sensor NISSAN PRIMERA 1999 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 753 of 2267

5 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-QG-102.

©INSPECTION END

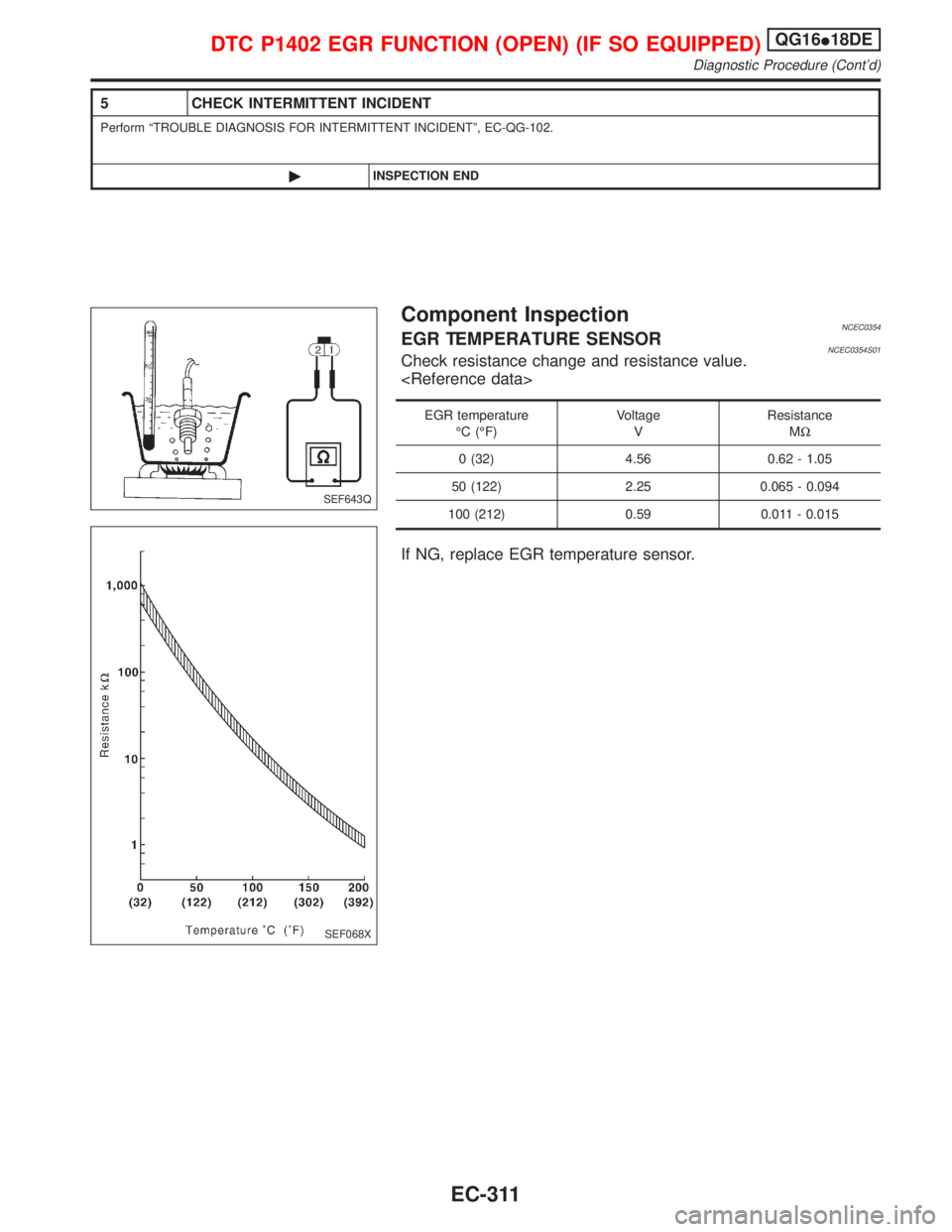

Component InspectionNCEC0354EGR TEMPERATURE SENSORNCEC0354S01Check resistance change and resistance value.

EGR temperature

ÉC (ÉF)Voltage

VResistance

MW

0 (32) 4.56 0.62 - 1.05

50 (122) 2.25 0.065 - 0.094

100 (212) 0.59 0.011 - 0.015

If NG, replace EGR temperature sensor.

SEF643Q

SEF068X

DTC P1402 EGR FUNCTION (OPEN) (IF SO EQUIPPED)QG16I18DE

Diagnostic Procedure (Cont'd)

EC-311

Page 778 of 2267

System DescriptionNCEC0444

Sensor Input Signal to ECMECM func-

tionActuator

Camshaft position sensor (PHASE) Engine speed

Fuel pump

controlFuel pump relay

Ignition switch Start signal

The ECM activates the fuel pump for several seconds after the ignition switch is turned on to improve engine

startability. If the ECM receives a 180É signal from the camshaft position sensor, it knows that the engine is

rotating, and causes the pump to perform. If the 180É signal is not received when the ignition switch is on, the

engine stalls. The ECM stops pump operation and prevents battery discharging, thereby improving safety. The

ECM does not directly drive the fuel pump. It controls the ON/OFF fuel pump relay, which in turn controls the

fuel pump.

Condition Fuel pump operation

Ignition switch is turned to ON. Operates for 1 second

Engine running and cranking Operates

When engine is stopped (Signal is not sent from camshaft position sensor.) Stops in 1.5 seconds

Except as shown aboveStops

Component DescriptionNCEC0501A turbine type design fuel pump is used in the fuel tank.

CONSULT-II Reference Value in Data Monitor

Mode

NCEC0445

MONITOR ITEM CONDITION SPECIFICATION

FUEL PUMP RLYIIgnition switch is turned to ON (Operates for 1 second)

IEngine running and cranking

IWhen engine is stopped (stops in 1.5 seconds)ON

IExcept as shown above OFF

AEC801

FUEL PUMPQG16I18DE

System Description

EC-336

Page 789 of 2267

JEF147Y

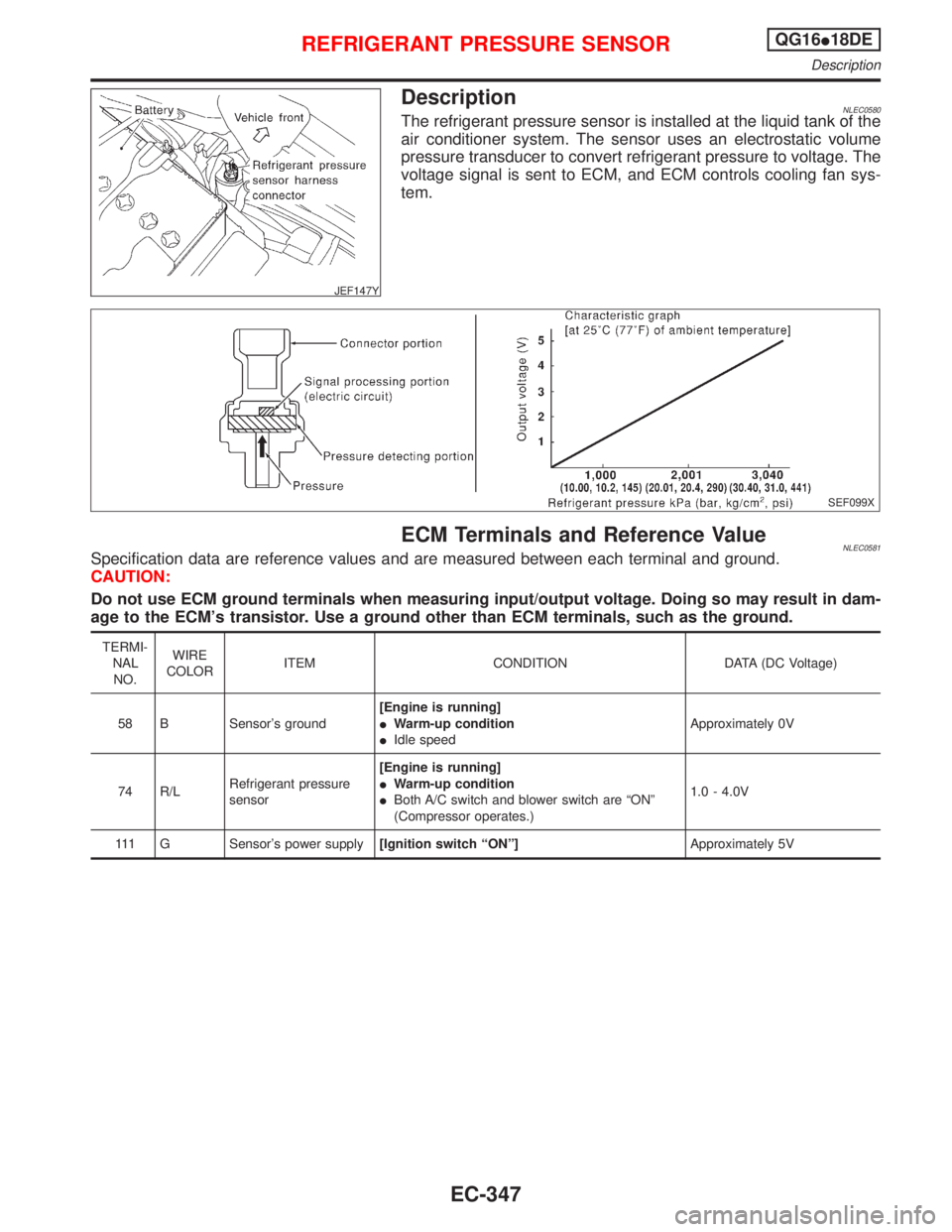

DescriptionNLEC0580The refrigerant pressure sensor is installed at the liquid tank of the

air conditioner system. The sensor uses an electrostatic volume

pressure transducer to convert refrigerant pressure to voltage. The

voltage signal is sent to ECM, and ECM controls cooling fan sys-

tem.

SEF099X

ECM Terminals and Reference ValueNLEC0581Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

58 B Sensor's ground[Engine is running]

IWarm-up condition

IIdle speedApproximately 0V

74 R/LRefrigerant pressure

sensor[Engine is running]

IWarm-up condition

IBoth A/C switch and blower switch are ªONº

(Compressor operates.)1.0 - 4.0V

111 G Sensor's power supply[Ignition switch ªONº]Approximately 5V

REFRIGERANT PRESSURE SENSORQG16I18DE

Description

EC-347

Page 790 of 2267

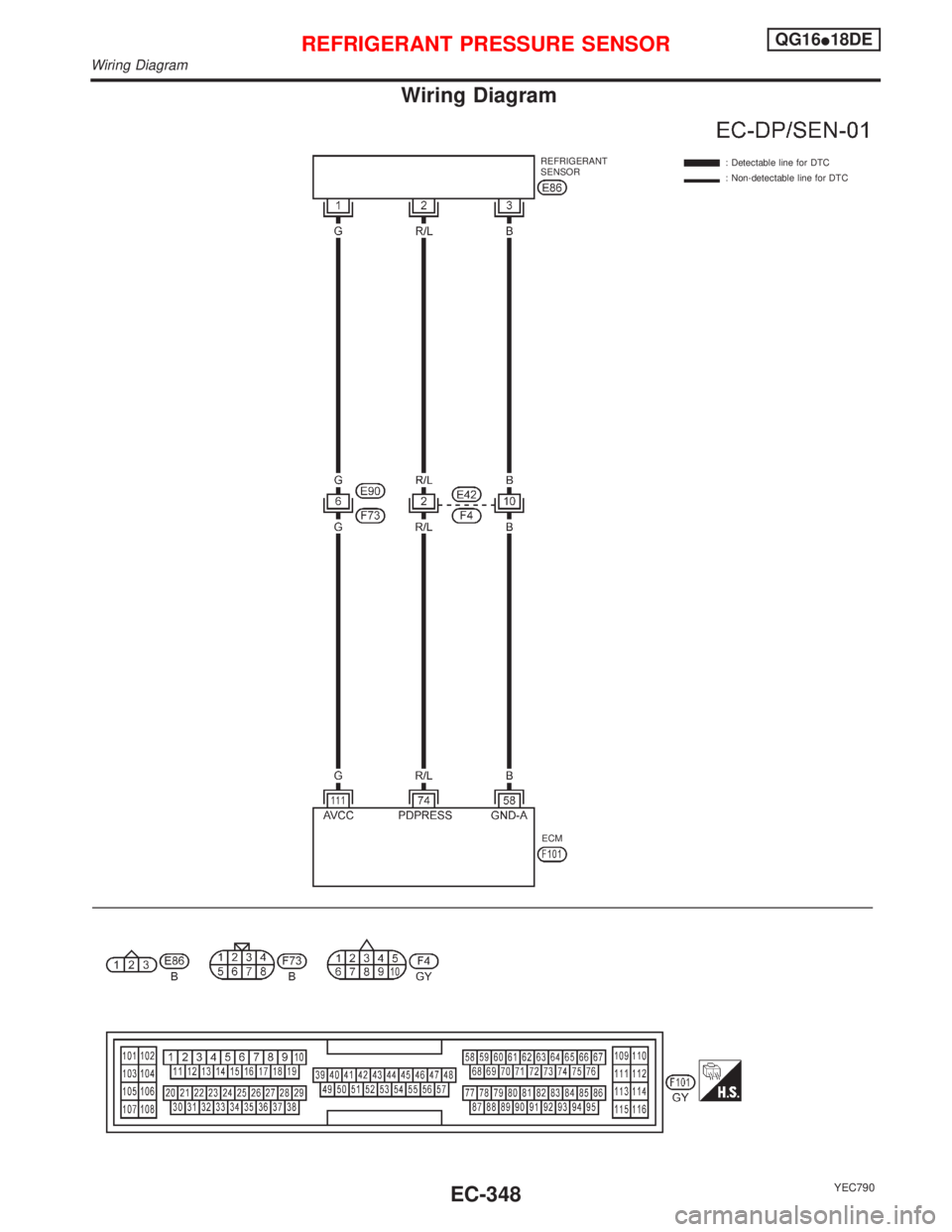

Wiring Diagram

YEC790

: Detectable line for DTC

: Non-detectable line for DTC REFRIGERANT

SENSOR

ECM

REFRIGERANT PRESSURE SENSORQG16I18DE

Wiring Diagram

EC-348

Page 791 of 2267

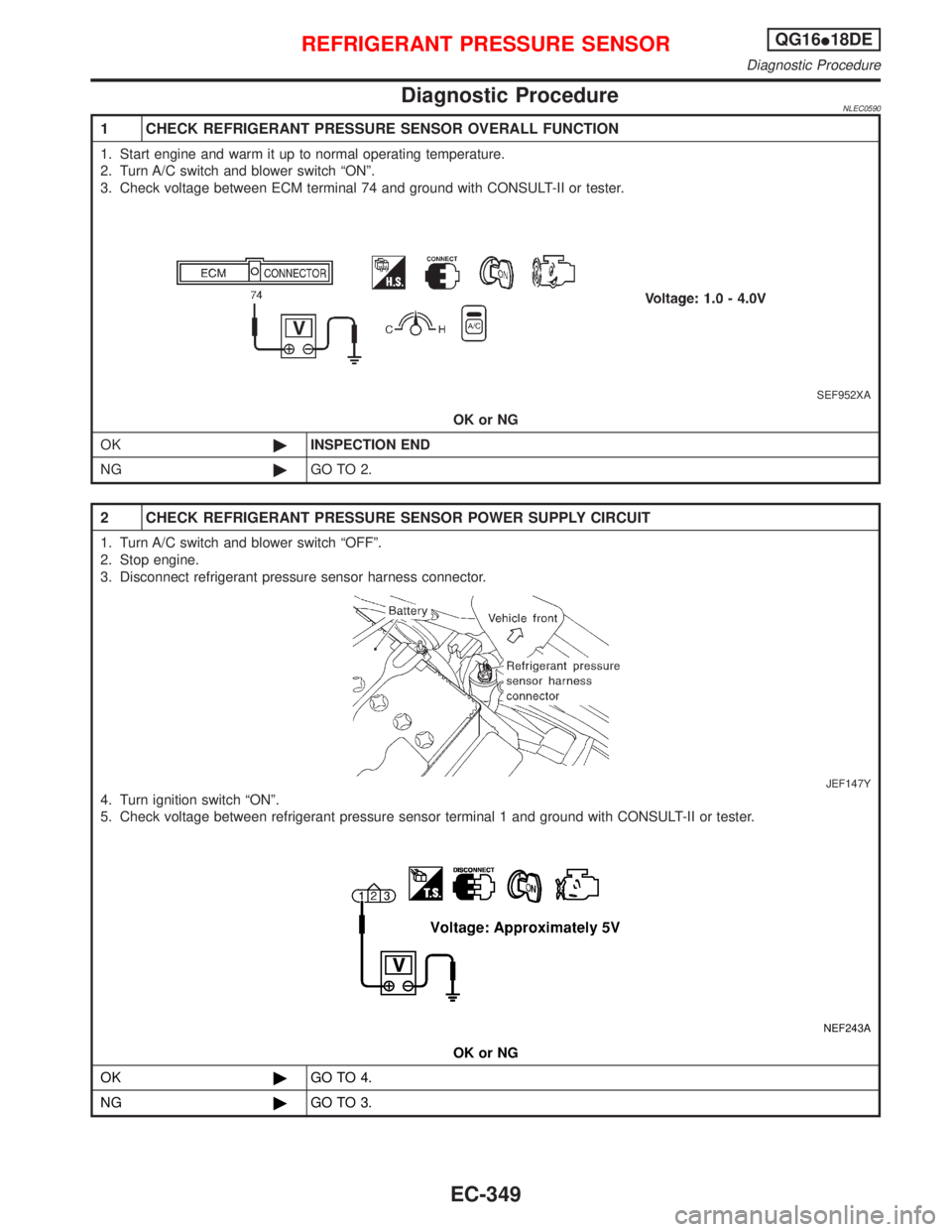

Diagnostic ProcedureNLEC0590

1 CHECK REFRIGERANT PRESSURE SENSOR OVERALL FUNCTION

1. Start engine and warm it up to normal operating temperature.

2. Turn A/C switch and blower switch ªONº.

3. Check voltage between ECM terminal 74 and ground with CONSULT-II or tester.

SEF952XA

OK or NG

OK©INSPECTION END

NG©GO TO 2.

2 CHECK REFRIGERANT PRESSURE SENSOR POWER SUPPLY CIRCUIT

1. Turn A/C switch and blower switch ªOFFº.

2. Stop engine.

3. Disconnect refrigerant pressure sensor harness connector.

JEF147Y

4. Turn ignition switch ªONº.

5. Check voltage between refrigerant pressure sensor terminal 1 and ground with CONSULT-II or tester.

NEF243A

OK or NG

OK©GO TO 4.

NG©GO TO 3.

REFRIGERANT PRESSURE SENSORQG16I18DE

Diagnostic Procedure

EC-349

Page 792 of 2267

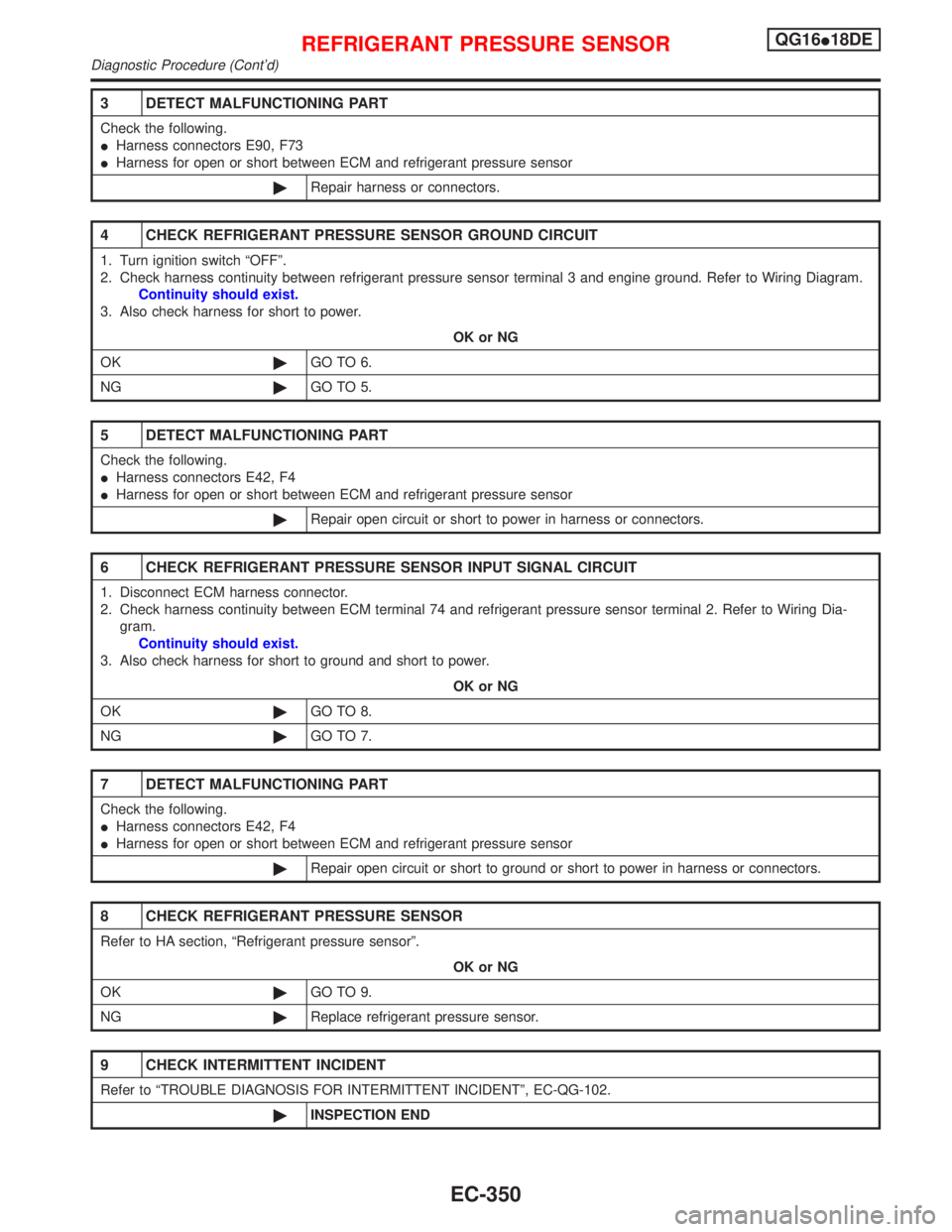

3 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors E90, F73

IHarness for open or short between ECM and refrigerant pressure sensor

©Repair harness or connectors.

4 CHECK REFRIGERANT PRESSURE SENSOR GROUND CIRCUIT

1. Turn ignition switch ªOFFº.

2. Check harness continuity between refrigerant pressure sensor terminal 3 and engine ground. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to power.

OK or NG

OK©GO TO 6.

NG©GO TO 5.

5 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors E42, F4

IHarness for open or short between ECM and refrigerant pressure sensor

©Repair open circuit or short to power in harness or connectors.

6 CHECK REFRIGERANT PRESSURE SENSOR INPUT SIGNAL CIRCUIT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 74 and refrigerant pressure sensor terminal 2. Refer to Wiring Dia-

gram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 8.

NG©GO TO 7.

7 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors E42, F4

IHarness for open or short between ECM and refrigerant pressure sensor

©Repair open circuit or short to ground or short to power in harness or connectors.

8 CHECK REFRIGERANT PRESSURE SENSOR

Refer to HA section, ªRefrigerant pressure sensorº.

OK or NG

OK©GO TO 9.

NG©Replace refrigerant pressure sensor.

9 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-QG-102.

©INSPECTION END

REFRIGERANT PRESSURE SENSORQG16I18DE

Diagnostic Procedure (Cont'd)

EC-350

Page 797 of 2267

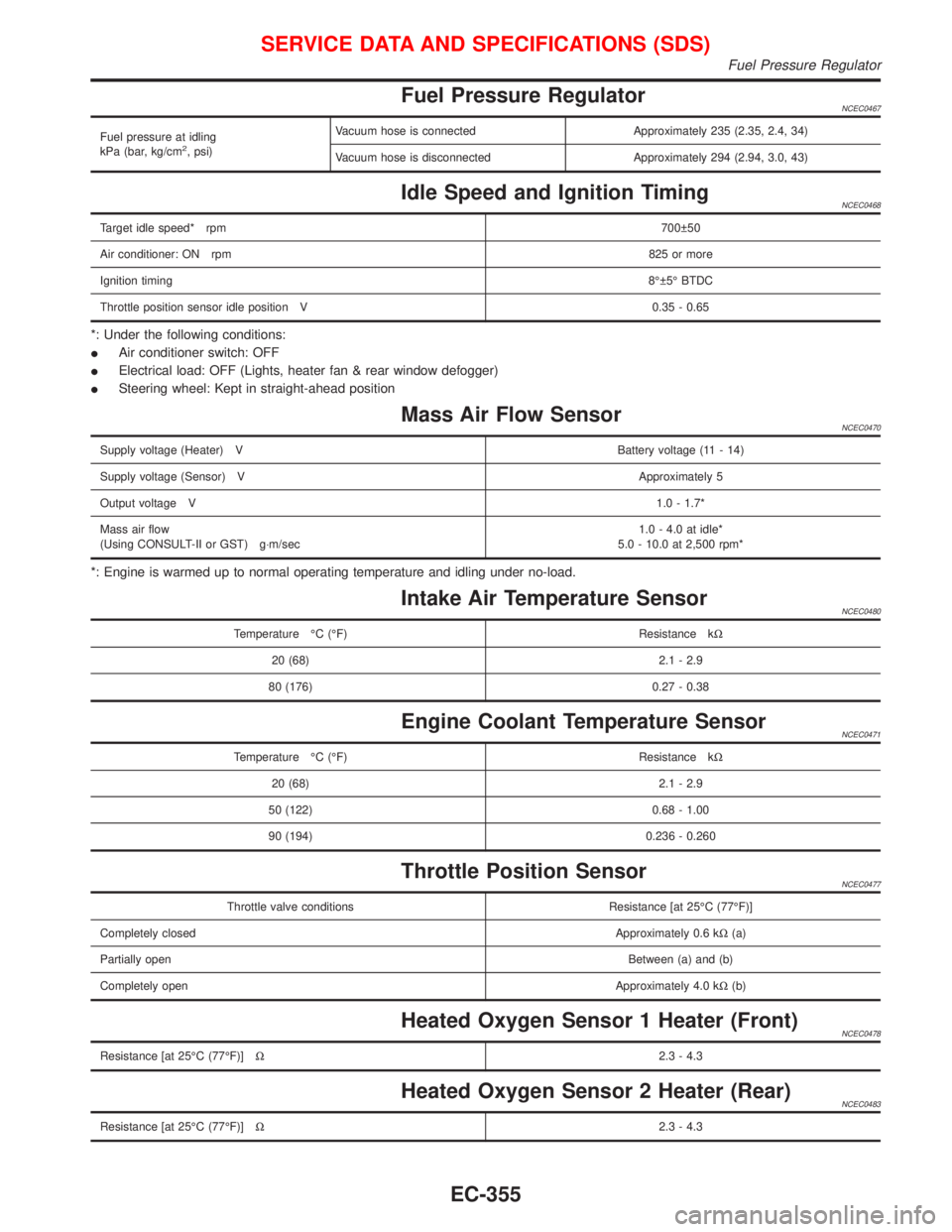

Fuel Pressure RegulatorNCEC0467

Fuel pressure at idling

kPa (bar, kg/cm2, psi)Vacuum hose is connected Approximately 235 (2.35, 2.4, 34)

Vacuum hose is disconnected Approximately 294 (2.94, 3.0, 43)

Idle Speed and Ignition TimingNCEC0468

Target idle speed* rpm700 50

Air conditioner: ON rpm825 or more

Ignition timing8É 5É BTDC

Throttle position sensor idle position V 0.35 - 0.65

*: Under the following conditions:

IAir conditioner switch: OFF

IElectrical load: OFF (Lights, heater fan & rear window defogger)

ISteering wheel: Kept in straight-ahead position

Mass Air Flow SensorNCEC0470

Supply voltage (Heater) VBattery voltage (11 - 14)

Supply voltage (Sensor) VApproximately 5

Output voltage V1.0 - 1.7*

Mass air flow

(Using CONSULT-II or GST) g×m/sec1.0 - 4.0 at idle*

5.0 - 10.0 at 2,500 rpm*

*: Engine is warmed up to normal operating temperature and idling under no-load.

Intake Air Temperature SensorNCEC0480

Temperature ÉC (ÉF) Resistance kW

20 (68) 2.1 - 2.9

80 (176) 0.27 - 0.38

Engine Coolant Temperature SensorNCEC0471

Temperature ÉC (ÉF) Resistance kW

20 (68) 2.1 - 2.9

50 (122) 0.68 - 1.00

90 (194) 0.236 - 0.260

Throttle Position SensorNCEC0477

Throttle valve conditions Resistance [at 25ÉC (77ÉF)]

Completely closedApproximately 0.6 kW(a)

Partially openBetween (a) and (b)

Completely openApproximately 4.0 kW(b)

Heated Oxygen Sensor 1 Heater (Front)NCEC0478

Resistance [at 25ÉC (77ÉF)]W2.3 - 4.3

Heated Oxygen Sensor 2 Heater (Rear)NCEC0483

Resistance [at 25ÉC (77ÉF)]W2.3 - 4.3

SERVICE DATA AND SPECIFICATIONS (SDS)

Fuel Pressure Regulator

EC-355

Page 798 of 2267

![NISSAN PRIMERA 1999 Electronic Repair Manual Crankshaft Position Sensor (POS)NCEC0558

Terminal No. (Polarity) ResistanceW[at 25ÉC (77ÉF)]

3 (+) - 1 (þ)

Except 0 or¥ 2 (+) - 1 (þ)

3 (+) - 2 (þ)

Camshaft Position Sensor (PHASE)NCEC0559

Termi NISSAN PRIMERA 1999 Electronic Repair Manual Crankshaft Position Sensor (POS)NCEC0558

Terminal No. (Polarity) ResistanceW[at 25ÉC (77ÉF)]

3 (+) - 1 (þ)

Except 0 or¥ 2 (+) - 1 (þ)

3 (+) - 2 (þ)

Camshaft Position Sensor (PHASE)NCEC0559

Termi](/img/5/57377/w960_57377-797.png)

Crankshaft Position Sensor (POS)NCEC0558

Terminal No. (Polarity) ResistanceW[at 25ÉC (77ÉF)]

3 (+) - 1 (þ)

Except 0 or¥ 2 (+) - 1 (þ)

3 (+) - 2 (þ)

Camshaft Position Sensor (PHASE)NCEC0559

Terminal No. (Polarity) ResistanceW[at 25ÉC (77ÉF)]

3 (+) - 1 (þ)

Except 0 or¥ 2 (+) - 1 (þ)

3 (+) - 2 (þ)

EGR Volume Control Valve (If so equipped)NCEC0560

Terminal No. ResistanceW[at 20ÉC (68ÉF)]

1-2

20-24 2-3

4-5

5-6

EGR Temperature Sensor (If so equipped)NCEC0472

EGR temperature

ÉC (ÉF)Voltage

VResistance

MW

0 (32) 4.56 0.62 - 1.05

50 (122) 2.25 0.065 - 0.094

100 (212) 0.59 0.011 - 0.015

EVAP Canister Purge Volume Control ValveNCEC0481

Resistance [at 20ÉC (68ÉF)]W31-35

IACV-AAC ValveNCEC0474

Terminal No. ResistanceW[at 20ÉC (68ÉF)]

1-2

20-24 2-3

4-5

5-6

InjectorNCEC0475

Resistance [at 25ÉC (77ÉF)]W13.5 - 17.5

SERVICE DATA AND SPECIFICATIONS (SDS)

Crankshaft Position Sensor (POS)

EC-356

Page 801 of 2267

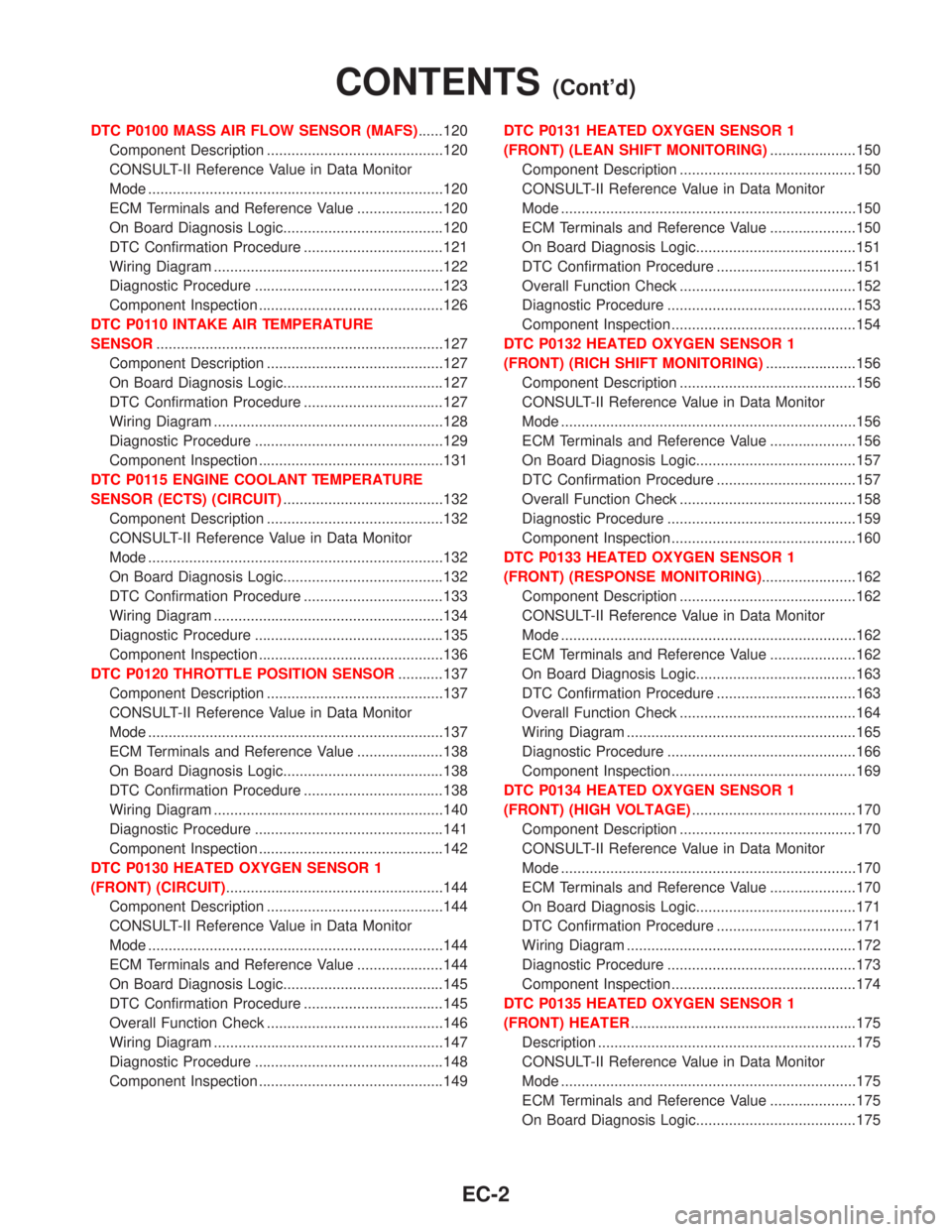

ENGINE CONTROL SYSTEM

SECTION

EC

CONTENTS

SR20DE

TROUBLE DIAGNOSIS - INDEX....................................6

Alphabetical & P No. Index for DTC ...........................6

PRECAUTIONS.............................................................10

Supplemental Restraint System (SRS)²AIR

BAG²and²SEAT BELT PRE-TENSIONER².............10

Precautions for On Board Diagnostic (OBD)

System of Engine and CVT .......................................10

Engine Fuel & Emission Control System .................. 11

Precautions ................................................................12

Wiring Diagrams and Trouble Diagnosis ...................13

PREPARATION.............................................................14

Special Service Tools ................................................14

Commercial Service Tool ...........................................14

ENGINE AND EMISSION CONTROL OVERALL

SYSTEM.........................................................................15

Engine Control Component Parts Location ...............15

Circuit Diagram ..........................................................19

System Diagram ........................................................20

Vacuum Hose Drawing ..............................................21

System Chart .............................................................22

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTION...............................................23

Multiport Fuel Injection (MFI) System .......................23

Distributor Ignition (DI) System .................................25

Air Conditioning Cut Control ......................................26

Fuel Cut Control (at no load & high engine

speed) ........................................................................27

Evaporative Emission System ...................................27

Positive Crankcase Ventilation ..................................30

BASIC SERVICE PROCEDURE...................................31

Fuel Pressure Release ..............................................31

Fuel Pressure Check .................................................31

Fuel Pressure Regulator Check ................................32

Injector .......................................................................32

Idle Speed/Ignition Timing/Idle Mixture Ratio

Adjustment .................................................................34Idle Air Volume Learning ...........................................46

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION...............................................................48

Introduction ................................................................48

Two Trip Detection Logic ...........................................48

Emission-related Diagnostic Information ...................49

Malfunction Indicator (MI) ..........................................58

OBD System Operation Chart ...................................63

CONSULT-II ...............................................................68

Generic Scan Tool (GST) ..........................................78

TROUBLE DIAGNOSIS - INTRODUCTION..................80

Introduction ................................................................80

Work Flow ..................................................................82

TROUBLE DIAGNOSIS - BASIC INSPECTION...........84

Basic Inspection.........................................................84

TROUBLE DIAGNOSIS - GENERAL

DESCRIPTION...............................................................92

DTC Inspection Priority Chart....................................92

Fail-safe Chart ...........................................................93

Symptom Matrix Chart ...............................................94

CONSULT-II Reference Value in Data Monitor

Mode ..........................................................................98

Major Sensor Reference Graph in Data Monitor

Mode ........................................................................100

ECM Terminals and Reference Value .....................103

TROUBLE DIAGNOSIS - SPECIFICATION VALUE.. 110

Description ............................................................... 110

Testing Condition ..................................................... 110

Inspection Procedure ............................................... 110

Diagnostic Procedure .............................................. 111

TROUBLE DIAGNOSIS FOR INTERMITTENT

INCIDENT..................................................................... 114

Description ............................................................... 114

Diagnostic Procedure .............................................. 114

TROUBLE DIAGNOSIS FOR POWER SUPPLY........ 115

Main Power Supply and Ground Circuit .................. 115

EC

Page 802 of 2267

DTC P0100 MASS AIR FLOW SENSOR (MAFS)......120

Component Description ...........................................120

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................120

ECM Terminals and Reference Value .....................120

On Board Diagnosis Logic.......................................120

DTC Confirmation Procedure ..................................121

Wiring Diagram ........................................................122

Diagnostic Procedure ..............................................123

Component Inspection .............................................126

DTC P0110 INTAKE AIR TEMPERATURE

SENSOR......................................................................127

Component Description ...........................................127

On Board Diagnosis Logic.......................................127

DTC Confirmation Procedure ..................................127

Wiring Diagram ........................................................128

Diagnostic Procedure ..............................................129

Component Inspection .............................................131

DTC P0115 ENGINE COOLANT TEMPERATURE

SENSOR (ECTS) (CIRCUIT).......................................132

Component Description ...........................................132

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................132

On Board Diagnosis Logic.......................................132

DTC Confirmation Procedure ..................................133

Wiring Diagram ........................................................134

Diagnostic Procedure ..............................................135

Component Inspection .............................................136

DTC P0120 THROTTLE POSITION SENSOR...........137

Component Description ...........................................137

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................137

ECM Terminals and Reference Value .....................138

On Board Diagnosis Logic.......................................138

DTC Confirmation Procedure ..................................138

Wiring Diagram ........................................................140

Diagnostic Procedure ..............................................141

Component Inspection .............................................142

DTC P0130 HEATED OXYGEN SENSOR 1

(FRONT) (CIRCUIT).....................................................144

Component Description ...........................................144

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................144

ECM Terminals and Reference Value .....................144

On Board Diagnosis Logic.......................................145

DTC Confirmation Procedure ..................................145

Overall Function Check ...........................................146

Wiring Diagram ........................................................147

Diagnostic Procedure ..............................................148

Component Inspection .............................................149DTC P0131 HEATED OXYGEN SENSOR 1

(FRONT) (LEAN SHIFT MONITORING).....................150

Component Description ...........................................150

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................150

ECM Terminals and Reference Value .....................150

On Board Diagnosis Logic.......................................151

DTC Confirmation Procedure ..................................151

Overall Function Check ...........................................152

Diagnostic Procedure ..............................................153

Component Inspection .............................................154

DTC P0132 HEATED OXYGEN SENSOR 1

(FRONT) (RICH SHIFT MONITORING)......................156

Component Description ...........................................156

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................156

ECM Terminals and Reference Value .....................156

On Board Diagnosis Logic.......................................157

DTC Confirmation Procedure ..................................157

Overall Function Check ...........................................158

Diagnostic Procedure ..............................................159

Component Inspection .............................................160

DTC P0133 HEATED OXYGEN SENSOR 1

(FRONT) (RESPONSE MONITORING).......................162

Component Description ...........................................162

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................162

ECM Terminals and Reference Value .....................162

On Board Diagnosis Logic.......................................163

DTC Confirmation Procedure ..................................163

Overall Function Check ...........................................164

Wiring Diagram ........................................................165

Diagnostic Procedure ..............................................166

Component Inspection .............................................169

DTC P0134 HEATED OXYGEN SENSOR 1

(FRONT) (HIGH VOLTAGE)........................................170

Component Description ...........................................170

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................170

ECM Terminals and Reference Value .....................170

On Board Diagnosis Logic.......................................171

DTC Confirmation Procedure ..................................171

Wiring Diagram ........................................................172

Diagnostic Procedure ..............................................173

Component Inspection .............................................174

DTC P0135 HEATED OXYGEN SENSOR 1

(FRONT) HEATER.......................................................175

Description ...............................................................175

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................175

ECM Terminals and Reference Value .....................175

On Board Diagnosis Logic.......................................175

CONTENTS(Cont'd)

EC-2