NISSAN PRIMERA 1999 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 1071 of 2267

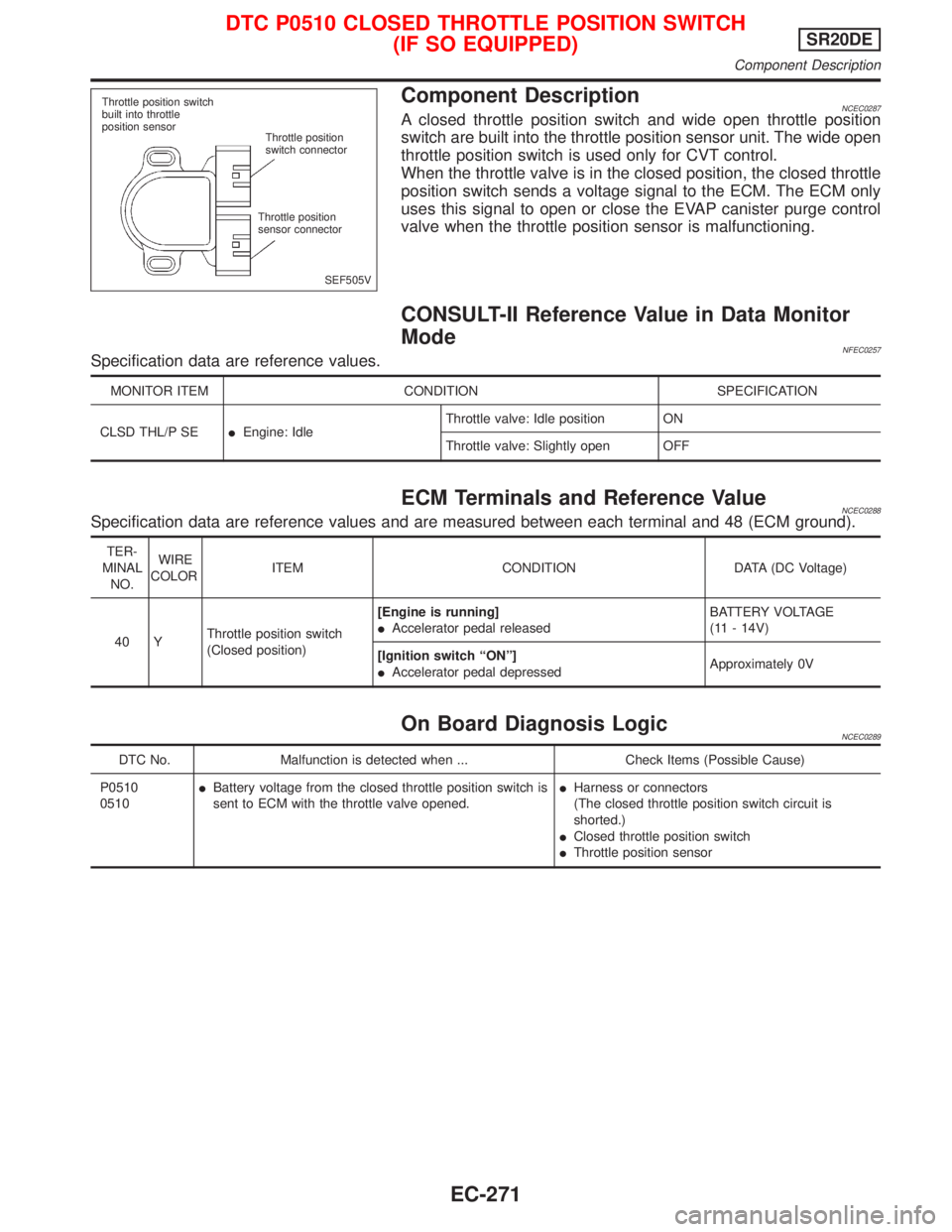

Component DescriptionNCEC0287A closed throttle position switch and wide open throttle position

switch are built into the throttle position sensor unit. The wide open

throttle position switch is used only for CVT control.

When the throttle valve is in the closed position, the closed throttle

position switch sends a voltage signal to the ECM. The ECM only

uses this signal to open or close the EVAP canister purge control

valve when the throttle position sensor is malfunctioning.

CONSULT-II Reference Value in Data Monitor

Mode

NFEC0257Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

CLSD THL/P SEIEngine: IdleThrottle valve: Idle position ON

Throttle valve: Slightly open OFF

ECM Terminals and Reference ValueNCEC0288Specification data are reference values and are measured between each terminal and 48 (ECM ground).

TER-

MINAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

40 YThrottle position switch

(Closed position)[Engine is running]

IAccelerator pedal releasedBATTERY VOLTAGE

(11 - 14V)

[Ignition switch ªONº]

IAccelerator pedal depressedApproximately 0V

On Board Diagnosis LogicNCEC0289

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P0510

0510IBattery voltage from the closed throttle position switch is

sent to ECM with the throttle valve opened.IHarness or connectors

(The closed throttle position switch circuit is

shorted.)

IClosed throttle position switch

IThrottle position sensor

SEF505V

Throttle position switch

built into throttle

position sensor

Throttle position

switch connector

Throttle position

sensor connector

DTC P0510 CLOSED THROTTLE POSITION SWITCH

(IF SO EQUIPPED)SR20DE

Component Description

EC-271

Page 1072 of 2267

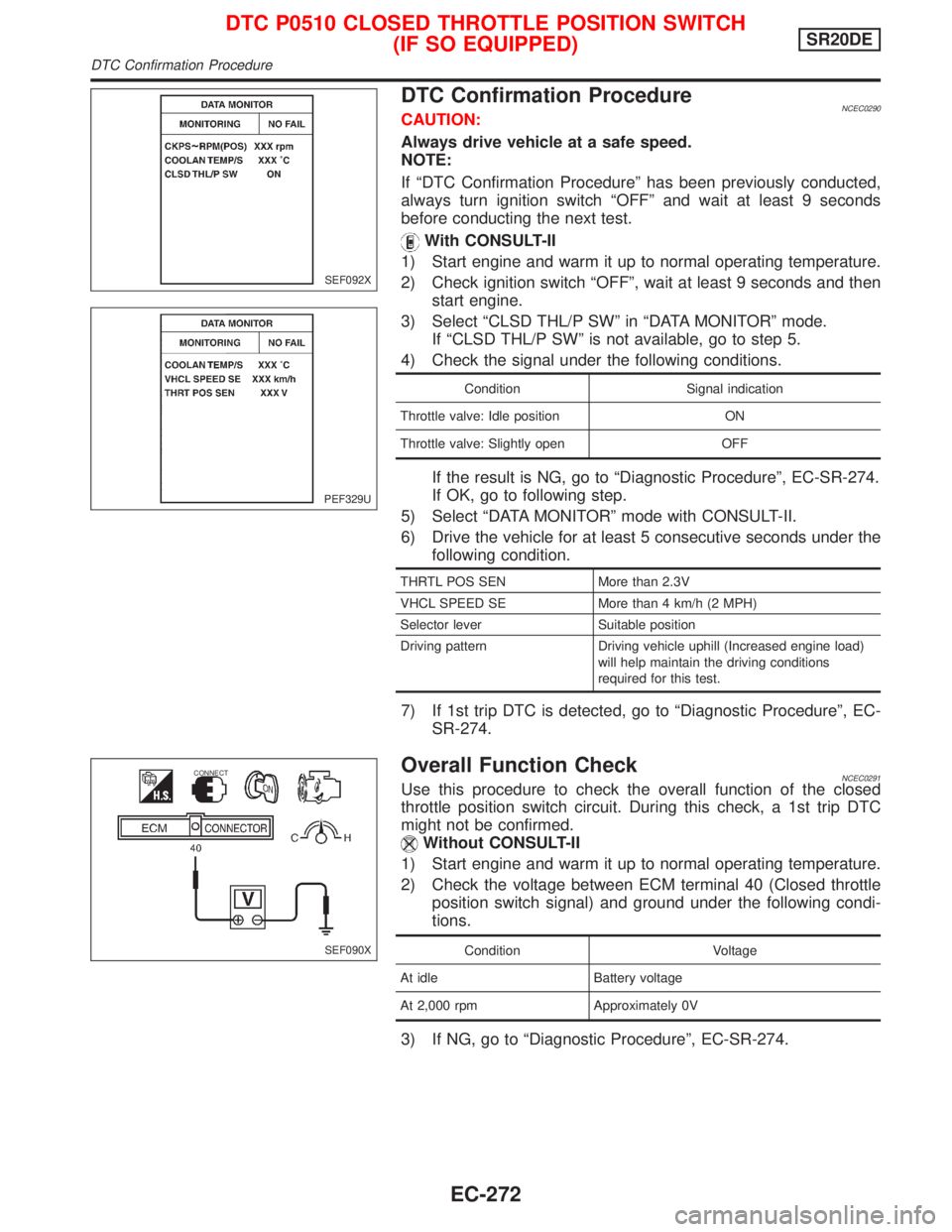

DTC Confirmation ProcedureNCEC0290CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 9 seconds

before conducting the next test.

With CONSULT-II

1) Start engine and warm it up to normal operating temperature.

2) Check ignition switch ªOFFº, wait at least 9 seconds and then

start engine.

3) Select ªCLSD THL/P SWº in ªDATA MONITORº mode.

If ªCLSD THL/P SWº is not available, go to step 5.

4) Check the signal under the following conditions.

Condition Signal indication

Throttle valve: Idle position ON

Throttle valve: Slightly open OFF

If the result is NG, go to ªDiagnostic Procedureº, EC-SR-274.

If OK, go to following step.

5) Select ªDATA MONITORº mode with CONSULT-II.

6) Drive the vehicle for at least 5 consecutive seconds under the

following condition.

THRTL POS SEN More than 2.3V

VHCL SPEED SE More than 4 km/h (2 MPH)

Selector lever Suitable position

Driving pattern Driving vehicle uphill (Increased engine load)

will help maintain the driving conditions

required for this test.

7) If 1st trip DTC is detected, go to ªDiagnostic Procedureº, EC-

SR-274.

Overall Function CheckNCEC0291Use this procedure to check the overall function of the closed

throttle position switch circuit. During this check, a 1st trip DTC

might not be confirmed.

Without CONSULT-II

1) Start engine and warm it up to normal operating temperature.

2) Check the voltage between ECM terminal 40 (Closed throttle

position switch signal) and ground under the following condi-

tions.

Condition Voltage

At idle Battery voltage

At 2,000 rpm Approximately 0V

3) If NG, go to ªDiagnostic Procedureº, EC-SR-274.

SEF092X

PEF329U

SEF090X

CONNECT

DTC P0510 CLOSED THROTTLE POSITION SWITCH

(IF SO EQUIPPED)SR20DE

DTC Confirmation Procedure

EC-272

Page 1073 of 2267

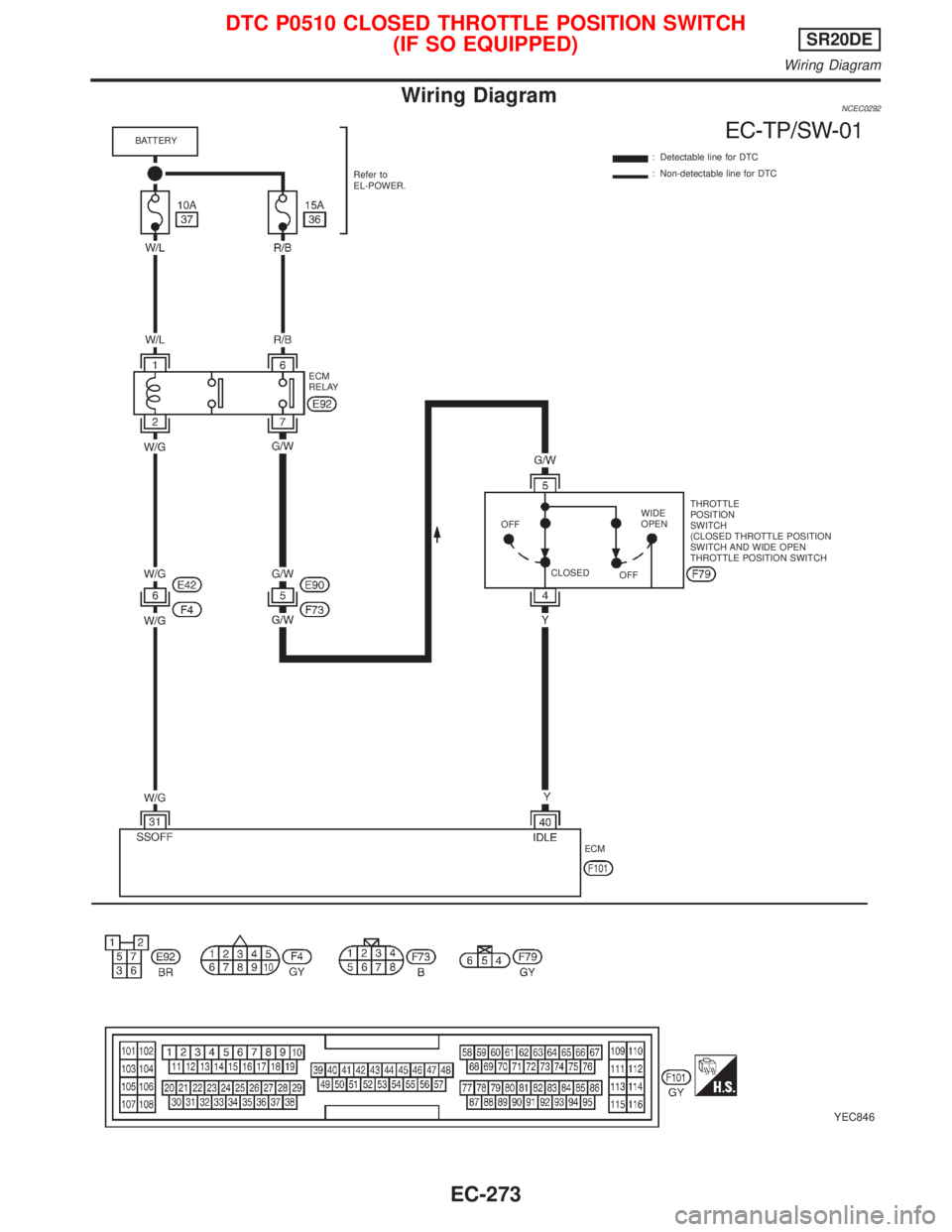

Wiring DiagramNCEC0292

YEC846

BATTERY

Refer to

EL-POWER.: Detectable line for DTC

: Non-detectable line for DTC

ECM

RELAY

OFF

CLOSEDWIDE

OPEN

OFFTHROTTLE

POSITION

SWITCH

(CLOSED THROTTLE POSITION

SWITCH AND WIDE OPEN

THROTTLE POSITION SWITCH

ECM

DTC P0510 CLOSED THROTTLE POSITION SWITCH

(IF SO EQUIPPED)SR20DE

Wiring Diagram

EC-273

Page 1074 of 2267

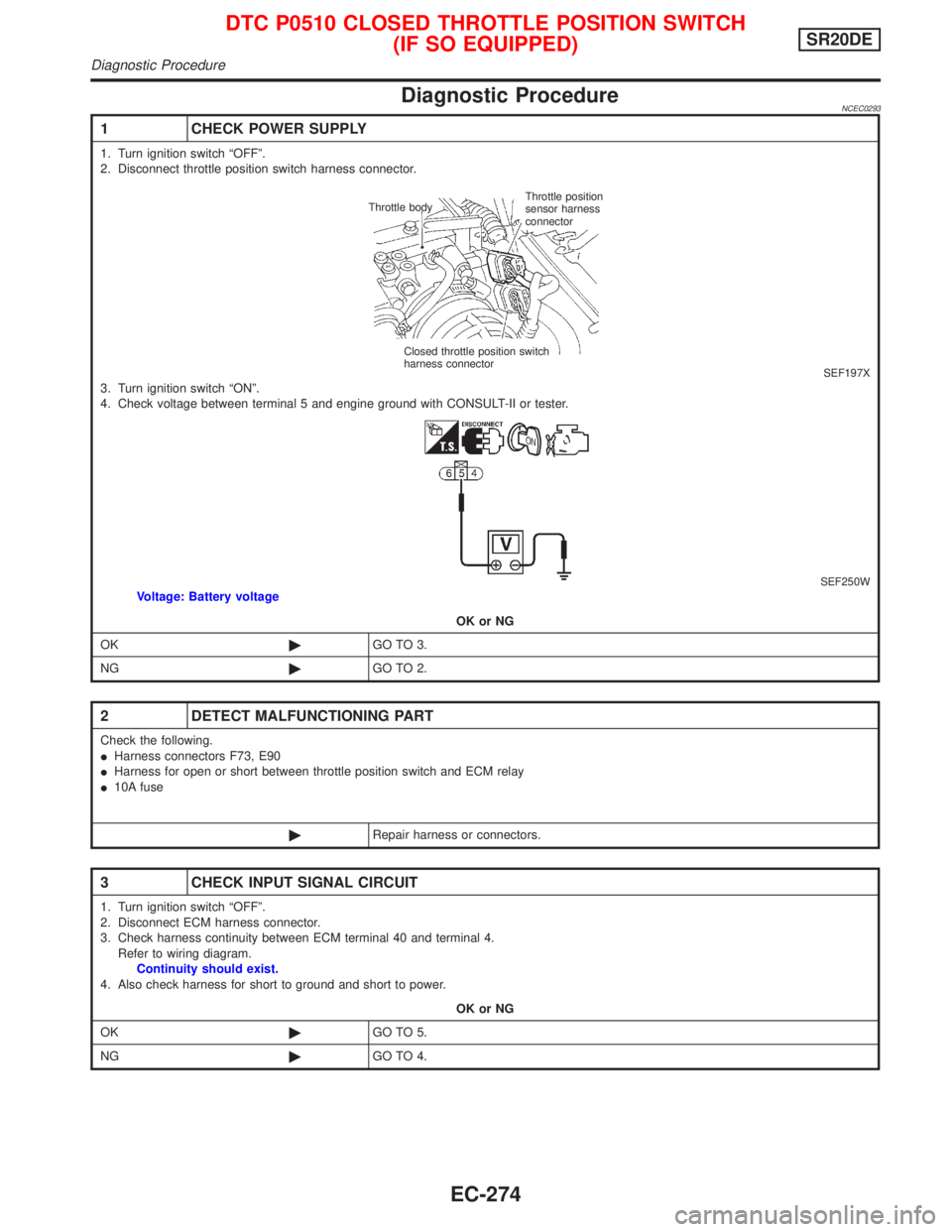

Diagnostic ProcedureNCEC0293

1 CHECK POWER SUPPLY

1. Turn ignition switch ªOFFº.

2. Disconnect throttle position switch harness connector.

SEF197X3. Turn ignition switch ªONº.

4. Check voltage between terminal 5 and engine ground with CONSULT-II or tester.

SEF250WVoltage: Battery voltage

OK or NG

OK©GO TO 3.

NG©GO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors F73, E90

IHarness for open or short between throttle position switch and ECM relay

I10A fuse

©Repair harness or connectors.

3 CHECK INPUT SIGNAL CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminal 40 and terminal 4.

Refer to wiring diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 5.

NG©GO TO 4.

Throttle bodyThrottle position

sensor harness

connector

Closed throttle position switch

harness connector

DTC P0510 CLOSED THROTTLE POSITION SWITCH

(IF SO EQUIPPED)SR20DE

Diagnostic Procedure

EC-274

Page 1075 of 2267

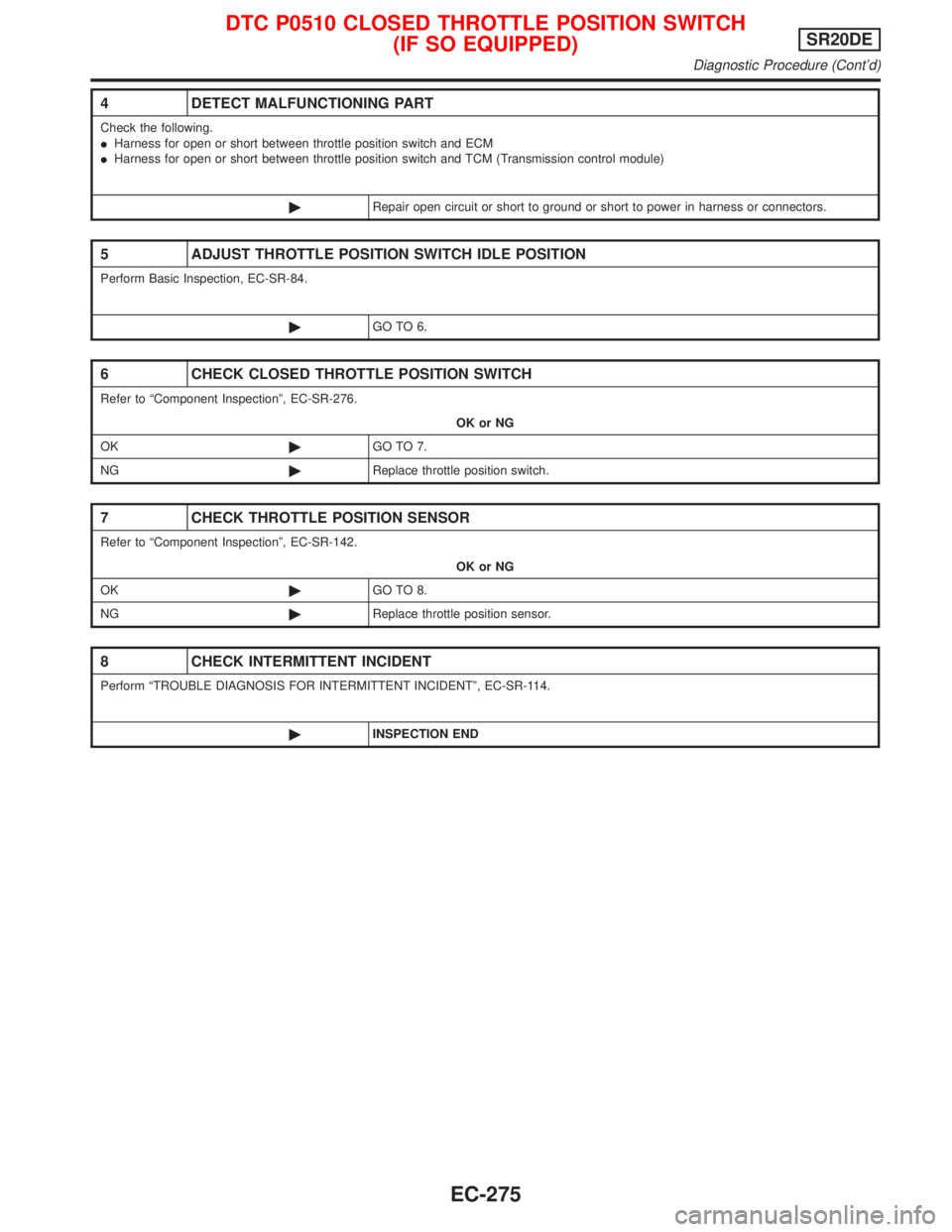

4 DETECT MALFUNCTIONING PART

Check the following.

IHarness for open or short between throttle position switch and ECM

IHarness for open or short between throttle position switch and TCM (Transmission control module)

©Repair open circuit or short to ground or short to power in harness or connectors.

5 ADJUST THROTTLE POSITION SWITCH IDLE POSITION

Perform Basic Inspection, EC-SR-84.

©GO TO 6.

6 CHECK CLOSED THROTTLE POSITION SWITCH

Refer to ªComponent Inspectionº, EC-SR-276.

OK or NG

OK©GO TO 7.

NG©Replace throttle position switch.

7 CHECK THROTTLE POSITION SENSOR

Refer to ªComponent Inspectionº, EC-SR-142.

OK or NG

OK©GO TO 8.

NG©Replace throttle position sensor.

8 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-SR-114.

©INSPECTION END

DTC P0510 CLOSED THROTTLE POSITION SWITCH

(IF SO EQUIPPED)SR20DE

Diagnostic Procedure (Cont'd)

EC-275

Page 1076 of 2267

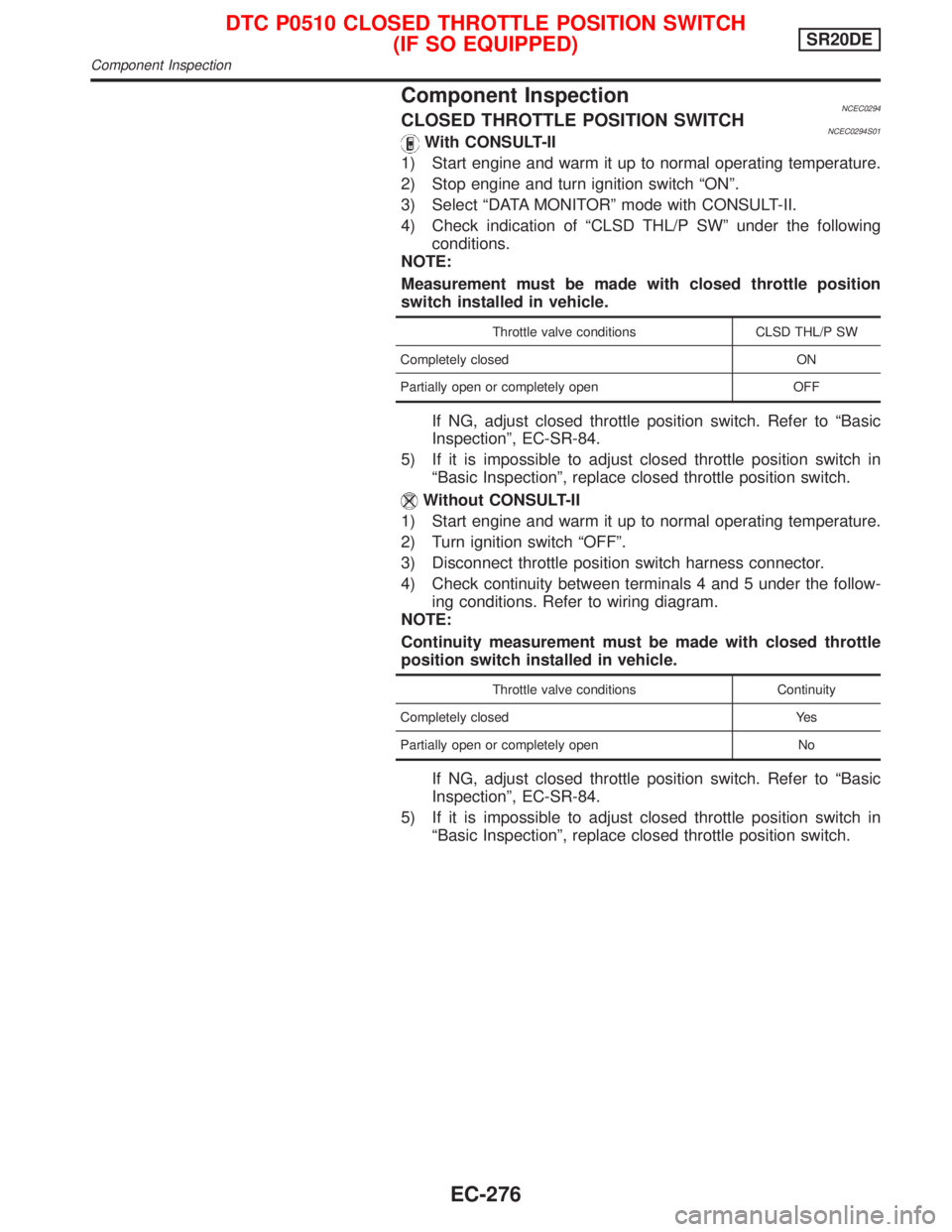

Component InspectionNCEC0294CLOSED THROTTLE POSITION SWITCHNCEC0294S01With CONSULT-II

1) Start engine and warm it up to normal operating temperature.

2) Stop engine and turn ignition switch ªONº.

3) Select ªDATA MONITORº mode with CONSULT-II.

4) Check indication of ªCLSD THL/P SWº under the following

conditions.

NOTE:

Measurement must be made with closed throttle position

switch installed in vehicle.

Throttle valve conditions CLSD THL/P SW

Completely closed ON

Partially open or completely open OFF

If NG, adjust closed throttle position switch. Refer to ªBasic

Inspectionº, EC-SR-84.

5) If it is impossible to adjust closed throttle position switch in

ªBasic Inspectionº, replace closed throttle position switch.

Without CONSULT-II

1) Start engine and warm it up to normal operating temperature.

2) Turn ignition switch ªOFFº.

3) Disconnect throttle position switch harness connector.

4) Check continuity between terminals 4 and 5 under the follow-

ing conditions. Refer to wiring diagram.

NOTE:

Continuity measurement must be made with closed throttle

position switch installed in vehicle.

Throttle valve conditions Continuity

Completely closed Yes

Partially open or completely open No

If NG, adjust closed throttle position switch. Refer to ªBasic

Inspectionº, EC-SR-84.

5) If it is impossible to adjust closed throttle position switch in

ªBasic Inspectionº, replace closed throttle position switch.

DTC P0510 CLOSED THROTTLE POSITION SWITCH

(IF SO EQUIPPED)SR20DE

Component Inspection

EC-276

Page 1077 of 2267

Component DescriptionNCEC0295The ECM consists of a microcomputer, diagnostic test mode

selector, and connectors for signal input and output and for power

supply. The ECM controls the engine.

On Board Diagnosis LogicNCEC0296

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P0605

0605IECM calculation function is malfunctioning.IECM

DTC Confirmation ProcedureNCEC0297NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 9 seconds

before conducting the next test.

With CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine.

4) Run engine for at least 1 second at idle speed.

5) If 1st trip DTC is detected, go to ªDiagnostic Procedureº, EC-

SR-278.

With GST

Follow the procedure ªWith CONSULT-IIº above.

SEF093X

NEF068A

DTC P0605 ECMSR20DE

Component Description

EC-277

Page 1078 of 2267

Diagnostic Procedure=NCEC0298

1 INSPECTION START

With CONSULT-II

1. Turn ignition switch ªONº.

2. Select ªSELF DIAG RESULTSº mode with CONSULT-II.

3. Touch ªERASEº.

4. Perform ªDTC Confirmation Procedureº.

See previous page.

5. Is the 1st trip DTC P0605 displayed again?

With GST

1. Turn ignition switch ªONº.

2. Select MODE 4 with GST.

3. Touch ªERASEº.

4. Perform ªDTC Confirmation Procedureº.

See previous page.

5. Is the 1st trip DTC P0605 displayed again?

YesorNo

Ye s©Replace ECM.

No©INSPECTION END

DTC P0605 ECMSR20DE

Diagnostic Procedure

EC-278

Page 1079 of 2267

System DescriptionNCEC0433COOLING FAN CONTROLNCEC0433S01

Sensor Input Signal to ECMECM func-

tionActuator

Vehicle speed sensor or ABS actuator and

electric unit (control unit)Vehicle speed

ECM Cooling fan relay(s) Engine coolant temperature sensor Engine coolant temperature

Air conditioner switch Air conditioner ªONº signal

Ignition switch Start signal

Refrigerant pressure sensor Refrigerant pressure

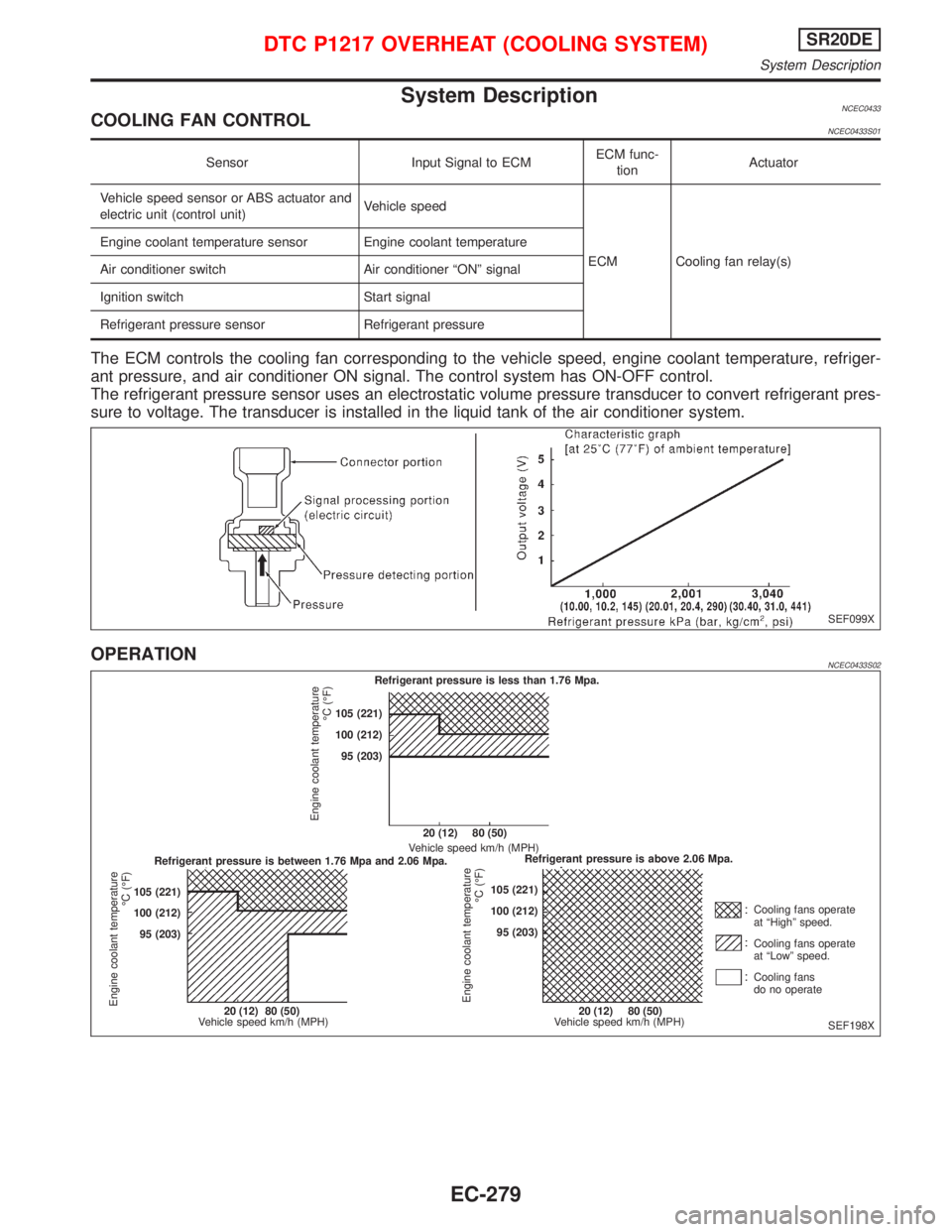

The ECM controls the cooling fan corresponding to the vehicle speed, engine coolant temperature, refriger-

ant pressure, and air conditioner ON signal. The control system has ON-OFF control.

The refrigerant pressure sensor uses an electrostatic volume pressure transducer to convert refrigerant pres-

sure to voltage. The transducer is installed in the liquid tank of the air conditioner system.

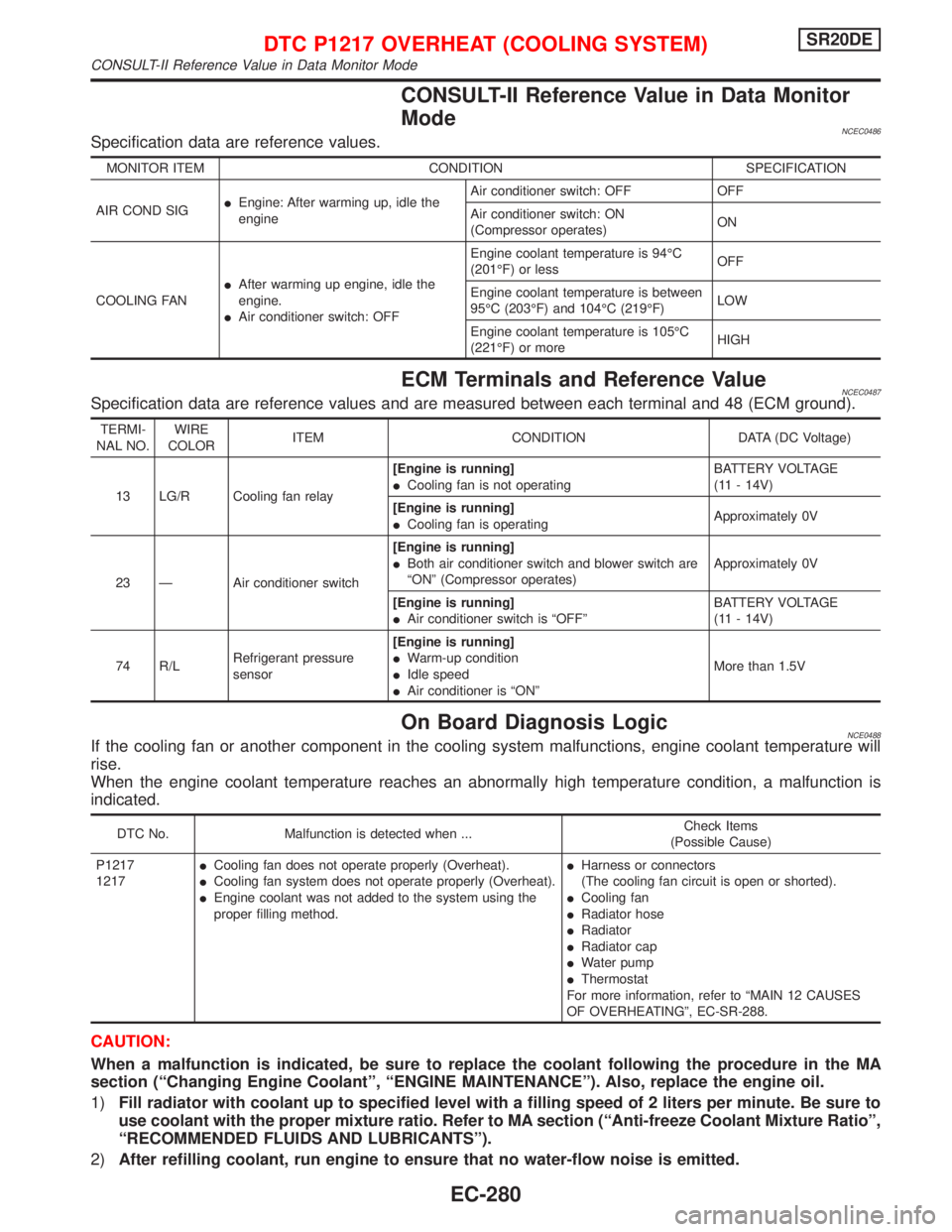

OPERATIONNCEC0433S02

SEF099X

SEF198X Refrigerant pressure is less than 1.76 Mpa.

Refrigerant pressure is between 1.76 Mpa and 2.06 Mpa.Refrigerant pressure is above 2.06 Mpa. 20 (12) 80 (50)

Vehicle speed km/h (MPH)

20 (12) 80 (50)

Vehicle speed km/h (MPH)20 (12) 80 (50)

Vehicle speed km/h (MPH)Cooling fans operate

at ªHighº speed.

Cooling fans operate

at ªLowº speed.

Cooling fans

do no operate 105 (221)

100 (212)

95 (203) 105 (221)

100 (212)

95 (203)105 (221)

100 (212)

95 (203)

Engine coolant temperature

ÉC (ÉF)

Engine coolant temperature

ÉC (ÉF)

Engine coolant temperature

ÉC (ÉF)

DTC P1217 OVERHEAT (COOLING SYSTEM)SR20DE

System Description

EC-279

Page 1080 of 2267

CONSULT-II Reference Value in Data Monitor

Mode

NCEC0486Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

AIR COND SIGIEngine: After warming up, idle the

engineAir conditioner switch: OFF OFF

Air conditioner switch: ON

(Compressor operates)ON

COOLING FANIAfter warming up engine, idle the

engine.

IAir conditioner switch: OFFEngine coolant temperature is 94ÉC

(201ÉF) or lessOFF

Engine coolant temperature is between

95ÉC (203ÉF) and 104ÉC (219ÉF)LOW

Engine coolant temperature is 105ÉC

(221ÉF) or moreHIGH

ECM Terminals and Reference ValueNCEC0487Specification data are reference values and are measured between each terminal and 48 (ECM ground).

TERMI-

NAL NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

13 LG/R Cooling fan relay[Engine is running]

ICooling fan is not operatingBATTERY VOLTAGE

(11 - 14V)

[Engine is running]

ICooling fan is operatingApproximately 0V

23 Ð Air conditioner switch[Engine is running]

IBoth air conditioner switch and blower switch are

ªONº (Compressor operates)Approximately 0V

[Engine is running]

IAir conditioner switch is ªOFFºBATTERY VOLTAGE

(11 - 14V)

74 R/LRefrigerant pressure

sensor[Engine is running]

IWarm-up condition

IIdle speed

IAir conditioner is ªONºMore than 1.5V

On Board Diagnosis LogicNCE0488If the cooling fan or another component in the cooling system malfunctions, engine coolant temperature will

rise.

When the engine coolant temperature reaches an abnormally high temperature condition, a malfunction is

indicated.

DTC No. Malfunction is detected when ...Check Items

(Possible Cause)

P1217

1217ICooling fan does not operate properly (Overheat).

ICooling fan system does not operate properly (Overheat).

IEngine coolant was not added to the system using the

proper filling method.IHarness or connectors

(The cooling fan circuit is open or shorted).

ICooling fan

IRadiator hose

IRadiator

IRadiator cap

IWater pump

IThermostat

For more information, refer to ªMAIN 12 CAUSES

OF OVERHEATINGº, EC-SR-288.

CAUTION:

When a malfunction is indicated, be sure to replace the coolant following the procedure in the MA

section (ªChanging Engine Coolantº, ªENGINE MAINTENANCEº). Also, replace the engine oil.

1)Fill radiator with coolant up to specified level with a filling speed of 2 liters per minute. Be sure to

use coolant with the proper mixture ratio. Refer to MA section (ªAnti-freeze Coolant Mixture Ratioº,

ªRECOMMENDED FLUIDS AND LUBRICANTSº).

2)After refilling coolant, run engine to ensure that no water-flow noise is emitted.

DTC P1217 OVERHEAT (COOLING SYSTEM)SR20DE

CONSULT-II Reference Value in Data Monitor Mode

EC-280