check engine NISSAN PRIMERA 1999 Electronic Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 136 of 2267

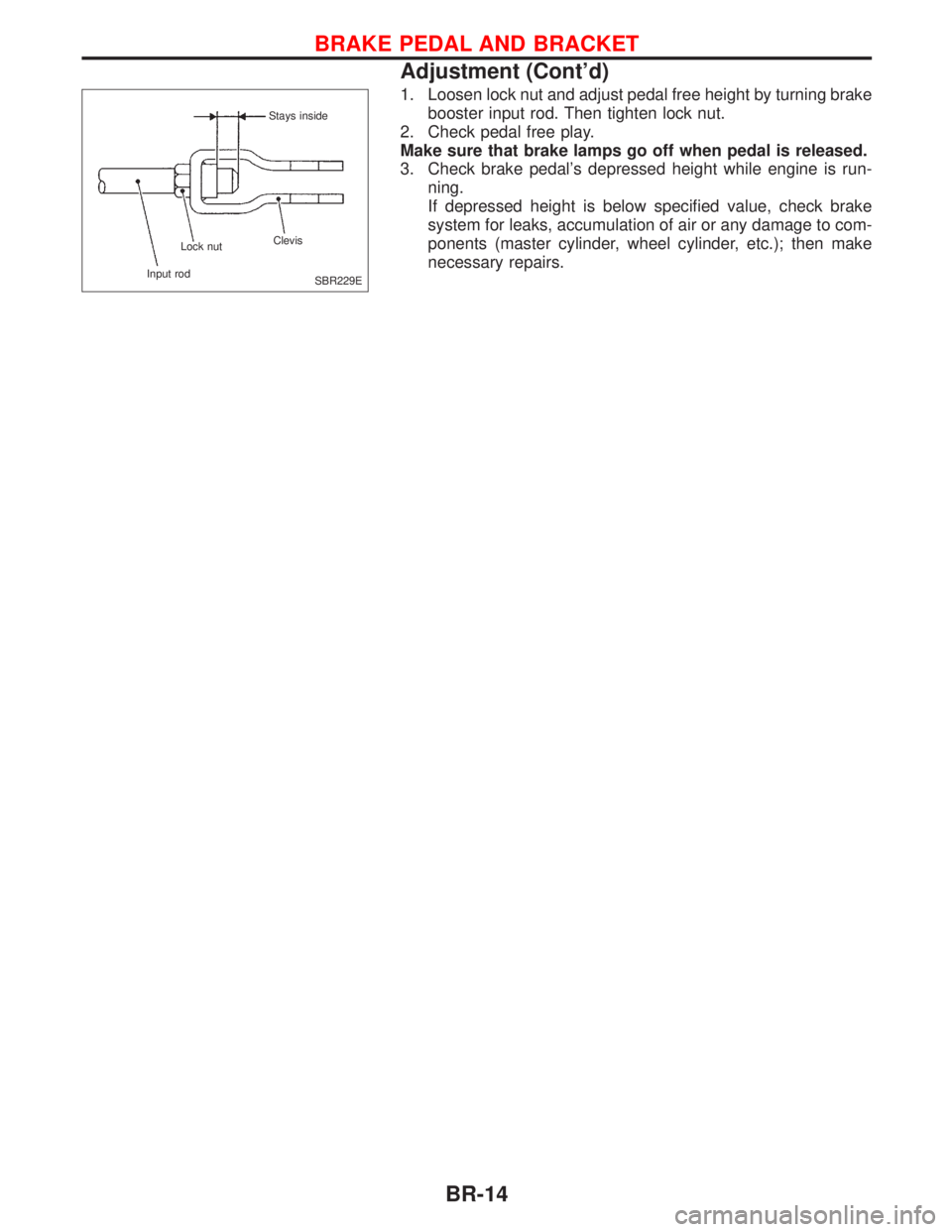

1. Loosen lock nut and adjust pedal free height by turning brake

booster input rod. Then tighten lock nut.

2. Check pedal free play.

Make sure that brake lamps go off when pedal is released.

3. Check brake pedal's depressed height while engine is run-

ning.

If depressed height is below specified value, check brake

system for leaks, accumulation of air or any damage to com-

ponents (master cylinder, wheel cylinder, etc.); then make

necessary repairs.

SBR229E Stays inside

Clevis

Lock nut

Input rod

BRAKE PEDAL AND BRACKET

Adjustment (Cont'd)

BR-14

Page 140 of 2267

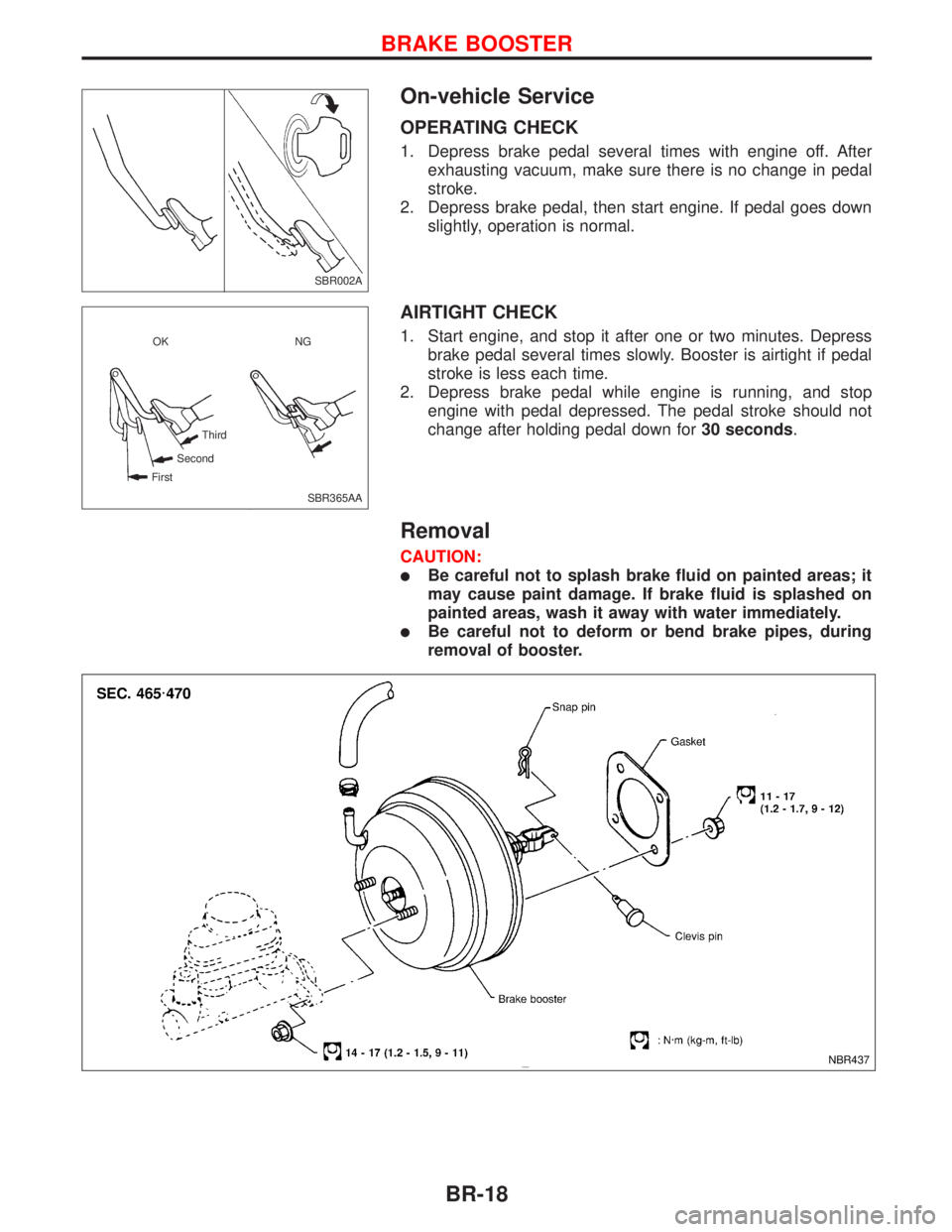

On-vehicle Service

OPERATING CHECK

1. Depress brake pedal several times with engine off. After

exhausting vacuum, make sure there is no change in pedal

stroke.

2. Depress brake pedal, then start engine. If pedal goes down

slightly, operation is normal.

AIRTIGHT CHECK

1. Start engine, and stop it after one or two minutes. Depress

brake pedal several times slowly. Booster is airtight if pedal

stroke is less each time.

2. Depress brake pedal while engine is running, and stop

engine with pedal depressed. The pedal stroke should not

change after holding pedal down for30 seconds.

Removal

CAUTION:

lBe careful not to splash brake fluid on painted areas; it

may cause paint damage. If brake fluid is splashed on

painted areas, wash it away with water immediately.

lBe careful not to deform or bend brake pipes, during

removal of booster.

SBR002A

SBR365AA OK NG

Third

Second

First

NBR437

BRAKE BOOSTER

BR-18

Page 143 of 2267

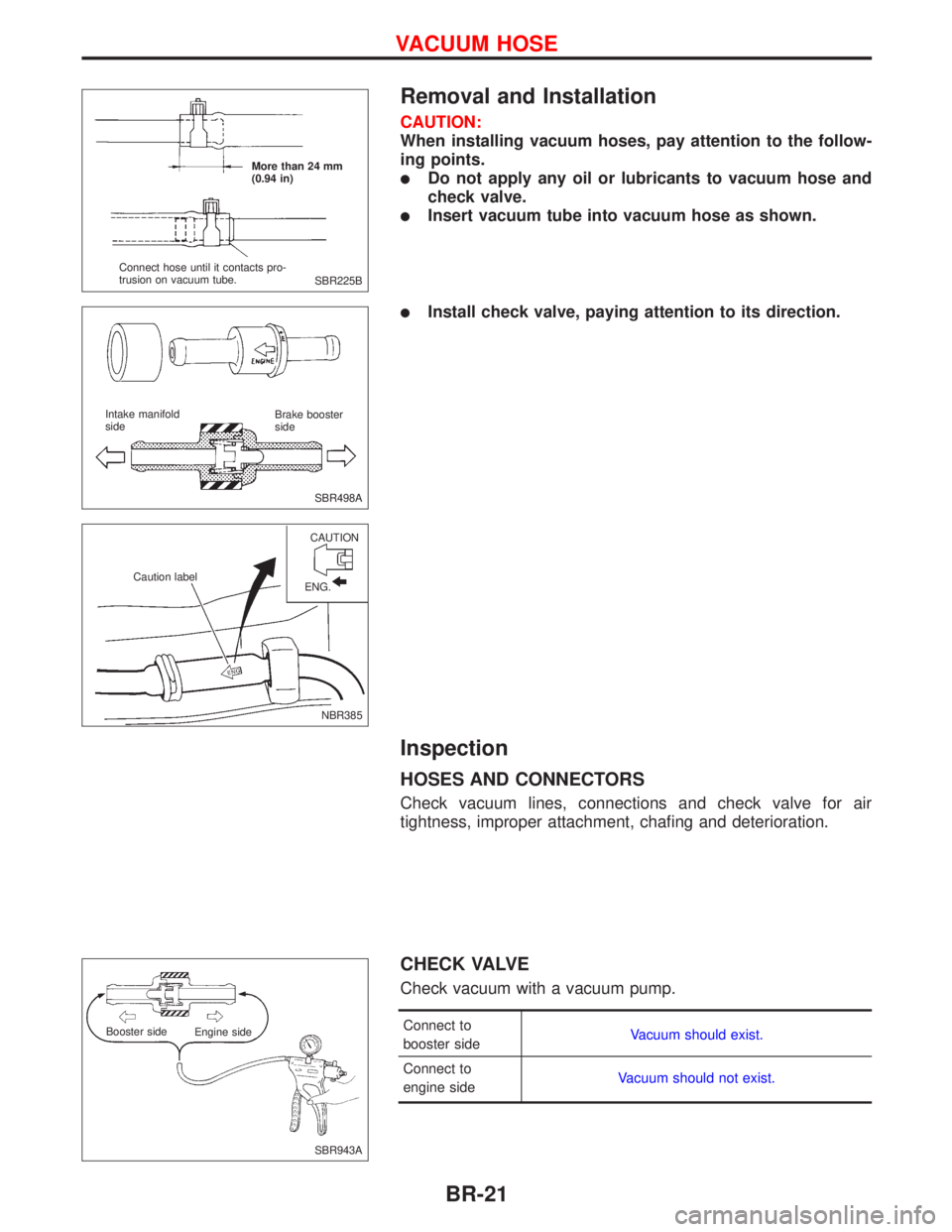

Removal and Installation

CAUTION:

When installing vacuum hoses, pay attention to the follow-

ing points.

lDo not apply any oil or lubricants to vacuum hose and

check valve.

lInsert vacuum tube into vacuum hose as shown.

lInstall check valve, paying attention to its direction.

Inspection

HOSES AND CONNECTORS

Check vacuum lines, connections and check valve for air

tightness, improper attachment, chafing and deterioration.

CHECK VALVE

Check vacuum with a vacuum pump.

Connect to

booster sideVacuum should exist.

Connect to

engine sideVacuum should not exist.

SBR225B More than 24 mm

(0.94 in)

Connect hose until it contacts pro-

trusion on vacuum tube.

SBR498A Intake manifold

sideBrake booster

side

NBR385 CAUTION

Caution label

ENG.

SBR943A Booster side

Engine side

VACUUM HOSE

BR-21

Page 144 of 2267

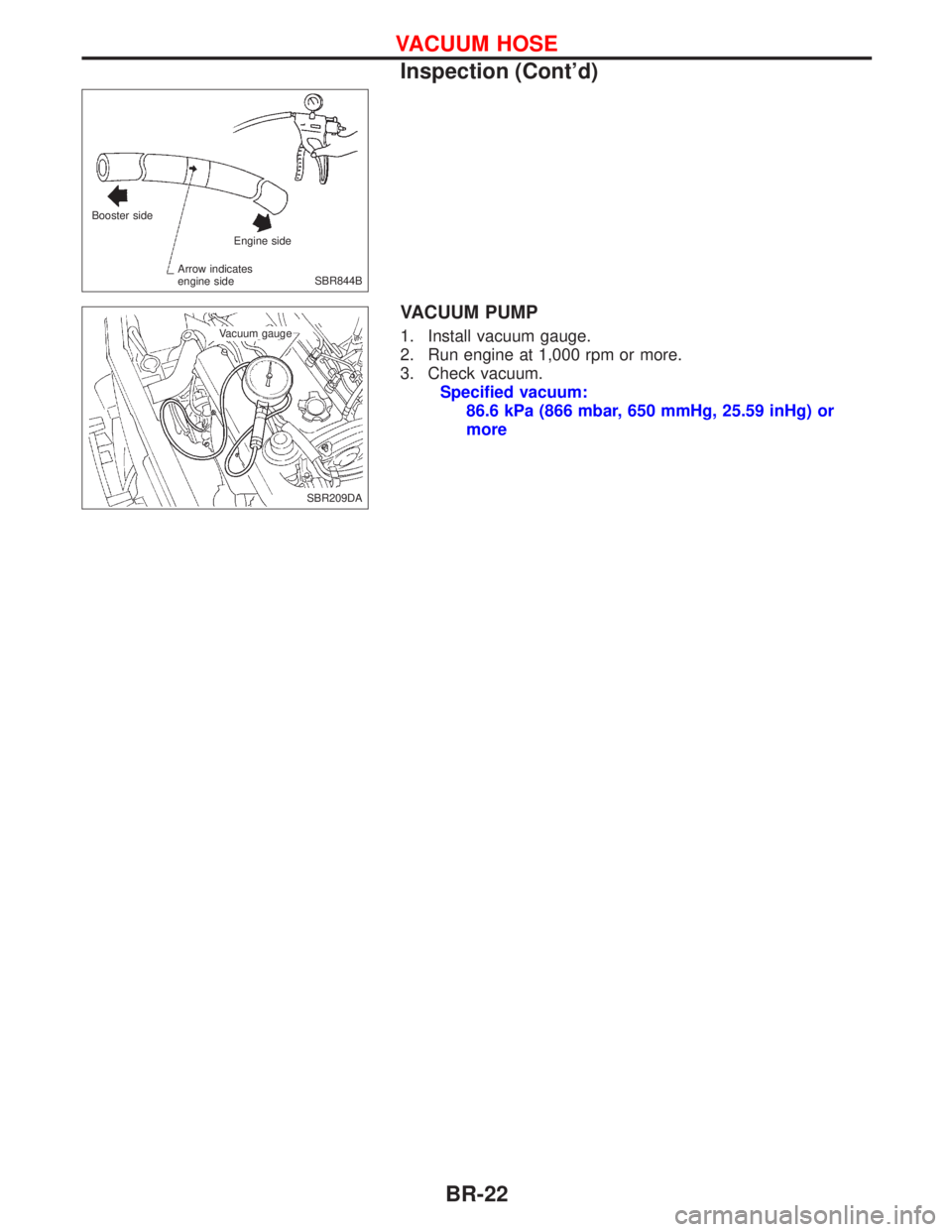

VACUUM PUMP

1. Install vacuum gauge.

2. Run engine at 1,000 rpm or more.

3. Check vacuum.

Specified vacuum:

86.6 kPa (866 mbar, 650 mmHg, 25.59 inHg) or

more

Booster side

Engine side

Arrow indicates

engine side

SBR844B

SBR209DA Vacuum gauge

VACUUM HOSE

Inspection (Cont'd)

BR-22

Page 171 of 2267

Inspection

1. Check control lever for wear or other damage. Replace if

necessary.

2. Check wires for discontinuity or deterioration. Replace if nec-

essary.

3. Check warning lamp and switch. Replace if necessary.

4. Check parts at each connecting portion and, if found

deformed or damaged, replace the parts.

Adjustment

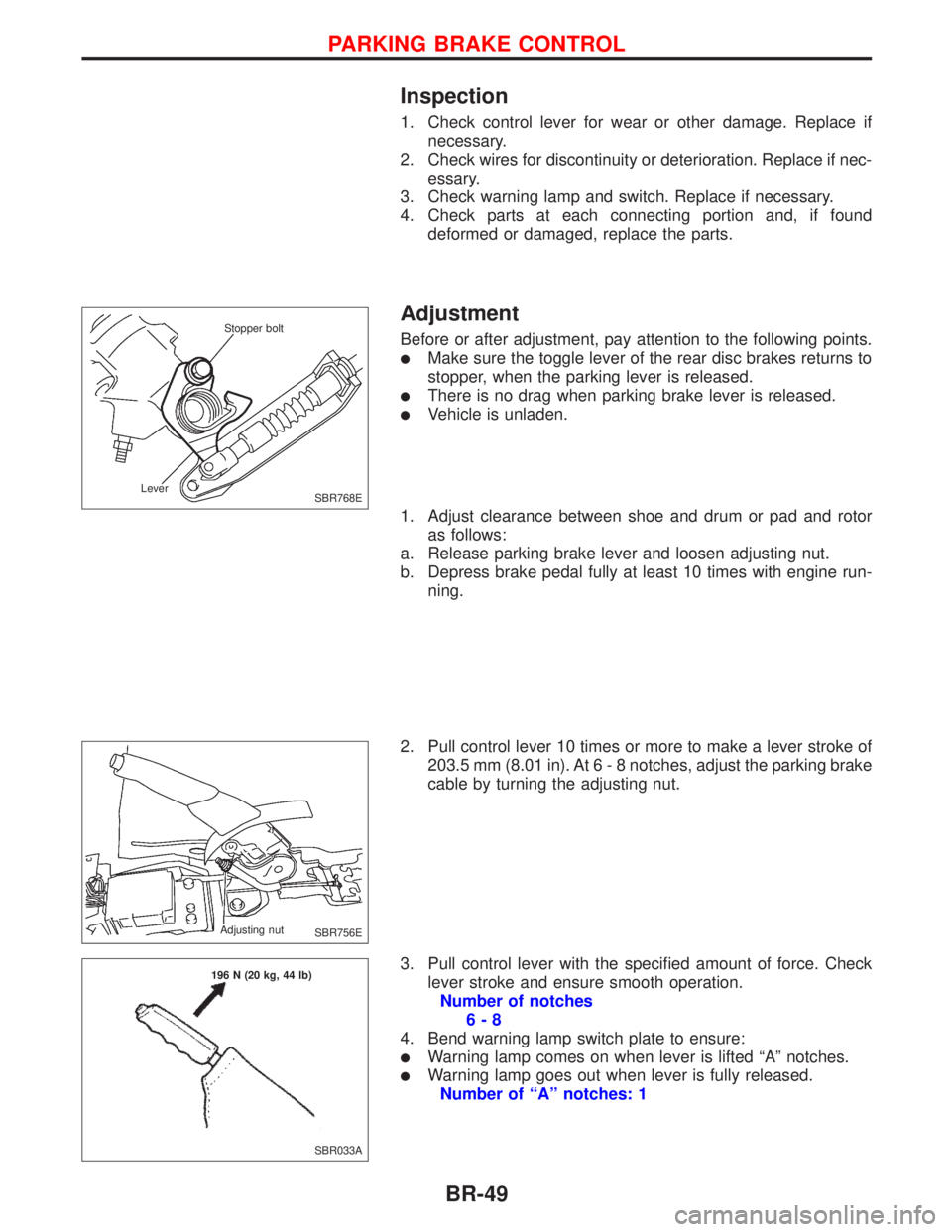

Before or after adjustment, pay attention to the following points.

lMake sure the toggle lever of the rear disc brakes returns to

stopper, when the parking lever is released.

lThere is no drag when parking brake lever is released.

lVehicle is unladen.

1. Adjust clearance between shoe and drum or pad and rotor

as follows:

a. Release parking brake lever and loosen adjusting nut.

b. Depress brake pedal fully at least 10 times with engine run-

ning.

2. Pull control lever 10 times or more to make a lever stroke of

203.5 mm (8.01 in). At6-8notches, adjust the parking brake

cable by turning the adjusting nut.

3. Pull control lever with the specified amount of force. Check

lever stroke and ensure smooth operation.

Number of notches

6-8

4. Bend warning lamp switch plate to ensure:

lWarning lamp comes on when lever is lifted ªAº notches.

lWarning lamp goes out when lever is fully released.

Number of ªAº notches: 1

SBR768E Stopper bolt

Lever

SBR756E Adjusting nut

SBR033A 196 N (20 kg, 44 lb)

PARKING BRAKE CONTROL

BR-49

Page 192 of 2267

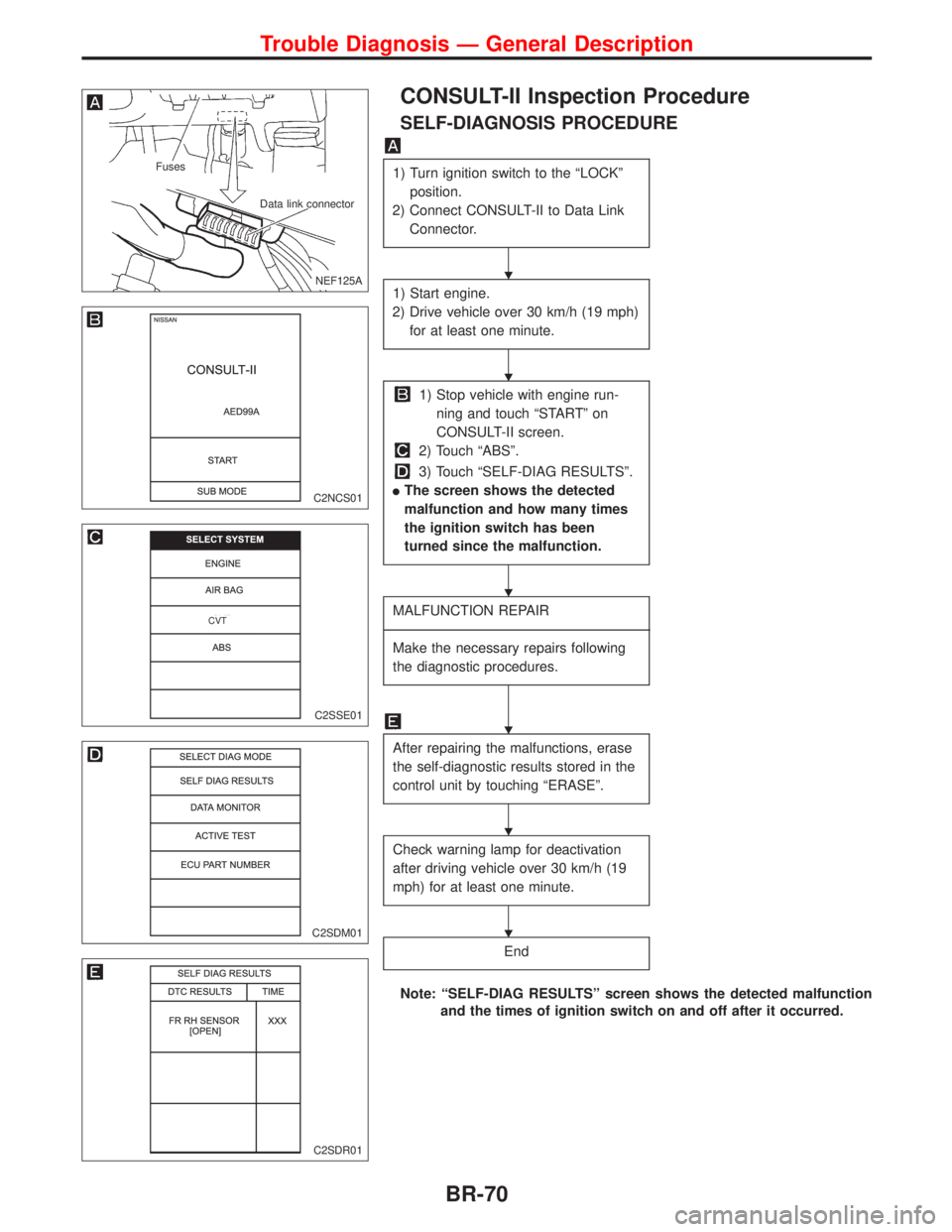

CONSULT-II Inspection Procedure

SELF-DIAGNOSIS PROCEDURE

1) Turn ignition switch to the ªLOCKº

position.

2) Connect CONSULT-II to Data Link

Connector.

1) Start engine.

2) Drive vehicle over 30 km/h (19 mph)

for at least one minute.

1) Stop vehicle with engine run-

ning and touch ªSTARTº on

CONSULT-II screen.

2) Touch ªABSº.

3) Touch ªSELF-DIAG RESULTSº.

lThe screen shows the detected

malfunction and how many times

the ignition switch has been

turned since the malfunction.

MALFUNCTION REPAIR

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Make the necessary repairs following

the diagnostic procedures.

After repairing the malfunctions, erase

the self-diagnostic results stored in the

control unit by touching ªERASEº.

Check warning lamp for deactivation

after driving vehicle over 30 km/h (19

mph) for at least one minute.

End

Note: ªSELF-DIAG RESULTSº screen shows the detected malfunction

and the times of ignition switch on and off after it occurred.

.NEF125A

Fuses

Data link connector

C2NCS01

C2SSE01

.CVT

C2SDM01

C2SDR01

H

H

H

H

H

H

Trouble Diagnosis Ð General Description

BR-70

Page 197 of 2267

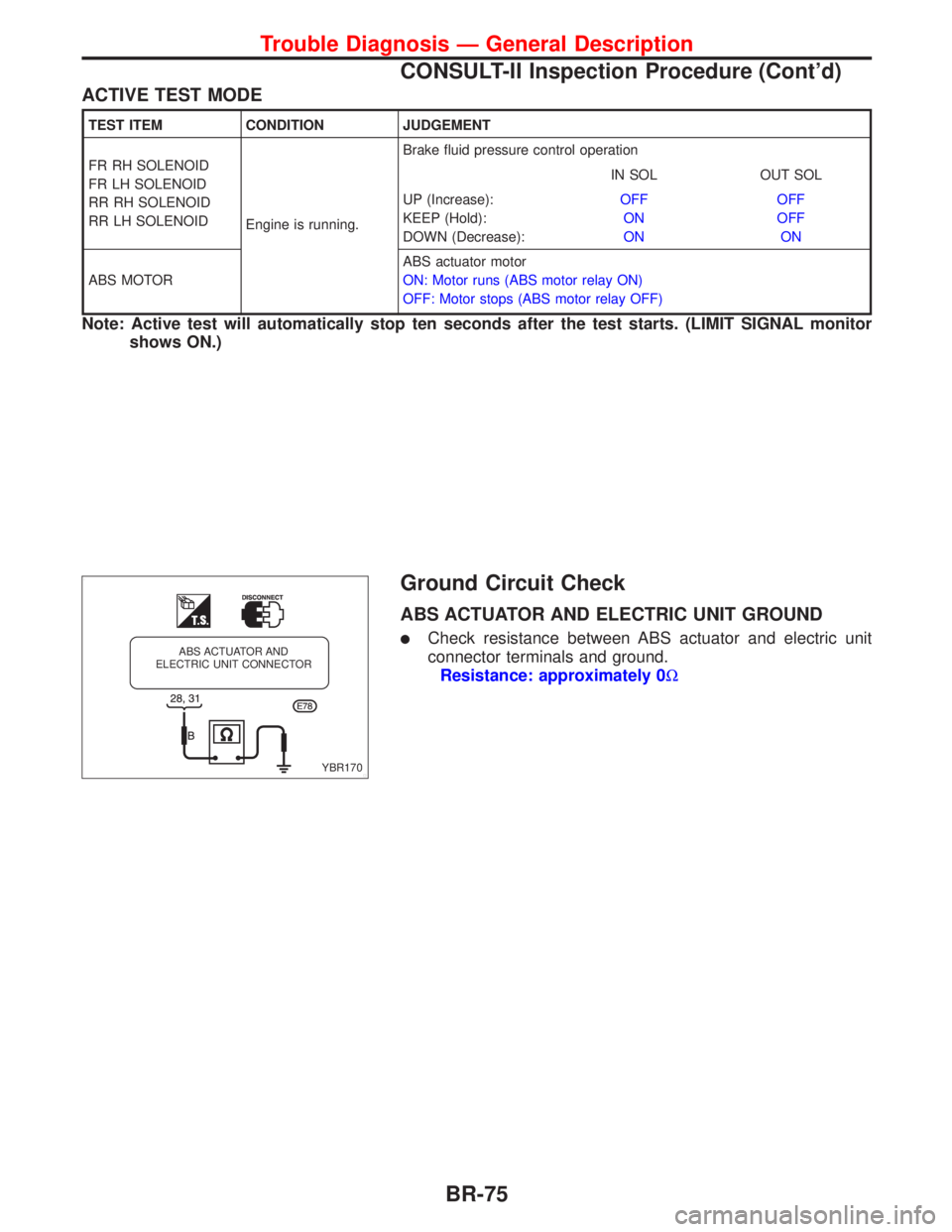

ACTIVE TEST MODE

TEST ITEM CONDITION JUDGEMENT

FR RH SOLENOID

FR LH SOLENOID

RR RH SOLENOID

RR LH SOLENOID

Engine is running.Brake fluid pressure control operation

IN SOL OUT SOL

UP (Increase):

KEEP (Hold):

DOWN (Decrease):OFF

ON

ONOFF

OFF

ON

ABS MOTORABS actuator motor

ON: Motor runs (ABS motor relay ON)

OFF: Motor stops (ABS motor relay OFF)

Note: Active test will automatically stop ten seconds after the test starts. (LIMIT SIGNAL monitor

shows ON.)

Ground Circuit Check

ABS ACTUATOR AND ELECTRIC UNIT GROUND

lCheck resistance between ABS actuator and electric unit

connector terminals and ground.

Resistance: approximately 0W

YBR170 ABS ACTUATOR AND

ELECTRIC UNIT CONNECTOR

Trouble Diagnosis Ð General Description

CONSULT-II Inspection Procedure (Cont'd)

BR-75

Page 201 of 2267

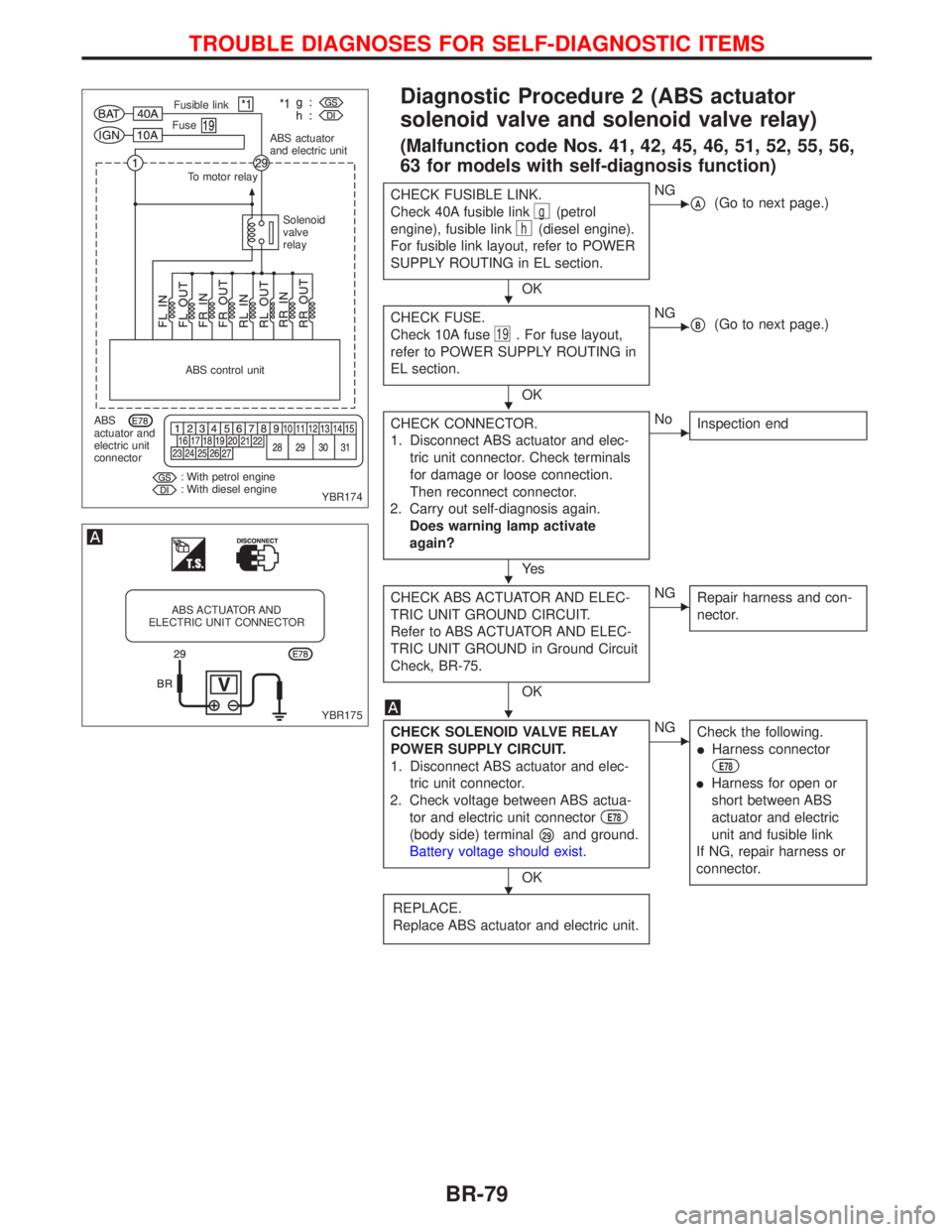

Diagnostic Procedure 2 (ABS actuator

solenoid valve and solenoid valve relay)

(Malfunction code Nos. 41, 42, 45, 46, 51, 52, 55, 56,

63 for models with self-diagnosis function)

CHECK FUSIBLE LINK.

Check 40A fusible link

g(petrol

engine), fusible link

h(diesel engine).

For fusible link layout, refer to POWER

SUPPLY ROUTING in EL section.

OK

ENGpA(Go to next page.)

CHECK FUSE.

Check 10A fuse

19. For fuse layout,

refer to POWER SUPPLY ROUTING in

EL section.

OK

ENGpB(Go to next page.)

CHECK CONNECTOR.

1. Disconnect ABS actuator and elec-

tric unit connector. Check terminals

for damage or loose connection.

Then reconnect connector.

2. Carry out self-diagnosis again.

Does warning lamp activate

again?

Ye s

ENo

Inspection end

CHECK ABS ACTUATOR AND ELEC-

TRIC UNIT GROUND CIRCUIT.

Refer to ABS ACTUATOR AND ELEC-

TRIC UNIT GROUND in Ground Circuit

Check, BR-75.

OK

ENG

Repair harness and con-

nector.

CHECK SOLENOID VALVE RELAY

POWER SUPPLY CIRCUIT.

1. Disconnect ABS actuator and elec-

tric unit connector.

2. Check voltage between ABS actua-

tor and electric unit connector

E78

(body side) terminalp29and ground.

Battery voltage should exist.

OK

ENG

Check the following.

lHarness connector

E78

lHarness for open or

short between ABS

actuator and electric

unit and fusible link

If NG, repair harness or

connector.

REPLACE.

Replace ABS actuator and electric unit.

YBR174 Fusible link

Fuse

ABS actuator

and electric unit

To motor relay

Solenoid

valve

relay

ABS control unit

ABS

actuator and

electric unit

connector

: With petrol engine

: With diesel engine

YBR175

ABS ACTUATOR AND

ELECTRIC UNIT CONNECTOR

H

H

H

H

H

TROUBLE DIAGNOSES FOR SELF-DIAGNOSTIC ITEMS

BR-79

Page 203 of 2267

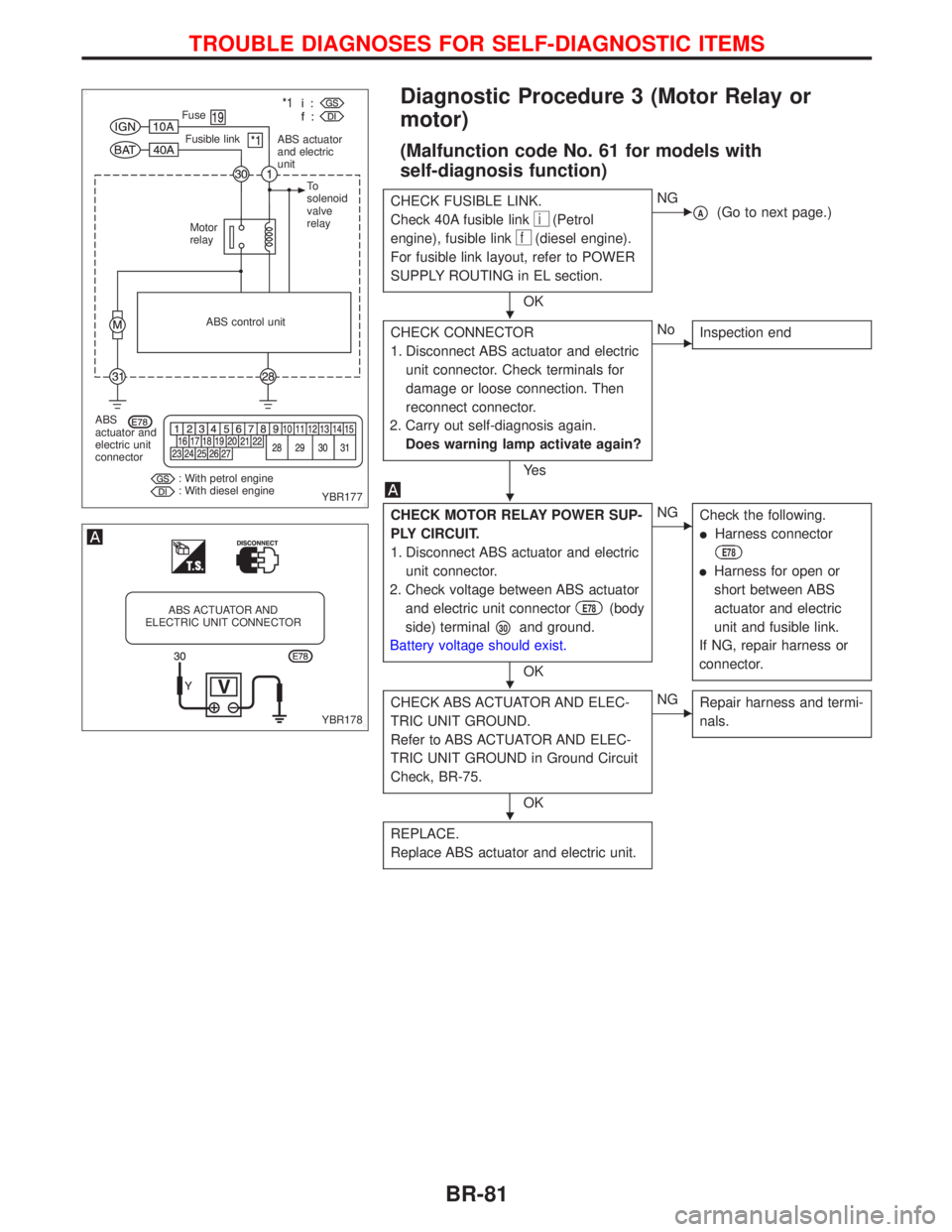

Diagnostic Procedure 3 (Motor Relay or

motor)

(Malfunction code No. 61 for models with

self-diagnosis function)

CHECK FUSIBLE LINK.

Check 40A fusible link

i(Petrol

engine), fusible link

f(diesel engine).

For fusible link layout, refer to POWER

SUPPLY ROUTING in EL section.

OK

ENG

pA(Go to next page.)

CHECK CONNECTOR

1. Disconnect ABS actuator and electric

unit connector. Check terminals for

damage or loose connection. Then

reconnect connector.

2. Carry out self-diagnosis again.

Does warning lamp activate again?

Ye s

ENo

Inspection end

CHECK MOTOR RELAY POWER SUP-

PLY CIRCUIT.

1. Disconnect ABS actuator and electric

unit connector.

2. Check voltage between ABS actuator

and electric unit connector

E78(body

side) terminal

p30and ground.

Battery voltage should exist.

OK

ENG

Check the following.

lHarness connector

E78

lHarness for open or

short between ABS

actuator and electric

unit and fusible link.

If NG, repair harness or

connector.

CHECK ABS ACTUATOR AND ELEC-

TRIC UNIT GROUND.

Refer to ABS ACTUATOR AND ELEC-

TRIC UNIT GROUND in Ground Circuit

Check, BR-75.

OK

ENG

Repair harness and termi-

nals.

REPLACE.

Replace ABS actuator and electric unit.

YBR177 Fusible link Fuse

ABS actuator

and electric

unit

Motor

relayTo

solenoid

valve

relay

ABS control unit

ABS

actuator and

electric unit

connector

: With petrol engine

: With diesel engine

YBR178

ABS ACTUATOR AND

ELECTRIC UNIT CONNECTOR

H

H

H

H

TROUBLE DIAGNOSES FOR SELF-DIAGNOSTIC ITEMS

BR-81

Page 209 of 2267

Diagnostic Procedure 9 (ABS does not

work.)

CHECK WARNING LAMP ACTIVATE.

Does the ABS warning lamp activate?

No

EYe s

Carry out self-diagnosis.

Refer to BR-67.

Go toin Diagnostic Procedure 7,

BR-86.

Note: ABS does not work when vehicle speed is under 10

km/h (6 MPH).

Diagnostic Procedure 10 (Pedal vibration and

noise)

INSPECTION START

1. Apply brake.

2. Start engine.

3. Does the symptom appear only

when engine is started?

No

EYe s

Carry out self-diagnosis.

Refer to BR-67.

CHECK IF SYMPTOM APPEARS.

Does the symptom appear when elec-

trical equipment switches (such as

headlamp) are operated?

Ye s

ENo

Go toin Diagnostic

Procedure 7, BR-86.

CHECK WHEEL SENSOR.

Check wheel sensor shield ground. For

location of shield ground, refer to wiring

diagram and ªHARNESS LAYOUTº in

EL section.

OK

ENG

Repair wheel sensor.

CHECK HARNESS CONNECTOR.

Check ABS actuator and electric unit

pin terminals for damage or the con-

nection of ABS actuator and electric

unit harness connector.

Reconnect ABS actuator and electric

unit harness connector. Then retest.

Note: ABS may operate and cause vibration under any of

the following conditions.

SAT797A Brake pedal

H

H

H

H

TROUBLE DIAGNOSES FOR SYMPTOMS

BR-87