NISSAN PULSAR 1987 Workshop Manual

Manufacturer: NISSAN, Model Year: 1987, Model line: PULSAR, Model: NISSAN PULSAR 1987Pages: 238, PDF Size: 28.91 MB

Page 131 of 238

Manual Transaxle and Drive Shafts 131

(19) Renew the rear mainshaft bearing outer race

as follows:

(a) Remove the bolts retaining the rear cover to

the transaxle case. (b) Remove the rear cover. O ring, spacer and

adjusting shim from the transaxle case. Discard the O

ring. (c) Using a suitable punch, tap the bearing outer

race out of the transaxle case. (e) Install the adjusting shim, spacer and a new O

ring to the transaxle case. Install the rear cover and

tighten the retain ing bolts securely.

(20) Renew the front mainshaft bearing outer

race as follows:

(a) Using a suitable puller, pull the outer race

out of the clutch housing.

(b) Ensure that the oil groove in the resin oil

channel is facing the oil pocket in the clutch housing. (c) Install the new outer race to the clutch

housing.

(21) Measure the end float of the input shaft fifth

gear using feeler gauges betw een the fifth gear and the

adjacent gear shoulder. Note the measurement for

later reference.

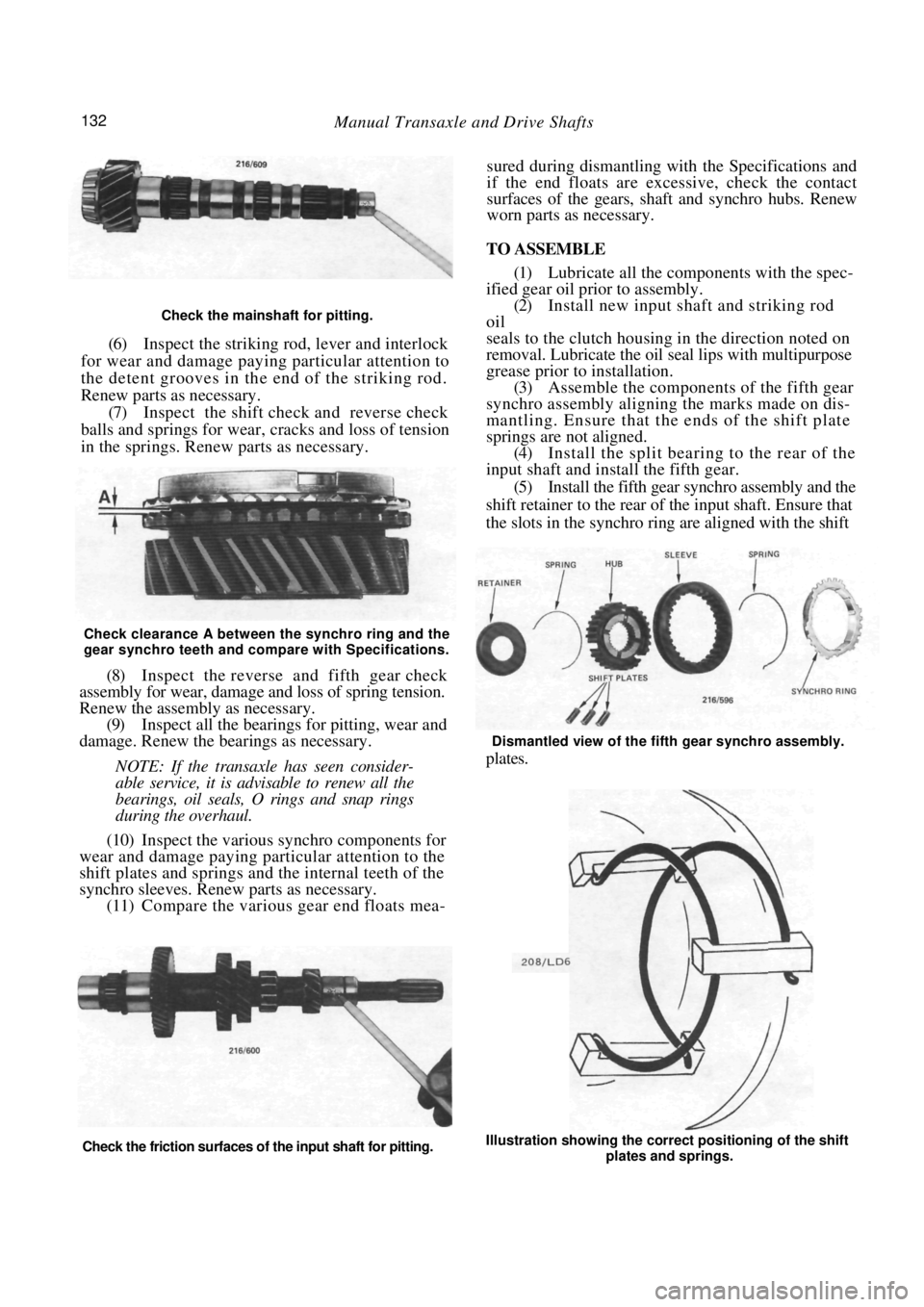

(22) Dismantle the input shaft as follows:

(a) Remove the snap ring and spacer from the

front of the input shaft. (b) Using a suitable puller, remove the bearing

from the front of the input shaft. Remove the bearing

retainer noting the installed direction. (c) Remove the snap ring from the rear of the

input shaft. (d) Remove the shift retainer, fifth gear synchro

assembly, fifth gear and th e split bearing from the rear

of the input shaft.

(23) Measure the end float of the mainshaft first,

second, third and fourth gears using feeler gauges

between the gear and the adjacent shaft shoulder.

Note the measurements for later reference.

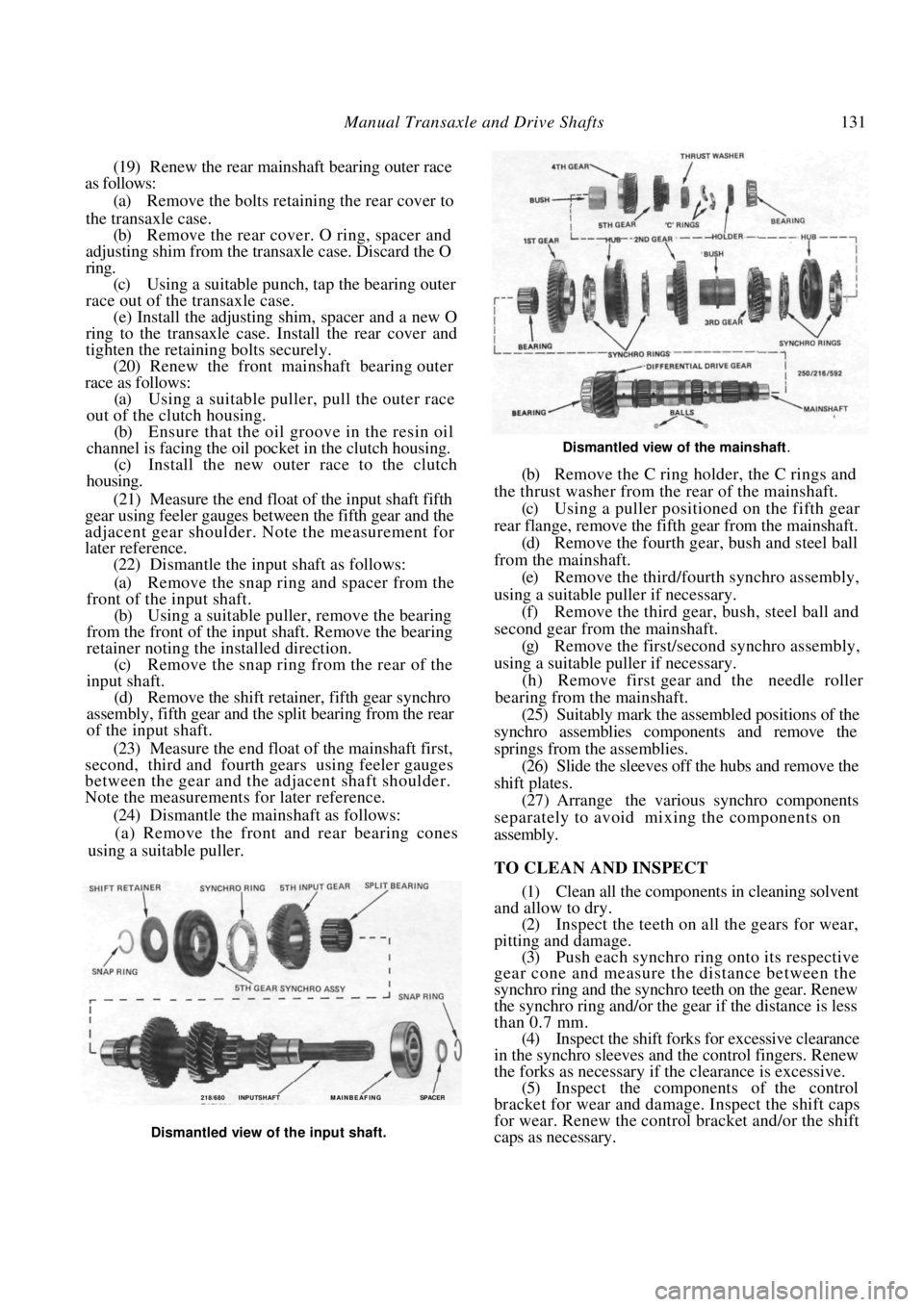

(24) Dismantle the mainshaft as follows:

(a) Remove the front and rear bearing cones

using a suitable puller.

Dismantled view of the mainshaft.

(b) Remove the C ring holder, the C rings and

the thrust washer from the rear of the mainshaft. (c) Using a puller positioned on the fifth gear

rear flange, remove the fifth gear from the mainshaft. (d) Remove the fourth gear , bush and steel ball

from the mainshaft. (e) Remove the third/fourth synchro assembly,

using a suitable puller if necessary. (f) Remove the third gear, bush, steel ball and

second gear from the mainshaft. (g) Remove the first/second synchro assembly,

using a suitable puller if necessary. (h) Remove first gear and the needle roller

bearing from the mainshaft.

(25) Suitably mark the assembled positions of the

synchro assemblies components and remove the

springs from the assemblies.

(26) Slide the sleeves off the hubs and remove the

shift plates.

(27) Arrange the various synchro components

separately to avoid mixing the components on

assembly.

TO CLEAN AND INSPECT

(1) Clean all the components in cleaning solvent

and allow to dry.

(2) Inspect the teeth on all the gears for wear,

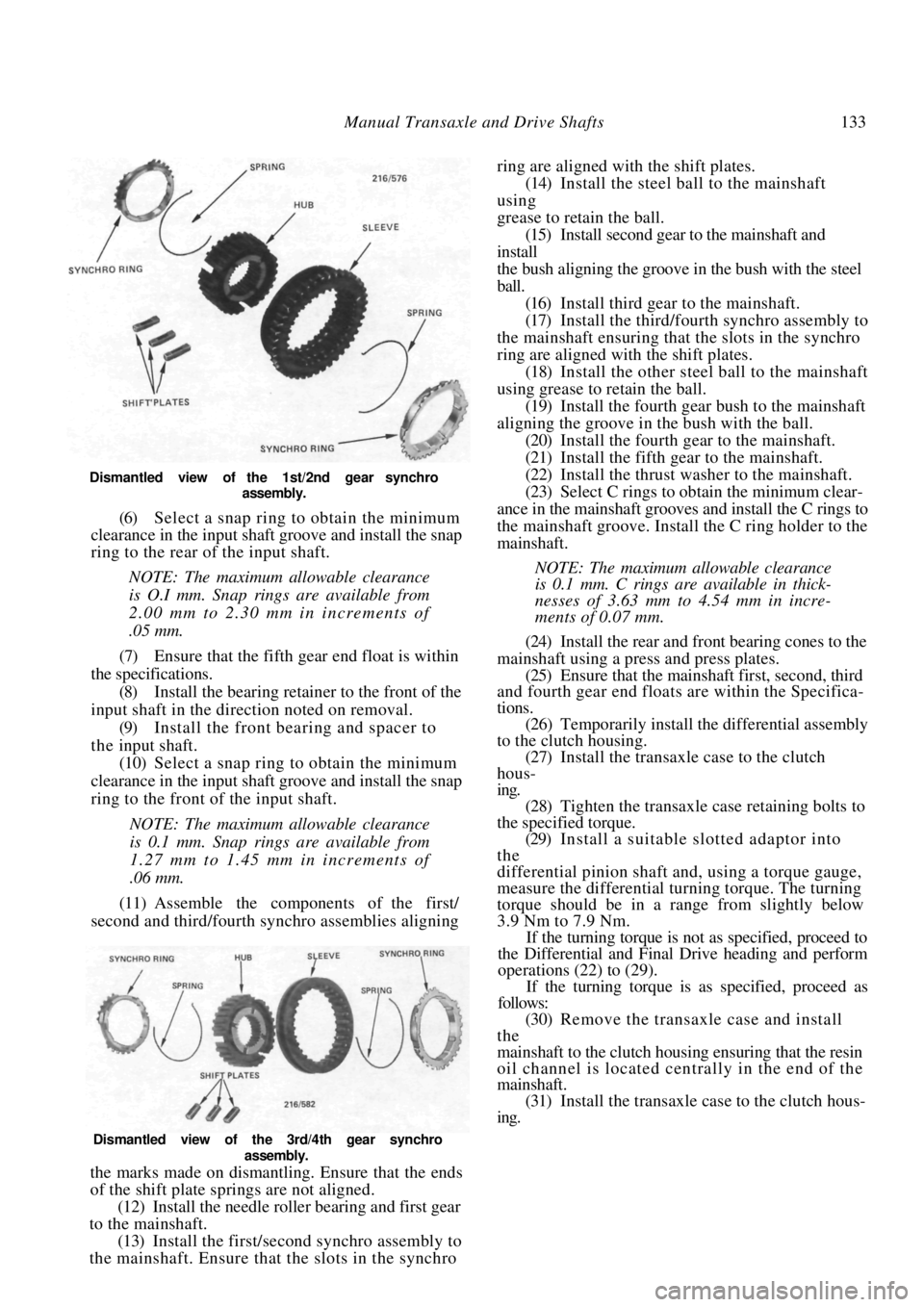

pitting and damage. (3) Push each synchro ring onto its respective

gear cone and measure the distance between the

synchro ring and the synchro teeth on the gear. Renew

the synchro ring and/or the gear if the distance is less

than 0.7 mm.

(4) Inspect the shift forks for excessive clearance

in the synchro sleeves and the control fingers. Renew

the forks as necessary if the clearance is excessive. (5) Inspect the components of the control

bracket for wear and damage. Inspect the shift caps

for wear. Renew the control bracket and/or the shift

caps as necessary.

218/680 INPUTSHAFT M AI N B E AF I N G SPACER

Dismantled view of the input shaft.

Page 132 of 238

132 Manual Transaxle and Drive Shafts

Check the mainshaft for pitting.

(6) Inspect the striking rod, lever and interlock

for wear and damage paying particular attention to

the detent grooves in the end of the striking rod.

Renew parts as necessary. (7) Inspect the shift check and reverse check

balls and springs for wear, cracks and loss of tension

in the springs. Renew parts as necessary.

Check clearance A between the synchro ring and the

gear synchro teeth and compare with Specifications.

(8) Inspect the reverse and fifth gear check

assembly for wear, damage and loss of spring tension.

Renew the assembly as necessary. (9) Inspect all the bearings for pitting, wear and

damage. Renew the bearings as necessary.

NOTE: If the transaxle has seen consider-

able service, it is advisable to renew all the

bearings, oil seals, O rings and snap rings

during the overhaul.

(10) Inspect the various synchro components for

wear and damage paying par ticular attention to the

shift plates and springs and the internal teeth of the

synchro sleeves. Renew parts as necessary. (11) Compare the various gear end floats mea- sured during dismantling with the Specifications and

if the end floats are excessive, check the contact

surfaces of the ge

ars, shaft and synchro hubs. Renew

worn parts as necessary.

TO ASSEMBLE

(1) Lubricate all the components with the spec-

ified gear oil prior to assembly. (2) Install new input shaft and striking rod

oil

seals to the clutch housing in the direction noted on

removal. Lubricate the oil seal lips with multipurpose

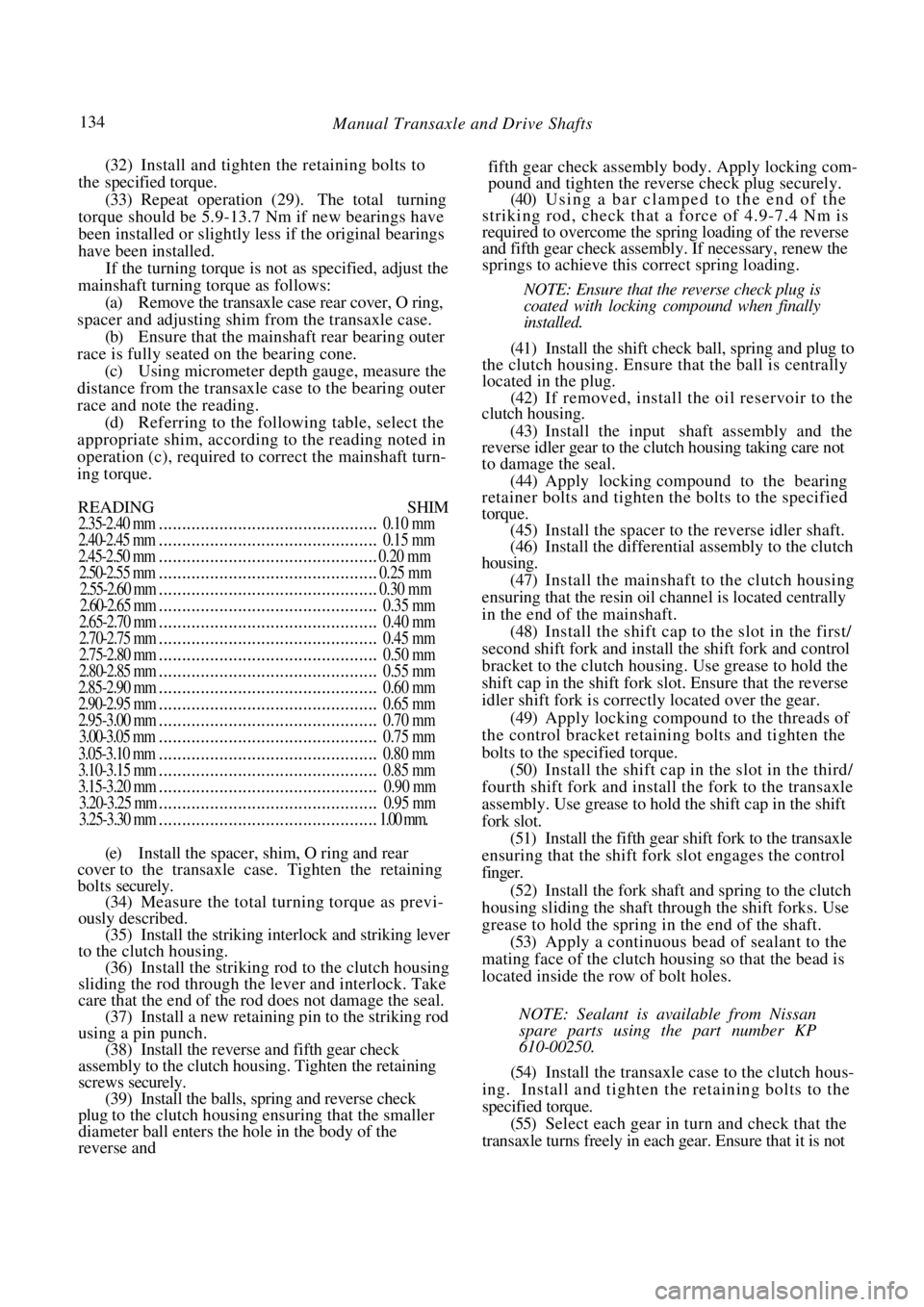

grease prior to installation. (3) Assemble the components of the fifth gear

synchro assembly aligning the marks made on dis-

mantling. Ensure that the ends of the shift plate

springs are not aligned.

(4) Install the split bearing to the rear of the

input shaft and install the fifth gear.

(5) Install the fifth gear sy nchro assembly and the

shift retainer to the rear of the input shaft. Ensure that

the slots in the synchro ring are aligned with the shift

plates.

Check the friction surfaces of the input shaft for pitting. Dismantled view of the fifth gear synchro assembly.

Illustration showing the correct positioning of the shift plates and springs.

Page 133 of 238

Manual Transaxle and Drive Shafts 133

Dismantled view of the 1st/2nd gear synchro assembly.

(6) Select a snap ring to obtain the minimum

clearance in the input shaft groove and install the snap

ring to the rear of the input shaft.

NOTE: The maximum allowable clearance

is O.I mm. Snap rings are available from

2.00 mm to 2.30 mm in increments of

.05 mm.

(7) Ensure that the fifth gear end float is within

the specifications. (8) Install the bearing retain er to the front of the

input shaft in the direction noted on removal.

(9) Install the front bearing and spacer to

the input shaft. (10) Select a snap ring to obtain the minimum

clearance in the input shaft groove and install the snap

ring to the front of the input shaft.

NOTE: The maximum allowable clearance

is 0.1 mm. Snap rings are available from

1.27 mm to 1.45 mm in increments of

.06 mm.

(11) Assemble the components of the first/

second and third/fourth sy nchro assemblies aligning

the marks made on dismantling. Ensure that the ends

of the shift plate springs are not aligned.

(12) Install the needle roller bearing and first gear

to the mainshaft.

(13) Install the firs t/second synchro assembly to

the mainshaft. Ensure that the slots in the synchro ring are aligned with the shift plates.

(14) Install the steel ball to the mainshaft

using

grease to retain the ball. (15) Install second gear to the mainshaft and

install

the bush aligning the groove in the bush with the steel

ball. (16) Install third gear to the mainshaft.

(17) Install the third/fourth synchro assembly to

the mainshaft ensuring that the slots in the synchro

ring are aligned with the shift plates.

(18) Install the other steel ball to the mainshaft

using grease to retain the ball. (19) Install the fourth gear bush to the mainshaft

aligning the groove in the bush with the ball. (20) Install the fourth gear to the mainshaft.

(21) Install the fifth gear to the mainshaft.

(22) Install the thrust washer to the mainshaft.

(23) Select C rings to obtain the minimum clear-

ance in the mainshaft grooves and install the C rings to

the mainshaft groove. Install the C ring holder to the

mainshaft.

NOTE: The maximum allowable clearance

is 0.1 mm. C rings are available in thick-

nesses of 3.63 mm to 4.54 mm in incre-

ments of 0.07 mm.

(24) Install the rear and front bearing cones to the

mainshaft using a press and press plates. (25) Ensure that the mainshaft first, second, third

and fourth gear end floats are within the Specifica-

tions.

(26) Temporarily install the differential assembly

to the clutch housing. (27) Install the transaxle case to the clutch

hous-

ing. (28) Tighten the transaxle case retaining bolts to

the specified torque. (29) Install a suitable slotted adaptor into

the

differential pinion shaft a nd, using a torque gauge,

measure the differential tu rning torque. The turning

torque should be in a range from slightly below

3.9 Nm to 7.9 Nm. If the turning torque is not as specified, proceed to

the Differential and Final Drive heading and perform

operations (22) to (29).

If the turning torque is as specified, proceed as

follows:

(30) Remove the transaxle case and install

the

mainshaft to the clutch housing ensuring that the resin

oil channel is located centrally in the end of the

mainshaft. (31) Install the transaxle case to the clutch hous-

ing.

Dismantled view of the 3rd/4th gear synchro

assembly.

Page 134 of 238

134 Manual Transaxle and Drive Shafts

(32) Install and tighten the retaining bolts to

the specified torque.

(33) Repeat operation (29). The total turning

torque should be 5.9-13.7 Nm if new bearings have

been installed or slightly l ess if the original bearings

have been installed. If the turning torque is no t as specified, adjust the

mainshaft turning torque as follows:

(a) Remove the transaxle case rear cover, O ring,

spacer and adjusting shim from the transaxle case.

(b) Ensure that the mainsh aft rear bearing outer

race is fully seated on the bearing cone. (c) Using micrometer depth gauge, measure the

distance from the transaxle case to the bearing outer

race and note the reading. (d) Referring to the following table, select the

appropriate shim, according to the reading noted in

operation (c), required to correct the mainshaft turn-

ing torque.

READING SHIM

2.35-2.40 mm............................................... 0.10 mm

2.40-2.45 mm............................................... 0.15 mm

2.45-2.50 mm...............................................0.20 mm

2.50-2.55 mm...............................................0.25 mm

2.55-2.60 mm...............................................0.30 mm

2.60-2.65 mm............................................... 0.35 mm

2.65-2.70 mm............................................... 0.40 mm

2.70-2.75 mm............................................... 0.45 mm

2.75-2.80 mm............................................... 0.50 mm

2.80-2.85 mm............................................... 0.55 mm

2.85-2.90 mm............................................... 0.60 mm

2.90-2.95 mm............................................... 0.65 mm

2.95-3.00 mm............................................... 0.70 mm

3.00-3.05 mm............................................... 0.75 mm

3.05-3.10 mm............................................... 0.80 mm

3.10-3.15 mm............................................... 0.85 mm

3.15-3.20 mm............................................... 0.90 mm

3.20-3.25 mm............................................... 0.95 mm

3.25-3.30 mm...............................................1.00 mm.

(e) Install the spacer, shim, O ring and rear

cover to the transaxle case. Tighten the retaining

bolts securely.

(34) Measure the total turning torque as previ-

ously described. (35) Install the striking interlock and striking lever

to the clutch housing. (36) Install the striking ro d to the clutch housing

sliding the rod through the lever and interlock. Take

care that the end of the rod does not damage the seal. (37) Install a new retaining pin to the striking rod

using a pin punch. (38) Install the reverse and fifth gear check

assembly to the clutch housing. Tighten the retaining

screws securely. (39) Install the balls, spring and reverse check

plug to the clutch housing ensuring that the smaller

diameter ball enters the hole in the body of the

reverse and fifth gear check assembly body. Apply locking com-

pound and tighten the reverse check plug securely.

(40) Using a bar clamped to the end of the

striking rod, check that a force of 4.9-7.4 Nm is

required to overcome the spring loading of the reverse

and fifth gear check assembly. If necessary, renew the

springs to achieve this correct spring loading.

NOTE: Ensure that the reverse check plug is

coated with locking compound when finally

installed.

(41) Install the shift check ball, spring and plug to

the clutch housing. Ensure that the ball is centrally

located in the plug.

(42) If removed, install the oil reservoir to the

clutch housing.

(43) Install the input shaft assembly and the

reverse idler gear to the clutch housing taking care not

to damage the seal.

(44) Apply locking compound to the bearing

retainer bolts and tighten the bolts to the specified

torque.

(45) Install the spacer to the reverse idler shaft.

(46) Install the differential assembly to the clutch

housing.

(47) Install the mainshaft to the clutch housing

ensuring that the resin oil ch annel is located centrally

in the end of the mainshaft. (48) Install the shift cap to the slot in the first/

second shift fork and install the shift fork and control

bracket to the clutch housing. Use grease to hold the

shift cap in the shift fork slot. Ensure that the reverse

idler shift fork is correctly located over the gear.

(49) Apply locking compound to the threads of

the control bracket retaining bolts and tighten the

bolts to the specified torque. (50) Install the shift cap in the slot in the third/

fourth shift fork and install the fork to the transaxle

assembly. Use grease to hold the shift cap in the shift

fork slot. (51) Install the fifth gear shift fork to the transaxle

ensuring that the shift fork slot engages the control

finger.

(52) Install the fork shaft an d spring to the clutch

housing sliding the shaft through the shift forks. Use

grease to hold the spring in the end of the shaft. (53) Apply a continuous bead of sealant to the

mating face of the clutch housing so that the bead is

located inside the row of bolt holes.

NOTE: Sealant is available from Nissan

spare parts using the part number KP

610-00250.

(54) Install the transaxle case to the clutch hous-

ing. Install and tighten the retaining bolts to the

specified torque. (55) Select each gear in turn and check that the

transaxle turns freely in each gear. Ensure that it is not

Page 135 of 238

Manual Transaxle and Drive Shafts 135

possible to move the striking rod from fifth gear to

reverse without first moving sideways in the neutral

gate.

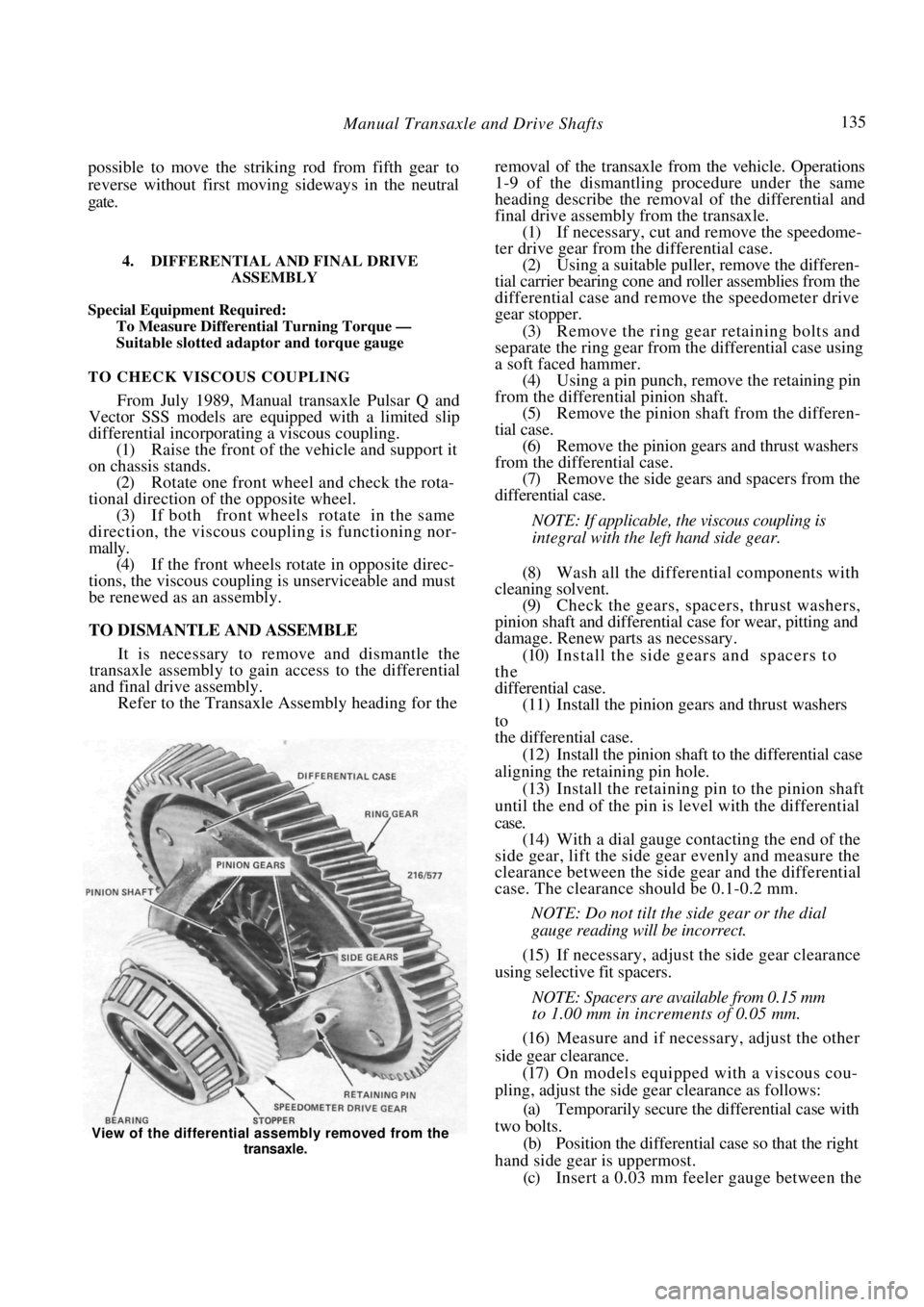

4. DIFFERENTIAL AND FINAL DRIVE ASSEMBLY

Special Equipment Required:

To Measure Differential Turning Torque —

Suitable slotted adaptor and torque gauge

TO CHECK VISCOUS COUPLING

From July 1989, Manual transaxle Pulsar Q and

Vector SSS models are equipped with a limited slip

differential incorporating a viscous coupling.

(1) Raise the front of the vehicle and support it

on chassis stands. (2) Rotate one front wheel and check the rota-

tional direction of the opposite wheel. (3) If both front wheels rotate in the same

direction, the viscous coupling is functioning nor-

mally. (4) If the front wheels rota te in opposite direc-

tions, the viscous coupling is unserviceable and must

be renewed as an assembly.

TO DISMANTLE AND ASSEMBLE

It is necessary to remove and dismantle the

transaxle assembly to gain access to the differential

and final drive assembly.

Refer to the Transaxle Assembly heading for the

removal of the transaxle from the vehicle. Operations

1-9 of the dismantling procedure under the same

heading describe the removal of the differential and

final drive assembly from the transaxle.

(1) If necessary, cut and remove the speedome-

ter drive gear from the differential case. (2) Using a suitable puller, remove the differen-

tial carrier bearing cone and roller assemblies from the

differential case and remove the speedometer drive

gear stopper.

(3) Remove the ring gear retaining bolts and

separate the ring gear from the differential case using

a soft faced hammer.

(4) Using a pin punch, remove the retaining pin

from the differential pinion shaft.

(5) Remove the pinion shaft from the differen-

tial case. (6) Remove the pinion gears and thrust washers

from the differential case. (7) Remove the side gears and spacers from the

differential case.

NOTE: If applicable, the viscous coupling is

integral with the left hand side gear.

(8) Wash all the differential components with

cleaning solvent. (9) Check the gears, spacer s, thrust washers,

pinion shaft and differential case for wear, pitting and

damage. Renew parts as necessary.

(10) Install the side gears and spacers to

the

differential case.

(11) Install the pinion gear s and thrust washers

to

the differential case.

(12) Install the pinion shaft to the differential case

aligning the retaining pin hole. (13) Install the retaining pin to the pinion shaft

until the end of the pin is level with the differential

case. (14) With a dial gauge contacting the end of the

side gear, lift the side gear evenly and measure the

clearance between the side gear and the differential

case. The clearance should be 0.1-0.2 mm.

NOTE: Do not tilt the side gear or the dial

gauge reading will be incorrect.

(15) If necessary, adjust the side gear clearance

using selective fit spacers.

NOTE: Spacers are available from 0.15 mm

to 1.00 mm in increments of 0.05 mm.

(16) Measure and if necessary, adjust the other

side gear clearance. (17) On models equipped with a viscous cou-

pling, adjust the side gear clearance as follows:

(a) Temporarily secure the differential case with

two bolts. (b) Position the differential case so that the right

hand side gear is uppermost. (c) Insert a 0.03 mm feeler gauge between the

View of the differential ass embly removed from the

transaxle.

Page 136 of 238

136 Manual Transaxle and Drive Shafts

right hand side gear and the adjacent spacer in an area

where there is no oil groove in the differential case.

(d) Insert another 0.03 mm feeler gauge diago-

nally opposite the first feeler gauge to avoid tilting the

side gear.

(e) Insert a splined adaptor into the right hand

side gear and attempt to rotate the gear by hand.

(f) If the gear cannot be rotated, change the

thickness of the left hand side gear spacer, repeating

the test until the gear can be rotated.

NOTE: Spacers are available in thicknesses

from 0.8 mm to 1.5 mm in increments of

0.1 mm.

(g) Remove the 0.03 mm feel er gauges and insert

0.09 mm feeler gauges to the same position. The gear

should lock.

(h) The spacer selection is correct when the right

hand side gear can be rotated with 0.03 mm feeler

gauges inserted but locks when 0.09 mm feeler gauges

are inserted.

(18) Install the ring gear to the differential case

with the chamfered edge of the ring gear inwards. (19) Install and tighten the retaining bolts in

a

diagonal sequence to the specified torque.

(20) Install a new speedometer drive gear to

the

differential case. Install the stopper adjacent to the

drive gear.

(21) Install the differentia] carrier bearing

cones

and roller assemblies to the differential case.

(22) Remove the adjusting shim from behind the

carrier bearing outer race in the transaxle case and

replace the outer race in the transaxle case.

(23) Install the differential assembly to the clutch

housing. (24) Install the transaxle case to the clutch housing

and tighten the retaining bolts to the specified torque.

(25) Mount a dial gauge to the clutch housing so

that the contact point is resting on the differential

case. (26) Insert a bar through the opposite side gear

and, contacting the pinion shaft, raise and lower the

differential case and measure the end float in the

carrier bearings. (27) Using the following table, select a shim to

correspond to the relevant end float.

END FLOAT SHIM THICKNESS

0.30-0.34 mm....................................................0.64 mm

0.34-0.38 mm................................................... 0.68 mm

0.38-0.42 mm................................................... 0.72 mm

0.42-0.46 mm................................................... 0.76 mm

0.46-0.50 mm................................................... 0.80 mm

0.50-0.54 mm................................................... 0.84 mm

0.54-0.58 mm................................................... 0.88 mm

0.58-0.62 mm................................................... 0.92 mm

0.62-0.66 mm................................................... 0.96 mm

0.66-0.70 mm................................................... 1.00 mm

0.70-0.74 mm................................................... 1.04 mm

0.74-0.78 mm ................................................... 1.08 mm

0.78-0.82 mm ................................................... 1.12 mm

0.82-0.86 mm ................................................... 1.16 mm

0.86-0.90 mm ................................................... 1.20 mm

0.90-0.94 mm ................................................... 1.24 mm

0.94-0.98 mm ................................................... 1.28 mm

0.98-1.02 mm ................................................... 1.32 mm

1.02-1.06 mm ................................................... 1.36 mm

1.06-1.10 mm ................................................... 1.40 mm

1.10-1.14 mm ................................................... 1.44 mm

1.14-1.18 mm ................................................... 1.48 mm

1.18-1.22 mm ................................................... 1.52 mm

1.22-1.26 mm ................................................... 1.56 mm

1.26-1.30 mm ................................................... 1.60 mm

1.30-1.34 mm ................................................... 1.64 mm

1.34-1.38 mm ................................................... 1.68 mm

1.38-1.42 mm ................................................... 1.72 mm

1.42-1.46 mm ................................................... 1.76 mm

The thickest shim available is 0.88 mm. Multiple

shims are required above this thickness.

(28) Install the shim behind the carrier

bearing

outer race in the transaxle case and assemble the unit

once more. (29) Using a suitable slotted adaptor engage the

pinion shaft and using a to rque gauge, measure the

differential turning torque. The turning torque when new carrier bearings

have been installed should be 3.9-7.8 Nm or slightly

lower if the original carrier bearings have been

replaced.

(30) Assemble the transaxle and measure the total

turning torque of the diff erential assembly and the

mainshaft. The total turning torque should be 5.9 to

13.7 Nm with new bearings or slightly lower if the

original bearings have been replaced.

5. GEAR LEVER ASSEMBLY

TO DISMANTLE AND ASSEMBLE

(1) Remove the gear lever knob and remove the

centre console as described in the Body section. If not

previously removed, remove the rubber boot sur-

rounding the gear lever. (2) Raise the front of the vehicle and support it

on chassis stands. Remove the catalytic converter and

heat shield as described in the Engine section.

(3) Remove the bolt and disconnect the control

rod from the bottom of the gear lever, noting the

position of the return spring and bracket.

(4) Remove the nuts retaining the gear lever

socket to the support rod. (5) Working inside the vehicle, lift the gear lever

out of the floor bracket. (6) Separate the lower rubber boot, socket,

spring seat, spring, upper ball seat and lower ball seat

from the gear lever, noting the location of each

component to aid assembly.

Page 137 of 238

Manual Transaxle and Drive Shafts 137

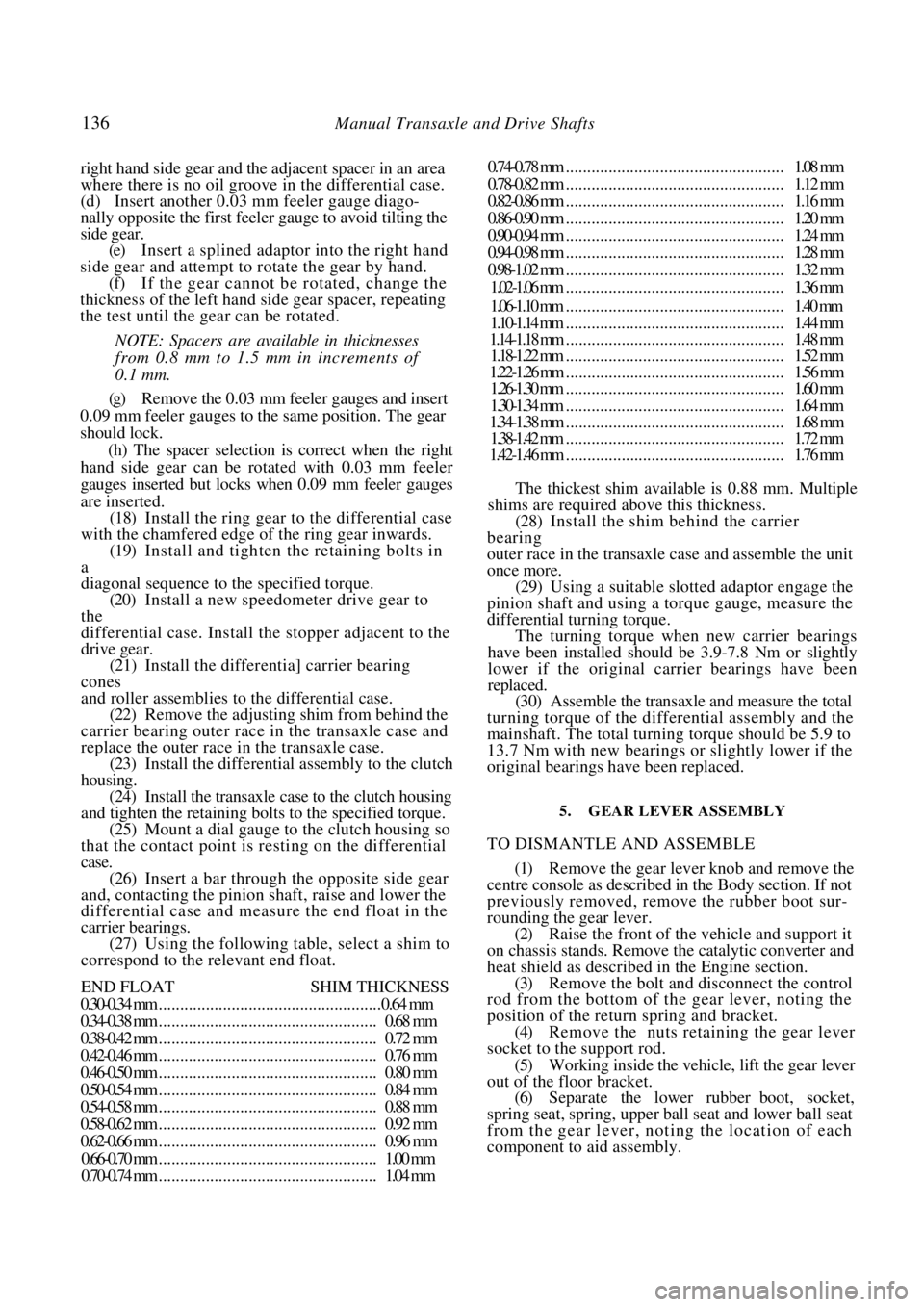

Dismantled view of the gear lever assembly.

(7) Remove the bushes, spacer and O rings from

the bottom of the gear lever.

(8) Remove the nuts retaining the floor bracket

to the vehicle floor panel and remove the bracket from

the vehicle. (9) If necessary, disconnect the control rod and

the support rod from the transaxle and remove the

rods from the vehicle. (10) Check all the components for deterioration,

wear and damage. Renew the unserviceable compo-

nents as necessary. Assembly is a reversal of the dismantling proce-

dure with attention to the following points:

(1) Install all the components to the locations

noted during dismantling.

(2) Lubricate all the pivot points with multipur-

pose grease prior to assembly. (3) Tighten all the nuts securely.

(4) Road test the vehicle and check for correct

gear selection.

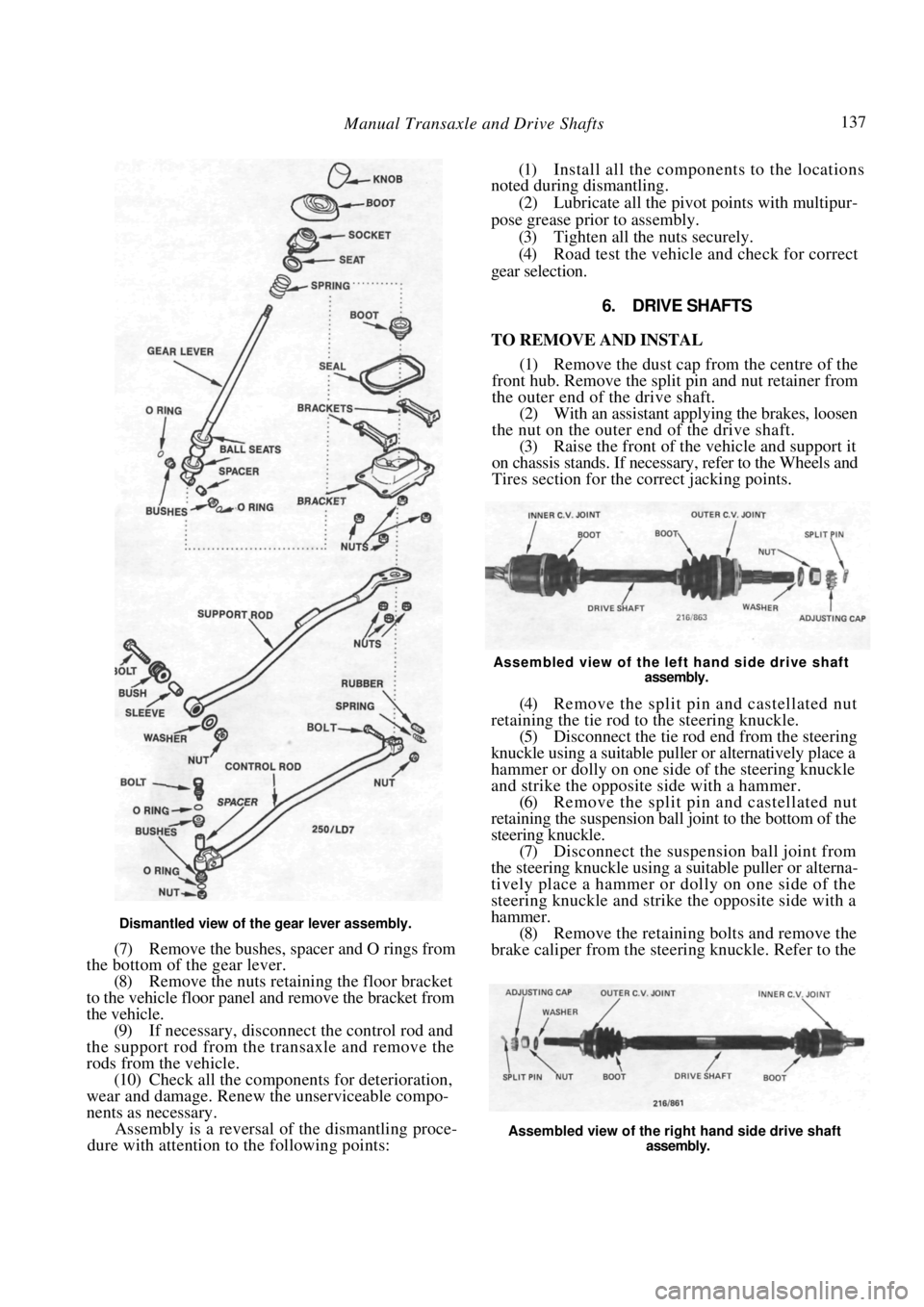

6. DRIVE SHAFTS

TO REMOVE AND INSTAL

(1) Remove the dust cap from the centre of the

front hub. Remove the split pin and nut retainer from

the outer end of the drive shaft. (2) With an assistant applying the brakes, loosen

the nut on the outer end of the drive shaft.

(3) Raise the front of the vehicle and support it

on chassis stands. If necessary, refer to the Wheels and

Tires section for the correct jacking points.

Assembled view of the left hand side drive shaft

assembly.

(4) Remove the split pin and castellated nut

retaining the tie rod to the steering knuckle. (5) Disconnect the tie rod end from the steering

knuckle using a suitable puller or alternatively place a

hammer or dolly on one side of the steering knuckle

and strike the opposite side with a hammer.

(6) Remove the split pin and castellated nut

retaining the suspension ball joint to the bottom of the

steering knuckle. (7) Disconnect the suspension ball joint from

the steering knuckle using a suitable puller or alterna-

tively place a hammer or dolly on one side of the

steering knuckle and strike the opposite side with a

hammer. (8) Remove the retaining bolts and remove the

brake caliper from the stee ring knuckle. Refer to the

Assembled view of the right hand side drive shaft

assembly.

Page 138 of 238

138 Manual Transaxle and Drive Shafts

Brakes section if necessary. Suspend the caliper with

wire or cord attached to the coil spring.

(9) Hold the steering knuckle and hub assembly

and tap the drive shaft out of the hub using a soft

faced hammer.

(10) Drain the oil from the transaxle into a

container.

(11) Prise the drive shaft out of the transaxle and

remove the drive shaft from the vehicle.

Installation is a reversal of the removal procedure

with attention to the following points:

(1) Ensure that the drive sh aft is firmly attached

to the differential side gear by attempting to pull the

shaft out of the gear. (2) Tighten all nuts securely and install new split

pins. (3) Fill the transaxle with the specified grade and

quantity of oil.

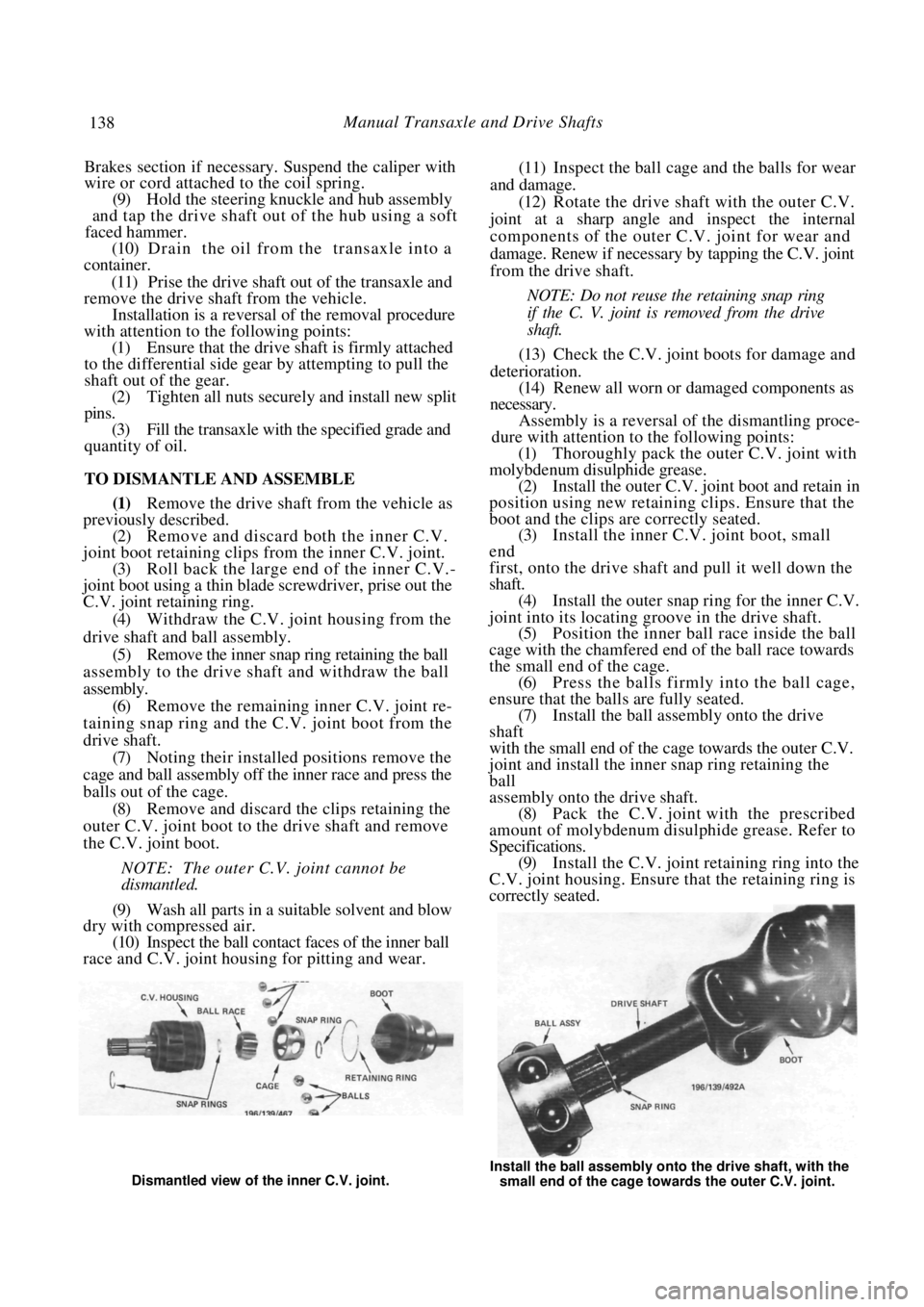

TO DISMANTLE AND ASSEMBLE

(1) Remove the drive shaft from the vehicle as

previously described.

(2) Remove and discard both the inner C.V.

joint boot retaining clips from the inner C.V. joint. (3) Roll back the large en d of the inner C.V.-

joint boot using a thin blade screwdriver, prise out the

C.V. joint retaining ring.

(4) Withdraw the C.V. joint housing from the

drive shaft and ball assembly. (5) Remove the inner snap ring retaining the ball

assembly to the drive shaft and withdraw the ball

assembly. (6) Remove the remaining inner C.V. joint re-

taining snap ring and the C.V. joint boot from the

drive shaft. (7) Noting their installed positions remove the

cage and ball assembly off the inner race and press the

balls out of the cage. (8) Remove and discard the clips retaining the

outer C.V. joint boot to the drive shaft and remove

the C.V. joint boot.

NOTE: The outer C.V. joint cannot be

dismantled.

(9) Wash all parts in a suitable solvent and blow

dry with compressed air.

(10) Inspect the ball contact faces of the inner ball

race and C.V. joint housing for pitting and wear.

(11) Inspect the ball cage and the balls for wear

and damage. (12) Rotate the drive shaft with the outer C.V.

joint at a sharp angle and inspect the internal

components of the outer C.V. joint for wear and

damage. Renew if necessary by tapping the C.V. joint

from the drive shaft.

NOTE: Do not reuse the retaining snap ring

if the C. V. joint is removed from the drive

shaft.

(13) Check the C.V. joint boots for damage and

deterioration. (14) Renew all worn or damaged components as

necessary. Assembly is a reversal of the dismantling proce-

dure with attention to the following points:

(1) Thoroughly pack the outer C.V. joint with

molybdenum disulphide grease. (2) Install the outer C.V. joint boot and retain in

position using new retaining clips. Ensure that the

boot and the clips ar e correctly seated.

(3) Install the inner C.V. joint boot, small

end

first, onto the drive shaft and pull it well down the

shaft. (4) Install the outer snap ri ng for the inner C.V.

joint into its locating groove in the drive shaft. (5) Position the inner ball race inside the ball

cage with the chamfered end of the ball race towards

the small end of the cage. (6) Press the balls firmly into the ball cage,

ensure that the balls are fully seated. (7) Install the ball assem bly onto the drive

shaft

with the small end of the cage towards the outer C.V.

joint and install the inner snap ring retaining the

ball

assembly onto the drive shaft.

(8) Pack the C.V. joint with the prescribed

amount of molybdenum disul phide grease. Refer to

Specifications. (9) Install the C.V. joint retaining ring into the

C.V. joint housing. Ensure that the retaining ring is

correctly seated.

Dismantled view of the inner C.V. joint. Install the ball assembly onto the drive shaft, with the

small end of the cage towards the outer C.V. joint.

Page 139 of 238

Manual Transaxle and Drive Shafts 139

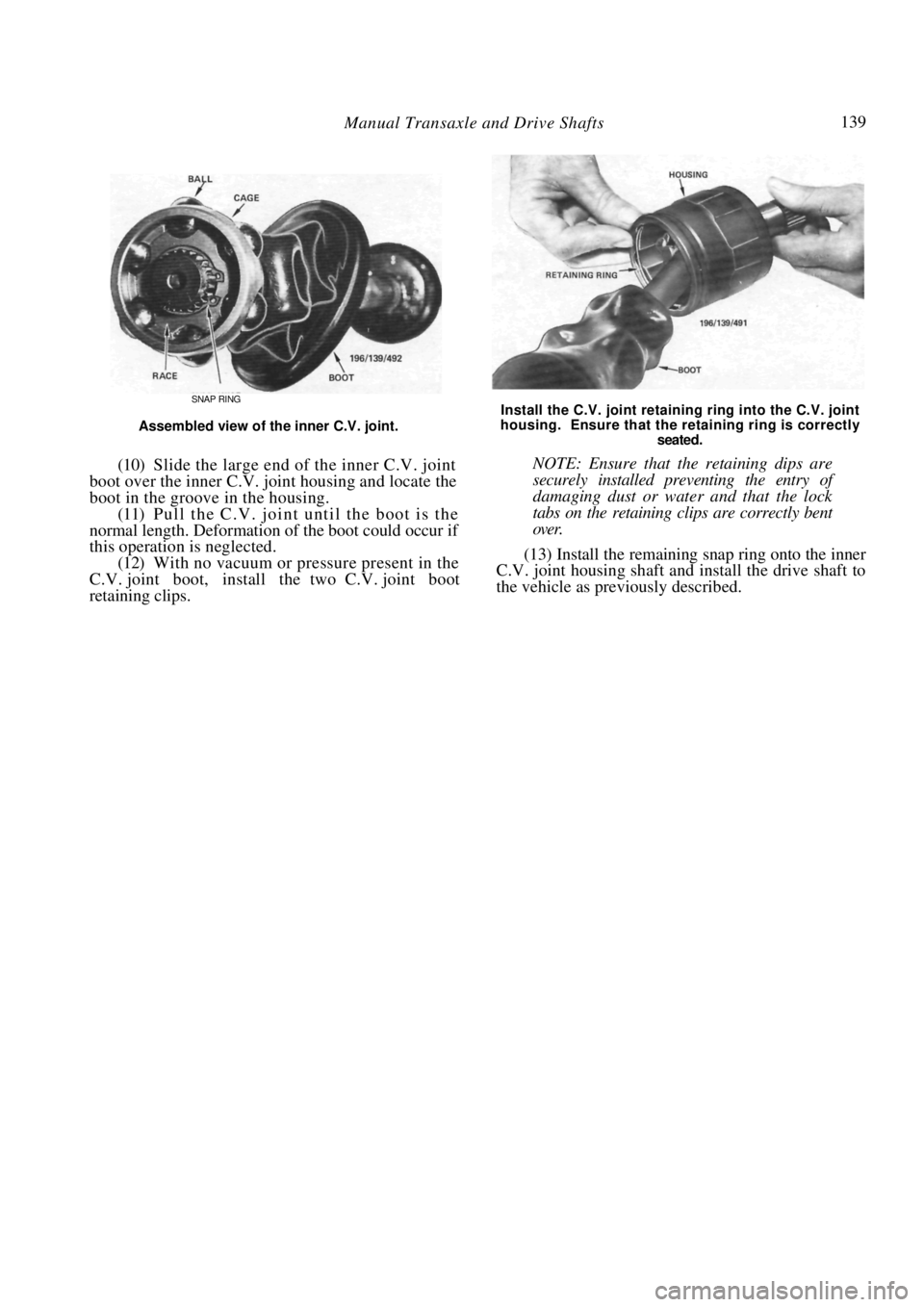

SNAP RING

Assembled view of the inner C.V. joint.

(10) Slide the large end of the inner C.V. joint

boot over the inner C.V. joint housing and locate the

boot in the groove in the housing.

(11) Pull the C.V. joint until the boot is the

normal length. Deformation of the boot could occur if

this operation is neglected. (12) With no vacuum or pressure present in the

C.V. joint boot, install the two C.V. joint boot

retaining clips.

Install the C.V. joint retain ing ring into the C.V. joint

housing. Ensure that the retaining ring is correctly

seated.

NOTE: Ensure that the retaining dips are

securely installed preven ting the entry of

damaging dust or water and that the lock

tabs on the retaining clips are correctly bent

over.

(13) Install the remaining snap ring onto the inner

C.V. joint housing shaft and install the drive shaft to

the vehicle as previously described.

Page 140 of 238

140

AUTOMATIC TRANSAXLE

SPECIFICATIONS

Make .............................................. JATCO RL3F01A

Type .....................3 speed and reverse epicyclic gear

train with lock up torque converter

Operation .................................... Automatic hydraulic

Lubricant:

Type....................................................... Dexron IT

Capacity................................................. 6.3 liters

TORQUE WRENCH SETTINGS

Drive plate to crankshaft bolls ........................60 Nm

Drive plate to torque converter bolts ..............49 Nm

Convener housing to engine ...........................22 Nm

Converter housing to transaxle ........................23 Nm

Transaxle sump to transaxle ............................. 7 Nm

Oil cooler pipe to transaxle .............................49 Nm

Selector shaft locknut .......................................42 Nm

Transaxle filter bolts.........................................12 Nm

1. AUTOMATIC TRANSAXLE TROUBLE SHOOTING

NO DRIVE IN D RANGE

{1) Low fluid level in transaxle: Check the fluid

level in the transaxle and top up if required.

(2) Incorrectly adjusted selector cable: Check

and adjust the selector cable as detailed. (3) Incorrect or contaminated transaxle fluid:

Drain and refill with the recommend type and quan-

tity of transaxle fluid.

NOTE: Check the possible causes in the

order given.

NO REVERSE IN R RANGE

(1) Low fluid level in transaxle: Check the fluid

level and top up if required. (2) Incorrectly adjusted selector linkage: Check

the condition of the selector cable, selector quadrant

and selector arm for wear and damage. Adjust as

required.

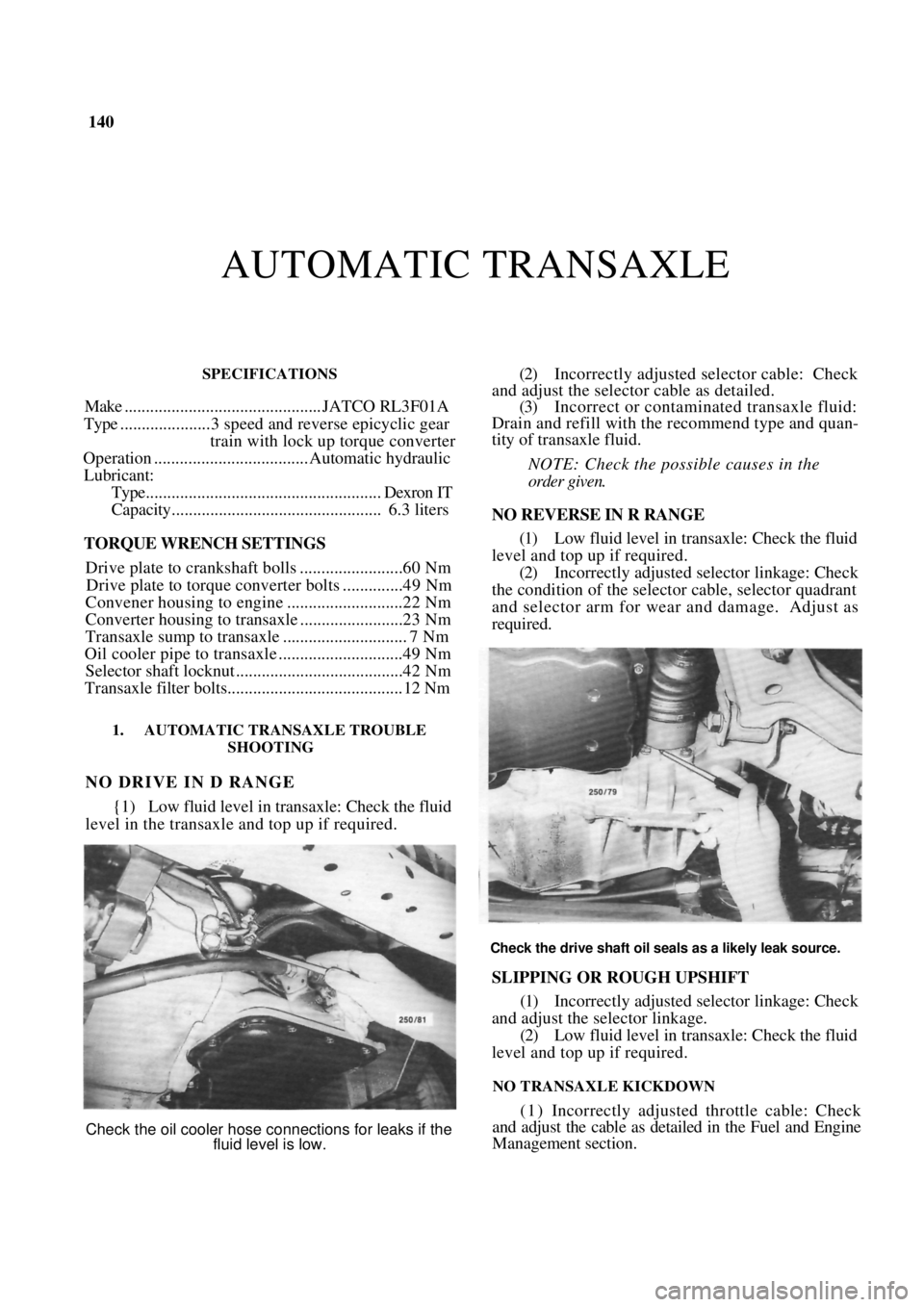

Check the drive shaft oil seals as a likely leak source.

SLIPPING OR ROUGH UPSHIFT

(1) Incorrectly adjusted selector linkage: Check

and adjust the selector linkage. (2) Low fluid level in transaxle: Check the fluid

level and top up if required.

NO TRANSAXLE KICKDOWN

(1) Incorrectly adjusted throttle cable: Check

and adjust the cable as detailed in the Fuel and Engine

Management section.

Check the oil cooler hose connections for leaks if the

fluid level is low.