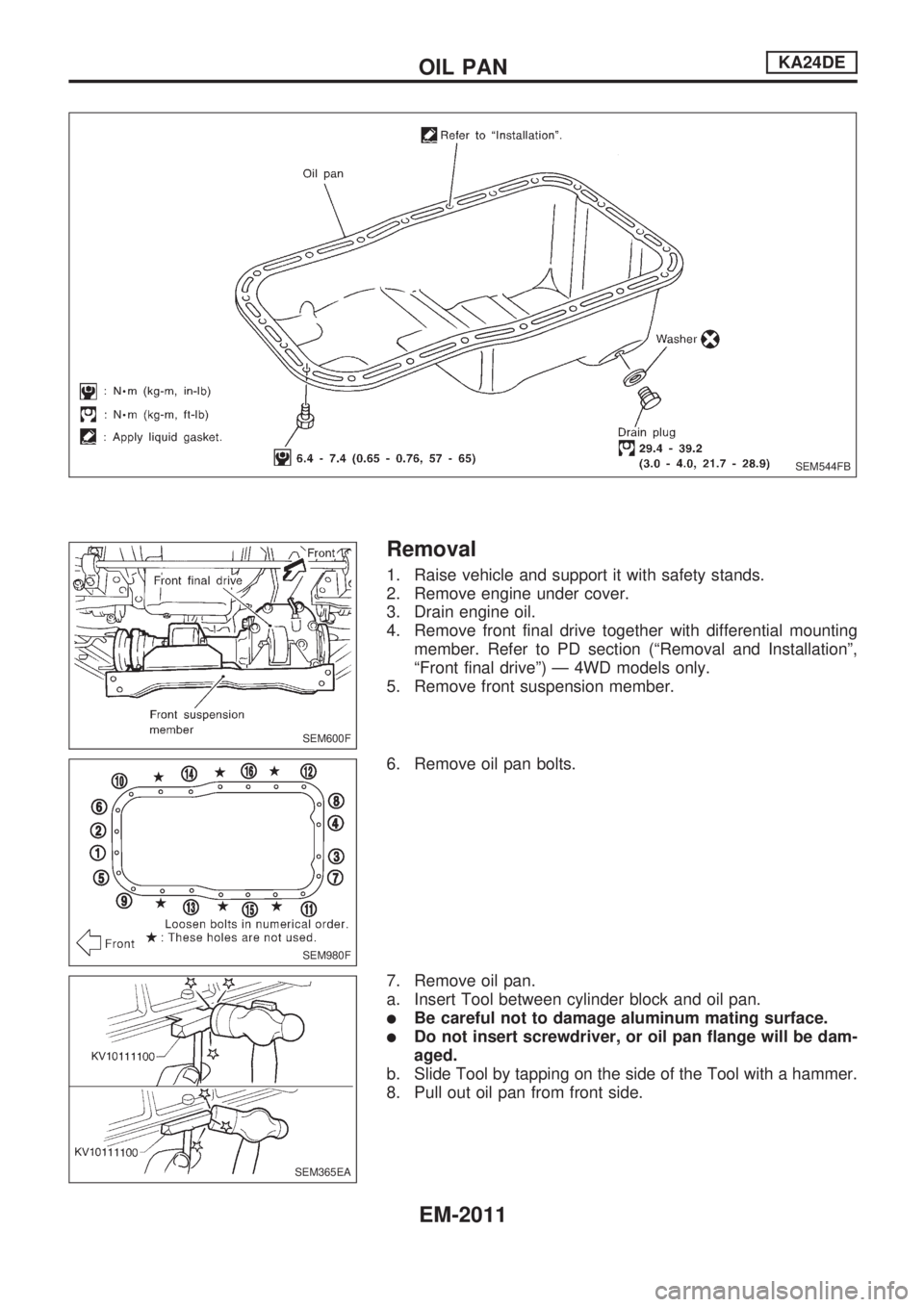

Removal

1. Raise vehicle and support it with safety stands.

2. Remove engine under cover.

3. Drain engine oil.

4. Remove front final drive together with differential mounting

member. Refer to PD section (ªRemoval and Installationº,

ªFront final driveº) Ð 4WD models only.

5. Remove front suspension member.

6. Remove oil pan bolts.

7. Remove oil pan.

a. Insert Tool between cylinder block and oil pan.

lBe careful not to damage aluminum mating surface.

lDo not insert screwdriver, or oil pan flange will be dam-

aged.

b. Slide Tool by tapping on the side of the Tool with a hammer.

8. Pull out oil pan from front side.

SEM544FB

SEM600F

SEM980F

SEM365EA

OIL PANKA24DE

EM-2011

Page 440 of 666

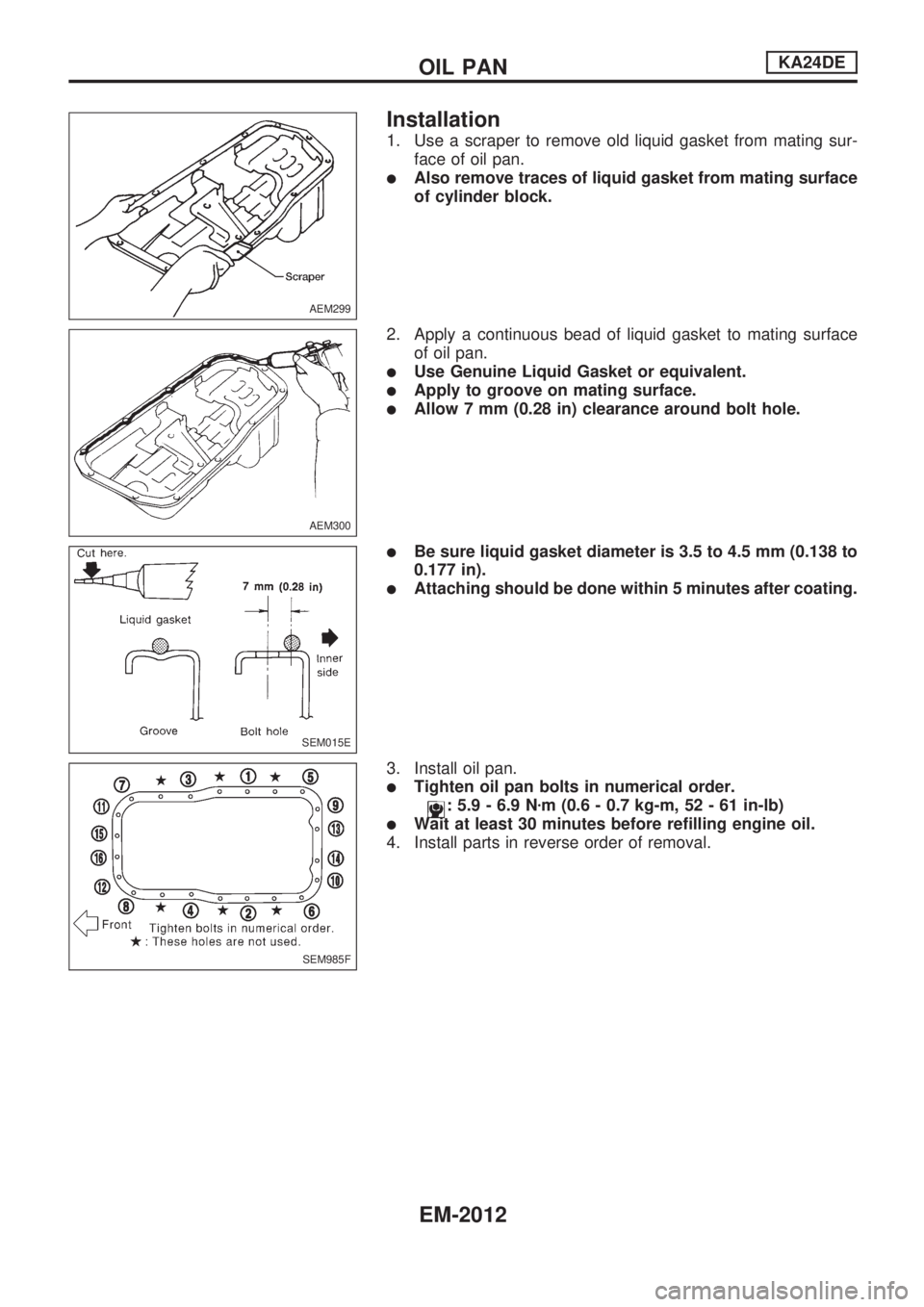

Installation

1. Use a scraper to remove old liquid gasket from mating sur-

face of oil pan.

lAlso remove traces of liquid gasket from mating surface

of cylinder block.

2. Apply a continuous bead of liquid gasket to mating surface

of oil pan.

lUse Genuine Liquid Gasket or equivalent.

lApply to groove on mating surface.

lAllow 7 mm (0.28 in) clearance around bolt hole.

lBe sure liquid gasket diameter is 3.5 to 4.5 mm (0.138 to

0.177 in).

lAttaching should be done within 5 minutes after coating.

3. Install oil pan.

lTighten oil pan bolts in numerical order.

: 5.9 - 6.9 Nzm (0.6 - 0.7 kg-m, 52 - 61 in-lb)

lWait at least 30 minutes before refilling engine oil.

4. Install parts in reverse order of removal.

AEM299

AEM300

SEM015E

SEM985F

OIL PANKA24DE

EM-2012

Trending: height adjustment, EL-2012, low oil pressure, fuel tank removal, fuel reserve, engine oil, gas type