check engine NISSAN PRIMERA 1999 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 1919 of 2267

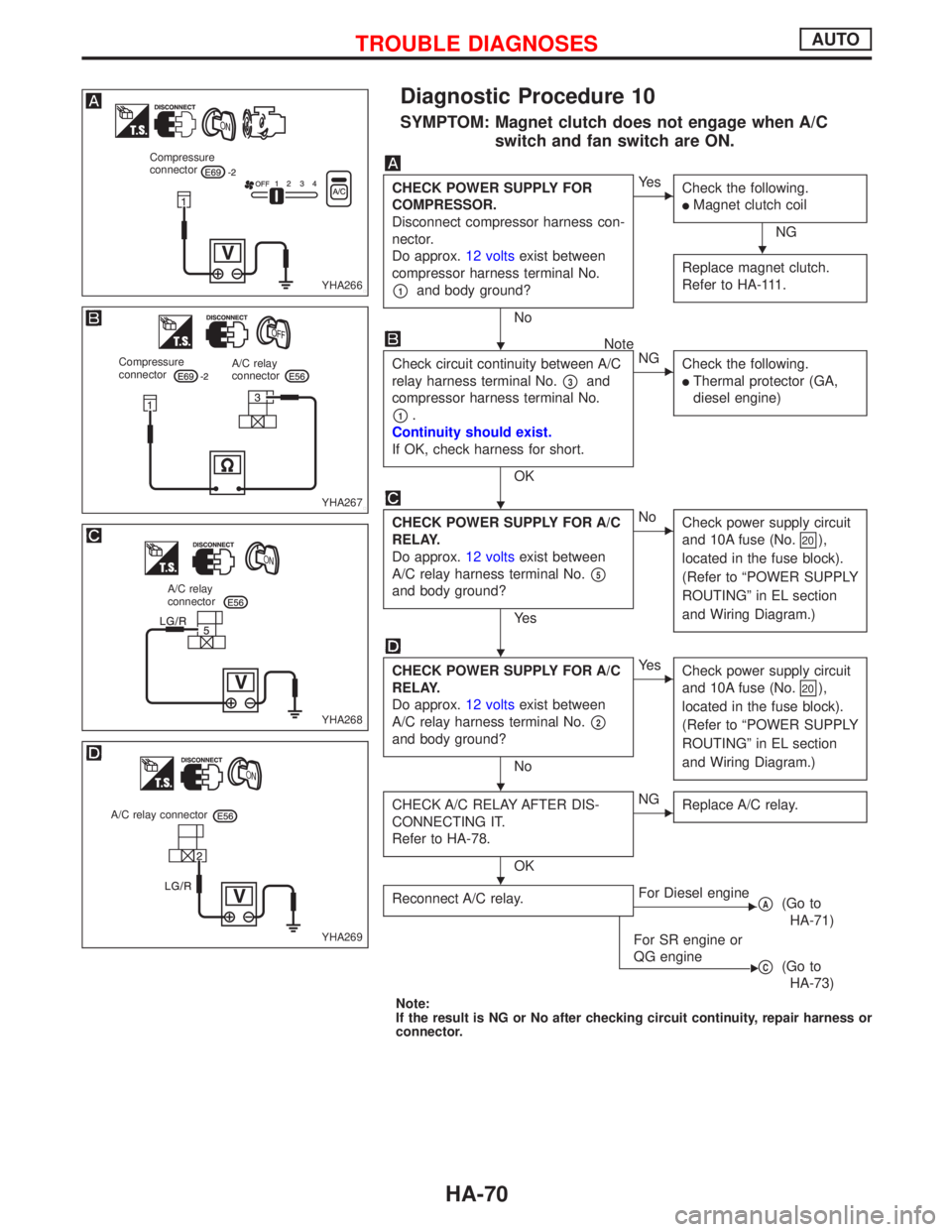

Diagnostic Procedure 10

SYMPTOM: Magnet clutch does not engage when A/C

switch and fan switch are ON.

CHECK POWER SUPPLY FOR

COMPRESSOR.

Disconnect compressor harness con-

nector.

Do approx.12 voltsexist between

compressor harness terminal No.

p1and body ground?

No

EYe s

Check the following.

lMagnet clutch coil

NG

Replace magnet clutch.

Refer to HA-111.

Note

Check circuit continuity between A/C

relay harness terminal No.

p3and

compressor harness terminal No.

p1.

Continuity should exist.

If OK, check harness for short.

OK

ENG

Check the following.

lThermal protector (GA,

diesel engine)

CHECK POWER SUPPLY FOR A/C

RELAY.

Do approx.12 voltsexist between

A/C relay harness terminal No.

p5

and body ground?

Ye s

ENo

Check power supply circuit

and 10A fuse (No.

20),

located in the fuse block).

(Refer to ªPOWER SUPPLY

ROUTINGº in EL section

and Wiring Diagram.)

CHECK POWER SUPPLY FOR A/C

RELAY.

Do approx.12 voltsexist between

A/C relay harness terminal No.

p2

and body ground?

No

EYe s

Check power supply circuit

and 10A fuse (No.

20),

located in the fuse block).

(Refer to ªPOWER SUPPLY

ROUTINGº in EL section

and Wiring Diagram.)

CHECK A/C RELAY AFTER DIS-

CONNECTING IT.

Refer to HA-78.

OK

ENG

Replace A/C relay.

Reconnect A/C relay.EFor Diesel enginepA(Go to

HA-71)

E

For SR engine or

QG engine

pC(Go to

HA-73)

Note:

If the result is NG or No after checking circuit continuity, repair harness or

connector.

YHA266

Compressure

connector

YHA267

Compressure

connectorA/C relay

connector

YHA268

A/C relay

connector

YHA269

A/C relay connector

H

H

H

H

H

H

TROUBLE DIAGNOSESAUTO

HA-70

Page 1936 of 2267

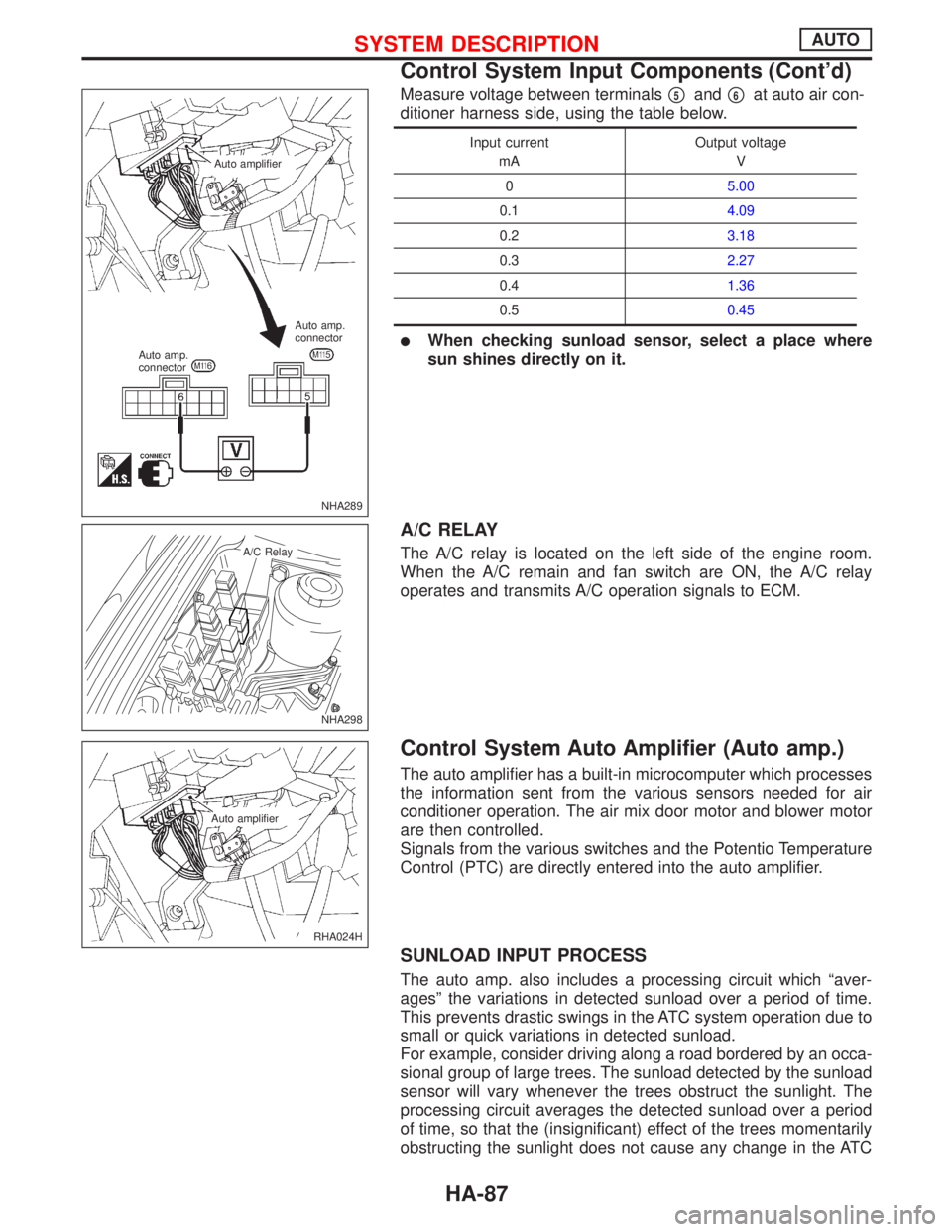

Measure voltage between terminalsp5andp6at auto air con-

ditioner harness side, using the table below.

Input current

mAOutput voltage

V

05.00

0.14.09

0.23.18

0.32.27

0.41.36

0.50.45

lWhen checking sunload sensor, select a place where

sun shines directly on it.

A/C RELAY

The A/C relay is located on the left side of the engine room.

When the A/C remain and fan switch are ON, the A/C relay

operates and transmits A/C operation signals to ECM.

Control System Auto Amplifier (Auto amp.)

The auto amplifier has a built-in microcomputer which processes

the information sent from the various sensors needed for air

conditioner operation. The air mix door motor and blower motor

are then controlled.

Signals from the various switches and the Potentio Temperature

Control (PTC) are directly entered into the auto amplifier.

SUNLOAD INPUT PROCESS

The auto amp. also includes a processing circuit which ªaver-

agesº the variations in detected sunload over a period of time.

This prevents drastic swings in the ATC system operation due to

small or quick variations in detected sunload.

For example, consider driving along a road bordered by an occa-

sional group of large trees. The sunload detected by the sunload

sensor will vary whenever the trees obstruct the sunlight. The

processing circuit averages the detected sunload over a period

of time, so that the (insignificant) effect of the trees momentarily

obstructing the sunlight does not cause any change in the ATC

NHA289 Auto amplifier

Auto amp.

connectorAuto amp.

connector

NHA298

.A/C Relay

RHA024H Auto amplifier

SYSTEM DESCRIPTIONAUTO

Control System Input Components (Cont'd)

HA-87

Page 1950 of 2267

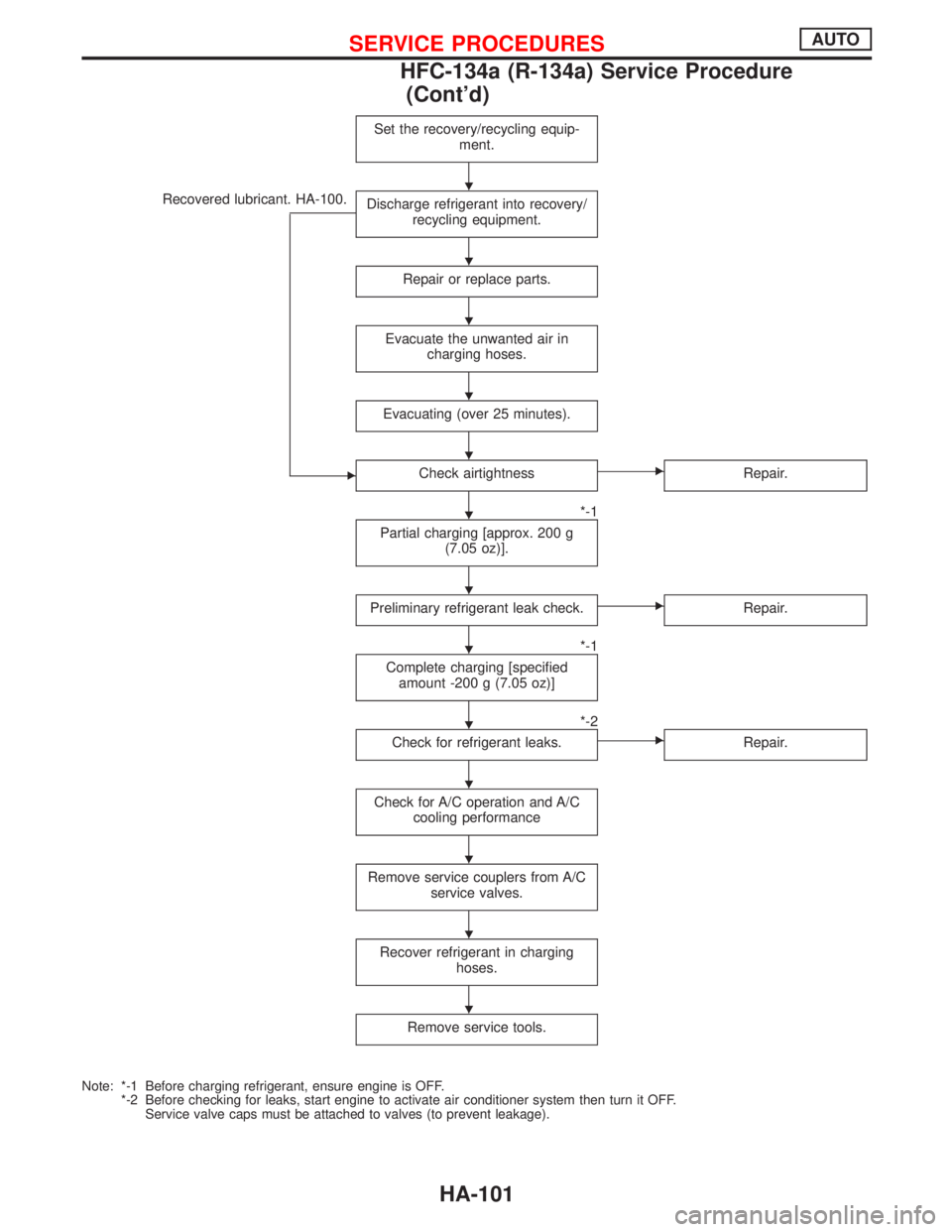

Recovered lubricant. HA-100.Set the recovery/recycling equip-

ment.Discharge refrigerant into recovery/

recycling equipment.

Repair or replace parts.

Evacuate the unwanted air in

charging hoses.

Evacuating (over 25 minutes).

ECheck airtightness

*-1

ERepair.

Partial charging [approx. 200 g

(7.05 oz)].

Preliminary refrigerant leak check.

*-1

ERepair.

Complete charging [specified

amount -200 g (7.05 oz)]

*-2

Check for refrigerant leaks.

ERepair.

Check for A/C operation and A/C

cooling performance

Remove service couplers from A/C

service valves.

Recover refrigerant in charging

hoses.

Remove service tools.

Note: *-1 Before charging refrigerant, ensure engine is OFF.

*-2 Before checking for leaks, start engine to activate air conditioner system then turn it OFF.

Service valve caps must be attached to valves (to prevent leakage).

H

H

H

H

H

H

H

H

H

H

H

H

H

SERVICE PROCEDURESAUTO

HFC-134a (R-134a) Service Procedure

(Cont'd)

HA-101

Page 1951 of 2267

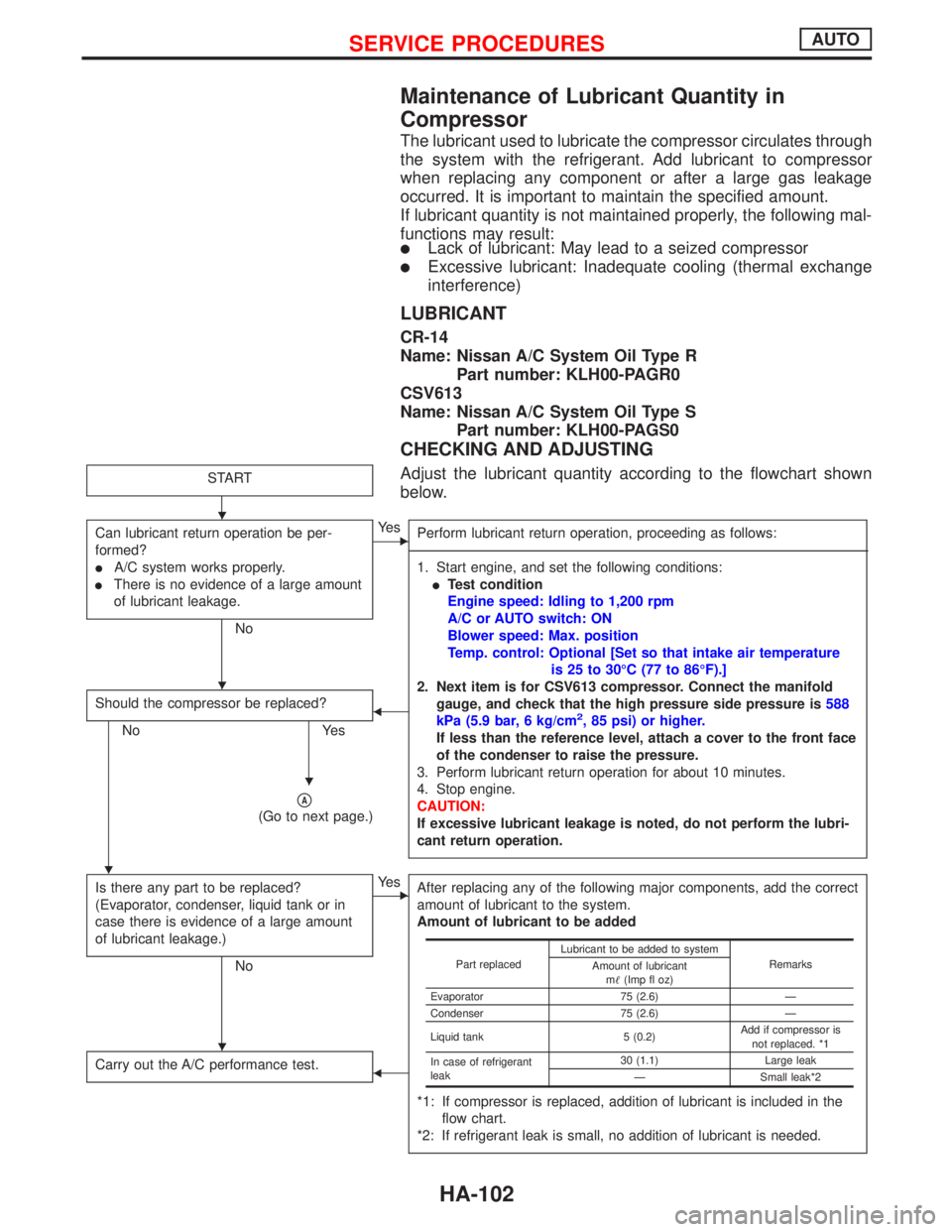

Maintenance of Lubricant Quantity in

Compressor

The lubricant used to lubricate the compressor circulates through

the system with the refrigerant. Add lubricant to compressor

when replacing any component or after a large gas leakage

occurred. It is important to maintain the specified amount.

If lubricant quantity is not maintained properly, the following mal-

functions may result:

lLack of lubricant: May lead to a seized compressor

lExcessive lubricant: Inadequate cooling (thermal exchange

interference)

LUBRICANT

CR-14

Name: Nissan A/C System Oil Type R

Part number: KLH00-PAGR0

CSV613

Name: Nissan A/C System Oil Type S

Part number: KLH00-PAGS0

CHECKING AND ADJUSTING

Adjust the lubricant quantity according to the flowchart shown

below.START

Can lubricant return operation be per-

formed?

lA/C system works properly.

lThere is no evidence of a large amount

of lubricant leakage.

No

EYe s

Perform lubricant return operation, proceeding as follows:

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1. Start engine, and set the following conditions:

lTest condition

Engine speed: Idling to 1,200 rpm

A/C or AUTO switch: ON

Blower speed: Max. position

Temp. control: Optional [Set so that intake air temperature

is 25 to 30ÉC (77 to 86ÉF).]

2. Next item is for CSV613 compressor. Connect the manifold

gauge, and check that the high pressure side pressure is588

kPa (5.9 bar, 6 kg/cm

2, 85 psi) or higher.

If less than the reference level, attach a cover to the front face

of the condenser to raise the pressure.

3. Perform lubricant return operation for about 10 minutes.

4. Stop engine.

CAUTION:

If excessive lubricant leakage is noted, do not perform the lubri-

cant return operation.

Should the compressor be replaced?

No Yes

F

pA

(Go to next page.)

Is there any part to be replaced?

(Evaporator, condenser, liquid tank or in

case there is evidence of a large amount

of lubricant leakage.)

No

EYe s

After replacing any of the following major components, add the correct

amount of lubricant to the system.

Amount of lubricant to be added

*1: If compressor is replaced, addition of lubricant is included in the

flow chart.

*2: If refrigerant leak is small, no addition of lubricant is needed.

Carry out the A/C performance test.F

Part replacedLubricant to be added to system

Remarks

Amount of lubricant

m(Imp fl oz)

Evaporator 75 (2.6) Ð

Condenser 75 (2.6) Ð

Liquid tank 5 (0.2)Add if compressor is

not replaced. *1

In case of refrigerant

leak30 (1.1) Large leak

Ð Small leak*2

H

H

H

H

H

SERVICE PROCEDURESAUTO

HA-102

Page 1956 of 2267

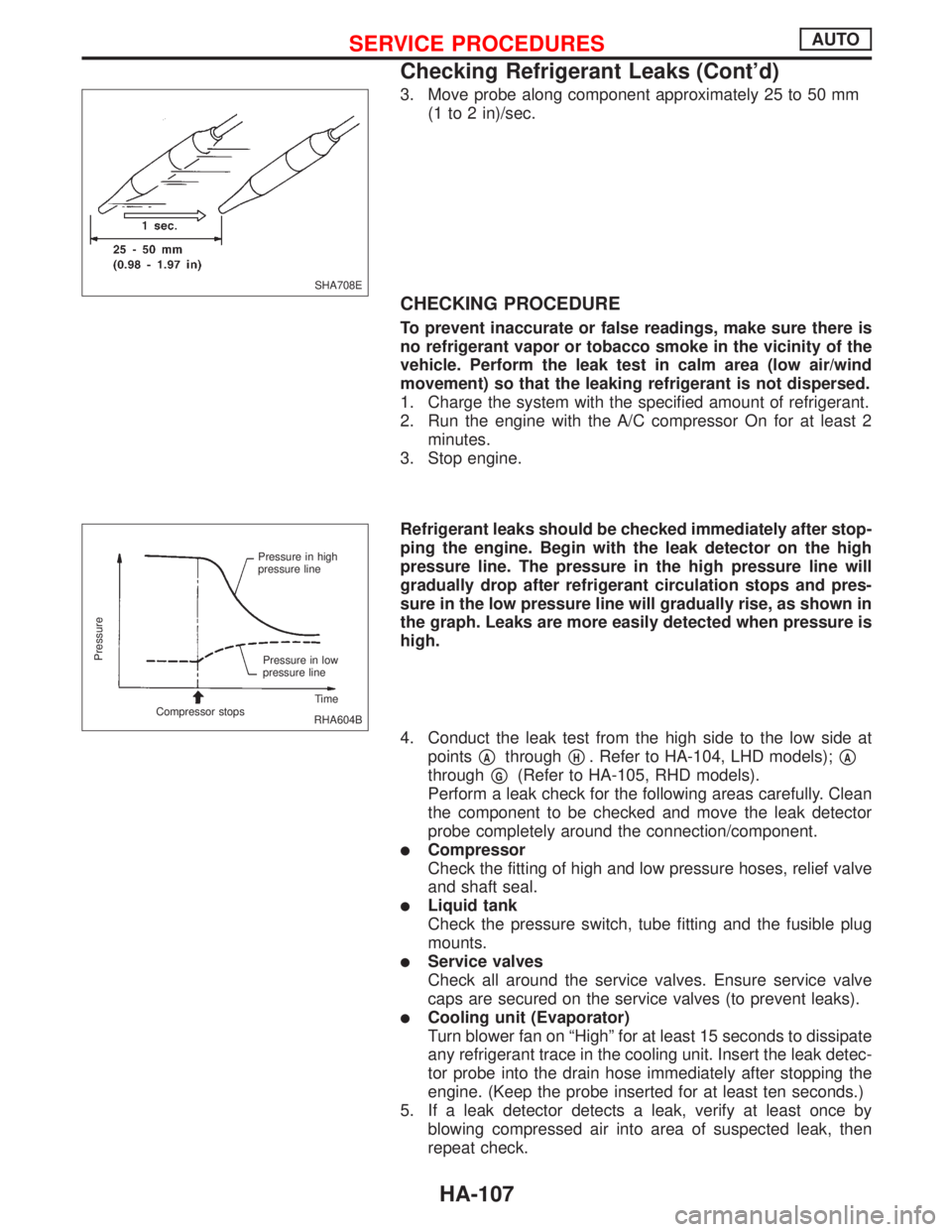

3. Move probe along component approximately 25 to 50 mm

(1 to 2 in)/sec.

CHECKING PROCEDURE

To prevent inaccurate or false readings, make sure there is

no refrigerant vapor or tobacco smoke in the vicinity of the

vehicle. Perform the leak test in calm area (low air/wind

movement) so that the leaking refrigerant is not dispersed.

1. Charge the system with the specified amount of refrigerant.

2. Run the engine with the A/C compressor On for at least 2

minutes.

3. Stop engine.

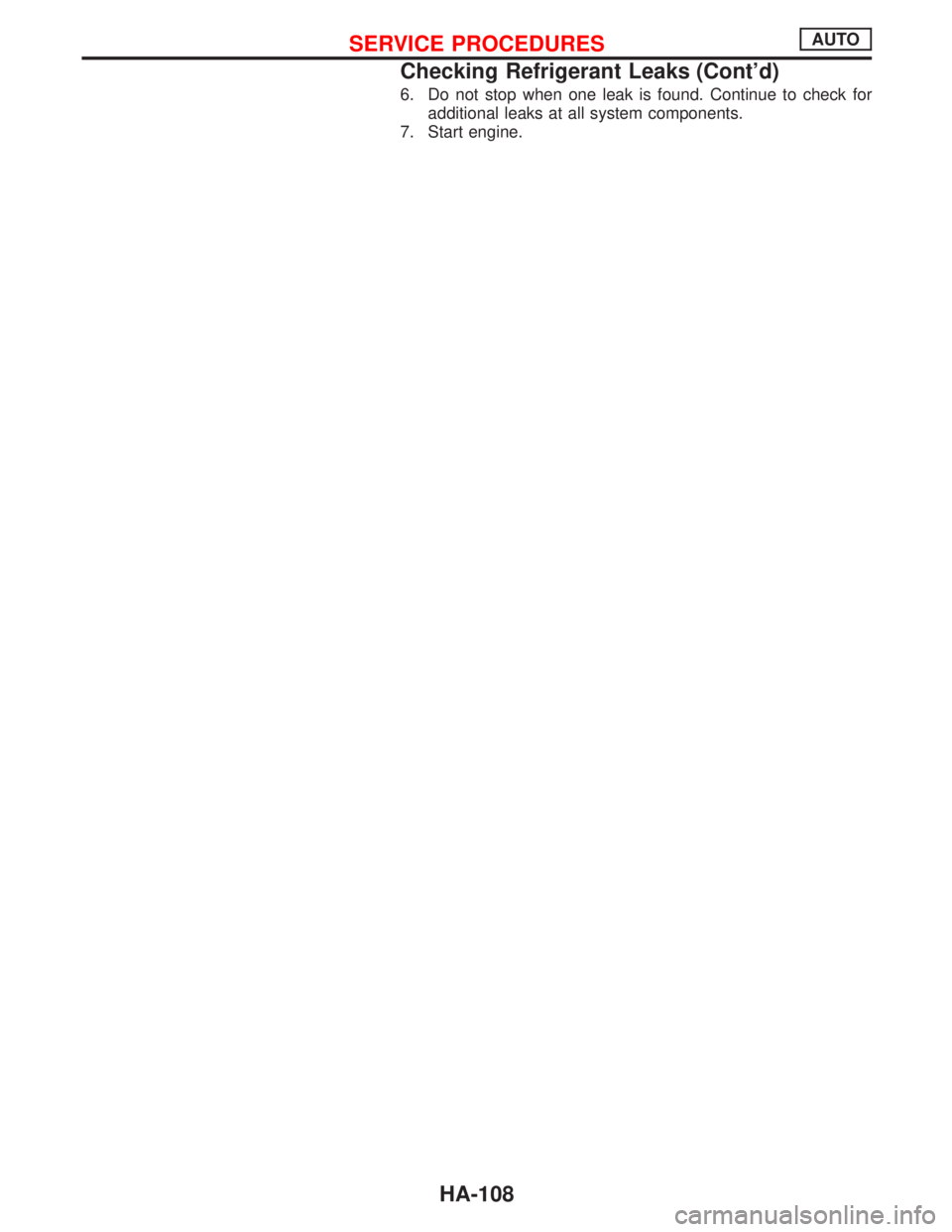

Refrigerant leaks should be checked immediately after stop-

ping the engine. Begin with the leak detector on the high

pressure line. The pressure in the high pressure line will

gradually drop after refrigerant circulation stops and pres-

sure in the low pressure line will gradually rise, as shown in

the graph. Leaks are more easily detected when pressure is

high.

4. Conduct the leak test from the high side to the low side at

points

pAthroughpH. Refer to HA-104, LHD models);pA

throughpG(Refer to HA-105, RHD models).

Perform a leak check for the following areas carefully. Clean

the component to be checked and move the leak detector

probe completely around the connection/component.

lCompressor

Check the fitting of high and low pressure hoses, relief valve

and shaft seal.

lLiquid tank

Check the pressure switch, tube fitting and the fusible plug

mounts.

lService valves

Check all around the service valves. Ensure service valve

caps are secured on the service valves (to prevent leaks).

lCooling unit (Evaporator)

Turn blower fan on ªHighº for at least 15 seconds to dissipate

any refrigerant trace in the cooling unit. Insert the leak detec-

tor probe into the drain hose immediately after stopping the

engine. (Keep the probe inserted for at least ten seconds.)

5. If a leak detector detects a leak, verify at least once by

blowing compressed air into area of suspected leak, then

repeat check.

SHA708E

RHA604B Pressure in high

pressure line

Pressure in low

pressure line

Time

Compressor stops

Pressure

SERVICE PROCEDURESAUTO

Checking Refrigerant Leaks (Cont'd)

HA-107

Page 1957 of 2267

6. Do not stop when one leak is found. Continue to check for

additional leaks at all system components.

7. Start engine.

SERVICE PROCEDURESAUTO

Checking Refrigerant Leaks (Cont'd)

HA-108

Page 1967 of 2267

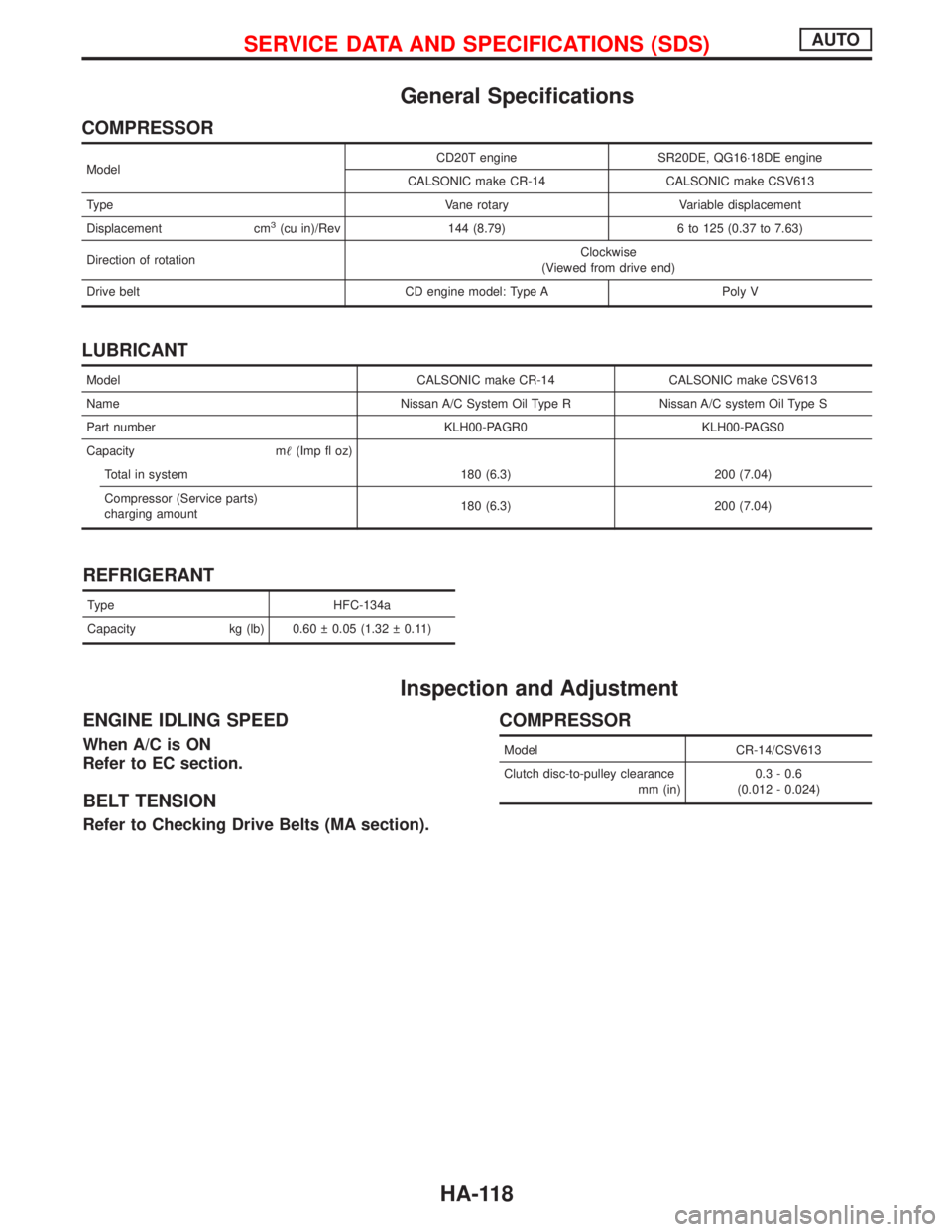

General Specifications

COMPRESSOR

ModelCD20T engine SR20DE, QG16×18DE engine

CALSONIC make CR-14 CALSONIC make CSV613

Type Vane rotary Variable displacement

Displacement cm

3(cu in)/Rev 144 (8.79) 6 to 125 (0.37 to 7.63)

Direction of rotationClockwise

(Viewed from drive end)

Drive belt CD engine model: Type A Poly V

LUBRICANT

Model CALSONIC make CR-14 CALSONIC make CSV613

Name Nissan A/C System Oil Type R Nissan A/C system Oil Type S

Part number KLH00-PAGR0 KLH00-PAGS0

Capacity m(Imp fl oz)

Total in system 180 (6.3) 200 (7.04)

Compressor (Service parts)

charging amount180 (6.3) 200 (7.04)

REFRIGERANT

Type HFC-134a

Capacity kg (lb) 0.60 0.05 (1.32 0.11)

Inspection and Adjustment

ENGINE IDLING SPEED

When A/C is ON

Refer to EC section.

BELT TENSION

Refer to Checking Drive Belts (MA section).

COMPRESSOR

Model CR-14/CSV613

Clutch disc-to-pulley clearance

mm (in)0.3 - 0.6

(0.012 - 0.024)

SERVICE DATA AND SPECIFICATIONS (SDS)AUTO

HA-118

Page 1971 of 2267

Evaporative emission (EVAP)

system ...............................EC-QG-25, EC-SR-27

Exhaust gas recirculation (EGR)

valve...........................................EC-QG-244, 305

Exhaust system ................................................FE-9

Exhaust system inspection ............................MA-48

Exterior ............................................................BT-31

F

FCUT - Wiring diagram ..........................EC-CD-101

F/FOG - Wiring diagram................................EL-110

Final drive (FF M/T) ...........................MT-32, 51, 71

Floor trim .........................................................BT-18

Fluid temperature sensor (A/T) .......................AT-94

Fluids..............................................................MA-16

Flywheel (clutch) .............................................CL-14

Flywheel runout..............................EM-60, 117, 177

Fog lamp, front ..............................................EL-110

Fog lamp, rear ...............................................EL-112

F/PUMP - Wiring

diagram..........................EC-QG-338, EC-SR-317

Freeze frame data ................EC-QG-38, EC-SR-50

Fresh vent door control linkage

adjustment ..................................................HA-83

FRO2 - Wiring diagram ........EC-QG-135, 154, 162,

EC-SR-147, 165, 172

FRO2/H - Wiring

diagram..........................EC-QG-168, EC-SR-177

Front axle ..........................................................FA-9

Front bumper ....................................................BT-5

Front disc brake .............................................BR-23

Front door .......................................................BT-13

Front fog lamp .......................................EL-110, 111

Front fog lamp removal and installation ...........BT-5

Front heated oxygen sensor

(HO2S) ......................................EC-QG-132, 139,

EC-SR-144, 150, 156, 162, 170

Front heated oxygen sensor (HO2S)

heater ............................EC-QG-166, EC-SR-175

Front passenger air bag .................................RS-17

Front seat ........................................................BT-40

Front seat belt ..................................................RS-3

Front suspension ............................................FA-26

Front washer .................................................EL-186

Front wiper ....................................................EL-186

FTS - Wiring diagram ............................EC-CD-105

FUEL - Wiring

diagram .........EC-QG-210, 217, EC-SR-213, 220

Fuel cut control (at no load & high

engine speed)....................EC-QG-25, EC-SR-27

Fuel cut solenoid valve ..........................EC-CD-100

Fuel filter ...............................EC-QG-29, EC-SR-31

Fuel filter replacement .......................MA-23, 33, 43

Fuel gauge ............................................EL-141, 146

Fuel injection system....................EC-QG-208, 215,

EC-SR-212, 218,

EC-CD-15, 18

Fuel injector ......................EC-QG-318, EC-SR-302

Fuel line inspection............................MA-22, 33, 43Fuel precautions ................................................GI-7

Fuel pressure check .............EC-QG-29, EC-SR-31

Fuel pressure regulator .........EC-QG-30, EC-SR-32

Fuel pressure release ...........EC-QG-29, EC-SR-31

Fuel pump .........................EC-QG-336, EC-SR-316

Fuel pump and gauge ......................................FE-7

Fuel pump relay ................EC-QG-336, EC-SR-316

Fuel system ......................................................FE-6

Fuel tank vacuum relief

valve ..................................EC-QG-26, EC-SR-28

Fuel temperature sensor .................EC-CD-17, 104

Fuse ..................................................EL-22, Foldout

Fuse block ....................................................Foldout

Fusible link ........................................EL-22, Foldout

G

Garage jack and safety stand .........................GI-47

Gauges..........................................................EL-138

Gear components (M/T) ...........................MT-16, 49

Generic scan tool (GST) .......EC-QG-66, EC-SR-78

GLOW - Wiring diagram ........................EC-CD-120

Glow plug .........................................EC-CD-15, 118

Glow relay ................................................EC-CD-15

GOVNR - Wiring diagram ........................EC-CD-79

Grille - See Exterior ........................................BT-38

Ground distribution..........................................EL-23

H

H/AIM - Wiring diagram ....................EL-87, 93, 200

Harness connector ............................................EL-6

Harness layout ..............................................EL-368

Hazard warning lamp ....................................EL-117

Headlamp..................................................EL-67, 69

Headlamp aiming control ................................EL-87

Headlamp washer .........................................EL-200

Headlining - See Roof trim .............................BT-25

Heated oxygen sensor (HO2S)

(front) ........................................EC-QG-132, 139,

EC-SR-144, 150, 156, 162, 170

Heated oxygen sensor (HO2S) heater

(front) .............................EC-QG-166, EC-SR-175

Heated oxygen sensor (HO2S) heater

(rear) ..............................EC-QG-203, EC-SR-207

Heated oxygen sensor (rear) ...............EC-QG-171,

EC-SR-180, 187,

194, 201

Heated oxygen sensor inspection ...........MA-27, 38

Heated seat .......................................BT-42, EL-234

HEATER - Wiring diagram .............................HA-40

HFC134a (R134a) system service

procedure ..................................................HA-100

HFC134a (R134a) system service tools ..........HA-8

H/LAMP - Wiring diagram ...............................EL-67

Hood..................................................................BT-5

Horn ..............................................................EL-203

HORN - Wiring diagram ................................EL-203

ALPHABETICAL INDEX

IDX-4

Page 1973 of 2267

O

Oil cooler (engine) ....................................LC-20, 30

Oil pan (engine) ...............................EM-17, 70, 129

Oil pressure (engine)............................LC-5, 16, 27

Oil pump (engine).................................LC-5, 17, 27

Oil pump regulator valve (engine) ....................LC-7

Oil seal replacement

(engine) ................................EM-29, 84, 138, 139

On board diagnostic

system ...............................EC-QG-36, EC-SR-48

Operational check (cool box) .........................HA-24

P

Park/Neutral position

switch.............................EC-QG-313, EC-SR-298

Park/neutral position switch (A/T) ...................AT-48

Parking brake control .....................................BR-48

Parking lamp .................................................EL-100

PCV (positive crankcase

ventilation) .........................EC-QG-28, EC-SR-30

PCV system inspection............................MA-26, 36

Periodic maintenance (for Europe) ..................MA-6

PGC/V - Wiring diagram ...EC-QG-264, EC-SR-252

PHASE - Wiring diagram .......................EC-QG-240

Pilot bushing replacement - See Pilot

converter ...................................................EM-117

Piston assembly..............EM-53, 60, 110, 117, 167,

175, 176, 185, 193, 199

Piston pin inspection.............EM-54, 110, 168, 171,

185, 193, 199

Piston ring inspection ....................EM-54, 111, 168,

185, 193, 199

Piston to bore clearance........................EM-56, 174

PNP/SW - Wiring

diagram..........................EC-QG-315, EC-SR-300

POWER - Wiring diagram...............................EL-12

Power door lock ....................................EL-245, 265

Power door mirror .........................................EL-231

Power seat ....................................................EL-233

Power steering fluid level...............................MA-53

Power steering oil pressure

switch.............................EC-QG-342, EC-SR-321

Power supply routing ......................................EL-10

Power transistor......................................EC-SR-311

Power transistor & ignition coil ..............EC-SR-306

Power window ...............................................EL-236

Pre-delivery inspection.....................................MA-4

Precautions (General) .......................................GI-4

Pressure test (A/T) ..........................................AT-35

PST/SW - Wiring

diagram..........................EC-QG-343, EC-SR-322

R

Radiator ..........................................LC-9, 13, 25, 36Rear axle (disc brake type) ..............................RA-5

Rear bumper ...........................................BT-7, 9, 11

Rear combination lamp removal and

installation ...................................................BT-37

Rear disc brake ........................................BR-33, 40

Rear door ........................................................BT-14

Rear drum brake ............................................BR-44

Rear fog lamp................................................EL-112

Rear heated oxygen sensor

(HO2S) ..EC-QG-171, EC-SR-180, 187, 194, 201

Rear heated oxygen sensor (HO2S)

heater ............................EC-QG-203, EC-SR-207

Rear seat ........................................................BT-43

Rear seat belt ...................................................RS-4

Rear suspension ..............................................RA-4

Rear washer..................................................EL-193

Rear window ...................................................BT-53

Rear window defogger ..................................EL-207

Rear wiper.....................................................EL-193

Refrigerant connection precaution ...................HA-4

Refrigerant general precaution.........................HA-4

Refrigerant lines ...........................................HA-104

Refrigerant pressure

sensor....................EC-QG-299, 347, EC-SR-289

Refrigeration cycle..........................................HA-12

Removal and installation (A/T) ......................AT-116

Revolution sensor (A/T) ............................AT-61, 65

R/FOG - Wiring diagram ...............................EL-112

Roof trim .........................................................BT-25

RRO2 - Wiring

diagram.....................EC-QG-174, 183, 191, 199,

EC-SR-183, 190, 197, 203

RRO2/H - Wiring

diagram..........................EC-QG-205, EC-SR-209

S

SAE J1930 terminology list .............................GI-51

Seal - See Exterior .........................................BT-31

SEAT - Wiring diagram .................................EL-233

Seat belt inspection .......................................MA-54

Seat belt pre-tensioner ...................................RS-13

Seat belt pre-tensioner disposal ....................RS-27

Seat, front .......................................................BT-40

Self-diagnostic results ...........EC-QG-46, EC-SR-59

Shift control components (M/T) .........MT-17, 50, 74

Shock absorber (rear).....................................RA-11

Side air bag ....................................................RS-19

Side trim ..........................................................BT-18

Side window - See Rear side window ............BT-55

S/LOCK - Wiring diagram .....................EL-248, 270

Spark plug replacement...........................MA-25, 35

Speedometer ........................................EL-141, 146

Spiral cable.....................................................RS-14

Spot lamp..............................................EL-130, 131

SROOF - Wiring diagram .............................EL-230

SRS - See Supplemental Restraint

System ..........................................................RS-8

SRS - Wiring diagram ....................................RS-33

ALPHABETICAL INDEX

IDX-6

Page 1976 of 2267

ENGINE LUBRICATION &

COOLING SYSTEMS

SECTION

LC

CONTENTS

PRECAUTION..................................................................2

PREPARATION................................................................3

Special Service Tools ..................................................3

QG

ENGINE LUBRICATION SYSTEM..................................4

Lubrication Circuit ........................................................4

Oil Pressure Check......................................................5

Oil Pump ......................................................................5

Oil Filter .......................................................................7

ENGINE COOLING SYSTEM..........................................8

Cooling Circuit .............................................................8

System Check..............................................................8

Water Pump ...............................................................10

Thermostat ................................................................. 11

Radiator .....................................................................13

SR20DE

ENGINE LUBRICATION SYSTEM................................15

Lubrication Circuit ......................................................15

Oil Pressure Check....................................................16

Oil Pump ....................................................................17

Oil Filter .....................................................................19

Oil Cooler ...................................................................20

ENGINE COOLING SYSTEM........................................21

Cooling Circuit ...........................................................21

System Check............................................................21

Cooling System Inspection ........................................21

Water Pump ...............................................................22

Thermostat .................................................................23

Radiator .....................................................................25

CD20T

ENGINE LUBRICATION SYSTEM................................26

Lubrication Circuit ......................................................26Oil Pressure Check....................................................27

Oil Pump ....................................................................27

Oil Cooler ...................................................................30

ENGINE COOLING SYSTEM........................................31

Cooling Circuit ...........................................................31

System Check............................................................32

Water Pump ...............................................................33

Thermostat .................................................................34

Radiator .....................................................................36

Overheating Cause Analysis .....................................37

QG

SERVICE DATA AND SPECIFICATIONS (SDS)..........39

Oil Pressure Check....................................................39

Oil Pump Inspection ..................................................39

Regulator Valve Inspection ........................................39

Thermostat .................................................................39

Radiator .....................................................................39

SR20DE

Oil Pressure Check....................................................40

Oil Pump Inspection ..................................................40

Regulator Valve Inspection ........................................40

Thermostat .................................................................40

Radiator .....................................................................40

CD20T

Oil Pressure Check....................................................41

Oil Pump Inspection ..................................................41

Thermostat .................................................................41

Radiator .....................................................................41

LC