NISSAN PULSAR 1987 Owners Manual

Manufacturer: NISSAN, Model Year: 1987, Model line: PULSAR, Model: NISSAN PULSAR 1987Pages: 238, PDF Size: 28.91 MB

Page 91 of 238

Fuel and Engine Management 91

components, erase the self diagnosis memory as

described under the following heading.

(7) Repeat the self diagnosis test procedure and

ensure that code 12 is displayed.

To Erase Memory

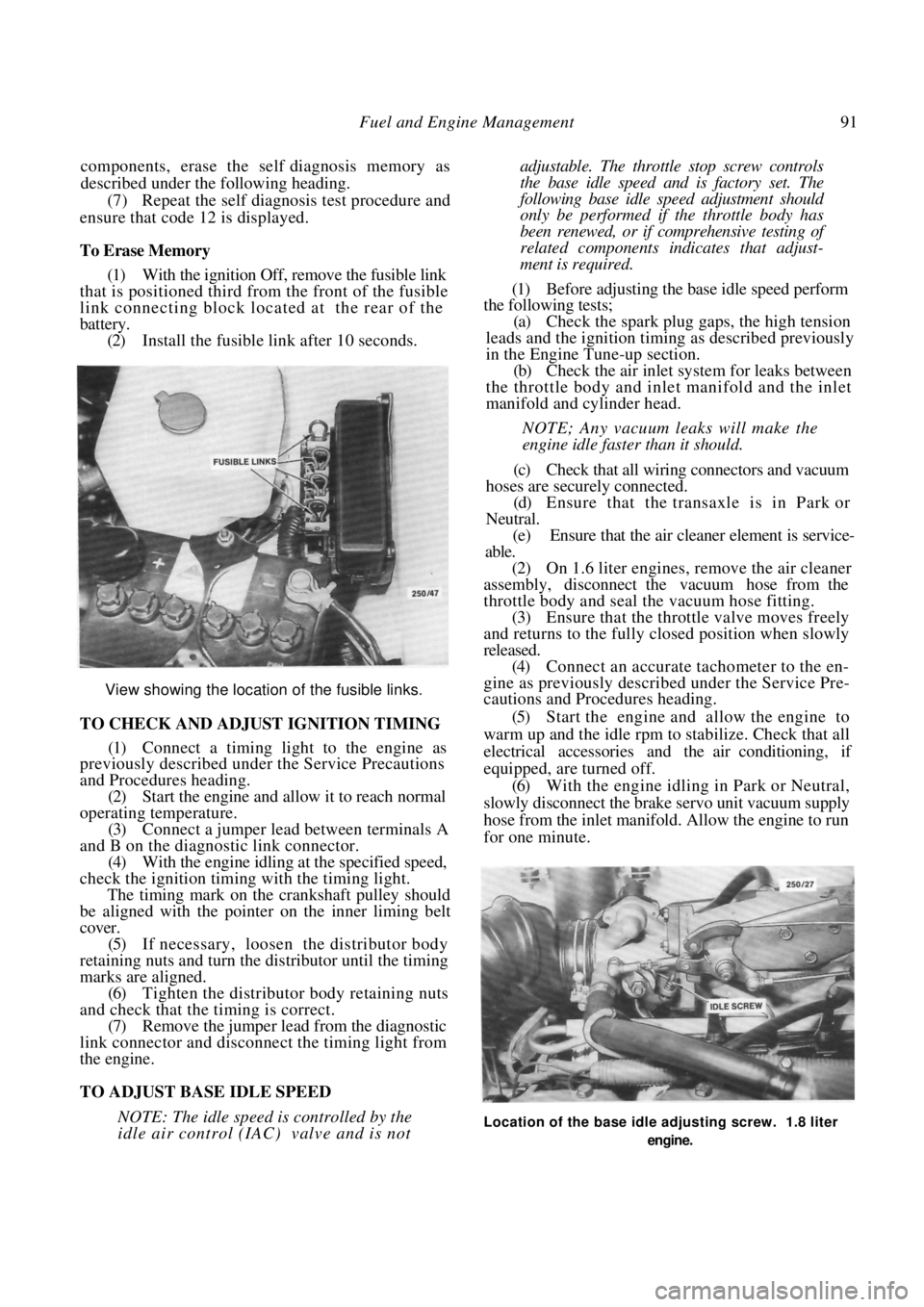

(1) With the ignition Off, remove the fusible link

that is positioned third from the front of the fusible

link connecting block located at the rear of the

battery. (2) Install the fusible link after 10 seconds.

View showing the location of the fusible links.

TO CHECK AND ADJUST IGNITION TIMING

(1) Connect a timing light to the engine as

previously described under the Service Precautions

and Procedures heading.

(2) Start the engine and allow it to reach normal

operating temperature. (3) Connect a jumper lead between terminals A

and B on the diagnostic link connector. (4) With the engine idling at the specified speed,

check the ignition timing with the timing light.

The timing mark on the crankshaft pulley should

be aligned with the pointer on the inner liming belt

cover.

(5) If necessary, loosen the distributor body

retaining nuts and turn the distributor until the timing

marks are aligned. (6) Tighten the distributor body retaining nuts

and check that the timing is correct. (7) Remove the jumper lead from the diagnostic

link connector and disconnect the timing light from

the engine.

TO ADJUST BASE IDLE SPEED

NOTE: The idle speed is controlled by the

idle air control (IAC) valve and is not

adjustable. The throttle stop screw controls

the base idle speed a nd is factory set. The

following base idle speed adjustment should

only be performed if the throttle body has

been renewed, or if comprehensive testing of

related components indicates that adjust-

ment is required.

(1) Before adjusting the base idle speed perform

the following tests;

(a) Check the spark plug gaps, the high tension

leads and the ignition timin g as described previously

in the Engine Tune-up section.

(b) Check the air inlet syst em for leaks between

the throttle body and inlet manifold and the inlet

manifold and cylinder head.

NOTE; Any vacuum leaks will make the

engine idle faster than it should.

(c) Check that all wiring connectors and vacuum

hoses are securely connected. (d) Ensure that the transaxle is in Park or

Neutral. (e) Ensure that the air cleaner element is service-

able.

(2) On 1.6 liter engines, remove the air cleaner

assembly, disconnect the vacuum hose from the

throttle body and seal the vacuum hose fitting.

(3) Ensure that the throttle valve moves freely

and returns to the fully closed position when slowly

released. (4) Connect an accurate tachometer to the en-

gine as previously descri bed under the Service Pre-

cautions and Procedures heading.

(5) Start the engine and allow the engine to

warm up and the idle rpm to stabilize. Check that all

electrical accessories and the air conditioning, if

equipped, are turned off. (6) With the engine idling in Park or Neutral,

slowly disconnect the brake servo unit vacuum supply

hose from the inlet manifold. Allow the engine to run

for one minute.

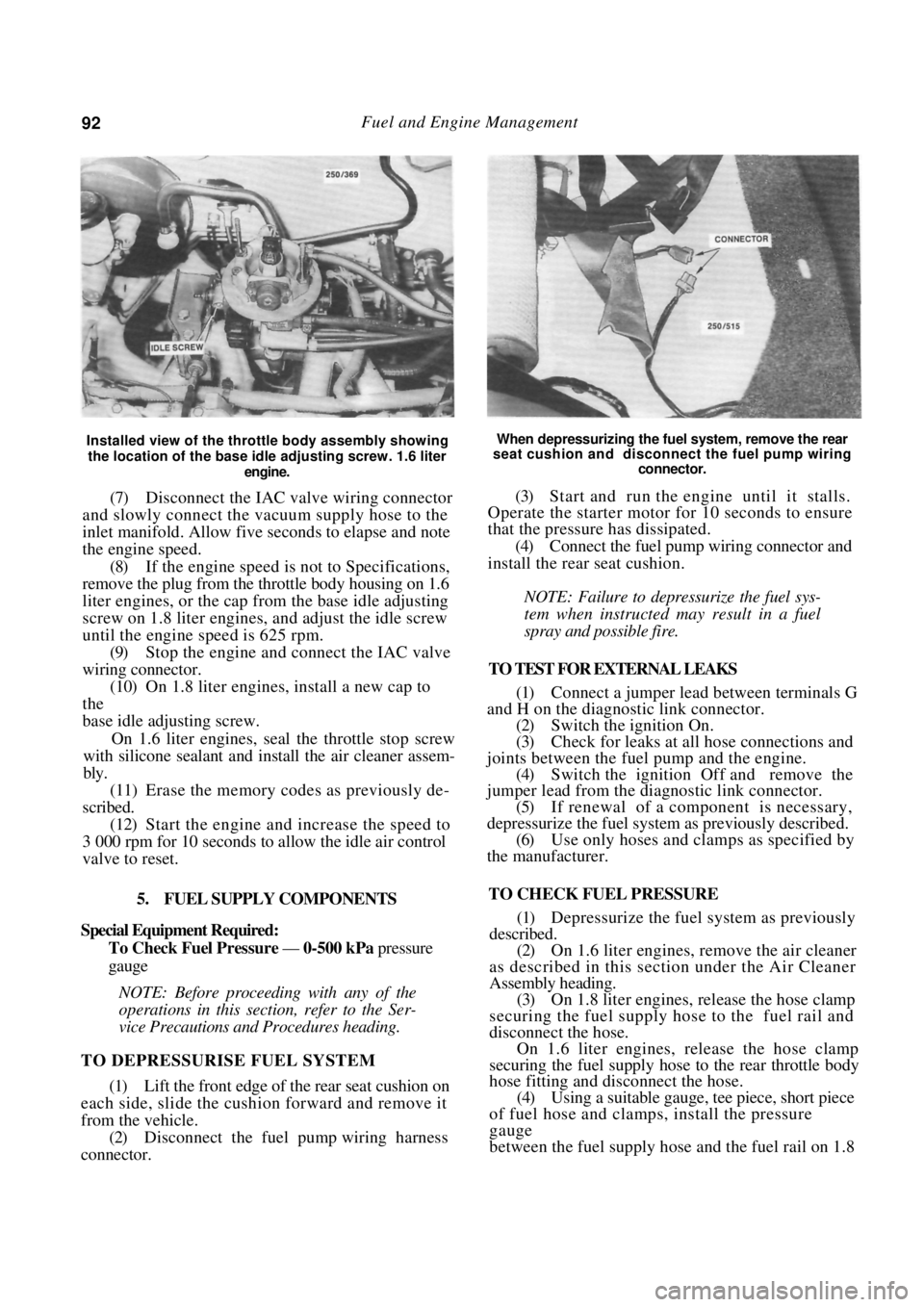

Location of the base idle adjusting screw. 1.8 liter

engine.

Page 92 of 238

92 Fuel and Engine Management

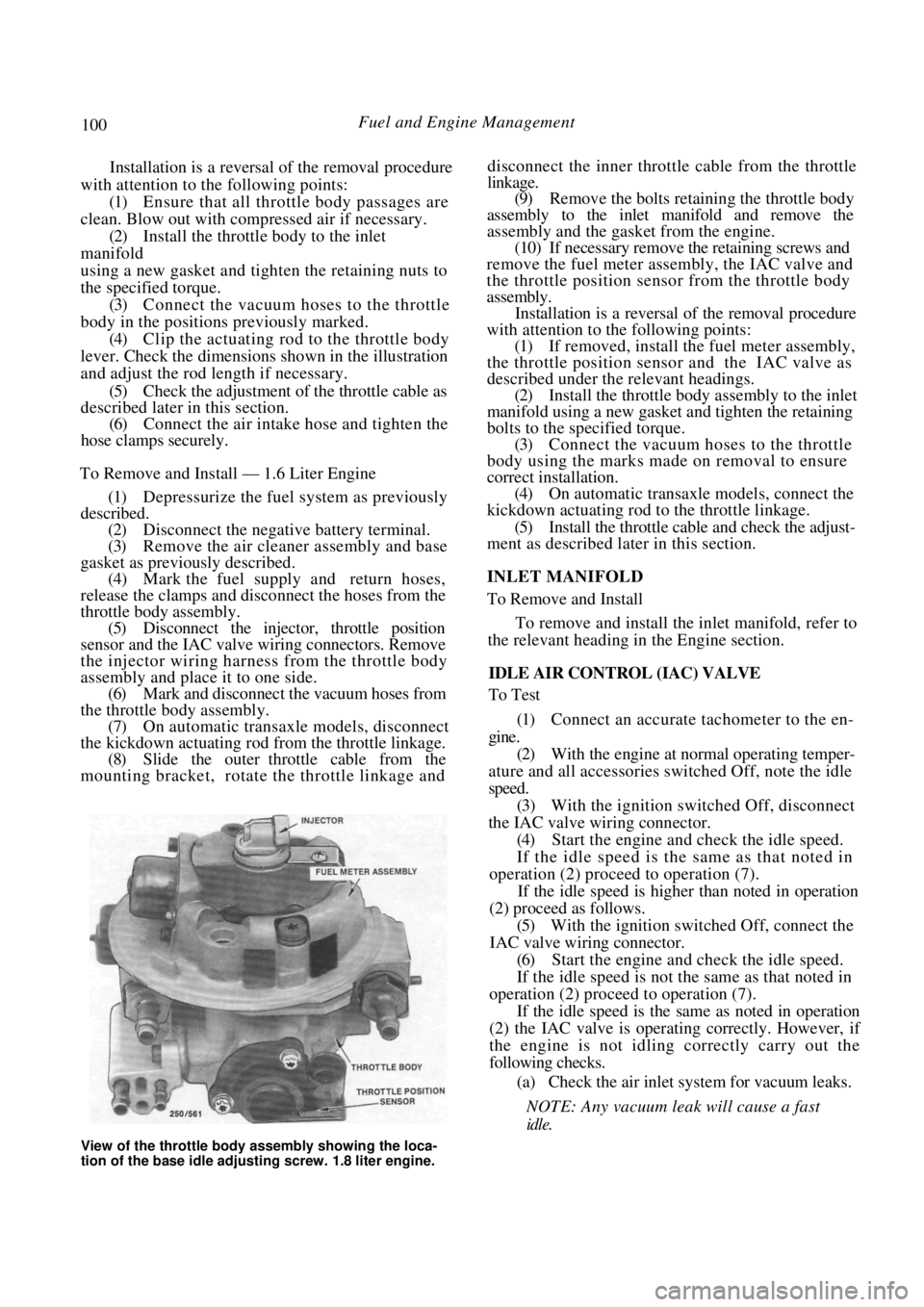

Installed view of the throttle body assembly showing

the location of the base idle adjusting screw. 1.6 liter

engine.

(7) Disconnect the IAC valve wiring connector

and slowly connect the vacuum supply hose to the

inlet manifold. Allow five seconds to elapse and note

the engine speed.

(8) If the engine speed is not to Specifications,

remove the plug from the throttle body housing on 1.6

liter engines, or the cap from the base idle adjusting

screw on 1.8 liter engines, and adjust the idle screw

until the engine speed is 625 rpm. (9) Stop the engine and connect the IAC valve

wiring connector. (10) On 1.8 liter engines, install a new cap to

the

base idle adjusting screw.

On 1.6 liter engines, seal the throttle stop screw

with silicone sealant and install the air cleaner assem-

bly.

(11) Erase the memory codes as previously de-

scribed.

(12) Start the engine and increase the speed to

3 000 rpm for 10 seconds to allow the idle air control

valve to reset.

5. FUEL SUPPLY COMPONENTS

Special Equipment Required:

To Check Fuel Pressure — 0-500 kPa pressure

gauge

NOTE: Before proceeding with any of the

operations in this section, refer to the Ser-

vice Precautions and Procedures heading.

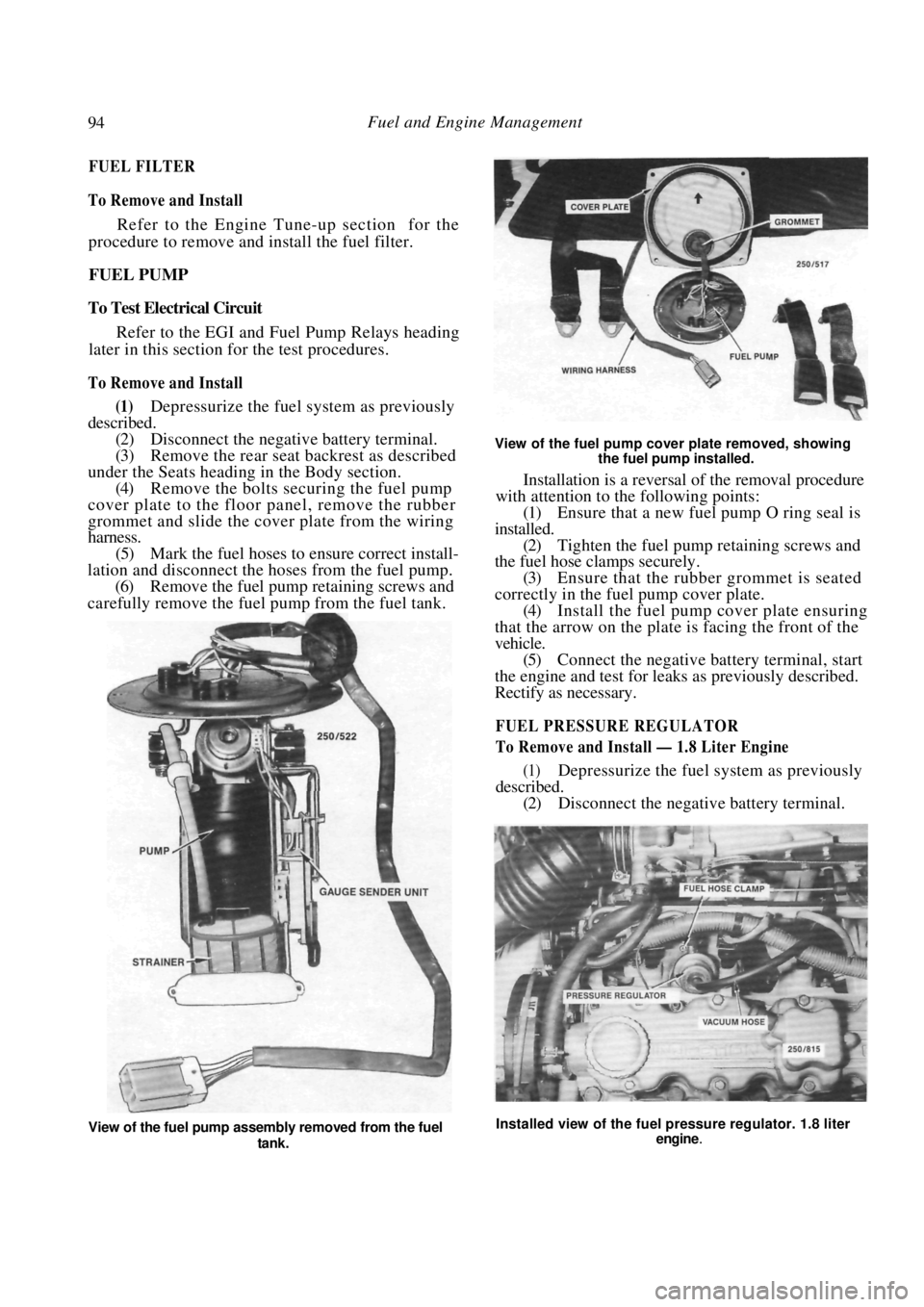

TO DEPRESSURISE FUEL SYSTEM

(1) Lift the front edge of the rear seat cushion on

each side, slide the cushion forward and remove it

from the vehicle. (2) Disconnect the fuel pump wiring harness

connector.

When depressurizing the fuel system, remove the rear

seat cushion and disconnect the fuel pump wiring

connector.

(3) Start and run the engine until it stalls.

Operate the starter motor for 10 seconds to ensure

that the pressure has dissipated.

(4) Connect the fuel pump wiring connector and

install the rear seat cushion.

NOTE: Failure to depressurize the fuel sys-

tem when instructed may result in a fuel

spray and possible fire.

TO TEST FOR EXTERNAL LEAKS

(1) Connect a jumper lead between terminals G

and H on the diagnostic link connector.

(2) Switch the ignition On.

(3) Check for leaks at all hose connections and

joints between the fuel pump and the engine. (4) Switch the ignition Off and remove the

jumper lead from the diagnostic link connector.

(5) If renewal of a component is necessary,

depressurize the fuel system as previously described. (6) Use only hoses and clamps as specified by

the manufacturer.

TO CHECK FUEL PRESSURE

(1) Depressurize the fuel system as previously

described. (2) On 1.6 liter engines, remove the air cleaner

as described in this section under the Air Cleaner

Assembly heading. (3) On 1.8 liter engines, release the hose clamp

securing the fuel supply hos e to the fuel rail and

disconnect the hose. On 1.6 liter engines, release the hose clamp

securing the fuel supply hose to the rear throttle body

hose fitting and disconnect the hose.

(4) Using a suitable gauge, tee piece, short piece

of fuel hose and clamps, install the pressure

gauge

between the fuel supply ho se and the fuel rail on 1.8

Page 93 of 238

Fuel and Engine Management 93

liter engines, or the throttle body hose fitting on 1.6

liter engines.

(5) Tighten all connectors securely. Check for

external leaks as previously described. (6) Start the engine and note the pressure while

the engine is idling.

(7) Switch the engine Off and check that the

residual pressure does not decrease.

If the fuel pressure is within Specifications and

does not decrease, the fuel system is in a serviceable

condition. Depressurize the fuel system and discon-

nect the pressure gauge.

If the fuel pressure is a bove Specifications proceed

to operation (9).

If the fuel pressure is below Specifications proceed

to the following operation.

If the fuel pressure decreases, an internal leak is

indicated. Proceed to the following heading and carry

out the test procedure.

Testing the fuel system pressure using a pressure

gauge. 1.8 liter engine.

NOTE: There may be a small initial de-

crease in pressure when the engine is

switched Off This is acceptable and does not

indicate a fault in the system.

(8) If the fuel pressure is below Specifications

proceed as follows:

(a) Check the fuel lines for blockages and kinks

or a blocked fuel filter or fuel pump pickup strainer. (b) If no fault can be found in the previous

checks, on 1.8 liter engines clamp the fuel return hose

at the fuel rail. On 1.6 liter engines, clamp the hose that is

connected to the front throttle body hose fitting.

(c) Connect a jumper lead between terminals G

and H on the diagnostic link connector and switch the

ignition On.

NOTE: Do not operate the fuel pump for

longer than is necessary to obtain a pressure

reading.

If the fuel pressure is less than 270 kPa on 1.8 liter

engines or 90 kPa on 1.6 liter engines, renew the fuel

pump.

If the fuel pressure is more than previously

specified, renew the pressure regulator assembly on

1.8 liter engines or the pressure regulator diaphragm

on 1.6 liter engines.

(9) If the fuel pressure in operation (6) is above

Specifications, proceed as follows:

(a) On 1.8 liter engines, disconnect the fuel

return hose from the pressure regulator outlet.

On 1.6 liter engines, disc onnect the fuel return

hose from the front throttle body hose fitting.

(b) Connect a suitable length of fuel hose to the

pressure regulator or the front throttle body hose

filling and place the opposite end of the hose into a

petroleum resistant container. (c) Connect a jumper lead between terminals G

and H on the diagnostic link connector and switch the

ignition On. If the fuel pressure is 230-270 kPa on 1.8 liter

engines or 62-90 kPa on 1.6 liter engines, locate and

remove the restriction in the fuel return hose or pipe.

If the fuel pressure is more than previously

specified, renew the pressure regulator assembly on

1.8 liter engines or the pressure regulator diaphragm

on 1.6 liter engines.

TO TEST FOR INTERNAL FUEL LEAKAGE

Check the residual fuel pressure as previously

described.

If the pressure has decreased it is an indication of

an internal leak. With the pressure gauge still at-

tached, proceed as follows:

(1) Switch the ignition On to pressurize the fuel

system.

(2) As the pressure begins to decrease clamp the

fuel supply hose shut. If the pressure remains steady

the fuel pump may be consid ered faulty and should be

renewed as described later in this section. (3) If the pressure continues to decrease switch

the ignition On after it has been Off at least 10

seconds. As the pressure begi ns to decrease clamp the

fuel return hose shut. If the pressure remain steady on 1.8 liter engines,

renew the pressure regulator. If the pressure continues

to decrease, leaking inject ors are indicated. Remove

the injectors as described later in this section to locate

the leaking injectors.

If the pressure remains stea dy on 1.6 liter engines,

renew the pressure regulator diaphragm as described

later in this section. If the pressure continues to

decrease remove the injector and renew the O ring

seals as described later in this section. If this fails to

rectify the fault remove the injector and clean or

renew the injector as necessary.

Page 94 of 238

94 Fuel and Engine Management

FUEL FILTER

To Remove and Install

Refer to the Engine Tune-up section for the

procedure to remove and install the fuel filter.

FUEL PUMP

To Test Electrical Circuit

Refer to the EGI and Fuel Pump Relays heading

later in this section for the test procedures.

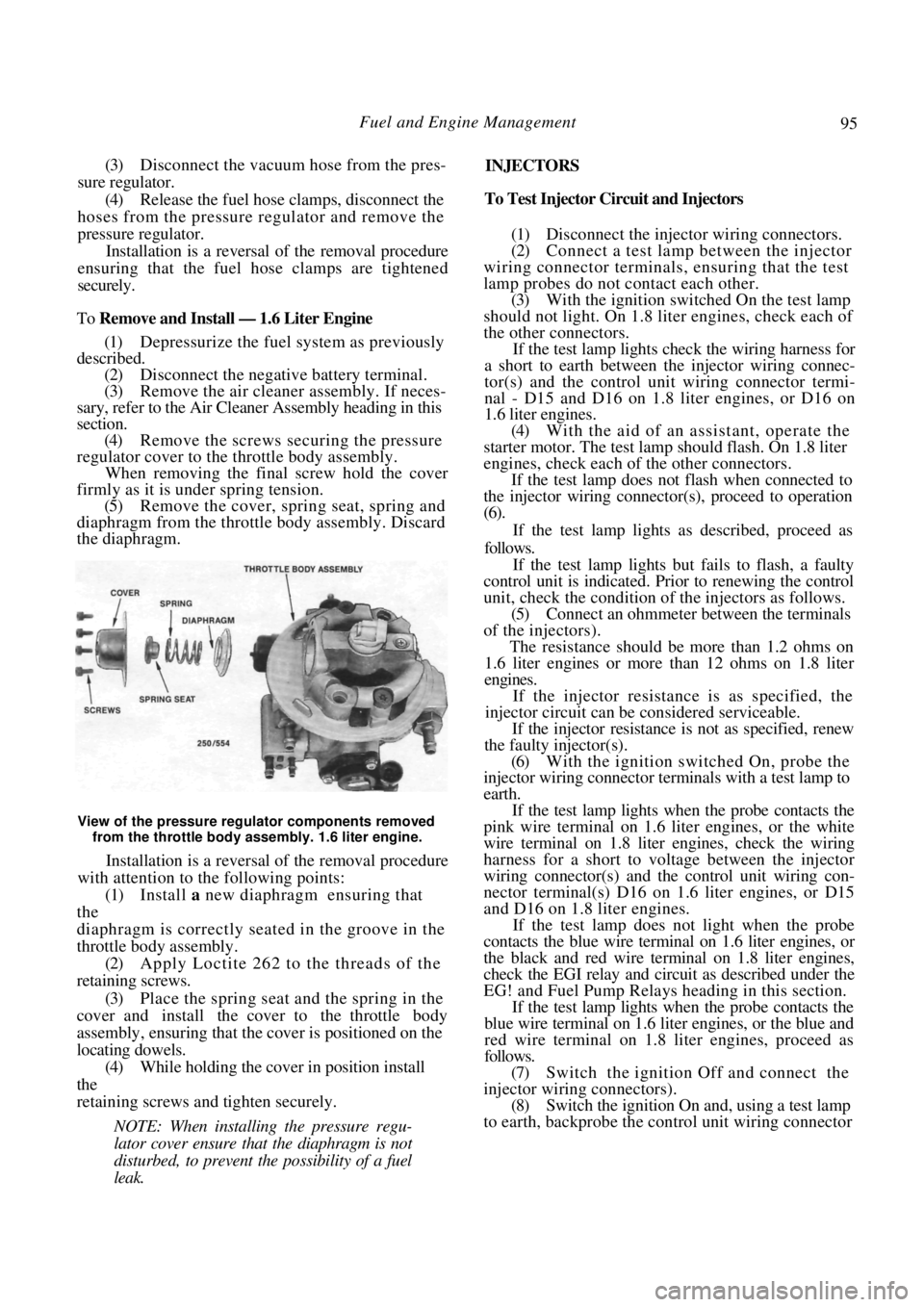

To Remove and Install

(1) Depressurize the fuel system as previously

described.

(2) Disconnect the negative battery terminal.

(3) Remove the rear seat backrest as described

under the Seats heading in the Body section.

(4) Remove the bolts securing the fuel pump

cover plate to the floor pa nel, remove the rubber

grommet and slide the cover plate from the wiring

harness. (5) Mark the fuel hoses to ensure correct install-

lation and disconnect the hoses from the fuel pump. (6) Remove the fuel pump retaining screws and

carefully remove the fuel pump from the fuel tank.

View of the fuel pump cover plate removed, showing

the fuel pump installed.

Installation is a reversal of the removal procedure

with attention to the following points:

(1) Ensure that a new fuel pump O ring seal is

installed. (2) Tighten the fuel pump retaining screws and

the fuel hose clamps securely.

(3) Ensure that the rubber grommet is seated

correctly in the fuel pump cover plate. (4) Install the fuel pump cover plate ensuring

that the arrow on the plate is facing the front of the

vehicle. (5) Connect the negative battery terminal, start

the engine and test for leaks as previously described.

Rectify as necessary.

FUEL PRESSURE REGULATOR

To Remove and Install — 1.8 Liter Engine

(1) Depressurize the fuel system as previously

described.

(2) Disconnect the negative battery terminal.

View of the fuel pump assembly removed from the fuel

tank. Installed view of the fuel pressure regulator. 1.8 liter

engine.

Page 95 of 238

Fuel and Engine Management 95

(3) Disconnect the vacuum hose from the pres-

sure regulator.

(4) Release the fuel hose clamps, disconnect the

hoses from the pressure regulator and remove the

pressure regulator. Installation is a reversal of the removal procedure

ensuring that the fuel hose clamps are tightened

securely.

To Remove and Install — 1.6 Liter Engine

(1) Depressurize the fuel system as previously

described. (2) Disconnect the negative battery terminal.

(3) Remove the air cleaner assembly. If neces-

sary, refer to the Air Cleane r Assembly heading in this

section. (4) Remove the screws securing the pressure

regulator cover to the throttle body assembly. When removing the final screw hold the cover

firmly as it is under spring tension.

(5) Remove the cover, spring seat, spring and

diaphragm from the thrott le body assembly. Discard

the diaphragm.

View of the pressure regulator components removed

from the throttle body assembly. 1.6 liter engine.

Installation is a reversal of the removal procedure

with attention to the following points:

(1) Install a new diaphragm ensuring that

the

diaphragm is correctly seat ed in the groove in the

throttle body assembly. (2) Apply Loctite 262 to the threads of the

retaining screws.

(3) Place the spring seat and the spring in the

cover and install the cover to the throttle body

assembly, ensuring that the cover is positioned on the

locating dowels. (4) While holding the cover in position install

the

retaining screws and tighten securely.

NOTE: When installing the pressure regu-

lator cover ensure that the diaphragm is not

disturbed, to prevent the possibility of a fuel

leak.

INJECTORS

To Test Injector Circuit and Injectors

(1) Disconnect the injector wiring connectors.

(2) Connect a test lamp between the injector

wiring connector terminals, ensuring that the test

lamp probes do not contact each other. (3) With the ignition switched On the test lamp

should not light. On 1.8 liter engines, check each of

the other connectors.

If the test lamp lights check the wiring harness for

a short to earth between the injector wiring connec-

tor(s) and the control unit wiring connector termi-

nal - D15 and D16 on 1.8 liter engines, or D16 on

1.6 liter engines.

(4) With the aid of an assistant, operate the

starter motor. The test lamp should flash. On 1.8 liter

engines, check each of the other connectors.

If the test lamp does not flash when connected to

the injector wiring connecto r(s), proceed to operation

(6).

If the test lamp lights as described, proceed as

follows.

If the test lamp lights but fails to flash, a faulty

control unit is indicated. Pr ior to renewing the control

unit, check the condition of the injectors as follows.

(5) Connect an ohmmeter between the terminals

of the injectors).

The resistance should be more than 1.2 ohms on

1.6 liter engines or more than 12 ohms on 1.8 liter

engines.

If the injector resistance is as specified, the

injector circuit can be considered serviceable.

If the injector resistance is not as specified, renew

the faulty injector(s).

(6) With the ignition switched On, probe the

injector wiring connector terminals with a test lamp to

earth.

If the test lamp lights when the probe contacts the

pink wire terminal on 1.6 liter engines, or the white

wire terminal on 1.8 liter engines, check the wiring

harness for a short to volt age between the injector

wiring connector(s) and the control unit wiring con-

nector terminal(s) D16 on 1.6 liter engines, or D15

and D16 on 1.8 liter engines.

If the test lamp does not light when the probe

contacts the blue wire termin al on 1.6 liter engines, or

the black and red wire term inal on 1.8 liter engines,

check the EGI relay and circ uit as described under the

EG! and Fuel Pump Relays heading in this section.

If the test lamp lights when the probe contacts the

blue wire terminal on 1.6 lite r engines, or the blue and

red wire terminal on 1.8 liter engines, proceed as

follows.

(7) Switch the ignition Off and connect the

injector wiring connectors). (8) Switch the ignition On and, using a test lamp

to earth, backprobe the cont rol unit wiring connector

Page 96 of 238

96 Fuel and Engine Management

terminal D16 on 1.6 liter engines, or D15 and D16

on

1.8 liter engines.

The test lamp should light.

If the test lamp does not light check the wiring

harness for continuity between the injector wiring

connector(s) and the control unit wiring connector

terminals.

Repair or renew the wiring harness as necessary.

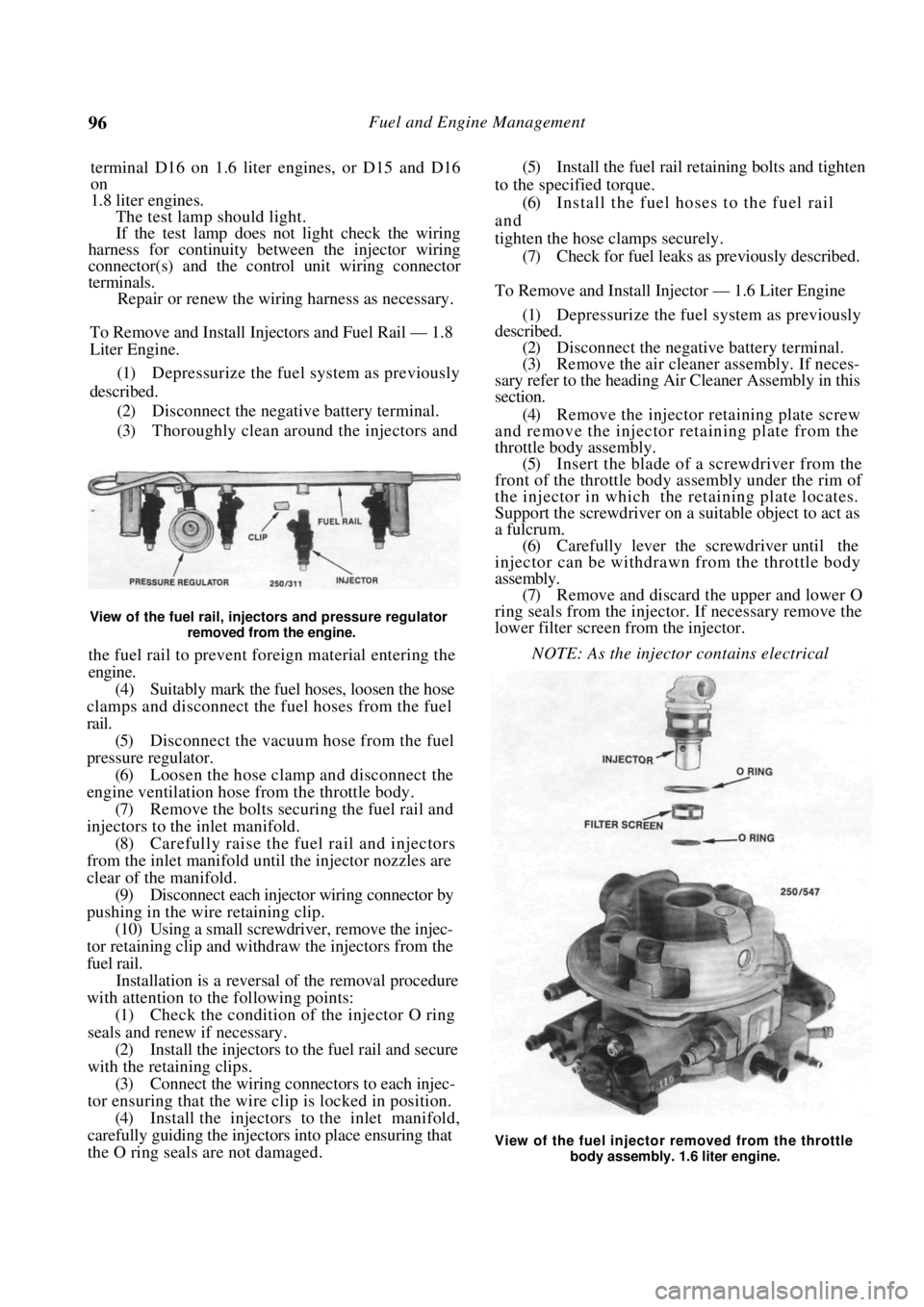

To Remove and Install Injectors and Fuel Rail — 1.8

Liter Engine.

(1) Depressurize the fuel system as previously

described.

(2) Disconnect the negative battery terminal.

(3) Thoroughly clean around the injectors and

View of the fuel rail, injectors and pressure regulator

removed from the engine.

the fuel rail to prevent foreign material entering the

engine.

(4) Suitably mark the fuel hoses, loosen the hose

clamps and disconnect the fuel hoses from the fuel

rail. (5) Disconnect the vacuum hose from the fuel

pressure regulator. (6) Loosen the hose clamp and disconnect the

engine ventilation hose from the throttle body. (7) Remove the bolts securing the fuel rail and

injectors to the inlet manifold. (8) Carefully raise the fuel rail and injectors

from the inlet manifold until the injector nozzles are

clear of the manifold. (9) Disconnect each injector wiring connector by

pushing in the wire retaining clip.

(10) Using a small screwdriver, remove the injec-

tor retaining clip and withdraw the injectors from the

fuel rail.

Installation is a reversal of the removal procedure

with attention to the following points:

(1) Check the condition of the injector O ring

seals and renew if necessary. (2) Install the injectors to the fuel rail and secure

with the retaining clips. (3) Connect the wiring connectors to each injec-

tor ensuring that the wire clip is locked in position. (4) Install the injectors to the inlet manifold,

carefully guiding the injectors into place ensuring that

the O ring seals are not damaged.

(5) Install the fuel rail retaining bolts and tighten

to the specified torque. (6) Install the fuel hoses to the fuel rail

and

tighten the hose clamps securely.

(7) Check for fuel leaks as previously described.

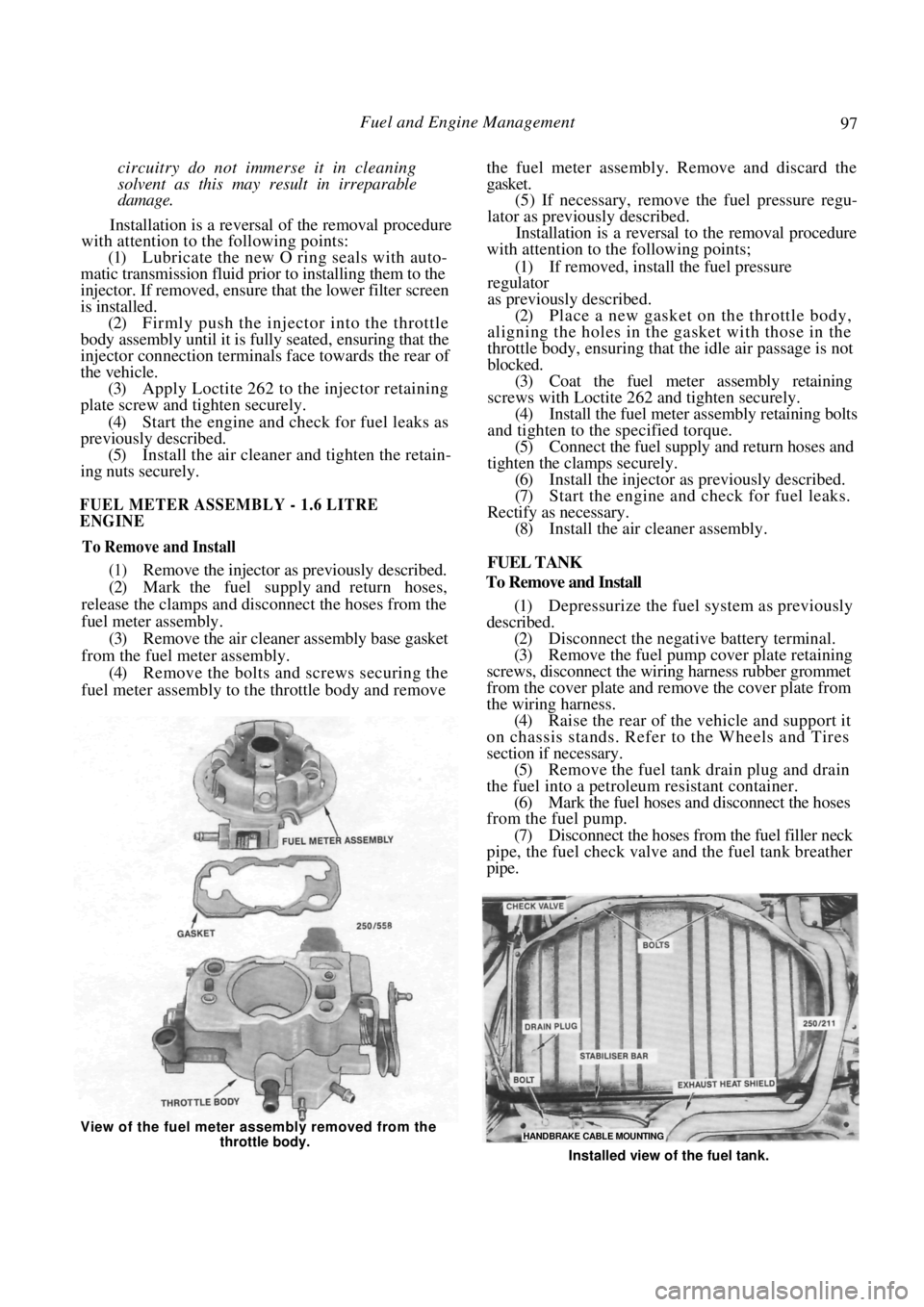

To Remove and Install Injector — 1.6 Liter Engine

(1) Depressurize the fuel system as previously

described. (2) Disconnect the negative battery terminal.

(3) Remove the air cleaner assembly. If neces-

sary refer to the heading Air Cleaner Assembly in this

section.

(4) Remove the injector retaining plate screw

and remove the injector retaining plate from the

throttle body assembly. (5) Insert the blade of a screwdriver from the

front of the throttle body assembly under the rim of

the injector in which the retaining plate locates.

Support the screwdriver on a suitable object to act as

a fulcrum. (6) Carefully lever the screwdriver until the

injector can be withdrawn from the throttle body

assembly.

(7) Remove and discard the upper and lower O

ring seals from the injector . If necessary remove the

lower filter screen from the injector.

NOTE: As the injector contains electrical

View of the fuel injector removed from the throttle body assembly. 1.6 liter engine.

Page 97 of 238

Fuel and Engine Management 97

circuitry do not immerse it in cleaning

solvent as this may result in irreparable

damage.

Installation is a reversal of the removal procedure

with attention to the following points:

(1) Lubricate the new O ring seals with auto-

matic transmission fluid prior to installing them to the

injector. If removed, ensure that the lower filter screen

is installed. (2) Firmly push the injector into the throttle

body assembly until it is fully seated, ensuring that the

injector connection terminals face towards the rear of

the vehicle.

(3) Apply Loctite 262 to the injector retaining

plate screw and tighten securely.

(4) Start the engine and check for fuel leaks as

previously described.

(5) Install the air cleaner and tighten the retain-

ing nuts securely.

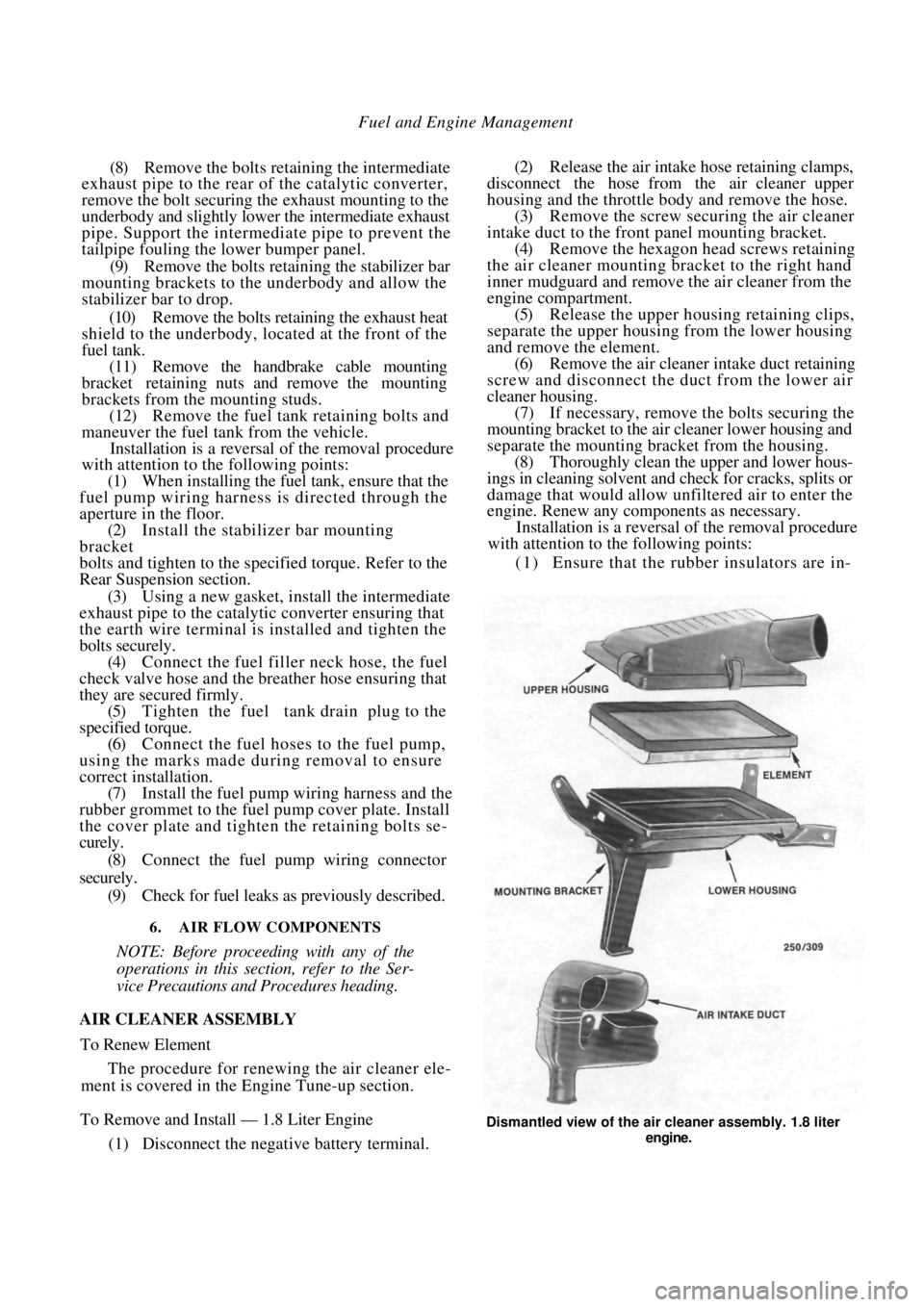

FUEL METER ASSEMBLY - 1.6 LITRE

ENGINE

To Remove and Install

(1) Remove the injector as previously described.

(2) Mark the fuel supp ly and return hoses,

release the clamps and disconnect the hoses from the

fuel meter assembly.

(3) Remove the air cleaner assembly base gasket

from the fuel meter assembly. (4) Remove the bolts and screws securing the

fuel meter assembly to the throttle body and remove the fuel meter assembly. Remove and discard the

gasket.

(5) If necessary, remove the fuel pressure regu-

lator as previously described.

Installation is a reversal to the removal procedure

with attention to the following points;

(1) If removed, install the fuel pressure

regulator

as previously described.

(2) Place a new gasket on the throttle body,

aligning the holes in the gasket with those in the

throttle body, ensuring that the idle air passage is not

blocked. (3) Coat the fuel meter assembly retaining

screws with Loctite 26 2 and tighten securely.

(4) Install the fuel meter assembly retaining bolts

and tighten to the specified torque.

(5) Connect the fuel supply and return hoses and

tighten the clamps securely. (6) Install the injector as previously described.

(7) Start the engine and check for fuel leaks.

Rectify as necessary. (8) Install the air cleaner assembly.

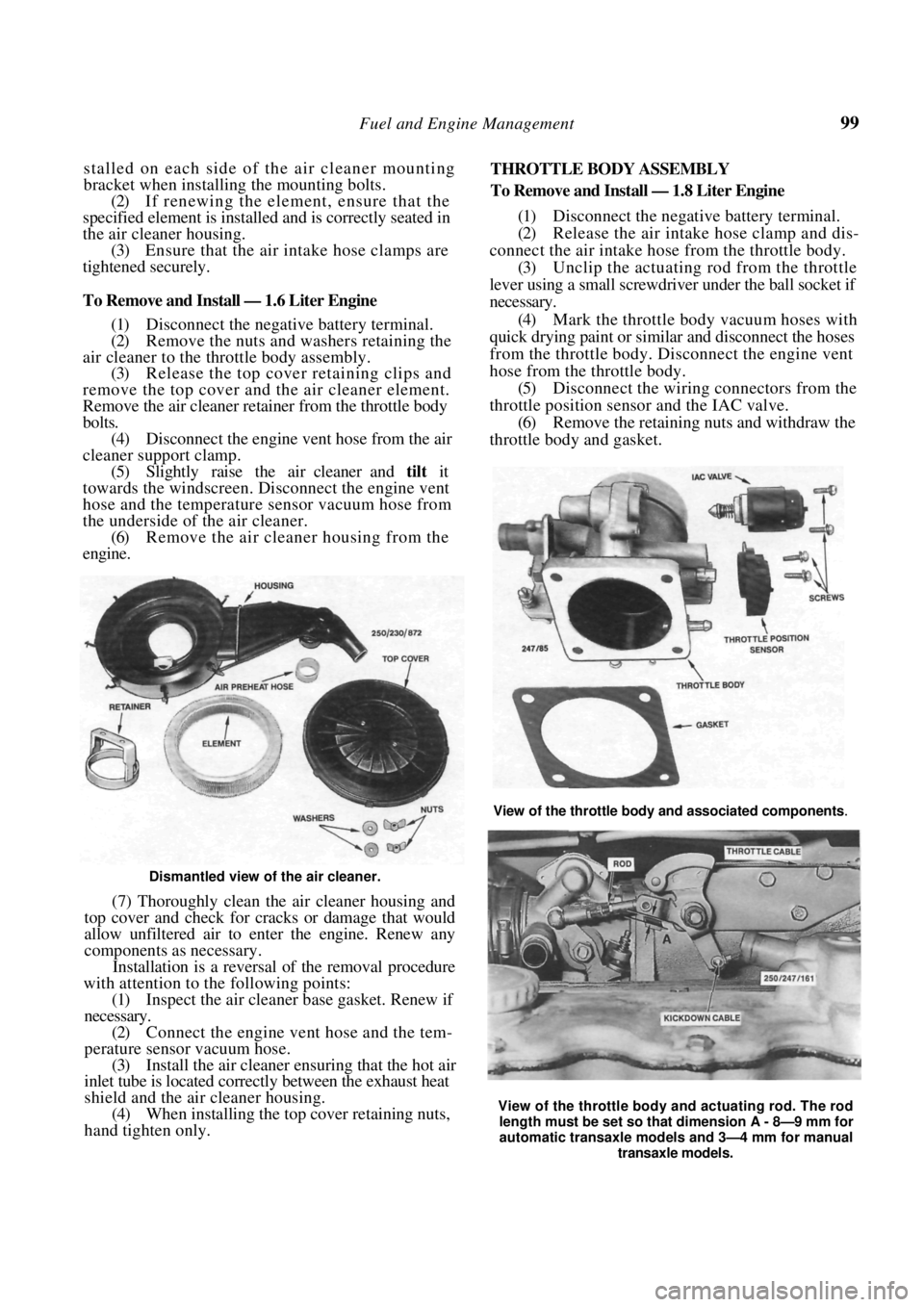

FUEL TANK

To Remove and Install

(1) Depressurize the fuel system as previously

described.

(2) Disconnect the negative battery terminal.

(3) Remove the fuel pump cover plate retaining

screws, disconnect the wi ring harness rubber grommet

from the cover plate and remove the cover plate from

the wiring harness. (4) Raise the rear of the vehicle and support it

on chassis stands. Refer to the Wheels and Tires

section if necessary. (5) Remove the fuel tank drain plug and drain

the fuel into a petroleum resistant container. (6) Mark the fuel hoses and disconnect the hoses

from the fuel pump.

(7) Disconnect the hoses from the fuel filler neck

pipe, the fuel check valve and the fuel tank breather

pipe.

View of the fuel meter assembly removed from the

throttle body. HANDBRAKE CABLE MOUNTING

Installed view of the fuel tank.

Page 98 of 238

Fuel and Engine Management

(8) Remove the bolts retaining the intermediate

exhaust pipe to the rear of the catalytic converter,

remove the bolt securing the exhaust mounting to the

underbody and slightly lower the intermediate exhaust

pipe. Support the intermediate pipe to prevent the

tailpipe fouling the lower bumper panel.

(9) Remove the bolts retaining the stabilizer bar

mounting brackets to the underbody and allow the

stabilizer bar to drop.

(10) Remove the bolts retaining the exhaust heat

shield to the underbody, located at the front of the

fuel tank. (11) Remove the handbrake cable mounting

bracket retaining nuts and remove the mounting

brackets from the mounting studs. (12) Remove the fuel tank retaining bolts and

maneuver the fuel tank from the vehicle. Installation is a reversal of the removal procedure

with attention to the following points:

(1) When installing the fuel tank, ensure that the

fuel pump wiring harness is directed through the

aperture in the floor. (2) Install the stabilizer bar mounting

bracket

bolts and tighten to the specified torque. Refer to the

Rear Suspension section.

(3) Using a new gasket, install the intermediate

exhaust pipe to the catalyti c converter ensuring that

the earth wire terminal is installed and tighten the

bolts securely. (4) Connect the fuel filler neck hose, the fuel

check valve hose and the breat her hose ensuring that

they are secured firmly. (5) Tighten the fuel tank drain plug to the

specified torque. (6) Connect the fuel hoses to the fuel pump,

using the marks made during removal to ensure

correct installation. (7) Install the fuel pump wiring harness and the

rubber grommet to the fuel pump cover plate. Install

the cover plate and tighten the retaining bolts se-

curely.

(8) Connect the fuel pump wiring connector

securely. (9) Check for fuel leaks as previously described.

6. AIR FLOW COMPONENTS

NOTE: Before proceeding with any of the

operations in this section, refer to the Ser-

vice Precautions and Procedures heading.

AIR CLEANER ASSEMBLY

To Renew Element

The procedure for renewing the air cleaner ele-

ment is covered in the Engine Tune-up section.

To Remove and Install — 1.8 Liter Engine

(1) Disconnect the negative battery terminal.

(2) Release the air intake hose retaining clamps,

disconnect the hose from the air cleaner upper

housing and the throttle body and remove the hose. (3) Remove the screw securing the air cleaner

intake duct to the front panel mounting bracket. (4) Remove the hexagon head screws retaining

the air cleaner mounting bracket to the right hand

inner mudguard and remove the air cleaner from the

engine compartment. (5) Release the upper housing retaining clips,

separate the upper housing from the lower housing

and remove the element. (6) Remove the air cleaner intake duct retaining

screw and disconnect the duct from the lower air

cleaner housing. (7) If necessary, remove the bolts securing the

mounting bracket to the ai r cleaner lower housing and

separate the mounting bracket from the housing. (8) Thoroughly clean the upper and lower hous-

ings in cleaning solvent and check for cracks, splits or

damage that would allow unfiltered air to enter the

engine. Renew any components as necessary.

Installation is a reversal of the removal procedure

with attention to the following points:

(1) Ensure that the r ubber insulators are in-

Dismantled view of the ai r cleaner assembly. 1.8 liter

engine.

Page 99 of 238

Fuel and Engine Management 99

stalled on each side of the air cleaner mounting

bracket when installing the mounting bolts.

(2) If renewing the element, ensure that the

specified element is installed and is correctly seated in

the air cleaner housing. (3) Ensure that the air intake hose clamps are

tightened securely.

To Remove and Install — 1.6 Liter Engine

(1) Disconnect the negative battery terminal.

(2) Remove the nuts and washers retaining the

air cleaner to the throttle body assembly. (3) Release the top cover retaining clips and

remove the top cover and the air cleaner element.

Remove the air cleaner retainer from the throttle body

bolts. (4) Disconnect the engine vent hose from the air

cleaner support clamp. (5) Slightly raise the air cleaner and tilt it

towards the windscreen. Disc onnect the engine vent

hose and the temperature sensor vacuum hose from

the underside of the air cleaner. (6) Remove the air cleaner housing from the

engine.

Dismantled view of the air cleaner.

(7) Thoroughly clean the air cleaner housing and

top cover and check for cracks or damage that would

allow unfiltered air to enter the engine. Renew any

components as necessary.

Installation is a reversal of the removal procedure

with attention to the following points:

(1) Inspect the air cleaner base gasket. Renew if

necessary. (2) Connect the engine vent hose and the tem-

perature sensor vacuum hose. (3) Install the air cleaner ensuring that the hot air

inlet tube is located correc tly between the exhaust heat

shield and the air cleaner housing. (4) When installing the top cover retaining nuts,

hand tighten only. THROTTLE BODY ASSEMBLY

To Remove and Install — 1.8 Liter Engine

(1)

Disconnect the negative battery terminal.

(2) Release the air intake hose clamp and dis-

connect the air intake hose from the throttle body. (3) Unclip the actuating rod from the throttle

lever using a small screwdriver under the ball socket if

necessary.

(4) Mark the throttle body vacuum hoses with

quick drying paint or similar and disconnect the hoses

from the throttle body. Disconnect the engine vent

hose from the throttle body. (5) Disconnect the wiring connectors from the

throttle position sensor and the IAC valve.

(6) Remove the retaining nuts and withdraw the

throttle body and gasket.

View of the throttle body and actuating rod. The rod

length must be set so that dimension A - 8—9 mm for

automatic transaxle models and 3—4 mm for manual

transaxle models.

View of the throttle body and associated components.

Page 100 of 238

100 Fuel and Engine Management

Installation is a reversal of the removal procedure

with attention to the following points:

(1) Ensure that all throttle body passages are

clean. Blow out with compressed air if necessary. (2) Install the throttle body to the inlet

manifold

using a new gasket and tighten the retaining nuts to

the specified torque. (3) Connect the vacuum hoses to the throttle

body in the positions previously marked. (4) Clip the actuating rod to the throttle body

lever. Check the dimensions shown in the illustration

and adjust the rod length if necessary.

(5) Check the adjustment of the throttle cable as

described later in this section.

(6) Connect the air intake hose and tighten the

hose clamps securely.

To Remove and Install — 1.6 Liter Engine

(1) Depressurize the fuel system as previously

described. (2) Disconnect the negative battery terminal.

(3) Remove the air cleane r assembly and base

gasket as previously described. (4) Mark the fuel supply and return hoses,

release the clamps and disconnect the hoses from the

throttle body assembly. (5) Disconnect the injector, throttle position

sensor and the IAC valve wiring connectors. Remove

the injector wiring harness from the throttle body

assembly and place it to one side.

(6) Mark and disconnect the vacuum hoses from

the throttle body assembly. (7) On automatic transaxle models, disconnect

the kickdown actuating rod from the throttle linkage.

(8) Slide the outer throttle cable from the

mounting bracket, rotate the throttle linkage and disconnect the inner throttle cable from the throttle

linkage.

(9)

Remove the bolts retaining the throttle body

assembly to the inlet manifold and remove the

assembly and the gasket from the engine. (10) If necessary remove the retaining screws and

remove the fuel meter assembly, the IAC valve and

the throttle position sensor from the throttle body

assembly. Installation is a reversal of the removal procedure

with attention to the following points:

(1) If removed, install the fuel meter assembly,

the throttle position sensor and the IAC valve as

described under the relevant headings. (2) Install the throttle body assembly to the inlet

manifold using a new gasket and tighten the retaining

bolts to the specified torque. (3) Connect the vacuum ho ses to the throttle

body using the marks made on removal to ensure

correct installation. (4) On automatic transaxle models, connect the

kickdown actuating rod to the throttle linkage.

(5) Install the throttle cable and check the adjust-

ment as described later in this section.

INLET MANIFOLD

To Remove and Install

To remove and install the inlet manifold, refer to

the relevant heading in the Engine section.

IDLE AIR CONTROL (IAC) VALVE

To Test

(1) Connect an accurate tachometer to the en-

gine. (2) With the engine at normal operating temper-

ature and all accessories switched Off, note the idle

speed.

(3) With the ignition switched Off, disconnect

the IAC valve wiring connector. (4) Start the engine and check the idle speed.

If the idle speed is the same as that noted in

operation (2) proceed to operation (7).

If the idle speed is higher than noted in operation

(2) proceed as follows.

(5) With the ignition switched Off, connect the

IAC valve wiring connector.

(6) Start the engine and check the idle speed.

If the idle speed is not the same as that noted in

operation (2) proceed to operation (7).

If the idle speed is the same as noted in operation

(2) the IAC valve is operating correctly. However, if

the engine is not idling correctly carry out the

following checks.

(a) Check the air inlet system for vacuum leaks.

NOTE: Any vacuum leak will cause a fast

idle.

View of the throttle body assembly showing the loca-

tion of the base idle adjusting screw. 1.8 literengine.