check engine NISSAN PRIMERA 1999 Electronic Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 210 of 2267

lApplying brake gradually when shifting or operating clutch.

lLow friction (slippery) road.

lHigh speed concerning.

lDriving over bumps and pot holes.

lEngine speed is over 5,000 rpm with vehicle stopped.

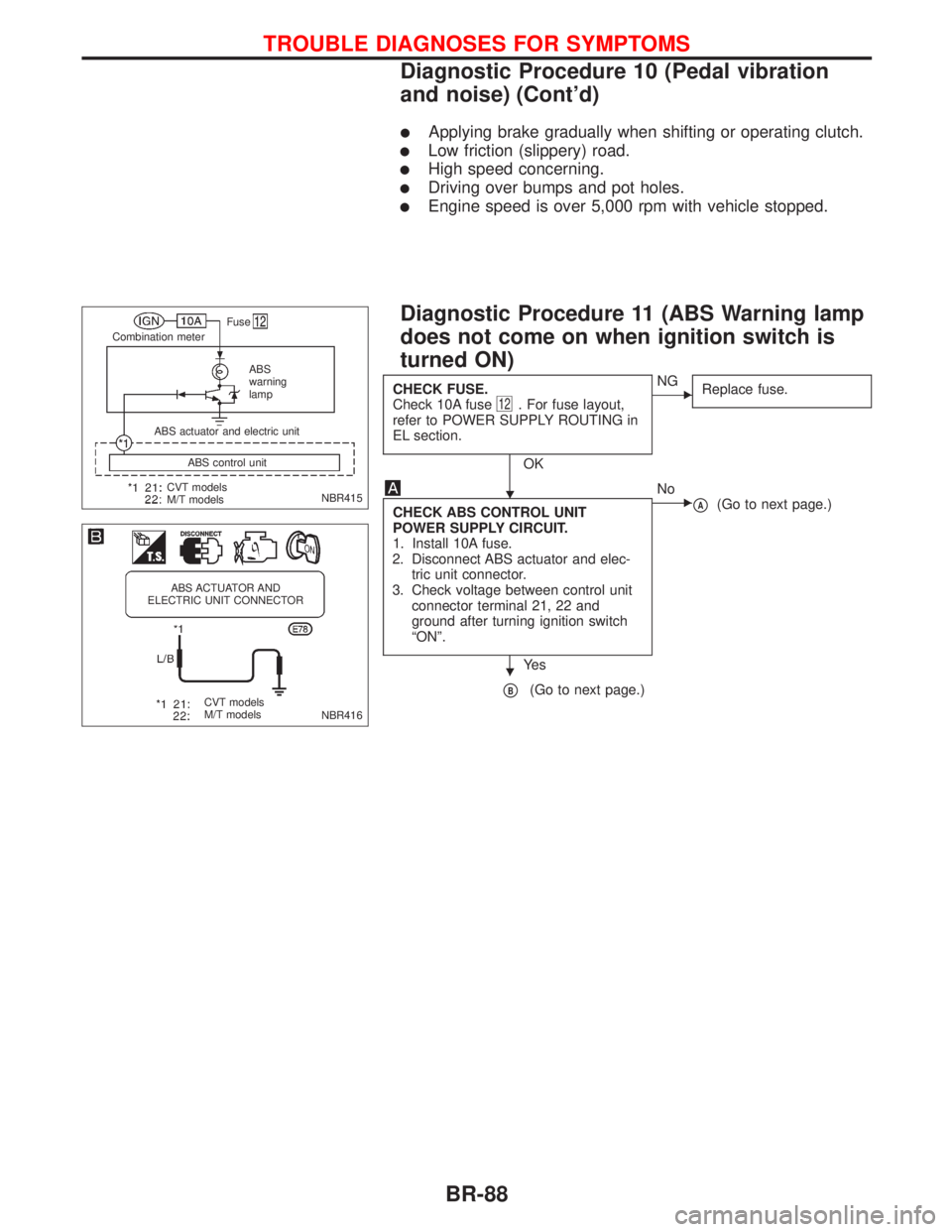

Diagnostic Procedure 11 (ABS Warning lamp

does not come on when ignition switch is

turned ON)

CHECK FUSE.

Check 10A fuse12. For fuse layout,

refer to POWER SUPPLY ROUTING in

EL section.

OK

ENG

Replace fuse.

CHECK ABS CONTROL UNIT

POWER SUPPLY CIRCUIT.

1. Install 10A fuse.

2. Disconnect ABS actuator and elec-

tric unit connector.

3. Check voltage between control unit

connector terminal 21, 22 and

ground after turning ignition switch

ªONº.

Ye s

ENo

pA(Go to next page.)

pB(Go to next page.)

NBR415

.Fuse

Combination meter

ABS

warning

lamp

CVT models

M/T modelsABS control unit ABS actuator and electric unit

NBR416

ABS ACTUATOR AND

ELECTRIC UNIT CONNECTOR

CVT models

M/T models

H

H

TROUBLE DIAGNOSES FOR SYMPTOMS

Diagnostic Procedure 10 (Pedal vibration

and noise) (Cont'd)

BR-88

Page 219 of 2267

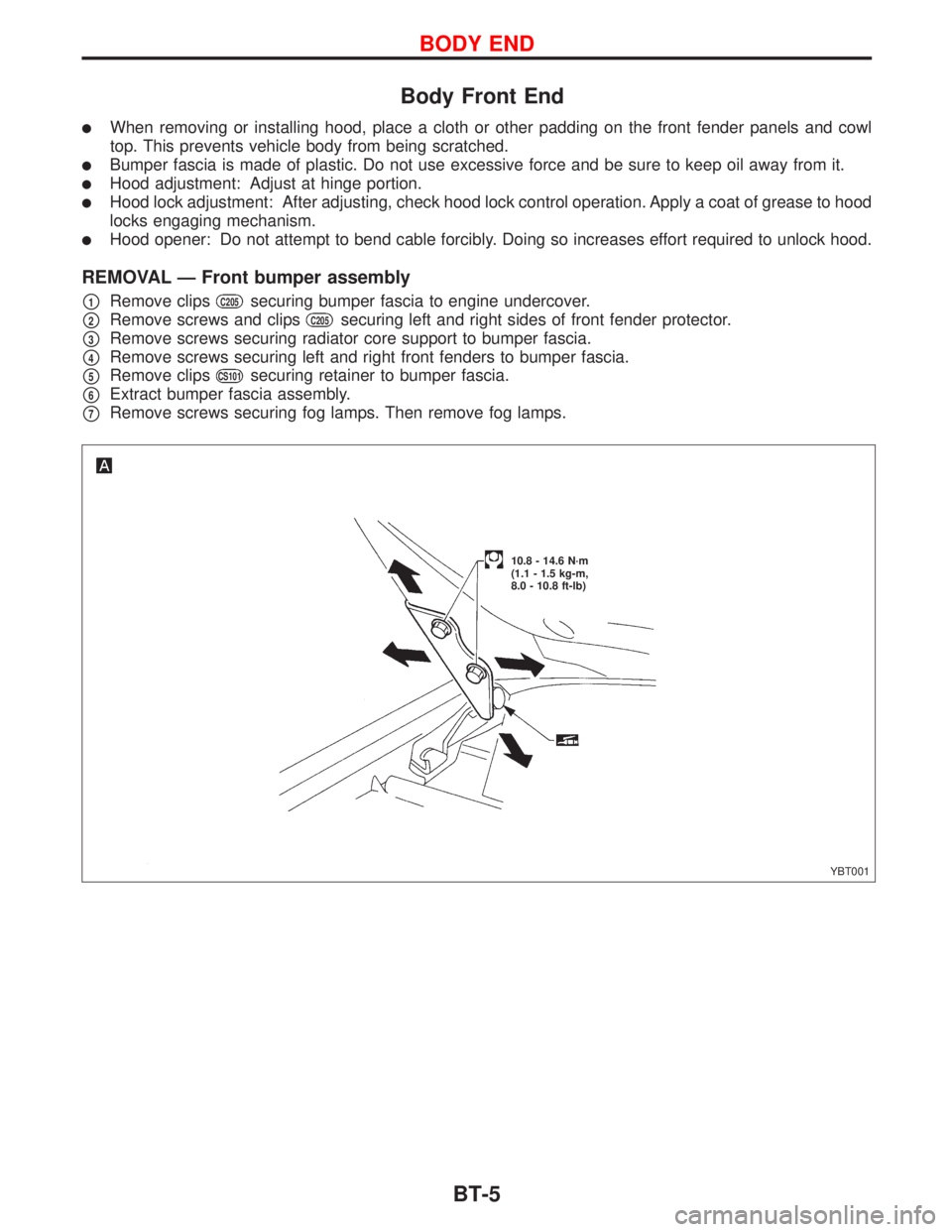

Body Front End

lWhen removing or installing hood, place a cloth or other padding on the front fender panels and cowl

top. This prevents vehicle body from being scratched.

lBumper fascia is made of plastic. Do not use excessive force and be sure to keep oil away from it.

lHood adjustment: Adjust at hinge portion.

lHood lock adjustment: After adjusting, check hood lock control operation. Apply a coat of grease to hood

locks engaging mechanism.

lHood opener: Do not attempt to bend cable forcibly. Doing so increases effort required to unlock hood.

REMOVAL Ð Front bumper assembly

p1Remove clipsC205securing bumper fascia to engine undercover.

p2Remove screws and clipsC205securing left and right sides of front fender protector.

p3Remove screws securing radiator core support to bumper fascia.

p4Remove screws securing left and right front fenders to bumper fascia.

p5Remove clipsCS101securing retainer to bumper fascia.

p6Extract bumper fascia assembly.

p7Remove screws securing fog lamps. Then remove fog lamps.

YBT001

10.8 - 14.6 N´m

(1.1 - 1.5 kg-m,

8.0 - 10.8 ft-lb)

BODY END

BT-5

Page 274 of 2267

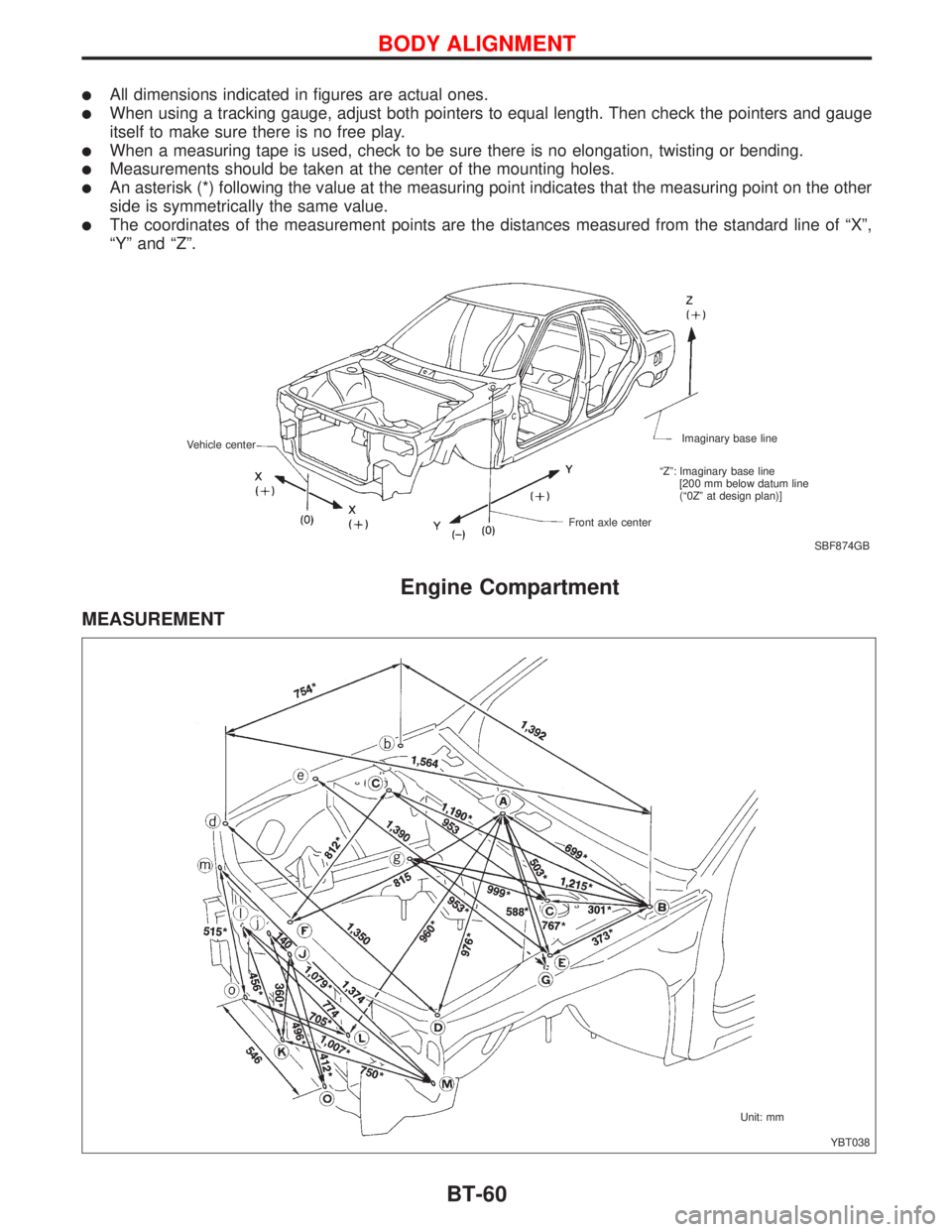

lAll dimensions indicated in figures are actual ones.

lWhen using a tracking gauge, adjust both pointers to equal length. Then check the pointers and gauge

itself to make sure there is no free play.

lWhen a measuring tape is used, check to be sure there is no elongation, twisting or bending.

lMeasurements should be taken at the center of the mounting holes.

lAn asterisk (*) following the value at the measuring point indicates that the measuring point on the other

side is symmetrically the same value.

lThe coordinates of the measurement points are the distances measured from the standard line of ªXº,

ªYº and ªZº.

Engine Compartment

MEASUREMENT

SBF874GB Imaginary base line

Front axle center Vehicle center

ªZº: Imaginary base line

[200 mm below datum line

(ª0Zº at design plan)]

YBT038 Unit: mm

BODY ALIGNMENT

BT-60

Page 281 of 2267

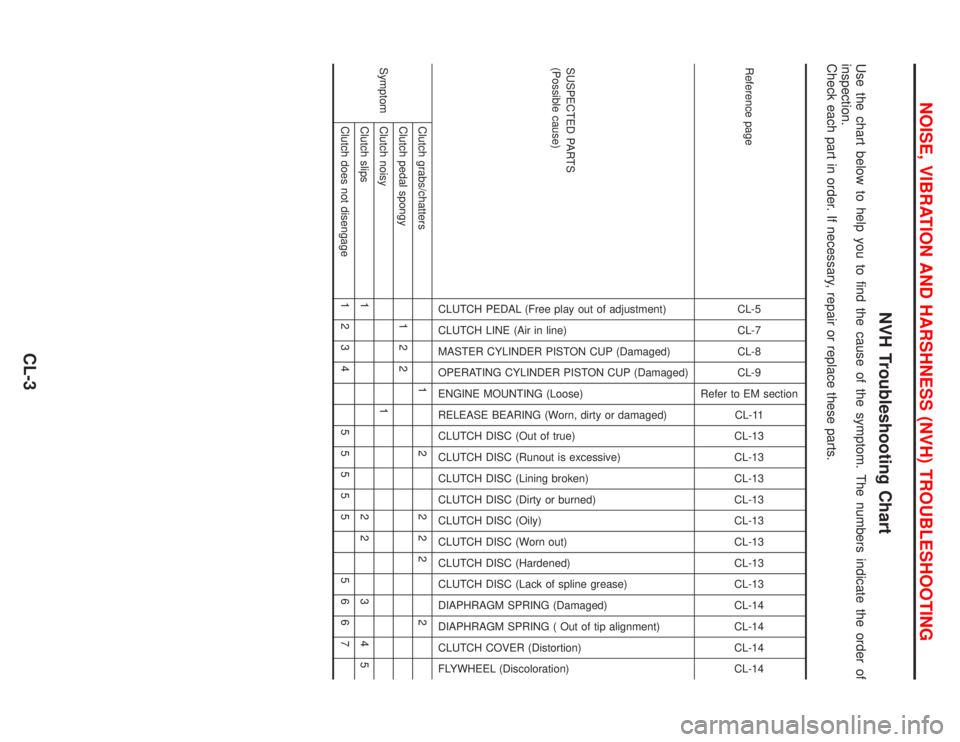

NVH Troubleshooting Chart

Use the chart below to help you to find the cause of the symptom. The numbers indicate the order of

inspection.

Check each part in order. If necessary, repair or replace these parts.

Reference pageCL-5

CL-7

CL-8

CL-9

Refer to EM section

CL-11

CL-13

CL-13

CL-13

CL-13

CL-13

CL-13

CL-13

CL-13

CL-14

CL-14

CL-14

CL-14

SUSPECTED PARTS

(Possible cause)

CLUTCH PEDAL (Free play out of adjustment)

CLUTCH LINE (Air in line)

MASTER CYLINDER PISTON CUP (Damaged)

OPERATING CYLINDER PISTON CUP (Damaged)

ENGINE MOUNTING (Loose)

RELEASE BEARING (Worn, dirty or damaged)

CLUTCH DISC (Out of true)

CLUTCH DISC (Runout is excessive)

CLUTCH DISC (Lining broken)

CLUTCH DISC (Dirty or burned)

CLUTCH DISC (Oily)

CLUTCH DISC (Worn out)

CLUTCH DISC (Hardened)

CLUTCH DISC (Lack of spline grease)

DIAPHRAGM SPRING (Damaged)

DIAPHRAGM SPRING ( Out of tip alignment)

CLUTCH COVER (Distortion)

FLYWHEEL (Discoloration)

SymptomClutch grabs/chatters 1 2 2 2 2 2

Clutch pedal spongy 1 2 2

Clutch noisy 1

Clutch slips 1 2 2 3 4 5

Clutch does not disengage 1 2 3 4 5 5 5 5 5 5 6 6 7

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

CL-3

Page 292 of 2267

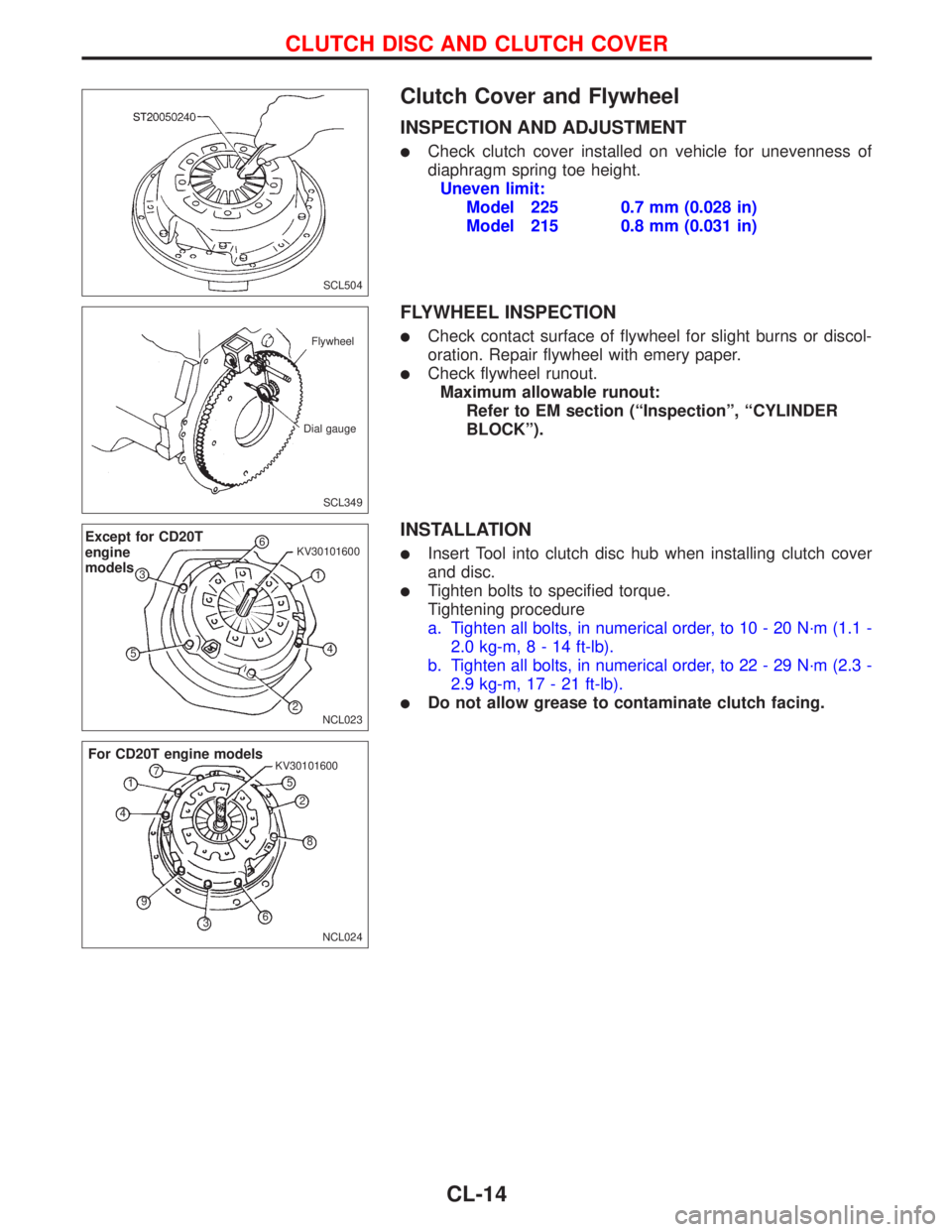

Clutch Cover and Flywheel

INSPECTION AND ADJUSTMENT

lCheck clutch cover installed on vehicle for unevenness of

diaphragm spring toe height.

Uneven limit:

Model 225 0.7 mm (0.028 in)

Model 215 0.8 mm (0.031 in)

FLYWHEEL INSPECTION

lCheck contact surface of flywheel for slight burns or discol-

oration. Repair flywheel with emery paper.

lCheck flywheel runout.

Maximum allowable runout:

Refer to EM section (ªInspectionº, ªCYLINDER

BLOCKº).

INSTALLATION

lInsert Tool into clutch disc hub when installing clutch cover

and disc.

lTighten bolts to specified torque.

Tightening procedure

a. Tighten all bolts, in numerical order, to 10 - 20 N´m (1.1 -

2.0 kg-m,8-14ft-lb).

b. Tighten all bolts, in numerical order, to 22 - 29 N´m (2.3 -

2.9 kg-m, 17 - 21 ft-lb).

lDo not allow grease to contaminate clutch facing.

SCL504

SCL349 Flywheel

Dial gauge

NCL023

Except for CD20T

engine

models6

1 KV30101600

4

2 53

NCL024 KV30101600

For CD20T engine models

1

2

3 45

6 7

8

9

CLUTCH DISC AND CLUTCH COVER

CL-14

Page 301 of 2267

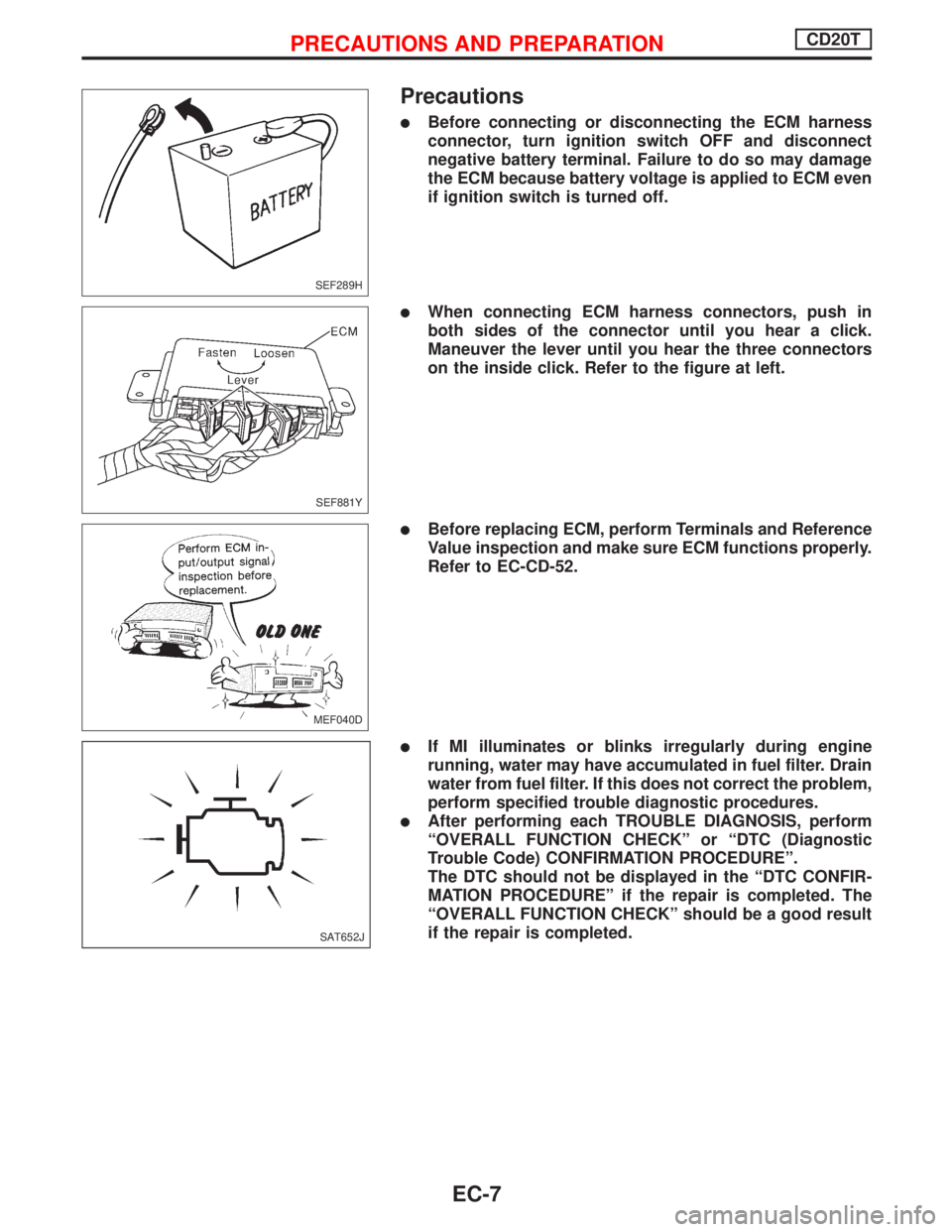

Precautions

lBefore connecting or disconnecting the ECM harness

connector, turn ignition switch OFF and disconnect

negative battery terminal. Failure to do so may damage

the ECM because battery voltage is applied to ECM even

if ignition switch is turned off.

lWhen connecting ECM harness connectors, push in

both sides of the connector until you hear a click.

Maneuver the lever until you hear the three connectors

on the inside click. Refer to the figure at left.

lBefore replacing ECM, perform Terminals and Reference

Value inspection and make sure ECM functions properly.

Refer to EC-CD-52.

lIf MI illuminates or blinks irregularly during engine

running, water may have accumulated in fuel filter. Drain

water from fuel filter. If this does not correct the problem,

perform specified trouble diagnostic procedures.

lAfter performing each TROUBLE DIAGNOSIS, perform

ªOVERALL FUNCTION CHECKº or ªDTC (Diagnostic

Trouble Code) CONFIRMATION PROCEDUREº.

The DTC should not be displayed in the ªDTC CONFIR-

MATION PROCEDUREº if the repair is completed. The

ªOVERALL FUNCTION CHECKº should be a good result

if the repair is completed.

SEF289H

SEF881Y

MEF040D

SAT652J

PRECAUTIONS AND PREPARATIONCD20T

EC-7

Page 325 of 2267

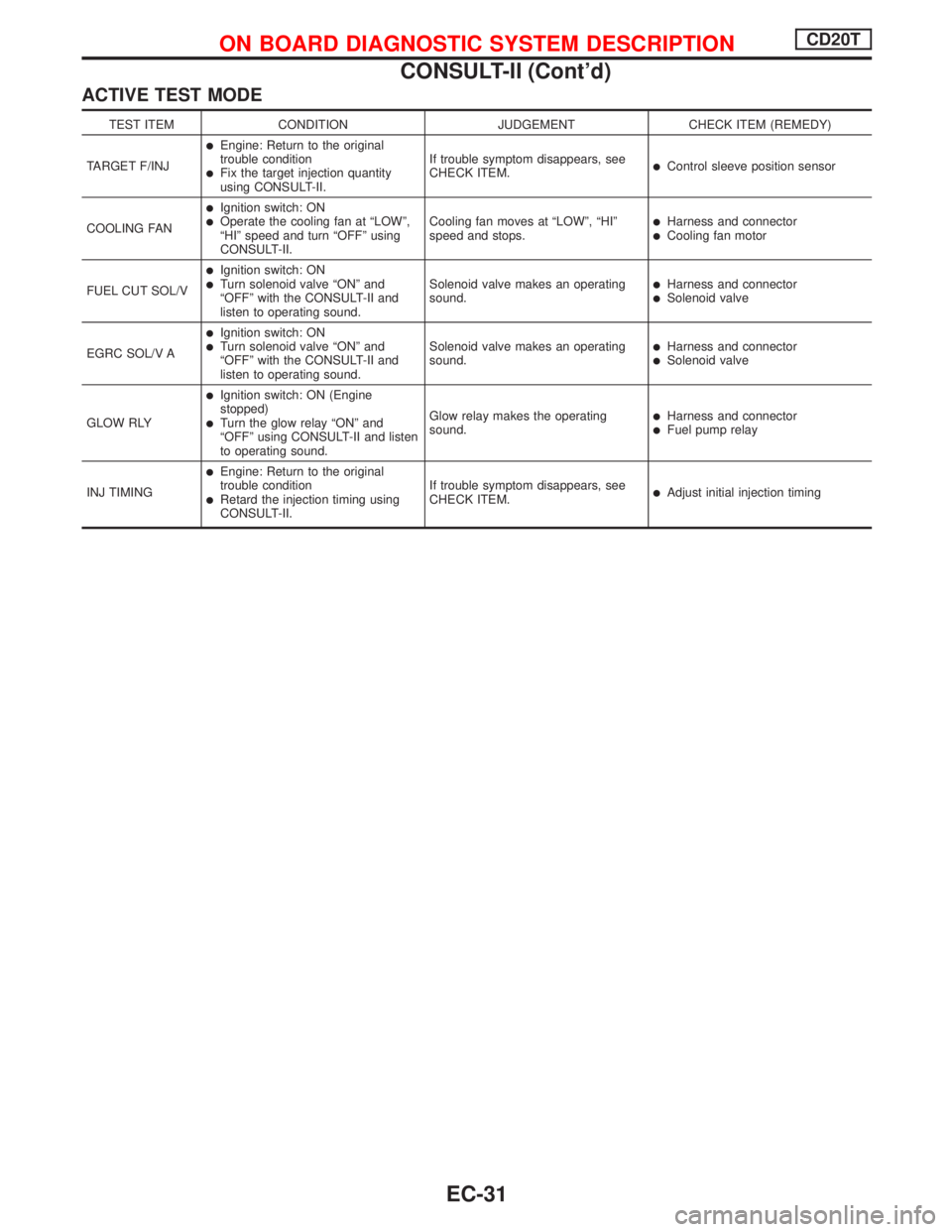

ACTIVE TEST MODE

TEST ITEM CONDITION JUDGEMENT CHECK ITEM (REMEDY)

TARGET F/INJ

lEngine: Return to the original

trouble condition

lFix the target injection quantity

using CONSULT-II.If trouble symptom disappears, see

CHECK ITEM.lControl sleeve position sensor

COOLING FAN

lIgnition switch: ONlOperate the cooling fan at ªLOWº,

ªHIº speed and turn ªOFFº using

CONSULT-II.Cooling fan moves at ªLOWº, ªHIº

speed and stops.lHarness and connectorlCooling fan motor

FUEL CUT SOL/V

lIgnition switch: ONlTurn solenoid valve ªONº and

ªOFFº with the CONSULT-II and

listen to operating sound.Solenoid valve makes an operating

sound.lHarness and connectorlSolenoid valve

EGRC SOL/V A

lIgnition switch: ONlTurn solenoid valve ªONº and

ªOFFº with the CONSULT-II and

listen to operating sound.Solenoid valve makes an operating

sound.lHarness and connectorlSolenoid valve

GLOW RLY

lIgnition switch: ON (Engine

stopped)

lTurn the glow relay ªONº and

ªOFFº using CONSULT-II and listen

to operating sound.Glow relay makes the operating

sound.lHarness and connectorlFuel pump relay

INJ TIMING

lEngine: Return to the original

trouble condition

lRetard the injection timing using

CONSULT-II.If trouble symptom disappears, see

CHECK ITEM.lAdjust initial injection timing

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONCD20T

CONSULT-II (Cont'd)

EC-31

Page 327 of 2267

Introduction

The engine has an ECM to control major systems such as fuel

injection control, fuel injection timing control, glow control

system, etc. The ECM accepts input signals from sensors and

instantly drive the electronic fuel injection pump use the data to

based on current ambient conditions. It is essential that both

input and output signals are correct and stable. At the same time,

it is important that there are no problems such as vacuum leaks,

or other problems with the engine.

It is much more difficult to diagnose a problem that occurs inter-

mittently rather than catastrophically. Most intermittent problems

are caused by poor electric connections or faulty wiring. In this

case, careful checking of suspected circuits may help prevent the

replacement of good parts.

A visual check only may not be sufficient to determine the cause

of the problems. A road test with CONSULT-II or a circuit tester

connected should be performed. Follow the ªWork Flowº on the

next page.

Before undertaking actual checks, take a few minutes to talk with

a customer who approaches with a driveability complaint. The

customer can supply good information about such problems,

especially intermittent ones. Find out what symptoms are present

and under what conditions they occur. A ªDiagnostic Worksheetº

like the example on next page should be used.

Start your diagnosis by looking for ªconventionalº problems first.

This will help troubleshoot driveability problems on a vehicle with

an electronically controlled engine.

SEF858S

SEF233G

SEF234G

TROUBLE DIAGNOSIS Ð IntroductionCD20T

EC-33

Page 330 of 2267

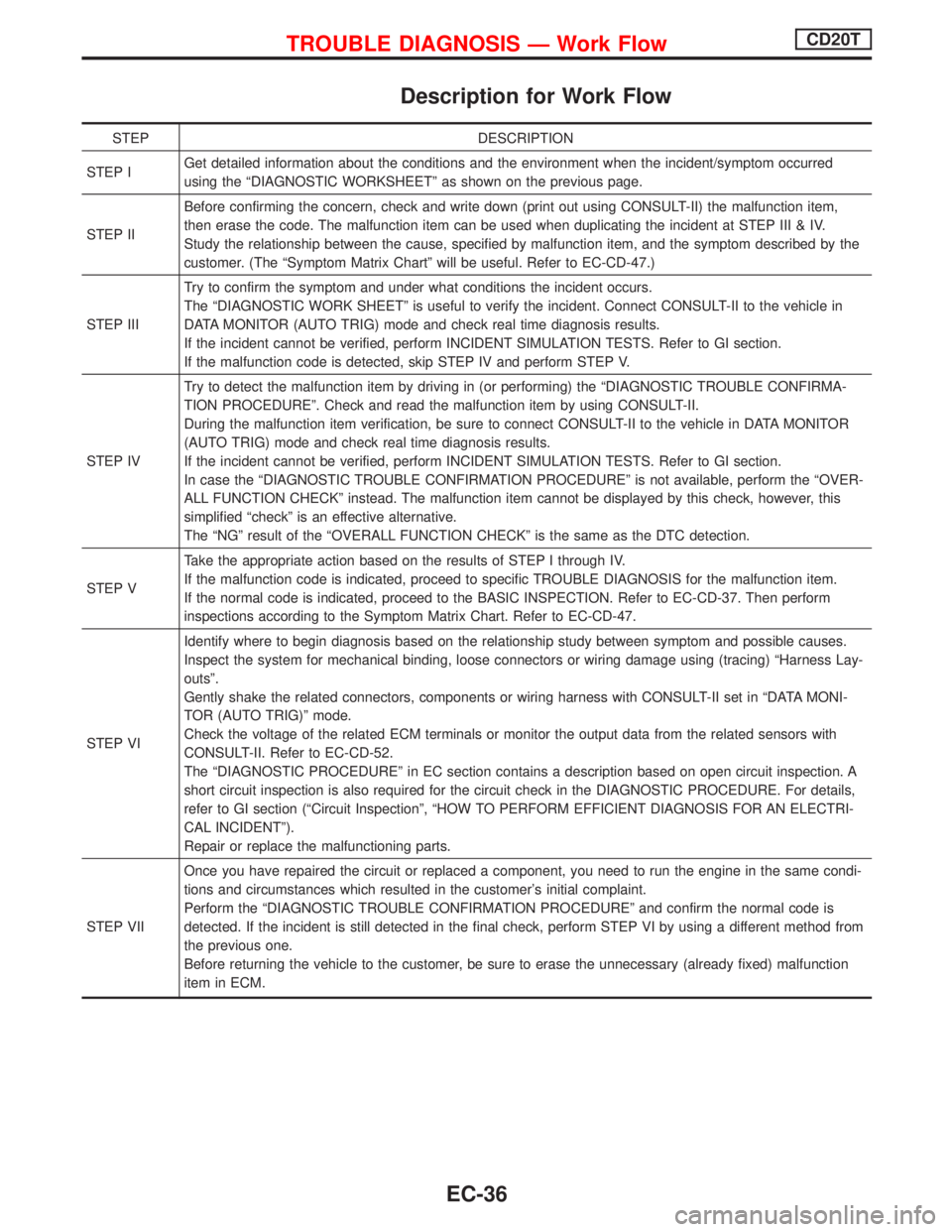

Description for Work Flow

STEP DESCRIPTION

STEP IGet detailed information about the conditions and the environment when the incident/symptom occurred

using the ªDIAGNOSTIC WORKSHEETº as shown on the previous page.

STEP IIBefore confirming the concern, check and write down (print out using CONSULT-II) the malfunction item,

then erase the code. The malfunction item can be used when duplicating the incident at STEP III & IV.

Study the relationship between the cause, specified by malfunction item, and the symptom described by the

customer. (The ªSymptom Matrix Chartº will be useful. Refer to EC-CD-47.)

STEP IIITry to confirm the symptom and under what conditions the incident occurs.

The ªDIAGNOSTIC WORK SHEETº is useful to verify the incident. Connect CONSULT-II to the vehicle in

DATA MONITOR (AUTO TRIG) mode and check real time diagnosis results.

If the incident cannot be verified, perform INCIDENT SIMULATION TESTS. Refer to GI section.

If the malfunction code is detected, skip STEP IV and perform STEP V.

STEP IVTry to detect the malfunction item by driving in (or performing) the ªDIAGNOSTIC TROUBLE CONFIRMA-

TION PROCEDUREº. Check and read the malfunction item by using CONSULT-II.

During the malfunction item verification, be sure to connect CONSULT-II to the vehicle in DATA MONITOR

(AUTO TRIG) mode and check real time diagnosis results.

If the incident cannot be verified, perform INCIDENT SIMULATION TESTS. Refer to GI section.

In case the ªDIAGNOSTIC TROUBLE CONFIRMATION PROCEDUREº is not available, perform the ªOVER-

ALL FUNCTION CHECKº instead. The malfunction item cannot be displayed by this check, however, this

simplified ªcheckº is an effective alternative.

The ªNGº result of the ªOVERALL FUNCTION CHECKº is the same as the DTC detection.

STEP VTake the appropriate action based on the results of STEP I through IV.

If the malfunction code is indicated, proceed to specific TROUBLE DIAGNOSIS for the malfunction item.

If the normal code is indicated, proceed to the BASIC INSPECTION. Refer to EC-CD-37. Then perform

inspections according to the Symptom Matrix Chart. Refer to EC-CD-47.

STEP VIIdentify where to begin diagnosis based on the relationship study between symptom and possible causes.

Inspect the system for mechanical binding, loose connectors or wiring damage using (tracing) ªHarness Lay-

outsº.

Gently shake the related connectors, components or wiring harness with CONSULT-II set in ªDATA MONI-

TOR (AUTO TRIG)º mode.

Check the voltage of the related ECM terminals or monitor the output data from the related sensors with

CONSULT-II. Refer to EC-CD-52.

The ªDIAGNOSTIC PROCEDUREº in EC section contains a description based on open circuit inspection. A

short circuit inspection is also required for the circuit check in the DIAGNOSTIC PROCEDURE. For details,

refer to GI section (ªCircuit Inspectionº, ªHOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRI-

CAL INCIDENTº).

Repair or replace the malfunctioning parts.

STEP VIIOnce you have repaired the circuit or replaced a component, you need to run the engine in the same condi-

tions and circumstances which resulted in the customer's initial complaint.

Perform the ªDIAGNOSTIC TROUBLE CONFIRMATION PROCEDUREº and confirm the normal code is

detected. If the incident is still detected in the final check, perform STEP VI by using a different method from

the previous one.

Before returning the vehicle to the customer, be sure to erase the unnecessary (already fixed) malfunction

item in ECM.

TROUBLE DIAGNOSIS Ð Work FlowCD20T

EC-36

Page 331 of 2267

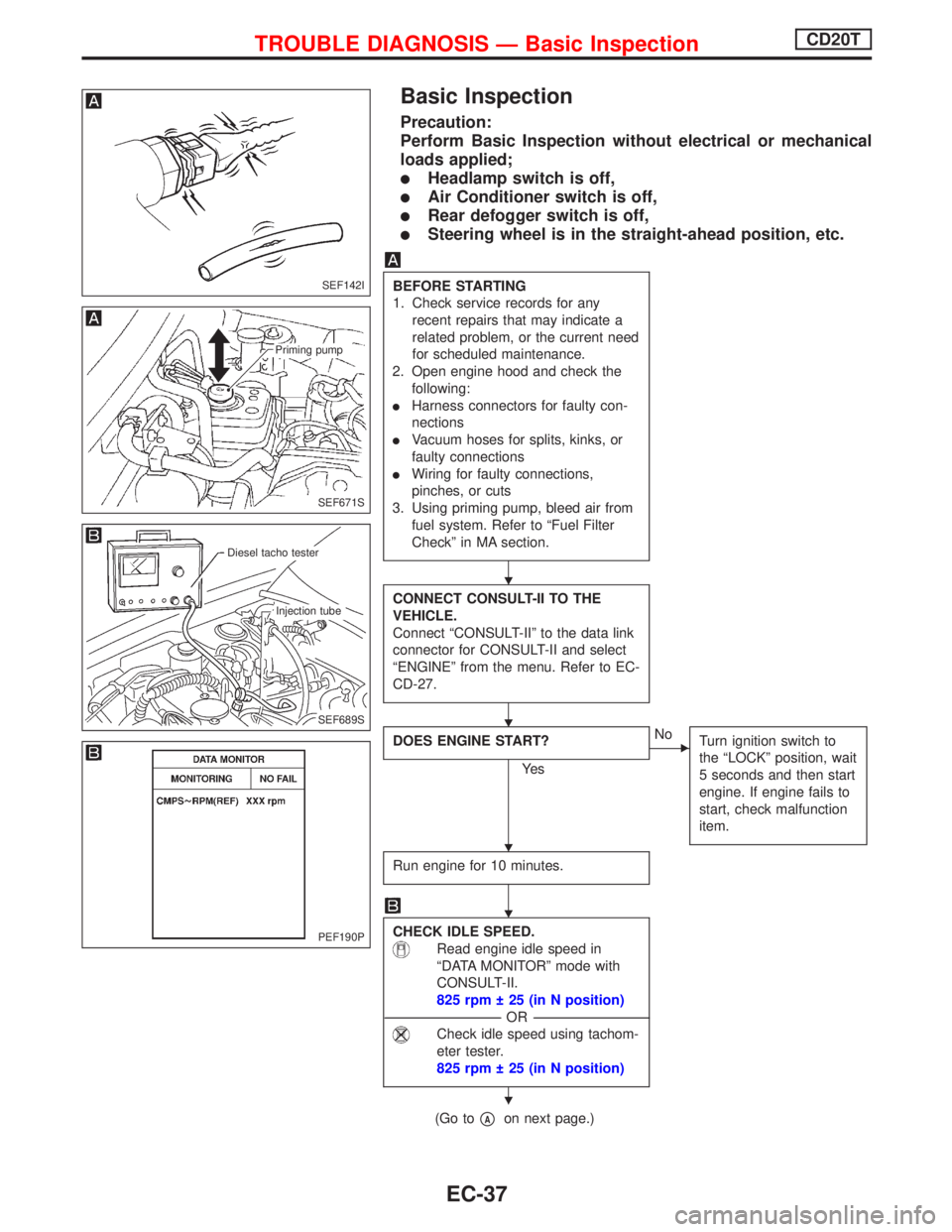

Basic Inspection

Precaution:

Perform Basic Inspection without electrical or mechanical

loads applied;

lHeadlamp switch is off,

lAir Conditioner switch is off,

lRear defogger switch is off,

lSteering wheel is in the straight-ahead position, etc.

BEFORE STARTING

1. Check service records for any

recent repairs that may indicate a

related problem, or the current need

for scheduled maintenance.

2. Open engine hood and check the

following:

lHarness connectors for faulty con-

nections

lVacuum hoses for splits, kinks, or

faulty connections

lWiring for faulty connections,

pinches, or cuts

3. Using priming pump, bleed air from

fuel system. Refer to ªFuel Filter

Checkº in MA section.

CONNECT CONSULT-II TO THE

VEHICLE.

Connect ªCONSULT-IIº to the data link

connector for CONSULT-II and select

ªENGINEº from the menu. Refer to EC-

CD-27.

DOES ENGINE START?

Ye s

ENo

Turn ignition switch to

the ªLOCKº position, wait

5 seconds and then start

engine. If engine fails to

start, check malfunction

item.

Run engine for 10 minutes.

CHECK IDLE SPEED.

Read engine idle speed in

ªDATA MONITORº mode with

CONSULT-II.

825 rpm 25 (in N position)

---------------------------------------------------------------------------------------------------------------------------------OR---------------------------------------------------------------------------------------------------------------------------------

Check idle speed using tachom-

eter tester.

825 rpm 25 (in N position)

(Go topAon next page.)

SEF142I

SEF671S

Priming pump

SEF689S

.Diesel tacho tester

.Injection tube

PEF190P

H

H

H

H

H

TROUBLE DIAGNOSIS Ð Basic InspectionCD20T

EC-37