check engine NISSAN PRIMERA 1999 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 1750 of 2267

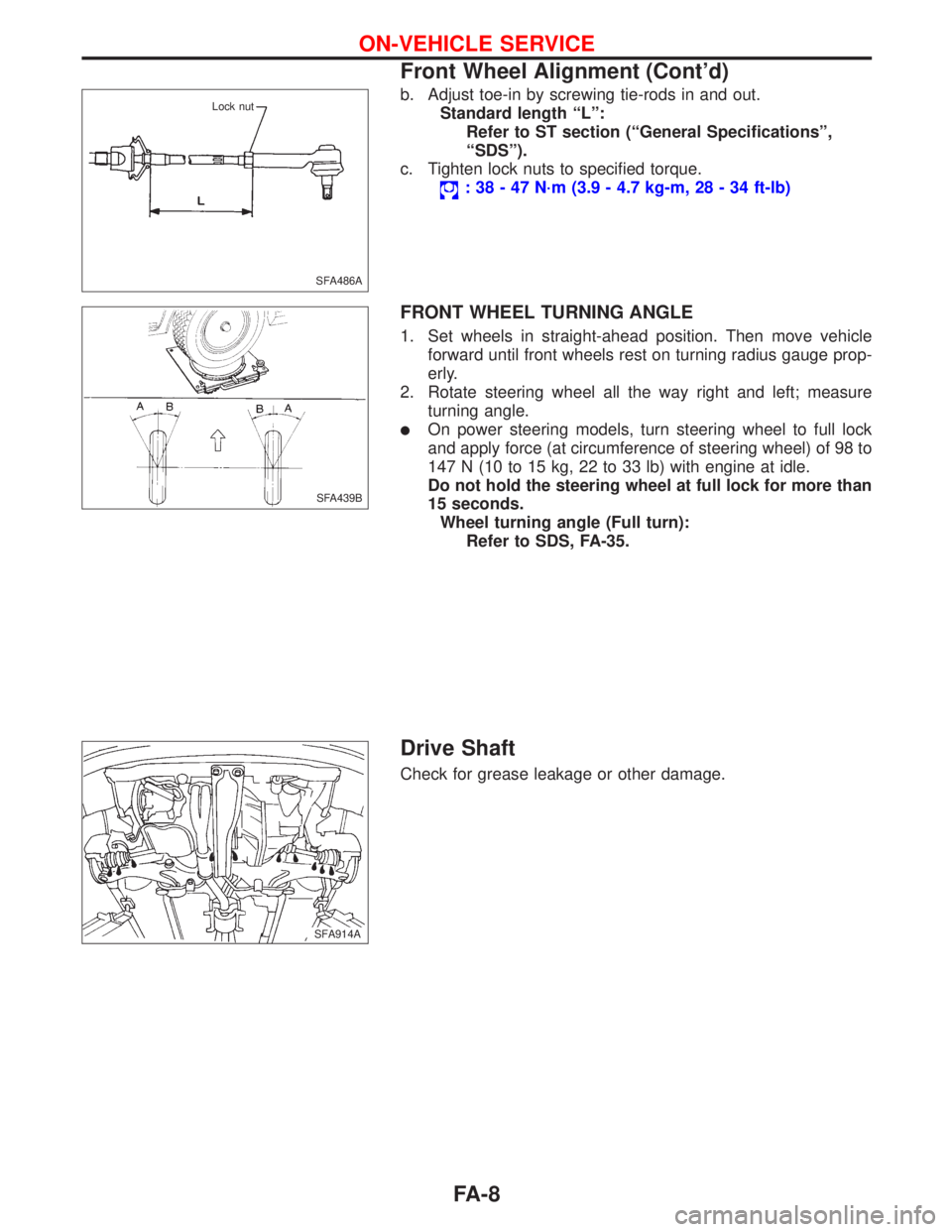

b. Adjust toe-in by screwing tie-rods in and out.

Standard length ªLº:

Refer to ST section (ªGeneral Specificationsº,

ªSDSº).

c. Tighten lock nuts to specified torque.

: 38 - 47 N´m (3.9 - 4.7 kg-m, 28 - 34 ft-lb)

FRONT WHEEL TURNING ANGLE

1. Set wheels in straight-ahead position. Then move vehicle

forward until front wheels rest on turning radius gauge prop-

erly.

2. Rotate steering wheel all the way right and left; measure

turning angle.

lOn power steering models, turn steering wheel to full lock

and apply force (at circumference of steering wheel) of 98 to

147 N (10 to 15 kg, 22 to 33 lb) with engine at idle.

Do not hold the steering wheel at full lock for more than

15 seconds.

Wheel turning angle (Full turn):

Refer to SDS, FA-35.

Drive Shaft

Check for grease leakage or other damage.

SFA486A Lock nut

SFA439B

.SFA914A

ON-VEHICLE SERVICE

Front Wheel Alignment (Cont'd)

FA-8

Page 1784 of 2267

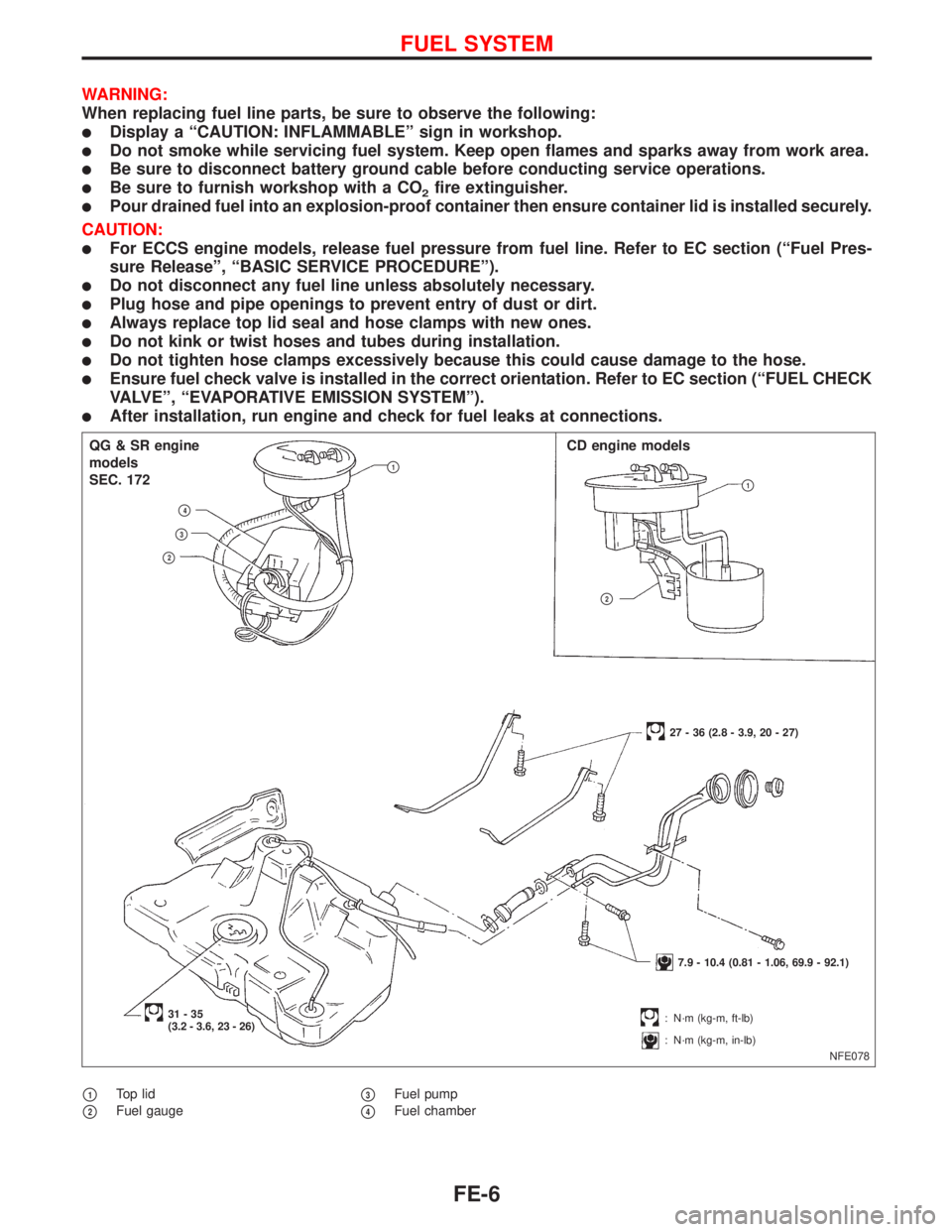

WARNING:

When replacing fuel line parts, be sure to observe the following:

lDisplay a ªCAUTION: INFLAMMABLEº sign in workshop.

lDo not smoke while servicing fuel system. Keep open flames and sparks away from work area.

lBe sure to disconnect battery ground cable before conducting service operations.

lBe sure to furnish workshop with a CO2fire extinguisher.

lPour drained fuel into an explosion-proof container then ensure container lid is installed securely.

CAUTION:

lFor ECCS engine models, release fuel pressure from fuel line. Refer to EC section (ªFuel Pres-

sure Releaseº, ªBASIC SERVICE PROCEDUREº).

lDo not disconnect any fuel line unless absolutely necessary.

lPlug hose and pipe openings to prevent entry of dust or dirt.

lAlways replace top lid seal and hose clamps with new ones.

lDo not kink or twist hoses and tubes during installation.

lDo not tighten hose clamps excessively because this could cause damage to the hose.

lEnsure fuel check valve is installed in the correct orientation. Refer to EC section (ªFUEL CHECK

VALVEº, ªEVAPORATIVE EMISSION SYSTEMº).

lAfter installation, run engine and check for fuel leaks at connections.

p1Top lid

p2Fuel gaugep3Fuel pump

p4Fuel chamber

NFE078

p1

QG & SR engine

models

SEC. 172

p4

p3

p2

CD engine models

p1

p2

27 - 36 (2.8 - 3.9, 20 - 27)

7.9 - 10.4 (0.81 - 1.06, 69.9 - 92.1)

31-35

(3.2 - 3.6, 23 - 26): N´m (kg-m, ft-lb)

: N´m (kg-m, in-lb)

FUEL SYSTEM

FE-6

Page 1787 of 2267

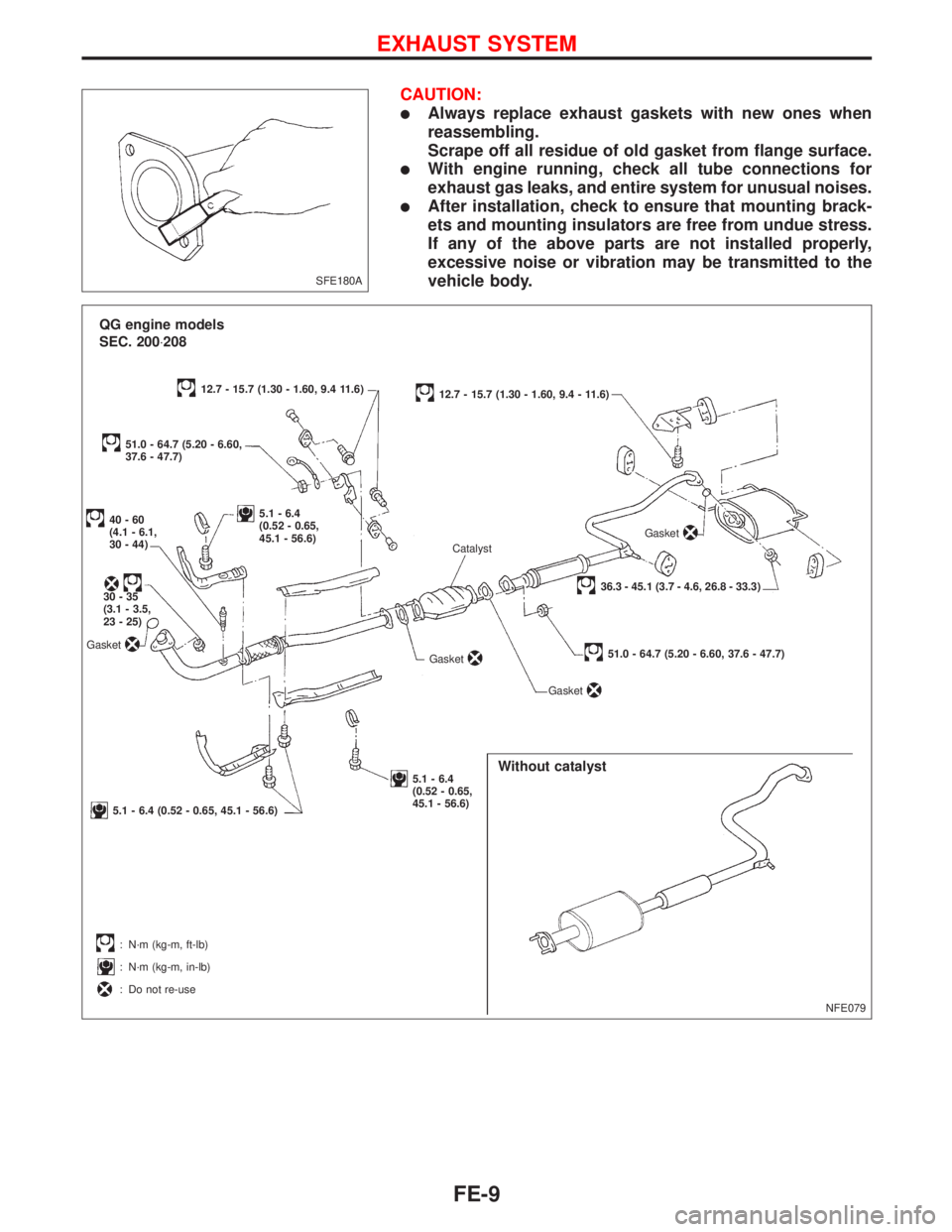

CAUTION:

lAlways replace exhaust gaskets with new ones when

reassembling.

Scrape off all residue of old gasket from flange surface.

lWith engine running, check all tube connections for

exhaust gas leaks, and entire system for unusual noises.

lAfter installation, check to ensure that mounting brack-

ets and mounting insulators are free from undue stress.

If any of the above parts are not installed properly,

excessive noise or vibration may be transmitted to the

vehicle body.

SFE180A

NFE079

QG engine models

SEC. 200×208

12.7 - 15.7 (1.30 - 1.60, 9.4 11.6)

51.0 - 64.7 (5.20 - 6.60,

37.6 - 47.7)

30-35

(3.1 - 3.5,

23 - 25)

5.1 - 6.4

(0.52 - 0.65,

45.1 - 56.6)

Gasket

Gasket

Gasket

51.0 - 64.7 (5.20 - 6.60, 37.6 - 47.7)

36.3 - 45.1 (3.7 - 4.6, 26.8 - 33.3)Gasket

12.7 - 15.7 (1.30 - 1.60, 9.4 - 11.6)

: N´m (kg-m, ft-lb)

: N´m (kg-m, in-lb)

: Do not re-use

5.1 - 6.4 (0.52 - 0.65, 45.1 - 56.6)

5.1 - 6.4

(0.52 - 0.65,

45.1 - 56.6)

40-60

(4.1 - 6.1,

30 - 44)

Catalyst

Without catalyst

EXHAUST SYSTEM

FE-9

Page 1796 of 2267

GENERAL INFORMATION

SECTION

GI

CONTENTS

MODIFICATIONS........................................................... 2

PRECAUTIONS............................................................. 3

Supplemental Restraint System (SRS)²AIR

BAG²and²SEAT BELT PRE-TENSIONER²............. 3

Precautions for NATS ................................................ 3

Precautions for Super Lock System .......................... 4

General Precautions .................................................. 4

Precautions for Multiport Fuel Injection System

or Engine Control Module.......................................... 6

Precautions for Three Way Catalyst.......................... 6

Precautions for Turbocharger .................................... 6

Precautions for Engine Oils ....................................... 6

Precautions for Fuel .................................................. 7

Precautions for Air Conditioning ................................ 8

HOW TO USE THIS MANUAL...................................... 9

HOW TO READ WIRING DIAGRAMS......................... 11

Sample/Wiring Diagram - EXAMPL - ....................... 11

Description ............................................................... 13

Wiring Diagram Codes (Cell Codes) ....................... 20

HOW TO CHECK TERMINAL..................................... 21

How to Probe Connectors ....................................... 21

How to Check Enlarged Contact Spring of

Terminal ................................................................... 22

Waterproof Connector Inspection ............................ 23

Terminal Lock Inspection ......................................... 23HOW TO PERFORM EFFICIENT DIAGNOSIS FOR

AN ELECTRICAL INCIDENT...................................... 24

Work Flow ................................................................ 24

Incident Simulation Tests ......................................... 25

Circuit Inspection ..................................................... 29

HOW TO FOLLOW TROUBLE DIAGNOSES............ 35

How to Follow Test Groups in Trouble Diagnoses .. 35

CONSULT-II CHECKING SYSTEM............................. 39

Function and System Application ............................ 39

Nickel Metal Hydride Battery Replacement............. 39

Checking Equipment................................................ 39

CONSULT-II Data Link Connector (DLC) Circuit .... 40

IDENTIFICATION INFORMATION............................... 41

Model Variation ........................................................ 41

Identification Number ............................................... 43

Dimensions .............................................................. 45

Wheels and Tires ..................................................... 45

LIFTING POINTS AND TOW TRUCK TOWING......... 46

Preparation .............................................................. 46

Board-on Lift ............................................................ 46

Garage Jack and Safety Stand ............................... 47

2-pole Lift ................................................................. 48

Tow Truck Towing .................................................... 49

TIGHTENING TORQUE OF STANDARD BOLTS...... 50

ISO 15031-2 TERMINOLOGY LIST............................ 51

ISO 15031-2 Terminology List ................................. 51

GI

Page 1800 of 2267

lBefore starting repairs which do not require battery power:

Turn off ignition switch.

Disconnect the negative battery terminal.

lTo prevent serious burns:

Avoid contact with hot metal parts.

Do not remove the radiator cap when the engine is hot.

lBefore servicing the vehicle:

Protect fenders, upholstery and carpeting with appropriate

covers.

Take care that keys, buckles or buttons do not scratch paint.

lClean all disassembled parts in the designated liquid or sol-

vent prior to inspection or assembly.

lReplace oil seals, gaskets, packings, O-rings, locking

washers, cotter pins, self-locking nuts, etc. with new ones.

lReplace inner and outer races of tapered roller bearings and

needle bearings as a set.

lArrange the disassembled parts in accordance with their

assembled locations and sequence.

lDo not touch the terminals of electrical components which

use microcomputers (such as ECMs).

Static electricity may damage internal electronic compo-

nents.

lAfter disconnecting vacuum or air hoses, attach a tag to

indicate the proper connection.

lUse only the fluids and lubricants specified in this manual.

lUse approved bonding agent, sealants or their equivalents

when required.

lUse tools and recommended special tools where specified

for safe and efficient service repairs.

lWhen repairing the fuel, oil, water, vacuum or exhaust

systems, check all affected lines for leaks.

lDispose of drained oil or solvent used for cleaning parts in

an appropriate manner.

SEF289H

SGI233

SGI234 Seat cover

Fender cover

PRECAUTIONS

General Precautions (Cont'd)

GI-5

Page 1801 of 2267

Precautions for Multiport Fuel Injection

System or Engine Control Module

lBefore connecting or disconnecting any harness connector

for the multiport fuel injection system or ECM (Engine Con-

trol Module):

Turn ignition switch to ªLOCKº position.

Disconnect negative battery terminal.

Otherwise, there may be damage to ECM.

lBefore disconnecting pressurized fuel line from fuel pump to

injectors, be sure to release fuel pressure.

lBe careful not to jar components such as ECM and mass air

flow sensor.

Precautions for Three Way Catalyst

If a large amount of unburned fuel flows into the catalyst, the

catalyst temperature will be excessively high. To prevent this,

follow the instructions below:

lUse unleaded gasoline only. Leaded gasoline will seriously

damage the three way catalyst.

lWhen checking for ignition spark or measuring engine

compression, make tests quickly and only when necessary.

lDo not run engine when the fuel tank level is low, otherwise

the engine may misfire causing damage to the catalyst.

Do not place the vehicle on flammable material. Keep flammable

material off the exhaust pipe and the three way catalyst.

Precautions for Turbocharger

The turbocharger turbine revolves at extremely high speeds and

becomes very hot. Therefore, it is essential to maintain a clean

supply of oil flowing through the turbocharger and to follow all

required maintenance instructions and operating procedures.

lAlways use the recommended oil. Follow the instructions for

proper time to change the oil and proper oil level.

lAvoid accelerating engine to a high rpm immediately after

starting.

lIf engine had been operating at high rpm for an extended

period of time, let it idle for a few minutes prior to shutting it

off.

Precautions for Engine Oils

Prolonged and repeated contact with used engine oil may cause

skin cancer. Try to avoid direct skin contact with used oil.

If skin contact is made, wash thoroughly with soap or hand

cleaner as soon as possible.

HEALTH PROTECTION PRECAUTIONS

lAvoid prolonged and repeated contact with oils, particularly

used engine oils.

SGI787

SGI292 Cold engine

PRECAUTIONS

GI-6

Page 1802 of 2267

lWear protective clothing, including impervious gloves where

practicable.

lDo not put oily rags in pockets.

lAvoid contaminating clothes, particularly underpants, with oil.

lHeavily soiled clothing and oil-impregnated footwear should

not be worn. Overalls must be cleaned regularly.

lFirst Aid treatment should be obtained immediately for open

cuts and wounds.

lUse barrier creams, applying them before each work period,

to help the removal of oil from the skin.

lWash with soap and water to ensure all oil is removed (skin

cleansers and nail brushes will help). Preparations contain-

ing lanolin replace the natural skin oils which have been

removed.

lDo not use gasoline, kerosine, diesel fuel, gas oil, thinners

or solvents for cleaning skin.

lIf skin disorders develop, obtain medical advice without

delay.

lWhere practicable, degrease components prior to handling.

lWhere there is a risk of eye contact, eye protection should

be worn, for example, chemical goggles or face shields; in

addition an eye wash facility should be provided.

ENVIRONMENTAL PROTECTION PRECAUTIONS

Burning used engine oil in small space heaters or boilers can be

recommended only for units of approved design. The heating

system must meet the requirements of HM Inspectorate of Pol-

lution for small burners of less than 0.4 MW. If in doubt check

with the appropriate local authority and/or manufacturer of the

approved appliance.

Dispose of used oil and used oil filters through authorized waste

disposal contractors to licensed waste disposal sites, or to the

waste oil reclamation trade. If in doubt, contact the local author-

ity for advice on disposal facilities.

It is illegal to pour used oil on to the ground, down sewers or

drains, or into water courses.

The regulations concerning the pollution of the environment

will vary between regions.

Precautions for Fuel

GASOLINE ENGINE:

Unleaded gasoline of at least 95 octane (RON)

CAUTION:

Do not use leaded gasoline. Using leaded gasoline will dam-

age the catalytic converter.

DIESEL ENGINE*:

Diesel fuel of at least 50 cetane

* If two types of diesel fuel are available, use summer or win-

ter fuel properly according to the following temperature con-

ditions.

lAbove þ7ÉC (20ÉF) ... Summer type diesel fuel.

lBelow þ7ÉC (20ÉF) ... Winter type diesel fuel.

PRECAUTIONS

Precautions for Engine Oils (Cont'd)

GI-7

Page 1805 of 2267

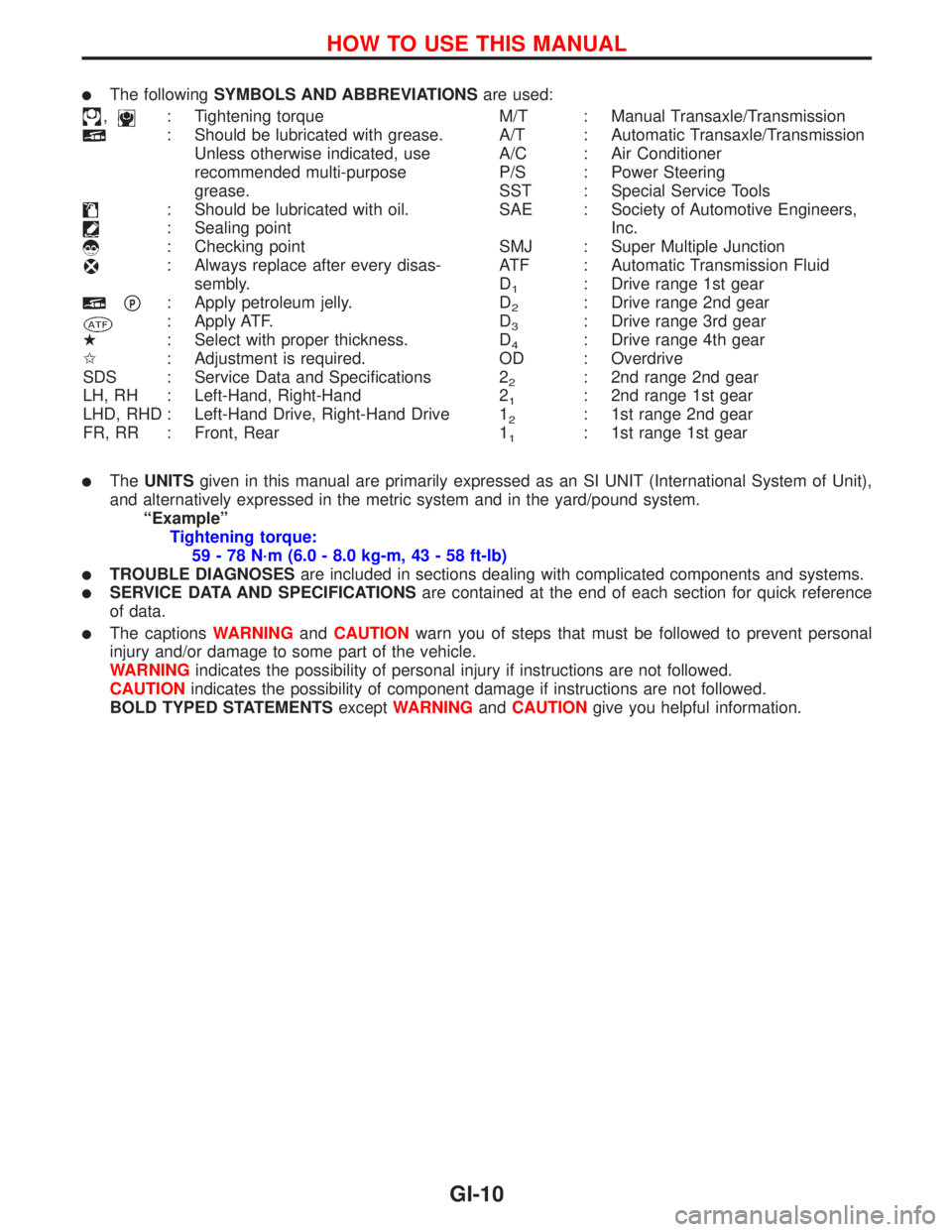

lThe followingSYMBOLS AND ABBREVIATIONSare used:

,: Tightening torque

: Should be lubricated with grease.

Unless otherwise indicated, use

recommended multi-purpose

grease.

: Should be lubricated with oil.

: Sealing point

: Checking point

: Always replace after every disas-

sembly.

pP: Apply petroleum jelly.

: Apply ATF.

H: Select with proper thickness.

I: Adjustment is required.

SDS : Service Data and Specifications

LH, RH : Left-Hand, Right-Hand

LHD, RHD : Left-Hand Drive, Right-Hand Drive

FR, RR : Front, RearM/T : Manual Transaxle/Transmission

A/T : Automatic Transaxle/Transmission

A/C : Air Conditioner

P/S : Power Steering

SST : Special Service Tools

SAE : Society of Automotive Engineers,

Inc.

SMJ : Super Multiple Junction

ATF : Automatic Transmission Fluid

D

1: Drive range 1st gear

D

2: Drive range 2nd gear

D

3: Drive range 3rd gear

D

4: Drive range 4th gear

OD : Overdrive

2

2: 2nd range 2nd gear

2

1: 2nd range 1st gear

1

2: 1st range 2nd gear

1

1: 1st range 1st gear

lTheUNITSgiven in this manual are primarily expressed as an SI UNIT (International System of Unit),

and alternatively expressed in the metric system and in the yard/pound system.

ªExampleº

Tightening torque:

59 - 78 N´m (6.0 - 8.0 kg-m, 43 - 58 ft-lb)

lTROUBLE DIAGNOSESare included in sections dealing with complicated components and systems.

lSERVICE DATA AND SPECIFICATIONSare contained at the end of each section for quick reference

of data.

lThe captionsWARNINGandCAUTIONwarn you of steps that must be followed to prevent personal

injury and/or damage to some part of the vehicle.

WARNINGindicates the possibility of personal injury if instructions are not followed.

CAUTIONindicates the possibility of component damage if instructions are not followed.

BOLD TYPED STATEMENTSexceptWARNINGandCAUTIONgive you helpful information.

HOW TO USE THIS MANUAL

GI-10

Page 1820 of 2267

Incident Simulation Tests

INTRODUCTION

Sometimes the symptom is not present when the vehicle is brought in for service. If possible, re-create the

conditions present at the time of the incident. Doing so may help avoid a No Trouble Found Diagnosis. The

following section illustrates ways to simulate the conditions/environment under which the owner experiences

an electrical incident.

The section is broken into the six following topics:

lVehicle vibration

lHeat sensitive

lFreezing

lWater intrusion

lElectrical load

lCold or hot start up

Get a thorough description of the incident from the customer. It is important for simulating the conditions of

the problem.

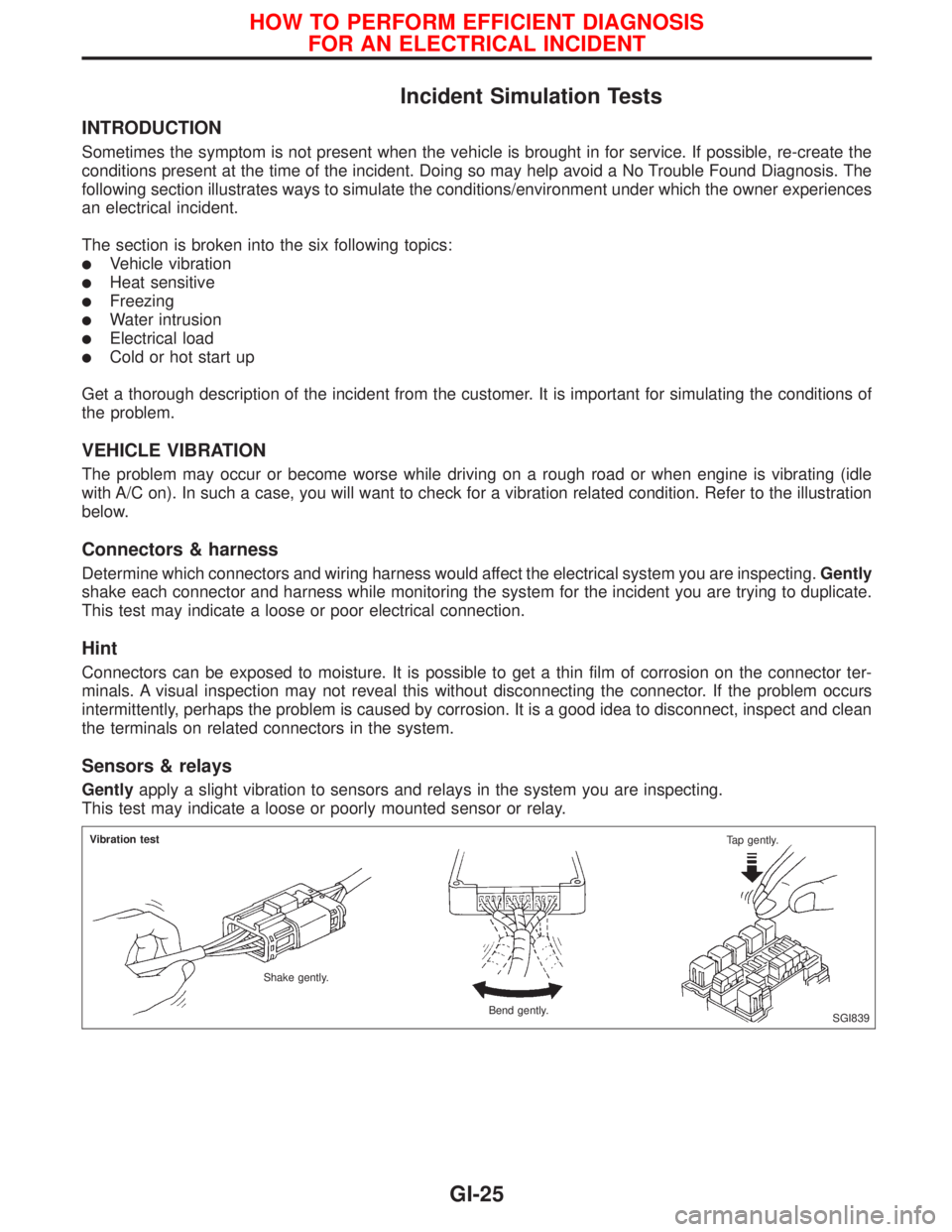

VEHICLE VIBRATION

The problem may occur or become worse while driving on a rough road or when engine is vibrating (idle

with A/C on). In such a case, you will want to check for a vibration related condition. Refer to the illustration

below.

Connectors & harness

Determine which connectors and wiring harness would affect the electrical system you are inspecting.Gently

shake each connector and harness while monitoring the system for the incident you are trying to duplicate.

This test may indicate a loose or poor electrical connection.

Hint

Connectors can be exposed to moisture. It is possible to get a thin film of corrosion on the connector ter-

minals. A visual inspection may not reveal this without disconnecting the connector. If the problem occurs

intermittently, perhaps the problem is caused by corrosion. It is a good idea to disconnect, inspect and clean

the terminals on related connectors in the system.

Sensors & relays

Gentlyapply a slight vibration to sensors and relays in the system you are inspecting.

This test may indicate a loose or poorly mounted sensor or relay.

SGI839 Vibration test

Shake gently.

Bend gently.Tap gently.

HOW TO PERFORM EFFICIENT DIAGNOSIS

FOR AN ELECTRICAL INCIDENT

GI-25

Page 1822 of 2267

Engine compartment

There are several reasons a vehicle or engine vibration could

cause an electrical complaint. Some of the things to check for

are:

lConnectors not fully seated.

lWiring harness not long enough and is being stressed due

to engine vibrations or rocking.

lWires laying across brackets or moving components.

lLoose, dirty or corroded ground wires.

lWires routed too close to hot components.

To inspect components under the hood, start by verifying the

integrity of ground connections. (Refer to GROUND INSPEC-

TION described later.) First check that the system is properly

grounded. Then check for loose connection bygently shaking

the wiring or components as previously explained. Using the

wiring diagrams inspect the wiring for continuity.

Behind the instrument panel

An improperly routed or improperly clamped harness can

become pinched during accessory installation. Vehicle vibration

can aggravate a harness which is routed along a bracket or near

a screw.

Under seating areas

An unclamped or loose harness can cause wiring to be pinched

by seat components (such as slide guides) during vehicle vibra-

tion. If the wiring runs under seating areas, inspect wire routing

for possible damage or pinching.

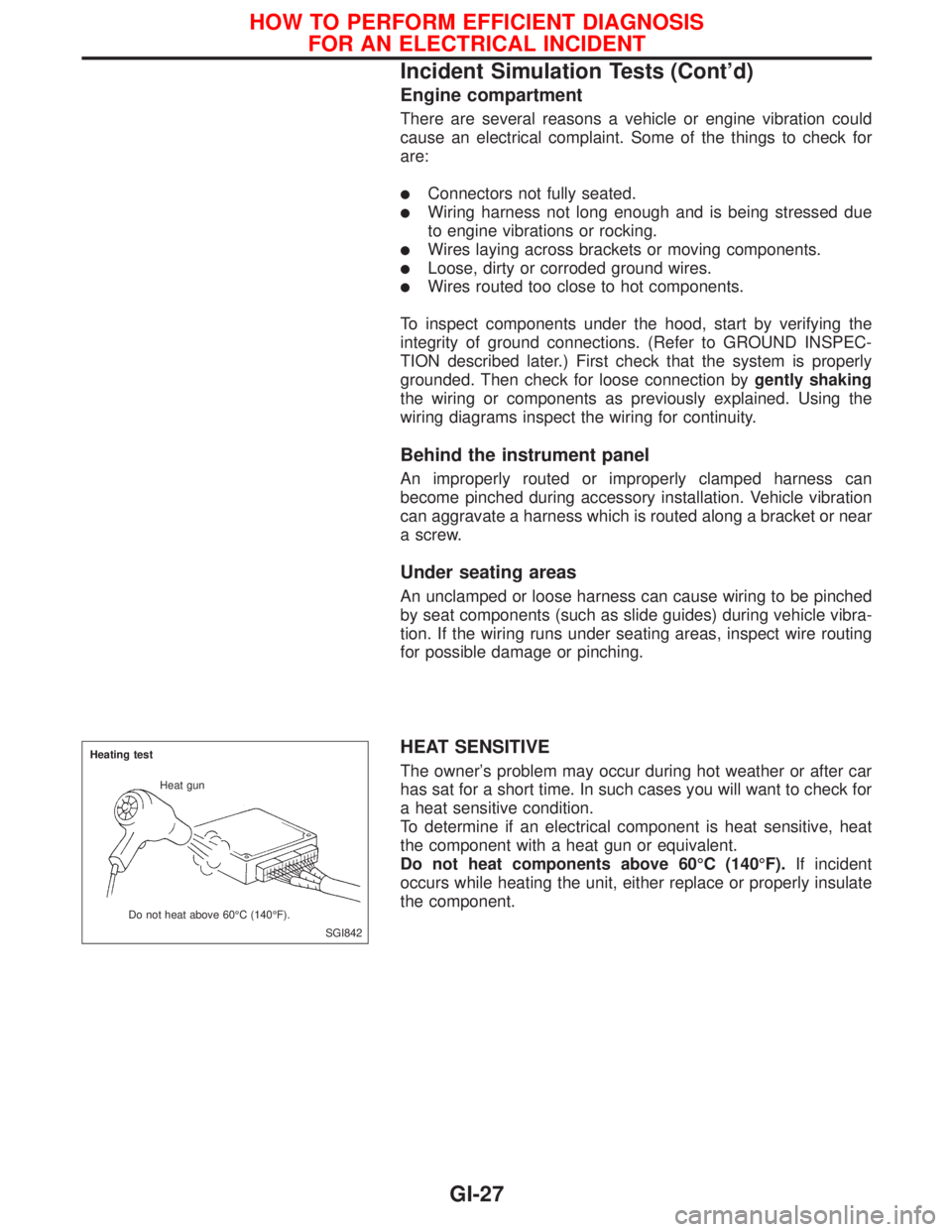

HEAT SENSITIVE

The owner's problem may occur during hot weather or after car

has sat for a short time. In such cases you will want to check for

a heat sensitive condition.

To determine if an electrical component is heat sensitive, heat

the component with a heat gun or equivalent.

Do not heat components above 60ÉC (140ÉF).If incident

occurs while heating the unit, either replace or properly insulate

the component.

SGI842 Heating test

Heat gun

Do not heat above 60ÉC (140ÉF).

HOW TO PERFORM EFFICIENT DIAGNOSIS

FOR AN ELECTRICAL INCIDENT

Incident Simulation Tests (Cont'd)

GI-27