NISSAN PRIMERA 1999 Electronic Manual PDF

Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 71 of 2267

DescriptionNCAT0055The torque converter clutch solenoid valve is activated, by the TCM

in response to signals sent from the vehicle speed and throttle

position sensors. Lock-up piston operation will then be controlled.

Lock-up operation, however, is prohibited when CVT fluid tempera-

ture is too low.

When the accelerator pedal is depressed (less than 2/8) in lock-up

condition, the engine speed should not change abruptly. If there is

a big jump in engine speed, there is no lock-up.

CONSULT-II REFERENCE VALUE IN DATA MONITOR

MODE

NCAT0055S01Remarks: Specification data are reference values.

Monitor item Condition Specification

Torque converter clutch solenoid valve

dutyLock-up ªOFFº

"

Lock-up ªONºApproximately 4%

"

Approximately 94%

TCM TERMINALS AND REFERENCE VALUENCAT0055S02Remarks: Specification data are reference values.

Terminal

No.Wire color Item ConditionJudgement

standard

3 GY/RTorque converter

clutch solenoid

valve

When CVT performs lock-up.Approx. 12.0V

When CVT does not perform lock-

up.Approx. 0V

ON BOARD DIAGNOSIS LOGICNCAT0055S03

Diagnostic trouble code Malfunction is detected when ... Check items (Possible cause)

: TCC SOLENOID/CIRC

TCM detects an improper voltage drop

when it tries to operate the solenoid

valve.IHarness or connectors

(The solenoid circuit is open or shorted.)

IT/C clutch solenoid valve

: P0740

: MI Code No. 0740

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION

PROCEDURE

NCAT0055S04NOTE:

If ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCE-

DUREº has been previously conducted, always turn ignition

switch ªOFFº and wait at least 5 seconds before conducting

the next test.

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

SAT651J

DTC P0740 TORQUE CONVERTER CLUTCH SOLENOID VALVE

Description

AT-69

Page 72 of 2267

With CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode for ªENGINEº with CON-

SULT-II and wait at least 10 seconds.

If the check result is ªNGº, go to ªDiagnostic Procedureº,

AT-72.

With GST

Follow the procedure ªWith CONSULT-IIº.

SAT654J

DTC P0740 TORQUE CONVERTER CLUTCH SOLENOID VALVE

Description (Cont'd)

AT-70

Page 73 of 2267

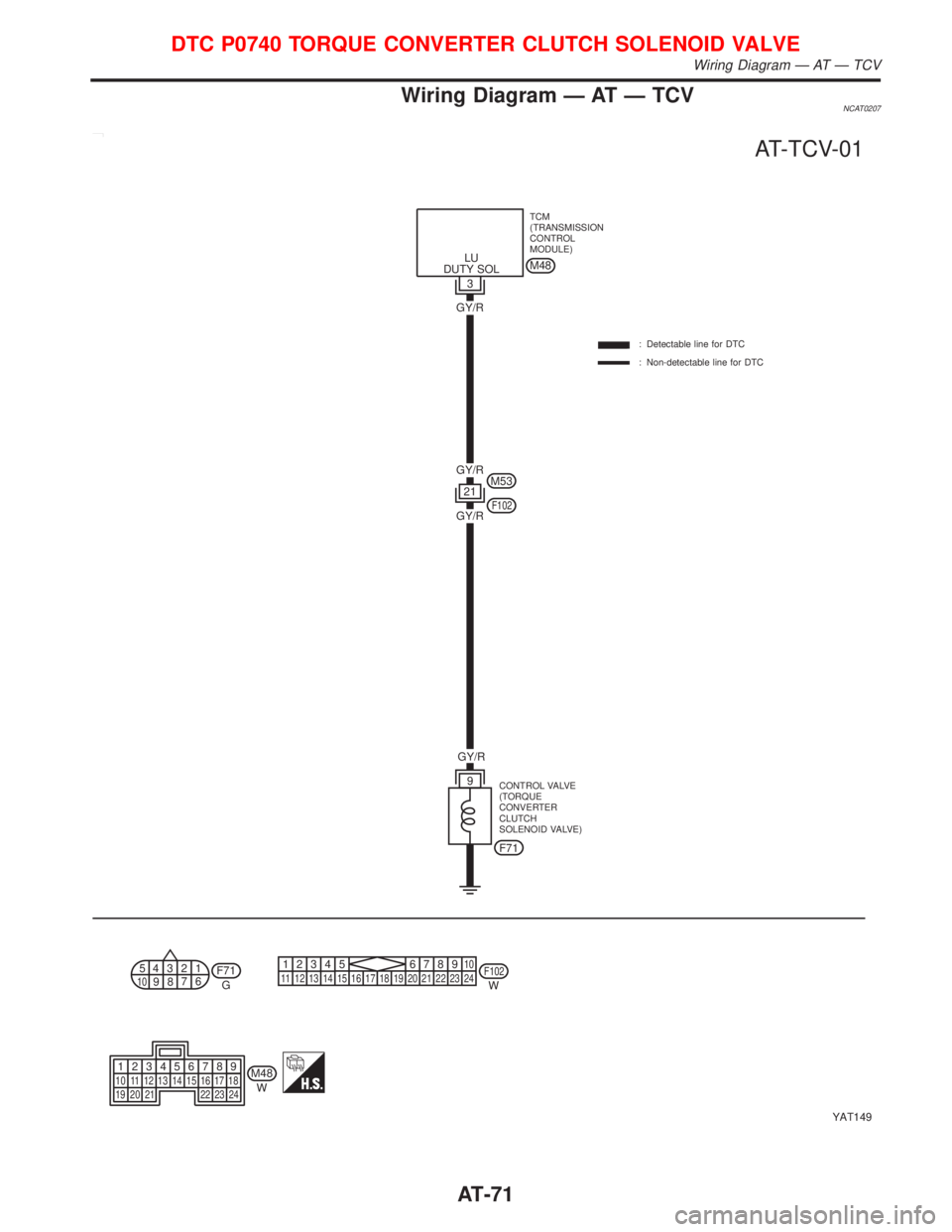

Wiring Diagram Ð AT Ð TCVNCAT0207

M48

GY/R GY/RF102

GY/R

M48

F71

AT-TCV-01

M53

5

15 16 17 1918620414313212721822923W 3

21LU

DUTY SOL

9

11110

24

W

3 2 1 45678

910 11 12 13 14 15 16 17 18

19 20 21 22 23 24

F71 GY/R

F10254

96 2

7 3

81

G10

YAT149

TCM

(TRANSMISSION

CONTROL

MODULE)

: Detectable line for DTC

: Non-detectable line for DTC

CONTROL VALVE

(TORQUE

CONVERTER

CLUTCH

SOLENOID VALVE)

DTC P0740 TORQUE CONVERTER CLUTCH SOLENOID VALVE

Wiring Diagram Ð AT Ð TCV

AT-71

Page 74 of 2267

Diagnostic ProcedureNCAT0056

1 CHECK GROUND CIRCUIT

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly connector in engine compartment.

3. Check resistance between terminal 9 and ground.

Resistance:

10-20W

OK or NG

OK©GO TO 2.

NG©Replace CVT assembly

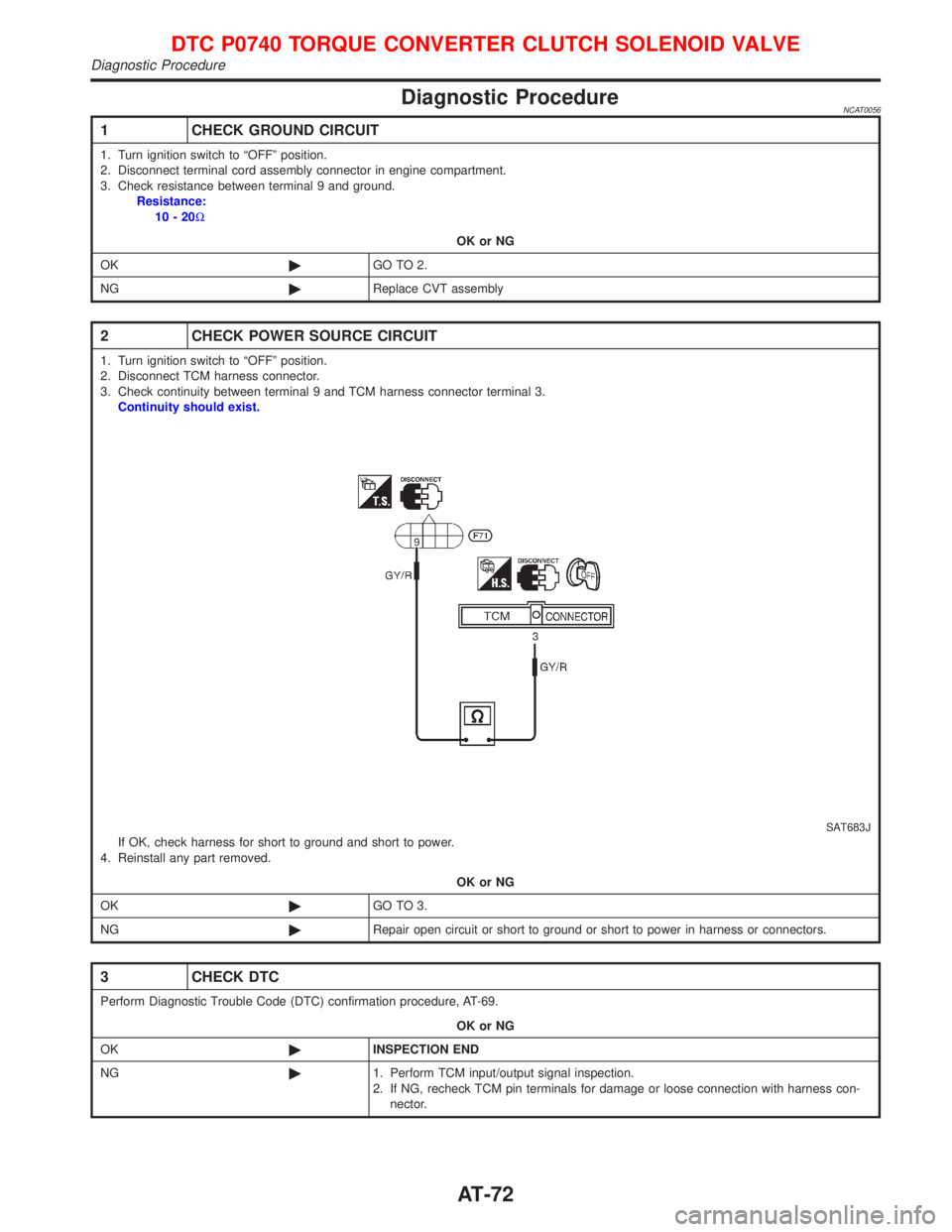

2 CHECK POWER SOURCE CIRCUIT

1. Turn ignition switch to ªOFFº position.

2. Disconnect TCM harness connector.

3. Check continuity between terminal 9 and TCM harness connector terminal 3.

Continuity should exist.

SAT683JIf OK, check harness for short to ground and short to power.

4. Reinstall any part removed.

OK or NG

OK©GO TO 3.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

3 CHECK DTC

Perform Diagnostic Trouble Code (DTC) confirmation procedure, AT-69.

OK or NG

OK©INSPECTION END

NG©1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose connection with harness con-

nector.

DTC P0740 TORQUE CONVERTER CLUTCH SOLENOID VALVE

Diagnostic Procedure

AT-72

Page 75 of 2267

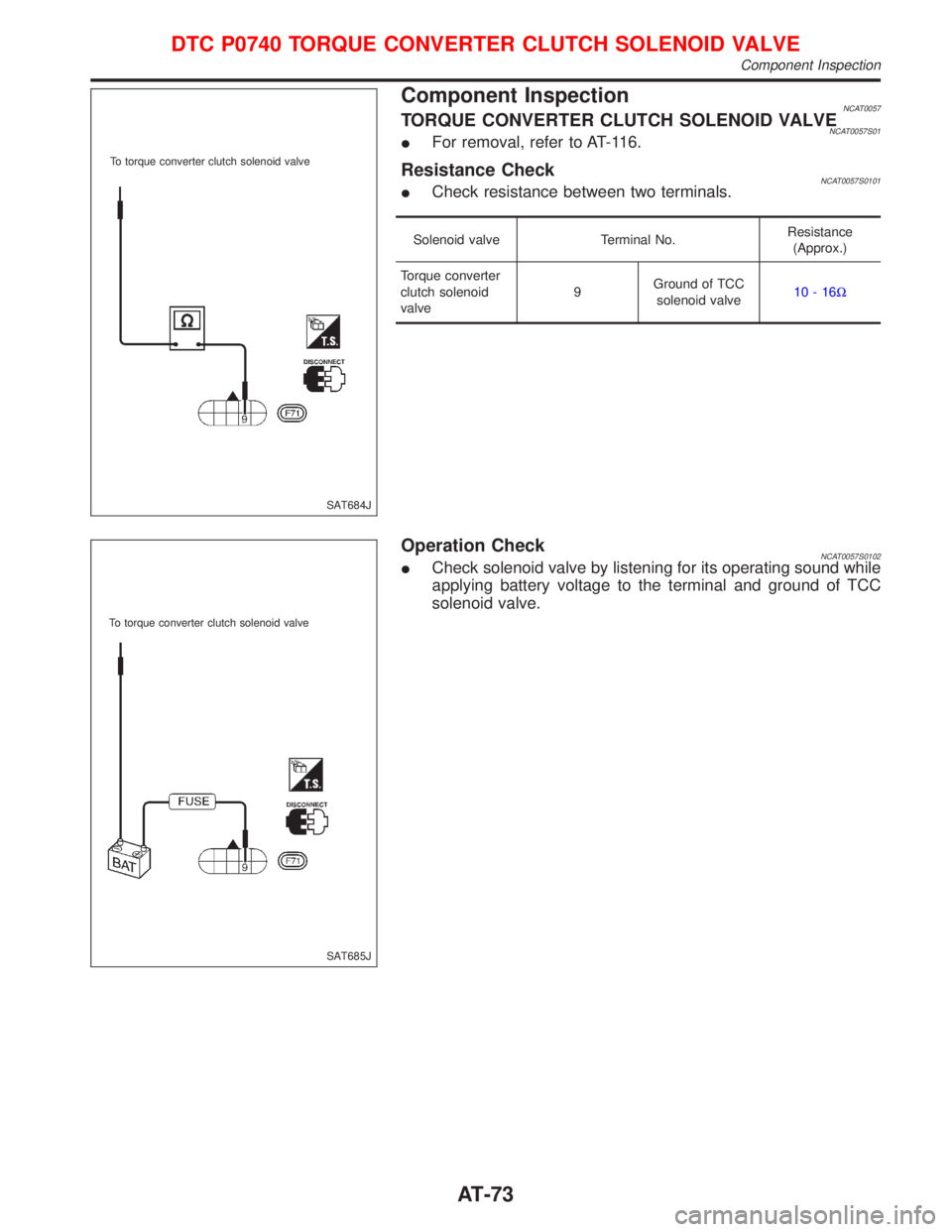

Component InspectionNCAT0057TORQUE CONVERTER CLUTCH SOLENOID VALVENCAT0057S01IFor removal, refer to AT-116.

Resistance CheckNCAT0057S0101ICheck resistance between two terminals.

Solenoid valve Terminal No.Resistance

(Approx.)

Torque converter

clutch solenoid

valve9Ground of TCC

solenoid valve10-16W

Operation CheckNCAT0057S0102ICheck solenoid valve by listening for its operating sound while

applying battery voltage to the terminal and ground of TCC

solenoid valve.

SAT684J To torque converter clutch solenoid valve

SAT685J To torque converter clutch solenoid valve

DTC P0740 TORQUE CONVERTER CLUTCH SOLENOID VALVE

Component Inspection

AT-73

Page 76 of 2267

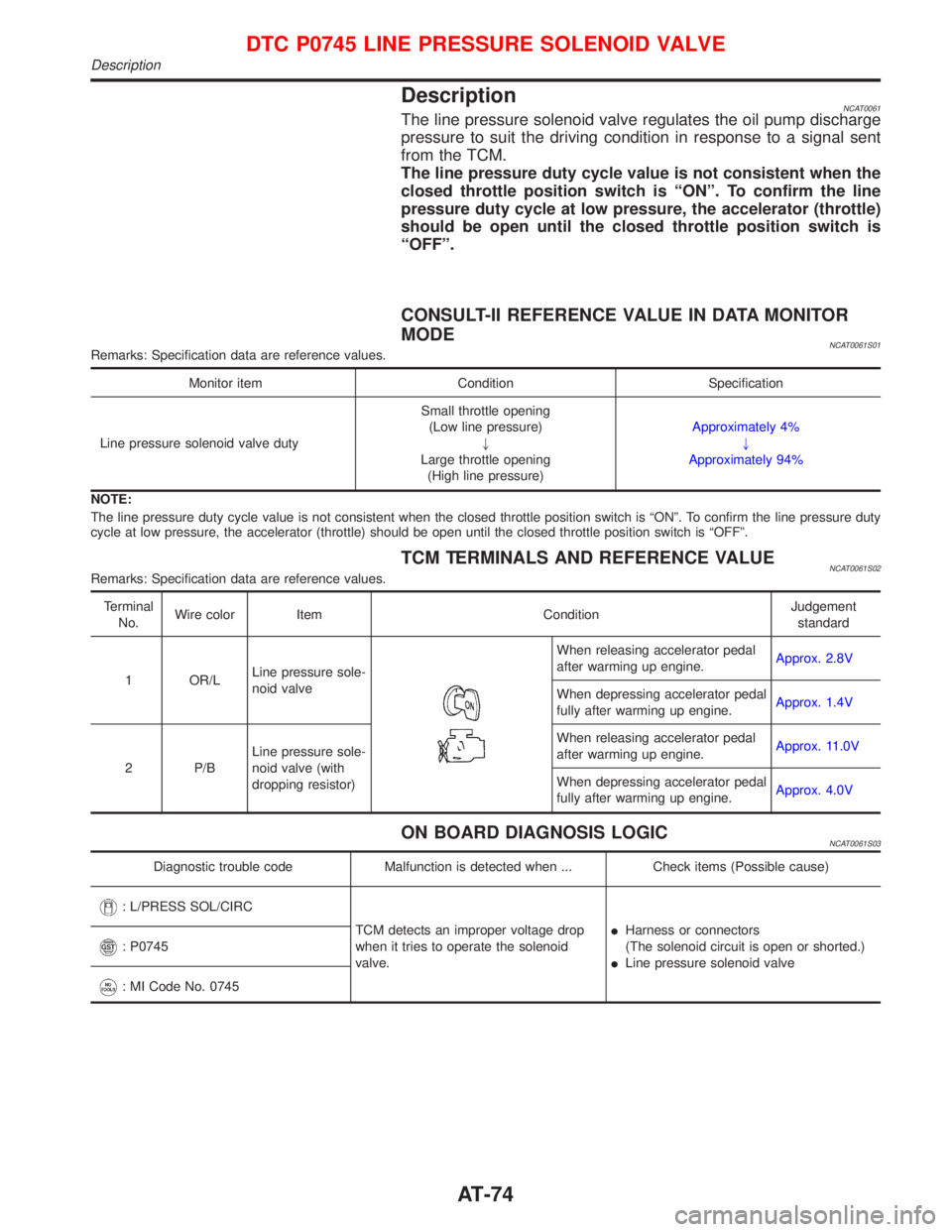

DescriptionNCAT0061The line pressure solenoid valve regulates the oil pump discharge

pressure to suit the driving condition in response to a signal sent

from the TCM.

The line pressure duty cycle value is not consistent when the

closed throttle position switch is ªONº. To confirm the line

pressure duty cycle at low pressure, the accelerator (throttle)

should be open until the closed throttle position switch is

ªOFFº.

CONSULT-II REFERENCE VALUE IN DATA MONITOR

MODE

NCAT0061S01Remarks: Specification data are reference values.

Monitor item Condition Specification

Line pressure solenoid valve dutySmall throttle opening

(Low line pressure)

"

Large throttle opening

(High line pressure)Approximately 4%

"

Approximately 94%

NOTE:

The line pressure duty cycle value is not consistent when the closed throttle position switch is ªONº. To confirm the line pressure duty

cycle at low pressure, the accelerator (throttle) should be open until the closed throttle position switch is ªOFFº.

TCM TERMINALS AND REFERENCE VALUENCAT0061S02Remarks: Specification data are reference values.

Terminal

No.Wire color Item ConditionJudgement

standard

1 OR/LLine pressure sole-

noid valve

When releasing accelerator pedal

after warming up engine.Approx. 2.8V

When depressing accelerator pedal

fully after warming up engine.Approx. 1.4V

2 P/BLine pressure sole-

noid valve (with

dropping resistor)When releasing accelerator pedal

after warming up engine.Approx. 11.0V

When depressing accelerator pedal

fully after warming up engine.Approx. 4.0V

ON BOARD DIAGNOSIS LOGICNCAT0061S03

Diagnostic trouble code Malfunction is detected when ... Check items (Possible cause)

: L/PRESS SOL/CIRC

TCM detects an improper voltage drop

when it tries to operate the solenoid

valve.IHarness or connectors

(The solenoid circuit is open or shorted.)

ILine pressure solenoid valve

: P0745

: MI Code No. 0745

DTC P0745 LINE PRESSURE SOLENOID VALVE

Description

AT-74

Page 77 of 2267

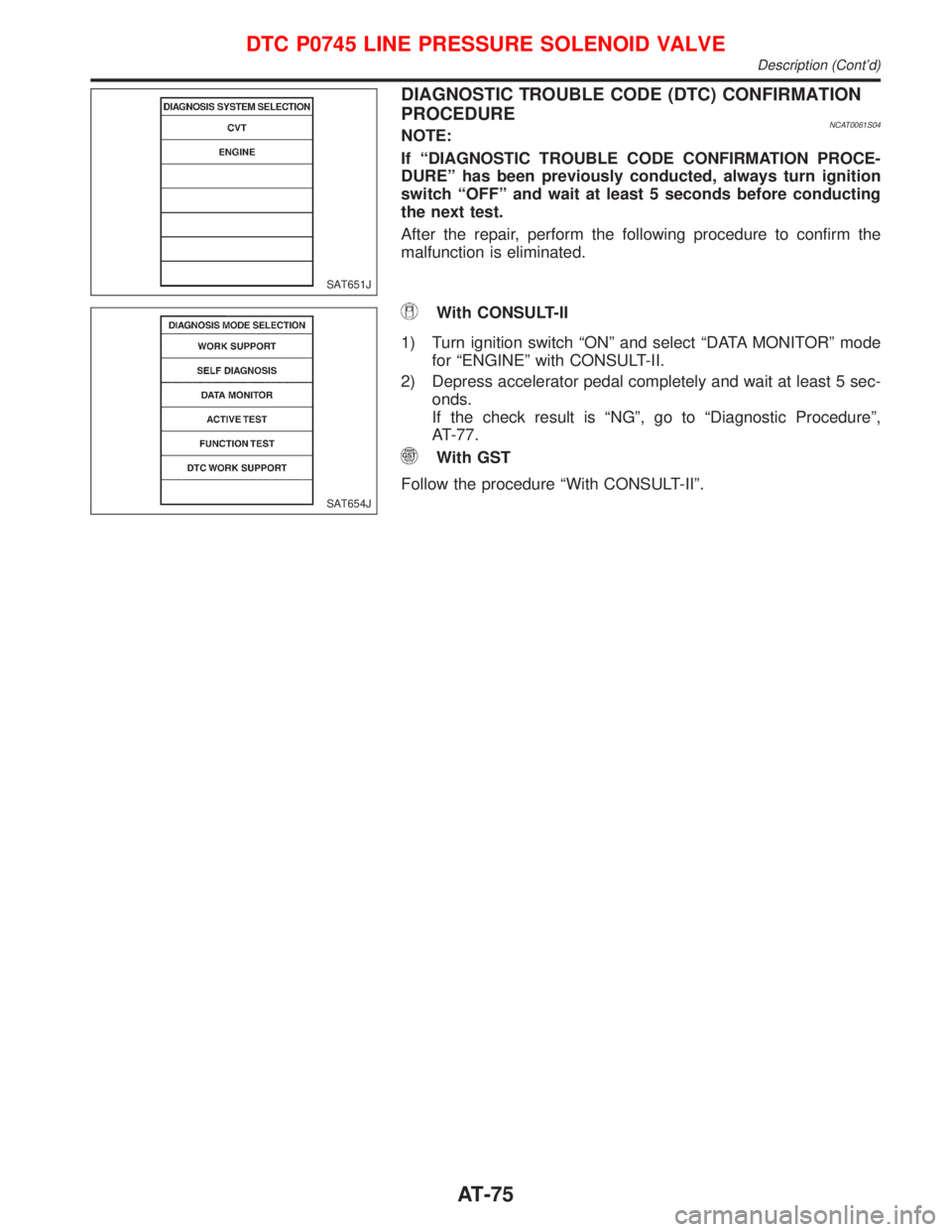

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION

PROCEDURE

NCAT0061S04NOTE:

If ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCE-

DUREº has been previously conducted, always turn ignition

switch ªOFFº and wait at least 5 seconds before conducting

the next test.

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

With CONSULT-II

1) Turn ignition switch ªONº and select ªDATA MONITORº mode

for ªENGINEº with CONSULT-II.

2) Depress accelerator pedal completely and wait at least 5 sec-

onds.

If the check result is ªNGº, go to ªDiagnostic Procedureº,

AT-77.

With GST

Follow the procedure ªWith CONSULT-IIº.

SAT651J

SAT654J

DTC P0745 LINE PRESSURE SOLENOID VALVE

Description (Cont'd)

AT-75

Page 78 of 2267

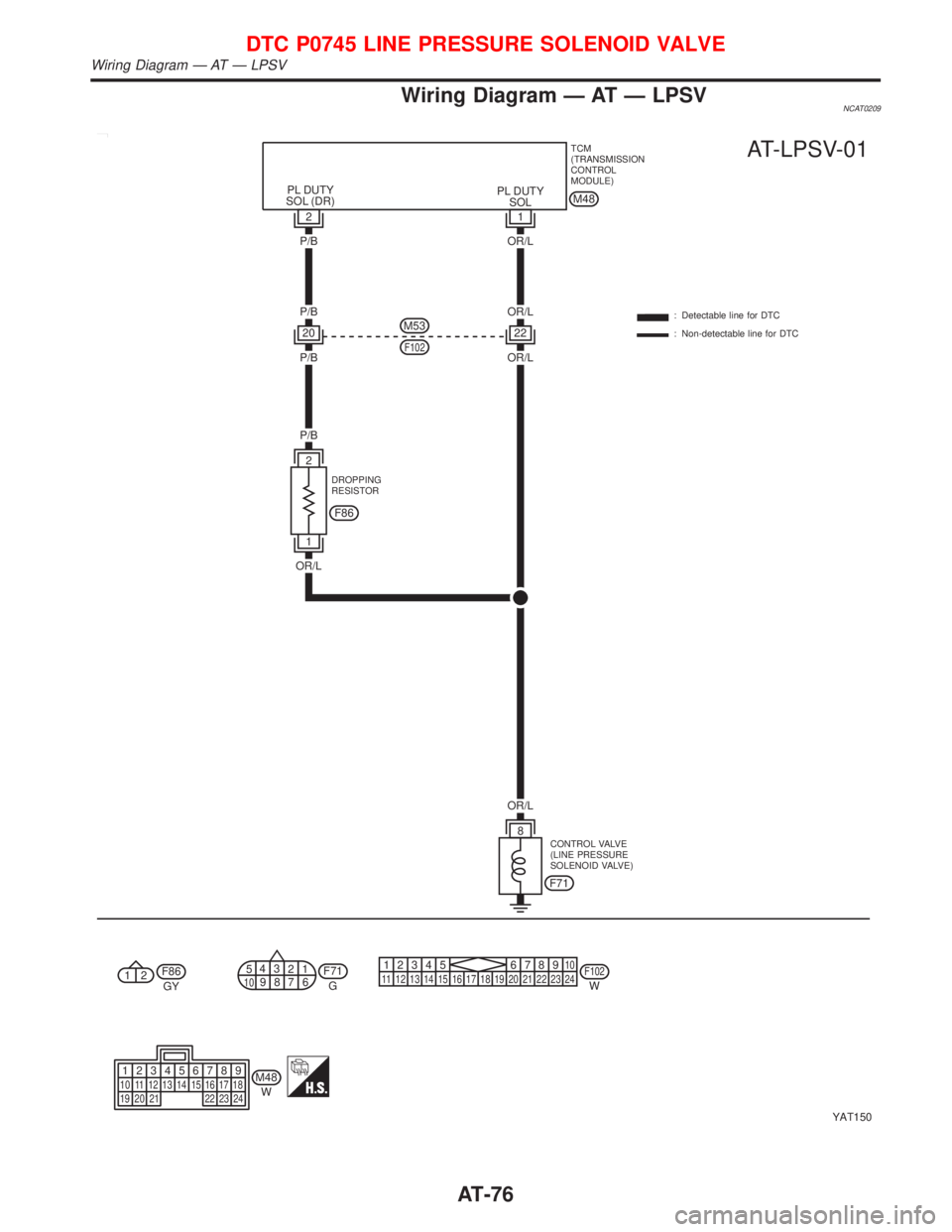

Wiring Diagram Ð AT Ð LPSVNCAT0209

OR/L P/B

OR/L P/B

OR/L P/B

P/B

OR/L22 20M53

M48

OR/L

M48

F86F102F71

AT-LPSV-01

515 16 17 1918620414313212721822923W 1 PL DUTY

SOL

8 2

2

1F86

11110

24

PL DUTY

SOL (DR)

W

3 2 1 45678

910 11 12 13 14 15 16 17 18

19 20 21 22 23 24

F71

F102

2 1

GY54

96 2

7 3

81

G10

YAT150

TCM

(TRANSMISSION

CONTROL

MODULE)

: Detectable line for DTC

: Non-detectable line for DTC

DROPPING

RESISTOR

CONTROL VALVE

(LINE PRESSURE

SOLENOID VALVE)

DTC P0745 LINE PRESSURE SOLENOID VALVE

Wiring Diagram Ð AT Ð LPSV

AT-76

Page 79 of 2267

Diagnostic ProcedureNCAT0062

1 CHECK GROUND CIRCUIT

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly connector in engine compartment.

3. Check resistance between terminal 8 and ground.

Resistance:

2.5-5W

OK or NG

OK©GO TO 2.

NG©Check the following items:

ILine pressure solenoid valve

Refer to ªComponent Inspectionº, AT-78.

IHarness of terminal cord assembly for short or open

2 CHECK POWER SOURCE CIRCUIT

1. Turn ignition switch to ªOFFº position.

2. Disconnect TCM harness connector.

3. Check resistance between terminal 8 and TCM harness connector terminal 2.

Resistance:

11.2 - 12.8W

OK or NG

OK©GO TO 3.

NG©Check the following items:

IDropping resistor

Refer to ªComponent Inspectionº, AT-78.

IHarness for short or open between TCM terminal 2 and terminal cord assembly (Main

harness)

3 CHECK POWER SOURCE CIRCUIT

1. Turn ignition switch to ªOFFº position.

2. Check continuity between terminal 8 and TCM harness connector terminal 1.

Continuity should exist.

If OK, check harness for short to ground and short to power.

3. Reinstall any part removed.

OK or NG

OK©GO TO 4.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

4 CHECK DTC

Perform Diagnostic Trouble Code (DTC) confirmation procedure, AT-75.

OK or NG

OK©INSPECTION END

NG©1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose connection with harness con-

nector.

DTC P0745 LINE PRESSURE SOLENOID VALVE

Diagnostic Procedure

AT-77

Page 80 of 2267

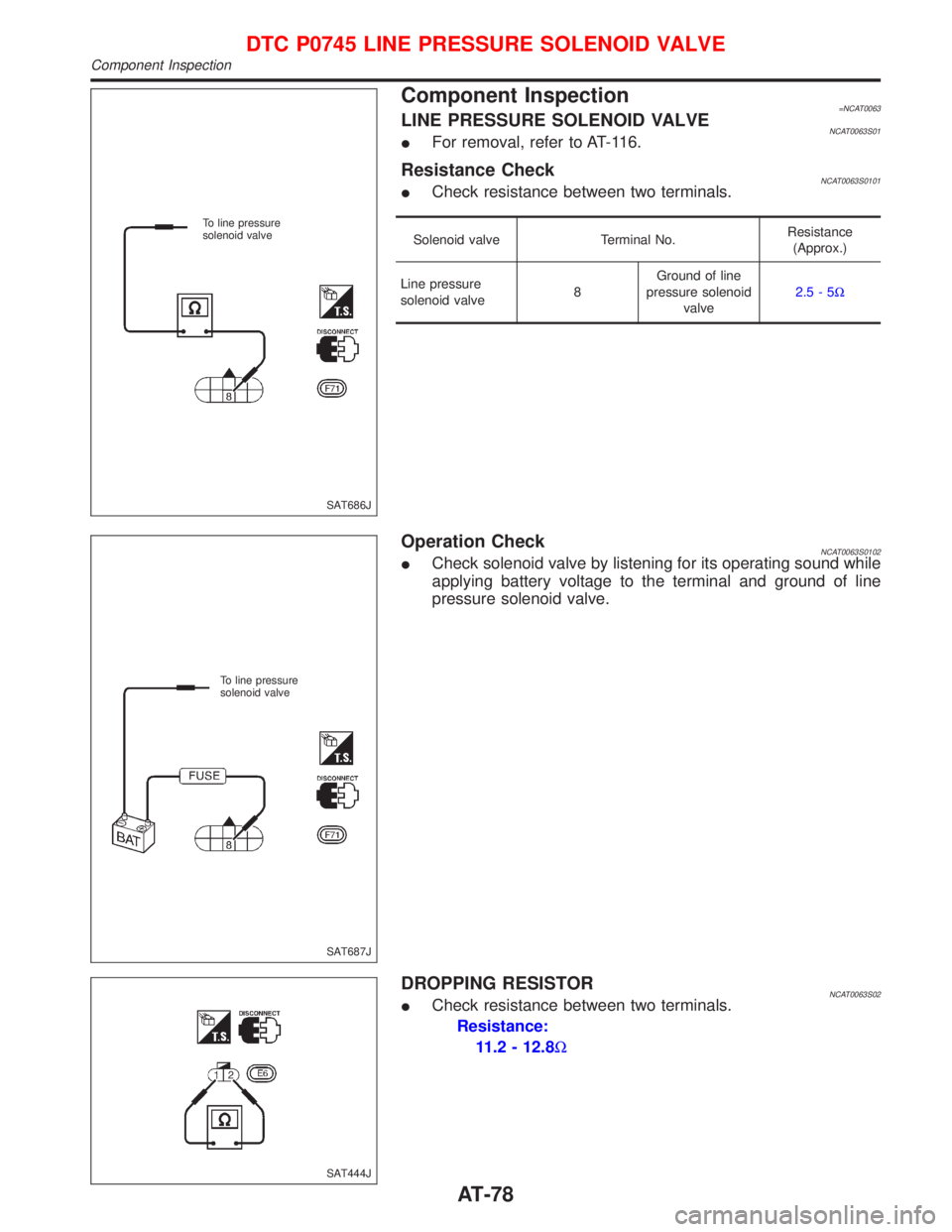

Component Inspection=NCAT0063LINE PRESSURE SOLENOID VALVENCAT0063S01IFor removal, refer to AT-116.

Resistance CheckNCAT0063S0101ICheck resistance between two terminals.

Solenoid valve Terminal No.Resistance

(Approx.)

Line pressure

solenoid valve8Ground of line

pressure solenoid

valve2.5-5W

Operation CheckNCAT0063S0102ICheck solenoid valve by listening for its operating sound while

applying battery voltage to the terminal and ground of line

pressure solenoid valve.

DROPPING RESISTORNCAT0063S02ICheck resistance between two terminals.

Resistance:

11.2 - 12.8W

SAT686J To line pressure

solenoid valve

SAT687J To line pressure

solenoid valve

SAT444J

DTC P0745 LINE PRESSURE SOLENOID VALVE

Component Inspection

AT-78