check engine NISSAN PRIMERA 1999 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 1830 of 2267

NOTICE

Trouble diagnoses indicates work procedures required to diag-

nose problems effectively. Observe the following instructions

before diagnosing.

1) Before performing trouble diagnoses, read the ªPrelimi-

nary Checkº, the ªSymptom Chartº or the ªWork Flowº.

2) After repairs, re-check that the problem has been com-

pletely eliminated.

3) Refer to Component Parts and Harness Connector Loca-

tion for the Systems described in each section for

identification/location of components and harness con-

nectors.

4) Refer to the Circuit Diagram for Quick Pinpoint Check.

If you need to check circuit continuity between harness

connectors in more detail, such as when a sub-harness

is used, refer to Wiring Diagram in each individual sec-

tion and Harness Layout in EL section for identification

of harness connectors.

5) When checking circuit continuity, ignition switch should

be in the ªLOCKº position.

6) Before checking voltage at connectors, check battery

voltage.

7) After accomplishing the Diagnostic Procedures and

Electrical Components Inspection, make sure that all

harness connectors are reconnected as they were.

How to Follow Test Groups in Trouble

Diagnoses

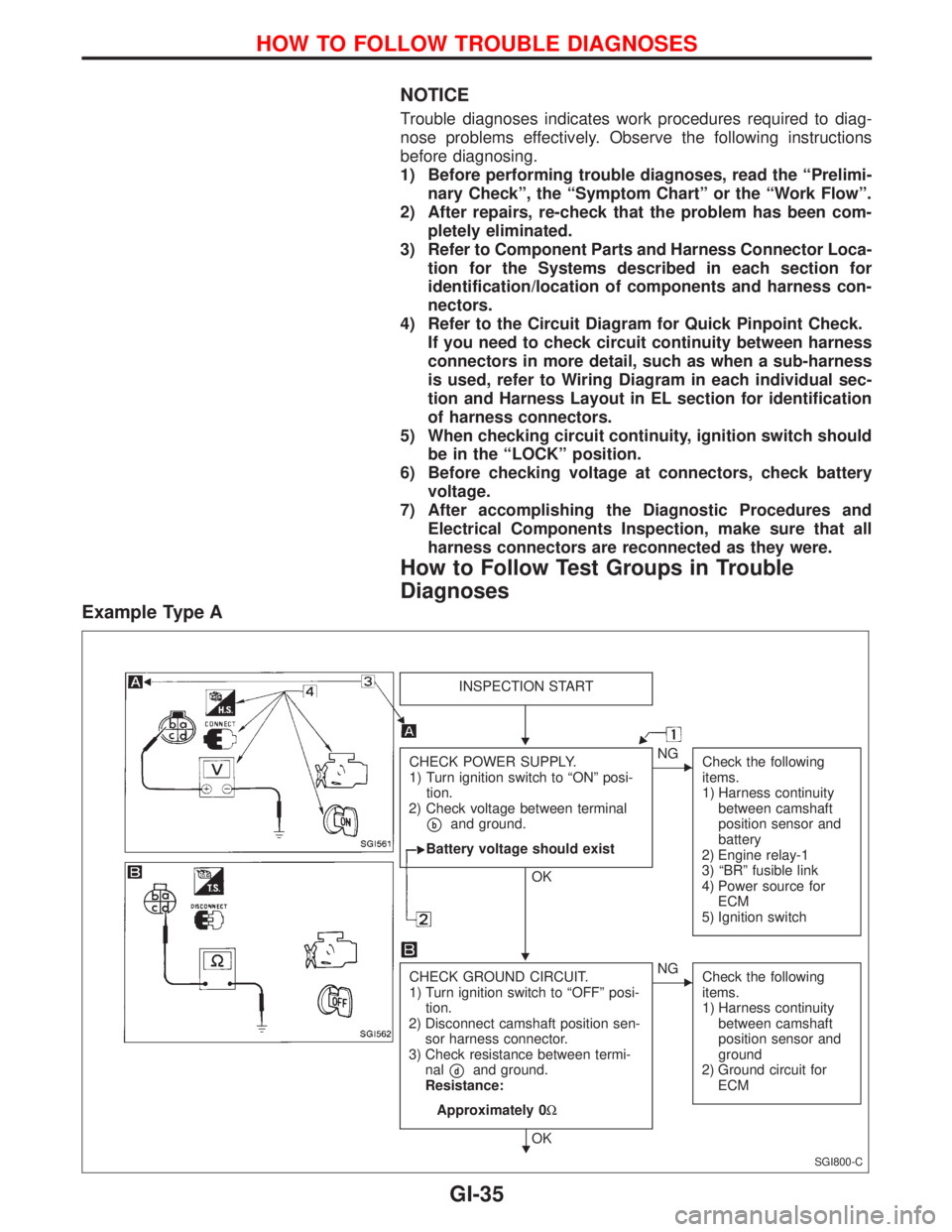

Example Type A

SGI800-C

INSPECTION START

CHECK POWER SUPPLY.

1) Turn ignition switch to ªONº posi-

tion.

2) Check voltage between terminal

pband ground.

Battery voltage should exist

OK

ENG

Check the following

items.

1) Harness continuity

between camshaft

position sensor and

battery

2) Engine relay-1

3) ªBRº fusible link

4) Power source for

ECM

5) Ignition switch

CHECK GROUND CIRCUIT.

1) Turn ignition switch to ªOFFº posi-

tion.

2) Disconnect camshaft position sen-

sor harness connector.

3) Check resistance between termi-

nal

pdand ground.

Resistance:

Approximately 0W

OK

ENG

Check the following

items.

1) Harness continuity

between camshaft

position sensor and

ground

2) Ground circuit for

ECM

H

H

H

HOW TO FOLLOW TROUBLE DIAGNOSES

GI-35

Page 1833 of 2267

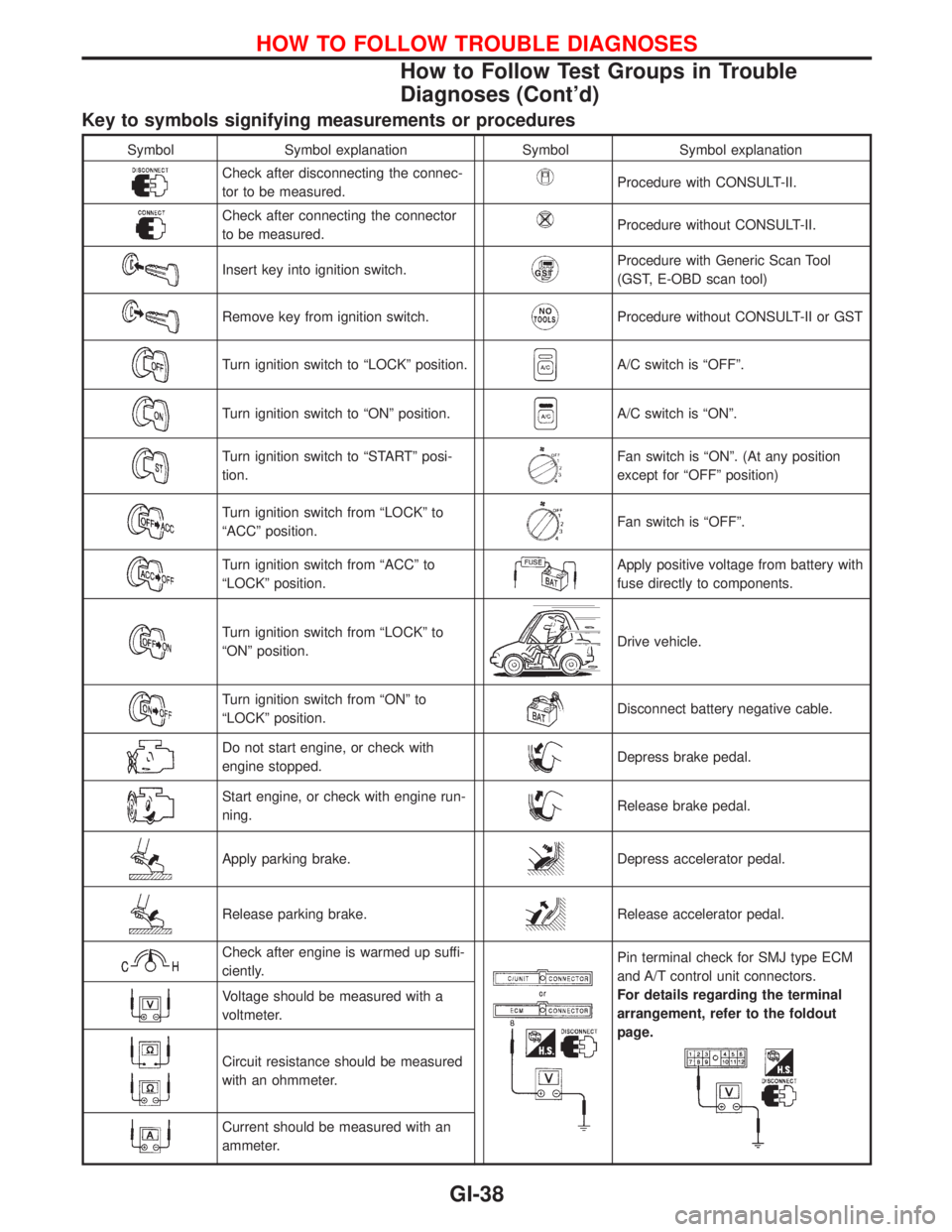

Key to symbols signifying measurements or procedures

Symbol Symbol explanation Symbol Symbol explanation

Check after disconnecting the connec-

tor to be measured.Procedure with CONSULT-II.

Check after connecting the connector

to be measured.Procedure without CONSULT-II.

Insert key into ignition switch.Procedure with Generic Scan Tool

(GST, E-OBD scan tool)

Remove key from ignition switch.Procedure without CONSULT-II or GST

Turn ignition switch to ªLOCKº position.A/C switch is ªOFFº.

Turn ignition switch to ªONº position.A/C switch is ªONº.

Turn ignition switch to ªSTARTº posi-

tion.Fan switch is ªONº. (At any position

except for ªOFFº position)

Turn ignition switch from ªLOCKº to

ªACCº position.Fan switch is ªOFFº.

Turn ignition switch from ªACCº to

ªLOCKº position.Apply positive voltage from battery with

fuse directly to components.

Turn ignition switch from ªLOCKº to

ªONº position.Drive vehicle.

Turn ignition switch from ªONº to

ªLOCKº position.Disconnect battery negative cable.

Do not start engine, or check with

engine stopped.Depress brake pedal.

Start engine, or check with engine run-

ning.Release brake pedal.

Apply parking brake.Depress accelerator pedal.

Release parking brake.Release accelerator pedal.

Check after engine is warmed up suffi-

ciently.Pin terminal check for SMJ type ECM

and A/T control unit connectors.

For details regarding the terminal

arrangement, refer to the foldout

page.

Voltage should be measured with a

voltmeter.

Circuit resistance should be measured

with an ohmmeter.

Current should be measured with an

ammeter.

HOW TO FOLLOW TROUBLE DIAGNOSES

How to Follow Test Groups in Trouble

Diagnoses (Cont'd)

GI-38

Page 1834 of 2267

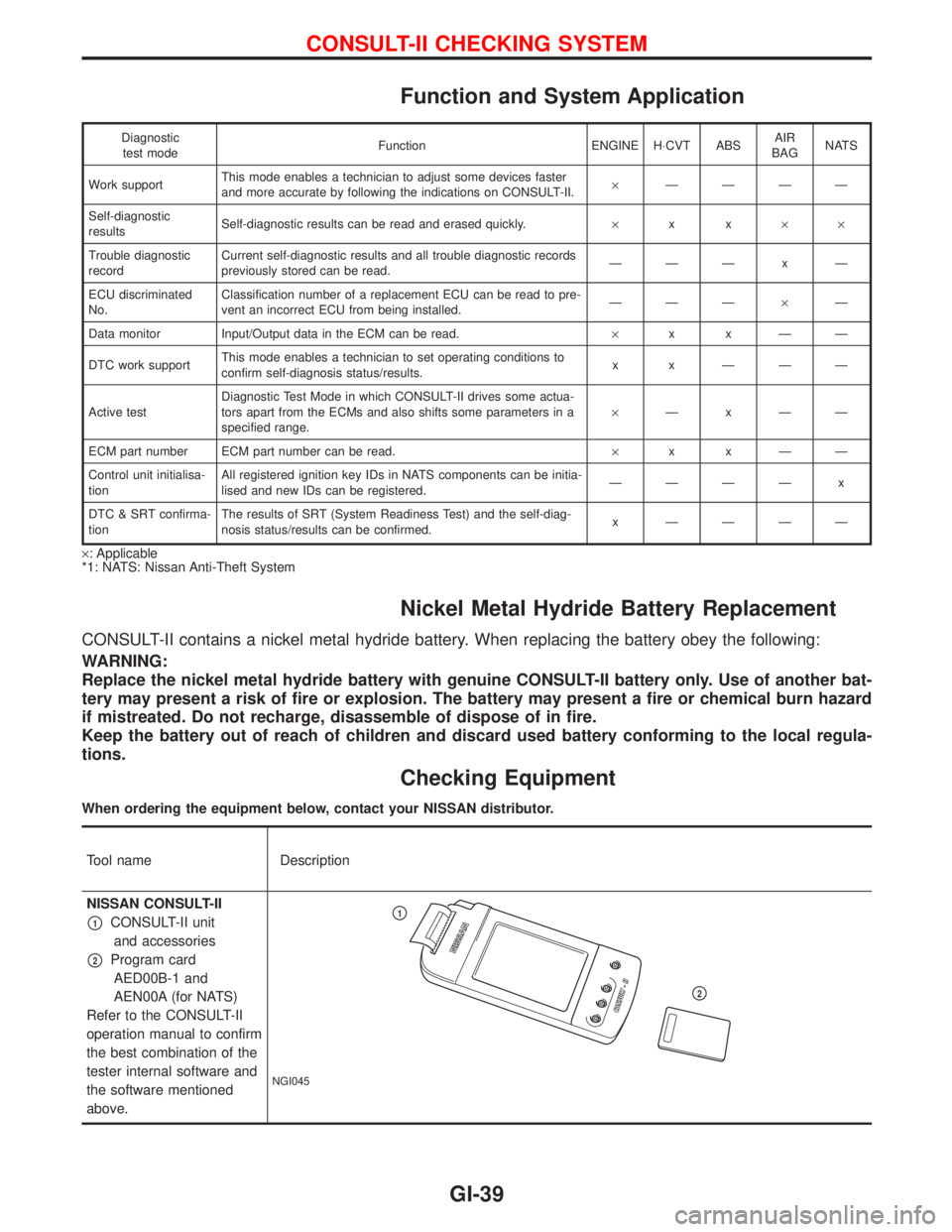

Function and System Application

Diagnostic

test modeFunction ENGINE H×CVT ABSAIR

BAGNATS

Work supportThis mode enables a technician to adjust some devices faster

and more accurate by following the indications on CONSULT-II.´ÐÐÐÐ

Self-diagnostic

resultsSelf-diagnostic results can be read and erased quickly.´xx´´

Trouble diagnostic

recordCurrent self-diagnostic results and all trouble diagnostic records

previously stored can be read.ÐÐÐxÐ

ECU discriminated

No.Classification number of a replacement ECU can be read to pre-

vent an incorrect ECU from being installed.ÐÐдÐ

Data monitor Input/Output data in the ECM can be read.´xxÐÐ

DTC work supportThis mode enables a technician to set operating conditions to

confirm self-diagnosis status/results.x x ÐÐÐ

Active testDiagnostic Test Mode in which CONSULT-II drives some actua-

tors apart from the ECMs and also shifts some parameters in a

specified range.´ÐxÐÐ

ECM part number ECM part number can be read.´xxÐÐ

Control unit initialisa-

tionAll registered ignition key IDs in NATS components can be initia-

lised and new IDs can be registered.ÐÐÐÐ x

DTC & SRT confirma-

tionThe results of SRT (System Readiness Test) and the self-diag-

nosis status/results can be confirmed.x ÐÐÐÐ

´: Applicable

*1: NATS: Nissan Anti-Theft System

Nickel Metal Hydride Battery Replacement

CONSULT-II contains a nickel metal hydride battery. When replacing the battery obey the following:

WARNING:

Replace the nickel metal hydride battery with genuine CONSULT-II battery only. Use of another bat-

tery may present a risk of fire or explosion. The battery may present a fire or chemical burn hazard

if mistreated. Do not recharge, disassemble of dispose of in fire.

Keep the battery out of reach of children and discard used battery conforming to the local regula-

tions.

Checking Equipment

When ordering the equipment below, contact your NISSAN distributor.

Tool name Description

NISSAN CONSULT-II

p1CONSULT-II unit

and accessories

p2Program card

AED00B-1 and

AEN00A (for NATS)

Refer to the CONSULT-II

operation manual to confirm

the best combination of the

tester internal software and

the software mentioned

above.

NGI045

p1

p2

CONSULT-II CHECKING SYSTEM

GI-39

Page 1847 of 2267

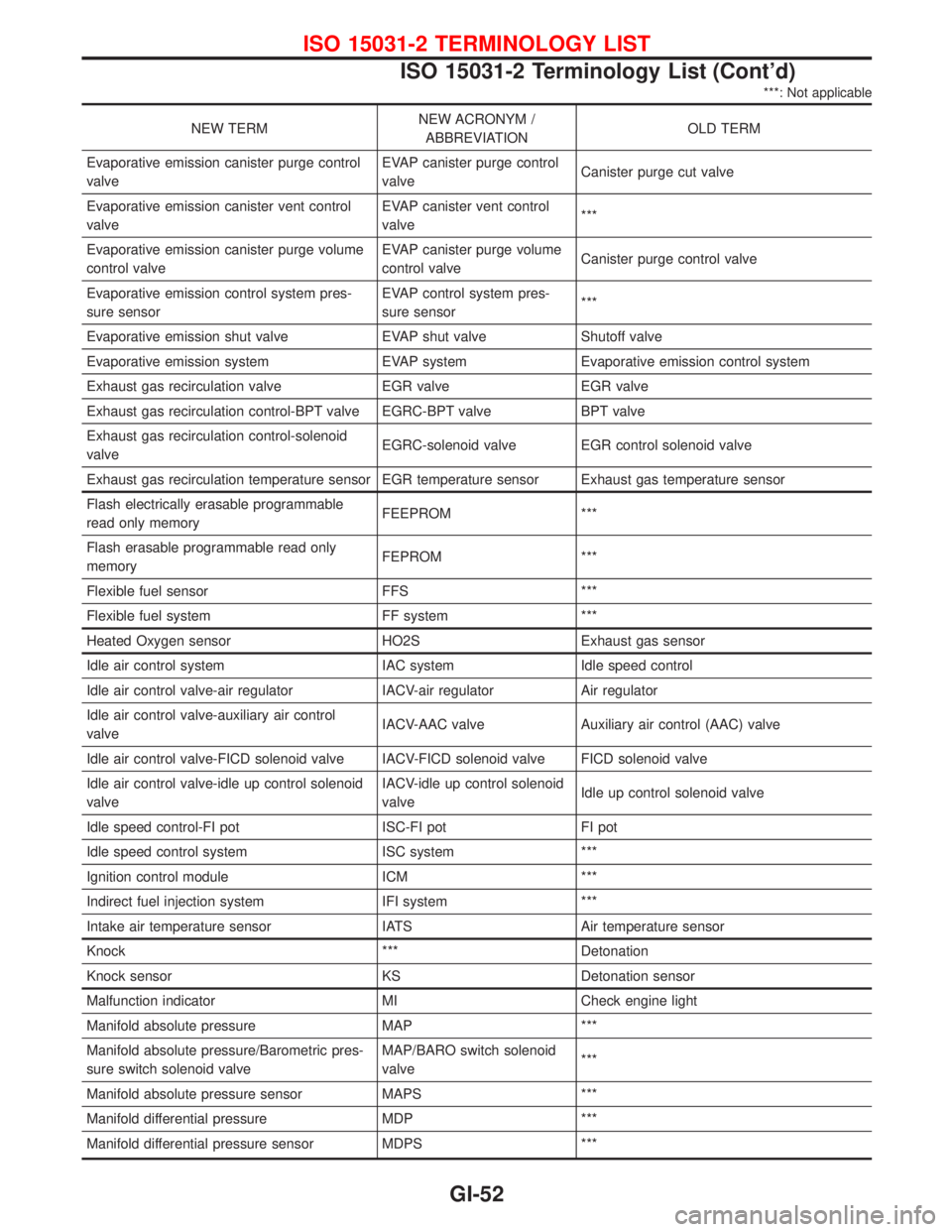

***: Not applicable

NEW TERMNEW ACRONYM /

ABBREVIATIONOLD TERM

Evaporative emission canister purge control

valveEVAP canister purge control

valveCanister purge cut valve

Evaporative emission canister vent control

valveEVAP canister vent control

valve***

Evaporative emission canister purge volume

control valveEVAP canister purge volume

control valveCanister purge control valve

Evaporative emission control system pres-

sure sensorEVAP control system pres-

sure sensor***

Evaporative emission shut valve EVAP shut valve Shutoff valve

Evaporative emission system EVAP system Evaporative emission control system

Exhaust gas recirculation valve EGR valve EGR valve

Exhaust gas recirculation control-BPT valve EGRC-BPT valve BPT valve

Exhaust gas recirculation control-solenoid

valveEGRC-solenoid valve EGR control solenoid valve

Exhaust gas recirculation temperature sensor EGR temperature sensor Exhaust gas temperature sensor

Flash electrically erasable programmable

read only memoryFEEPROM ***

Flash erasable programmable read only

memoryFEPROM ***

Flexible fuel sensor FFS ***

Flexible fuel system FF system ***

Heated Oxygen sensor HO2S Exhaust gas sensor

Idle air control system IAC system Idle speed control

Idle air control valve-air regulator IACV-air regulator Air regulator

Idle air control valve-auxiliary air control

valveIACV-AAC valve Auxiliary air control (AAC) valve

Idle air control valve-FICD solenoid valve IACV-FICD solenoid valve FICD solenoid valve

Idle air control valve-idle up control solenoid

valveIACV-idle up control solenoid

valveIdle up control solenoid valve

Idle speed control-FI pot ISC-FI pot FI pot

Idle speed control system ISC system ***

Ignition control module ICM ***

Indirect fuel injection system IFI system ***

Intake air temperature sensor IATS Air temperature sensor

Knock *** Detonation

Knock sensor KS Detonation sensor

Malfunction indicator MI Check engine light

Manifold absolute pressure MAP ***

Manifold absolute pressure/Barometric pres-

sure switch solenoid valveMAP/BARO switch solenoid

valve***

Manifold absolute pressure sensor MAPS ***

Manifold differential pressure MDP ***

Manifold differential pressure sensor MDPS ***

ISO 15031-2 TERMINOLOGY LIST

ISO 15031-2 Terminology List (Cont'd)

GI-52

Page 1856 of 2267

Precautions for Servicing Compressor

lPlug all openings to prevent moisture and foreign matter from entering.

lWhen the compressor is removed, store it in the same position as it is when mounted on the car.

lWhen replacing or repairing compressor, follow ªMaintenance of Lubricant Quantity in Compres-

sorº exactly. Refer to HA-102.

lKeep friction surfaces between clutch and pulley clean. If the surface is contaminated, with

lubricant, wipe it off by using a clean waste cloth moistened with thinner.

lAfter compressor service operation, turn the compressor shaft by hand more than five turns in

both directions. This will equally distribute lubricant inside the compressor. After the compres-

sor is installed, let the engine idle and operate the compressor for one hour.

lAfter replacing the compressor magnet clutch, apply voltage to the new one and check for nor-

mal operation.

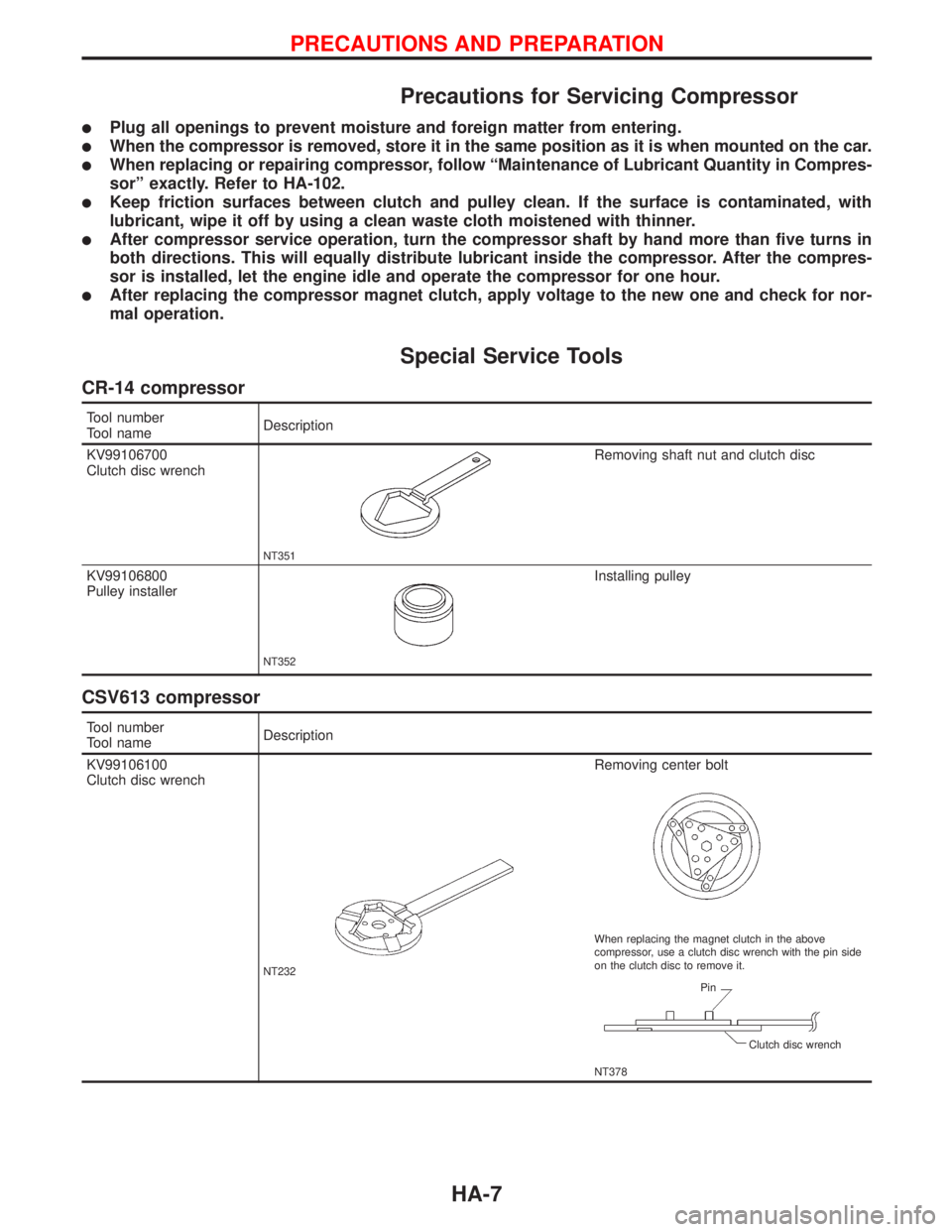

Special Service Tools

CR-14 compressor

Tool number

Tool nameDescription

KV99106700

Clutch disc wrench

NT351

Removing shaft nut and clutch disc

KV99106800

Pulley installer

NT352

Installing pulley

CSV613 compressor

Tool number

Tool nameDescription

KV99106100

Clutch disc wrench

NT232

Removing center bolt

NT378 When replacing the magnet clutch in the above

compressor, use a clutch disc wrench with the pin side

on the clutch disc to remove it.

Pin

Clutch disc wrench

PRECAUTIONS AND PREPARATION

HA-7

Page 1873 of 2267

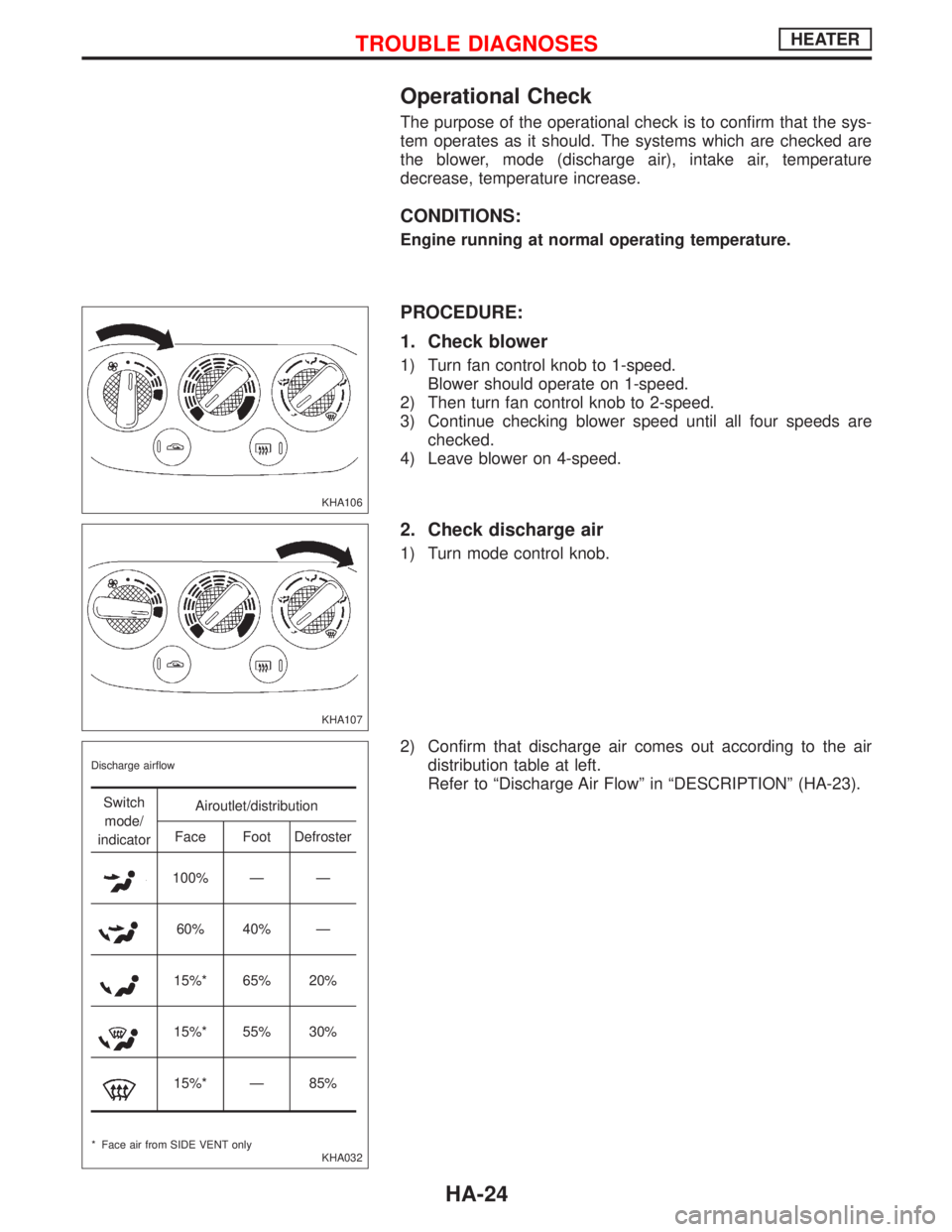

Operational Check

The purpose of the operational check is to confirm that the sys-

tem operates as it should. The systems which are checked are

the blower, mode (discharge air), intake air, temperature

decrease, temperature increase.

CONDITIONS:

Engine running at normal operating temperature.

PROCEDURE:

1. Check blower

1) Turn fan control knob to 1-speed.

Blower should operate on 1-speed.

2) Then turn fan control knob to 2-speed.

3) Continue checking blower speed until all four speeds are

checked.

4) Leave blower on 4-speed.

2. Check discharge air

1) Turn mode control knob.

2) Confirm that discharge air comes out according to the air

distribution table at left.

Refer to ªDischarge Air Flowº in ªDESCRIPTIONº (HA-23).

KHA106

KHA107

KHA032 Discharge airflow

Switch

mode/

indicatorAiroutlet/distribution

Face Foot Defroster

100% Ð Ð

60% 40% Ð

15%* 65% 20%

15%* 55% 30%

15%* Ð 85%

* Face air from SIDE VENT only

TROUBLE DIAGNOSESHEATER

HA-24

Page 1880 of 2267

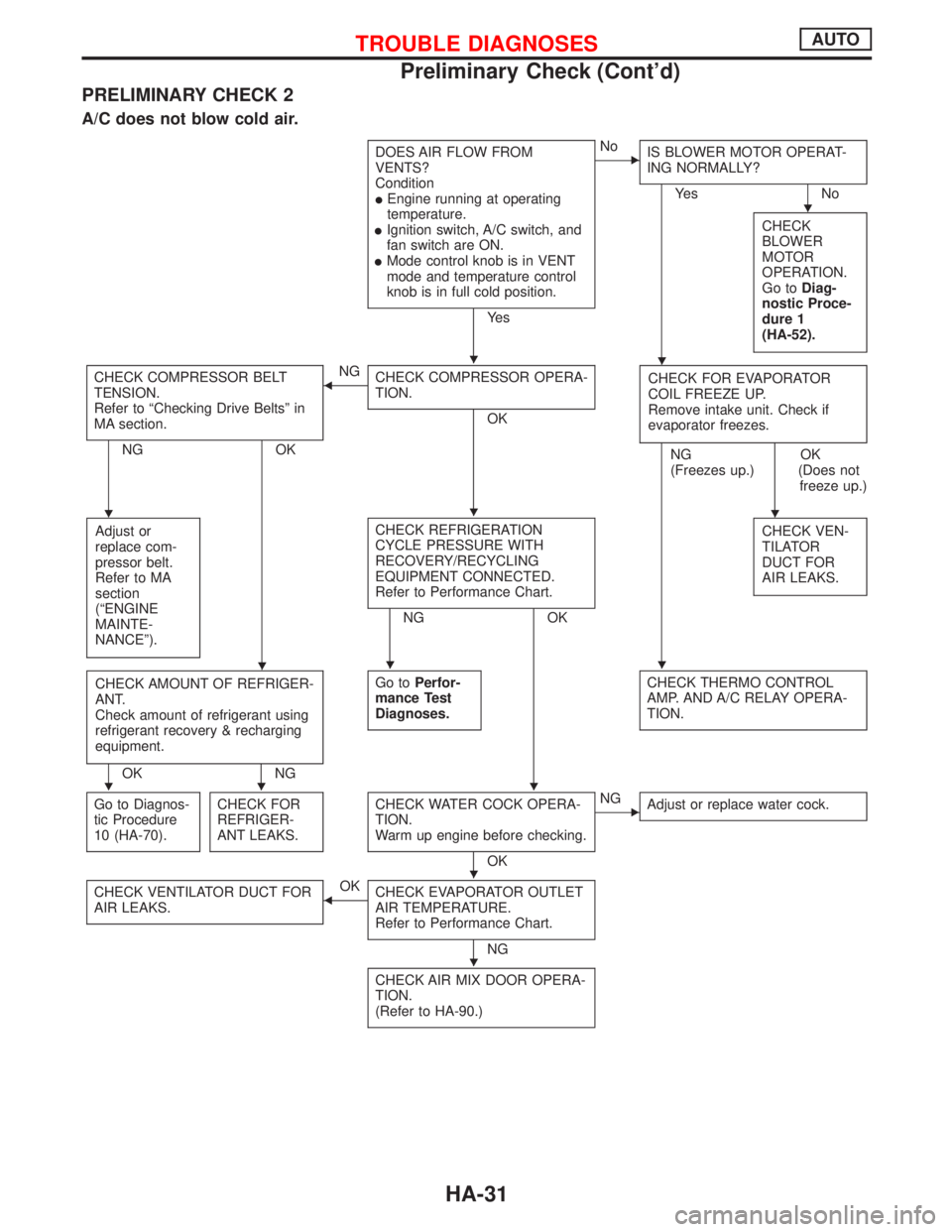

PRELIMINARY CHECK 2

A/C does not blow cold air.

DOES AIR FLOW FROM

VENTS?

Condition

lEngine running at operating

temperature.

lIgnition switch, A/C switch, and

fan switch are ON.

lMode control knob is in VENT

mode and temperature control

knob is in full cold position.

Ye s

ENo

IS BLOWER MOTOR OPERAT-

ING NORMALLY?

Ye s N o

CHECK

BLOWER

MOTOR

OPERATION.

Go toDiag-

nostic Proce-

dure 1

(HA-52).

CHECK COMPRESSOR BELT

TENSION.

Refer to ªChecking Drive Beltsº in

MA section.

NG OK

FNG

CHECK COMPRESSOR OPERA-

TION.

OKCHECK FOR EVAPORATOR

COIL FREEZE UP.

Remove intake unit. Check if

evaporator freezes.

NG

(Freezes up.)OK

(Does not

freeze up.)

Adjust or

replace com-

pressor belt.

Refer to MA

section

(ªENGINE

MAINTE-

NANCEº).

CHECK REFRIGERATION

CYCLE PRESSURE WITH

RECOVERY/RECYCLING

EQUIPMENT CONNECTED.

Refer to Performance Chart.

NG OKCHECK VEN-

TILATOR

DUCT FOR

AIR LEAKS.

CHECK AMOUNT OF REFRIGER-

ANT.

Check amount of refrigerant using

refrigerant recovery & recharging

equipment.

OK NGGo toPerfor-

mance Test

Diagnoses.

CHECK THERMO CONTROL

AMP. AND A/C RELAY OPERA-

TION.

Go to Diagnos-

tic Procedure

10 (HA-70).CHECK FOR

REFRIGER-

ANT LEAKS.CHECK WATER COCK OPERA-

TION.

Warm up engine before checking.

OK

ENG

Adjust or replace water cock.

CHECK VENTILATOR DUCT FOR

AIR LEAKS.FOK

CHECK EVAPORATOR OUTLET

AIR TEMPERATURE.

Refer to Performance Chart.

NG

CHECK AIR MIX DOOR OPERA-

TION.

(Refer to HA-90.)

H

HH

HHH

HHH

HHH

H

H

TROUBLE DIAGNOSESAUTO

Preliminary Check (Cont'd)

HA-31

Page 1881 of 2267

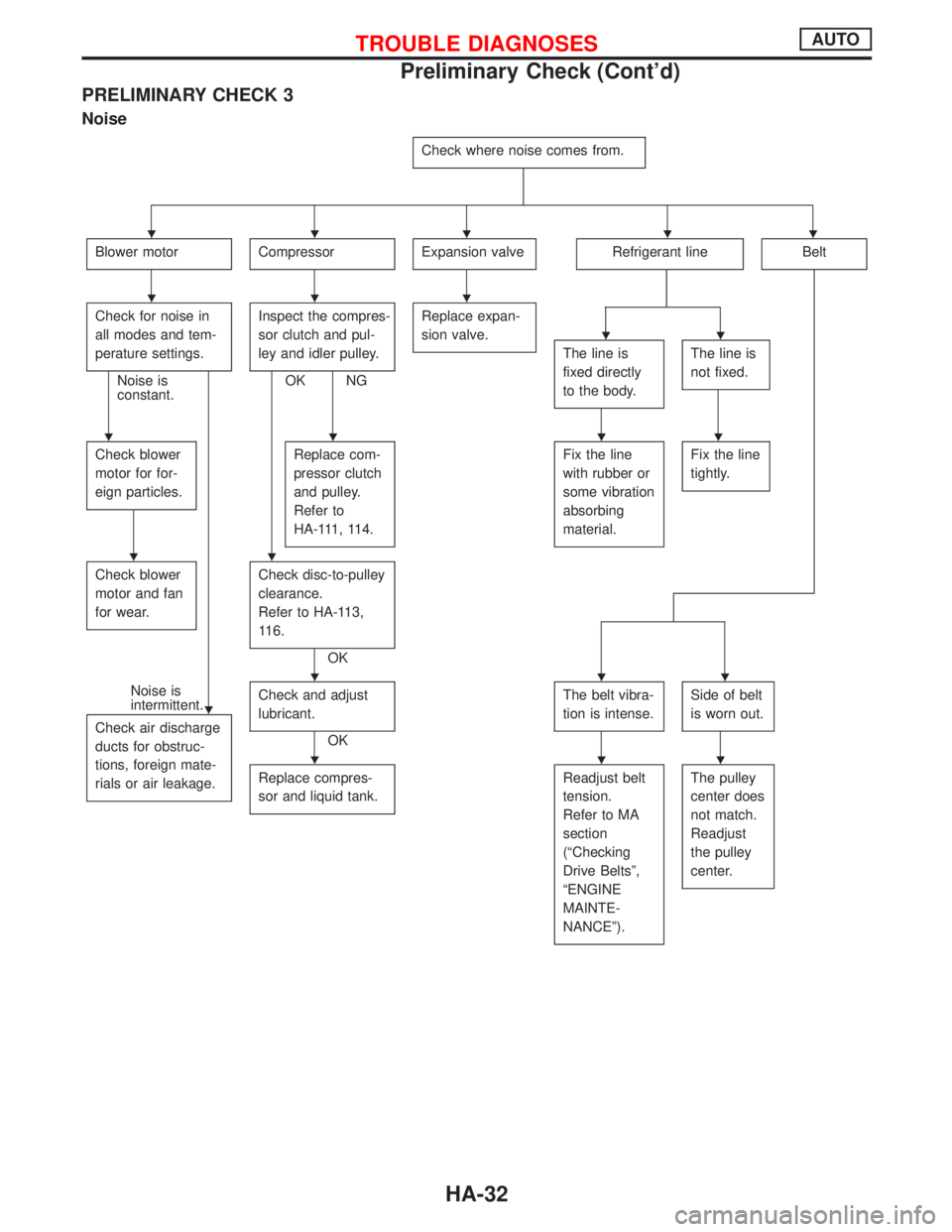

PRELIMINARY CHECK 3

Noise

Check where noise comes from.

Blower motorCompressorExpansion valveRefrigerant lineBelt

Check for noise in

all modes and tem-

perature settings.

Noise is

constant.Inspect the compres-

sor clutch and pul-

ley and idler pulley.OK NGReplace expan-

sion valve.

The line is

fixed directly

to the body.The line is

not fixed.

Check blower

motor for for-

eign particles.Replace com-

pressor clutch

and pulley.

Refer to

HA-111, 114.Fix the line

with rubber or

some vibration

absorbing

material.Fix the line

tightly.

Check blower

motor and fan

for wear.Check disc-to-pulley

clearance.

Refer to HA-113,

116.

OK

Noise is

intermittent.

Check air discharge

ducts for obstruc-

tions, foreign mate-

rials or air leakage.Check and adjust

lubricant.

OKThe belt vibra-

tion is intense.

Side of belt

is worn out.

Replace compres-

sor and liquid tank.Readjust belt

tension.

Refer to MA

section

(ªChecking

Drive Beltsº,

ªENGINE

MAINTE-

NANCEº).The pulley

center does

not match.

Readjust

the pulley

center.

HHHHH

HHH

HH

HHHH

HH

H

HHH

HHH

TROUBLE DIAGNOSESAUTO

Preliminary Check (Cont'd)

HA-32

Page 1885 of 2267

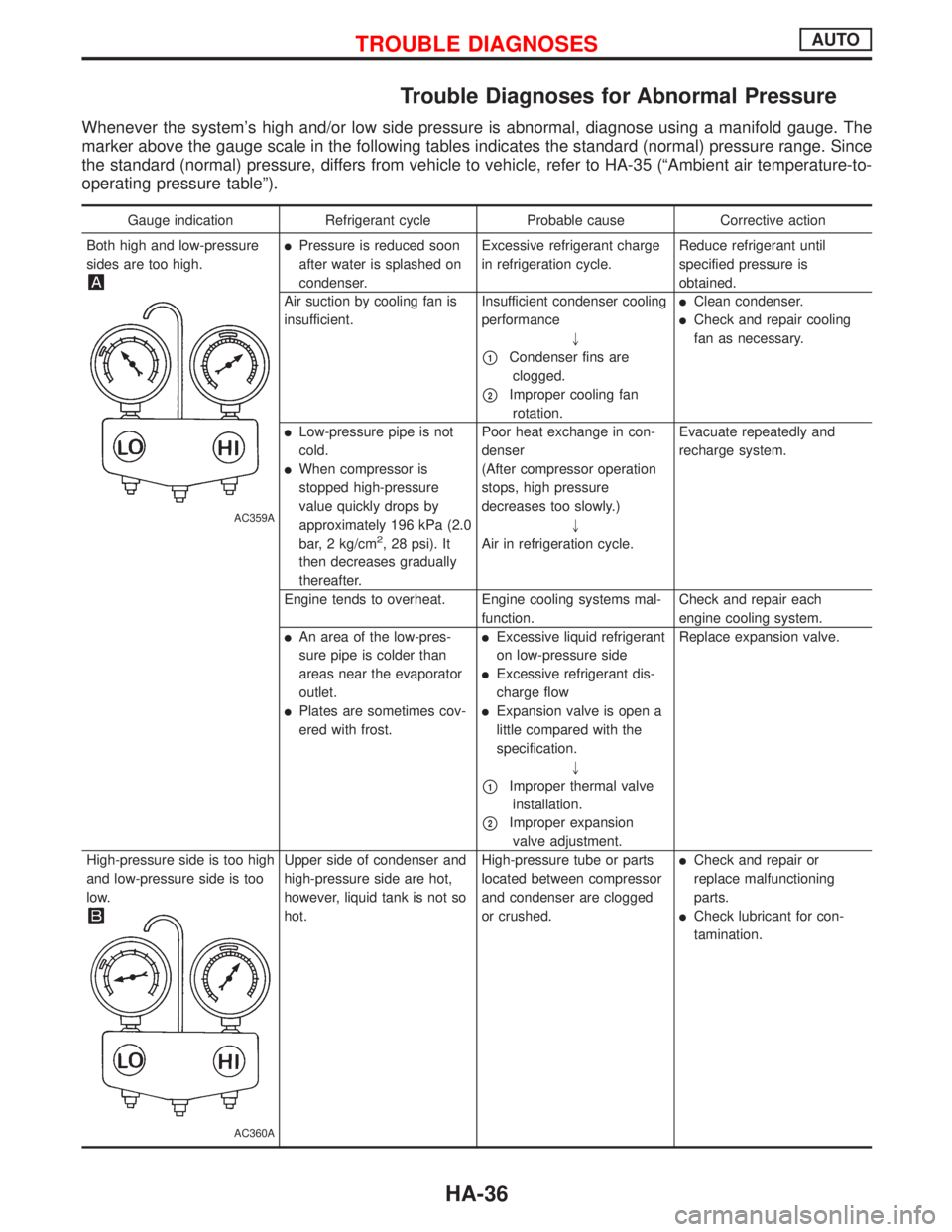

Trouble Diagnoses for Abnormal Pressure

Whenever the system's high and/or low side pressure is abnormal, diagnose using a manifold gauge. The

marker above the gauge scale in the following tables indicates the standard (normal) pressure range. Since

the standard (normal) pressure, differs from vehicle to vehicle, refer to HA-35 (ªAmbient air temperature-to-

operating pressure tableº).

Gauge indication Refrigerant cycle Probable cause Corrective action

Both high and low-pressure

sides are too high.

AC359A

lPressure is reduced soon

after water is splashed on

condenser.Excessive refrigerant charge

in refrigeration cycle.Reduce refrigerant until

specified pressure is

obtained.

Air suction by cooling fan is

insufficient.Insufficient condenser cooling

performance

"

p1Condenser fins are

clogged.

p2Improper cooling fan

rotation.

lClean condenser.

lCheck and repair cooling

fan as necessary.

lLow-pressure pipe is not

cold.

lWhen compressor is

stopped high-pressure

value quickly drops by

approximately 196 kPa (2.0

bar, 2 kg/cm

2, 28 psi). It

then decreases gradually

thereafter.Poor heat exchange in con-

denser

(After compressor operation

stops, high pressure

decreases too slowly.)

"

Air in refrigeration cycle.Evacuate repeatedly and

recharge system.

Engine tends to overheat. Engine cooling systems mal-

function.Check and repair each

engine cooling system.

lAn area of the low-pres-

sure pipe is colder than

areas near the evaporator

outlet.

lPlates are sometimes cov-

ered with frost.

lExcessive liquid refrigerant

on low-pressure side

lExcessive refrigerant dis-

charge flow

lExpansion valve is open a

little compared with the

specification.

"

p1Improper thermal valve

installation.

p2Improper expansion

valve adjustment.Replace expansion valve.

High-pressure side is too high

and low-pressure side is too

low.

AC360A

Upper side of condenser and

high-pressure side are hot,

however, liquid tank is not so

hot.High-pressure tube or parts

located between compressor

and condenser are clogged

or crushed.lCheck and repair or

replace malfunctioning

parts.

lCheck lubricant for con-

tamination.

TROUBLE DIAGNOSESAUTO

HA-36

Page 1914 of 2267

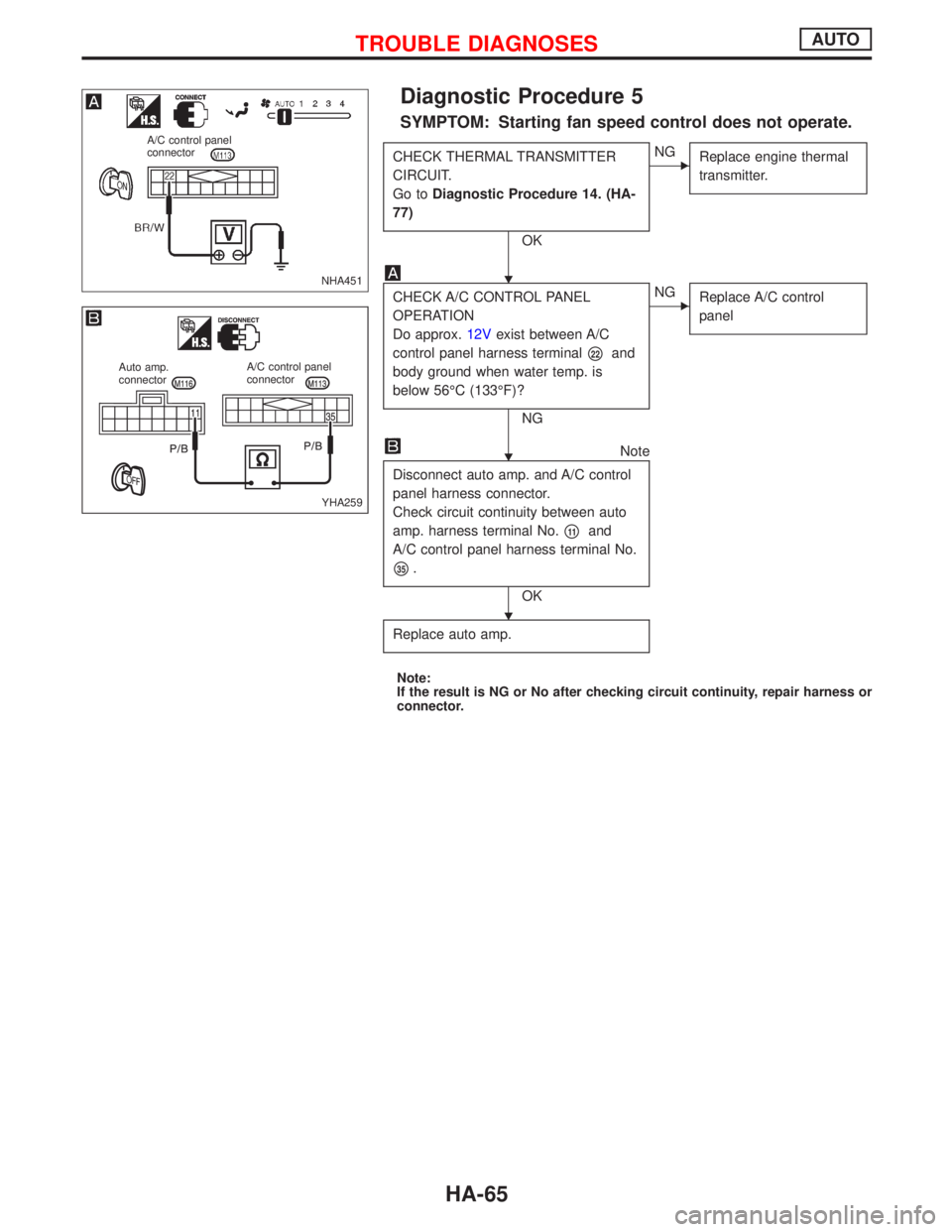

Diagnostic Procedure 5

SYMPTOM: Starting fan speed control does not operate.

CHECK THERMAL TRANSMITTER

CIRCUIT.

Go toDiagnostic Procedure 14. (HA-

77)

OK

ENG

Replace engine thermal

transmitter.

CHECK A/C CONTROL PANEL

OPERATION

Do approx.12Vexist between A/C

control panel harness terminal

p22and

body ground when water temp. is

below 56ÉC (133ÉF)?

NG

ENG

Replace A/C control

panel

Note

Disconnect auto amp. and A/C control

panel harness connector.

Check circuit continuity between auto

amp. harness terminal No.

p11and

A/C control panel harness terminal No.

p35.

OK

Replace auto amp.

Note:

If the result is NG or No after checking circuit continuity, repair harness or

connector.

NHA451

A/C control panel

connector

YHA259

Auto amp.

connectorA/C control panel

connector

H

H

H

TROUBLE DIAGNOSESAUTO

HA-65