NISSAN PRIMERA 1999 Electronic Manual PDF

Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 61 of 2267

DescriptionNCAT0220The primary speed sensor detects the primary pulley revolution

speed and sends a signal to the ECM.

TCM TERMINALS AND REFERENCE VALUENCAT0220S01Remarks: Specification data are reference values.

Terminal

No.Wire color Item ConditionJudgement

standard

38 G/YPrimary speed

sensorWhen driving (L position, 20 km/h), the pulse measurement by

using the pulse measurement function of CONSULT-II.Approx. 900 Hz

ON BOARD DIAGNOSIS LOGICNCAT0220S02

Diagnostic trouble code Malfunction is detected when ... Check items (Possible cause)

: PRI SPEED SIG/CIRC

TCM does not receive the proper voltage

signal from the sensor.IHarness or connectors

(The sensor circuit is open or shorted.)

IPrimary speed sensor

: P0715

: MI Code No. 0715

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION

PROCEDURE

NCAT0220S03CAUTION:

IAlways drive vehicle at a safe speed.

IBe careful not to rev engine into the red zone on the

tachometer.

NOTE:

If ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCE-

DUREº has been previously conducted, always turn ignition

switch ªOFFº and wait at least 5 seconds before conducting

the next test.

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

With CONSULT-II

1) Turn ignition switch ªONº and select ªDATA MONITORº mode

for ªENGINEº with CONSULT-II.

2) Start engine and maintain the following conditions for at least

5 consecutive seconds.

VHCL SPEED SE: 10 km/h (6 MPH) or more

THRTL POS SEN: More than 1.3V

Selector lever: D position

ENG SPEED: 450 rpm or more

Driving location: Driving the vehicle uphill (increased

engine load) will help maintain the driving conditions

required for this test.

If the check result is NG, go to ªDiagnostic Procedureº, AT-61.

With GST

Follow the procedure ªWith CONSULT-IIº.

SAT651J

SAT971J

SAT654J

DTC P0715 PRIMARY SPEED SENSOR

Description

AT-59

Page 62 of 2267

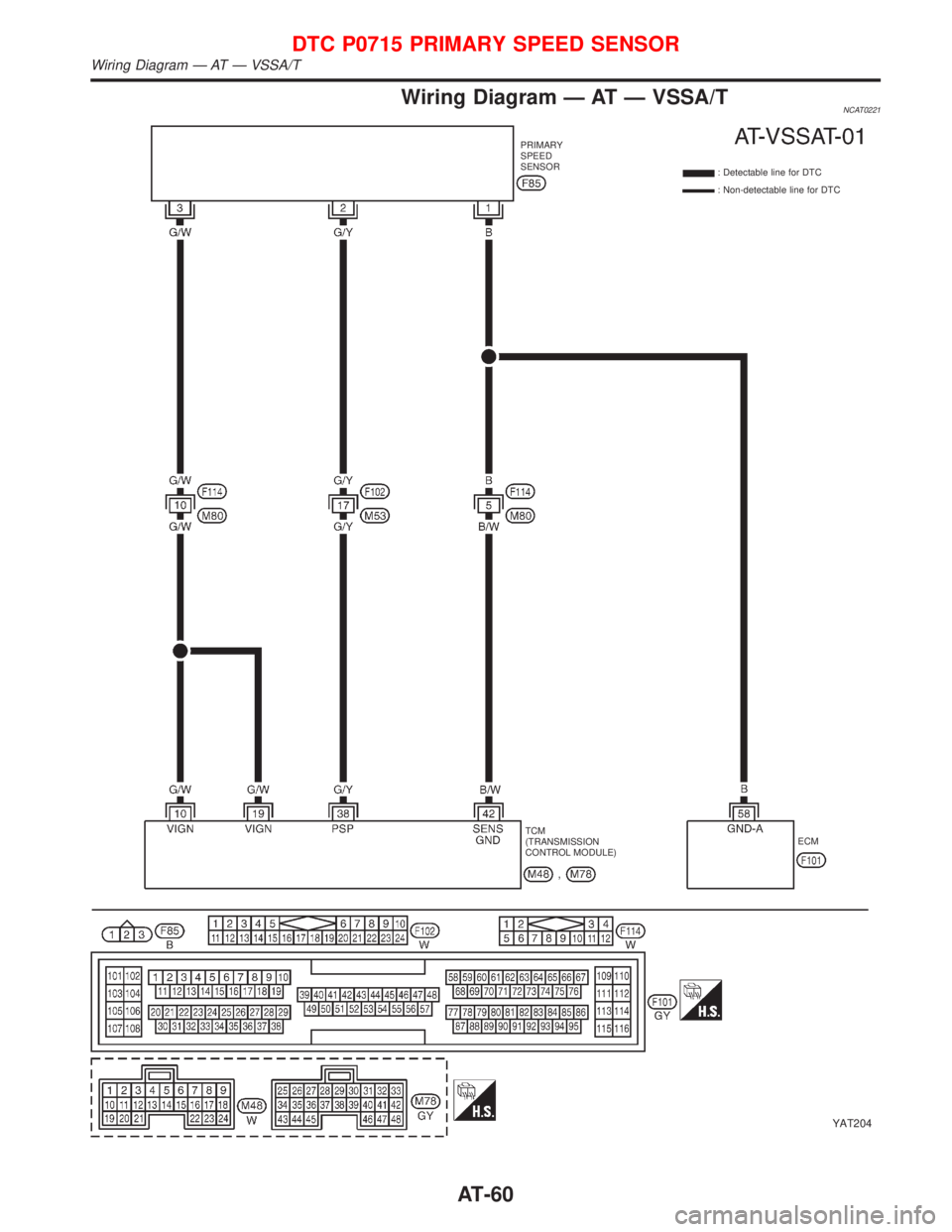

Wiring Diagram Ð AT Ð VSSA/TNCAT0221

YAT204

PRIMARY

SPEED

SENSOR

: Detectable line for DTC

: Non-detectable line for DTC

TCM

(TRANSMISSION

CONTROL MODULE)ECM

DTC P0715 PRIMARY SPEED SENSOR

Wiring Diagram Ð AT Ð VSSA/T

AT-60

Page 63 of 2267

Diagnostic ProcedureNCAT0222

1 CHECK PRIMARY SPEED SENSOR

Refer to ªComponent Inspectionº AT-65.

OK or NG

OK (With CONSULT-II)©GO TO 2.

OK (Without CONSULT-II)©GO TO 3.

NG©Repair or replace primary speed sensor.

2 CHECK INPUT SIGNAL (With CONSULT-II)

With CONSULT-II

1. Start engine.

2. Select ªECU INPUT SIGNALSº in ªDATA MONITORº mode for ªCVTº with CONSULT-II.

3. Read out the value of ªI/P PULLY SPDº while driving.

Check the value changes according to driving speed. (Almost same value as engine speed)

OK or NG

OK©GO TO 4.

NG©Check the following items:

IHarness for short or open between TCM, ECM and primary speed sensor (Main har-

ness)

IGround circuit for ECM

Refer to EC section (ªTROUBLE DIAGNOSIS FOR POWER SUPPLYº).

3 CHECK DTC

Perform Diagnostic Trouble Code (DTC) confirmation procedure, AT-62.

OK or NG

OK©INSPECTION END

NG©1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose connection with harness con-

nector.

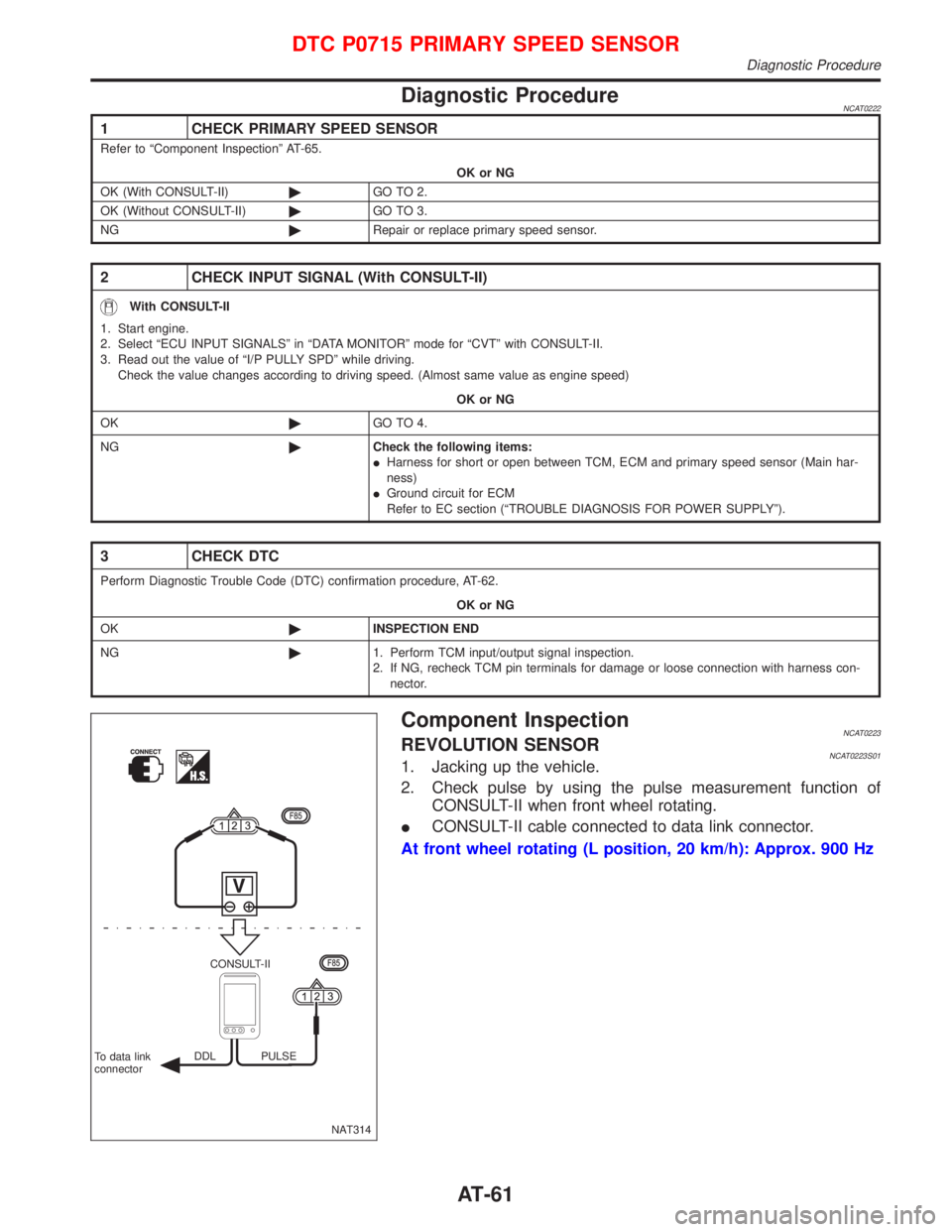

Component InspectionNCAT0223REVOLUTION SENSORNCAT0223S011. Jacking up the vehicle.

2. Check pulse by using the pulse measurement function of

CONSULT-II when front wheel rotating.

ICONSULT-II cable connected to data link connector.

At front wheel rotating (L position, 20 km/h): Approx. 900 Hz

NAT314 CONSULT-II

To data link

connectorDDL PULSE

DTC P0715 PRIMARY SPEED SENSOR

Diagnostic Procedure

AT-61

Page 64 of 2267

DescriptionNCAT0038The vehicle speed sensor CVT secondary speed sensor detects

the revolution of the idler gear parking pawl lock gear and emits a

pulse signal. The pulse signal is sent to the TCM which converts it

into vehicle speed.

TCM TERMINALS AND REFERENCE VALUENCAT0038S01Remarks: Specification data are reference values.

Terminal

No.Wire color Item ConditionJudgement

standard

29 G/RSecondary speed

sensorWhen driving (D position, 20 km/h), the pulse measurement by

using the pulse measurement function of CONSULT-II.

ICONSULT-II cable connected to data link connector.

IThis inspection cannot be measured by circuit tester.Approx. 600 Hz

42 BThrottle position

sensor

(Ground)

ÐÐ

ON BOARD DIAGNOSIS LOGICNCAT0038S02

Diagnostic trouble code Malfunction is detected when ... Check items (Possible cause)

: VEH SPD SEN/CIR AT

TCM does not receive the proper voltage

signal from the sensor.IHarness or connectors

(The sensor circuit is open or shorted.)

ISecondary speed sensor

: P0720

: MI Code No. 0720

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION

PROCEDURE

NCAT0038S03CAUTION:

IAlways drive vehicle at a safe speed.

IBe careful not to rev engine into the red zone on the

tachometer.

NOTE:

If ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCE-

DUREº has been previously conducted, always turn ignition

switch ªOFFº and wait at least 5 seconds before conducting

the next test.

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

SAT651J

DTC P0720 VEHICLE SPEED SENSOR CVT (SECONDARY SPEED SENSOR)

Description

AT-62

Page 65 of 2267

With CONSULT-II

1) Turn ignition switch ªONº and select ªDATA MONITORº mode

for ªENGINEº with CONSULT-II.

2) Start engine and maintain the following conditions for at least

12 consecutive seconds.

THRTL POS SEN: More than 1.3V

Selector lever: D position

Driving location: Driving the vehicle uphill (increased

engine load) will help maintain the driving conditions

required for this test.

If the check result is NG, go to ªDIAGNOSTIC PROCEDUREº,

AT-65.

With GST

Follow the procedure ªWith CONSULT-IIº.

SAT971J

SAT654J

DTC P0720 VEHICLE SPEED SENSOR CVT (SECONDARY SPEED SENSOR)

Description (Cont'd)

AT-63

Page 66 of 2267

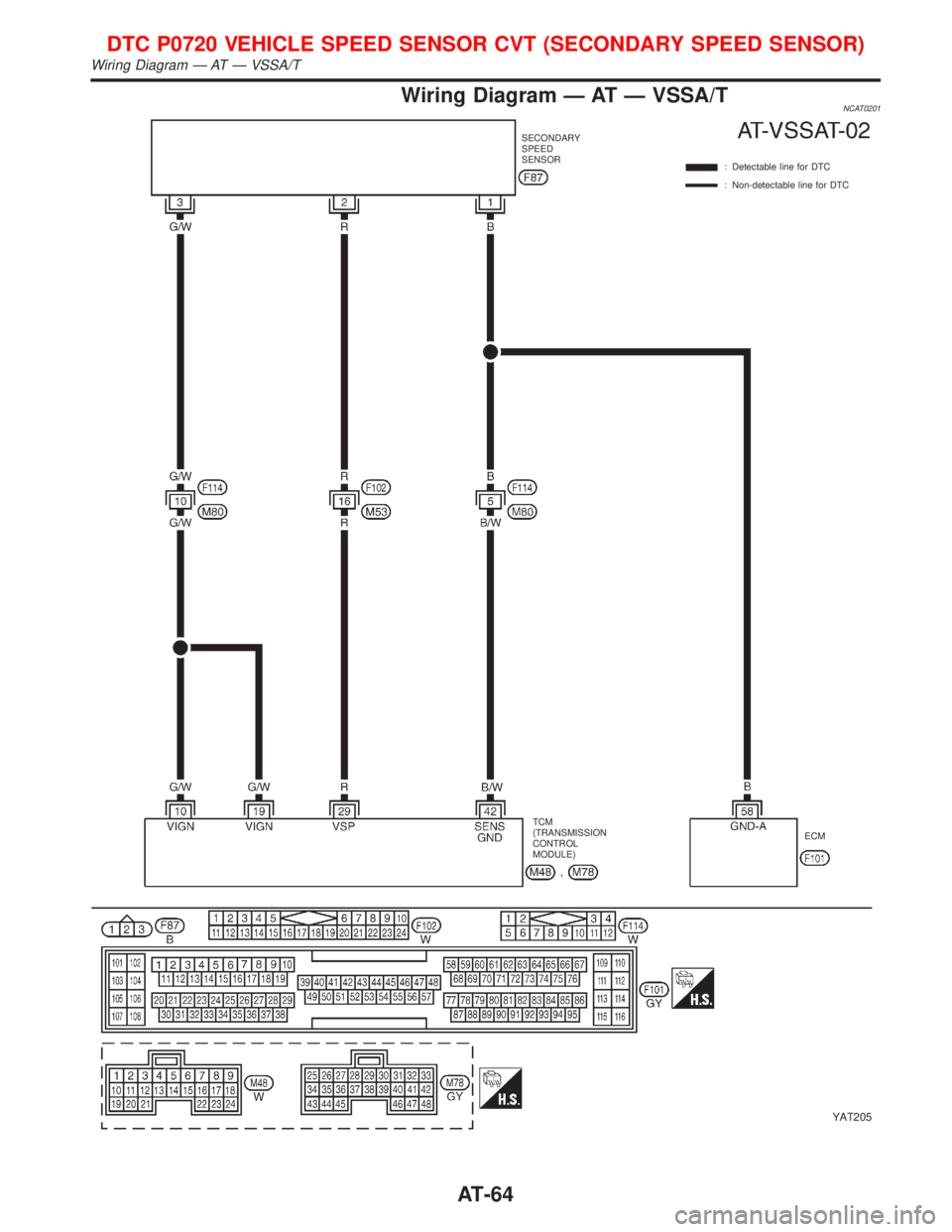

Wiring Diagram Ð AT Ð VSSA/TNCAT0201

YAT205

SECONDARY

SPEED

SENSOR

: Detectable line for DTC

: Non-detectable line for DTC

TCM

(TRANSMISSION

CONTROL

MODULE)ECM

DTC P0720 VEHICLE SPEED SENSOR CVT (SECONDARY SPEED SENSOR)

Wiring Diagram Ð AT Ð VSSA/T

AT-64

Page 67 of 2267

Diagnostic ProcedureNCAT0039

1 CHECK SECONDARY SPEED SENSOR

Refer to ªComponent Inspectionº AT-65.

OK or NG

OK (With CONSULT-II)©GO TO 2.

OK (Without CONSULT-II)©GO TO 3.

NG©Repair or replace secondary speed sensor.

2 CHECK INPUT SIGNAL (With CONSULT-II)

With CONSULT-II

1. Start engine.

2. Select ªECU INPUT SIGNALSº in ªDATA MONITORº mode for ªCVTº with CONSULT-II.

3. Read out the value of ªVEHICLE SPEEDº while driving.

Check the value changes according to driving speed.

OK or NG

OK©GO TO 4.

NG©Check the following items:

IHarness for short or open between TCM, ECM and secondary speed sensor (Main

harness)

IGround circuit for ECM

Refer to EC section (ªTROUBLE DIAGNOSIS FOR POWER SUPPLYº).

3 CHECK DTC

Perform Diagnostic Trouble Code (DTC) confirmation procedure, AT-62.

OK or NG

OK©INSPECTION END

NG©1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose connection with harness con-

nector.

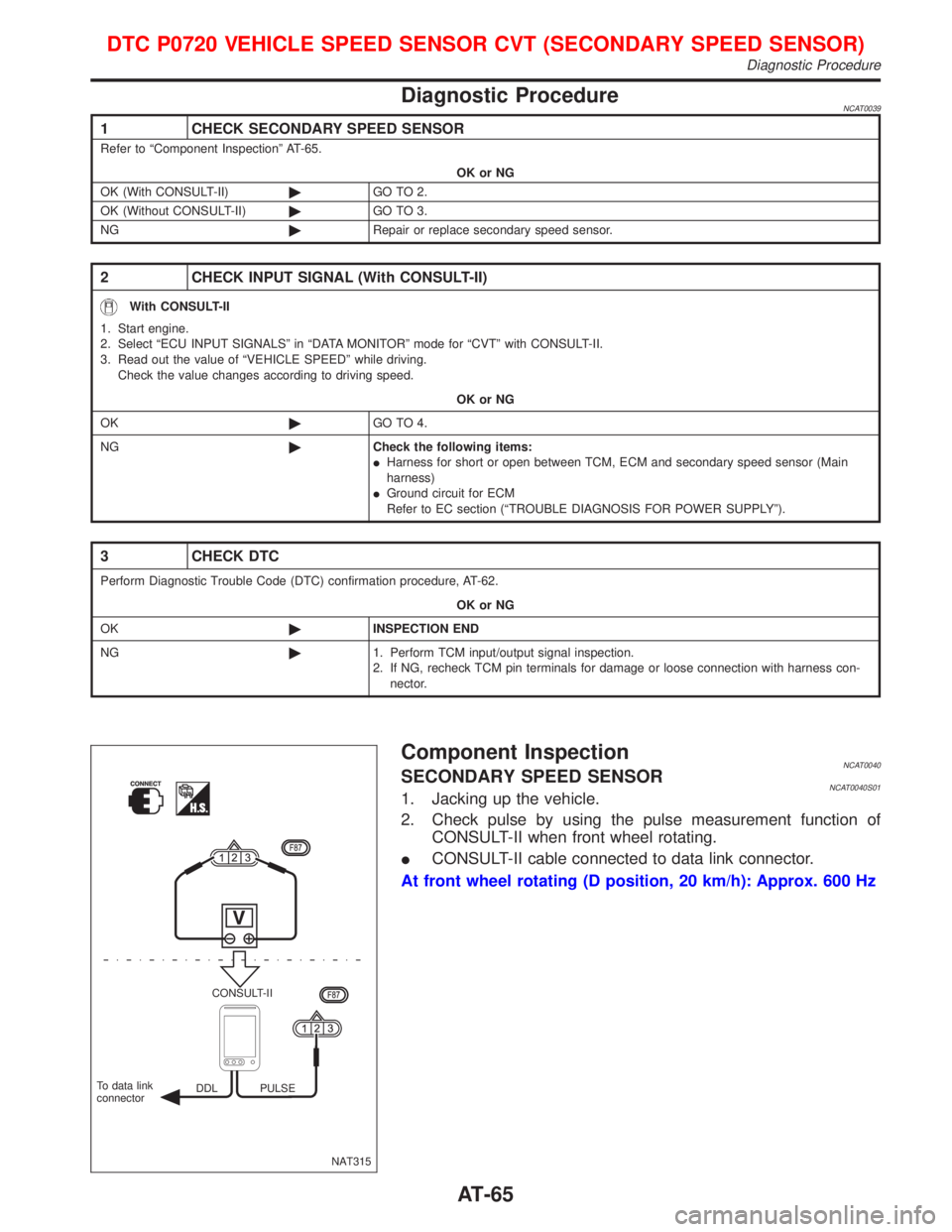

Component InspectionNCAT0040SECONDARY SPEED SENSORNCAT0040S011. Jacking up the vehicle.

2. Check pulse by using the pulse measurement function of

CONSULT-II when front wheel rotating.

ICONSULT-II cable connected to data link connector.

At front wheel rotating (D position, 20 km/h): Approx. 600 Hz

NAT315 CONSULT-II

DDL PULSE To data link

connector

DTC P0720 VEHICLE SPEED SENSOR CVT (SECONDARY SPEED SENSOR)

Diagnostic Procedure

AT-65

Page 68 of 2267

DescriptionNCAT0041The engine speed signal is sent from the ECM to the TCM.

TCM TERMINALS AND REFERENCE VALUENCAT0041S01Remarks: Specification data are reference values.

Terminal

No.Wire color Item ConditionJudgement

standard

39 L/OREngine speed

signal

When engine runs at idle speed.0.5 - 1.5V

ON BOARD DIAGNOSIS LOGICNCAT0041S02

Diagnostic trouble code Malfunction is detected when ... Check item (Possible cause)

: ENGINE SPEED SIG

TCM does not receive the proper voltage

signal from ECM.IHarness or connectors

(The sensor circuit is open or shorted.)

: P0725

: MI Code No. 0725

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION

PROCEDURE

NCAT0041S03CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCE-

DUREº has been previously conducted, always turn ignition

switch ªOFFº and wait at least 5 seconds before conducting

the next test.

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

With CONSULT-II

1) Turn ignition switch ªONº and select ªDATA MONITORº mode

for ªENGINEº with CONSULT-II.

2) Start engine and maintain the following conditions for at least

10 consecutive seconds.

VHCL SPEED SE: 10 km/h (6 MPH) or more

THRTL POS SEN: More than 1.3V

Selector lever: D position

If the check result is ªNGº, go to ªDiagnostic Procedureº,

AT-68.

With GST

Follow the procedure ªWith CONSULT-IIº.

SAT651J

SAT654J

DTC P0725 ENGINE SPEED SIGNAL

Description

AT-66

Page 69 of 2267

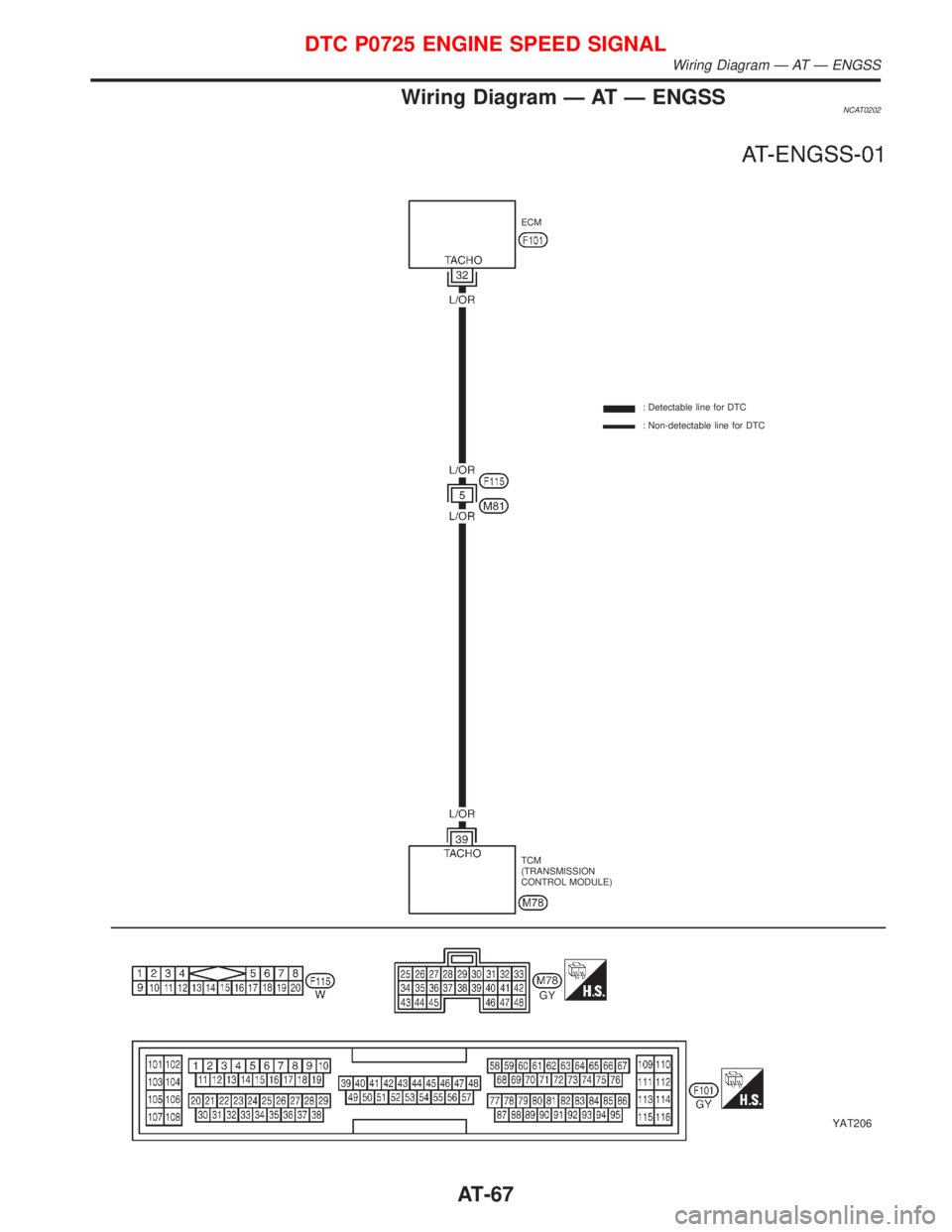

Wiring Diagram Ð AT Ð ENGSSNCAT0202

YAT206

ECM

: Detectable line for DTC

: Non-detectable line for DTC

TCM

(TRANSMISSION

CONTROL MODULE)

DTC P0725 ENGINE SPEED SIGNAL

Wiring Diagram Ð AT Ð ENGSS

AT-67

Page 70 of 2267

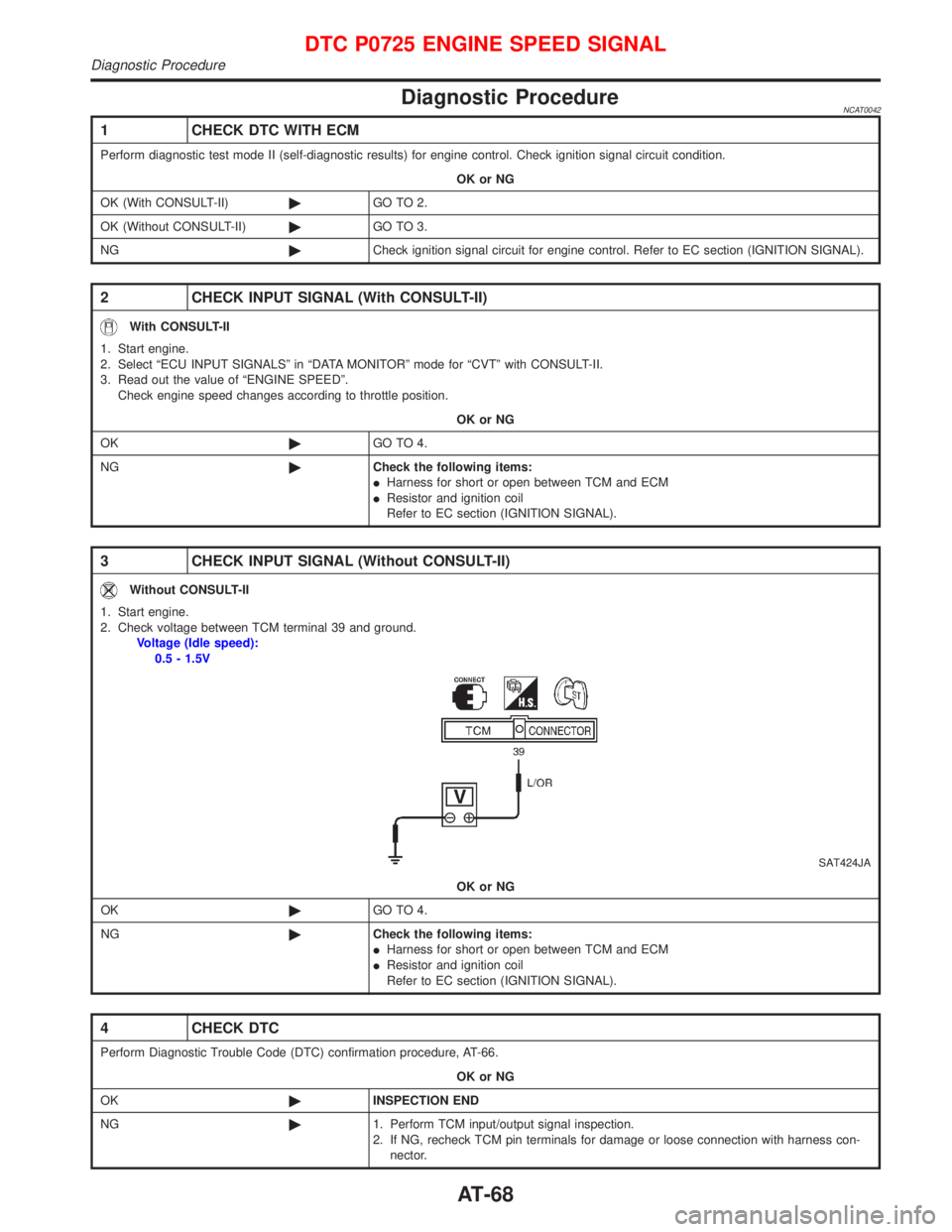

Diagnostic ProcedureNCAT0042

1 CHECK DTC WITH ECM

Perform diagnostic test mode II (self-diagnostic results) for engine control. Check ignition signal circuit condition.

OK or NG

OK (With CONSULT-II)©GO TO 2.

OK (Without CONSULT-II)©GO TO 3.

NG©Check ignition signal circuit for engine control. Refer to EC section (IGNITION SIGNAL).

2 CHECK INPUT SIGNAL (With CONSULT-II)

With CONSULT-II

1. Start engine.

2. Select ªECU INPUT SIGNALSº in ªDATA MONITORº mode for ªCVTº with CONSULT-II.

3. Read out the value of ªENGINE SPEEDº.

Check engine speed changes according to throttle position.

OK or NG

OK©GO TO 4.

NG©Check the following items:

IHarness for short or open between TCM and ECM

IResistor and ignition coil

Refer to EC section (IGNITION SIGNAL).

3 CHECK INPUT SIGNAL (Without CONSULT-II)

Without CONSULT-II

1. Start engine.

2. Check voltage between TCM terminal 39 and ground.

Voltage (Idle speed):

0.5 - 1.5V

SAT424JA

OK or NG

OK©GO TO 4.

NG©Check the following items:

IHarness for short or open between TCM and ECM

IResistor and ignition coil

Refer to EC section (IGNITION SIGNAL).

4 CHECK DTC

Perform Diagnostic Trouble Code (DTC) confirmation procedure, AT-66.

OK or NG

OK©INSPECTION END

NG©1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose connection with harness con-

nector.

DTC P0725 ENGINE SPEED SIGNAL

Diagnostic Procedure

AT-68