NISSAN PRIMERA 1999 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 1091 of 2267

DTC Confirmation ProcedureNCEC0330NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 5 seconds

before conducting the next test.

With CONSULT-II

1) Turn ignition switch ªONº and select ªDATA MONITORº mode

with CONSULT-II.

2) Start engine and run it for at least 4 minutes at idle speed.

3) If 1st trip DTC is detected, go to ªDiagnostic Procedureº, EC-

SR-293.

With GST

Follow the procedure ªWith CONSULT-IIº above.

NEF068A

DTC P1336 CRANKSHAFT POSITION SENSOR

(CKPS) (OBD) (COG)SR20DE

DTC Confirmation Procedure

EC-291

Page 1092 of 2267

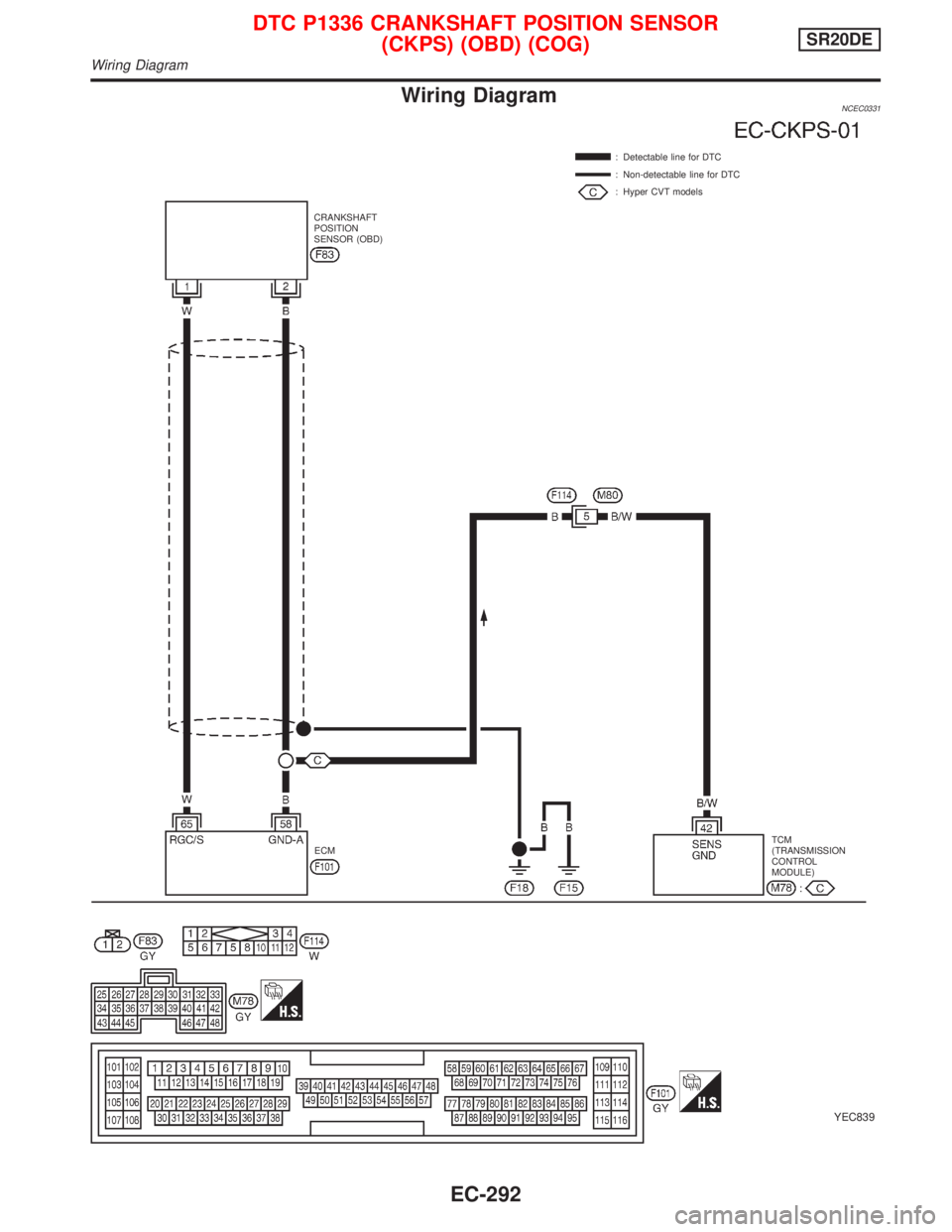

Wiring DiagramNCEC0331

YEC839

: Detectable line for DTC

: Non-detectable line for DTC

: Hyper CVT models

ECMTCM

(TRANSMISSION

CONTROL

MODULE) CRANKSHAFT

POSITION

SENSOR (OBD)

DTC P1336 CRANKSHAFT POSITION SENSOR

(CKPS) (OBD) (COG)SR20DE

Wiring Diagram

EC-292

Page 1093 of 2267

Diagnostic ProcedureNCEC0332

1 RETIGHTEN GROUND SCREWS

1. Turn ignition switch ªOFFº.

2. Loosen and retighten engine ground screws.

©GO TO 2.

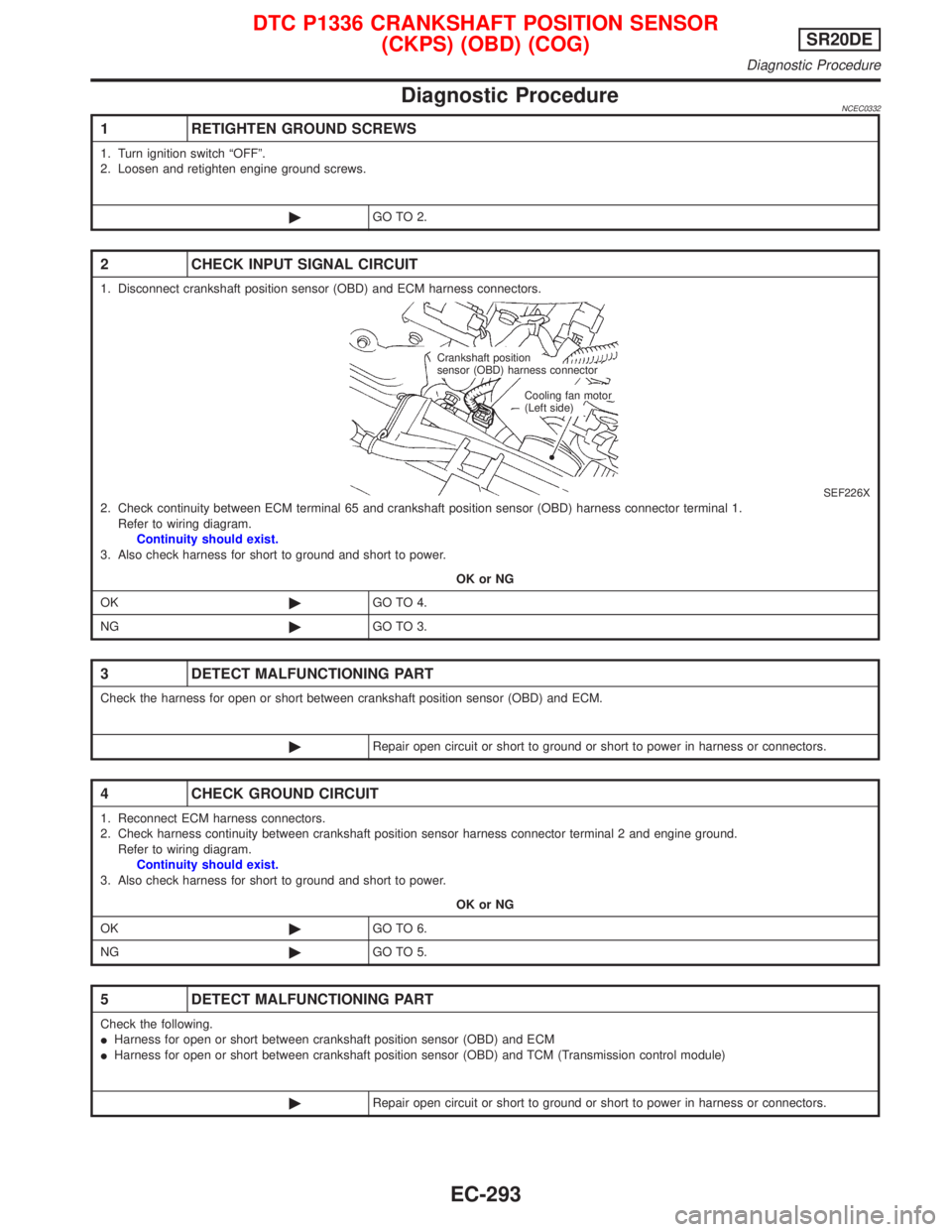

2 CHECK INPUT SIGNAL CIRCUIT

1. Disconnect crankshaft position sensor (OBD) and ECM harness connectors.

SEF226X2. Check continuity between ECM terminal 65 and crankshaft position sensor (OBD) harness connector terminal 1.

Refer to wiring diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 4.

NG©GO TO 3.

3 DETECT MALFUNCTIONING PART

Check the harness for open or short between crankshaft position sensor (OBD) and ECM.

©Repair open circuit or short to ground or short to power in harness or connectors.

4 CHECK GROUND CIRCUIT

1. Reconnect ECM harness connectors.

2. Check harness continuity between crankshaft position sensor harness connector terminal 2 and engine ground.

Refer to wiring diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 6.

NG©GO TO 5.

5 DETECT MALFUNCTIONING PART

Check the following.

IHarness for open or short between crankshaft position sensor (OBD) and ECM

IHarness for open or short between crankshaft position sensor (OBD) and TCM (Transmission control module)

©Repair open circuit or short to ground or short to power in harness or connectors.

Crankshaft position

sensor (OBD) harness connector

Cooling fan motor

(Left side)

DTC P1336 CRANKSHAFT POSITION SENSOR

(CKPS) (OBD) (COG)SR20DE

Diagnostic Procedure

EC-293

Page 1094 of 2267

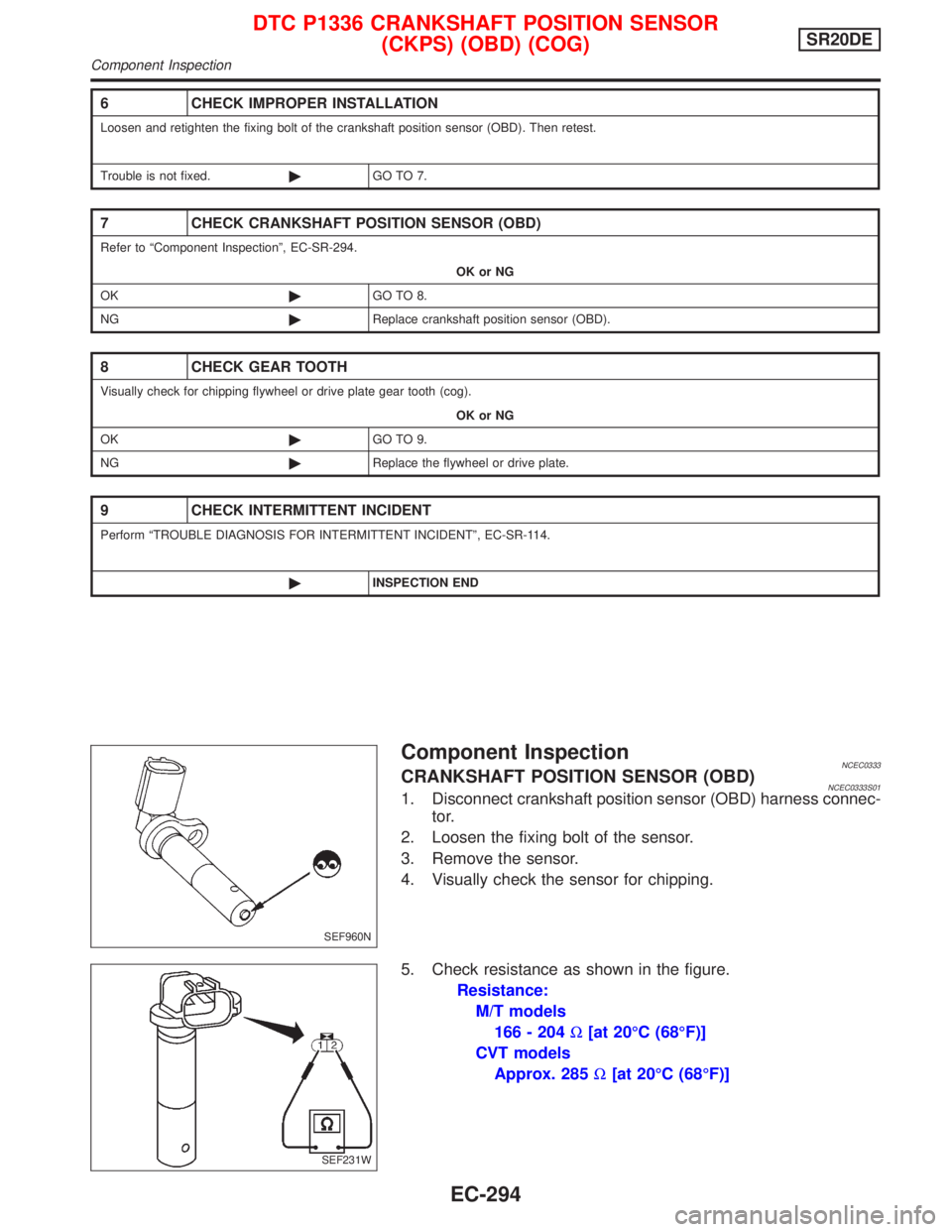

Component InspectionNCEC0333CRANKSHAFT POSITION SENSOR (OBD)NCEC0333S011. Disconnect crankshaft position sensor (OBD) harness connec-

tor.

2. Loosen the fixing bolt of the sensor.

3. Remove the sensor.

4. Visually check the sensor for chipping.

5. Check resistance as shown in the figure.

Resistance:

M/T models

166 - 204W[at 20ÉC (68ÉF)]

CVT models

Approx. 285W[at 20ÉC (68ÉF)]

6 CHECK IMPROPER INSTALLATION

Loosen and retighten the fixing bolt of the crankshaft position sensor (OBD). Then retest.

Trouble is not fixed.©GO TO 7.

7 CHECK CRANKSHAFT POSITION SENSOR (OBD)

Refer to ªComponent Inspectionº, EC-SR-294.

OK or NG

OK©GO TO 8.

NG©Replace crankshaft position sensor (OBD).

8 CHECK GEAR TOOTH

Visually check for chipping flywheel or drive plate gear tooth (cog).

OK or NG

OK©GO TO 9.

NG©Replace the flywheel or drive plate.

9 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-SR-114.

©INSPECTION END

SEF960N

SEF231W

DTC P1336 CRANKSHAFT POSITION SENSOR

(CKPS) (OBD) (COG)SR20DE

Component Inspection

EC-294

Page 1095 of 2267

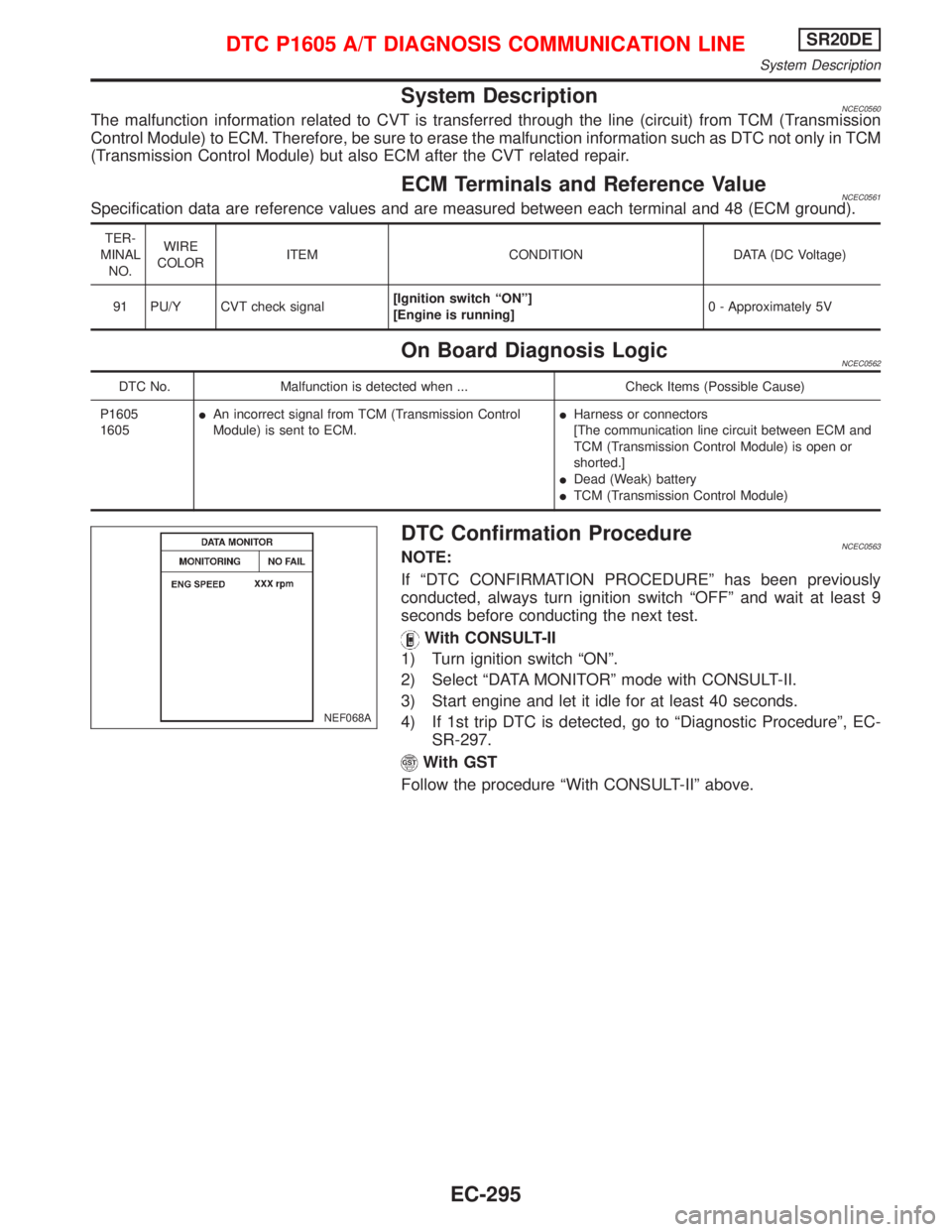

System DescriptionNCEC0560The malfunction information related to CVT is transferred through the line (circuit) from TCM (Transmission

Control Module) to ECM. Therefore, be sure to erase the malfunction information such as DTC not only in TCM

(Transmission Control Module) but also ECM after the CVT related repair.

ECM Terminals and Reference ValueNCEC0561Specification data are reference values and are measured between each terminal and 48 (ECM ground).

TER-

MINAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

91 PU/Y CVT check signal[Ignition switch ªONº]

[Engine is running]0 - Approximately 5V

On Board Diagnosis LogicNCEC0562

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P1605

1605IAn incorrect signal from TCM (Transmission Control

Module) is sent to ECM.IHarness or connectors

[The communication line circuit between ECM and

TCM (Transmission Control Module) is open or

shorted.]

IDead (Weak) battery

ITCM (Transmission Control Module)

DTC Confirmation ProcedureNCEC0563NOTE:

If ªDTC CONFIRMATION PROCEDUREº has been previously

conducted, always turn ignition switch ªOFFº and wait at least 9

seconds before conducting the next test.

With CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and let it idle for at least 40 seconds.

4) If 1st trip DTC is detected, go to ªDiagnostic Procedureº, EC-

SR-297.

With GST

Follow the procedure ªWith CONSULT-IIº above.

NEF068A

DTC P1605 A/T DIAGNOSIS COMMUNICATION LINESR20DE

System Description

EC-295

Page 1096 of 2267

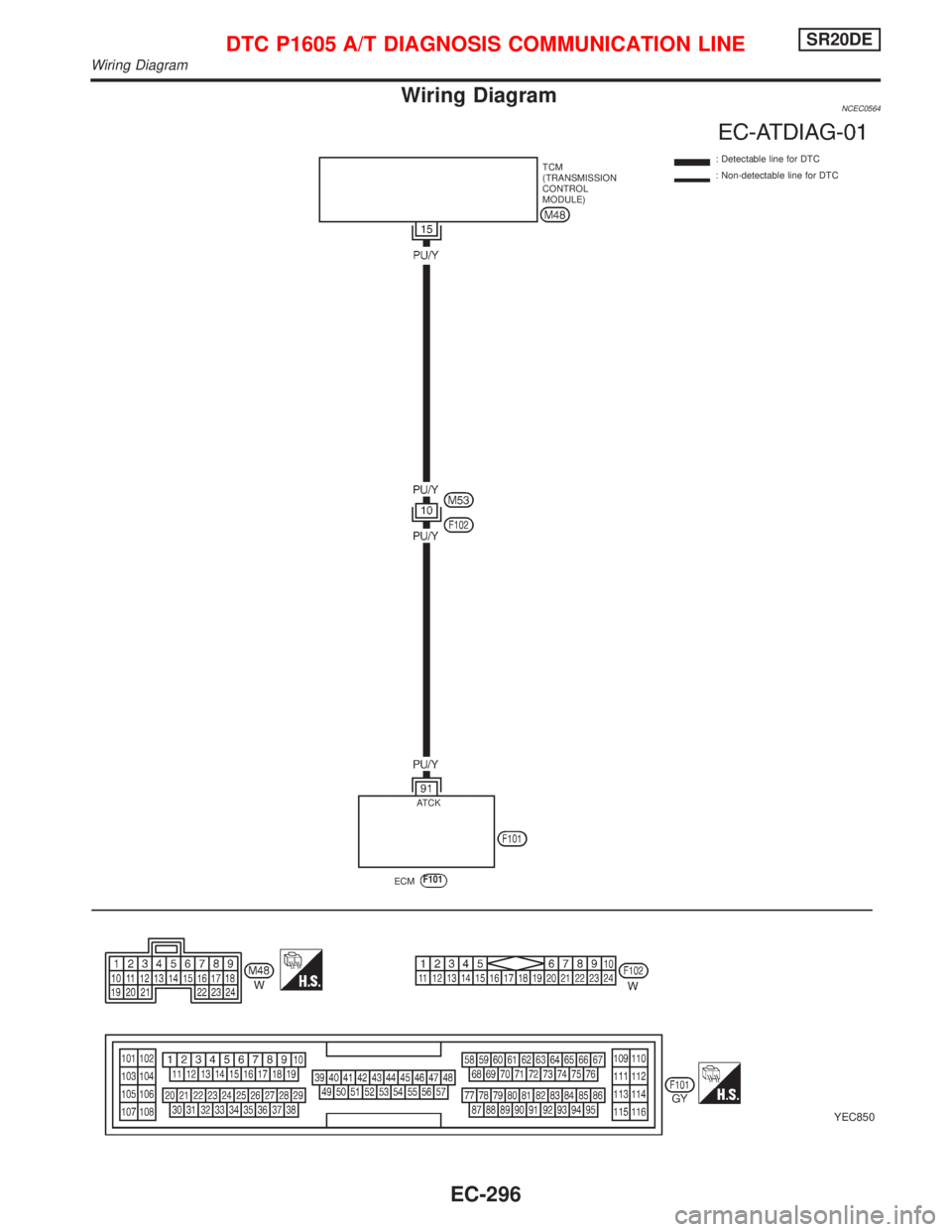

Wiring DiagramNCEC0564

YEC850

: Detectable line for DTC

: Non-detectable line for DTC TCM

(TRANSMISSION

CONTROL

MODULE)

ECM

F101

.ATCK

DTC P1605 A/T DIAGNOSIS COMMUNICATION LINESR20DE

Wiring Diagram

EC-296

Page 1097 of 2267

Diagnostic ProcedureNCEC0565

1 CHECK INPUT SIGNAL CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector and TCM harness connector. Refer to A/T section for TCM location.

3. Check harness continuity between ECM terminal 91 and TCM terminal 15. Refer to wiring diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 2.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

2 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-SR-114.

©INSPECTION END

DTC P1605 A/T DIAGNOSIS COMMUNICATION LINESR20DE

Diagnostic Procedure

EC-297

Page 1098 of 2267

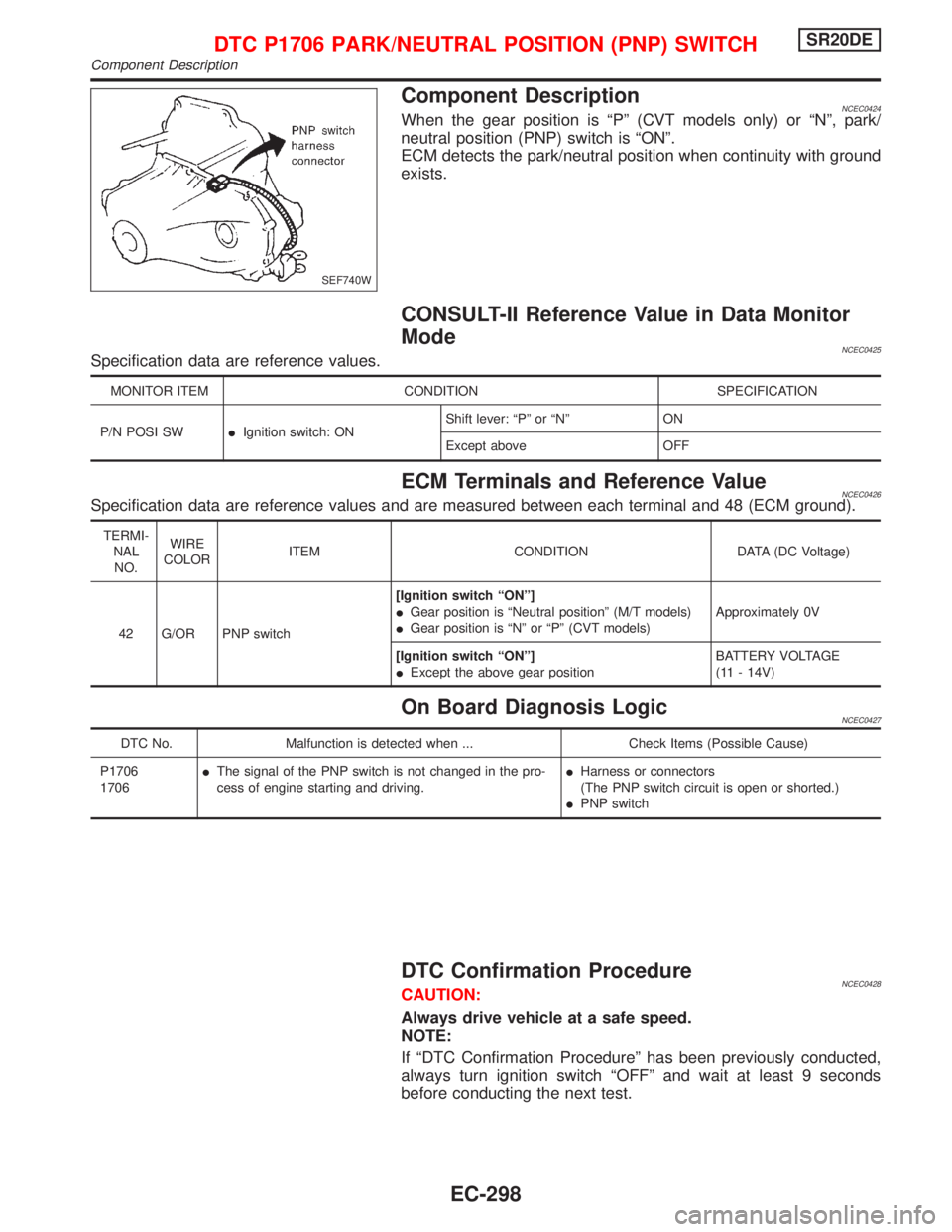

Component DescriptionNCEC0424When the gear position is ªPº (CVT models only) or ªNº, park/

neutral position (PNP) switch is ªONº.

ECM detects the park/neutral position when continuity with ground

exists.

CONSULT-II Reference Value in Data Monitor

Mode

NCEC0425Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

P/N POSI SWIIgnition switch: ONShift lever: ªPº or ªNº ON

Except above OFF

ECM Terminals and Reference ValueNCEC0426Specification data are reference values and are measured between each terminal and 48 (ECM ground).

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

42 G/OR PNP switch[Ignition switch ªONº]

IGear position is ªNeutral positionº (M/T models)

IGear position is ªNº or ªPº (CVT models)Approximately 0V

[Ignition switch ªONº]

IExcept the above gear positionBATTERY VOLTAGE

(11 - 14V)

On Board Diagnosis LogicNCEC0427

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P1706

1706IThe signal of the PNP switch is not changed in the pro-

cess of engine starting and driving.IHarness or connectors

(The PNP switch circuit is open or shorted.)

IPNP switch

DTC Confirmation ProcedureNCEC0428CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 9 seconds

before conducting the next test.

SEF740W

DTC P1706 PARK/NEUTRAL POSITION (PNP) SWITCHSR20DE

Component Description

EC-298

Page 1099 of 2267

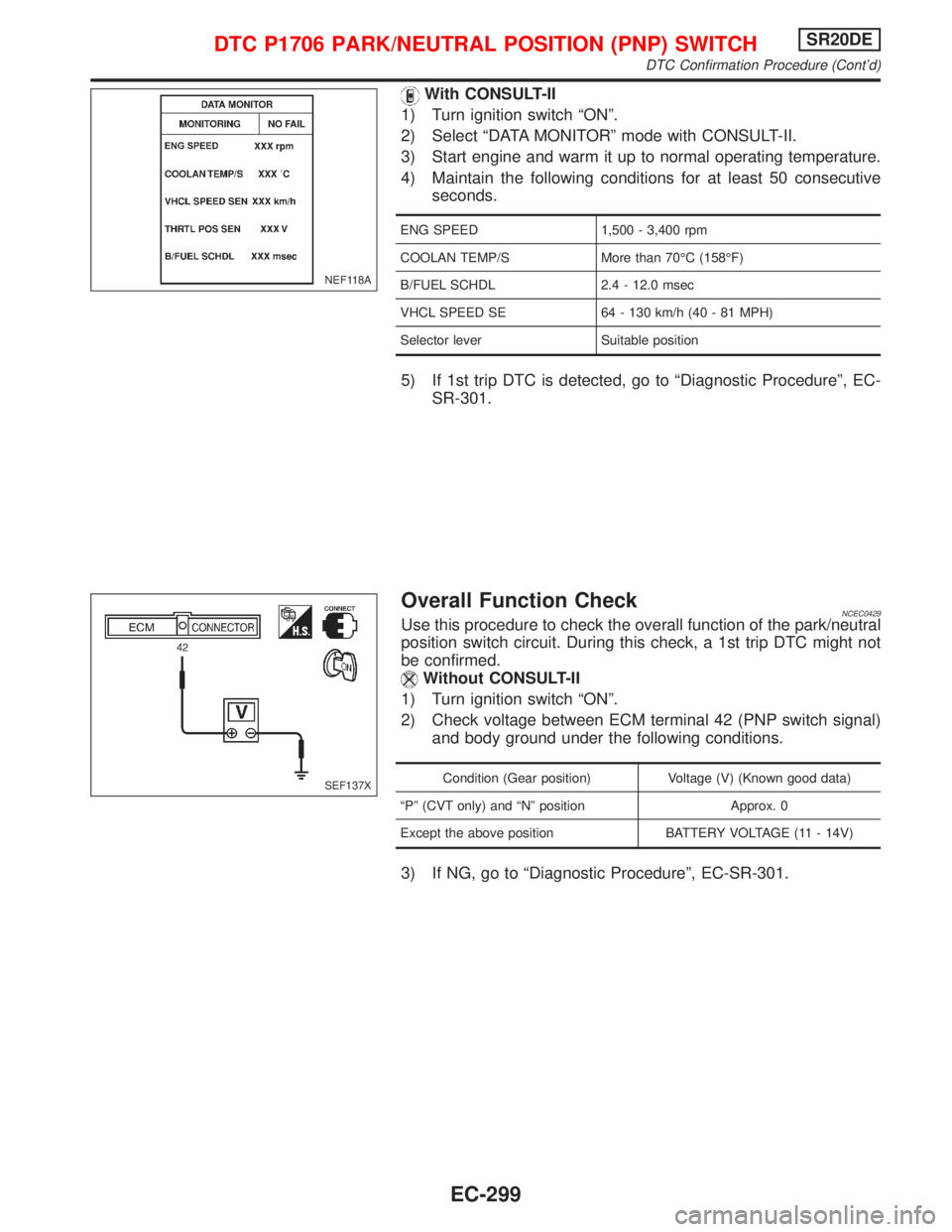

With CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and warm it up to normal operating temperature.

4) Maintain the following conditions for at least 50 consecutive

seconds.

ENG SPEED 1,500 - 3,400 rpm

COOLAN TEMP/S More than 70ÉC (158ÉF)

B/FUEL SCHDL 2.4 - 12.0 msec

VHCL SPEED SE 64 - 130 km/h (40 - 81 MPH)

Selector lever Suitable position

5) If 1st trip DTC is detected, go to ªDiagnostic Procedureº, EC-

SR-301.

Overall Function CheckNCEC0429Use this procedure to check the overall function of the park/neutral

position switch circuit. During this check, a 1st trip DTC might not

be confirmed.

Without CONSULT-II

1) Turn ignition switch ªONº.

2) Check voltage between ECM terminal 42 (PNP switch signal)

and body ground under the following conditions.

Condition (Gear position) Voltage (V) (Known good data)

ªPº (CVT only) and ªNº position Approx. 0

Except the above position BATTERY VOLTAGE (11 - 14V)

3) If NG, go to ªDiagnostic Procedureº, EC-SR-301.

NEF118A

SEF137X

DTC P1706 PARK/NEUTRAL POSITION (PNP) SWITCHSR20DE

DTC Confirmation Procedure (Cont'd)

EC-299

Page 1100 of 2267

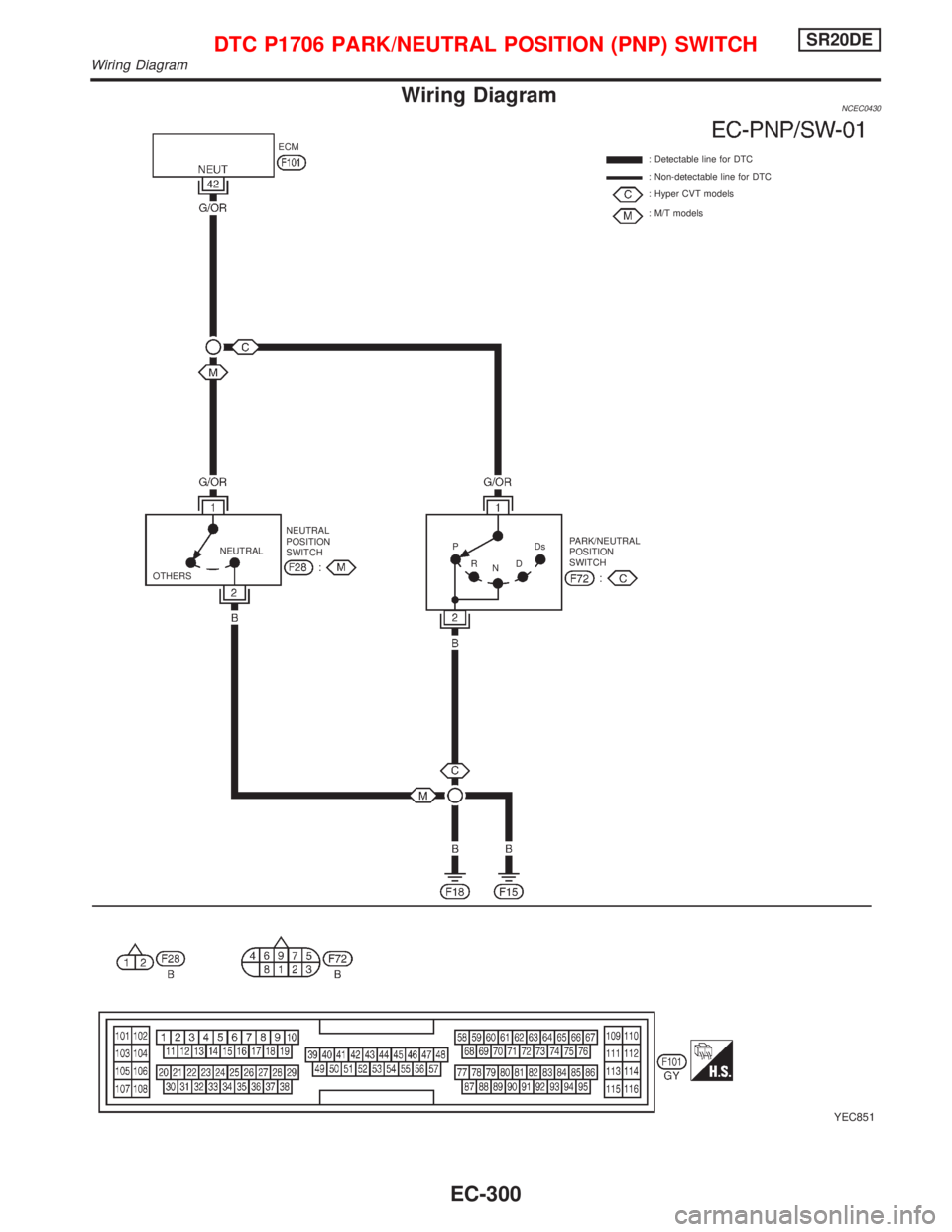

Wiring DiagramNCEC0430

YEC851

: Detectable line for DTC

: Non-detectable line for DTC

: Hyper CVT models

: M/T models ECM

PARK/NEUTRAL

POSITION

SWITCH NEUTRAL

POSITION

SWITCH NEUTRAL

OTHERSP

R

NDDs

DTC P1706 PARK/NEUTRAL POSITION (PNP) SWITCHSR20DE

Wiring Diagram

EC-300