NISSAN PULSAR 1987 Workshop Manual

Manufacturer: NISSAN, Model Year: 1987, Model line: PULSAR, Model: NISSAN PULSAR 1987Pages: 238, PDF Size: 28.91 MB

Page 161 of 238

Front Suspension 161

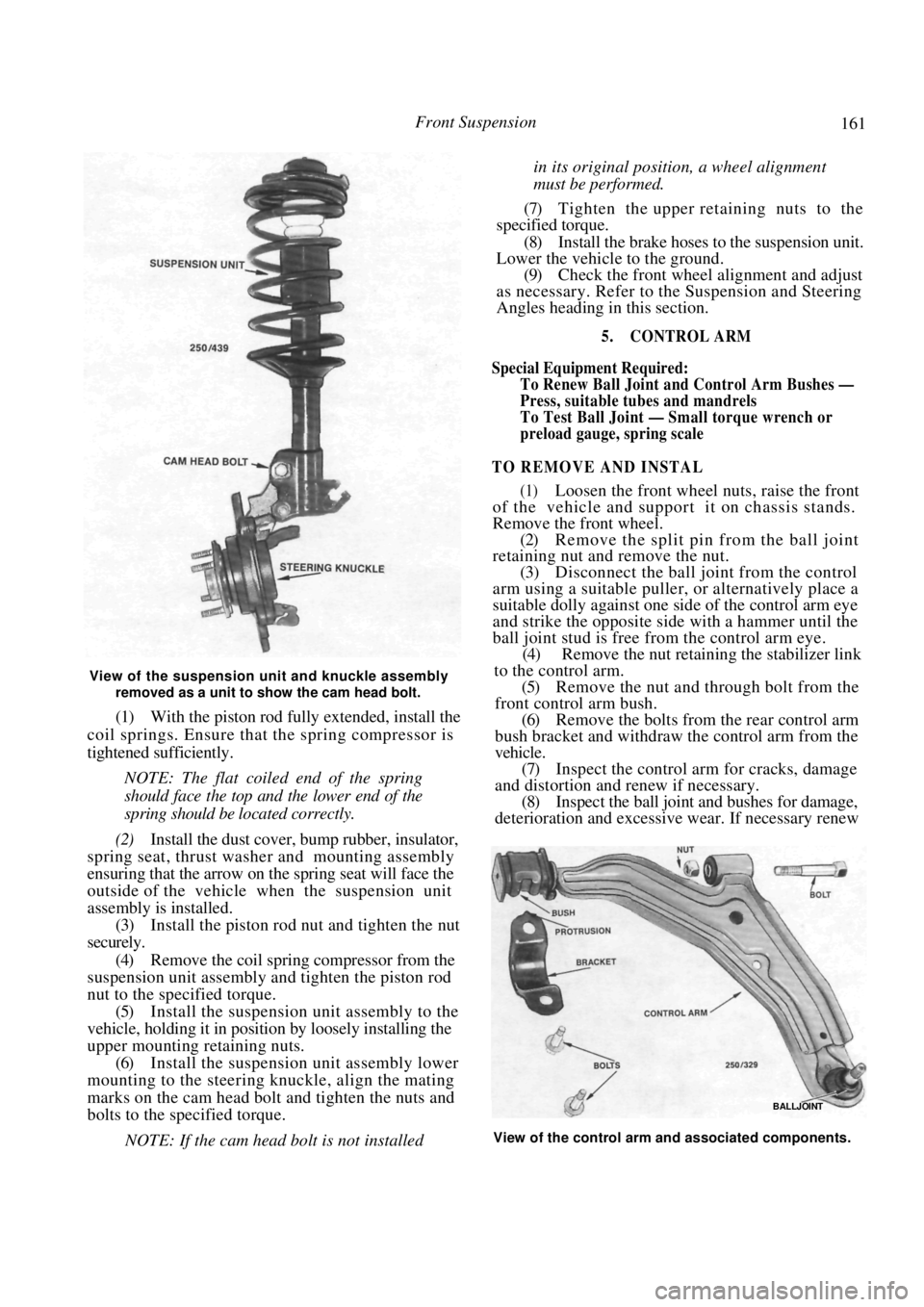

View of the suspension unit and knuckle assembly removed as a unit to show the cam head bolt.

(1) With the piston rod fully extended, install the

coil springs. Ensure that the spring compressor is

tightened sufficiently.

NOTE: The flat coiled end of the spring

should face the top and the lower end of the

spring should be located correctly.

(2) Install the dust cover, bump rubber, insulator,

spring seat, thrust washer and mounting assembly

ensuring that the arrow on the spring seat will face the

outside of the vehicle when the suspension unit

assembly is installed.

(3) Install the piston rod nut and tighten the nut

securely.

(4) Remove the coil spring compressor from the

suspension unit assembly and tighten the piston rod

nut to the specified torque. (5) Install the suspension unit assembly to the

vehicle, holding it in position by loosely installing the

upper mounting retaining nuts. (6) Install the suspension unit assembly lower

mounting to the steering knuckle, align the mating

marks on the cam head bolt and tighten the nuts and

bolts to the specified torque.

NOTE: If the cam head bolt is not installed

in its original position, a wheel alignment

must be performed.

(7) Tighten the upper retaining nuts to the

specified torque.

(8) Install the brake hoses to the suspension unit.

Lower the vehicle to the ground.

(9) Check the front wheel alignment and adjust

as necessary. Refer to the Suspension and Steering

Angles heading in this section.

5. CONTROL ARM

Special Equipment Required:

To Renew Ball Joint and Control Arm Bushes —

Press, suitable t ubes and mandrels

To Test Ball Joint — Small torque wrench or

preload gauge, spring scale

TO REMOVE AND INSTAL

(1) Loosen the front wheel nuts, raise the front

of the vehicle and support it on chassis stands.

Remove the front wheel.

(2) Remove the split pin from the ball joint

retaining nut and remove the nut.

(3) Disconnect the ball joint from the control

arm using a suitable puller, or alternatively place a

suitable dolly against one si de of the control arm eye

and strike the opposite side with a hammer until the

ball joint stud is free from the control arm eye. (4) Remove the nut retaining the stabilizer link

to the control arm.

(5) Remove the nut and through bolt from the

front control arm bush. (6) Remove the bolts from the rear control arm

bush bracket and withdraw the control arm from the

vehicle. (7) Inspect the control arm for cracks, damage

and distortion and renew if necessary. (8) Inspect the ball joint and bushes for damage,

deterioration and excessive wear. If necessary renew

BALLJOINT

View of the control arm and associated components.

Page 162 of 238

162 Front Suspension

the ball joint or bushes as described later in this

section.

Installation is a reversal of the removal procedure

with attention to the following points:

(1) When installing the control arm bush

bracket, ensure that the protrusion on the bracket is

towards the inside of the vehicle.

(2) Do not fully tighten the control arm bush

bolts and through bolt nut until the curb weight of the

vehicle is on the suspension.

NOTE: Curb weight is with the vehicle

unladen except for a full tank of fuel and

normal amounts of oil and water and with

the spare lyre, jack and hand tools in their

normal positions.

(3) Tighten the ball joint nut to the specified

torque and retain with a new split pin.

TO CHECK AND RENEW BALL JOINT

(1) Remove the control arm from the vehicle as

previously described.

(2) Install the ball joint nut and turn the ball

joint at least ten revolutions to ensure that the ball

joint is correctly seated. (3) Using a spring scale with the hook placed

over the split pin hole, check the ball joint swinging

torque. A new ball joint should measure 15.7-80.4 N

and a used ball joint should measure 7.8-80.4 N.

Renew the ball joint if necessary. (4) Using a small torque wrench or preload

gauge, measure the force requi red to rotate the ball

joint. A new ball joint should measure between

1.0-4.9 Nm and a used ball joint should measure

between 0.5-4.9 Nm. Renew the ball joint if neces-

sary.

(5) To renew the ball joint, remove the snap ring

from the stud end of the ball joint using snap ring

pliers. (6) Support the control arm in a press, ball joint

stud uppermost, with a suitable tube that is large

enough for the ball joint to pass through. (7) Press the ball joint out from the control arm.

(8) Press a new ball joint into the control arm

using a suitable tube that pushes on the outer circum-

ference of the joint only.

(9) Install the snap ring and install the

control

arm to the vehicle as previously described.

TO RENEW CONTROL ARM BUSHES

(1) Remove the control arm from the vehicle as

previously described. Mark the position of the rear

control arm bush. (2) To remove the rear control arm bush use a

bearing puller and a press. When installing the bush

use a suitable tube that pushes on the inner edge of the

bush only. NOTE: Ensure that the bush is installed

with the flat portion in its original location.

(3)

To remove the front control arm bush use a

suitable tube that pushes on the outer circumference

of the bush and a split tu be supporting the control

arm. (4) After the bush has been pressed out approx-

imately half way, cut the protruding part of the bush

using a hacksaw. Cutting the bush in this way will

allow removal.

(5) Support the control arm and push the new

bush in from the outside using a suitable tube that

pushes on the outer circumference only. (6) Install the control ar m to the vehicle as

previously described.

6. STABILISER BAR

TO REMOVE AND INSTAL

(1) Raise the front of the vehicle and support it

on chassis stands.

(2) Remove the bolts at the flexible joint retain-

ing the front engine pipe to the exhaust pipe located

below the stabilizer bar. (3) Remove the bolt from the exhaust pipe

mounting below the stabilizer bar. Disconnect the

exhaust pipe at the flexible joint and allow the front of

the pipe to hang down. (4) Remove the stabilizer bar bracket retaining

bolts and remove the stabilizer bar brackets from the

vehicle. (5) Remove the stabilizer bar lower link nuts

from each control arm. When removing the lower nuts

it may be necessary to hold the upper nuts with a

spanner.

(6) Maneuver the stabilizer bar from the

vehicle.

Installation is a reversal of the removal procedure

with attention to the following points:

(1) Ensure that the stabilizer bar mounting rub-

bers are in a serviceable condition and secure in the

mounting brackets.

Dismantled view of one end of the stabilizer bar.

Page 163 of 238

Front Suspension 163

(2) Ensure that the stabilizer bar links are in

good condition. Renew if necessary.

(3) When installing the stabilizer bar ensure that

the links are installed perpendicular to the control arm

with the ball joint socket face parallel to the end of the

stabilizer bar. (4) Ensure that the brackets are installed with

the flat portion facing towards the front of the vehicle.

Tighten the retaining bolts securely.

7. SUSPENSION AND STEERING ANGLES

ADJUSTMENT

NOTE: Extensive knowledge and special-

ised equipment are required to measure and

correct the suspension and steering angles

with the exception of the front wheel toe in.

Therefore, as it is not a viable proposition

for the average person to carry out a com-

plete wheel alignment, the vehicle should be

taken to a wheel alignment specialist.

Prior to carrying out a wheel alignment, a thor-

ough inspection of the steering linkage, front hub

bearings, ball joints and suspension units should be

carried out. Faulty components should be renewed or

repaired as necessary.

The tread of the front ti res should be examined

for excessive or uneven wear as certain conditions of

tire wear are indicative of damaged or worn compo-

nents in the suspension, stee ring linkage and/or wheels

and bearings. Refer to the heading Tire Wear Trouble

Shooting in the Wheels and Tires section. If the tires

are found to be defective, renew them with serviceable

lyres.

TO CHECK AND ADJUST TOE IN/OUT

NOTE: The vehicle s hould be unladen ex-

cept for the normal amount of fuel and with

the tires inflated to the correct pressures.

(1) With the vehicle on a level floor, raise the

front of the vehicle and s upport it on chassis stands.

(2) Spin each front wheel in turn and using a

piece of chalk, mark a line around the periphery of

each tire as near to the centre as possible. (3) Lower the vehicle to the ground and bounce

the front several times to stabilize the suspension. (4) Set the wheels in the straight ahead position.

(5) Mark the centre chalk line on both tires at a

point approximately 200 mm above the floor and

forward of the suspension. (6) Using a tape measure, measure and record

the distance between the two marked points on the

tire centers.

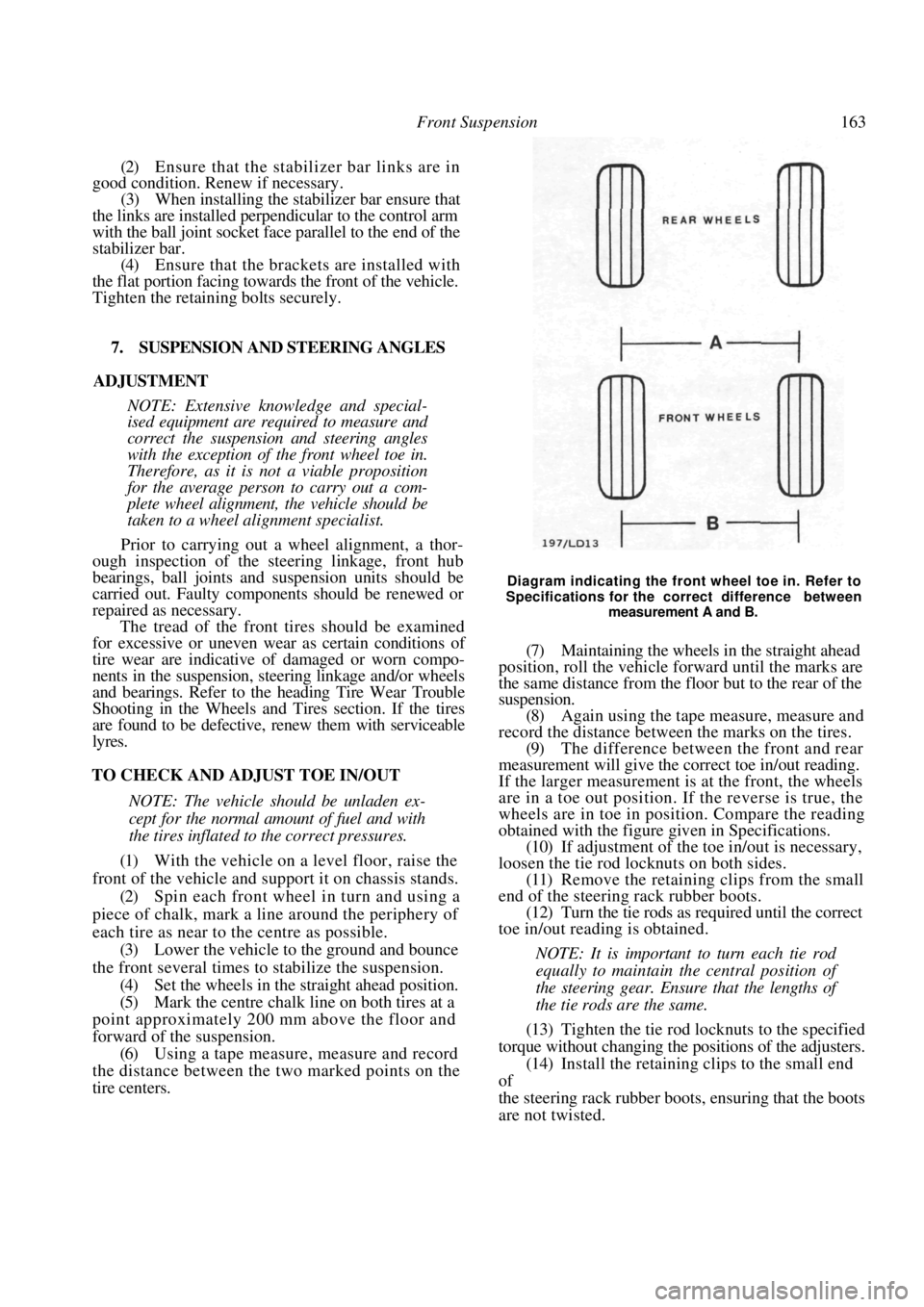

Diagram indicating the front wheel toe in. Refer to

Specifications for the correct difference between

measurement A and B.

(7) Maintaining the wheels in the straight ahead

position, roll the vehicle forward until the marks are

the same distance from the floor but to the rear of the

suspension. (8) Again using the tape measure, measure and

record the distance between the marks on the tires.

(9) The difference between the front and rear

measurement will give the correct toe in/out reading.

If the larger measurement is at the front, the wheels

are in a toe out position. If the reverse is true, the

wheels are in toe in position. Compare the reading

obtained with the figure given in Specifications.

(10) If adjustment of the to e in/out is necessary,

loosen the tie rod locknuts on both sides. (11) Remove the retaining clips from the small

end of the steering rack rubber boots. (12) Turn the tie rods as required until the correct

toe in/out reading is obtained.

NOTE: It is important to turn each tie rod

equally to maintain the central position of

the steering gear. Ensure that the lengths of

the tie rods are the same.

(13) Tighten the tie rod locknuts to the specified

torque without changing the positions of the adjusters.

(14) Install the retaining clips to the small end

of

the steering rack rubber boots, ensuring that the boots

are not twisted.

Page 164 of 238

164

REAR SUSPENSION

SPECIFICATIONS

Type........................... Independent MacPherson strut

Shock absorber.................... Oil filled, non-repairable

Maximum hub bearing end float ................. 0.05 mm

Rear wheel alignment:

Toe out ........................................3 mm ± 2 mm

Camber ............................................. - 1 ° ± 4 5 '

TORQUE WRENCH SETTINGS

Hub retaining nut ......................................... 255 Nm

Suspension unit retaining nuts ....................... 29 Nm

Upper mounting retaining nut ........................ 72 Nm

Suspension unit to knuckle nuts .................. 118 Nm

Control arms to knuckle nut ........................ 118 Nm

Control arms to crossmember nut ............... 118 Nm

Stabiliser bar mounting bracket bolts .......... 108 Nm

Stabiliser bar retaining nut.............................. 83 Nm

Backing plate bolts........................................... 45 Nm

1. REAR SUSPENSION TROUBLE SHOOTING

REAR END NOISE

( 1 ) Defective suspension unit or mounting: Re-

new the faulty components.

(2) Loose or worn control arm bushes or pivot

bolts: Check and tighten or renew the worn compo-

nents. (3) Broken coil spring: Renew the coil spring,

preferably in matching pairs. (4) Worn rear hub bearing: Check and renew the

hub bearing as necessary. (5) Loose or worn stabilizer bar bushes: Check

and tighten or renew the worn components.

NOTE: As a quick guide to suspension unit

condition, bounce the vehicle up and down

(one side at a time) and observe if the vehicle

comes to rest in a single movement If the

vehicle bounces two or three times before

coming to rest the susp ension unit is suspect.

If suspect, remove the suspension unit and

check for fractures and leaks. If the

suspension unit is found to be unserviceable,

it is good practice to install two new

suspension units as a matching pair.

To check the control arm bushes or pivot

bolts, insert a lever between the suspect unit

and its mounting and lever the unit back

and forth checking for excessive movement.

Check the coil springs visually for breaks.

If the spring is found to be unserviceable, it

is good practice to install two new coil

springs as a matching pair.

Rear hub bearing noise can be diagnosed

by raising and supporting the rear of the

vehicle, spinning one wheel at a time and

listening for a rumbling noise.

POOR OR ERRATIC ROAD HOLDING ABILITY

(1) Low or uneven tire pressure: Inflate to the

recommended pressures.

(2) Incorrect rear wheel alignment: Check and

adjust the rear wheel alignment as necessary.

(3) Defective suspension unit: Renew the faulty

suspension unit, preferably in pairs. (4) Loose or broken stabilizer bar: Check and

tighten or renew the faulty components.

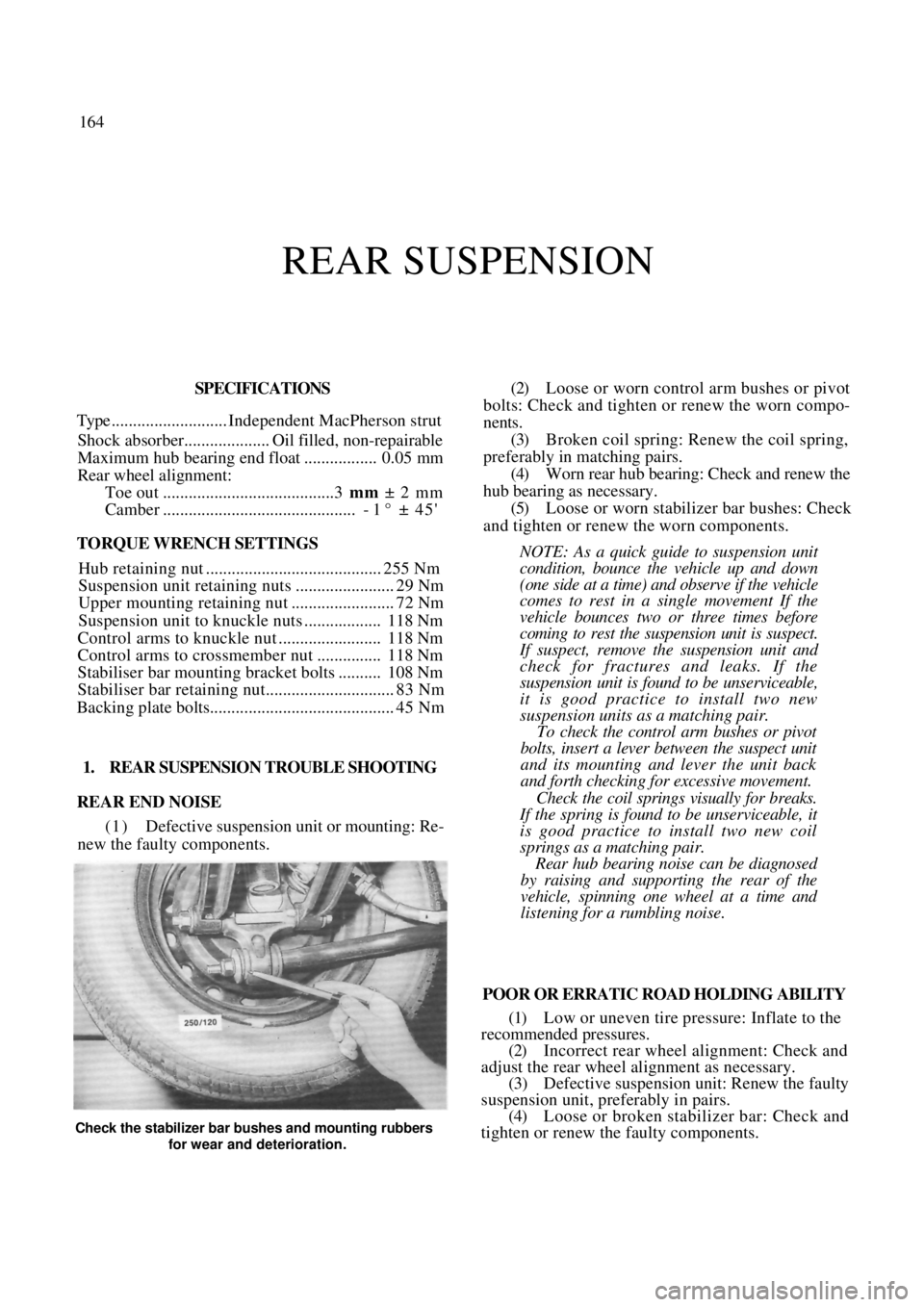

Check the stabilizer bar bushes and mounting rubbers

for wear and deterioration.

Page 165 of 238

Rear Suspension 165

Checking the rear control arm outer pivot bolt for security.

(5) Loose or worn control arm bushes or pivot

bolts: Check and tighten or renew the worn compo-

nents.

NOTE: Check the service ability of the sus-

pension units, control arm bushes and pivot

bolts as previously described.

If incorrect rear wheel alignment is sus-

pected, it is recommended that the vehicle be

taken to a wheel alignment specialist or a

Nissan dealer to be checked and if necessary

adjusted.

Visually inspect the stabilizer bar for

damage.

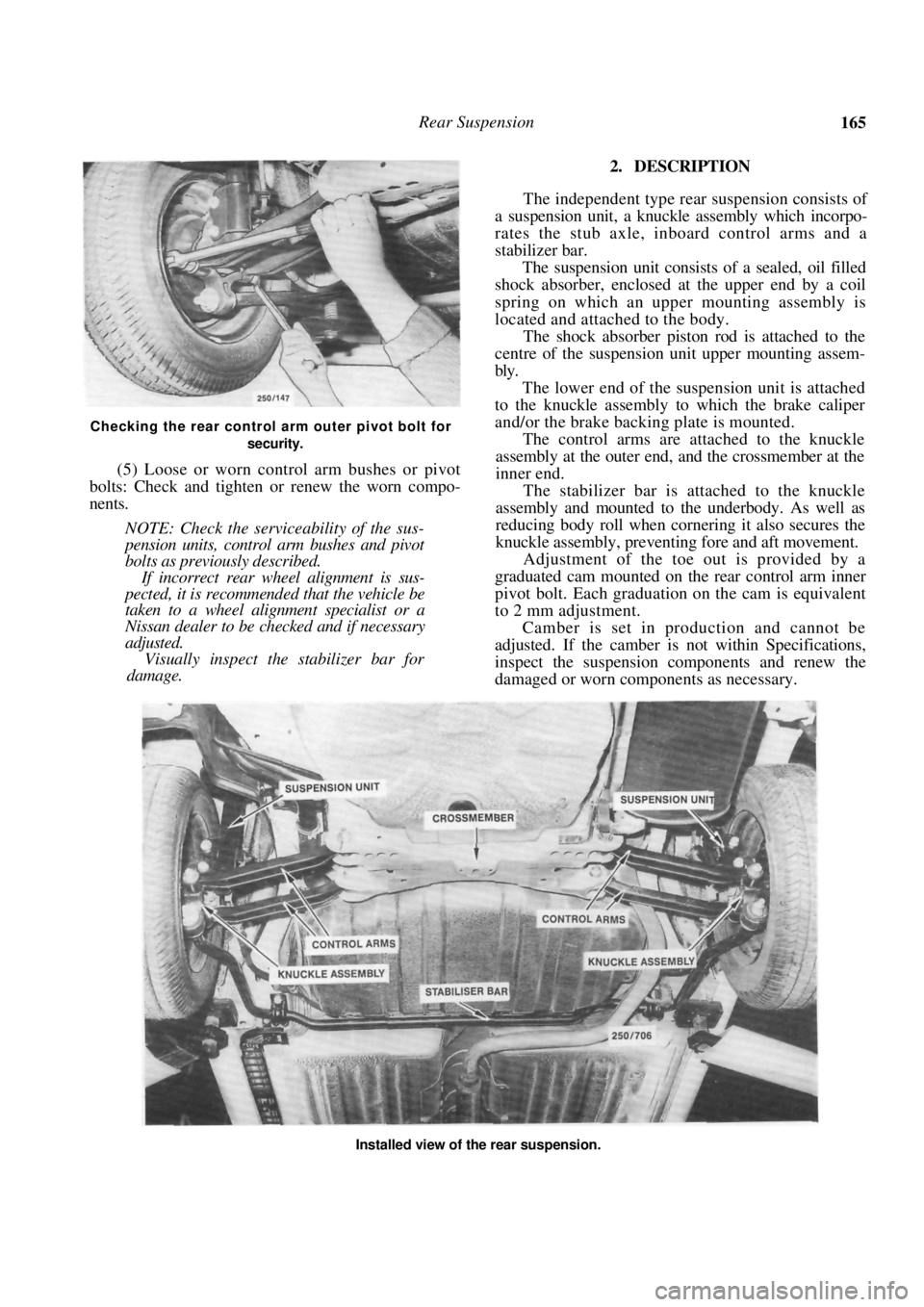

2. DESCRIPTION

The independent type rear suspension consists of

a suspension unit, a knuckle assembly which incorpo-

rates the stub axle, inboard control arms and a

stabilizer bar.

The suspension unit consists of a sealed, oil filled

shock absorber, enclosed at the upper end by a coil

spring on which an upper mounting assembly is

located and attached to the body.

The shock absorber piston rod is attached to the

centre of the suspension unit upper mounting assem-

bly.

The lower end of the suspension unit is attached

to the knuckle assembly to which the brake caliper

and/or the brake backing plate is mounted.

The control arms are attached to the knuckle

assembly at the outer end, and the crossmember at the

inner end.

The stabilizer bar is attached to the knuckle

assembly and mounted to the underbody. As well as

reducing body roll when cornering it also secures the

knuckle assembly, preventing fore and aft movement.

Adjustment of the toe out is provided by a

graduated cam mounted on the rear control arm inner

pivot bolt. Each graduation on the cam is equivalent

to 2 mm adjustment.

Camber is set in production and cannot be

adjusted. If the camber is not within Specifications,

inspect the suspension components and renew the

damaged or worn components as necessary.

Installed view of the rear suspension.

Page 166 of 238

166 Rear Suspension

3. REAR HUB

Special Equipment Required

To Check Hub Bearing End Float — Dial gauge

To Renew Bearing — Press and suitable drift

TO REMOVE AND INSTAL

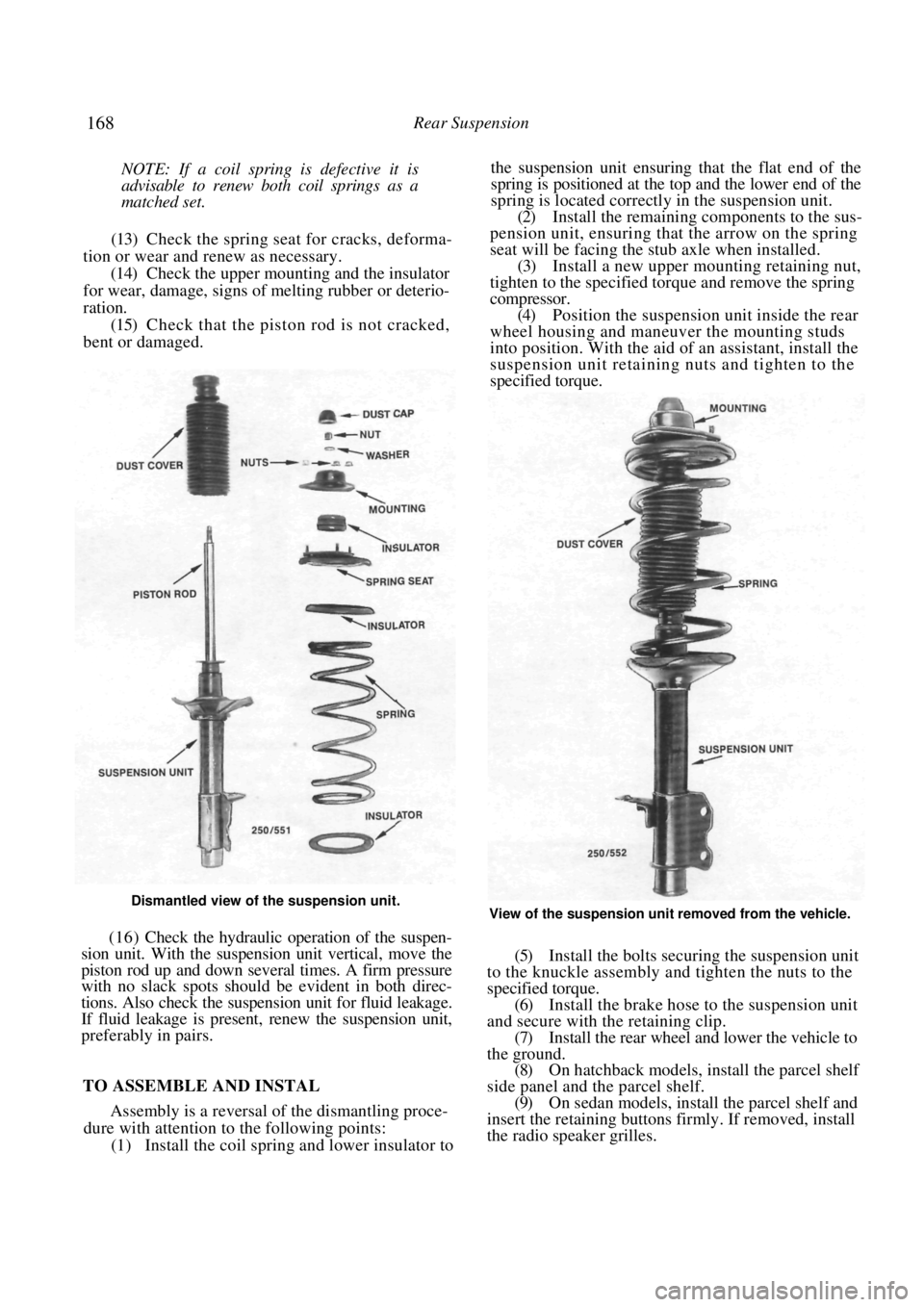

(1) Raise the rear of the vehicle and support it

on chassis stands. Remove the rear wheel and release

the handbrake.

(2) On models with rear drum brakes, proceed

to operation (6).

(3) Remove the clip securing the brake hose to

the suspension unit and disengage the hose.

(4) Remove the bolts securing the brake caliper

to the knuckle assembly. (5) Slide the caliper from the disc and support it

away from the working area, ensuring that no excess

strain is placed on the brake hose. (6) Rotate the hub and check that it rotates

smoothly. If it does not rotate smoothly, renew the

hub bearing. (7) Mount a dial gauge with the plunger posi-

tioned against the outer face of the hub. Move the hub

back and forth in line with the stub axle and note the

reading on the dial gauge. If the end float exceeds

Specifications, renew the hub bearing.

(8) Remove the hub grease cap from the rear

hub. (9) Remove the split pin from the stub axle and

remove the nut retainer, the hub retaining nut and

washer. Remove the hub assembly from the stub axle. Installation is a reversal of the removal procedure

with attention to the following points:

(1) Tighten the hub retaining nut to the specified

torque. (2) Check the hub bearing end float as previ-

ously described.

(3) On models with disc brakes, install the brake

caliper and tighten the retaining bolts to the torque

specified in the Brakes section. Install the brake hose to

the suspension unit and secure with the retaining clip.

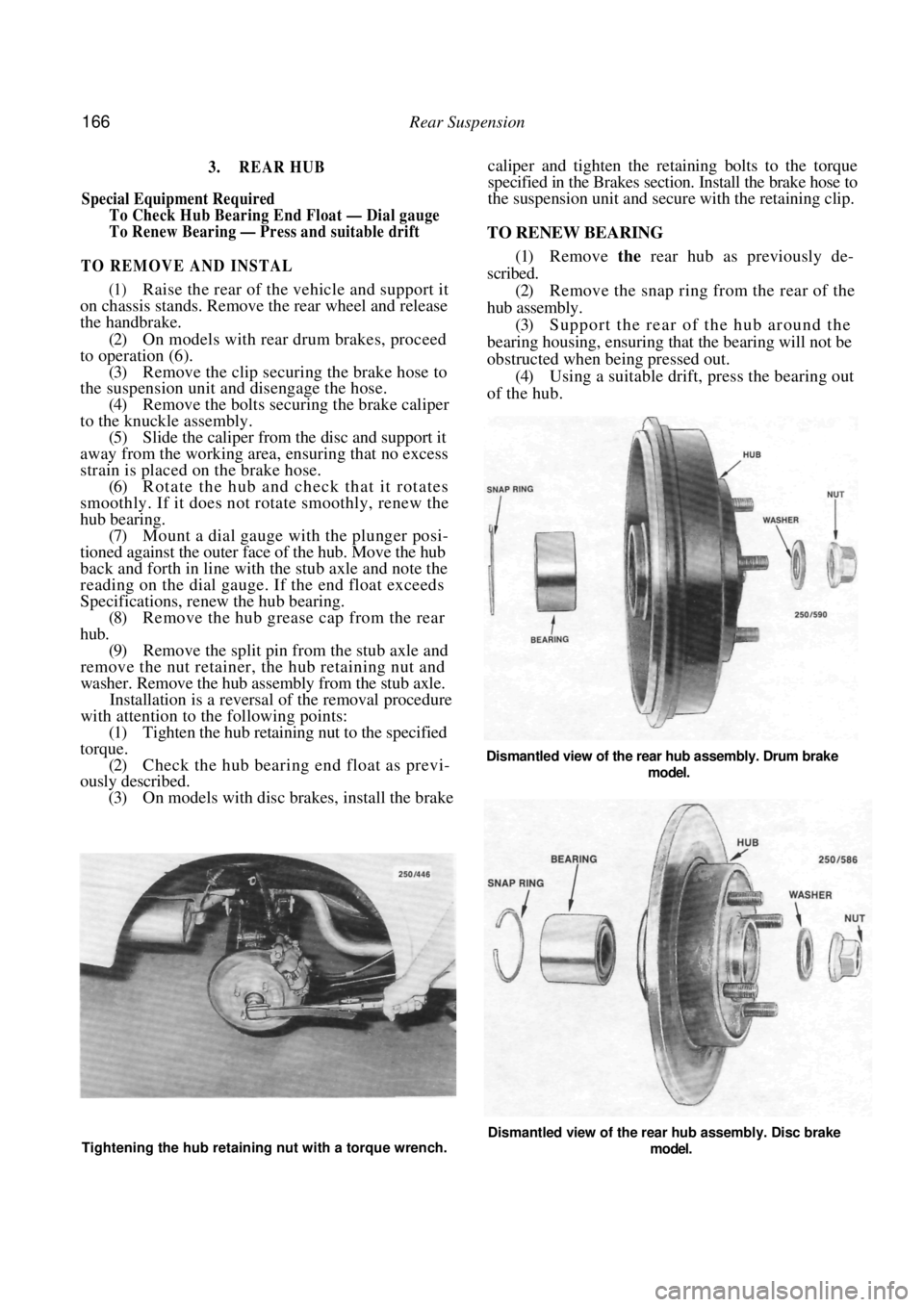

TO RENEW BEARING

(1) Remove the rear hub as previously de-

scribed. (2) Remove the snap ring from the rear of the

hub assembly. (3) Support the rear of the hub around the

bearing housing, ensuring that the bearing will not be

obstructed when being pressed out. (4) Using a suitable drift, press the bearing out

of the hub.

Dismantled view of the rear hub assembly. Drum brake

model.

Tightening the hub retaining nut with a torque wrench. Dismantled view of the rear hub assembly. Disc brake

model.

Page 167 of 238

Rear Suspension 167

NOTE: When a wheel bearing has been

removed from the hub it must be renewed.

(5) Press the new bearing into the hub, ensuring

that pressure is not exerted on the inner race of the

bearing and that the bearin g seal is not damaged. Do

not apply grease or oil to the mating surfaces of the

bearing and the hub.

NOTE: When installing the new bearing,

the press load must not exceed 3 tonnes.

(6) Inspect the snap ring for wear or cracks and

renew as necessary. Install the snap ring into the hub

ensuring that it is secur ely located in the groove.

(7) Apply multi-purpose grease to the bearing

sealing lip and install the hub as previously described.

4. SUSPENSION UNIT

Special Equipment Required:

To Dismantle — Spring compressor

TO REMOVE AND DISMANTLE

(1) On hatchback models, remove the rear par-

cel shelf and lower the rear seat backrests. Remove the

parcel shelf side panel re taining screws and remove

the relevant side panel.

(2) On sedan models, prise out the parcel shelf

retaining buttons using a suitable instrument and

withdraw the parcel shelf from the vehicle. If the rear

radio speakers are installed, remove the speaker grille

retaining screws and separate the speaker grilles from

the speakers prior to withdrawing the parcel shelf

from the vehicle. (3) Raise the rear of the vehicle and support it

on chassis stands as describe d in the Wheels and Tires

section. Remove the rear wheel from the vehicle.

View of the suspension unit with the spring compres-

sors installed.

(4) Remove the clip securing the brake hose to

the suspension unit and disengage the hose from the

suspension unit. (5) Support the weight of the knuckle assembly

and remove the bolts and nuts securing the suspension

unit to the knuckle assembly.

(6) Remove the nuts securing the suspension

unit to the body panel and maneuver the suspension

unit from the vehicle. (7) Thoroughly clean the suspension unit and

secure it in a soft jawed vice.

(8) Remove the dust cap from the upper mount-

ing and while holding the end of the piston rod with

an adjustable spanner, loosen the upper mounting

retaining nut. Do not re move the retaining nut.

(9) Using a suitable spring compressor, com-

press the coil spring and remove the upper mounting

retaining nut and washer. (10) Remove the upper mounting, insulator and

spring seat from th e suspension unit.

(11) Withdraw the upper insulator, coil spring,

lower insulator and dust cover from the suspension

unit. (12) Check the coil spring for cracks, deformation

and damage. Compare the free length with a new coil

spring and renew as necessary.

Location of the suspension unit retaining nuts. Hatch-

back model.

Page 168 of 238

168 Rear Suspension

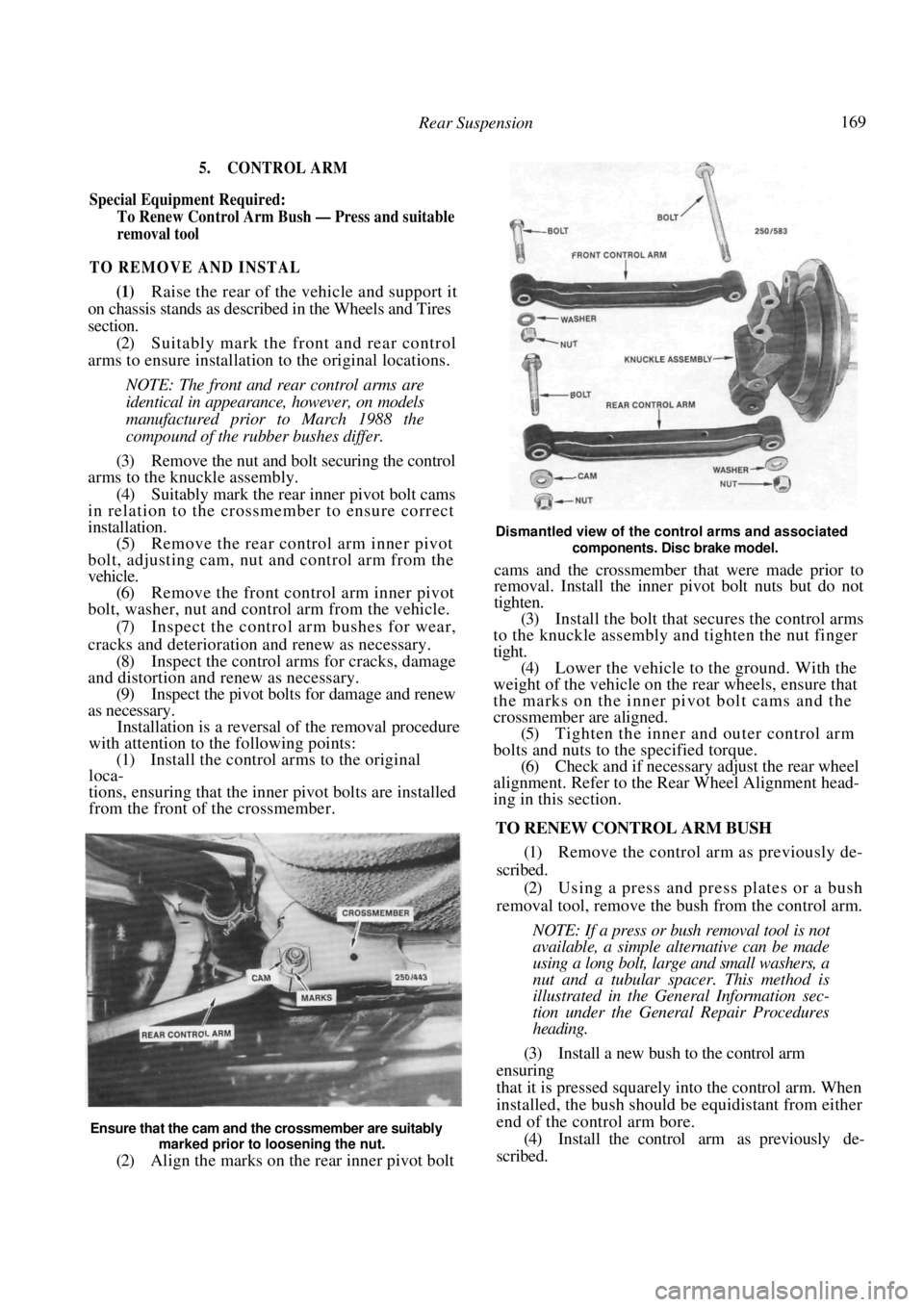

NOTE: If a coil spring is defective it is

advisable to renew both coil springs as a

matched set.

(13) Check the spring seat for cracks, deforma-

tion or wear and renew as necessary.

(14) Check the upper mounting and the insulator

for wear, damage, signs of melting rubber or deterio-

ration. (15) Check that the piston rod is not cracked,

bent or damaged.

Dismantled view of the suspension unit.

(16 ) Check the hydraulic operation of the suspen-

sion unit. With the suspension unit vertical, move the

piston rod up and down severa l times. A firm pressure

with no slack spots should be evident in both direc-

tions. Also check the suspen sion unit for fluid leakage.

If fluid leakage is present, renew the suspension unit,

preferably in pairs.

TO ASSEMBLE AND INSTAL

Assembly is a reversal of the dismantling proce-

dure with attention to the following points:

(1) Install the coil spring and lower insulator to

the suspension unit ensuring th at the flat end of the

spring is positioned at the top and the lower end of the

spring is located correctly in the suspension unit.

(2) Install the remaining co mponents to the sus-

pension unit, ensuring that the arrow on the spring

seat will be facing the stub axle when installed.

(3) Install a new upper mounting retaining nut,

tighten to the specified tor que and remove the spring

compressor. (4) Position the suspension unit inside the rear

wheel housing and maneuver the mounting studs

into position. With the aid of an assistant, install the

suspension unit retaining nuts and tighten to the

specified torque.

View of the suspension unit removed from the vehicle.

(5) Install the bolts securin g the suspension unit

to the knuckle assembly and tighten the nuts to the

specified torque.

(6) Install the brake hose to the suspension unit

and secure with the retaining clip. (7) Install the rear wheel and lower the vehicle to

the ground. (8) On hatchback models, install the parcel shelf

side panel and the parcel shelf. (9) On sedan models, install the parcel shelf and

insert the retaining buttons firmly. If removed, install

the radio speaker grilles.

Page 169 of 238

Rear Suspension 169

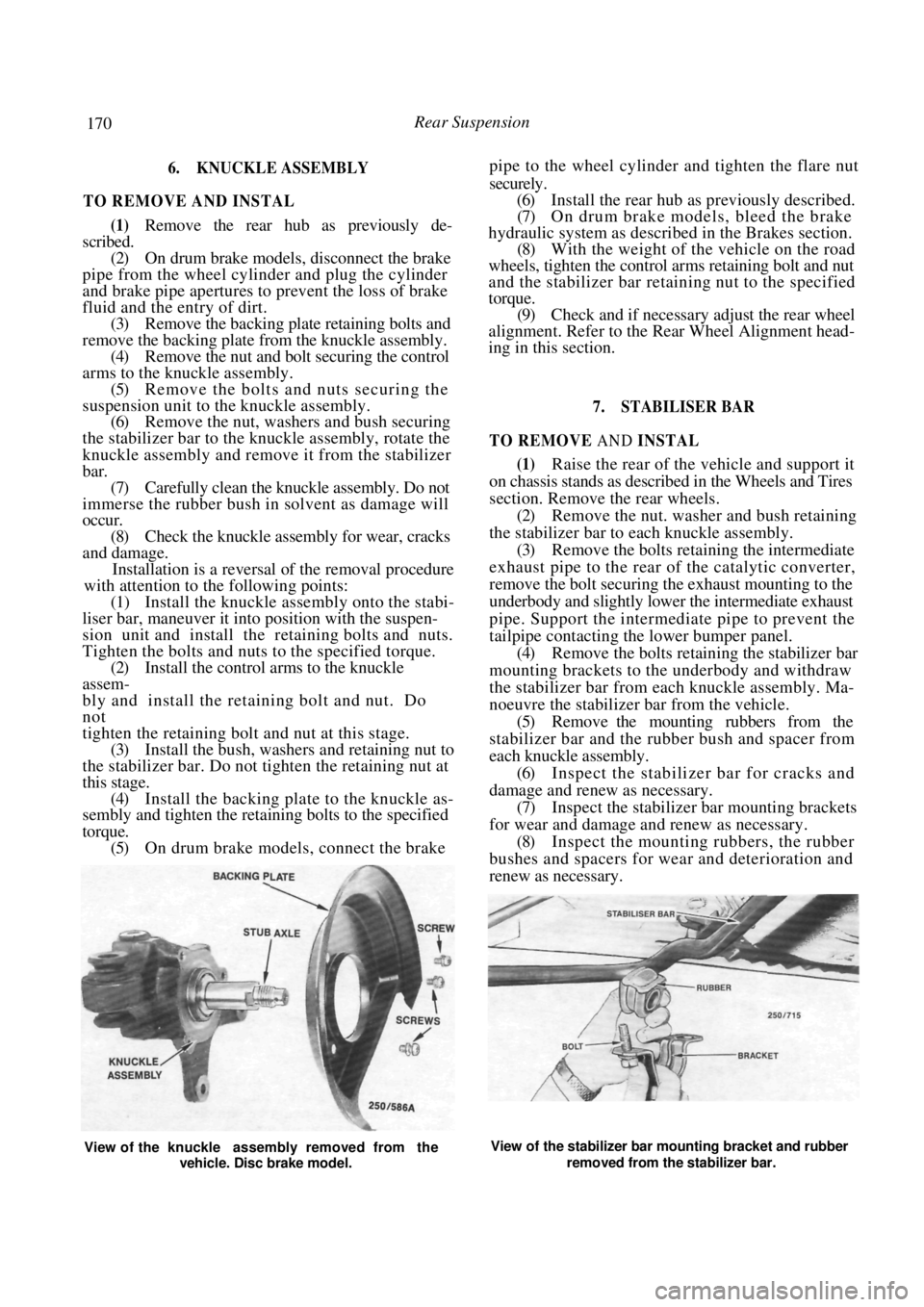

5. CONTROL ARM

Special Equipment Required:

To Renew Control Arm Bush — Press and suitable

removal tool

TO REMOVE AND INSTAL

(1) Raise the rear of the vehicle and support it

on chassis stands as describe d in the Wheels and Tires

section.

(2) Suitably mark the front and rear control

arms to ensure installation to the original locations.

NOTE: The front and rear control arms are

identical in appearance, however, on models

manufactured prior to March 1988 the

compound of the rubber bushes differ.

(3) Remove the nut and bolt securing the control

arms to the knuckle assembly.

(4) Suitably mark the rear inner pivot bolt cams

in relation to the crossmember to ensure correct

installation.

(5) Remove the rear control arm inner pivot

bolt, adjusting cam, nut and control arm from the

vehicle. (6) Remove the front control arm inner pivot

bolt, washer, nut and control arm from the vehicle.

(7) Inspect the control arm bushes for wear,

cracks and deterioration and renew as necessary. (8) Inspect the control arms for cracks, damage

and distortion and renew as necessary.

(9) Inspect the pivot bolts for damage and renew

as necessary. Installation is a reversal of the removal procedure

with attention to the following points:

(1) Install the control arms to the original

loca-

tions, ensuring that the inner pivot bolts are installed

from the front of the crossmember.

(2) Align the marks on the rear inner pivot bolt

Dismantled view of the control arms and associated

components. Disc brake model.

cams and the crossmember that were made prior to

removal. Install the inner pivot bolt nuts but do not

tighten.

(3) Install the bolt that secures the control arms

to the knuckle assembly and tighten the nut finger

tight. (4) Lower the vehicle to the ground. With the

weight of the vehicle on th e rear wheels, ensure that

the marks on the inner pivot bolt cams and the

crossmember are aligned. (5) Tighten the inner and outer control arm

bolts and nuts to the specified torque. (6) Check and if necessary adjust the rear wheel

alignment. Refer to the Re ar Wheel Alignment head-

ing in this section.

TO RENEW CONTROL ARM BUSH

(1) Remove the control arm as previously de-

scribed. (2) Using a press and press plates or a bush

removal tool, remove the bush from the control arm.

NOTE: If a press or bush removal tool is not

available, a simple alternative can be made

using a long bolt, large and small washers, a

nut and a tubular spacer. This method is

illustrated in the General Information sec-

tion under the General Repair Procedures

heading.

(3) Install a new bush to the control arm

ensuring

that it is pressed squarely into the control arm. When

installed, the bush should be equidistant from either

end of the control arm bore. (4) Install the control arm as previously de-

scribed.

Ensure that the cam and the crossmember are suitably

marked prior to loosening the nut.

Page 170 of 238

170 Rear Suspension

6. KNUCKLE ASSEMBLY

TO REMOVE AND INSTAL

(1) Remove the rear hub as previously de-

scribed.

(2) On drum brake models, disconnect the brake

pipe from the wheel cylinder and plug the cylinder

and brake pipe apertures to prevent the loss of brake

fluid and the entry of dirt. (3) Remove the backing plate retaining bolts and

remove the backing plate from the knuckle assembly. (4) Remove the nut and bolt securing the control

arms to the knuckle assembly. (5) Remove the bolts and nuts securing the

suspension unit to the knuckle assembly. (6) Remove the nut, washers and bush securing

the stabilizer bar to the knuckle assembly, rotate the

knuckle assembly and remove it from the stabilizer

bar. (7) Carefully clean the knuckle assembly. Do not

immerse the rubber bush in solvent as damage will

occur.

(8) Check the knuckle assembly for wear, cracks

and damage. Installation is a reversal of the removal procedure

with attention to the following points:

(1) Install the knuckle assembly onto the stabi-

liser bar, maneuver it into position with the suspen-

sion unit and install the retaining bolts and nuts.

Tighten the bolts and nuts to the specified torque.

(2) Install the control arms to the knuckle

assem-

bly and install the retaining bolt and nut. Do

not

tighten the retaining bolt and nut at this stage. (3) Install the bush, washers and retaining nut to

the stabilizer bar. Do not tighten the retaining nut at

this stage. (4) Install the backing plate to the knuckle as-

sembly and tighten the retaining bolts to the specified

torque.

(5) On drum brake models, connect the brake

pipe to the wheel cylinder and tighten the flare nut

securely.

(6) Install the rear hub as previously described.

(7) On drum brake models, bleed the brake

hydraulic system as described in the Brakes section.

(8) With the weight of the vehicle on the road

wheels, tighten the control arms retaining bolt and nut

and the stabilizer bar retaining nut to the specified

torque. (9) Check and if necessary adjust the rear wheel

alignment. Refer to the Re ar Wheel Alignment head-

ing in this section.

7. STABILISER BAR

TO REMOVE AND INSTAL

(1) Raise the rear of the vehicle and support it

on chassis stands as describe d in the Wheels and Tires

section. Remove the rear wheels.

(2) Remove the nut. washer and bush retaining

the stabilizer bar to each knuckle assembly. (3) Remove the bolts retain ing the intermediate

exhaust pipe to the rear of the catalytic converter,

remove the bolt securing the exhaust mounting to the

underbody and slightly lower the intermediate exhaust

pipe. Support the intermediate pipe to prevent the

tailpipe contacting the lower bumper panel. (4) Remove the bolts retaining the stabilizer bar

mounting brackets to the underbody and withdraw

the stabilizer ba r from each knuckle assembly. Ma-

noeuvre the stabilizer bar from the vehicle.

(5) Remove the mounting rubbers from the

stabilizer bar and the rubber bush and spacer from

each knuckle assembly. (6) Inspect the stabilizer bar for cracks and

damage and renew as necessary. (7) Inspect the stabilizer bar mounting brackets

for wear and damage and renew as necessary. (8) Inspect the mounting rubbers, the rubber

bushes and spacers for wear and deterioration and

renew as necessary.

View of the knuckle assembly removed from the

vehicle. Disc brake model. View of the stabilizer bar mounting bracket and rubber

removed from the stabilizer bar.