NISSAN PRIMERA 1999 Electronic Workshop Manual

Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 51 of 2267

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION

PROCEDURE

NCAT0032S03CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCE-

DUREº has been previously conducted, always turn ignition

switch ªOFFº and wait at least 5 seconds before conducting

the next test.

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

With CONSULT-II

1) Turn ignition switch ªONº and select ªDATA MONITORº mode

for ªCVTº with CONSULT-II.

2) Make sure that output voltage of CVT fluid temperature sne-

sor is within the range below.

FLUID TEMP SEN: 0.5 - 1.5V

If out of range, drive the vehicle to decrease the voltage

(warm up the fluid) or stop engine to increase the voltage

(cool down the fluid)

3) Select ªDATA MONITORº mode for ªENGINEº with CONSULT-

II.

4) Start engine and maintain the following conditions for at least

15 consecutive seconds.

VHCL SPEED SE: 10 km/h (6 MPH) or more

THRTL POS SEN: More than 1.3V

Selector lever: D position

ENG SPEED: 450 rpm or more

If the check result is ªNGº, go to ªDiagnostic Procedureº,

AT-51.

With GST

Follow the procedure ªWith CONSULT-IIº.

SAT651J

SAT654J

DTC P0705 PARK/NEUTRAL POSITION (PNP) SWITCH

Description (Cont'd)

AT-49

Page 52 of 2267

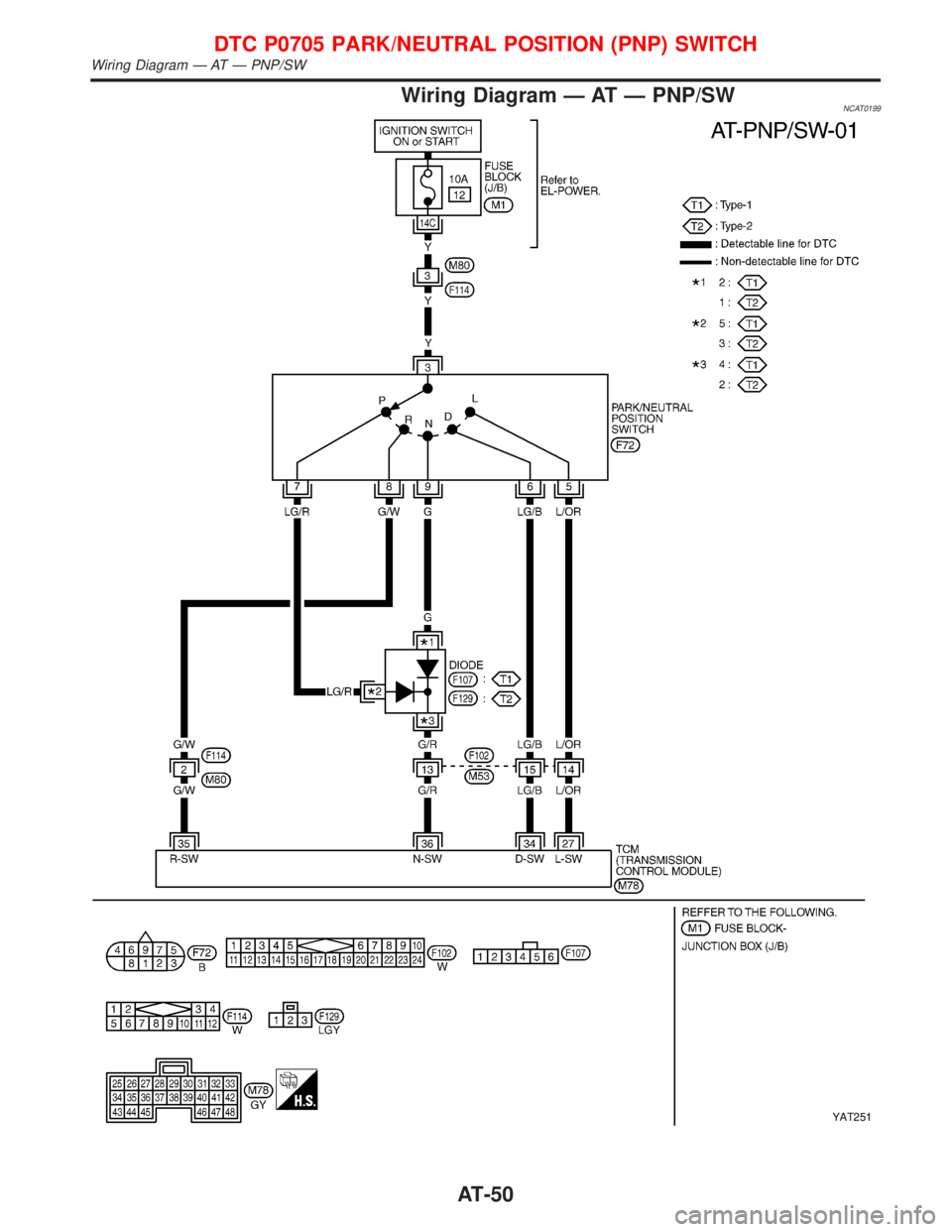

Wiring Diagram Ð AT Ð PNP/SWNCAT0199

YAT251

DTC P0705 PARK/NEUTRAL POSITION (PNP) SWITCH

Wiring Diagram Ð AT Ð PNP/SW

AT-50

Page 53 of 2267

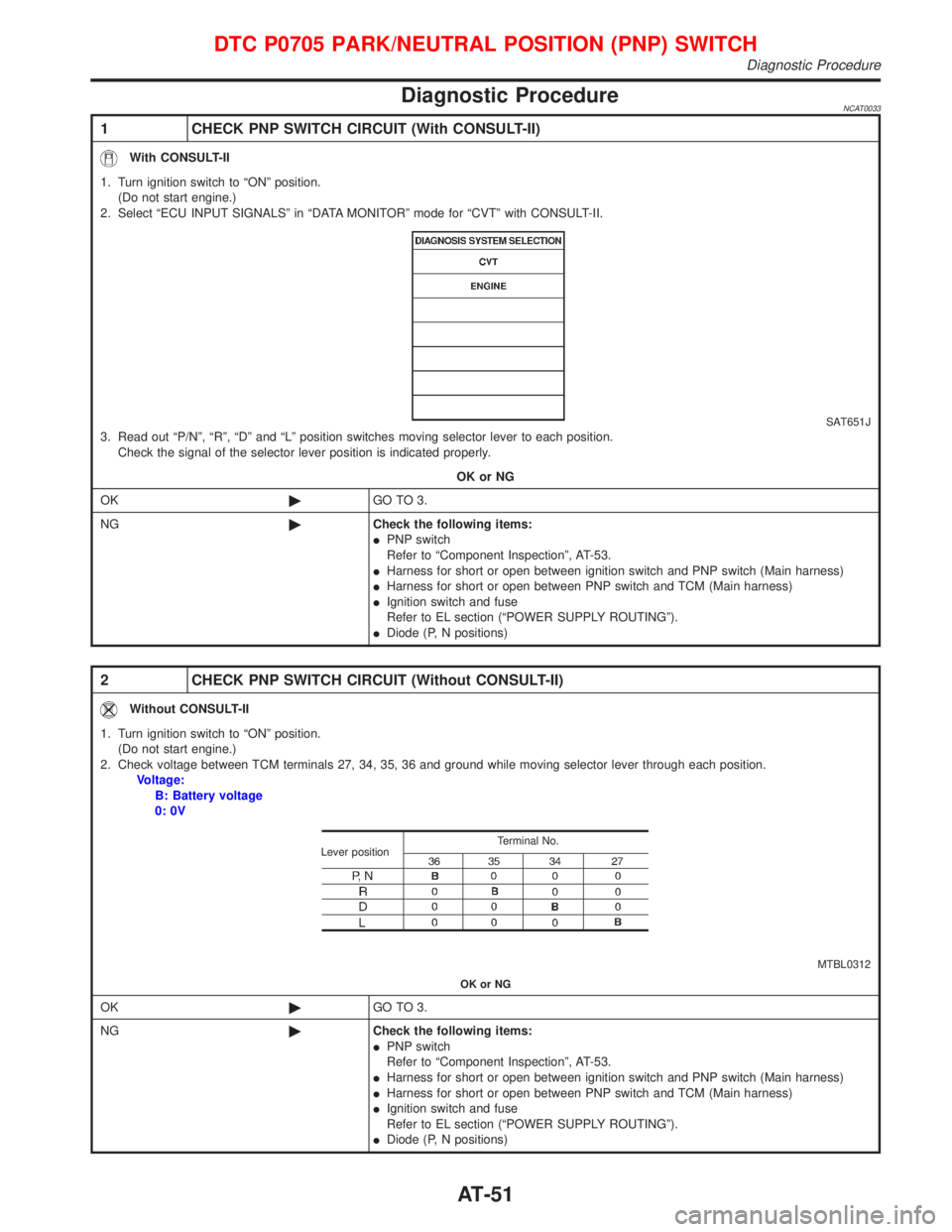

Diagnostic ProcedureNCAT0033

1 CHECK PNP SWITCH CIRCUIT (With CONSULT-II)

With CONSULT-II

1. Turn ignition switch to ªONº position.

(Do not start engine.)

2. Select ªECU INPUT SIGNALSº in ªDATA MONITORº mode for ªCVTº with CONSULT-II.

SAT651J3. Read out ªP/Nº, ªRº, ªDº and ªLº position switches moving selector lever to each position.

Check the signal of the selector lever position is indicated properly.

OK or NG

OK©GO TO 3.

NG©Check the following items:

IPNP switch

Refer to ªComponent Inspectionº, AT-53.

IHarness for short or open between ignition switch and PNP switch (Main harness)

IHarness for short or open between PNP switch and TCM (Main harness)

IIgnition switch and fuse

Refer to EL section (ªPOWER SUPPLY ROUTINGº).

IDiode (P, N positions)

2 CHECK PNP SWITCH CIRCUIT (Without CONSULT-II)

Without CONSULT-II

1. Turn ignition switch to ªONº position.

(Do not start engine.)

2. Check voltage between TCM terminals 27, 34, 35, 36 and ground while moving selector lever through each position.

Voltage:

B: Battery voltage

0: 0V

MTBL0312 Terminal No.

Lever position

OK or NG

OK©GO TO 3.

NG©Check the following items:

IPNP switch

Refer to ªComponent Inspectionº, AT-53.

IHarness for short or open between ignition switch and PNP switch (Main harness)

IHarness for short or open between PNP switch and TCM (Main harness)

IIgnition switch and fuse

Refer to EL section (ªPOWER SUPPLY ROUTINGº).

IDiode (P, N positions)

DTC P0705 PARK/NEUTRAL POSITION (PNP) SWITCH

Diagnostic Procedure

AT-51

Page 54 of 2267

3 CHECK DTC

Perform Diagnostic Trouble Code (DTC) confirmation procedure, AT-49.

OK or NG

OK©INSPECTION END

NG©1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose connection with harness con-

nector.

DTC P0705 PARK/NEUTRAL POSITION (PNP) SWITCH

Diagnostic Procedure (Cont'd)

AT-52

Page 55 of 2267

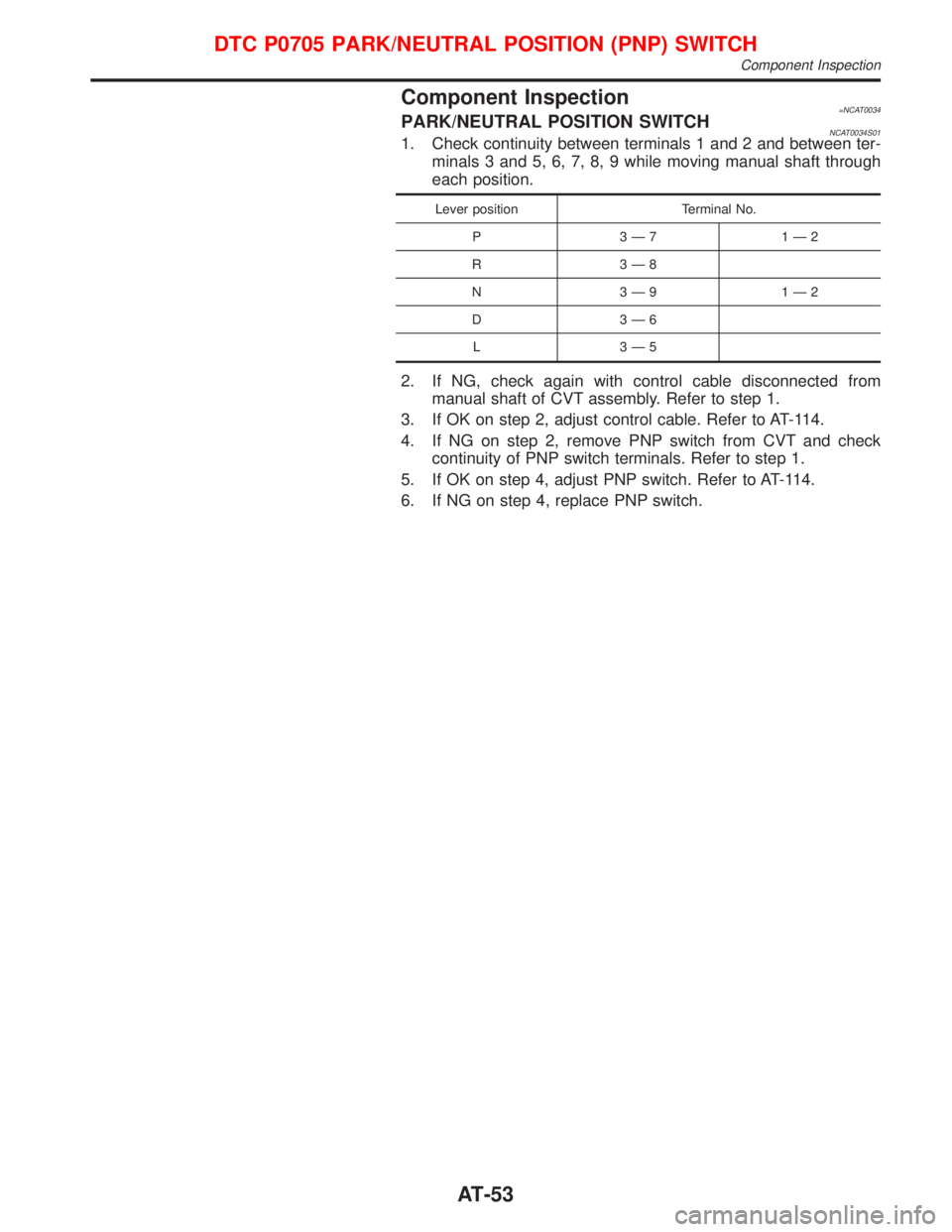

Component Inspection=NCAT0034PARK/NEUTRAL POSITION SWITCHNCAT0034S011. Check continuity between terminals 1 and 2 and between ter-

minals 3 and 5, 6, 7, 8, 9 while moving manual shaft through

each position.

Lever position Terminal No.

P 3Ð7 1Ð2

R 3Ð8

N 3Ð9 1Ð2

D 3Ð6

L 3Ð5

2. If NG, check again with control cable disconnected from

manual shaft of CVT assembly. Refer to step 1.

3. If OK on step 2, adjust control cable. Refer to AT-114.

4. If NG on step 2, remove PNP switch from CVT and check

continuity of PNP switch terminals. Refer to step 1.

5. If OK on step 4, adjust PNP switch. Refer to AT-114.

6. If NG on step 4, replace PNP switch.

DTC P0705 PARK/NEUTRAL POSITION (PNP) SWITCH

Component Inspection

AT-53

Page 56 of 2267

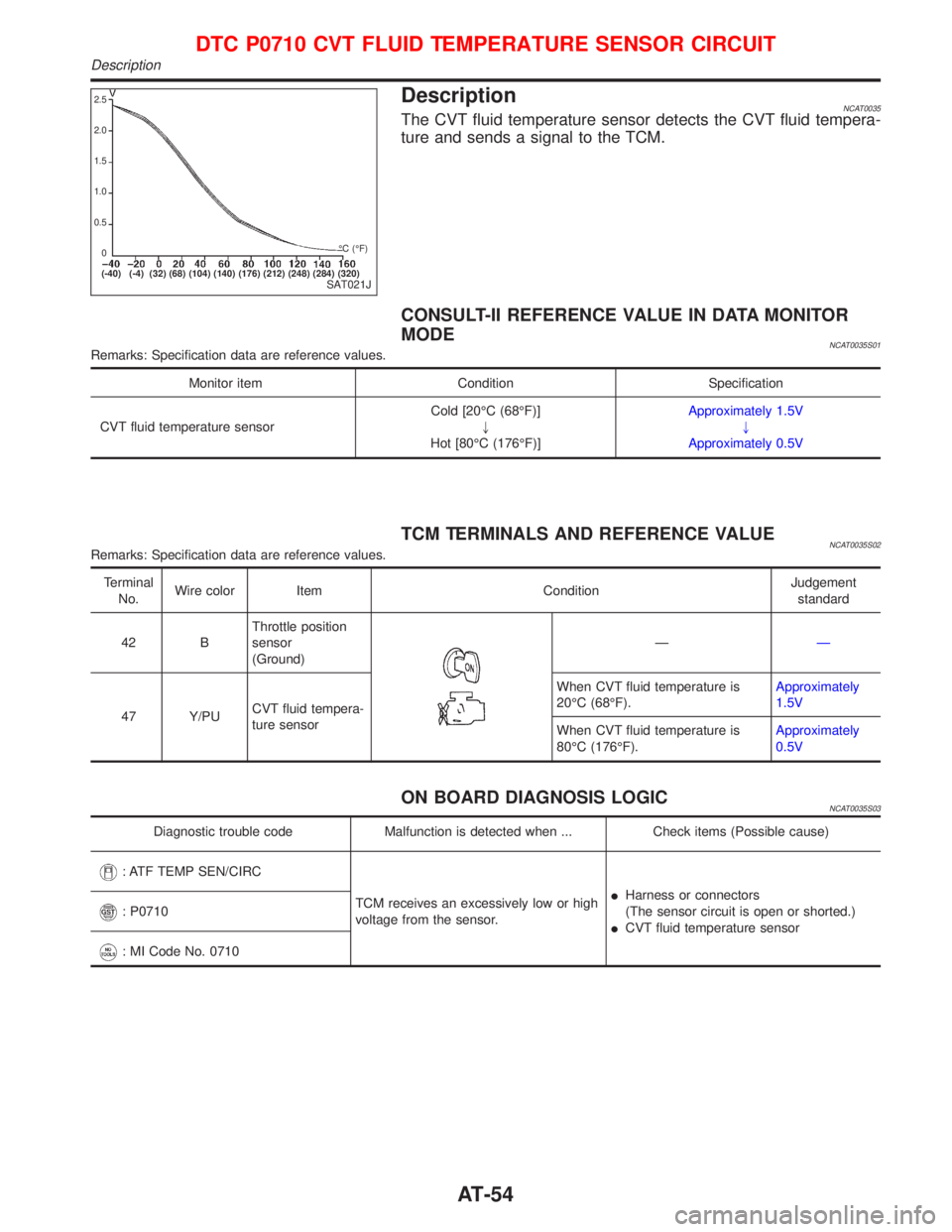

DescriptionNCAT0035The CVT fluid temperature sensor detects the CVT fluid tempera-

ture and sends a signal to the TCM.

CONSULT-II REFERENCE VALUE IN DATA MONITOR

MODE

NCAT0035S01Remarks: Specification data are reference values.

Monitor item Condition Specification

CVT fluid temperature sensorCold [20ÉC (68ÉF)]

"

Hot [80ÉC (176ÉF)]Approximately 1.5V

"

Approximately 0.5V

TCM TERMINALS AND REFERENCE VALUENCAT0035S02Remarks: Specification data are reference values.

Terminal

No.Wire color Item ConditionJudgement

standard

42 BThrottle position

sensor

(Ground)

ÐÐ

47 Y/PUCVT fluid tempera-

ture sensorWhen CVT fluid temperature is

20ÉC (68ÉF).Approximately

1.5V

When CVT fluid temperature is

80ÉC (176ÉF).Approximately

0.5V

ON BOARD DIAGNOSIS LOGICNCAT0035S03

Diagnostic trouble code Malfunction is detected when ... Check items (Possible cause)

: ATF TEMP SEN/CIRC

TCM receives an excessively low or high

voltage from the sensor.IHarness or connectors

(The sensor circuit is open or shorted.)

ICVT fluid temperature sensor

: P0710

: MI Code No. 0710

SAT021J

2.5

2.0

1.5

1.0

0.5

0

(-40) (-4) (32) (68) (104) (140) (176) (212) (248) (284) (320)ÉC (ÉF)

DTC P0710 CVT FLUID TEMPERATURE SENSOR CIRCUIT

Description

AT-54

Page 57 of 2267

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION

PROCEDURE

NCAT0035S04CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCE-

DUREº has been previously conducted, always turn ignition

switch ªOFFº and wait at least 5 seconds before conducting

the next test.

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

With CONSULT-II

1) Turn ignition switch ªONº and select ªDATA MONITORº mode

for ªENGINEº with CONSULT-II.

2) Start engine and maintain the following conditions for at least

10 minutes (Total). (It is not necessary to maintain continu-

ously.)

ENG SPEED: 450 rpm or more

VHCL SPEED SE: 10 km/h (6 MPH) or more

THRTL POS SEN: More than 1.3 V

Selector lever: D position

If the check result is NG, go to ªDiagnostic Procedureº, AT-57.

With GST

Follow the procedure ªWith CONSULT-IIº.

SAT651J

SAT654J

DTC P0710 CVT FLUID TEMPERATURE SENSOR CIRCUIT

Description (Cont'd)

AT-55

Page 58 of 2267

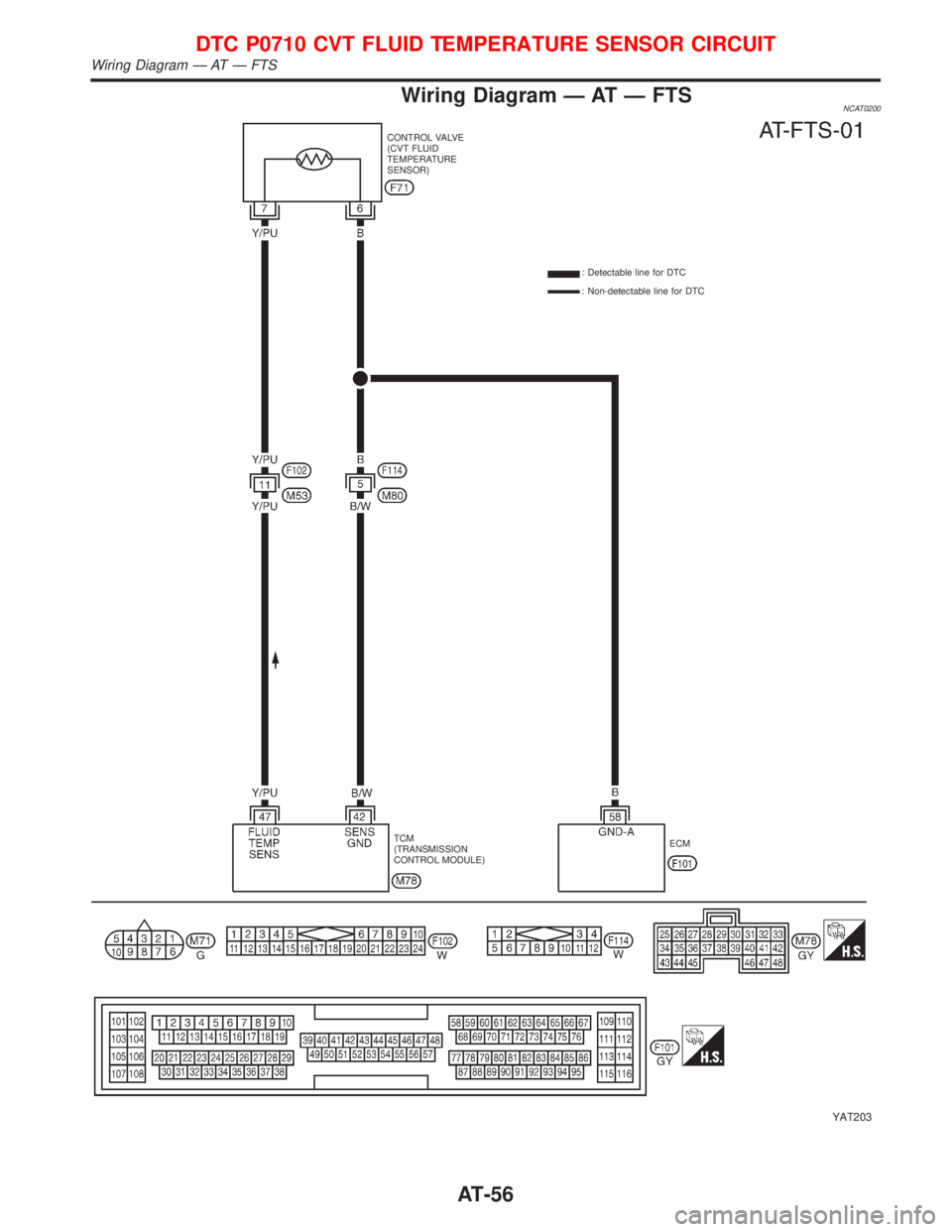

Wiring Diagram Ð AT Ð FTSNCAT0200

YAT203

CONTROL VALVE

(CVT FLUID

TEMPERATURE

SENSOR)

: Detectable line for DTC

: Non-detectable line for DTC

TCM

(TRANSMISSION

CONTROL MODULE)ECM

DTC P0710 CVT FLUID TEMPERATURE SENSOR CIRCUIT

Wiring Diagram Ð AT Ð FTS

AT-56

Page 59 of 2267

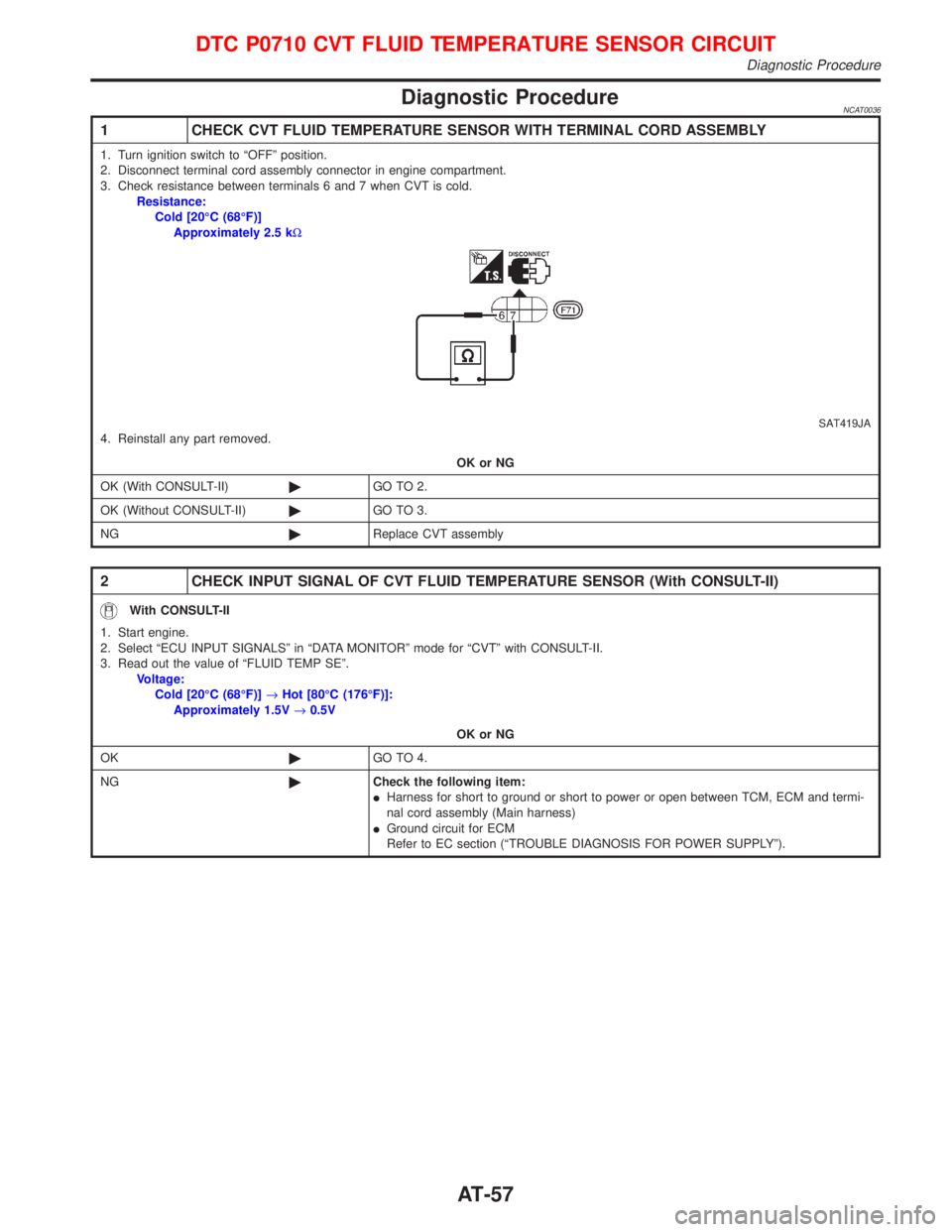

Diagnostic ProcedureNCAT0036

1 CHECK CVT FLUID TEMPERATURE SENSOR WITH TERMINAL CORD ASSEMBLY

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly connector in engine compartment.

3. Check resistance between terminals 6 and 7 when CVT is cold.

Resistance:

Cold [20ÉC (68ÉF)]

Approximately 2.5 kW

SAT419JA4. Reinstall any part removed.

OK or NG

OK (With CONSULT-II)©GO TO 2.

OK (Without CONSULT-II)©GO TO 3.

NG©Replace CVT assembly

2 CHECK INPUT SIGNAL OF CVT FLUID TEMPERATURE SENSOR (With CONSULT-II)

With CONSULT-II

1. Start engine.

2. Select ªECU INPUT SIGNALSº in ªDATA MONITORº mode for ªCVTº with CONSULT-II.

3. Read out the value of ªFLUID TEMP SEº.

Voltage:

Cold [20ÉC (68ÉF)]®Hot [80ÉC (176ÉF)]:

Approximately 1.5V®0.5V

OK or NG

OK©GO TO 4.

NG©Check the following item:

IHarness for short to ground or short to power or open between TCM, ECM and termi-

nal cord assembly (Main harness)

IGround circuit for ECM

Refer to EC section (ªTROUBLE DIAGNOSIS FOR POWER SUPPLYº).

DTC P0710 CVT FLUID TEMPERATURE SENSOR CIRCUIT

Diagnostic Procedure

AT-57

Page 60 of 2267

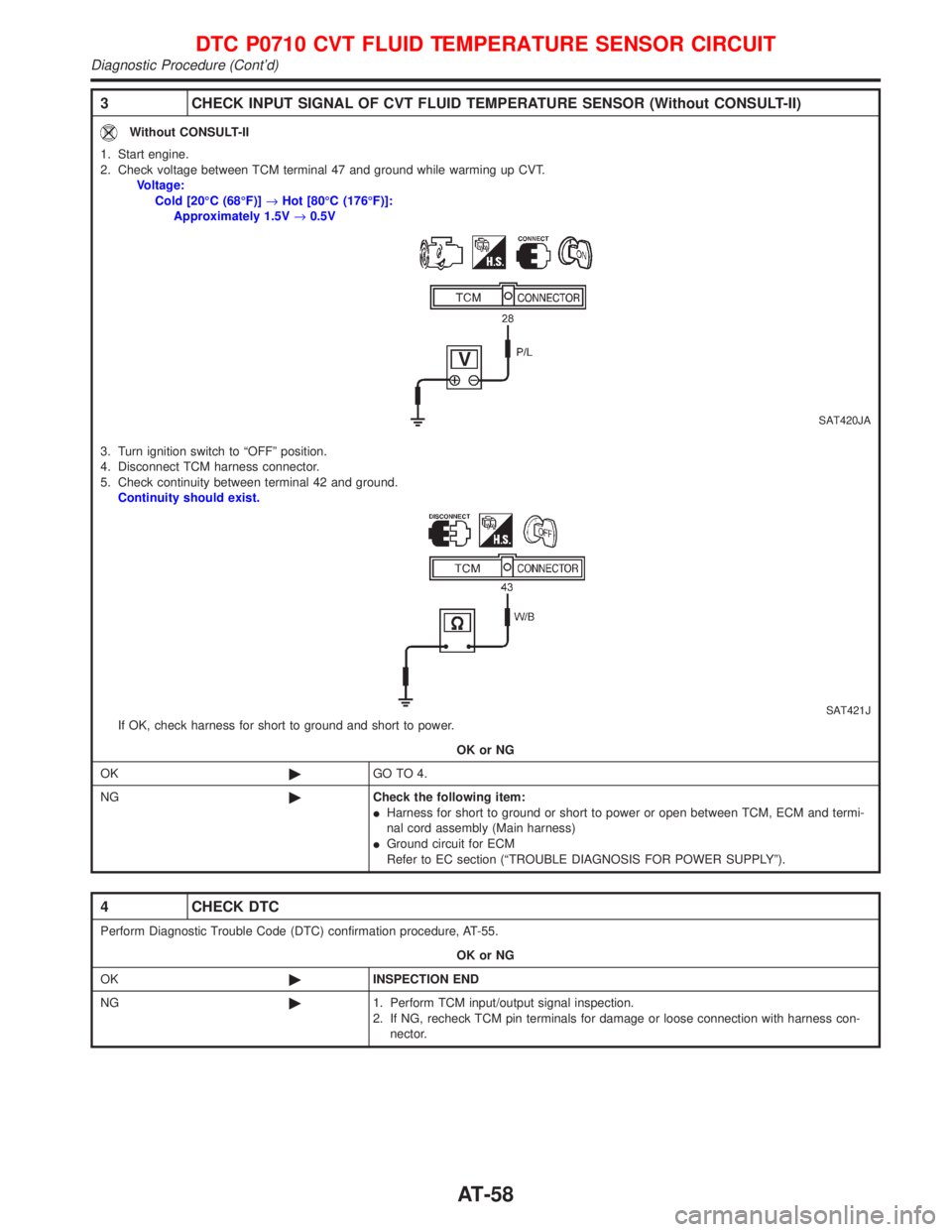

3 CHECK INPUT SIGNAL OF CVT FLUID TEMPERATURE SENSOR (Without CONSULT-II)

Without CONSULT-II

1. Start engine.

2. Check voltage between TCM terminal 47 and ground while warming up CVT.

Voltage:

Cold [20ÉC (68ÉF)]®Hot [80ÉC (176ÉF)]:

Approximately 1.5V®0.5V

SAT420JA

3. Turn ignition switch to ªOFFº position.

4. Disconnect TCM harness connector.

5. Check continuity between terminal 42 and ground.

Continuity should exist.

SAT421JIf OK, check harness for short to ground and short to power.

OK or NG

OK©GO TO 4.

NG©Check the following item:

IHarness for short to ground or short to power or open between TCM, ECM and termi-

nal cord assembly (Main harness)

IGround circuit for ECM

Refer to EC section (ªTROUBLE DIAGNOSIS FOR POWER SUPPLYº).

4 CHECK DTC

Perform Diagnostic Trouble Code (DTC) confirmation procedure, AT-55.

OK or NG

OK©INSPECTION END

NG©1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose connection with harness con-

nector.

DTC P0710 CVT FLUID TEMPERATURE SENSOR CIRCUIT

Diagnostic Procedure (Cont'd)

AT-58