service NISSAN PULSAR 1987 Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1987, Model line: PULSAR, Model: NISSAN PULSAR 1987Pages: 238, PDF Size: 28.91 MB

Page 82 of 238

82

FUEL AND ENGINE MANAGEMENT

CAUTION: To prevent severe electrical shock, extreme care must be taken when

working on or near the electronic ignition system as dangerous high tension voltages

are produced in both the primary and secondary circuits. See the text fo\

r

precautionary notes.

SPECIFICATIONS

FUEL INJECTION

Type:

1.6 liter engine .................................. Single point

1.8 liter engine................................... Multi point

FUEL PUMP

Type ................................................................ Electric

Pressure at idle:

1.6 liter engine ..................................... 62-90 kPa

1.8 liter engine ................................ 190-230 kPa

FUEL FILTER

Type ................................................ Inline, disposable

AIR FILTER

Type ................................... Disposable paper element

DISTRIBUTOR

Make ........................................................ Delco Remy

Advance contro l .......................................... Electronic

Rotation of rotor .................................. Anti-clockwise

Firing order....................................................1 -3-4-2

ADJUSTMENTS

Base idle speed ..................................... 550-650 rpm

Ignition timing.......................................... 10° BTDC

TORQUE WRENCH SETTINGS

Throttle body nuts.......................................... 10 Nm

*Throttle body bolts ........................................ 12 Nm

*Fuel hose fittings............................................ 35 Nm

Fuel rail bolts ....................................................8 Nm

Fuel tank drain plug ........................................ 24 Nm

Coolant temperature sensor ............................ 12 Nm

Oxygen sensor .................................................. 40 Nm

MAT sensor..................................................... 14 Nm

*1.6 liter engine

l . 8 liter engine

1. FUEL AND ENGINE MANAGEMENT

TROUBLE SHOOTING

NOTE: The following Trouble Shooting pro-

cedures are basic checks only. If these pro-

cedures fail to locate the fault, refer to the

System Diagnosis and Adjustments heading

for more thorough testing.

Prior to performing any of the following

operations, refer to the Service Precautions

and Procedures heading.

ENGINE WILL NOT START OR HARD TO

START

(1) Water in the fuel: Dr ain the fuel from the

system and renew the fuel filter.

(2) Fault in the power supply: Check the battery,

fusible links and fuses. Check for clean, secure con-

nections, particularly the earth connections. Check the

EG1 and fuel pump relays.

NOTE: If the fuel pump relay fails, power

will be supplied to the fuel pump via the oil

pressure switch. When starting the engine,

Check that the MAP sensor hose is not blocked or split

and ensure that all electrical connections are clean and

secure.

Page 86 of 238

86 Fuel and Engine Management

other. The fuel pressure is maintained at a constant

pressure relevant to the manifold vacuum. A dispos-

able paper element fuel filter is mounted on the engine

bulkhead.

The amount of fuel injected is relevant to the time

the injector remains open. The basic time the injector

remains open is governed by the control unit which

uses information from the various sensors to give

optimum engine efficiency for given conditions.

The idle air control (IAC) valve controls the fast

idle speed during engine warm up and maintains the

basic idle speed at a set value by compensating for

loads such as air conditioning or the selection of Drive

on automatic transaxle models.

The throttle body assembly is mounted to the

inlet manifold and controls the amount of air entering

the engine by the action of the throttle valve.

Efficient operation of the EFI system depends on

accurate signals being receiv ed by the control unit and

controlled air flow beyond the throttle valve. There-

fore it is essential that all air, fuel and electrical

connections be clean and tight.

3. SERVICE PRECAUTIONS AND

PROCEDURES

Electronic ignition systems can produce danger-

ously high voltages in both the primary and secondary

circuits. For this reason, extreme care must be taken

when working on or near the ignition system.

Do not start the engine if the battery terminals are

not clean and tight.

Do not use the fast charge or boost settings on a

battery charger to start the engine.

Do not disconnect the battery terminals while the

engine is running.

Disconnect the battery terminals before charging

the battery.

Disconnect the negative ba ttery terminal before

working on the engine management system.

Do not subject the control unit to temperatures

above 80 deg C.

Ensure that all wiring connectors are clean and

tight.

Disconnect the battery terminals and the control

unit wiring connectors before attempting any welding

operations.

Do not direct a steam cleaning or pressure

washing nozzle at engine management components

when cleaning the engine.

Ensure that the ignition is Off prior to disconnect-

ing the battery terminals, fusible links or the control

unit wiring connectors.

TO CONNECT ELECTRICAL TEST

EQUIPMENT

NOTE: Some types of tachometers, timing

lights and ignition system analysers are not

compatible with this engine management

system and may result in incorrect readings.

It is therefore recommended that the man-

ufacturer of the lest equipment be consulted

before proceeding to use the equipment.

If a test procedure requires the use of a

test lamp or voltmeter, ensure that only the

specified instrument is used to prevent mis-

leading diagnosis.

MULTIMETER

It is essential that in all tests where voltage or

resistance is to be measur ed, a digital display multi-

meter with a minimum 10 megohms impedance be

used.

The correct method of backprobing the wiring connec-

tors. The meter test probe should be modified with a piece of thin wire as shown.

All meter readings are to be performed with the

component wiring connectors installed unless other-

wise instructed. This can be done by inserting the

meter test probes from the wiring harness side of the

connector or backprobing. If the test probes are not

thin, they should be modified by attaching a thin piece

of wire to the end, giving a fine point that will not

damage the connector. Ensure that the wire is making

good contact with the probe.

If sealing plugs or boots are removed from wiring

connectors to facilitate bac kprobing, ensure that they

are correctly installed at the conclusion of the test

procedure.

To identify wiring connector terminals refer to the

wiring circuit diagrams.

Test Lamp

To avoid damage to the electronic components

when testing, the use of an LED (light emitting diode)

test lamp is recommended.

Page 89 of 238

Fuel and Engine Management 89

The procedure for fabricating an LED test lamp is

fully described in the El ectrical System section.

If a conventional test lamp with a filament type

bulb is to be used, ensure that the current draw of the

test lamp does not exceed 0.3 amp to avoid damage to

the electronic components.

To check the current draw connect an accurate

ammeter, such as the multimeter described previ-

ously, in series with the test lamp and a battery.

If the ammeter reads less than 0.3 amp the test

lamp is suitable.

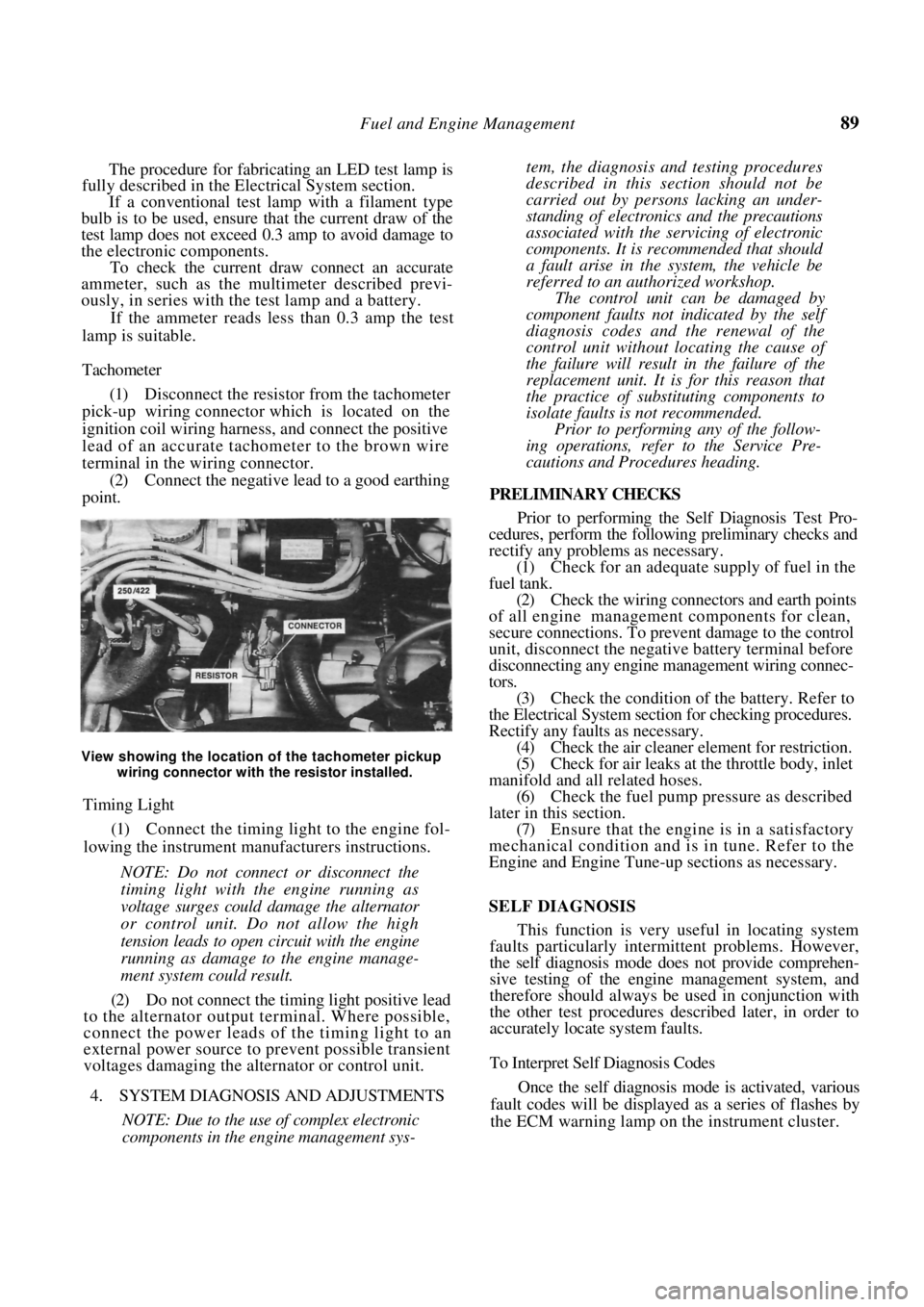

Tachometer

(1) Disconnect the resistor from the tachometer

pick-up wiring connector which is located on the

ignition coil wiring harness, and connect the positive

lead of an accurate tachometer to the brown wire

terminal in the wiring connector. (2) Connect the negative lead to a good earthing

point.

View showing the location of the tachometer pickup

wiring connector with the resistor installed.

Timing Light

(1) Connect the timing light to the engine fol-

lowing the instrument manufacturers instructions.

NOTE: Do not connect or disconnect the

timing light with the engine running as

voltage surges could damage the alternator

or control unit. Do not allow the high

tension leads to open circuit with the engine

running as damage to the engine manage-

ment system could result.

(2) Do not connect the timing light positive lead

to the alternator output terminal. Where possible,

connect the power leads of the timing light to an

external power source to prevent possible transient

voltages damaging the alternator or control unit.

4. SYSTEM DIAGNOSIS AND ADJUSTMENTS

NOTE: Due to the use of complex electronic

components in the engine management sys-

tem, the diagnosis and testing procedures

described in this section should not be

carried out by persons lacking an under-

standing of electronics and the precautions

associated with the servicing of electronic

components. It is rec ommended that should

a fault arise in the system, the vehicle be

referred to an authorized workshop.

The control unit can be damaged by

component faults not indicated by the self

diagnosis codes and the renewal of the

control unit without lo cating the cause of

the failure will result in the failure of the

replacement unit. It is for this reason that

the practice of substituting components to

isolate faults is not recommended.

Prior to performing any of the follow-

ing operations, refer to the Service Pre-

cautions and Procedures heading.

PRELIMINARY CHECKS

Prior to performing the Self Diagnosis Test Pro-

cedures, perform the following preliminary checks and

rectify any problems as necessary.

(1) Check for an adequate supply of fuel in the

fuel tank. (2) Check the wiring connectors and earth points

of all engine management components for clean,

secure connections. To prevent damage to the control

unit, disconnect the negative battery terminal before

disconnecting any engine ma nagement wiring connec-

tors. (3) Check the condition of the battery. Refer to

the Electrical System sectio n for checking procedures.

Rectify any faults as necessary. (4) Check the air cleaner element for restriction.

(5) Check for air leaks at the throttle body, inlet

manifold and all related hoses. (6) Check the fuel pump pr essure as described

later in this section. (7) Ensure that the engine is in a satisfactory

mechanical condition and is in tune. Refer to the

Engine and Engine Tune-up sections as necessary.

SELF DIAGNOSIS

This function is very useful in locating system

faults particularly intermittent problems. However,

the self diagnosis mode does not provide comprehen-

sive testing of the engine management system, and

therefore should always be used in conjunction with

the other test procedures described later, in order to

accurately locate system faults.

To Interpret Self Diagnosis Codes

Once the self diagnosis mode is activated, various

fault codes will be displayed as a series of flashes by

the ECM warning lamp on the instrument cluster.

Page 91 of 238

Fuel and Engine Management 91

components, erase the self diagnosis memory as

described under the following heading.

(7) Repeat the self diagnosis test procedure and

ensure that code 12 is displayed.

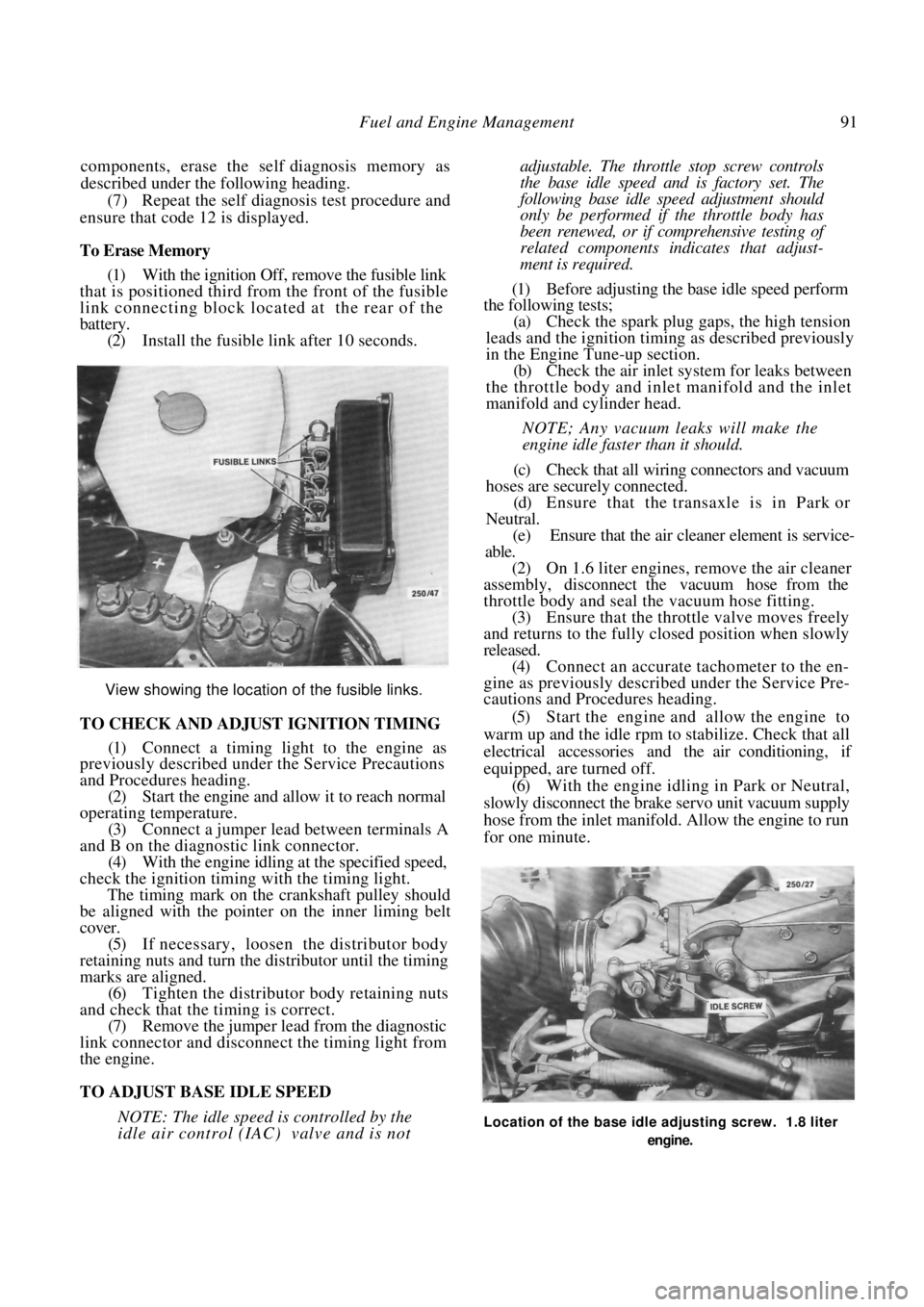

To Erase Memory

(1) With the ignition Off, remove the fusible link

that is positioned third from the front of the fusible

link connecting block located at the rear of the

battery. (2) Install the fusible link after 10 seconds.

View showing the location of the fusible links.

TO CHECK AND ADJUST IGNITION TIMING

(1) Connect a timing light to the engine as

previously described under the Service Precautions

and Procedures heading.

(2) Start the engine and allow it to reach normal

operating temperature. (3) Connect a jumper lead between terminals A

and B on the diagnostic link connector. (4) With the engine idling at the specified speed,

check the ignition timing with the timing light.

The timing mark on the crankshaft pulley should

be aligned with the pointer on the inner liming belt

cover.

(5) If necessary, loosen the distributor body

retaining nuts and turn the distributor until the timing

marks are aligned. (6) Tighten the distributor body retaining nuts

and check that the timing is correct. (7) Remove the jumper lead from the diagnostic

link connector and disconnect the timing light from

the engine.

TO ADJUST BASE IDLE SPEED

NOTE: The idle speed is controlled by the

idle air control (IAC) valve and is not

adjustable. The throttle stop screw controls

the base idle speed a nd is factory set. The

following base idle speed adjustment should

only be performed if the throttle body has

been renewed, or if comprehensive testing of

related components indicates that adjust-

ment is required.

(1) Before adjusting the base idle speed perform

the following tests;

(a) Check the spark plug gaps, the high tension

leads and the ignition timin g as described previously

in the Engine Tune-up section.

(b) Check the air inlet syst em for leaks between

the throttle body and inlet manifold and the inlet

manifold and cylinder head.

NOTE; Any vacuum leaks will make the

engine idle faster than it should.

(c) Check that all wiring connectors and vacuum

hoses are securely connected. (d) Ensure that the transaxle is in Park or

Neutral. (e) Ensure that the air cleaner element is service-

able.

(2) On 1.6 liter engines, remove the air cleaner

assembly, disconnect the vacuum hose from the

throttle body and seal the vacuum hose fitting.

(3) Ensure that the throttle valve moves freely

and returns to the fully closed position when slowly

released. (4) Connect an accurate tachometer to the en-

gine as previously descri bed under the Service Pre-

cautions and Procedures heading.

(5) Start the engine and allow the engine to

warm up and the idle rpm to stabilize. Check that all

electrical accessories and the air conditioning, if

equipped, are turned off. (6) With the engine idling in Park or Neutral,

slowly disconnect the brake servo unit vacuum supply

hose from the inlet manifold. Allow the engine to run

for one minute.

Location of the base idle adjusting screw. 1.8 liter

engine.

Page 93 of 238

Fuel and Engine Management 93

liter engines, or the throttle body hose fitting on 1.6

liter engines.

(5) Tighten all connectors securely. Check for

external leaks as previously described. (6) Start the engine and note the pressure while

the engine is idling.

(7) Switch the engine Off and check that the

residual pressure does not decrease.

If the fuel pressure is within Specifications and

does not decrease, the fuel system is in a serviceable

condition. Depressurize the fuel system and discon-

nect the pressure gauge.

If the fuel pressure is a bove Specifications proceed

to operation (9).

If the fuel pressure is below Specifications proceed

to the following operation.

If the fuel pressure decreases, an internal leak is

indicated. Proceed to the following heading and carry

out the test procedure.

Testing the fuel system pressure using a pressure

gauge. 1.8 liter engine.

NOTE: There may be a small initial de-

crease in pressure when the engine is

switched Off This is acceptable and does not

indicate a fault in the system.

(8) If the fuel pressure is below Specifications

proceed as follows:

(a) Check the fuel lines for blockages and kinks

or a blocked fuel filter or fuel pump pickup strainer. (b) If no fault can be found in the previous

checks, on 1.8 liter engines clamp the fuel return hose

at the fuel rail. On 1.6 liter engines, clamp the hose that is

connected to the front throttle body hose fitting.

(c) Connect a jumper lead between terminals G

and H on the diagnostic link connector and switch the

ignition On.

NOTE: Do not operate the fuel pump for

longer than is necessary to obtain a pressure

reading.

If the fuel pressure is less than 270 kPa on 1.8 liter

engines or 90 kPa on 1.6 liter engines, renew the fuel

pump.

If the fuel pressure is more than previously

specified, renew the pressure regulator assembly on

1.8 liter engines or the pressure regulator diaphragm

on 1.6 liter engines.

(9) If the fuel pressure in operation (6) is above

Specifications, proceed as follows:

(a) On 1.8 liter engines, disconnect the fuel

return hose from the pressure regulator outlet.

On 1.6 liter engines, disc onnect the fuel return

hose from the front throttle body hose fitting.

(b) Connect a suitable length of fuel hose to the

pressure regulator or the front throttle body hose

filling and place the opposite end of the hose into a

petroleum resistant container. (c) Connect a jumper lead between terminals G

and H on the diagnostic link connector and switch the

ignition On. If the fuel pressure is 230-270 kPa on 1.8 liter

engines or 62-90 kPa on 1.6 liter engines, locate and

remove the restriction in the fuel return hose or pipe.

If the fuel pressure is more than previously

specified, renew the pressure regulator assembly on

1.8 liter engines or the pressure regulator diaphragm

on 1.6 liter engines.

TO TEST FOR INTERNAL FUEL LEAKAGE

Check the residual fuel pressure as previously

described.

If the pressure has decreased it is an indication of

an internal leak. With the pressure gauge still at-

tached, proceed as follows:

(1) Switch the ignition On to pressurize the fuel

system.

(2) As the pressure begins to decrease clamp the

fuel supply hose shut. If the pressure remains steady

the fuel pump may be consid ered faulty and should be

renewed as described later in this section. (3) If the pressure continues to decrease switch

the ignition On after it has been Off at least 10

seconds. As the pressure begi ns to decrease clamp the

fuel return hose shut. If the pressure remain steady on 1.8 liter engines,

renew the pressure regulator. If the pressure continues

to decrease, leaking inject ors are indicated. Remove

the injectors as described later in this section to locate

the leaking injectors.

If the pressure remains stea dy on 1.6 liter engines,

renew the pressure regulator diaphragm as described

later in this section. If the pressure continues to

decrease remove the injector and renew the O ring

seals as described later in this section. If this fails to

rectify the fault remove the injector and clean or

renew the injector as necessary.

Page 95 of 238

Fuel and Engine Management 95

(3) Disconnect the vacuum hose from the pres-

sure regulator.

(4) Release the fuel hose clamps, disconnect the

hoses from the pressure regulator and remove the

pressure regulator. Installation is a reversal of the removal procedure

ensuring that the fuel hose clamps are tightened

securely.

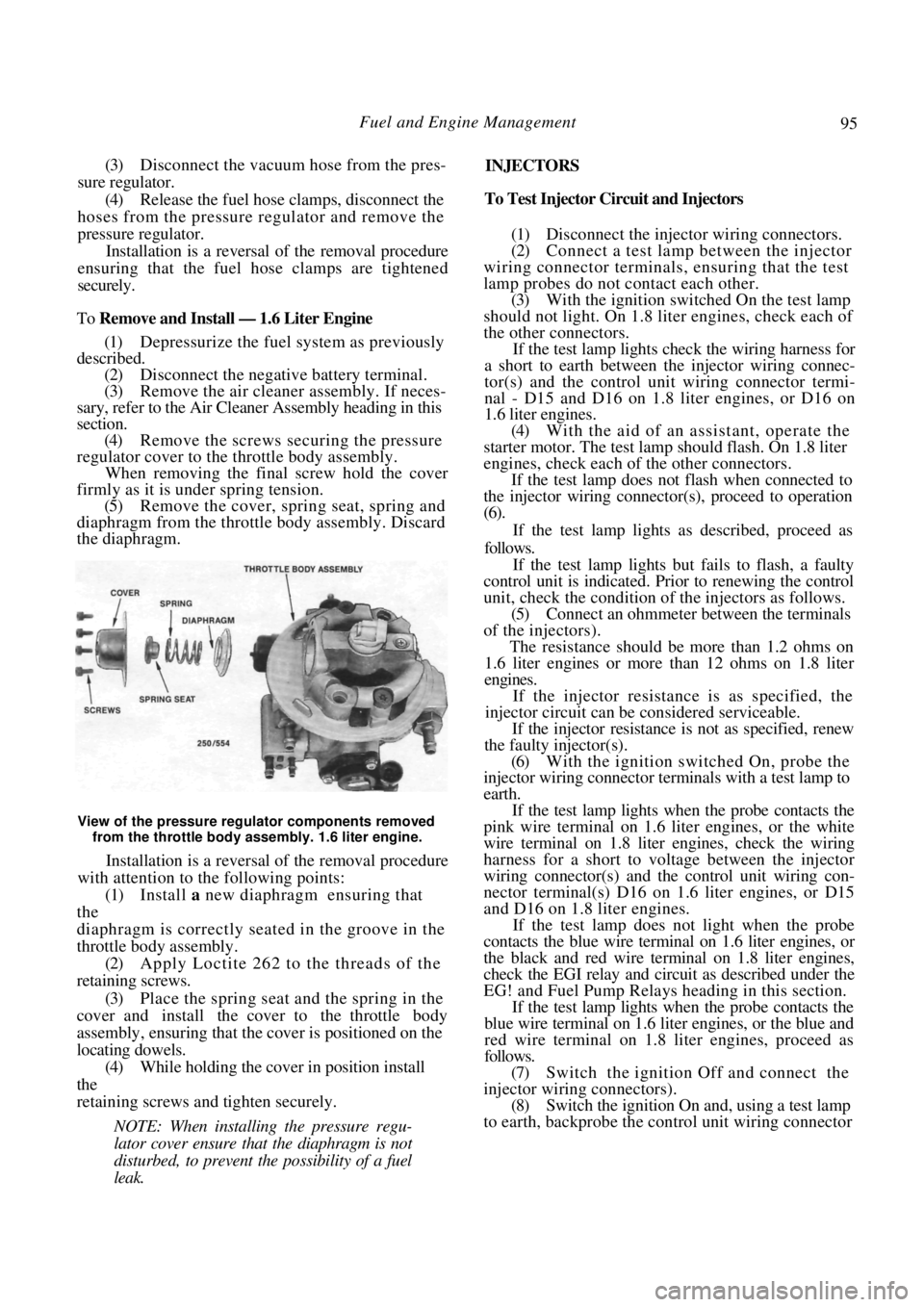

To Remove and Install — 1.6 Liter Engine

(1) Depressurize the fuel system as previously

described. (2) Disconnect the negative battery terminal.

(3) Remove the air cleaner assembly. If neces-

sary, refer to the Air Cleane r Assembly heading in this

section. (4) Remove the screws securing the pressure

regulator cover to the throttle body assembly. When removing the final screw hold the cover

firmly as it is under spring tension.

(5) Remove the cover, spring seat, spring and

diaphragm from the thrott le body assembly. Discard

the diaphragm.

View of the pressure regulator components removed

from the throttle body assembly. 1.6 liter engine.

Installation is a reversal of the removal procedure

with attention to the following points:

(1) Install a new diaphragm ensuring that

the

diaphragm is correctly seat ed in the groove in the

throttle body assembly. (2) Apply Loctite 262 to the threads of the

retaining screws.

(3) Place the spring seat and the spring in the

cover and install the cover to the throttle body

assembly, ensuring that the cover is positioned on the

locating dowels. (4) While holding the cover in position install

the

retaining screws and tighten securely.

NOTE: When installing the pressure regu-

lator cover ensure that the diaphragm is not

disturbed, to prevent the possibility of a fuel

leak.

INJECTORS

To Test Injector Circuit and Injectors

(1) Disconnect the injector wiring connectors.

(2) Connect a test lamp between the injector

wiring connector terminals, ensuring that the test

lamp probes do not contact each other. (3) With the ignition switched On the test lamp

should not light. On 1.8 liter engines, check each of

the other connectors.

If the test lamp lights check the wiring harness for

a short to earth between the injector wiring connec-

tor(s) and the control unit wiring connector termi-

nal - D15 and D16 on 1.8 liter engines, or D16 on

1.6 liter engines.

(4) With the aid of an assistant, operate the

starter motor. The test lamp should flash. On 1.8 liter

engines, check each of the other connectors.

If the test lamp does not flash when connected to

the injector wiring connecto r(s), proceed to operation

(6).

If the test lamp lights as described, proceed as

follows.

If the test lamp lights but fails to flash, a faulty

control unit is indicated. Pr ior to renewing the control

unit, check the condition of the injectors as follows.

(5) Connect an ohmmeter between the terminals

of the injectors).

The resistance should be more than 1.2 ohms on

1.6 liter engines or more than 12 ohms on 1.8 liter

engines.

If the injector resistance is as specified, the

injector circuit can be considered serviceable.

If the injector resistance is not as specified, renew

the faulty injector(s).

(6) With the ignition switched On, probe the

injector wiring connector terminals with a test lamp to

earth.

If the test lamp lights when the probe contacts the

pink wire terminal on 1.6 liter engines, or the white

wire terminal on 1.8 liter engines, check the wiring

harness for a short to volt age between the injector

wiring connector(s) and the control unit wiring con-

nector terminal(s) D16 on 1.6 liter engines, or D15

and D16 on 1.8 liter engines.

If the test lamp does not light when the probe

contacts the blue wire termin al on 1.6 liter engines, or

the black and red wire term inal on 1.8 liter engines,

check the EGI relay and circ uit as described under the

EG! and Fuel Pump Relays heading in this section.

If the test lamp lights when the probe contacts the

blue wire terminal on 1.6 lite r engines, or the blue and

red wire terminal on 1.8 liter engines, proceed as

follows.

(7) Switch the ignition Off and connect the

injector wiring connectors). (8) Switch the ignition On and, using a test lamp

to earth, backprobe the cont rol unit wiring connector

Page 104 of 238

104 Fuel and Engine Management

(3) Gently pull the outer throttle cable until the

inner cable remains taut without moving the throttle

linkage. (4) Install the snap ring into the groove

posi-

tioned second from the insulator.

(5) Depress the throttle pedal and check that the

throttle valve opens fully and returns to the idle

position when the pedal is released. (6) On 1.6 liter engines, install the air

cleaner

assembly.

7. ELECTRONIC COMPONENTS

NOTE: Before proceeding with any of the

operations in this section, refer to the Ser-

vice Precautions and Procedures heading.

TO CHECK IGNITION SYSTEM

(1) Perform the test procedure described in the

Roadside Trouble Shooting section. Repair or renew

components as necessary. (2) Perform the self diagnosis test procedure as

previously described and rectify any faults. If there is

no spark, proceed as follows. (3) Disconnect the 4 pin wiring connector from

the distributor and check for spark at a spark plug

high tension lead using the test spark plug. If there is a spark, renew the pickup coil in the

distributor.

If there is no spark, proceed as follows.

(4) Connect the coil high tension lead to the test

spark plug and check for spark.

If there is a spark, check the distributor cap and

rotor for cracks and moisture. Repair or renew as

necessary.

If there is no spark, proceed as follows.

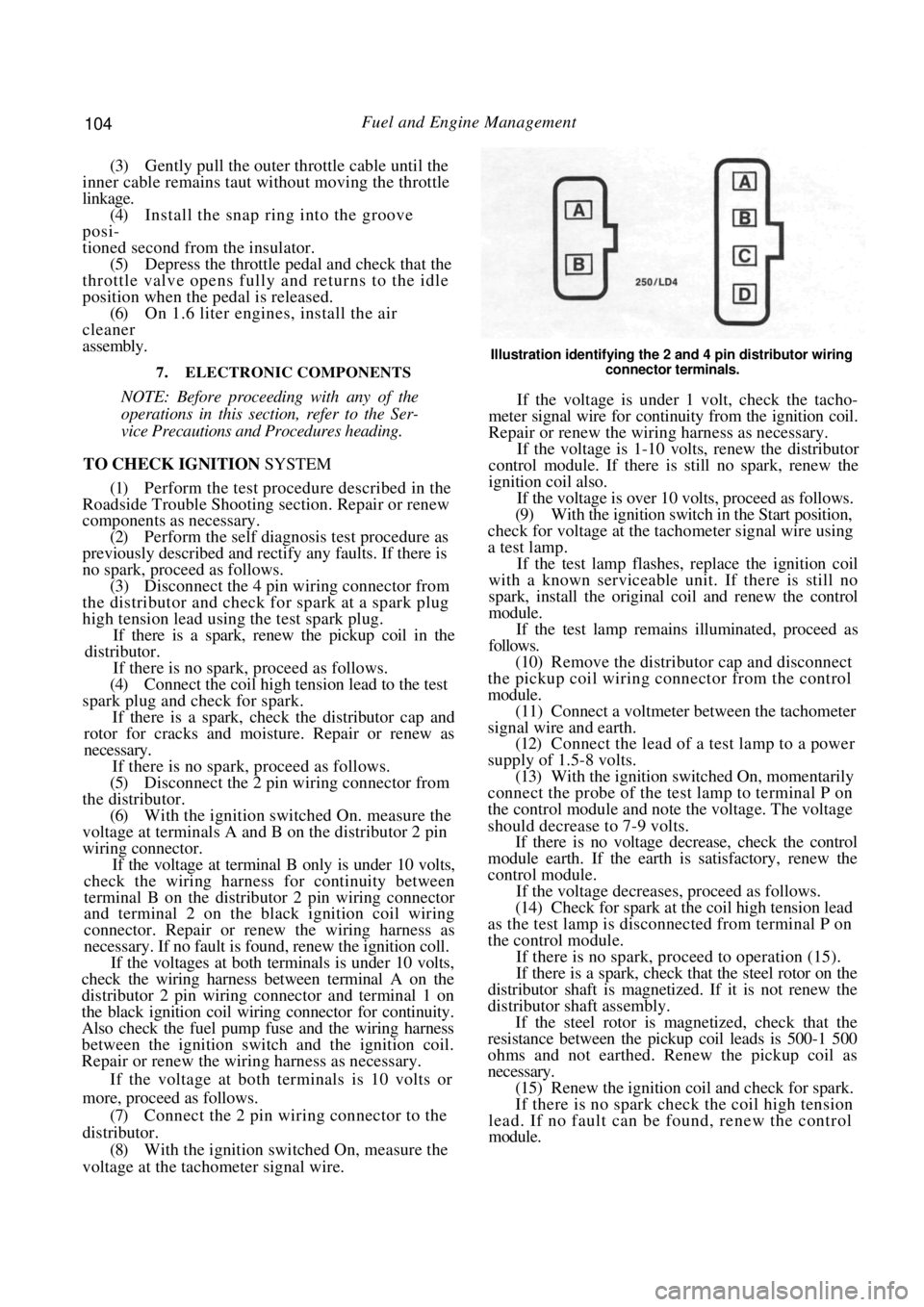

(5) Disconnect the 2 pin wiring connector from

the distributor. (6) With the ignition switched On. measure the

voltage at terminals A and B on the distributor 2 pin

wiring connector. If the voltage at terminal B only is under 10 volts,

check the wiring harness for continuity between

terminal B on the distributor 2 pin wiring connector

and terminal 2 on the black ignition coil wiring

connector. Repair or renew the wiring harness as

necessary. If no fault is found, renew the ignition coll.

If the voltages at both terminals is under 10 volts,

check the wiring harness between terminal A on the

distributor 2 pin wiring connector and terminal 1 on

the black ignition coil wiring connector for continuity.

Also check the fuel pump fuse and the wiring harness

between the ignition switch and the ignition coil.

Repair or renew the wiring harness as necessary.

If the voltage at both terminals is 10 volts or

more, proceed as follows.

(7) Connect the 2 pin wiring connector to the

distributor. (8) With the ignition switched On, measure the

voltage at the tachometer signal wire.

Illustration identifying the 2 and 4 pin distributor wiring

connector terminals.

If the voltage is under 1 volt, check the tacho-

meter signal wire for continuity from the ignition coil.

Repair or renew the wiring harness as necessary.

If the voltage is 1-10 volts, renew the distributor

control module. If there is still no spark, renew the

ignition coil also.

If the voltage is over 10 volts, proceed as follows.

(9) With the ignition switch in the Start position,

check for voltage at the tachometer signal wire using

a test lamp.

If the test lamp flashes, replace the ignition coil

with a known serviceable un it. If there is still no

spark, install the original coil and renew the control

module.

If the test lamp remains illuminated, proceed as

follows.

(10) Remove the distributor cap and disconnect

the pickup coil wiring co nnector from the control

module. (11) Connect a voltmeter between the tachometer

signal wire and earth. (12) Connect the lead of a test lamp to a power

supply of 1.5-8 volts. (13) With the ignition switched On, momentarily

connect the probe of the test lamp to terminal P on

the control module and note the voltage. The voltage

should decrease to 7-9 volts. If there is no voltage decrease, check the control

module earth. If the earth is satisfactory, renew the

control module.

If the voltage decreases , proceed as follows.

(14) Check for spark at the coil high tension lead

as the test lamp is disconnected from terminal P on

the control module.

If there is no spark, proceed to operation (15).

If there is a spark, check that the steel rotor on the

distributor shaft is magnetized. If it is not renew the

distributor shaft assembly.

If the steel rotor is magnetized, check that the

resistance between the pickup coil leads is 500-1 500

ohms and not earthed. Renew the pickup coil as

necessary.

(15) Renew the ignition coil and check for spark.

If there is no spark check the coil high tension

lead. If no fault can be found, renew the control

module.

Page 108 of 238

108 Fuel and Engine Management

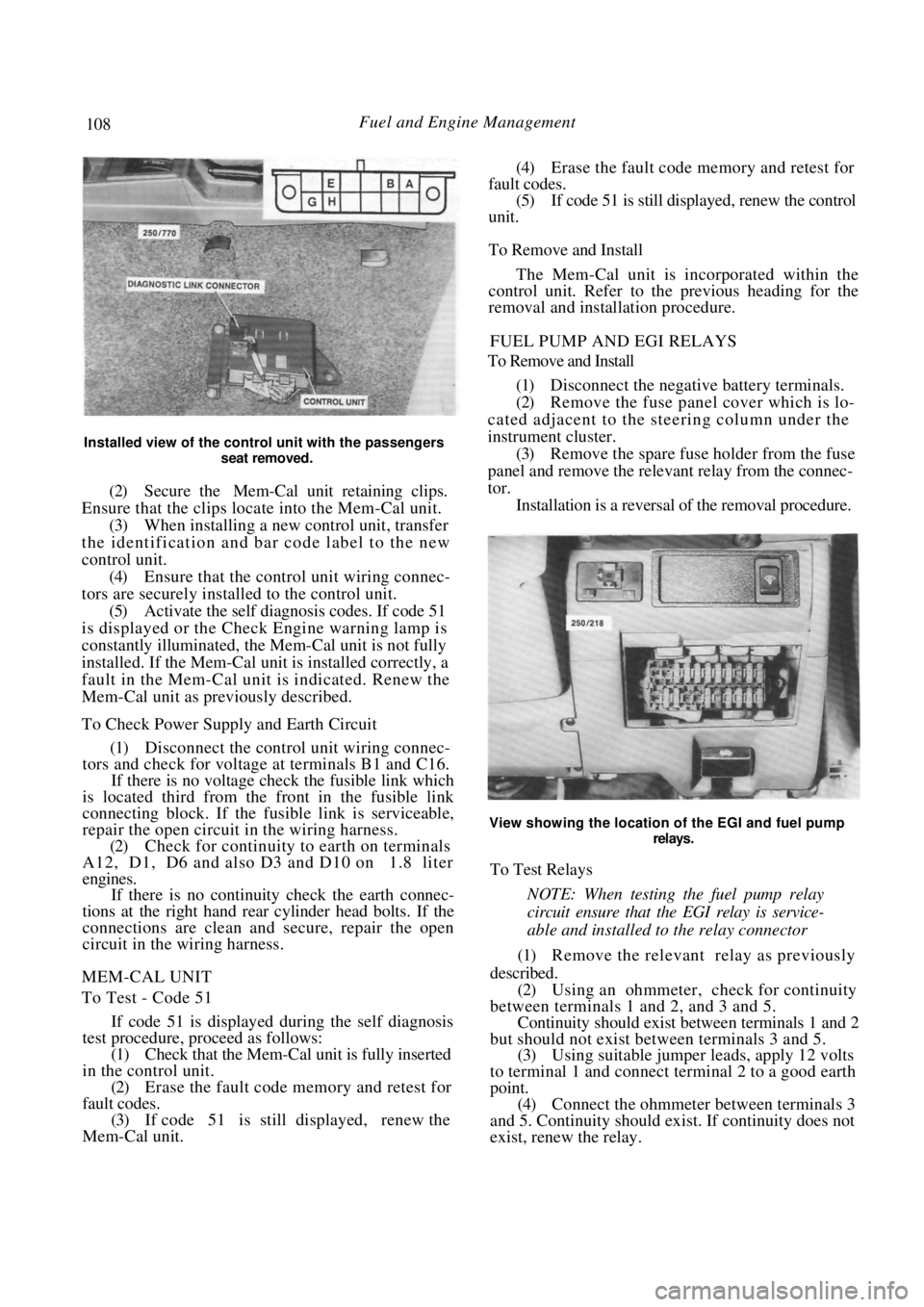

Installed view of the control unit with the passengers seat removed.

(2) Secure the Mem-Cal unit retaining clips.

Ensure that the clips locate into the Mem-Cal unit. (3) When installing a new control unit, transfer

the identification and bar code label to the new

control unit. (4) Ensure that the control unit wiring connec-

tors are securely installed to the control unit. (5) Activate the self diagnosis codes. If code 51

is displayed or the Check Engine warning lamp is

constantly illuminated, the Mem-Cal unit is not fully

installed. If the Mem-Cal uni t is installed correctly, a

fault in the Mem-Cal unit is indicated. Renew the

Mem-Cal unit as previously described.

To Check Power Supply and Earth Circuit

(1) Disconnect the control unit wiring connec-

tors and check for voltage at terminals B1 and C16.

If there is no voltage check the fusible link which

is located third from the front in the fusible link

connecting block. If the fu sible link is serviceable,

repair the open circuit in the wiring harness.

(2) Check for continuity to earth on terminals

A12, D1, D6 and also D3 and D10 on 1.8 liter

engines.

If there is no continuity check the earth connec-

tions at the right hand rear cylinder head bolts. If the

connections are clean and secure, repair the open

circuit in the wiring harness.

MEM-CAL UNIT

To Test - Code 51

If code 51 is displayed during the self diagnosis

test procedure, pr oceed as follows:

(1) Check that the Mem-Cal unit is fully inserted

in the control unit. (2) Erase the fault code memory and retest for

fault codes. (3) If code 51 is still displayed, renew the

Mem-Cal unit.

(4) Erase the fault code memory and retest for

fault codes. (5) If code 51 is still displayed, renew the control

unit.

To Remove and Install

The Mem-Cal unit is incorporated within the

control unit. Refer to the previous heading for the

removal and installation procedure.

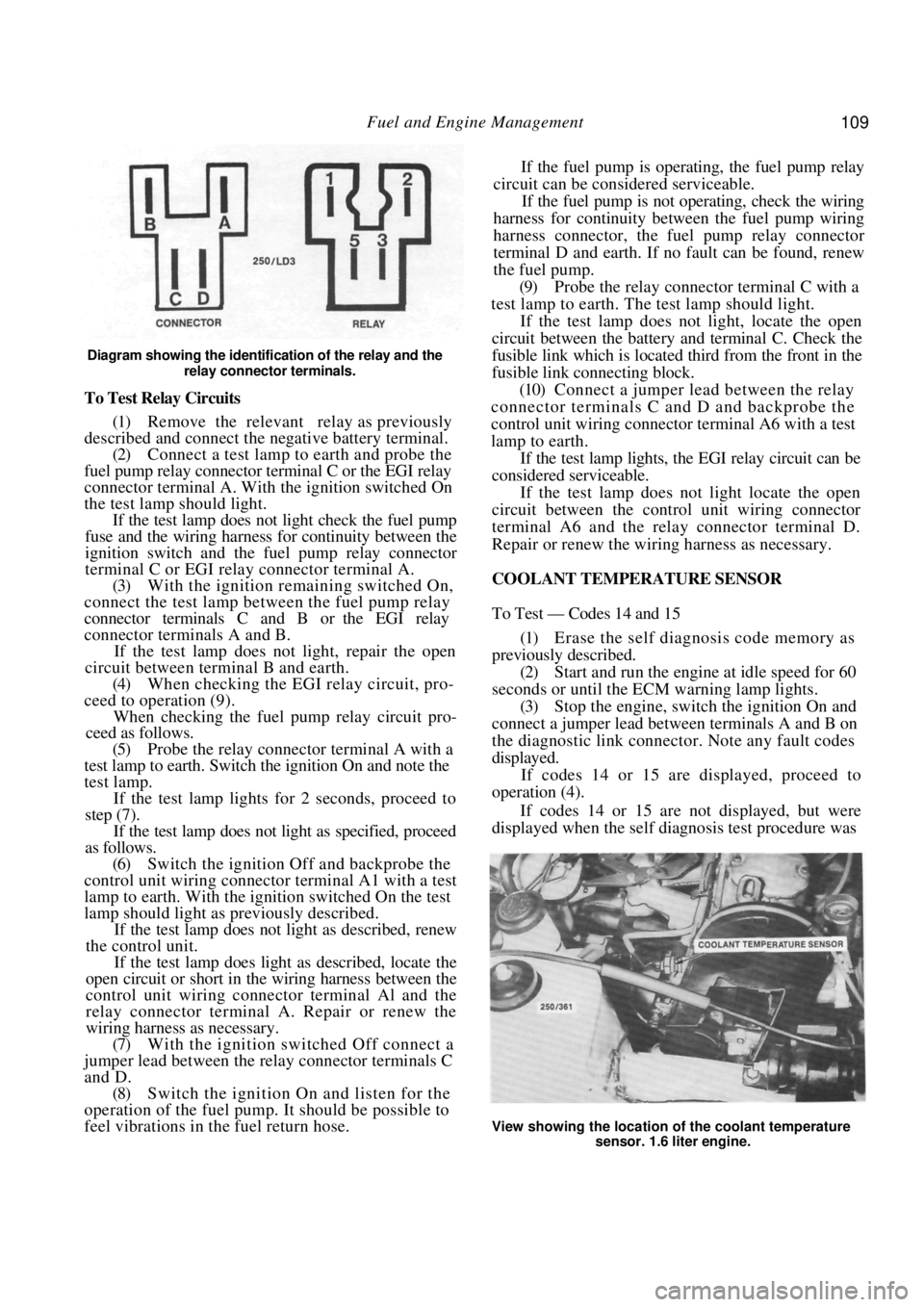

FUEL PUMP AND EGI RELAYS

To Remove and Install

(1) Disconnect the negative battery terminals.

(2) Remove the fuse panel cover which is lo-

cated adjacent to the steering column under the

instrument cluster. (3) Remove the spare fuse holder from the fuse

panel and remove the releva nt relay from the connec-

tor. Installation is a reversal of the removal procedure.

View showing the location of the EGI and fuel pump

relays.

To Test Relays

NOTE: When testing the fuel pump relay

circuit ensure that th e EGI relay is service-

able and installed to the relay connector

(1) Remove the relevant relay as previously

described. (2) Using an ohmmeter, check for continuity

between terminals 1 and 2, and 3 and 5. Continuity should exist be tween terminals 1 and 2

but should not exist between terminals 3 and 5.

(3) Using suitable jumper leads, apply 12 volts

to terminal 1 and connect terminal 2 to a good earth

point. (4) Connect the ohmmeter between terminals 3

and 5. Continuity should exist. If continuity does not

exist, renew the relay.

Page 109 of 238

Fuel and Engine Management 109

Diagram showing the identification of the relay and the relay connector terminals.

To Test Relay Circuits

(1) Remove the relevant relay as previously

described and connect the ne gative battery terminal.

(2) Connect a test lamp to earth and probe the

fuel pump relay connector terminal C or the EGI relay

connector terminal A. With the ignition switched On

the test lamp should light. If the test lamp does not light check the fuel pump

fuse and the wiring harness for continuity between the

ignition switch and the fuel pump relay connector

terminal C or EGI rela y connector terminal A.

(3) With the ignition remaining switched On,

connect the test lamp between the fuel pump relay

connector terminals C and B or the EGI relay

connector terminals A and B.

If the test lamp does not light, repair the open

circuit between terminal B and earth.

(4) When checking the EGI relay circuit, pro-

ceed to operation (9).

When checking the fuel pu mp relay circuit pro-

ceed as follows.

(5) Probe the relay connector terminal A with a

test lamp to earth. Switch the ignition On and note the

test lamp.

If the test lamp lights for 2 seconds, proceed to

step (7).

If the test lamp does not light as specified, proceed

as follows.

(6) Switch the ignition Off and backprobe the

control unit wiring connector terminal A1 with a test

lamp to earth. With the ignition switched On the test

lamp should light as previously described.

If the test lamp does not light as described, renew

the control unit.

If the test lamp does light as described, locate the

open circuit or short in the wiring harness between the

control unit wiring connector terminal Al and the

relay connector terminal A. Repair or renew the

wiring harness as necessary.

(7) With the ignition switched Off connect a

jumper lead between the relay connector terminals C

and D. (8) Switch the ignition On and listen for the

operation of the fuel pump. It should be possible to

feel vibrations in the fuel return hose. If the fuel pump is operating, the fuel pump relay

circuit can be considered serviceable.

If the fuel pump is not operating, check the wiring

harness for continuity between the fuel pump wiring

harness connector, the fuel pump relay connector

terminal D and earth. If no fault can be found, renew

the fuel pump.

(9) Probe the relay connector terminal C with a

test lamp to earth. The test lamp should light.

If the test lamp does not light, locate the open

circuit between the battery and terminal C. Check the

fusible link which is located third from the front in the

fusible link connecting block.

(10) Connect a jumper lead between the relay

connector terminals C and D and backprobe the

control unit wiring connector terminal A6 with a test

lamp to earth.

If the test lamp lights, the EGI relay circuit can be

considered serviceable.

If the test lamp does not light locate the open

circuit between the contro l unit wiring connector

terminal A6 and the relay connector terminal D.

Repair or renew the wiring harness as necessary.

COOLANT TEMPERATURE SENSOR

To Test — Codes 14 and 15

(1) Erase the self diagnosis code memory as

previously described. (2) Start and run the engine at idle speed for 60

seconds or until the ECM warning lamp lights.

(3) Stop the engine, switch the ignition On and

connect a jumper lead between terminals A and B on

the diagnostic link connect or. Note any fault codes

displayed. If codes 14 or 15 are displayed, proceed to

operation (4).

If codes 14 or 15 are not displayed, but were

displayed when the self diagnosis test procedure was

View showing the location of the coolant temperature

sensor. 1.6 liter engine.

Page 114 of 238

114 Fuel and Engine Management

(6) Check the vehicle for the following:

(a) Low fuel pressure.

(b) Contaminated fuel.

(c) Vacuum leaks at the inlet manifold, engine

vacuum hoses and engine ventilation hoses. (d) Exhaust manifold leaks before the oxygen

sensor. (e) Correct MAP sensor operation.

(f) Blocked oxygen sensor metal vent cover eg.

plugged with mud etc. (g) Fuel injectors) partially blocked. Refer to a

fuel injection specialis t or a Nissan dealer.

If the above items have been checked and no

faults have been found, a faulty oxygen sensor is

indicated. Renew the oxygen sensor, run the engine

and ensure that no fault codes are set.

To Test — Code 45

(1) Run the engine until normal operating tem-

perature is attained. (2) With the ignition switched Off, connect a

jumper lead between terminals B and A on the

diagnostic link connector. (3) Start and run the engine at approximately

1 600-1 800 rpm for 2 minutes and note the ECM

warning lamp. If the ECM warning lamp is on more than off or

flashes at the rate of twice per second, proceed to the

following operation.

If the ECM warning lamp flashes evenly at the

rate of once per second an intermittent fault is

indicated. Proceed as follows:

(a) Check for faulty wiri ng connections. Check

that all wiring connectors are clean and secure. (b) Check that all earth wires are secure.

(4) Switch the engine Off and disconnect the

oxygen sensor wiring connector. (5) Using a jumper lead, connect the oxygen

sensor wiring connector to a suitable engine earth. (6) Start and run the engine at 1 600-1 800 rpm

and note the ECM warning lamp.

If the ECM warning lamp extinguishes for at least

30 seconds, proceed to operation (7).

If the ECM warning lamp flashes on more than off

or flashes at the rate of twice per second, switch the

engine Off and disconnect the control unit wiring

connectors. Using an ohmmeter, check that there is no

resistance between the co ntrol unit wiring connector

terminal D6 and earth. Repair or renew the wiring as

necessary.

If no fault can be found in the wiring harness,

renew the control unit.

NOTE: The wiring harness for terminal D6

earths through the righ t hand rear cylinder

head bolt.

(7) Check the vehicl e for the following:

(a) High fuel pressure.

(b) Leaking injector(s).

(c) Faulty ignition wiring.

(d) Charcoal canister purge system blocked or

restricted.

(e) Faulty coolant temper ature sensor circuit.

(f) Faulty MAT sensor circuit (1.8 liter engine).

(g) MAP sensor operation.

(h) Throttle position sensor operation.

If the above items have been checked and no

faults have been found, a faulty oxygen sensor is

indicated.

Renew the oxygen sensor, run the engine and

ensure that no fault codes are set.

To Remove and Install

(1) If the engine is cold, run the engine for

approximately two minutes to allow easy oxygen

sensor removal. (2) Disconnect the negative battery terminal and

the oxygen sensor connector.

View of the oxygen sensor removed from the exhaust

manifold.

(3) Remove the exhaust manifold heat shield

retaining bolts and remove the heat shield from the

engine.

(4) Remove the oxygen sensor with a short ring

spanner using care not to damage the sensor wire. Installation is a reversal of the removal procedure

with attention to the following points:

(1) When installing a sensor that has previously

been removed, coat the sen sor threads with anti-seize

compound. Nissan recommend a mixture of liquid

graphite and glass beads. (2) Install the sensor and tighten to the specified

torque. (3) Connect the electrical connector ensuring

that the wiring is secured away from the exhaust. (4) Install the heat shield and tighten the retain-

ing bolts securely. On 1.6 liter engines, ensure that the hot air inlet

tube is located correctly be tween the heat shield and

the air cleaner housing.

(5) Start the engine and check for leaks.

VEHICLE SPEED SENSOR

To Test - Code 24

(1) Check the fuel pump and meter fuses. If the

fuses are serviceable, proceed to operation (5). If a

fuse is blown, rectify the cause and renew the fuse.