check engine NISSAN PRIMERA 1999 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 1580 of 2267

PressureNCEM0019S1302Check valve spring pressure at specified spring height.

Pressure:

Standard

370.0 N (37.73 kg, 83.19 lb) at 23.64 mm

(0.9307 in)

Limit

More than 347.8 N (35.46 kg, 78.19 lb) at

23.64 mm (0.9307 in)

If it exceeds the limit, replace spring.

VALVE LIFTER AND VALVE SHIMNCEM0019S161. Check contact and sliding surfaces for wear or scratches.

2. Check diameter of valve lifter and valve lifter guide bore.

Valve lifter outside diameter:

29.960 - 29.975 mm (1.1795 - 1.1801 in)

Lifter guide inside diameter:

30.000 - 30.021 mm (1.1811 - 1.1819 in)

Clearance between valve lifter and valve lifter guide:

0.025 - 0.065 mm (0.0010 - 0.0024 in)

If it exceeds the limit, replace valve lifter or cylinder head which

exceeds the standard diameter tolerance.

Valve ClearanceNCEM0041CHECKINGNCEM0041S01Check valve clearance while engine is warm and not running.

1. Remove rocker cover.

2. Remove all spark plugs.

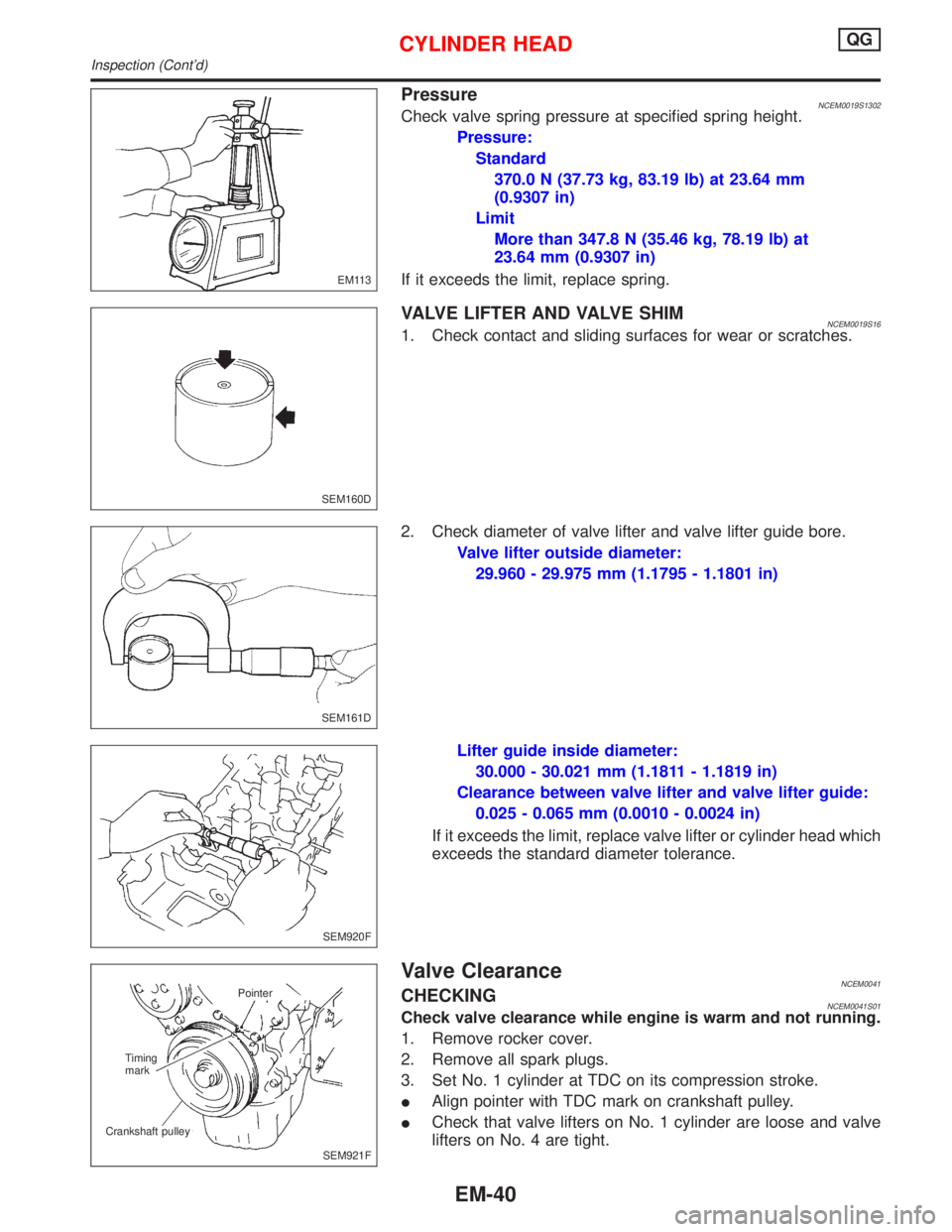

3. Set No. 1 cylinder at TDC on its compression stroke.

IAlign pointer with TDC mark on crankshaft pulley.

ICheck that valve lifters on No. 1 cylinder are loose and valve

lifters on No. 4 are tight.

EM113

SEM160D

SEM161D

SEM920F

SEM921F Pointer

Timing

mark

Crankshaft pulley

CYLINDER HEADQG

Inspection (Cont'd)

EM-40

Page 1581 of 2267

IIf not, turn crankshaft one revolution (360É) and align as

described above.

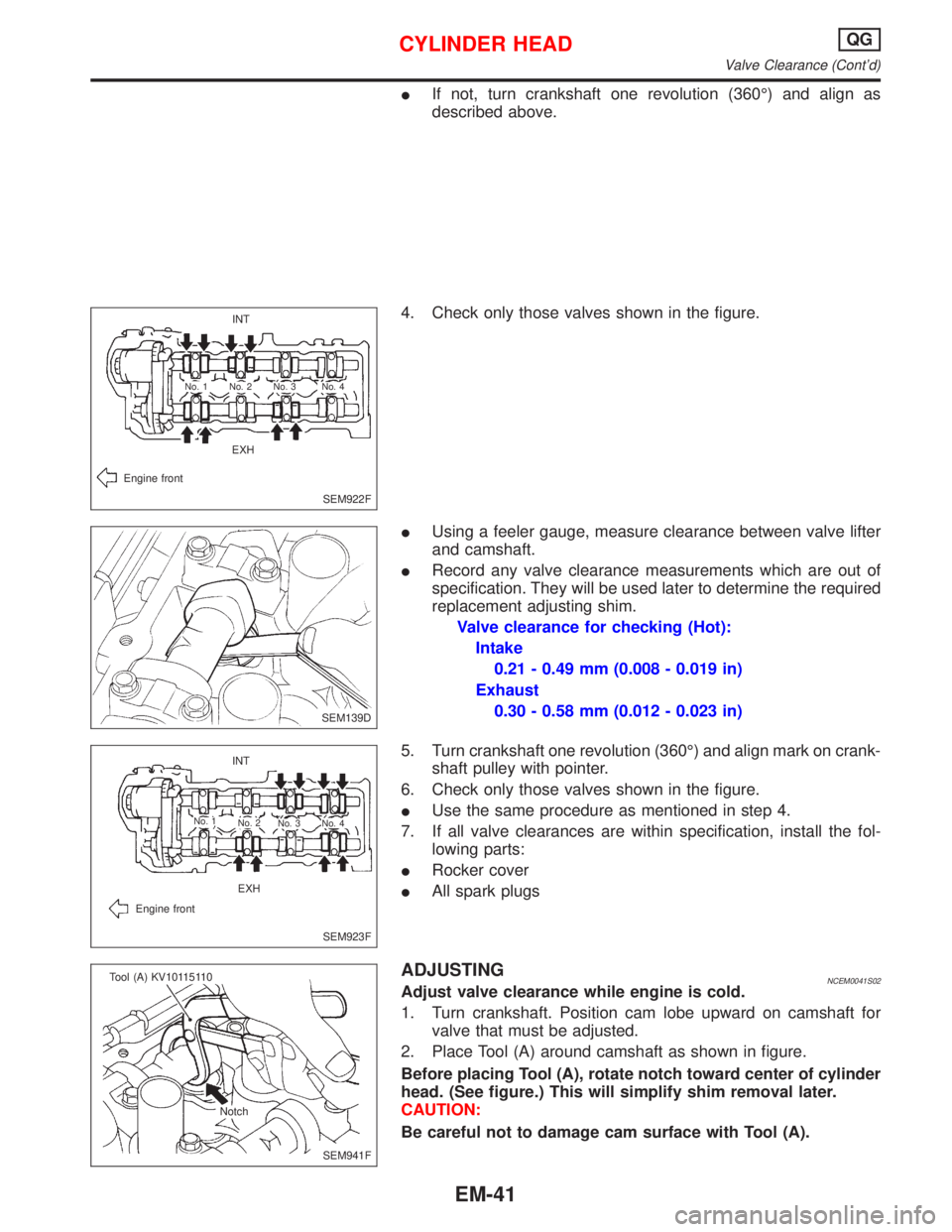

4. Check only those valves shown in the figure.

IUsing a feeler gauge, measure clearance between valve lifter

and camshaft.

IRecord any valve clearance measurements which are out of

specification. They will be used later to determine the required

replacement adjusting shim.

Valve clearance for checking (Hot):

Intake

0.21 - 0.49 mm (0.008 - 0.019 in)

Exhaust

0.30 - 0.58 mm (0.012 - 0.023 in)

5. Turn crankshaft one revolution (360É) and align mark on crank-

shaft pulley with pointer.

6. Check only those valves shown in the figure.

IUse the same procedure as mentioned in step 4.

7. If all valve clearances are within specification, install the fol-

lowing parts:

IRocker cover

IAll spark plugs

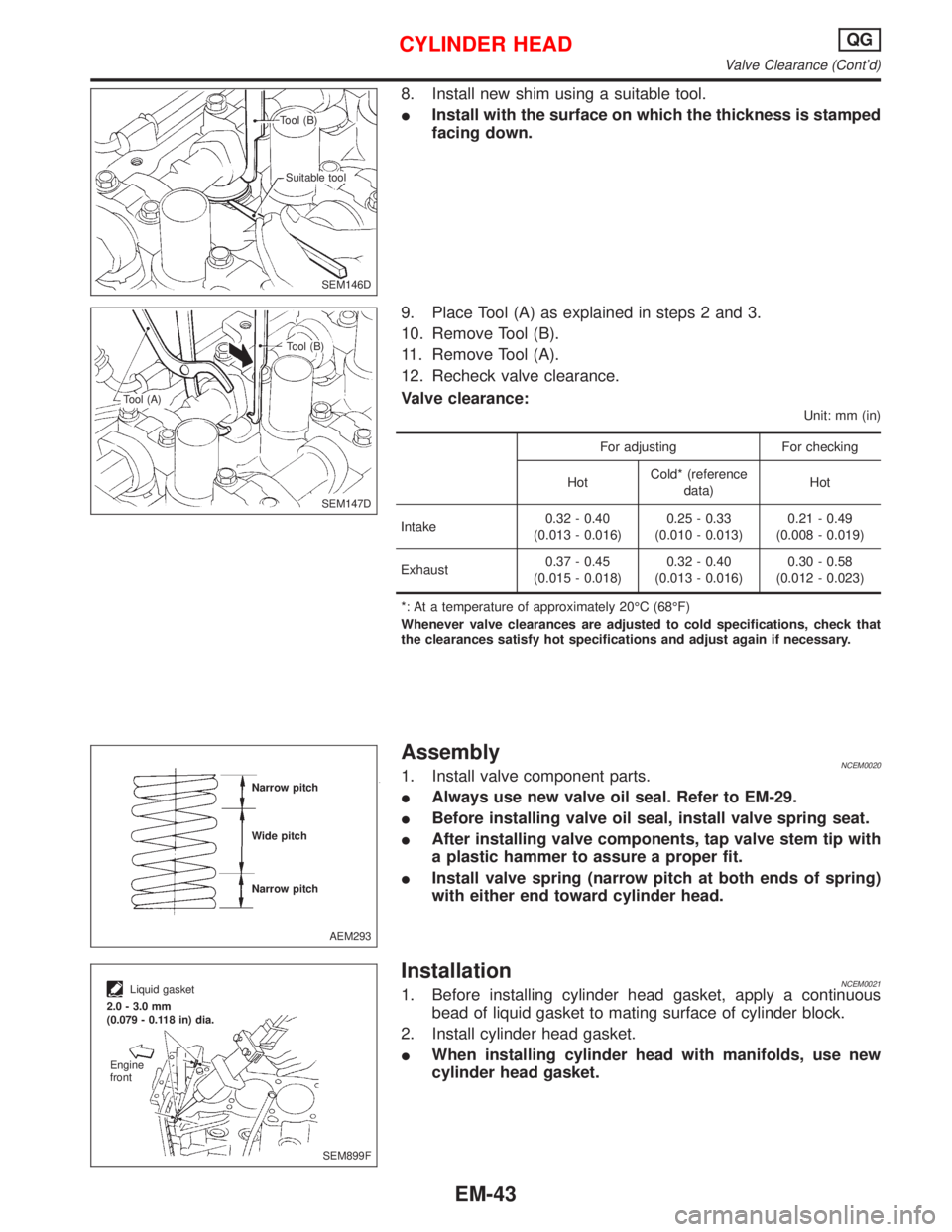

ADJUSTINGNCEM0041S02Adjust valve clearance while engine is cold.

1. Turn crankshaft. Position cam lobe upward on camshaft for

valve that must be adjusted.

2. Place Tool (A) around camshaft as shown in figure.

Before placing Tool (A), rotate notch toward center of cylinder

head. (See figure.) This will simplify shim removal later.

CAUTION:

Be careful not to damage cam surface with Tool (A).

SEM922F INT

EXH

Engine front

No. 4 No. 3 No. 2 No. 1

.SEM139D

SEM923F INT

EXH

Engine front

No. 1

No. 2

No. 3 No. 4

SEM941F Tool (A) KV10115110

Notch

CYLINDER HEADQG

Valve Clearance (Cont'd)

EM-41

Page 1583 of 2267

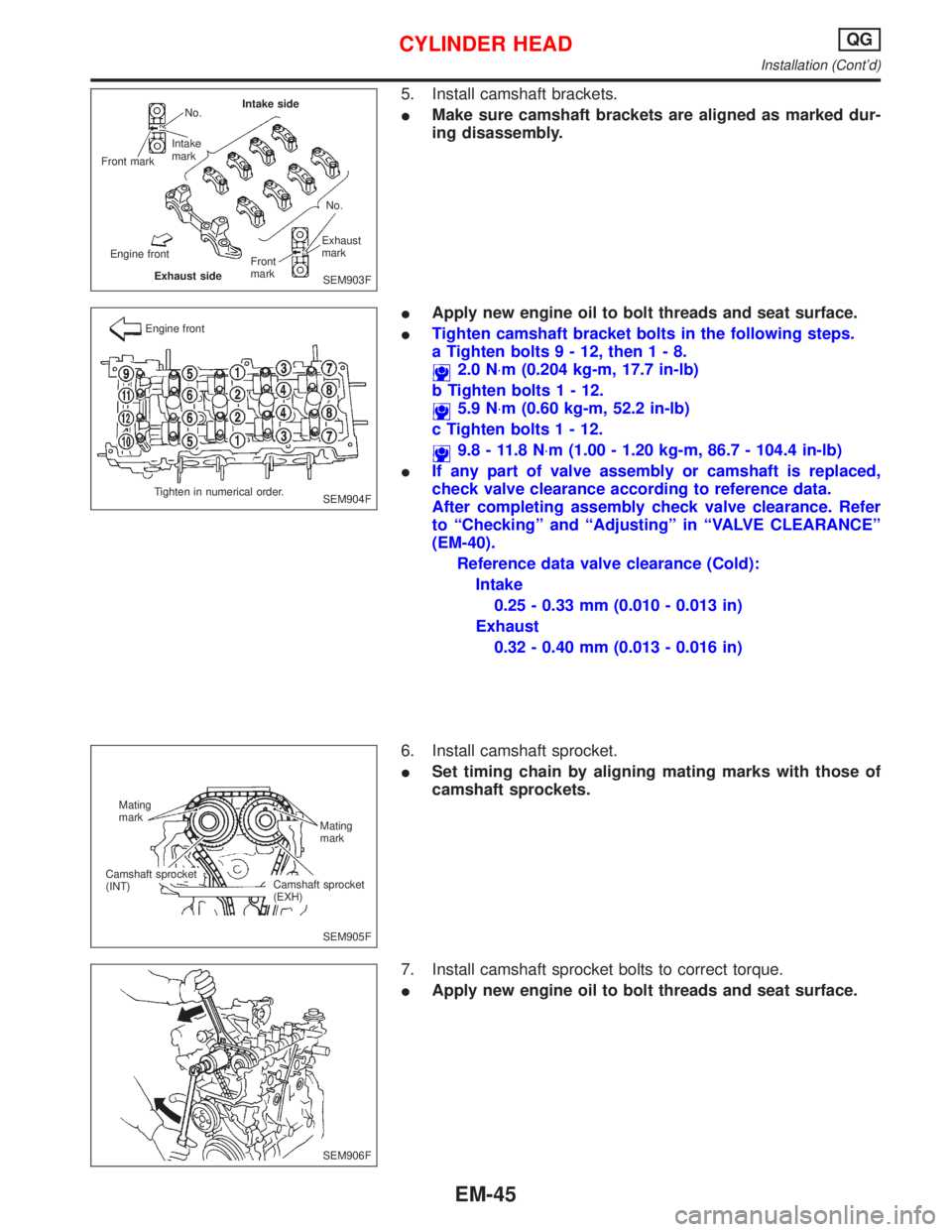

8. Install new shim using a suitable tool.

IInstall with the surface on which the thickness is stamped

facing down.

9. Place Tool (A) as explained in steps 2 and 3.

10. Remove Tool (B).

11. Remove Tool (A).

12. Recheck valve clearance.

Valve clearance:

Unit: mm (in)

For adjusting For checking

HotCold* (reference

data)Hot

Intake0.32 - 0.40

(0.013 - 0.016)0.25 - 0.33

(0.010 - 0.013)0.21 - 0.49

(0.008 - 0.019)

Exhaust0.37 - 0.45

(0.015 - 0.018)0.32 - 0.40

(0.013 - 0.016)0.30 - 0.58

(0.012 - 0.023)

*: At a temperature of approximately 20ÉC (68ÉF)

Whenever valve clearances are adjusted to cold specifications, check that

the clearances satisfy hot specifications and adjust again if necessary.

AssemblyNCEM00201. Install valve component parts.

IAlways use new valve oil seal. Refer to EM-29.

IBefore installing valve oil seal, install valve spring seat.

IAfter installing valve components, tap valve stem tip with

a plastic hammer to assure a proper fit.

IInstall valve spring (narrow pitch at both ends of spring)

with either end toward cylinder head.

InstallationNCEM00211. Before installing cylinder head gasket, apply a continuous

bead of liquid gasket to mating surface of cylinder block.

2. Install cylinder head gasket.

IWhen installing cylinder head with manifolds, use new

cylinder head gasket.

SEM146D Tool (B)

Suitable tool

SEM147D Tool (B)

Tool (A)

AEM293 Narrow pitch

Wide pitch

Narrow pitch

SEM899F

Liquid gasket

2.0 - 3.0 mm

(0.079 - 0.118 in) dia.

Engine

front

CYLINDER HEADQG

Valve Clearance (Cont'd)

EM-43

Page 1585 of 2267

5. Install camshaft brackets.

IMake sure camshaft brackets are aligned as marked dur-

ing disassembly.

IApply new engine oil to bolt threads and seat surface.

ITighten camshaft bracket bolts in the following steps.

a Tighten bolts9-12,then1-8.

2.0 N×m (0.204 kg-m, 17.7 in-lb)

b Tighten bolts1-12.

5.9 N×m (0.60 kg-m, 52.2 in-lb)

c Tighten bolts1-12.

9.8 - 11.8 N×m (1.00 - 1.20 kg-m, 86.7 - 104.4 in-lb)

IIf any part of valve assembly or camshaft is replaced,

check valve clearance according to reference data.

After completing assembly check valve clearance. Refer

to ªCheckingº and ªAdjustingº in ªVALVE CLEARANCEº

(EM-40).

Reference data valve clearance (Cold):

Intake

0.25 - 0.33 mm (0.010 - 0.013 in)

Exhaust

0.32 - 0.40 mm (0.013 - 0.016 in)

6. Install camshaft sprocket.

ISet timing chain by aligning mating marks with those of

camshaft sprockets.

7. Install camshaft sprocket bolts to correct torque.

IApply new engine oil to bolt threads and seat surface.

SEM903F No.

Intake

mark

Front markIntake side

No.

Exhaust

mark

Front

mark

Exhaust side Engine front

SEM904F Engine front

Tighten in numerical order.

SEM905F Mating

mark

Mating

mark

Camshaft sprocket

(EXH) Camshaft sprocket

(INT)

SEM906F

CYLINDER HEADQG

Installation (Cont'd)

EM-45

Page 1587 of 2267

Power Steering Fluid and Linesº, ªCHASSIS AND BODY

MAINTENANCEº).

21. Drive belts.

For adjusting drive belt deflection, refer to MA section (ªCheck-

ing Drive Beltsº, ªENGINE MAINTENANCEº).

22. Reinstall parts in reverse order of removal.

CYLINDER HEADQG

Installation (Cont'd)

EM-47

Page 1605 of 2267

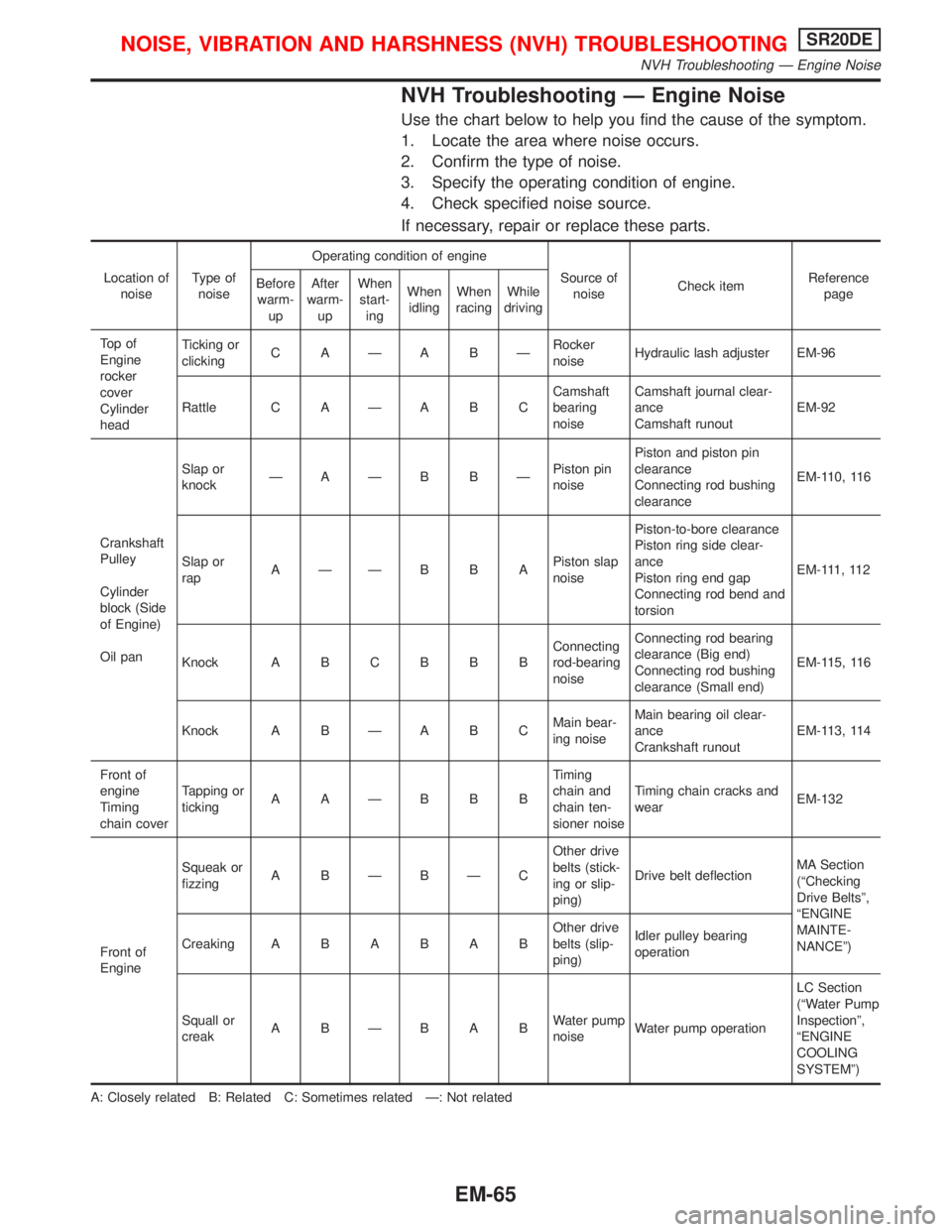

NVH Troubleshooting Ð Engine Noise

Use the chart below to help you find the cause of the symptom.

1. Locate the area where noise occurs.

2. Confirm the type of noise.

3. Specify the operating condition of engine.

4. Check specified noise source.

If necessary, repair or replace these parts.

Location of

noiseType of

noiseOperating condition of engine

Source of

noiseCheck itemReference

page Before

warm-

upAfter

warm-

upWhen

start-

ingWhen

idlingWhen

racingWhile

driving

To p o f

Engine

rocker

cover

Cylinder

headTicking or

clickingC AÐA BÐRocker

noiseHydraulic lash adjuster EM-96

Rattle C A Ð A B CCamshaft

bearing

noiseCamshaft journal clear-

ance

Camshaft runoutEM-92

Crankshaft

Pulley

Cylinder

block (Side

of Engine)

Oil panSlap or

knockÐAÐB BÐPiston pin

noisePiston and piston pin

clearance

Connecting rod bushing

clearanceEM-110, 116

Slap or

rapAÐÐB B APiston slap

noisePiston-to-bore clearance

Piston ring side clear-

ance

Piston ring end gap

Connecting rod bend and

torsionEM-111, 112

Knock A B C B B BConnecting

rod-bearing

noiseConnecting rod bearing

clearance (Big end)

Connecting rod bushing

clearance (Small end)EM-115, 116

Knock A B Ð A B CMain bear-

ing noiseMain bearing oil clear-

ance

Crankshaft runoutEM-113, 114

Front of

engine

Timing

chain coverTapping or

tickingAAÐBBBTiming

chain and

chain ten-

sioner noiseTiming chain cracks and

wearEM-132

Front of

EngineSqueak or

fizzingA BÐBÐCOther drive

belts (stick-

ing or slip-

ping)Drive belt deflectionMA Section

(ªChecking

Drive Beltsº,

ªENGINE

MAINTE-

NANCEº) CreakingABABABOther drive

belts (slip-

ping)Idler pulley bearing

operation

Squall or

creakABÐBABWater pump

noiseWater pump operationLC Section

(ªWater Pump

Inspectionº,

ªENGINE

COOLING

SYSTEMº)

A: Closely related B: Related C: Sometimes related Ð: Not related

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGSR20DE

NVH Troubleshooting Ð Engine Noise

EM-65

Page 1609 of 2267

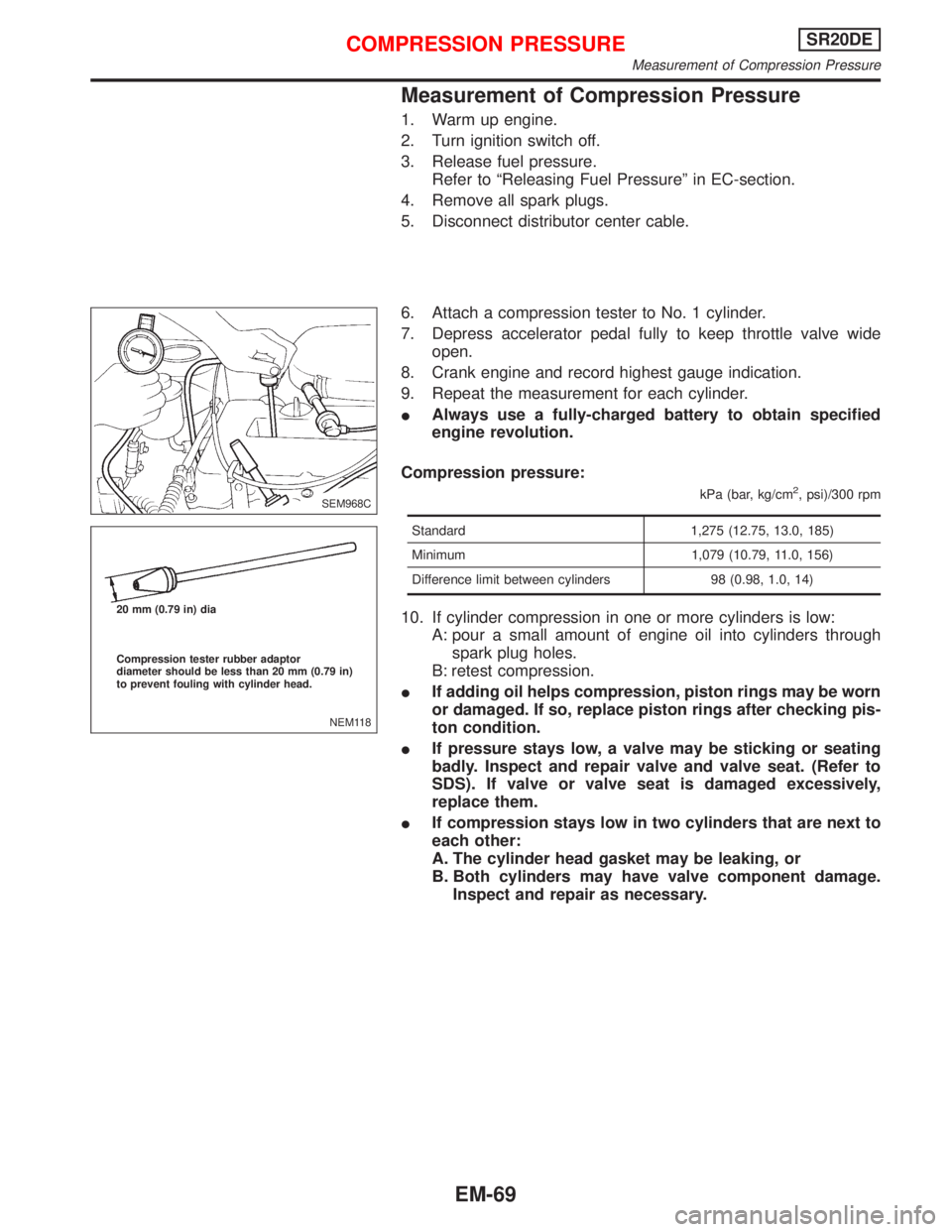

Measurement of Compression Pressure

1. Warm up engine.

2. Turn ignition switch off.

3. Release fuel pressure.

Refer to ªReleasing Fuel Pressureº in EC-section.

4. Remove all spark plugs.

5. Disconnect distributor center cable.

6. Attach a compression tester to No. 1 cylinder.

7. Depress accelerator pedal fully to keep throttle valve wide

open.

8. Crank engine and record highest gauge indication.

9. Repeat the measurement for each cylinder.

IAlways use a fully-charged battery to obtain specified

engine revolution.

Compression pressure:

kPa (bar, kg/cm2, psi)/300 rpm

Standard 1,275 (12.75, 13.0, 185)

Minimum 1,079 (10.79, 11.0, 156)

Difference limit between cylinders 98 (0.98, 1.0, 14)

10. If cylinder compression in one or more cylinders is low:

A: pour a small amount of engine oil into cylinders through

spark plug holes.

B: retest compression.

IIf adding oil helps compression, piston rings may be worn

or damaged. If so, replace piston rings after checking pis-

ton condition.

IIf pressure stays low, a valve may be sticking or seating

badly. Inspect and repair valve and valve seat. (Refer to

SDS). If valve or valve seat is damaged excessively,

replace them.

IIf compression stays low in two cylinders that are next to

each other:

A. The cylinder head gasket may be leaking, or

B. Both cylinders may have valve component damage.

Inspect and repair as necessary.

SEM968C

NEM118 20 mm (0.79 in) dia

Compression tester rubber adaptor

diameter should be less than 20 mm (0.79 in)

to prevent fouling with cylinder head.

COMPRESSION PRESSURESR20DE

Measurement of Compression Pressure

EM-69

Page 1619 of 2267

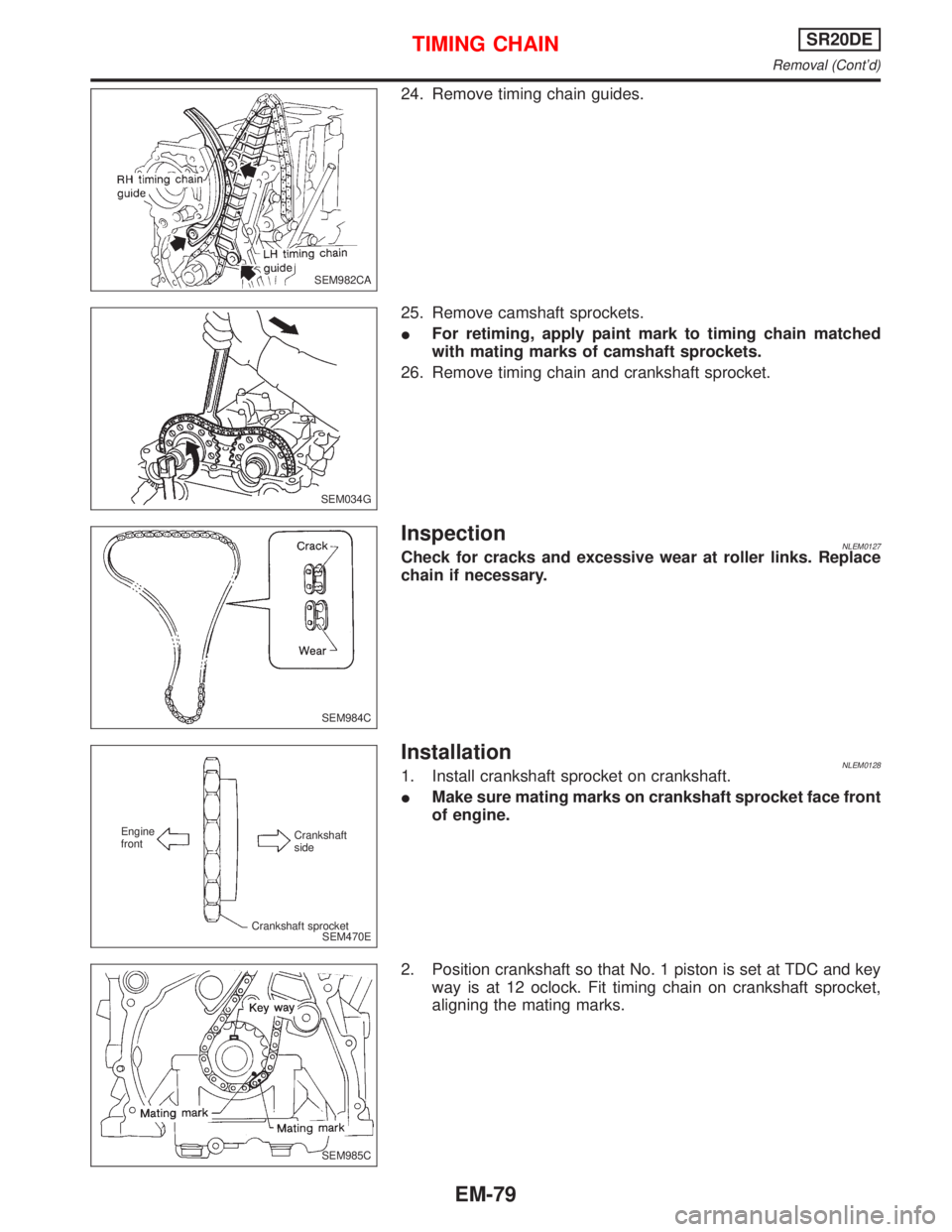

24. Remove timing chain guides.

25. Remove camshaft sprockets.

IFor retiming, apply paint mark to timing chain matched

with mating marks of camshaft sprockets.

26. Remove timing chain and crankshaft sprocket.

InspectionNLEM0127Check for cracks and excessive wear at roller links. Replace

chain if necessary.

InstallationNLEM01281. Install crankshaft sprocket on crankshaft.

IMake sure mating marks on crankshaft sprocket face front

of engine.

2. Position crankshaft so that No. 1 piston is set at TDC and key

way is at 12 oclock. Fit timing chain on crankshaft sprocket,

aligning the mating marks.

SEM982CA

SEM034G

SEM984C

SEM470E Engine

frontCrankshaft

side

Crankshaft sprocket

SEM985C

TIMING CHAINSR20DE

Removal (Cont'd)

EM-79

Page 1623 of 2267

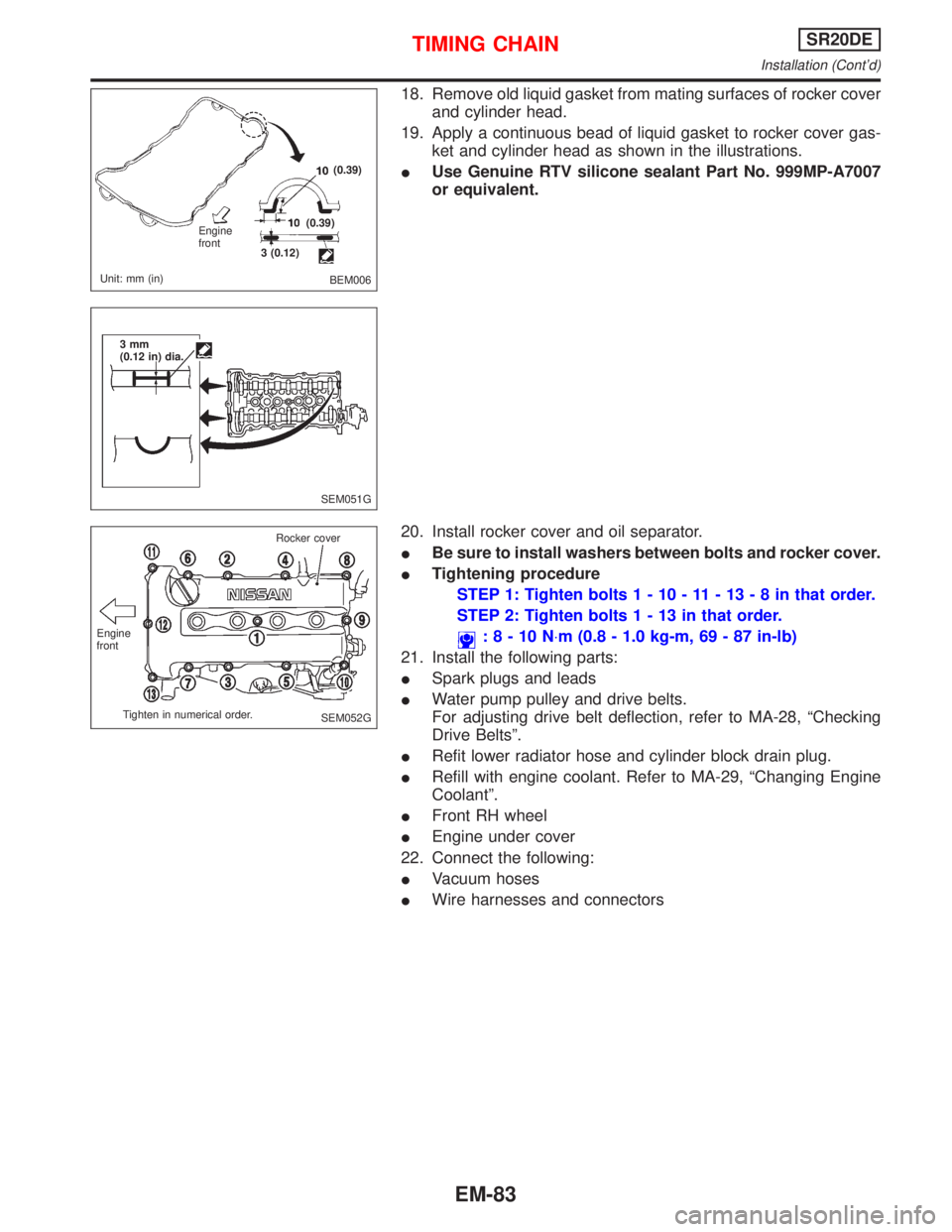

18. Remove old liquid gasket from mating surfaces of rocker cover

and cylinder head.

19. Apply a continuous bead of liquid gasket to rocker cover gas-

ket and cylinder head as shown in the illustrations.

IUse Genuine RTV silicone sealant Part No. 999MP-A7007

or equivalent.

20. Install rocker cover and oil separator.

IBe sure to install washers between bolts and rocker cover.

ITightening procedure

STEP 1: Tighten bolts1-10-11-13-8inthat order.

STEP 2: Tighten bolts1-13inthat order.

:8-10N×m (0.8 - 1.0 kg-m, 69 - 87 in-lb)

21. Install the following parts:

ISpark plugs and leads

IWater pump pulley and drive belts.

For adjusting drive belt deflection, refer to MA-28, ªChecking

Drive Beltsº.

IRefit lower radiator hose and cylinder block drain plug.

IRefill with engine coolant. Refer to MA-29, ªChanging Engine

Coolantº.

IFront RH wheel

IEngine under cover

22. Connect the following:

IVacuum hoses

IWire harnesses and connectors

BEM006 Engine

front

Unit: mm (in)3 (0.12)(0.39)

(0.39)

SEM051G 3mm

(0.12 in) dia.

SEM052G Engine

front

Tighten in numerical order.Rocker cover

TIMING CHAINSR20DE

Installation (Cont'd)

EM-83

Page 1631 of 2267

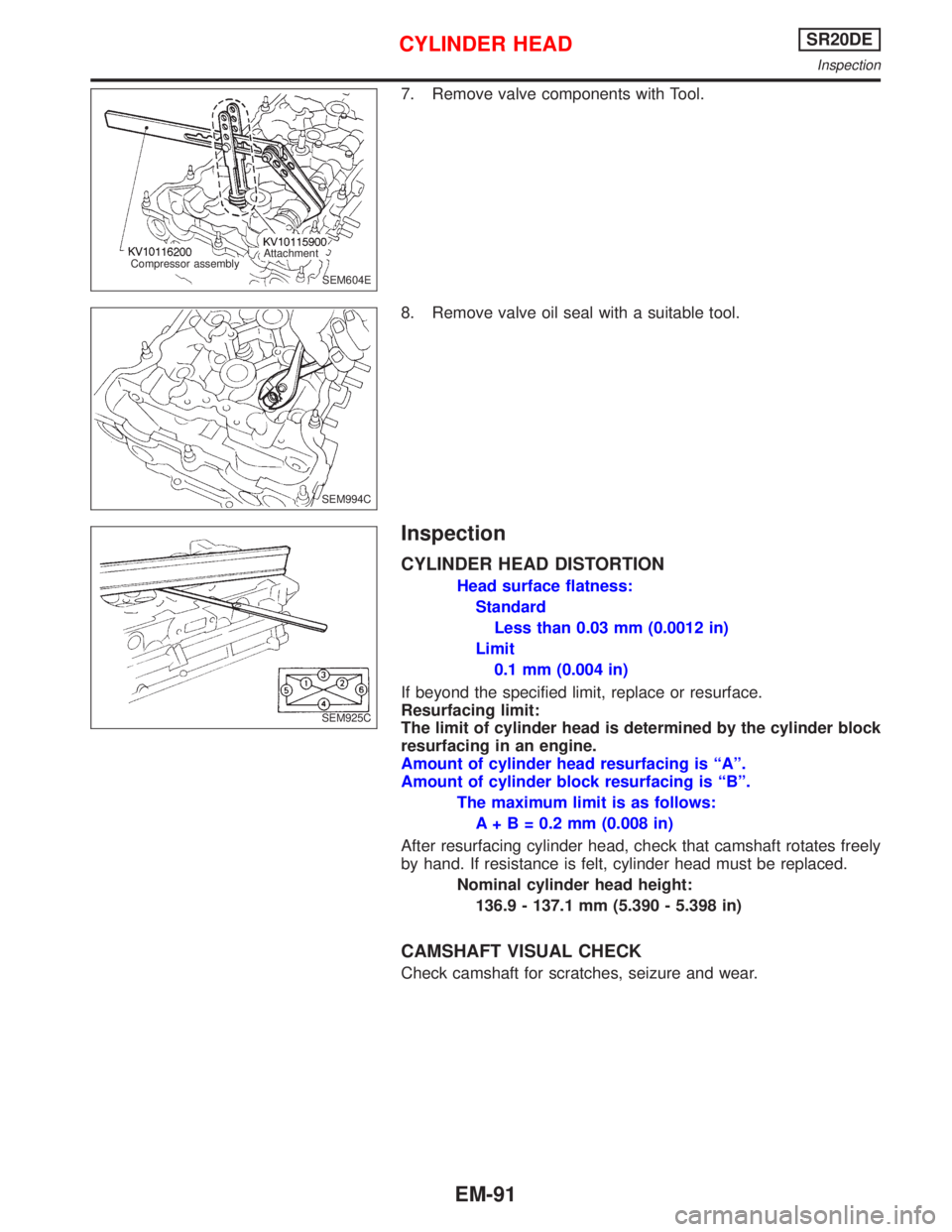

7. Remove valve components with Tool.

8. Remove valve oil seal with a suitable tool.

Inspection

CYLINDER HEAD DISTORTION

Head surface flatness:

Standard

Less than 0.03 mm (0.0012 in)

Limit

0.1 mm (0.004 in)

If beyond the specified limit, replace or resurface.

Resurfacing limit:

The limit of cylinder head is determined by the cylinder block

resurfacing in an engine.

Amount of cylinder head resurfacing is ªAº.

Amount of cylinder block resurfacing is ªBº.

The maximum limit is as follows:

A + B = 0.2 mm (0.008 in)

After resurfacing cylinder head, check that camshaft rotates freely

by hand. If resistance is felt, cylinder head must be replaced.

Nominal cylinder head height:

136.9 - 137.1 mm (5.390 - 5.398 in)

CAMSHAFT VISUAL CHECK

Check camshaft for scratches, seizure and wear.

SEM604E Compressor assemblyAttachment

SEM994C

SEM925C

CYLINDER HEADSR20DE

Inspection

EM-91