check engine NISSAN PRIMERA 1999 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 1638 of 2267

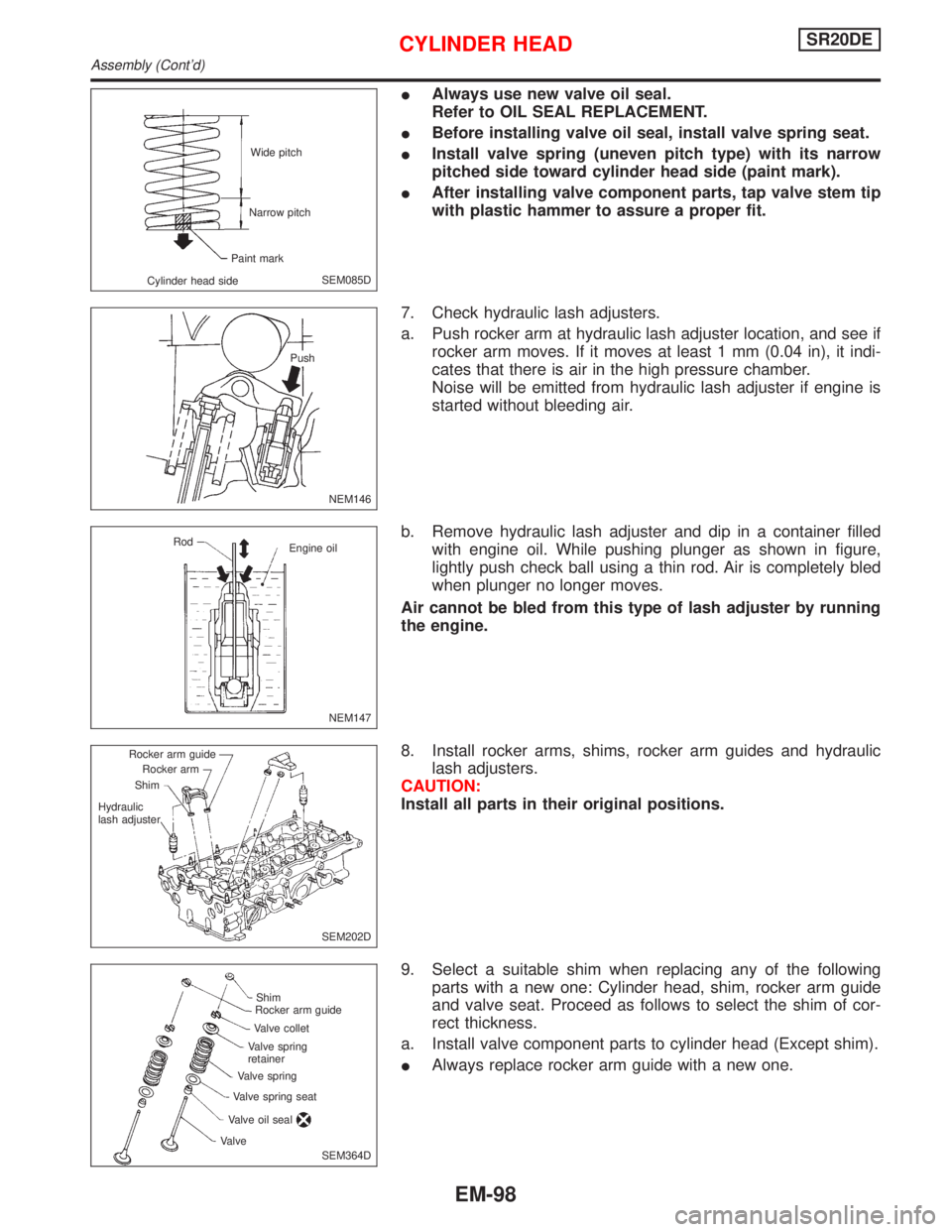

IAlways use new valve oil seal.

Refer to OIL SEAL REPLACEMENT.

IBefore installing valve oil seal, install valve spring seat.

IInstall valve spring (uneven pitch type) with its narrow

pitched side toward cylinder head side (paint mark).

IAfter installing valve component parts, tap valve stem tip

with plastic hammer to assure a proper fit.

7. Check hydraulic lash adjusters.

a. Push rocker arm at hydraulic lash adjuster location, and see if

rocker arm moves. If it moves at least 1 mm (0.04 in), it indi-

cates that there is air in the high pressure chamber.

Noise will be emitted from hydraulic lash adjuster if engine is

started without bleeding air.

b. Remove hydraulic lash adjuster and dip in a container filled

with engine oil. While pushing plunger as shown in figure,

lightly push check ball using a thin rod. Air is completely bled

when plunger no longer moves.

Air cannot be bled from this type of lash adjuster by running

the engine.

8. Install rocker arms, shims, rocker arm guides and hydraulic

lash adjusters.

CAUTION:

Install all parts in their original positions.

9. Select a suitable shim when replacing any of the following

parts with a new one: Cylinder head, shim, rocker arm guide

and valve seat. Proceed as follows to select the shim of cor-

rect thickness.

a. Install valve component parts to cylinder head (Except shim).

IAlways replace rocker arm guide with a new one.

SEM085D Wide pitch

Narrow pitch

Paint mark

Cylinder head side

NEM146 Push

NEM147 Rod

Engine oil

SEM202D Rocker arm guide

Rocker arm

Shim

Hydraulic

lash adjuster

SEM364D Shim

Rocker arm guide

Valve collet

Valve spring

retainer

Valve spring

Valve spring seat

Valve oil sealValve

CYLINDER HEADSR20DE

Assembly (Cont'd)

EM-98

Page 1652 of 2267

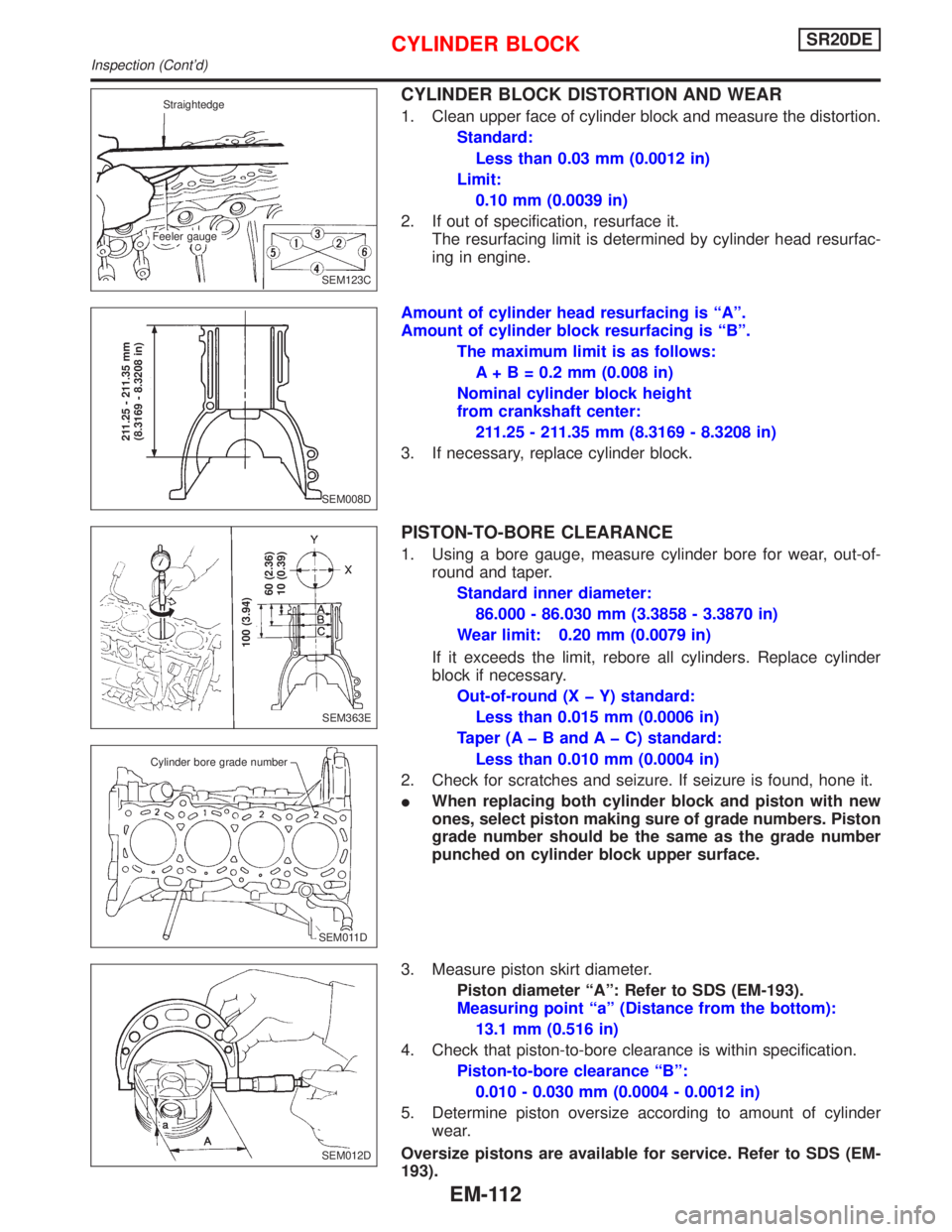

CYLINDER BLOCK DISTORTION AND WEAR

1. Clean upper face of cylinder block and measure the distortion.

Standard:

Less than 0.03 mm (0.0012 in)

Limit:

0.10 mm (0.0039 in)

2. If out of specification, resurface it.

The resurfacing limit is determined by cylinder head resurfac-

ing in engine.

Amount of cylinder head resurfacing is ªAº.

Amount of cylinder block resurfacing is ªBº.

The maximum limit is as follows:

A + B = 0.2 mm (0.008 in)

Nominal cylinder block height

from crankshaft center:

211.25 - 211.35 mm (8.3169 - 8.3208 in)

3. If necessary, replace cylinder block.

PISTON-TO-BORE CLEARANCE

1. Using a bore gauge, measure cylinder bore for wear, out-of-

round and taper.

Standard inner diameter:

86.000 - 86.030 mm (3.3858 - 3.3870 in)

Wear limit: 0.20 mm (0.0079 in)

If it exceeds the limit, rebore all cylinders. Replace cylinder

block if necessary.

Out-of-round (X þ Y) standard:

Less than 0.015 mm (0.0006 in)

Taper (A þ B and A þ C) standard:

Less than 0.010 mm (0.0004 in)

2. Check for scratches and seizure. If seizure is found, hone it.

IWhen replacing both cylinder block and piston with new

ones, select piston making sure of grade numbers. Piston

grade number should be the same as the grade number

punched on cylinder block upper surface.

3. Measure piston skirt diameter.

Piston diameter ªAº: Refer to SDS (EM-193).

Measuring point ªaº (Distance from the bottom):

13.1 mm (0.516 in)

4. Check that piston-to-bore clearance is within specification.

Piston-to-bore clearance ªBº:

0.010 - 0.030 mm (0.0004 - 0.0012 in)

5. Determine piston oversize according to amount of cylinder

wear.

Oversize pistons are available for service. Refer to SDS (EM-

193).

SEM123C Straightedge

Feeler gauge

SEM008D

211.25 - 211.35 mm

(8.3169 - 8.3208 in)

SEM363E

100 (3.94)

60 (2.36)

10 (0.39)

.SEM011D

Cylinder bore grade number

SEM012D

CYLINDER BLOCKSR20DE

Inspection (Cont'd)

EM-112

Page 1662 of 2267

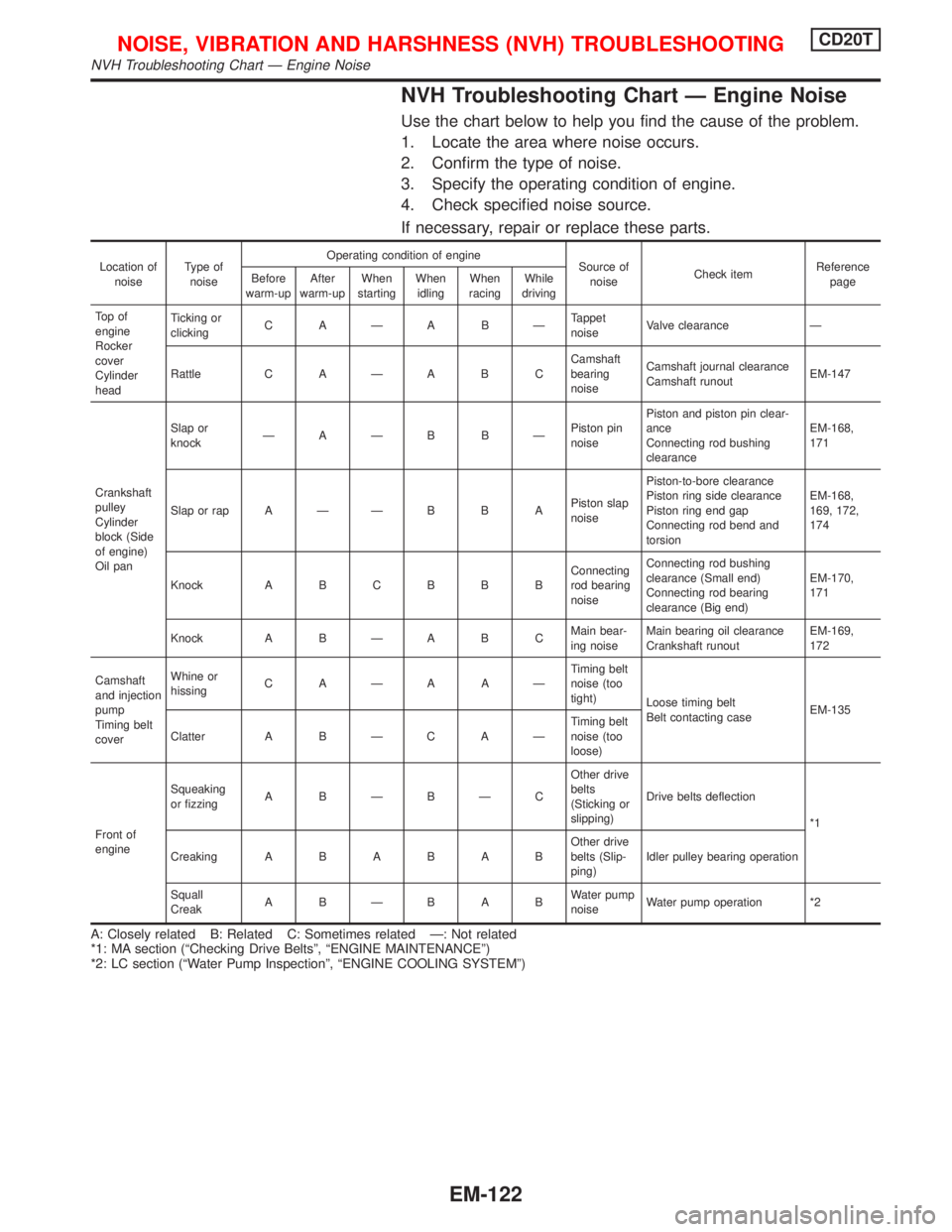

NVH Troubleshooting Chart Ð Engine Noise

Use the chart below to help you find the cause of the problem.

1. Locate the area where noise occurs.

2. Confirm the type of noise.

3. Specify the operating condition of engine.

4. Check specified noise source.

If necessary, repair or replace these parts.

Location of

noiseType of

noiseOperating condition of engine

Source of

noiseCheck itemReference

page Before

warm-upAfter

warm-upWhen

startingWhen

idlingWhen

racingWhile

driving

To p o f

engine

Rocker

cover

Cylinder

headTicking or

clickingCAÐABÐTappet

noiseValve clearance Ð

Rattle C A Ð A B CCamshaft

bearing

noiseCamshaft journal clearance

Camshaft runoutEM-147

Crankshaft

pulley

Cylinder

block (Side

of engine)

Oil panSlap or

knockÐAÐB BÐPiston pin

noisePiston and piston pin clear-

ance

Connecting rod bushing

clearanceEM-168,

171

Slap or rap A Ð Ð B B APiston slap

noisePiston-to-bore clearance

Piston ring side clearance

Piston ring end gap

Connecting rod bend and

torsionEM-168,

169, 172,

174

Knock A B C B B BConnecting

rod bearing

noiseConnecting rod bushing

clearance (Small end)

Connecting rod bearing

clearance (Big end)EM-170,

171

Knock A B Ð A B CMain bear-

ing noiseMain bearing oil clearance

Crankshaft runoutEM-169,

172

Camshaft

and injection

pump

Timing belt

coverWhine or

hissingCAÐAAÐTiming belt

noise (too

tight)

Loose timing belt

Belt contacting caseEM-135

Clatter A B Ð C A ÐTiming belt

noise (too

loose)

Front of

engineSqueaking

or fizzingABÐBÐCOther drive

belts

(Sticking or

slipping)Drive belts deflection

*1

CreakingABABABOther drive

belts (Slip-

ping)Idler pulley bearing operation

Squall

CreakABÐBABWater pump

noiseWater pump operation *2

A: Closely related B: Related C: Sometimes related Ð: Not related

*1: MA section (ªChecking Drive Beltsº, ªENGINE MAINTENANCEº)

*2: LC section (ªWater Pump Inspectionº, ªENGINE COOLING SYSTEMº)

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGCD20T

NVH Troubleshooting Chart Ð Engine Noise

EM-122

Page 1673 of 2267

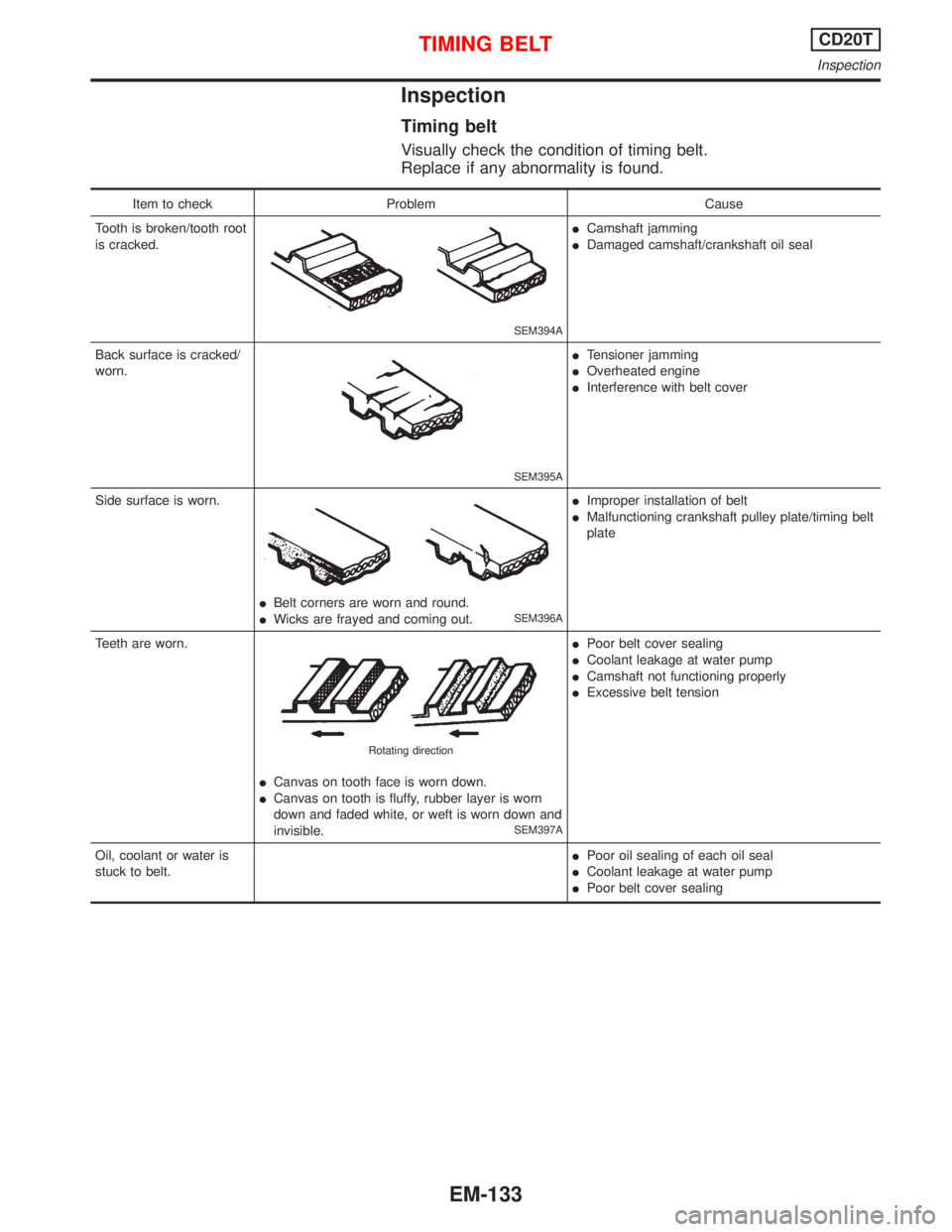

Inspection

Timing belt

Visually check the condition of timing belt.

Replace if any abnormality is found.

Item to check Problem Cause

Tooth is broken/tooth root

is cracked.

SEM394A

ICamshaft jamming

IDamaged camshaft/crankshaft oil seal

Back surface is cracked/

worn.

SEM395A

ITensioner jamming

IOverheated engine

IInterference with belt cover

Side surface is worn.

IBelt corners are worn and round.

IWicks are frayed and coming out.SEM396A

IImproper installation of belt

IMalfunctioning crankshaft pulley plate/timing belt

plate

Teeth are worn.

ICanvas on tooth face is worn down.

ICanvas on tooth is fluffy, rubber layer is worn

down and faded white, or weft is worn down and

invisible.

SEM397A Rotating direction

IPoor belt cover sealing

ICoolant leakage at water pump

ICamshaft not functioning properly

IExcessive belt tension

Oil, coolant or water is

stuck to belt.IPoor oil sealing of each oil seal

ICoolant leakage at water pump

IPoor belt cover sealing

TIMING BELTCD20T

Inspection

EM-133

Page 1688 of 2267

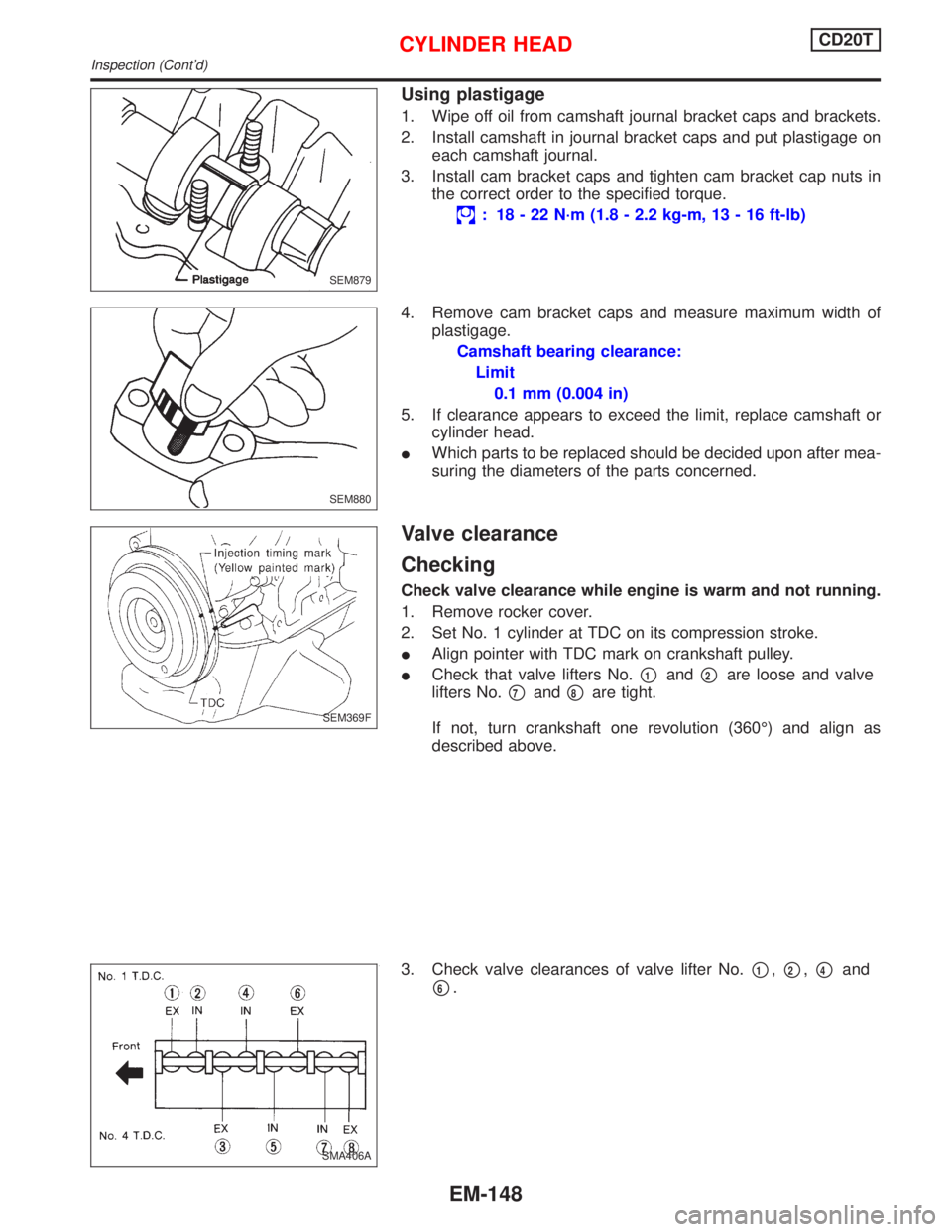

Using plastigage

1. Wipe off oil from camshaft journal bracket caps and brackets.

2. Install camshaft in journal bracket caps and put plastigage on

each camshaft journal.

3. Install cam bracket caps and tighten cam bracket cap nuts in

the correct order to the specified torque.

: 18 - 22 N´m (1.8 - 2.2 kg-m, 13 - 16 ft-lb)

4. Remove cam bracket caps and measure maximum width of

plastigage.

Camshaft bearing clearance:

Limit

0.1 mm (0.004 in)

5. If clearance appears to exceed the limit, replace camshaft or

cylinder head.

IWhich parts to be replaced should be decided upon after mea-

suring the diameters of the parts concerned.

Valve clearance

Checking

Check valve clearance while engine is warm and not running.

1. Remove rocker cover.

2. Set No. 1 cylinder at TDC on its compression stroke.

IAlign pointer with TDC mark on crankshaft pulley.

ICheck that valve lifters No.

p1andp2are loose and valve

lifters No.

p7andp8are tight.

If not, turn crankshaft one revolution (360É) and align as

described above.

3. Check valve clearances of valve lifter No.

p1,p2,p4and

p6.

SEM879

SEM880

SEM369F

SMA406A

CYLINDER HEADCD20T

Inspection (Cont'd)

EM-148

Page 1689 of 2267

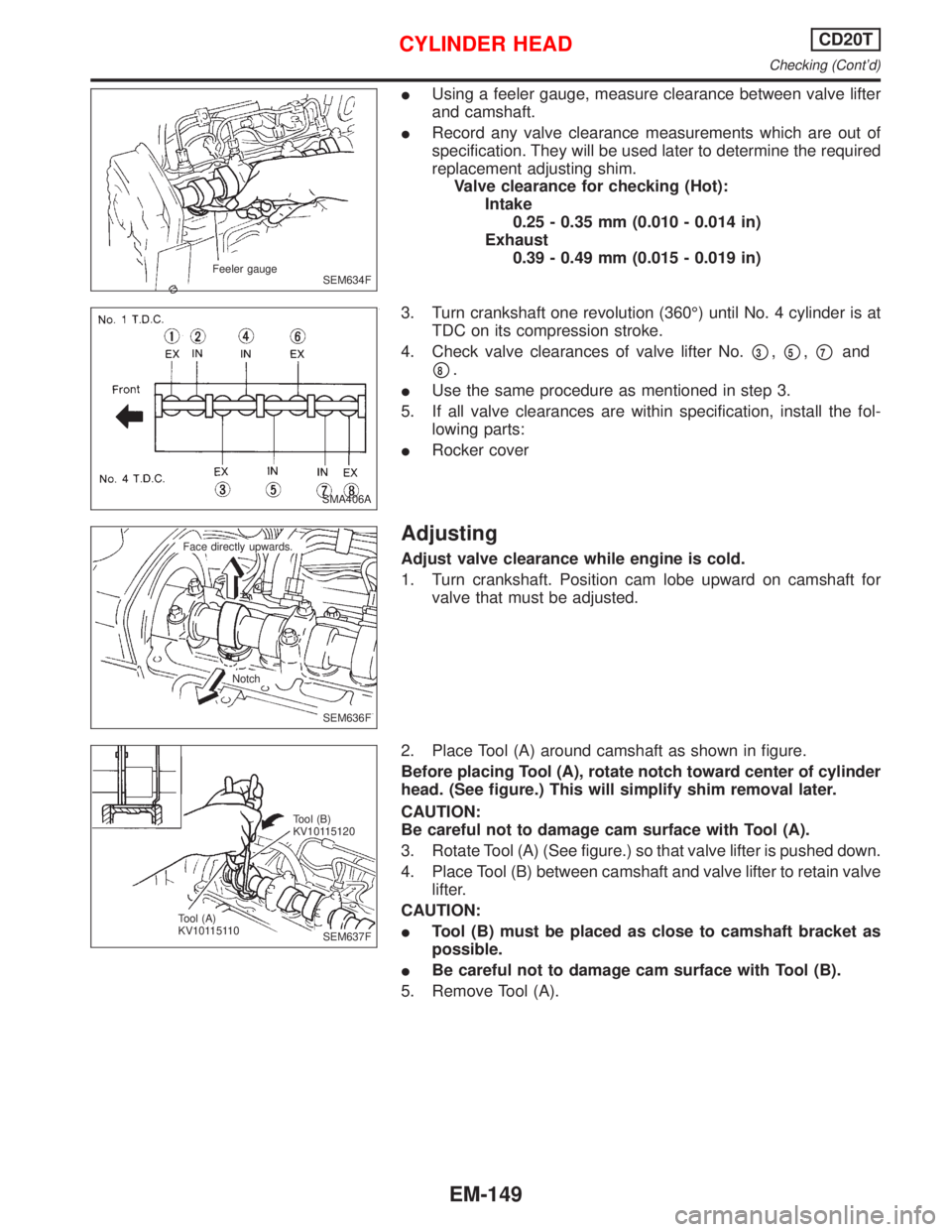

IUsing a feeler gauge, measure clearance between valve lifter

and camshaft.

IRecord any valve clearance measurements which are out of

specification. They will be used later to determine the required

replacement adjusting shim.

Valve clearance for checking (Hot):

Intake

0.25 - 0.35 mm (0.010 - 0.014 in)

Exhaust

0.39 - 0.49 mm (0.015 - 0.019 in)

3. Turn crankshaft one revolution (360É) until No. 4 cylinder is at

TDC on its compression stroke.

4. Check valve clearances of valve lifter No.

p3,p5,p7and

p8.

IUse the same procedure as mentioned in step 3.

5. If all valve clearances are within specification, install the fol-

lowing parts:

IRocker cover

Adjusting

Adjust valve clearance while engine is cold.

1. Turn crankshaft. Position cam lobe upward on camshaft for

valve that must be adjusted.

2. Place Tool (A) around camshaft as shown in figure.

Before placing Tool (A), rotate notch toward center of cylinder

head. (See figure.) This will simplify shim removal later.

CAUTION:

Be careful not to damage cam surface with Tool (A).

3. Rotate Tool (A) (See figure.) so that valve lifter is pushed down.

4. Place Tool (B) between camshaft and valve lifter to retain valve

lifter.

CAUTION:

ITool (B) must be placed as close to camshaft bracket as

possible.

IBe careful not to damage cam surface with Tool (B).

5. Remove Tool (A).

SEM634F Feeler gauge

SMA406A

.SEM636F Face directly upwards.

Notch

.SEM637F Tool (B)

KV10115120

Tool (A)

KV10115110

CYLINDER HEADCD20T

Checking (Cont'd)

EM-149

Page 1691 of 2267

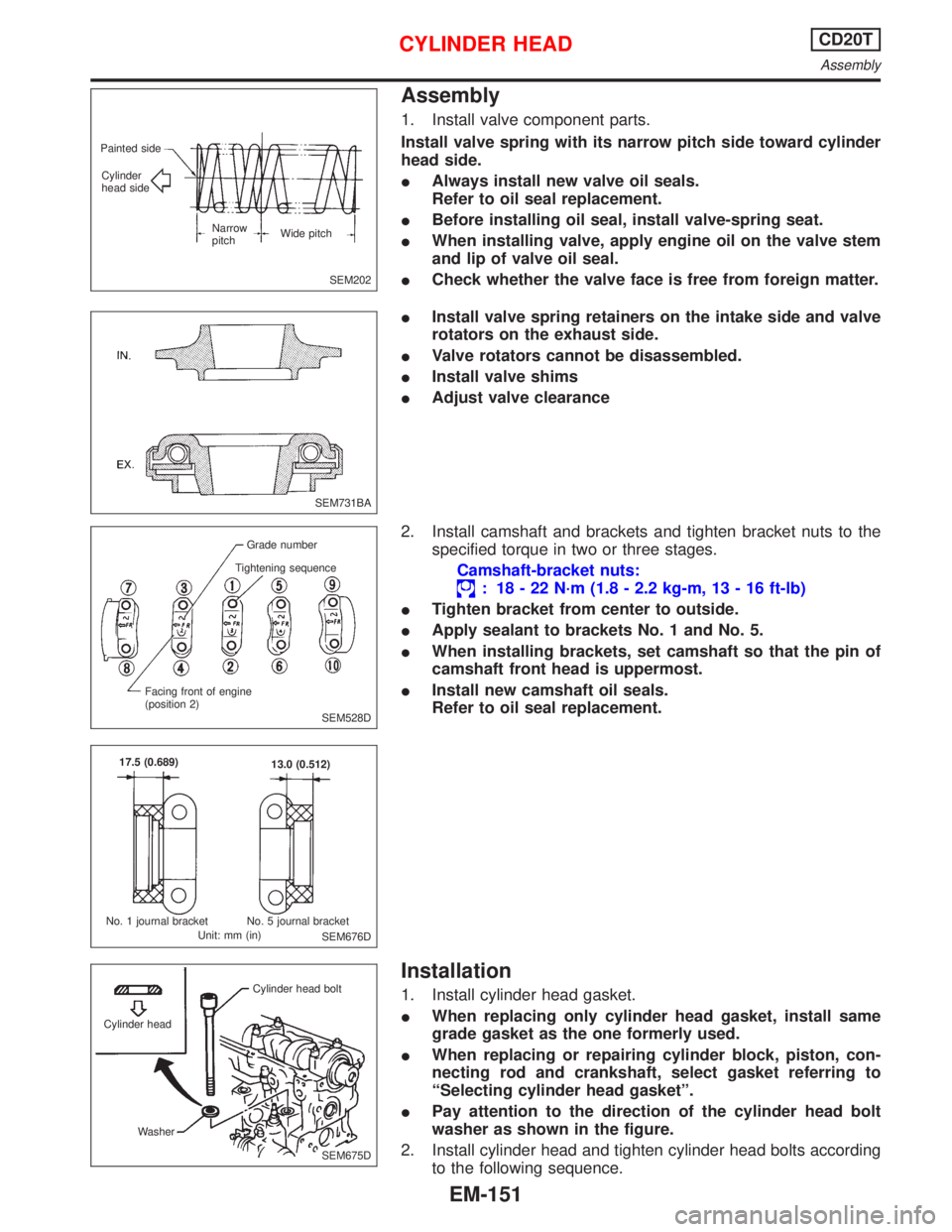

Assembly

1. Install valve component parts.

Install valve spring with its narrow pitch side toward cylinder

head side.

IAlways install new valve oil seals.

Refer to oil seal replacement.

IBefore installing oil seal, install valve-spring seat.

IWhen installing valve, apply engine oil on the valve stem

and lip of valve oil seal.

ICheck whether the valve face is free from foreign matter.

IInstall valve spring retainers on the intake side and valve

rotators on the exhaust side.

IValve rotators cannot be disassembled.

IInstall valve shims

IAdjust valve clearance

2. Install camshaft and brackets and tighten bracket nuts to the

specified torque in two or three stages.

Camshaft-bracket nuts:

: 18 - 22 N´m (1.8 - 2.2 kg-m, 13 - 16 ft-lb)

ITighten bracket from center to outside.

IApply sealant to brackets No. 1 and No. 5.

IWhen installing brackets, set camshaft so that the pin of

camshaft front head is uppermost.

IInstall new camshaft oil seals.

Refer to oil seal replacement.

Installation

1. Install cylinder head gasket.

IWhen replacing only cylinder head gasket, install same

grade gasket as the one formerly used.

IWhen replacing or repairing cylinder block, piston, con-

necting rod and crankshaft, select gasket referring to

ªSelecting cylinder head gasketº.

IPay attention to the direction of the cylinder head bolt

washer as shown in the figure.

2. Install cylinder head and tighten cylinder head bolts according

to the following sequence.

SEM202 Painted side

Cylinder

head side

Narrow

pitchWide pitch

SEM731BA

SEM528D Grade number

Tightening sequence

Facing front of engine

(position 2)

SEM676D 17.5 (0.689)

13.0 (0.512)

No. 1 journal bracket No. 5 journal bracket

Unit: mm (in)

SEM675D Cylinder headCylinder head bolt

Washer

CYLINDER HEADCD20T

Assembly

EM-151

Page 1713 of 2267

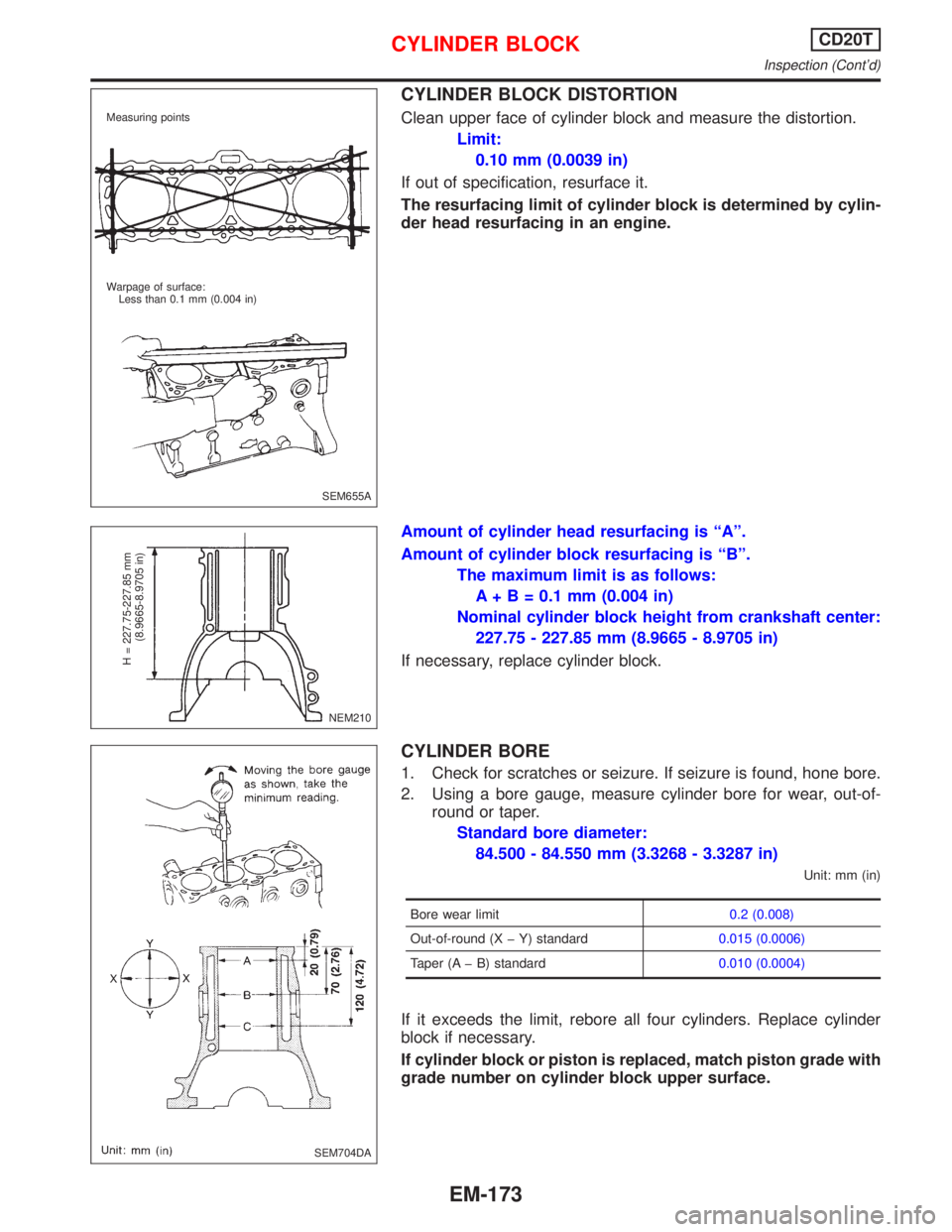

CYLINDER BLOCK DISTORTION

Clean upper face of cylinder block and measure the distortion.

Limit:

0.10 mm (0.0039 in)

If out of specification, resurface it.

The resurfacing limit of cylinder block is determined by cylin-

der head resurfacing in an engine.

Amount of cylinder head resurfacing is ªAº.

Amount of cylinder block resurfacing is ªBº.

The maximum limit is as follows:

A + B = 0.1 mm (0.004 in)

Nominal cylinder block height from crankshaft center:

227.75 - 227.85 mm (8.9665 - 8.9705 in)

If necessary, replace cylinder block.

CYLINDER BORE

1. Check for scratches or seizure. If seizure is found, hone bore.

2. Using a bore gauge, measure cylinder bore for wear, out-of-

round or taper.

Standard bore diameter:

84.500 - 84.550 mm (3.3268 - 3.3287 in)

Unit: mm (in)

Bore wear limit0.2 (0.008)

Out-of-round (X þ Y) standard0.015 (0.0006)

Taper (A þ B) standard0.010 (0.0004)

If it exceeds the limit, rebore all four cylinders. Replace cylinder

block if necessary.

If cylinder block or piston is replaced, match piston grade with

grade number on cylinder block upper surface.

SEM655A Measuring points

Warpage of surface:

Less than 0.1 mm (0.004 in)

NEM210

H = 227.75-227.85 mm

(8.9665-8.9705 in)

SEM704DA

CYLINDER BLOCKCD20T

Inspection (Cont'd)

EM-173

Page 1744 of 2267

Precautions

lWhen installing each rubber part, final tightening must

be carried out under unladen condition* with tires on

ground.

*: Fuel, radiator coolant and engine oil full. Spare tire,

jack, hand tools and mats in designated positions.

lWhen removing each suspension part, check wheel

alignment and adjust if necessary.

lUse Tool when removing or installing brake tubes.

lAlways torque brake lines when installing.

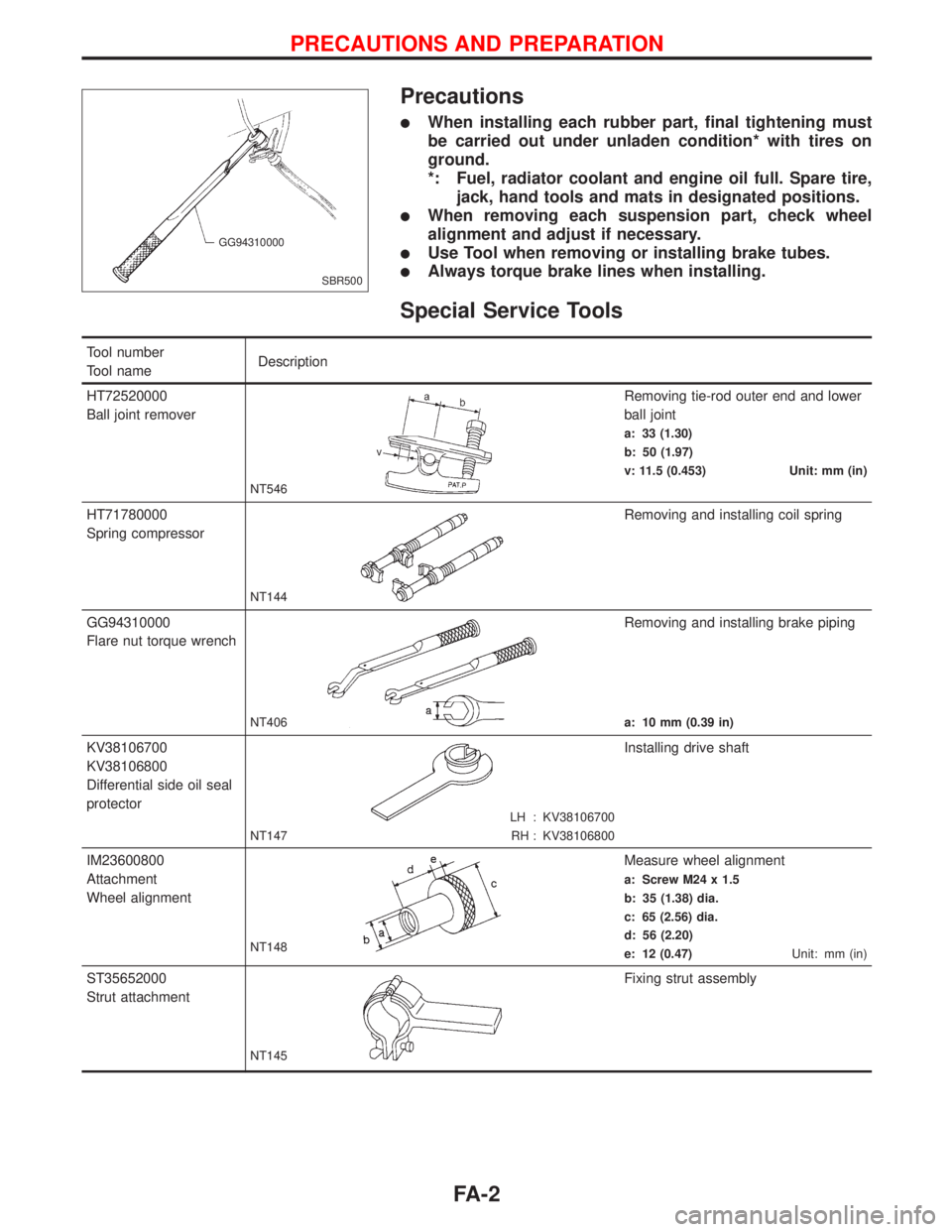

Special Service Tools

Tool number

Tool nameDescription

HT72520000

Ball joint remover

NT546

Removing tie-rod outer end and lower

ball joint

a: 33 (1.30)

b: 50 (1.97)

v: 11.5 (0.453) Unit: mm (in)

HT71780000

Spring compressor

NT144

Removing and installing coil spring

GG94310000

Flare nut torque wrench

NT406

Removing and installing brake piping

a: 10 mm (0.39 in)

KV38106700

KV38106800

Differential side oil seal

protector

LH : KV38106700

RH : KV38106800 NT147

Installing drive shaft

IM23600800

Attachment

Wheel alignment

NT148

Measure wheel alignment

a: Screw M24 x 1.5

b: 35 (1.38) dia.

c: 65 (2.56) dia.

d: 56 (2.20)

e: 12 (0.47)Unit: mm (in)

ST35652000

Strut attachment

NT145

Fixing strut assembly

SBR500 GG94310000

PRECAUTIONS AND PREPARATION

FA-2

Page 1748 of 2267

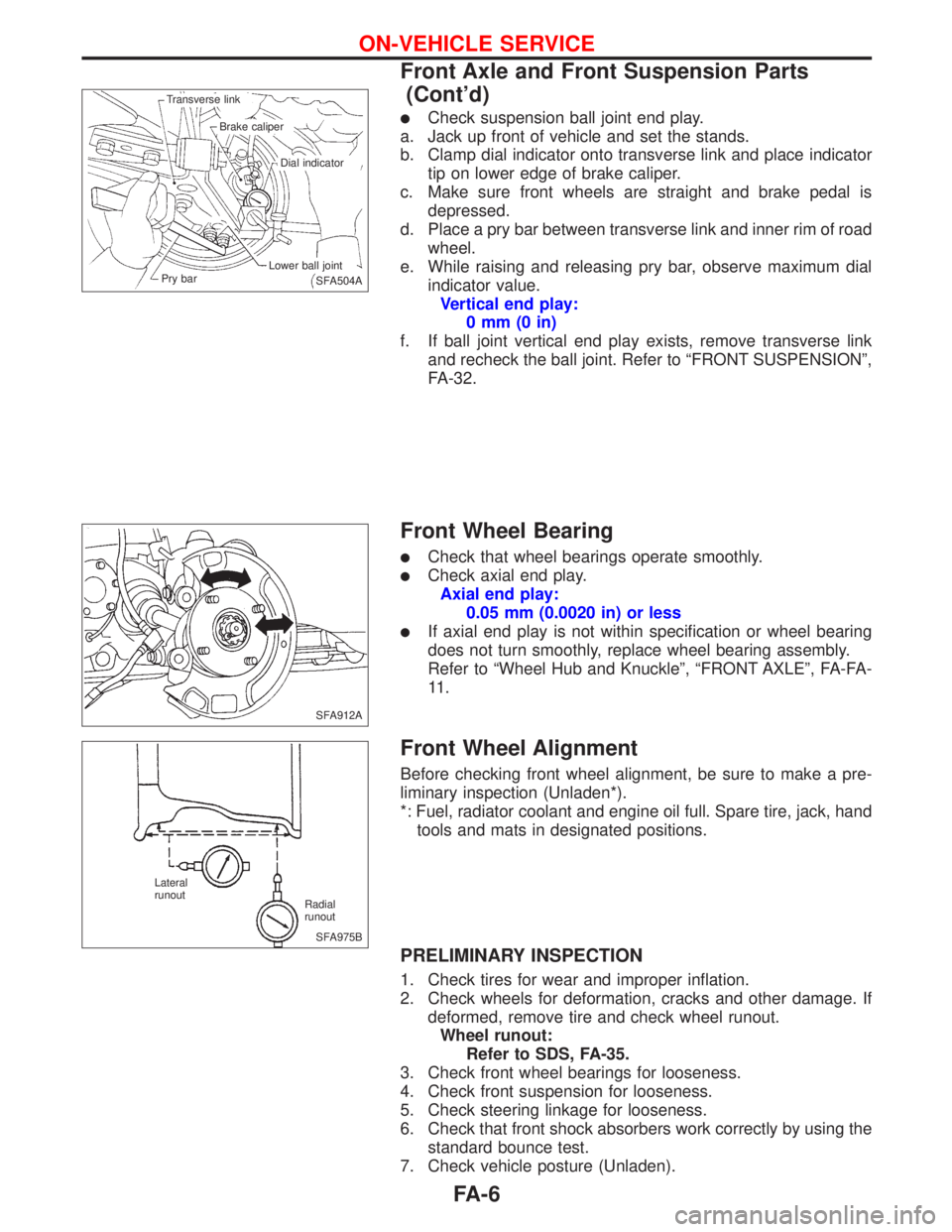

lCheck suspension ball joint end play.

a. Jack up front of vehicle and set the stands.

b. Clamp dial indicator onto transverse link and place indicator

tip on lower edge of brake caliper.

c. Make sure front wheels are straight and brake pedal is

depressed.

d. Place a pry bar between transverse link and inner rim of road

wheel.

e. While raising and releasing pry bar, observe maximum dial

indicator value.

Vertical end play:

0mm(0in)

f. If ball joint vertical end play exists, remove transverse link

and recheck the ball joint. Refer to ªFRONT SUSPENSIONº,

FA-32.

Front Wheel Bearing

lCheck that wheel bearings operate smoothly.

lCheck axial end play.

Axial end play:

0.05 mm (0.0020 in) or less

lIf axial end play is not within specification or wheel bearing

does not turn smoothly, replace wheel bearing assembly.

Refer to ªWheel Hub and Knuckleº, ªFRONT AXLEº, FA-FA-

11 .

Front Wheel Alignment

Before checking front wheel alignment, be sure to make a pre-

liminary inspection (Unladen*).

*: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand

tools and mats in designated positions.

PRELIMINARY INSPECTION

1. Check tires for wear and improper inflation.

2. Check wheels for deformation, cracks and other damage. If

deformed, remove tire and check wheel runout.

Wheel runout:

Refer to SDS, FA-35.

3. Check front wheel bearings for looseness.

4. Check front suspension for looseness.

5. Check steering linkage for looseness.

6. Check that front shock absorbers work correctly by using the

standard bounce test.

7. Check vehicle posture (Unladen).

SFA504A Transverse link

Brake caliper

Dial indicator

Lower ball joint

Pry bar

SFA912A

SFA975B Lateral

runout

Radial

runout

ON-VEHICLE SERVICE

Front Axle and Front Suspension Parts

(Cont'd)

FA-6