NISSAN TEANA 2008 Service Manual

Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 1091 of 5121

![NISSAN TEANA 2008 Service Manual BRC-150

< PRECAUTION >[VDC/TCS/ABS]

PRECAUTIONS

Precaution for Brake Control

INFOID:0000000003767032

When starting engine or when starting vehicle just after starting engine, brake pedal may vibrate NISSAN TEANA 2008 Service Manual BRC-150

< PRECAUTION >[VDC/TCS/ABS]

PRECAUTIONS

Precaution for Brake Control

INFOID:0000000003767032

When starting engine or when starting vehicle just after starting engine, brake pedal may vibrate](/img/5/57391/w960_57391-1090.png)

BRC-150

< PRECAUTION >[VDC/TCS/ABS]

PRECAUTIONS

Precaution for Brake Control

INFOID:0000000003767032

When starting engine or when starting vehicle just after starting engine, brake pedal may vibrate or motor

operating noise may be heard from engine compartment. This is normal condition.

When an error is indicated by ABS or another warning lamp, collect all necessary information from customer

(what symptoms are present under what conditions) and check for estimate causes before starting diagnos-

tic servicing. Besides electrical system inspection, check brake booster operation, brake fluid level, and oil

leaks.

If tire size and type are used in an improper combination, or brake pads are not Genuine NISSAN parts,

stopping distance or steering stability may deteriorate.

ABS might be out of order or malfunctions by putting a radio (wiring inclusive), an antenna and a lead-in wire

near the control unit.

If aftermarket parts (car stereo, CD player, etc.) have been installed, check for incidents such as harness

pinches, open circuits, and improper wiring.

VDC system may not operate normally or a VDC OFF indicator lamp or SLIP indicator lamp may light.

- When replacing the following parts with parts other than genuine parts or making modifications: Suspension

related parts (shock absorber, spring, bushing, etc.), tires, wheels (other than specified sizes), brake-related

parts (pad, rotor, caliper, etc.), engine-related parts (muffler, ECM, etc.) and body reinforcement-related parts

(roll bar, tower bar, etc.).

- When driving with worn or deteriorated suspension, tires and brake-related parts.

Precautions for Harness RepairINFOID:0000000003843440

COMMUNICATION LINE

Solder the repaired area and wrap tape around the soldered area.

NOTE:

A fray of twisted lines must be within 110 mm (4.33 in).

Bypass connection is never allowed at the repaired area.

NOTE:

Bypass connection may cause communication error as spliced

wires that are separate from the main line or twisted lines lose

noise immunity.

Replace the applicable harness as an assembly if error is detected

on the shield lines of communication line.

SKIB8766E

SKIB8767E

Page 1092 of 5121

![NISSAN TEANA 2008 Service Manual WHEEL SENSOR

BRC-151

< ON-VEHICLE REPAIR >[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

ON-VEHICLE REPAIR

WHEEL SENSOR

FRONT WHEEL SENSOR

FRONT WHEEL SENSOR : Exploded ViewINFOID:0000000003767300

NOT NISSAN TEANA 2008 Service Manual WHEEL SENSOR

BRC-151

< ON-VEHICLE REPAIR >[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

ON-VEHICLE REPAIR

WHEEL SENSOR

FRONT WHEEL SENSOR

FRONT WHEEL SENSOR : Exploded ViewINFOID:0000000003767300

NOT](/img/5/57391/w960_57391-1091.png)

WHEEL SENSOR

BRC-151

< ON-VEHICLE REPAIR >[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

ON-VEHICLE REPAIR

WHEEL SENSOR

FRONT WHEEL SENSOR

FRONT WHEEL SENSOR : Exploded ViewINFOID:0000000003767300

NOTE:

The above figure shows left side. Right side is the mirror image.

FRONT WHEEL SENSOR : Removal and InstallationINFOID:0000000003767301

REMOVAL

Be careful with the following when removing sensor.

CAUTION:

Do not twist sensor harness as much as possible, when removing it. Pull sensors out without pulling

sensor harness.

Be careful to avoid damaging sensor edges or rotor teeth. Remove wheel sensor first before remov-

ing front or rear wheel hub. This is to avoid damage to sensor wiring and loss of sensor function.

INSTALLATION

Be careful with the following when installing wheel sensor. Tighten installation bolts to the specified torques.

Refer to BRC-151, "

FRONT WHEEL SENSOR : Exploded View".

CAUTION:

When installing, make sure there is no foreign material such as iron chips on and in the mounting

hole of the wheel sensor. Make sure no foreign material has been caught in the sensor rotor. Remove

any foreign material and clean the mount.

1. Front LH wheel sensor 2. Front LH wheel sensor connector

: Vehicle front

Refer to GI section GI-4, "

Components" for symbol marks in the figure.

JSFIA0221GB

Page 1093 of 5121

![NISSAN TEANA 2008 Service Manual BRC-152

< ON-VEHICLE REPAIR >[VDC/TCS/ABS]

WHEEL SENSOR

Completely push in rubber grommets of strut bracket and body bracket until they lock when install-

ing wheel sensor so that the wheel sensor h NISSAN TEANA 2008 Service Manual BRC-152

< ON-VEHICLE REPAIR >[VDC/TCS/ABS]

WHEEL SENSOR

Completely push in rubber grommets of strut bracket and body bracket until they lock when install-

ing wheel sensor so that the wheel sensor h](/img/5/57391/w960_57391-1092.png)

BRC-152

< ON-VEHICLE REPAIR >[VDC/TCS/ABS]

WHEEL SENSOR

Completely push in rubber grommets of strut bracket and body bracket until they lock when install-

ing wheel sensor so that the wheel sensor harness will not be twisted. Install grommet groove onto

bracket with orange line on the harness facing bracket opening (mounting hole). There should be no

twists in the harness when installed.

REAR WHEEL SENSOR

REAR WHEEL SENSOR : Exploded ViewINFOID:0000000003767302

NOTE:

The above figure shows left side. Right side is the mirror image.

REAR WHEEL SENSOR : Removal and InstallationINFOID:0000000003767303

REMOVAL

Be careful with the following when removing sensor.

CAUTION:

Do not twist sensor harness as much as possible, when removing it. Pull sensors out without pulling

sensor harness.

Be careful to avoid damaging sensor edges or rotor teeth. Remove wheel sensor first before remov-

ing front or rear wheel hub. This is to avoid damage to sensor wiring and loss of sensor function.

INSTALLATION

Be careful with the following when installing wheel sensor. Tighten installation bolts to the specified torques.

Refer to BRC-152, "

REAR WHEEL SENSOR : Exploded View".

CAUTION:

When installing, make sure there is no foreign material such as iron chips on and in the mounting hole

of the wheel sensor. Make sure no foreign material has been caught in the sensor rotor. Remove any

foreign material and clean the mount.

1. Rear LH wheel sensor connector 2. Rear LH wheel sensor

: Vehicle front

Refer to GI section GI-4, "

Components" for symbol marks in the figure.

JSFIA0222GB

Page 1094 of 5121

![NISSAN TEANA 2008 Service Manual SENSOR ROTOR

BRC-153

< ON-VEHICLE REPAIR >[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

SENSOR ROTOR

FRONT SENSOR ROTOR

FRONT SENSOR ROTOR : Exploded ViewINFOID:0000000003767304

Refer to FAX-8, "Expl NISSAN TEANA 2008 Service Manual SENSOR ROTOR

BRC-153

< ON-VEHICLE REPAIR >[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

SENSOR ROTOR

FRONT SENSOR ROTOR

FRONT SENSOR ROTOR : Exploded ViewINFOID:0000000003767304

Refer to FAX-8, "Expl](/img/5/57391/w960_57391-1093.png)

SENSOR ROTOR

BRC-153

< ON-VEHICLE REPAIR >[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

SENSOR ROTOR

FRONT SENSOR ROTOR

FRONT SENSOR ROTOR : Exploded ViewINFOID:0000000003767304

Refer to FAX-8, "Exploded View".

FRONT SENSOR ROTOR : Removal and InstallationINFOID:0000000003767305

REMOVAL

Sensor rotor cannot be disassembled. Remove the sensor rotor together with hub bearing assembly. Refer to

FA X - 8 , "

Exploded View".

INSTALLATION

Sensor rotor cannot be disassembled. Install the sensor rotor together with hub bearing assembly. Refer to

FA X - 8 , "

Exploded View".

REAR SENSOR ROTOR

REAR SENSOR ROTOR : Exploded ViewINFOID:0000000003767306

Refer to RAX-4, "Exploded View".

REAR SENSOR ROTOR : Removal and InstallationINFOID:0000000003767307

REMOVAL

Sensor rotor cannot be disassembled. Remove the sensor rotor together with hub bearing assembly. Refer to

RAX-4, "

Exploded View".

INSTALLATION

Sensor rotor cannot be disassembled. Install the sensor rotor together with hub bearing assembly. Refer to

RAX-4, "

Exploded View".

Page 1095 of 5121

![NISSAN TEANA 2008 Service Manual BRC-154

< ON-VEHICLE REPAIR >[VDC/TCS/ABS]

ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

Exploded ViewINFOID:0000000003767308

Removal and InstallationINFO NISSAN TEANA 2008 Service Manual BRC-154

< ON-VEHICLE REPAIR >[VDC/TCS/ABS]

ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

Exploded ViewINFOID:0000000003767308

Removal and InstallationINFO](/img/5/57391/w960_57391-1094.png)

BRC-154

< ON-VEHICLE REPAIR >[VDC/TCS/ABS]

ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

Exploded ViewINFOID:0000000003767308

Removal and InstallationINFOID:0000000003767299

REMOVAL

CAUTION:

Before servicing, disconnect the battery cable from negative terminal.

To remove brake tube, use a flare nut wrench to prevent flare nuts and brake tube from being dam-

aged. To install, use flare nut crowfoot and torque wrench.

Do not apply excessive impact to ABS actuator and electric unit (control unit), such as dropping it.

Do not remove and install actuator by holding harness.

After work is completed, bleed air from brake tube. Refer to BR-10, "

Bleeding Brake System".

1. Remove cowl top cover. Refer to EXT-20, "

Exploded View".

2. Disconnect ABS actuator and electric unit (control unit) connector.

3. Loosen brake tube flare nuts, then remove brake tubes from ABS actuator and electric unit (control unit).

4. Remove ABS actuator and electric unit (control unit) bracket mounting nuts.

5. Remove ABS actuator and electric unit (control unit) from vehicle.

INSTALLATION

Note the following, and install in the reverse order of removal.

CAUTION:

Before servicing, disconnect the battery cable from negative terminal.

1. ABS actuator and electric unit (control

unit)2. Bushing 3. Bracket

A. From master cylinder secondary side B. From master cylinder primary side C. To front LH brake caliper

D. To rear RH brake caliper E. To rear LH brake caliper F. To front RH brake caliper

: Vehicle front

Refer to GI section GI-4, "

Components" for symbol marks in the figure.

JSFIA0223GB

Page 1096 of 5121

![NISSAN TEANA 2008 Service Manual ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

BRC-155

< ON-VEHICLE REPAIR >[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

To remove brake tube, use a flare nut wrench to prevent flare nuts and brake NISSAN TEANA 2008 Service Manual ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

BRC-155

< ON-VEHICLE REPAIR >[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

To remove brake tube, use a flare nut wrench to prevent flare nuts and brake](/img/5/57391/w960_57391-1095.png)

ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

BRC-155

< ON-VEHICLE REPAIR >[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

To remove brake tube, use a flare nut wrench to prevent flare nuts and brake tube from being dam-

aged. To install, use flare nut crowfoot and torque wrench.

Do not apply excessive impact to ABS actuator and electric unit (control unit), such as dropping it.

Do not remove and install actuator by holding harness.

After work is completed, bleed air from brake tube. Refer to BR-10, "

Bleeding Brake System".

After installing harness connector in the ABS actuator and electric unit (control unit), make sure

connector is securely locked.

When replacing ABS actuator and electric unit (control unit), make sure to adjust neutral position of

steering angle sensor. Refer to BRC-66, "

ADJUSTMENT OF STEERING ANGLE SENSOR NEUTRAL

POSITION : Description".

Install ABS actuator and electric unit (control unit) as per the follow-

ing steps.

1. Temporarily tighten mounting bolt (1) because the bracket (2) is

temporarily being hold.

2. Tighten mounting bolt (3) while holding the bracket.

3. Tighten mounting bolts to the specified torque in the order of (4),

(1).

JSFIA0271ZZ

Page 1097 of 5121

![NISSAN TEANA 2008 Service Manual BRC-156

< ON-VEHICLE REPAIR >[VDC/TCS/ABS]

YAW RATE/SIDE G SENSOR

YAW RATE/SIDE G SENSOR

Exploded ViewINFOID:0000000003767352

Removal and InstallationINFOID:0000000003767353

REMOVAL

CAUTION:

Do not dr NISSAN TEANA 2008 Service Manual BRC-156

< ON-VEHICLE REPAIR >[VDC/TCS/ABS]

YAW RATE/SIDE G SENSOR

YAW RATE/SIDE G SENSOR

Exploded ViewINFOID:0000000003767352

Removal and InstallationINFOID:0000000003767353

REMOVAL

CAUTION:

Do not dr](/img/5/57391/w960_57391-1096.png)

BRC-156

< ON-VEHICLE REPAIR >[VDC/TCS/ABS]

YAW RATE/SIDE G SENSOR

YAW RATE/SIDE G SENSOR

Exploded ViewINFOID:0000000003767352

Removal and InstallationINFOID:0000000003767353

REMOVAL

CAUTION:

Do not drop or strike yaw rate/side G sensor, or do not use power tool etc., because yaw rate/side G

sensor is sensitive to the impact.

1. Remove center console. Refer to IP-22, "

Exploded View".

2. Remove rear ventilator duct. Refer to VTL-54, "

REAR VENTILATOR DUCT 2 : Exploded View".

3. Disconnect yaw rate/side G sensor harness connector.

4. Remove mounting nuts. Remove yaw rate/side G sensor.

INSTALLATION

Note the following, and install in the reverse order of removal.

CAUTION:

Do not drop or strike yaw rate/side G sensor, or do not use power tool etc., because yaw rate/side G

sensor is sensitive to the impact.

1. Yaw rate/side G sensor 2. Bracket

: Vehicle front

Refer to GI section GI-4, "

Components" for symbol makes in the figure.

JSFIA0224GB

Page 1098 of 5121

![NISSAN TEANA 2008 Service Manual STEERING ANGLE SENSOR

BRC-157

< ON-VEHICLE REPAIR >[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

STEERING ANGLE SENSOR

Exploded ViewINFOID:0000000003767354

Removal and InstallationINFOID:000000000376 NISSAN TEANA 2008 Service Manual STEERING ANGLE SENSOR

BRC-157

< ON-VEHICLE REPAIR >[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

STEERING ANGLE SENSOR

Exploded ViewINFOID:0000000003767354

Removal and InstallationINFOID:000000000376](/img/5/57391/w960_57391-1097.png)

STEERING ANGLE SENSOR

BRC-157

< ON-VEHICLE REPAIR >[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

STEERING ANGLE SENSOR

Exploded ViewINFOID:0000000003767354

Removal and InstallationINFOID:0000000003767355

REMOVAL

1. Remove spiral cable assembly. Refer to SR-9, "Exploded View".

2. Remove steering angle sensor from spiral cable assembly.

INSTALLATION

Note the following, and install in the reverse order of removal.

CAUTION:

Never reuse steering angle sensor.

When installing steering angle sensor, tighten it to the specified torque with an electric screwdriver.

Be sure to tighten it completely with no floating and tilting.

After work, make sure to adjust neutral position of steering angle sensor. Refer to BRC-66,

"ADJUSTMENT OF STEERING ANGLE SENSOR NEUTRAL POSITION : Description".

1. Steering angle sensor

: Vehicle front

Refer to GI section GI-4, "

Components" for symbol marks in the figure.

JSFIA0237GB

Page 1099 of 5121

CHG

CHG-1

ELECTRICAL & POWER CONTROL

C

DE

F

G H

I

J

K L

B

SECTION CHG

A

O P

N

CONTENTS

CHARGING SYSTEM

BASIC INSPECTION .......

.............................2

DIAGNOSIS AND REPAIR WORKFLOW ..... .....2

Work Flow ........................................................... ......2

FUNCTION DIAGNOSIS ...............................5

CHARGING SYSTEM ..................................... .....5

System Diagram .................................................. ......5

System Description ...................................................5

Component Parts Location ........................................5

Component Description ............................................5

POWER GENERATION VOLTAGE VARI-

ABLE CONTROL SYSTEM ............................ .....

7

System Diagram .................................................. ......7

System Description ...................................................7

Component Parts Location ........................................7

Component Description .............................................8

COMPONENT DIAGNOSIS ..........................9

B TERMINAL CIRCUIT .................................. .....9

Description .......................................................... ......9

Diagnosis Procedure .................................................9

L TERMINAL CIRCUIT (OPEN) .........................10

Description .......................................................... ....10

Diagnosis Procedure ...............................................10

L TERMINAL CIRCUIT (SHORT) .......................12

Description .......................................................... ....12

Diagnosis Procedure ...............................................12

S TERMINAL CIRCUIT ......................................13

Description .......................................................... ....13

Diagnosis Procedure ...............................................13

CHARGING SYSTEM ..................................... ....14

Wiring Diagram - CHARGING SYSTEM - ........... ....14

SYMPTOM DIAGNOSIS ..............................17

CHARGING SYSTEM .......................................17

Symptom Table ................................................... ....17

PRECAUTION ..............................................18

PRECAUTIONS .................................................18

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ....

18

PREPARATION ...........................................19

PREPARATION .................................................19

Special Service Tools .......................................... ....19

ON-VEHICLE MAINTENANCE ....................20

CHARGING SYSTEM PRELIMINARY IN-

SPECTION ....... ................................ .................

20

Inspection Procedure ........................................... ....20

ON-VEHICLE REPAIR .................................21

ALTERNATOR . ................................ .................21

Exploded View ..................................................... ....21

Removal and Installation .........................................22

Disassembly and Assembly .....................................23

Inspection ................................................................24

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .............................................

25

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

25

Alternator ............................................................. ....25

Page 1100 of 5121

CHG-2

< BASIC INSPECTION >

DIAGNOSIS AND REPAIR WORKFLOW

BASIC INSPECTION

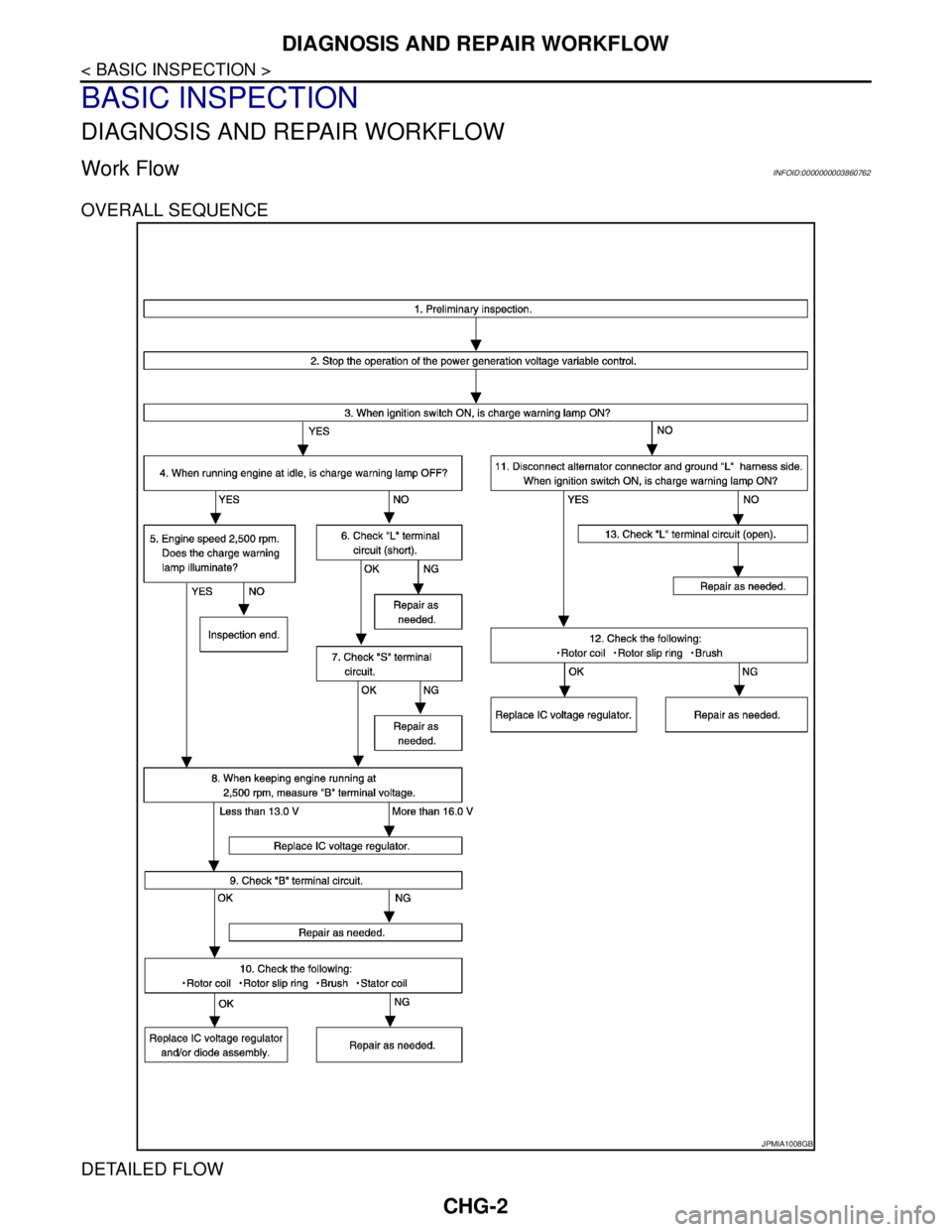

DIAGNOSIS AND REPAIR WORKFLOW

Work FlowINFOID:0000000003860762

OVERALL SEQUENCE

DETAILED FLOW

JPMIA1008GB