Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

NCEC0002The Supplemental Restraint System ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº, used along with a seat

belt, help to reduce the risk or severity of injury to the driver and front passenger in a frontal collision. The

Supplemental Restraint System consists of air bag modules (located in the center of the steering wheel and

on the instrument panel on the passenger side), seat belt pre-tensioners, a diagnosis sensor unit, warning

lamp, wiring harness and spiral cable.

In addition to the supplemental air bag modules for a frontal collision, the supplemental side air bag used along

with the seat belt helps to reduce the risk or severity of injury to the driver and front passenger in a side col-

lision. The supplemental side air bag consists of air bag modules (located in the outer side of front seats),

satellite sensor, diagnosis sensor unit (one of components of supplemental air bags for a frontal collision),

wiring harness, warning lamp (one of components of supplemental air bags for a frontal collision). Information

necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

ITo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be performed

by an authorized NISSAN dealer.

IImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system.

IDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses (except ªSEAT BELT PRE-TENSIONERº connector) can be

identified with yellow harness connector (and with yellow harness protector or yellow insulation

tape before the harness connectors).

Precautions for On Board Diagnostic (OBD)

System of Engine

NCEC0003The ECM has an on board diagnostic system. It will light up the malfunction indicator (MI) to warn the driver

of a malfunction causing emission deterioration.

CAUTION:

IBe sure to turn the ignition switch ªOFFº and disconnect the negative battery terminal before any

repair or inspection work. The open/short circuit of related switches, sensors, solenoid valves, etc.

will cause the MI to light up.

IBe sure to connect and lock the connectors securely after work. A loose (unlocked) connector will

cause the MI to light up due to the open circuit. (Be sure the connector is free from water, grease,

dirt, bent terminals, etc.)

ICertain systems and components, especially those related to OBD, may use a new style slide-

locking type harness connector.

For description and how to disconnect, refer to EL section, ªDescriptionº, ªHARNESS CONNEC-

TORº.

IBe sure to route and secure the harnesses properly after work. The interference of the harness with

a bracket, etc. may cause the MI to light up due to the short circuit.

IBe sure to connect rubber tubes properly after work. A misconnected or disconnected rubber tube

may cause the MI to light up due to the malfunction of the EGR system or fuel injection system,

etc.

IBe sure to erase the unnecessary malfunction information (repairs completed) from the ECM before

returning the vehicle to the customer.

PRECAUTIONSQG16I18DE

Supplemental Restraint System (SRS) ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº

EC-9

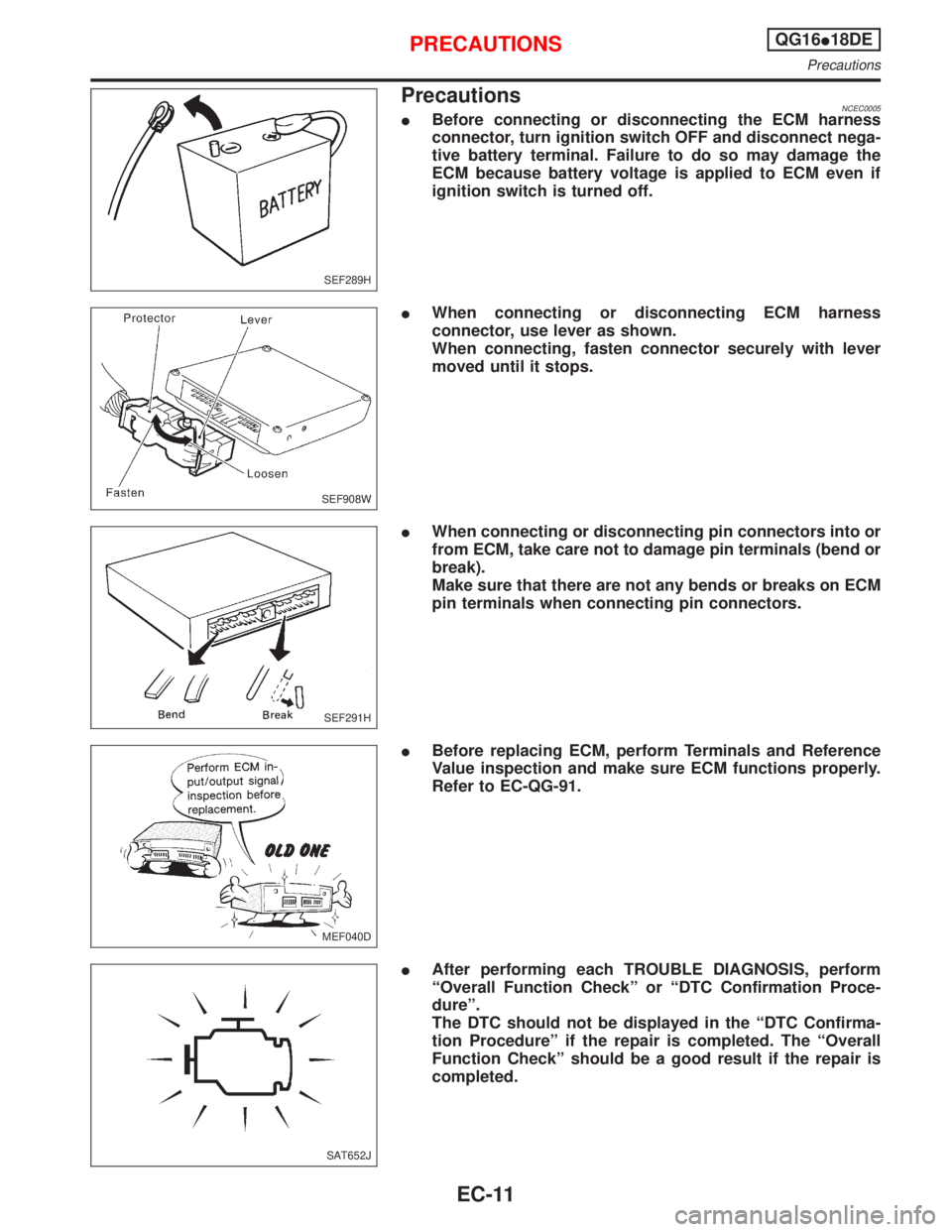

PrecautionsNCEC0005IBefore connecting or disconnecting the ECM harness

connector, turn ignition switch OFF and disconnect nega-

tive battery terminal. Failure to do so may damage the

ECM because battery voltage is applied to ECM even if

ignition switch is turned off.

IWhen connecting or disconnecting ECM harness

connector, use lever as shown.

When connecting, fasten connector securely with lever

moved until it stops.

IWhen connecting or disconnecting pin connectors into or

from ECM, take care not to damage pin terminals (bend or

break).

Make sure that there are not any bends or breaks on ECM

pin terminals when connecting pin connectors.

IBefore replacing ECM, perform Terminals and Reference

Value inspection and make sure ECM functions properly.

Refer to EC-QG-91.

IAfter performing each TROUBLE DIAGNOSIS, perform

ªOverall Function Checkº or ªDTC Confirmation Proce-

dureº.

The DTC should not be displayed in the ªDTC Confirma-

tion Procedureº if the repair is completed. The ªOverall

Function Checkº should be a good result if the repair is

completed.

SEF289H

SEF908W

SEF291H

MEF040D

SAT652J

PRECAUTIONSQG16I18DE

Precautions

EC-11

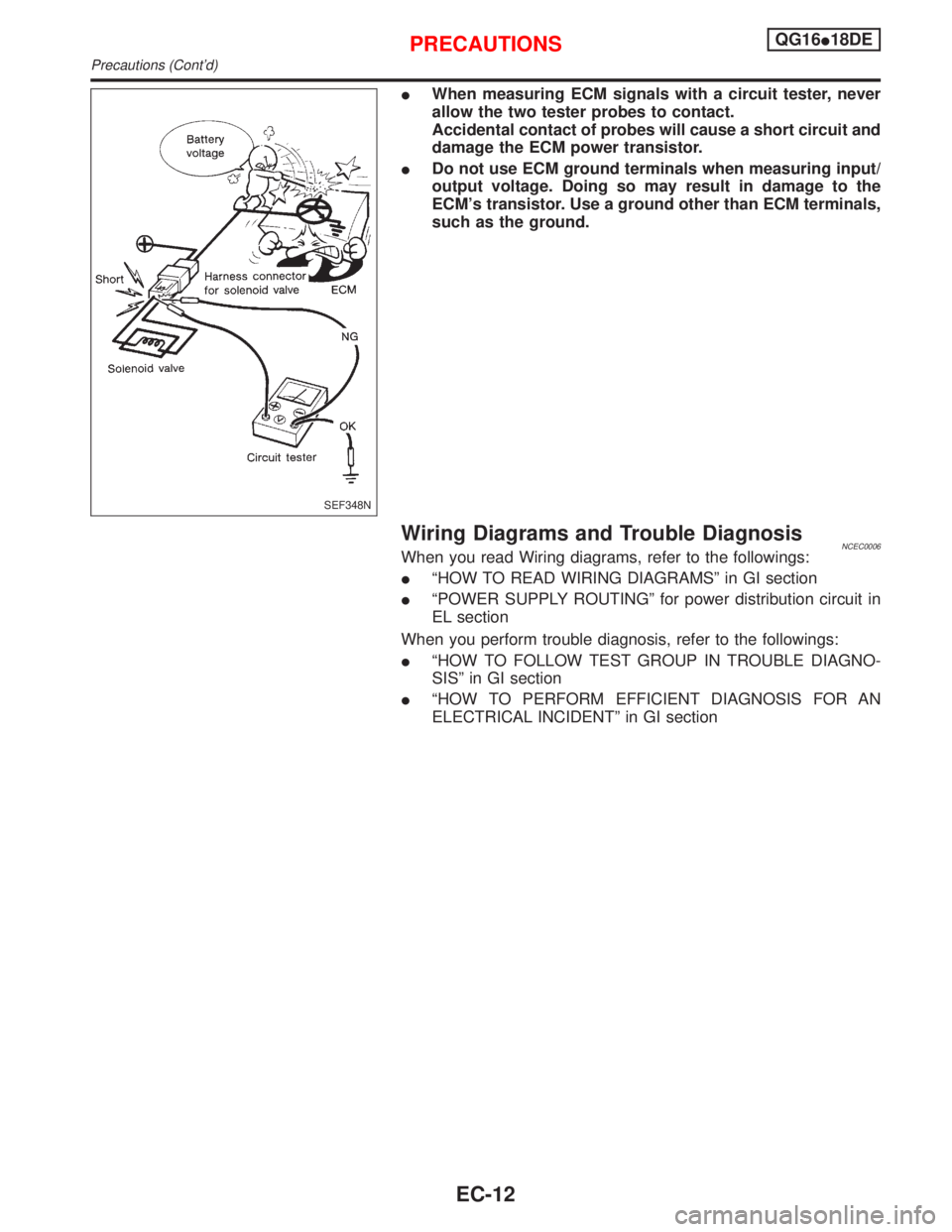

IWhen measuring ECM signals with a circuit tester, never

allow the two tester probes to contact.

Accidental contact of probes will cause a short circuit and

damage the ECM power transistor.

IDo not use ECM ground terminals when measuring input/

output voltage. Doing so may result in damage to the

ECM's transistor. Use a ground other than ECM terminals,

such as the ground.

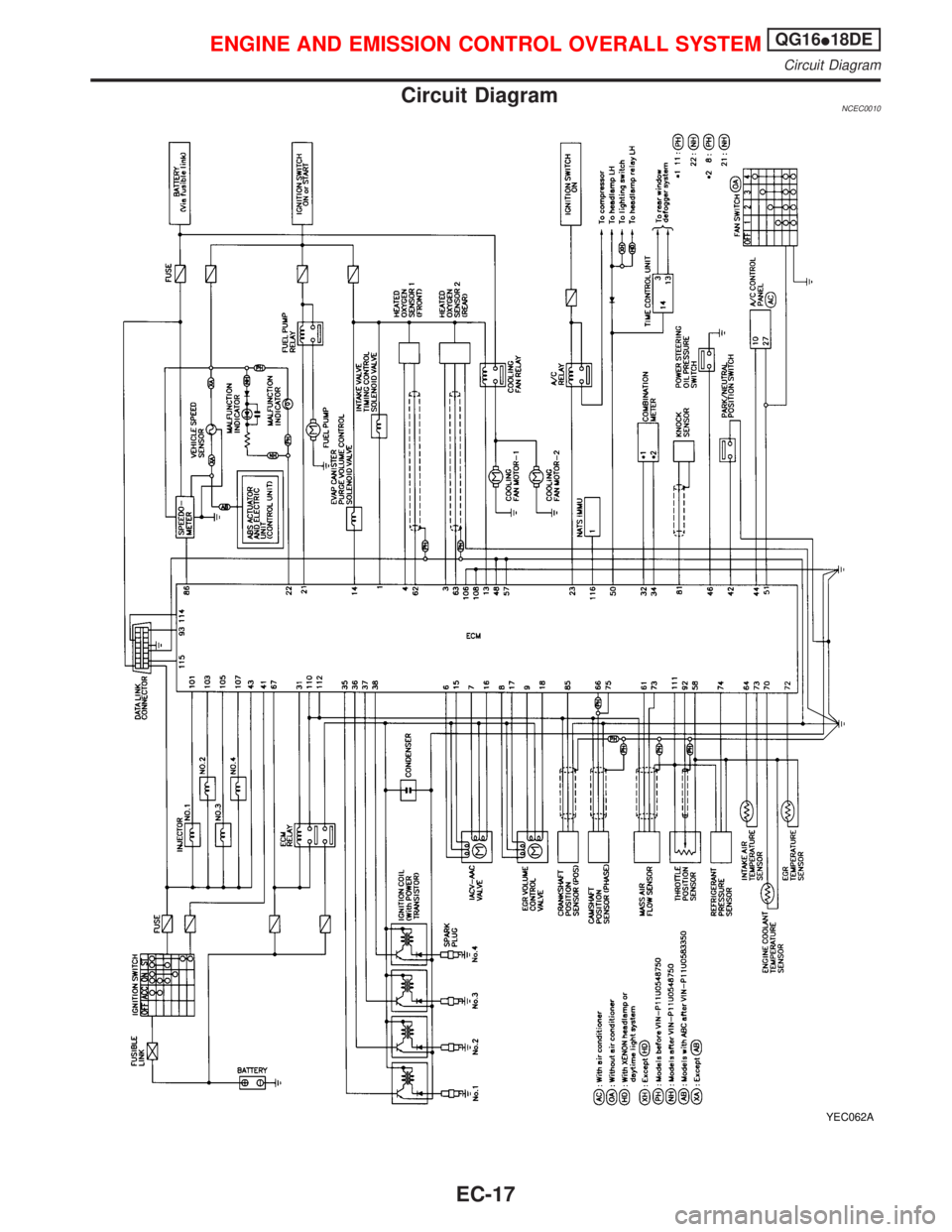

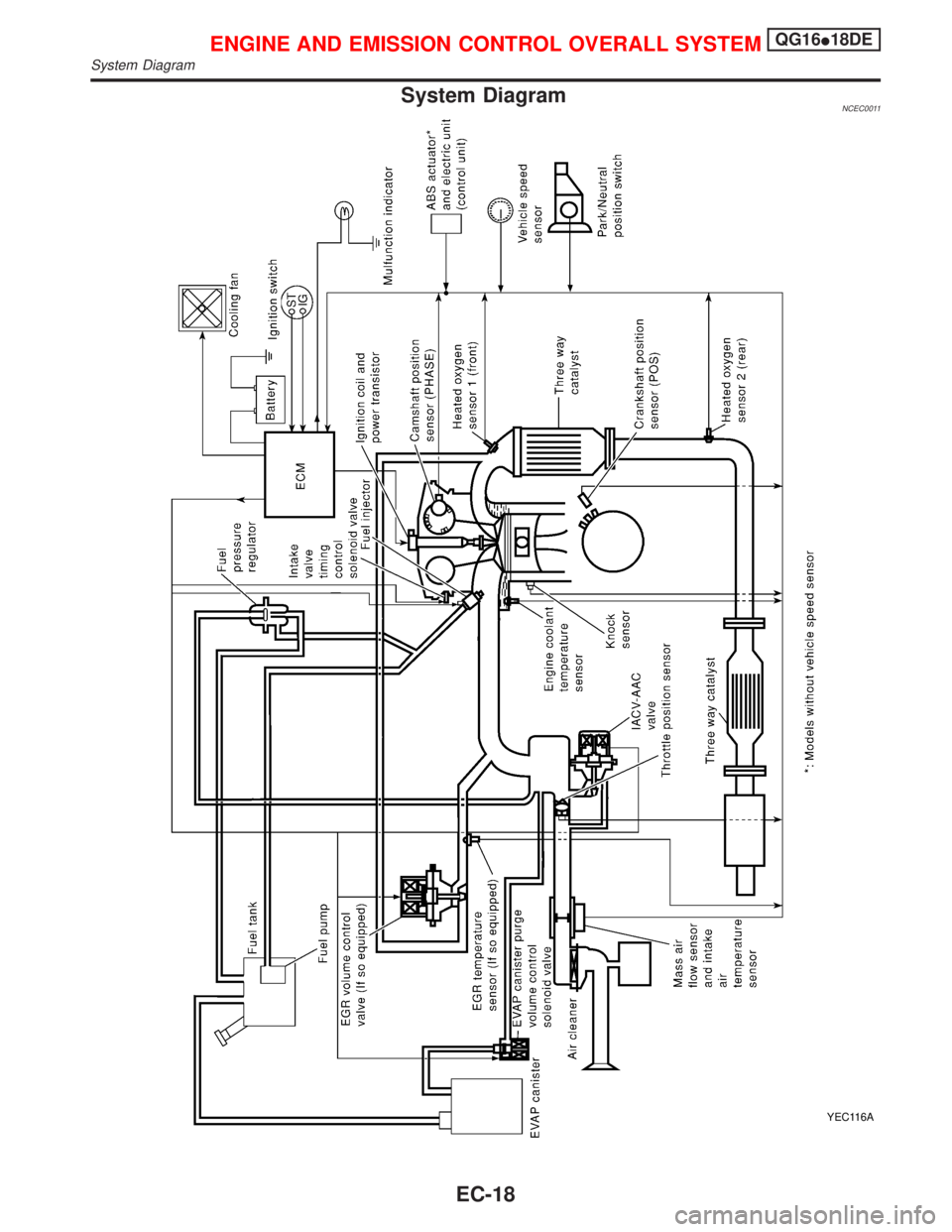

Wiring Diagrams and Trouble DiagnosisNCEC0006When you read Wiring diagrams, refer to the followings:

IªHOW TO READ WIRING DIAGRAMSº in GI section

IªPOWER SUPPLY ROUTINGº for power distribution circuit in

EL section

When you perform trouble diagnosis, refer to the followings:

IªHOW TO FOLLOW TEST GROUP IN TROUBLE DIAGNO-

SISº in GI section

IªHOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN

ELECTRICAL INCIDENTº in GI section

SEF348N

PRECAUTIONSQG16I18DE

Precautions (Cont'd)

EC-12

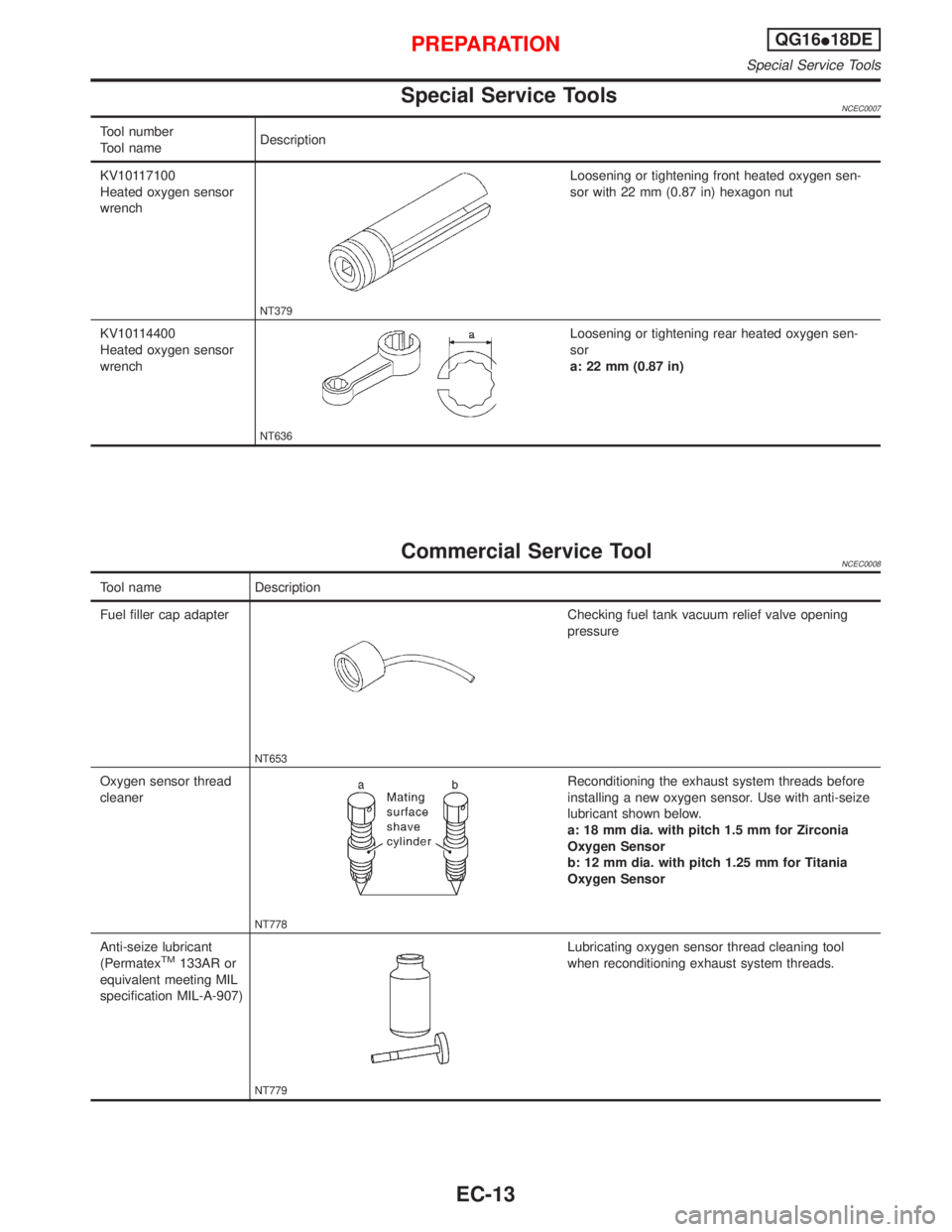

Special Service ToolsNCEC0007

Tool number

Tool nameDescription

KV10117100

Heated oxygen sensor

wrench

NT379

Loosening or tightening front heated oxygen sen-

sor with 22 mm (0.87 in) hexagon nut

KV10114400

Heated oxygen sensor

wrench

NT636

Loosening or tightening rear heated oxygen sen-

sor

a: 22 mm (0.87 in)

Commercial Service ToolNCEC0008

Tool name Description

Fuel filler cap adapter

NT653

Checking fuel tank vacuum relief valve opening

pressure

Oxygen sensor thread

cleaner

NT778

Reconditioning the exhaust system threads before

installing a new oxygen sensor. Use with anti-seize

lubricant shown below.

a: 18 mm dia. with pitch 1.5 mm for Zirconia

Oxygen Sensor

b: 12 mm dia. with pitch 1.25 mm for Titania

Oxygen Sensor

Anti-seize lubricant

(Permatex

TM133AR or

equivalent meeting MIL

specification MIL-A-907)

NT779

Lubricating oxygen sensor thread cleaning tool

when reconditioning exhaust system threads.

PREPARATIONQG16I18DE

Special Service Tools

EC-13