NISSAN TEANA 2008 Service Manual

Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 1121 of 5121

CHG

ALTERNATOR

CHG-23

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

L B A

O

P N

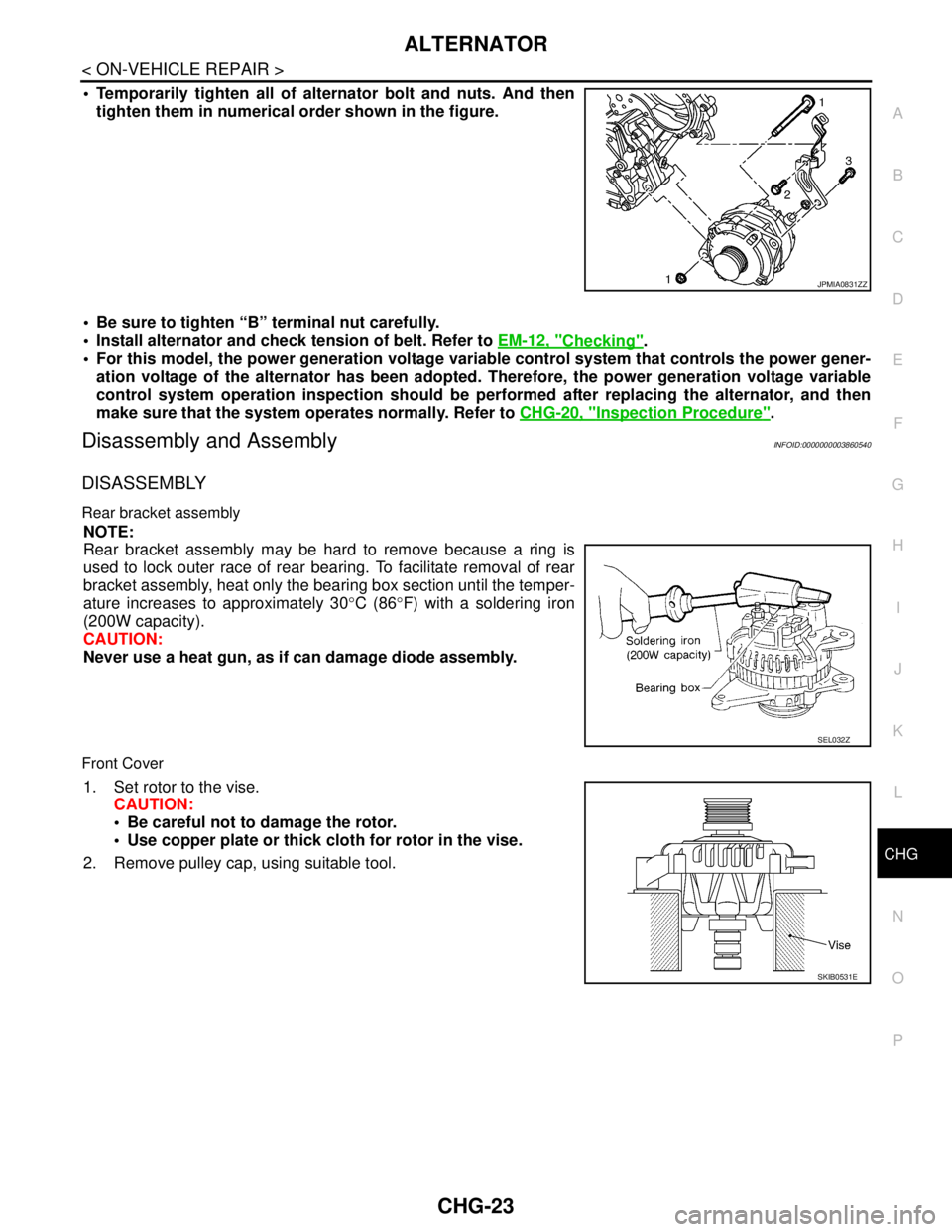

Temporarily tighten all of alternator bolt and nuts. And then

tighten them in numerical order shown in the figure.

Be sure to tighten “B” terminal nut carefully.

Install alternator and check tension of belt. Refer to EM-12, "

Checking".

For this model, the power generation voltage variable control system that controls the power gener-

ation voltage of the alternator has been adopted. Therefore, the power generation voltage variable

control system operation inspection should be performed after replacing the alternator, and then

make sure that the system operates normally. Refer to CHG-20, "

Inspection Procedure".

Disassembly and AssemblyINFOID:0000000003860540

DISASSEMBLY

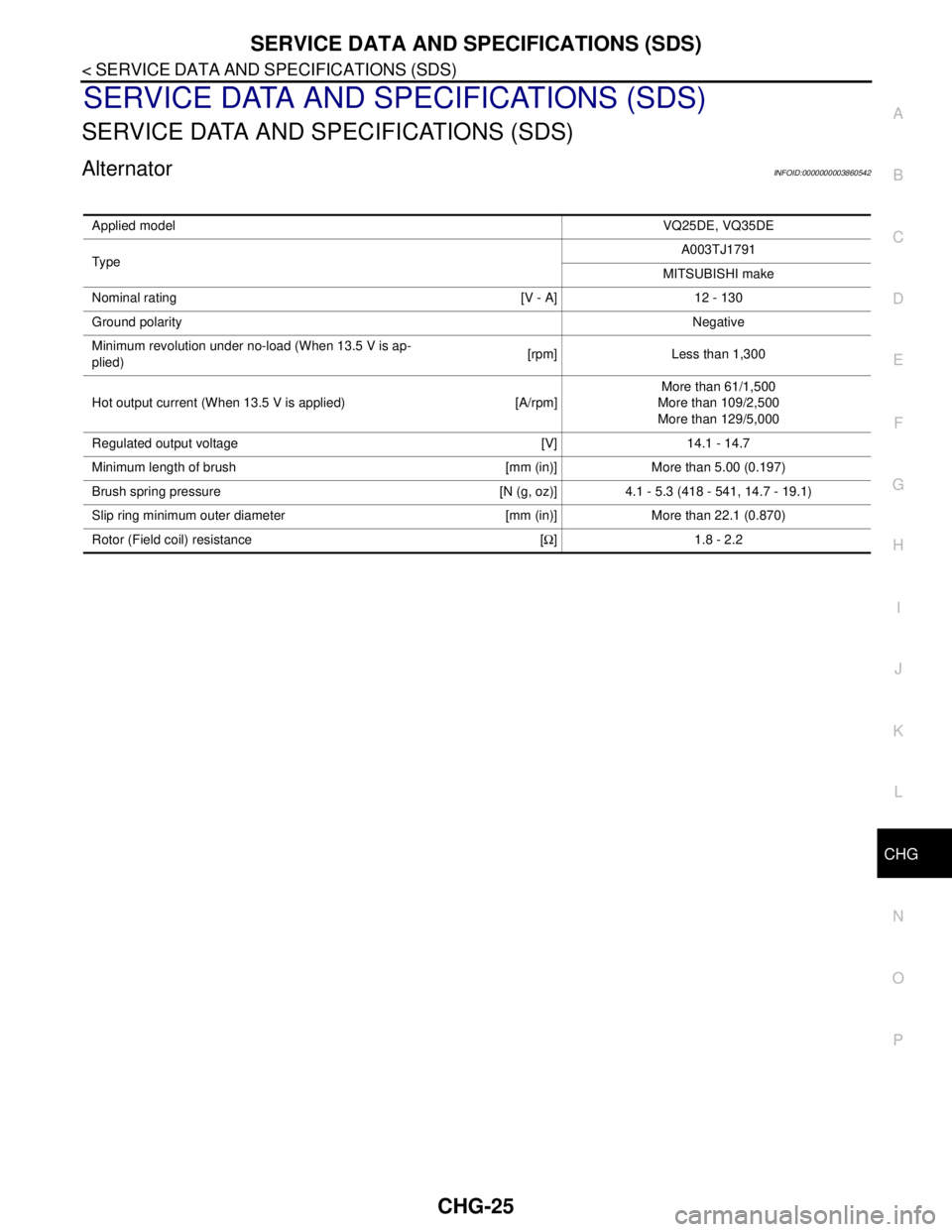

Rear bracket assembly

NOTE:

Rear bracket assembly may be hard to remove because a ring is

used to lock outer race of rear bearing. To facilitate removal of rear

bracket assembly, heat only the bearing box section until the temper-

ature increases to approximately 30°C (86°F) with a soldering iron

(200W capacity).

CAUTION:

Never use a heat gun, as if can damage diode assembly.

Front Cover

1. Set rotor to the vise.

CAUTION:

Be careful not to damage the rotor.

Use copper plate or thick cloth for rotor in the vise.

2. Remove pulley cap, using suitable tool.

JPMIA0831ZZ

SEL032Z

SKIB0531E

Page 1122 of 5121

![NISSAN TEANA 2008 Service Manual CHG-24

< ON-VEHICLE REPAIR >

ALTERNATOR

3. Remove alternator pulley, using alternator pulley adaptor (A)

[SST:KV10118200].

ASSEMBLY

Rear Bearing

CAUTION:

Never reuse rear bearing. Replace with a new NISSAN TEANA 2008 Service Manual CHG-24

< ON-VEHICLE REPAIR >

ALTERNATOR

3. Remove alternator pulley, using alternator pulley adaptor (A)

[SST:KV10118200].

ASSEMBLY

Rear Bearing

CAUTION:

Never reuse rear bearing. Replace with a new](/img/5/57391/w960_57391-1121.png)

CHG-24

< ON-VEHICLE REPAIR >

ALTERNATOR

3. Remove alternator pulley, using alternator pulley adaptor (A)

[SST:KV10118200].

ASSEMBLY

Rear Bearing

CAUTION:

Never reuse rear bearing. Replace with a new one.

Never lubricate rear bearing outer race.

Rear bracket assembly Installation

1. Fit brush assembly, diode assembly, regulator assembly and

stator.

2. Push brushed up with fingers and install them to rotor.

NOTE:

Take care not damage slip ring sliding surface.

InspectionINFOID:0000000003860541

ALTERNATOR PULLEY INSPECTION

Perform the following.

Make sure that alternator pulley does not rattle.

Make sure that alternator pulley nut is tight.

JSMIA0063ZZ

SKIB4529E

SKIB4530E

Page 1123 of 5121

CHG

SERVICE DATA AND SPECIFICATIONS (SDS)

CHG-25

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

D

E

F

G

H

I

J

K

L B A

O

P N

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

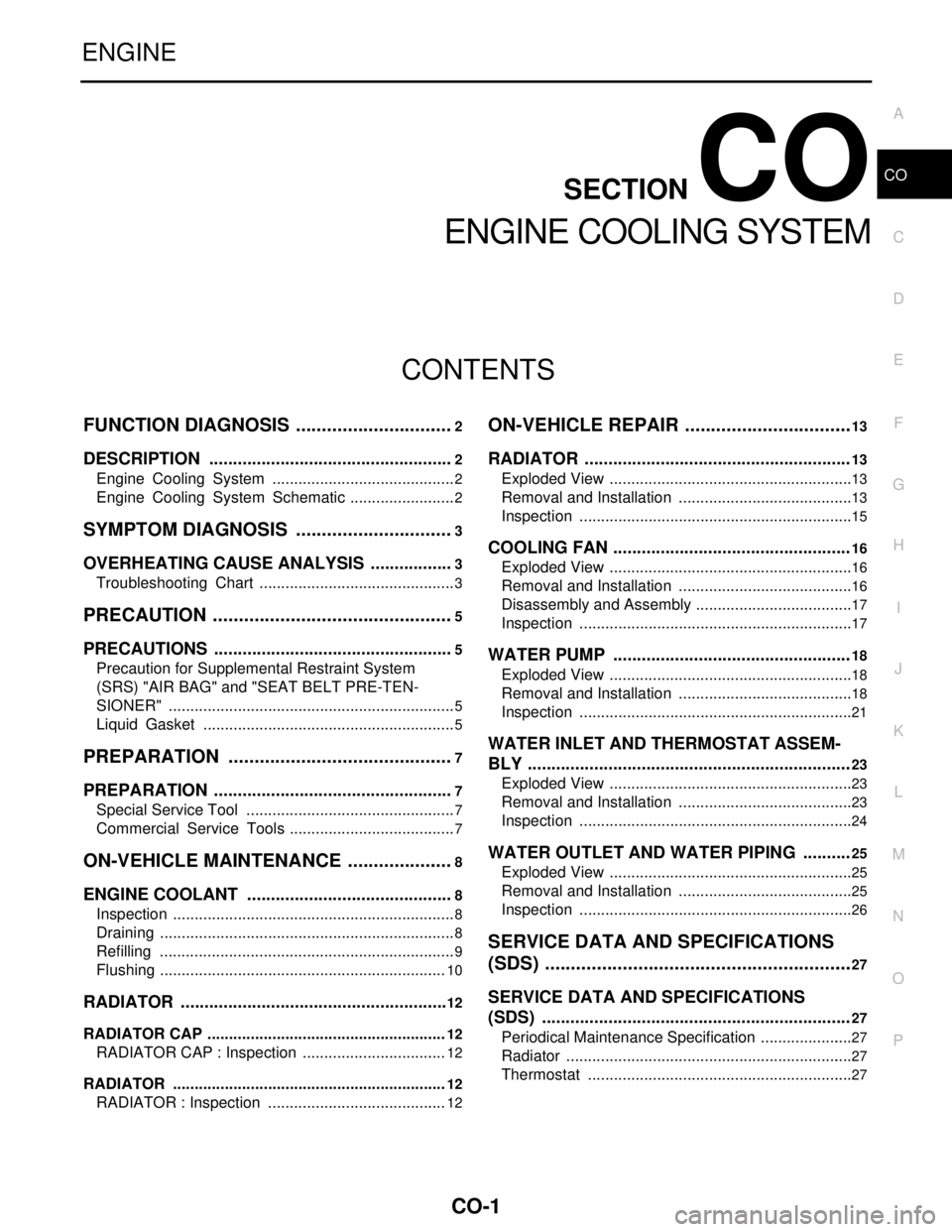

AlternatorINFOID:0000000003860542

Applied modelVQ25DE, VQ35DE

Typ eA003TJ1791

MITSUBISHI make

Nominal rating [V - A] 12 - 130

Ground polarityNegative

Minimum revolution under no-load (When 13.5 V is ap-

plied)[rpm] Less than 1,300

Hot output current (When 13.5 V is applied) [A/rpm]More than 61/1,500

More than 109/2,500

More than 129/5,000

Regulated output voltage [V] 14.1 - 14.7

Minimum length of brush [mm (in)] More than 5.00 (0.197)

Brush spring pressure [N (g, oz)] 4.1 - 5.3 (418 - 541, 14.7 - 19.1)

Slip ring minimum outer diameter [mm (in)] More than 22.1 (0.870)

Rotor (Field coil) resistance [Ω] 1.8 - 2.2

Page 1124 of 5121

CO-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION CO

A

CO

N

O P

CONTENTS

ENGINE COOLING SYSTEM

FUNCTION DIAGNOSIS .. .............................2

DESCRIPTION ............................................... .....2

Engine Cooling System ..................................... ......2

Engine Cooling System Schematic .........................2

SYMPTOM DIAGNOSIS ...............................3

OVERHEATING CAUSE ANALYSIS ............. .....3

Troubleshooting Chart ........................................ ......3

PRECAUTION ...............................................5

PRECAUTIONS .............................................. .....5

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

5

Liquid Gasket ...........................................................5

PREPARATION ............................................7

PREPARATION .............................................. .....7

Special Service Tool ........................................... ......7

Commercial Service Tools .......................................7

ON-VEHICLE MAINTENANCE .....................8

ENGINE COOLANT ....................................... .....8

Inspection ............................................................ ......8

Draining .....................................................................8

Refilling .....................................................................9

Flushing ...................................................................10

RADIATOR .........................................................12

RADIATOR CAP .................................................... ....12

RADIATOR CAP : Inspection ..................................12

RADIATOR ............................................................ ....12

RADIATOR : Inspection ..........................................12

ON-VEHICLE REPAIR .................................13

RADIATOR ....... ................................ .................13

Exploded View ..................................................... ....13

Removal and Installation .........................................13

Inspection ................................................................15

COOLING FAN ..................................................16

Exploded View .........................................................16

Removal and Installation .........................................16

Disassembly and Assembly .....................................17

Inspection ................................................................17

WATER PUMP ..................................................18

Exploded View .........................................................18

Removal and Installation .........................................18

Inspection ................................................................21

WATER INLET AND THERMOSTAT ASSEM-

BLY ....................................................................

23

Exploded View .........................................................23

Removal and Installation .........................................23

Inspection ................................................................24

WATER OUTLET AND WATER PIPING ..........25

Exploded View .........................................................25

Removal and Installation .........................................25

Inspection ................................................................26

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .............................................

27

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

27

Periodical Maintenance Specification .................. ....27

Radiator ...................................................................27

Thermostat ..............................................................27

Page 1125 of 5121

CO-2

< FUNCTION DIAGNOSIS >

DESCRIPTION

FUNCTION DIAGNOSIS

DESCRIPTION

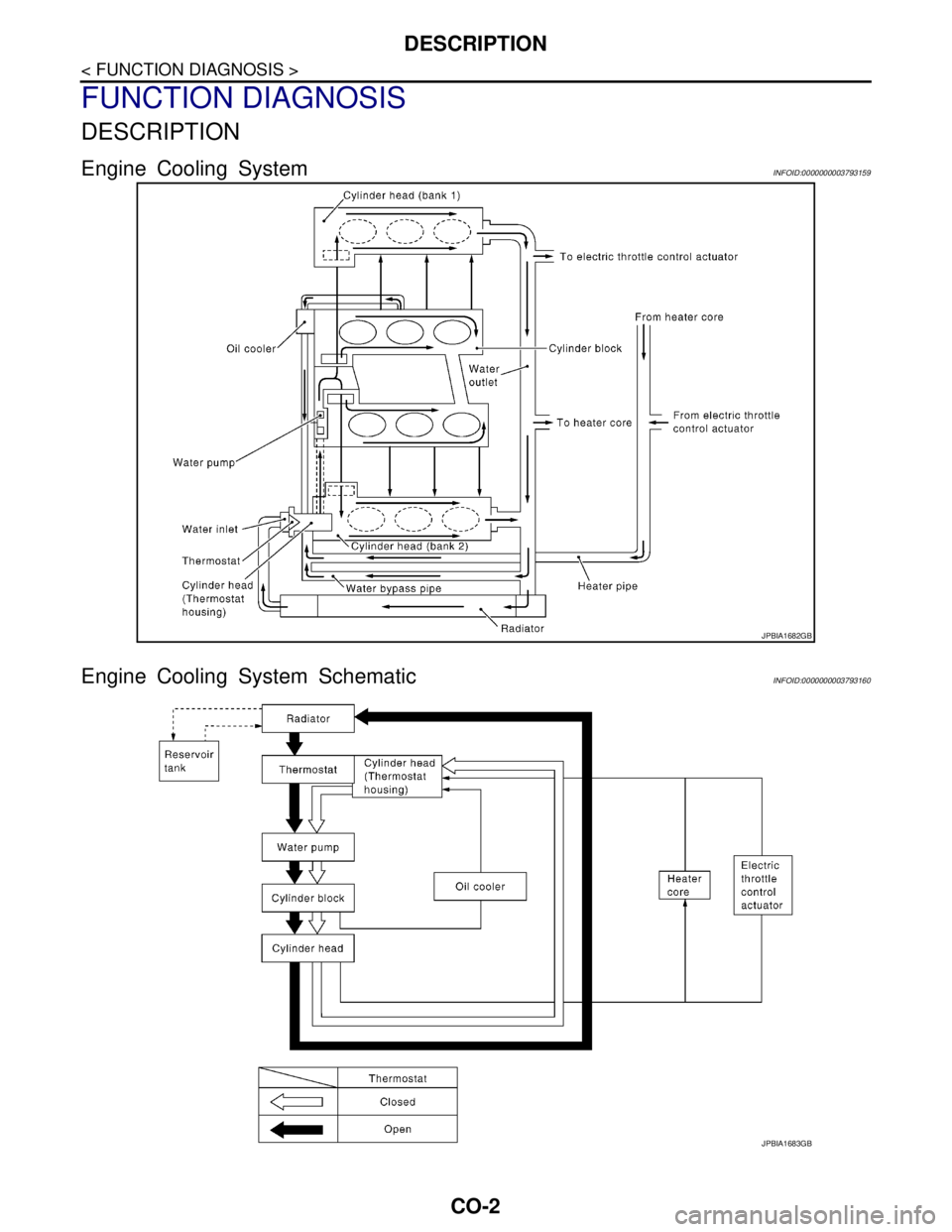

Engine Cooling SystemINFOID:0000000003793159

Engine Cooling System SchematicINFOID:0000000003793160

JPBIA1682GB

JPBIA1683GB

Page 1126 of 5121

OVERHEATING CAUSE ANALYSIS

CO-3

< SYMPTOM DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

MA

CO

N

P O

SYMPTOM DIAGNOSIS

OVERHEATING CAUSE ANALYSIS

Troubleshooting ChartINFOID:0000000003793161

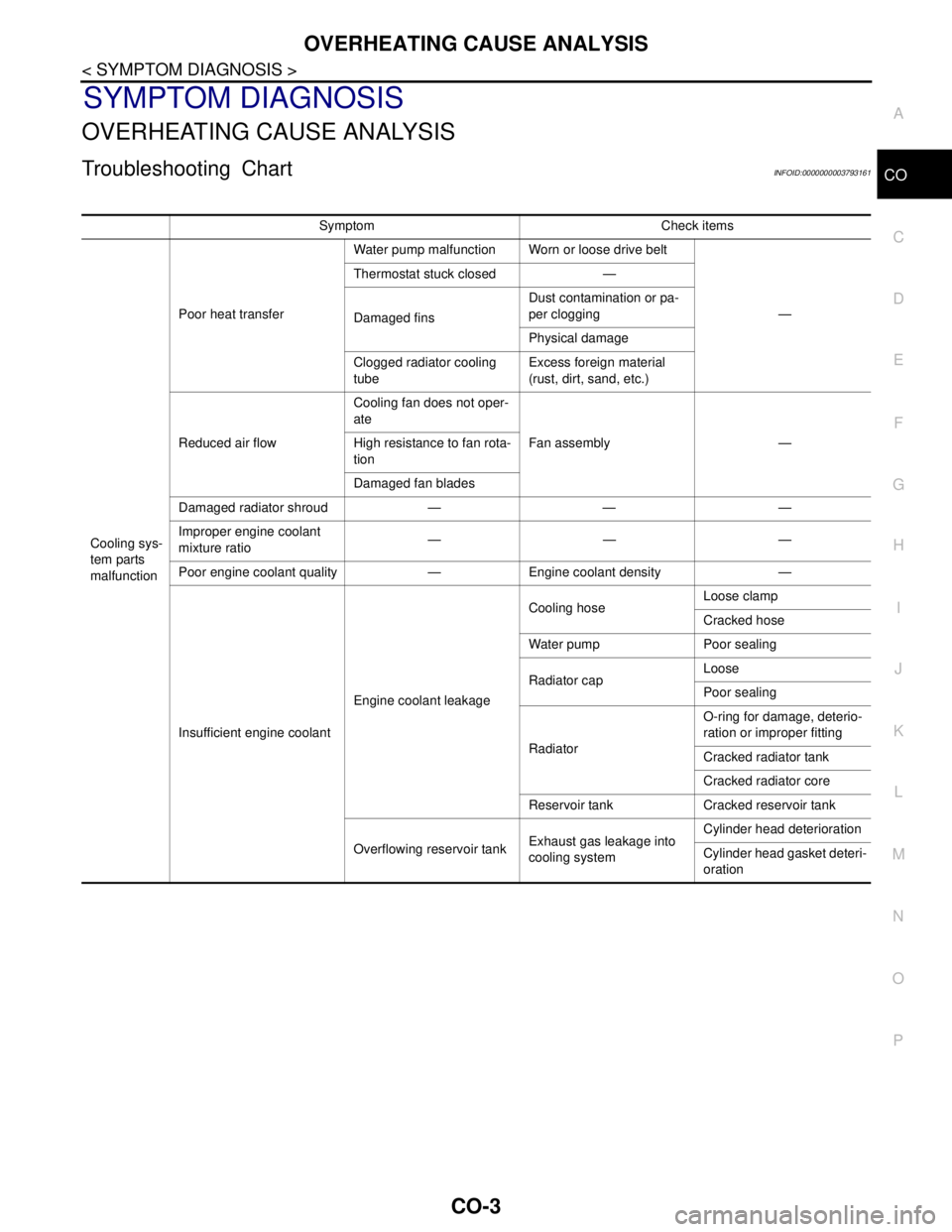

Symptom Check items

Cooling sys-

tem parts

malfunctionPoor heat transferWater pump malfunction Worn or loose drive belt

— Thermostat stuck closed —

Damaged finsDust contamination or pa-

per clogging

Physical damage

Clogged radiator cooling

tubeExcess foreign material

(rust, dirt, sand, etc.)

Reduced air flowCooling fan does not oper-

ate

Fan assembly — High resistance to fan rota-

tion

Damaged fan blades

Damaged radiator shroud — — —

Improper engine coolant

mixture ratio———

Poor engine coolant quality — Engine coolant density —

Insufficient engine coolantEngine coolant leakageCooling hoseLoose clamp

Cracked hose

Water pump Poor sealing

Radiator capLoose

Poor sealing

RadiatorO-ring for damage, deterio-

ration or improper fitting

Cracked radiator tank

Cracked radiator core

Reservoir tank Cracked reservoir tank

Overflowing reservoir tankExhaust gas leakage into

cooling systemCylinder head deterioration

Cylinder head gasket deteri-

oration

Page 1127 of 5121

CO-4

< SYMPTOM DIAGNOSIS >

OVERHEATING CAUSE ANALYSIS

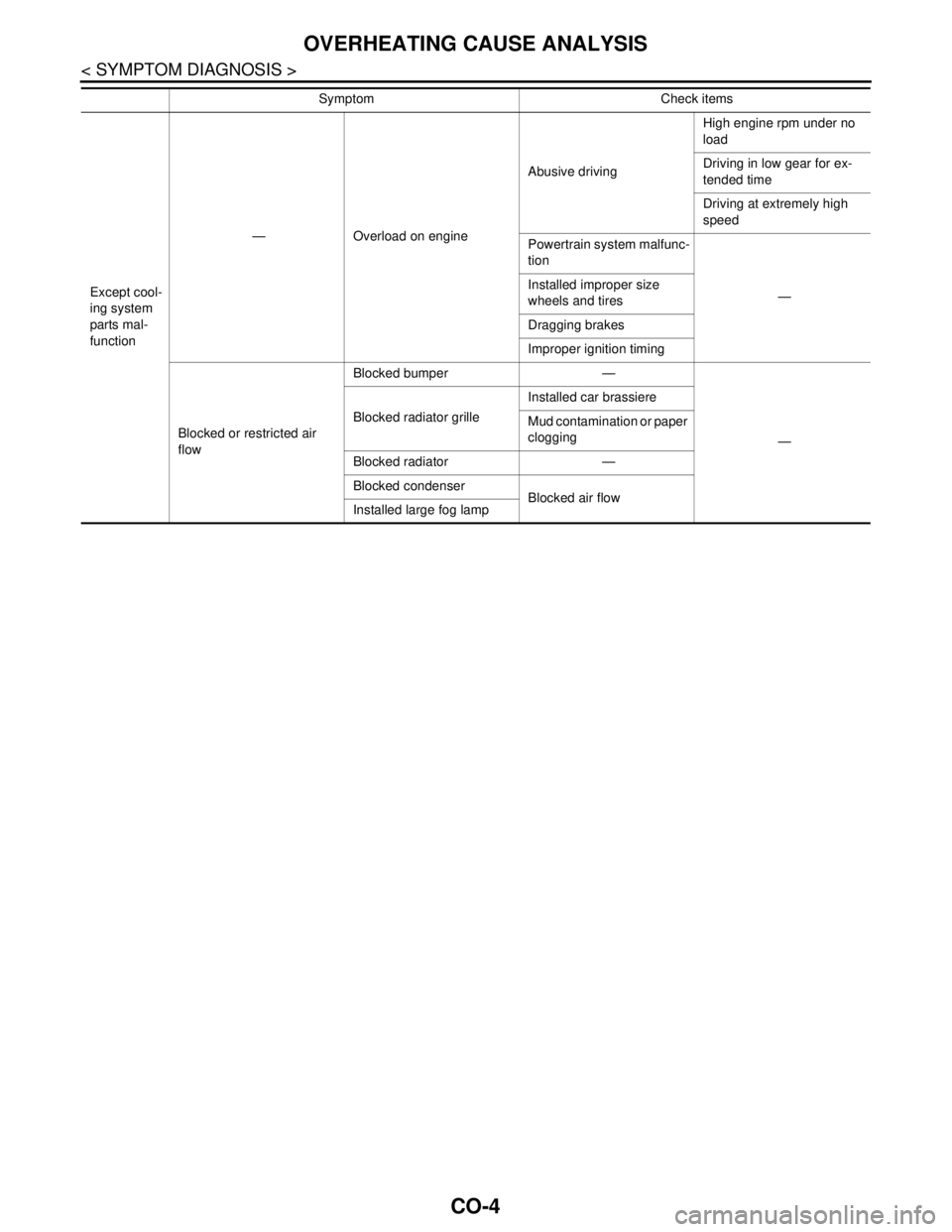

Except cool-

ing system

parts mal-

function— Overload on engineAbusive drivingHigh engine rpm under no

load

Driving in low gear for ex-

tended time

Driving at extremely high

speed

Powertrain system malfunc-

tion

— Installed improper size

wheels and tires

Dragging brakes

Improper ignition timing

Blocked or restricted air

flowBlocked bumper —

— Blocked radiator grilleInstalled car brassiere

Mud contamination or paper

clogging

Blocked radiator —

Blocked condenser

Blocked air flow

Installed large fog lamp Symptom Check items

Page 1128 of 5121

PRECAUTIONS

CO-5

< PRECAUTION >

C

D

E

F

G

H

I

J

K

L

MA

CO

N

P O

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000003801896

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SRS AIRBAG” and “SEAT BELT” of this

Service Manual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SRS AIRBAG”.

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

Liquid GasketINFOID:0000000003793163

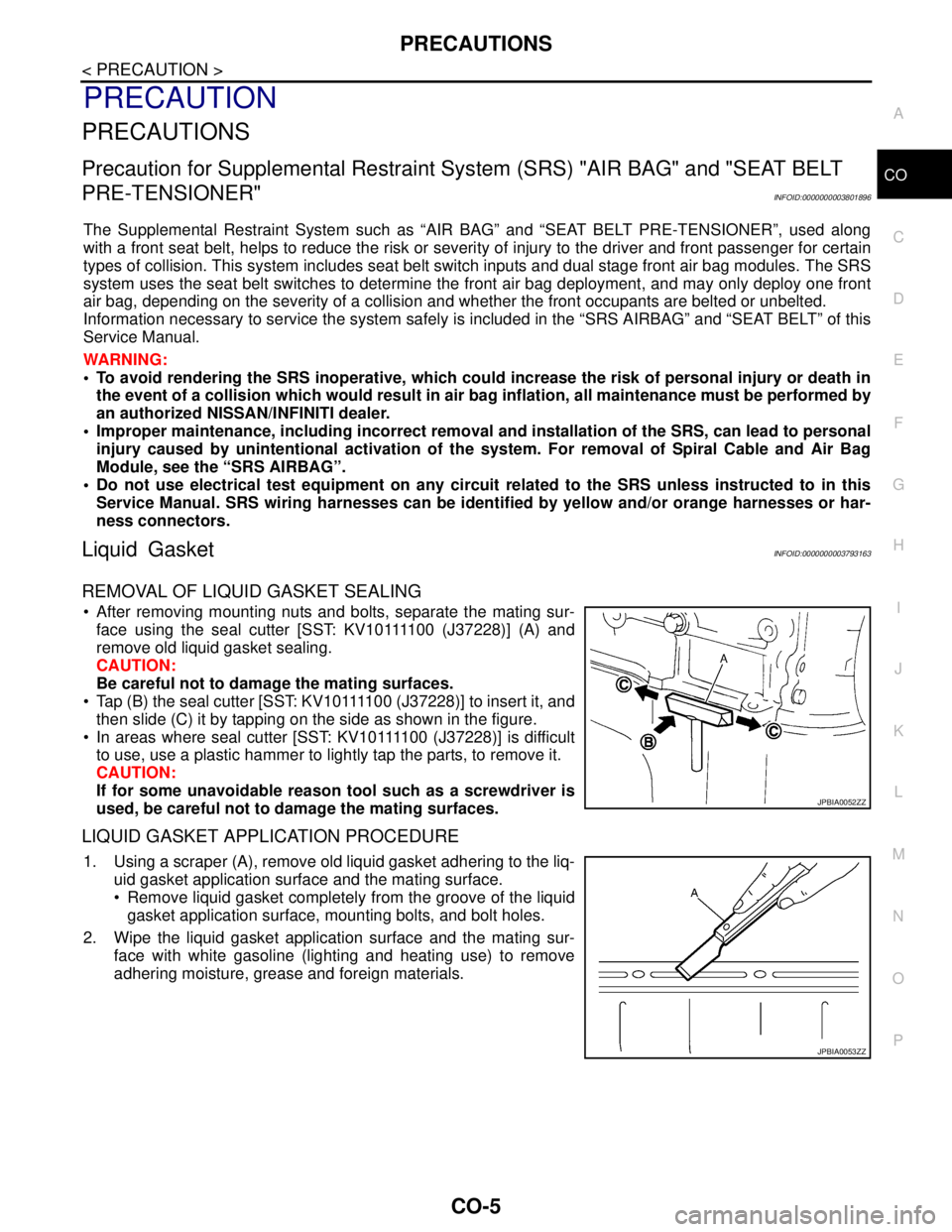

REMOVAL OF LIQUID GASKET SEALING

After removing mounting nuts and bolts, separate the mating sur-

f a c e u s i n g t h e s e a l c u t t e r [ S S T: K V 1 0 1111 0 0 ( J37228)] (A) and

remove old liquid gasket sealing.

CAUTION:

Be careful not to damage the mating surfaces.

Tap (B) the seal cutter [SST: KV10111100 (J37228)] to insert it, and

then slide (C) it by tapping on the side as shown in the figure.

In areas where seal cutter [SST: KV10111100 (J37228)] is difficult

to use, use a plastic hammer to lightly tap the parts, to remove it.

CAUTION:

If for some unavoidable reason tool such as a screwdriver is

used, be careful not to damage the mating surfaces.

LIQUID GASKET APPLICATION PROCEDURE

1. Using a scraper (A), remove old liquid gasket adhering to the liq-

uid gasket application surface and the mating surface.

Remove liquid gasket completely from the groove of the liquid

gasket application surface, mounting bolts, and bolt holes.

2. Wipe the liquid gasket application surface and the mating sur-

face with white gasoline (lighting and heating use) to remove

adhering moisture, grease and foreign materials.

JPBIA0052ZZ

JPBIA0053ZZ

Page 1129 of 5121

CO-6

< PRECAUTION >

PRECAUTIONS

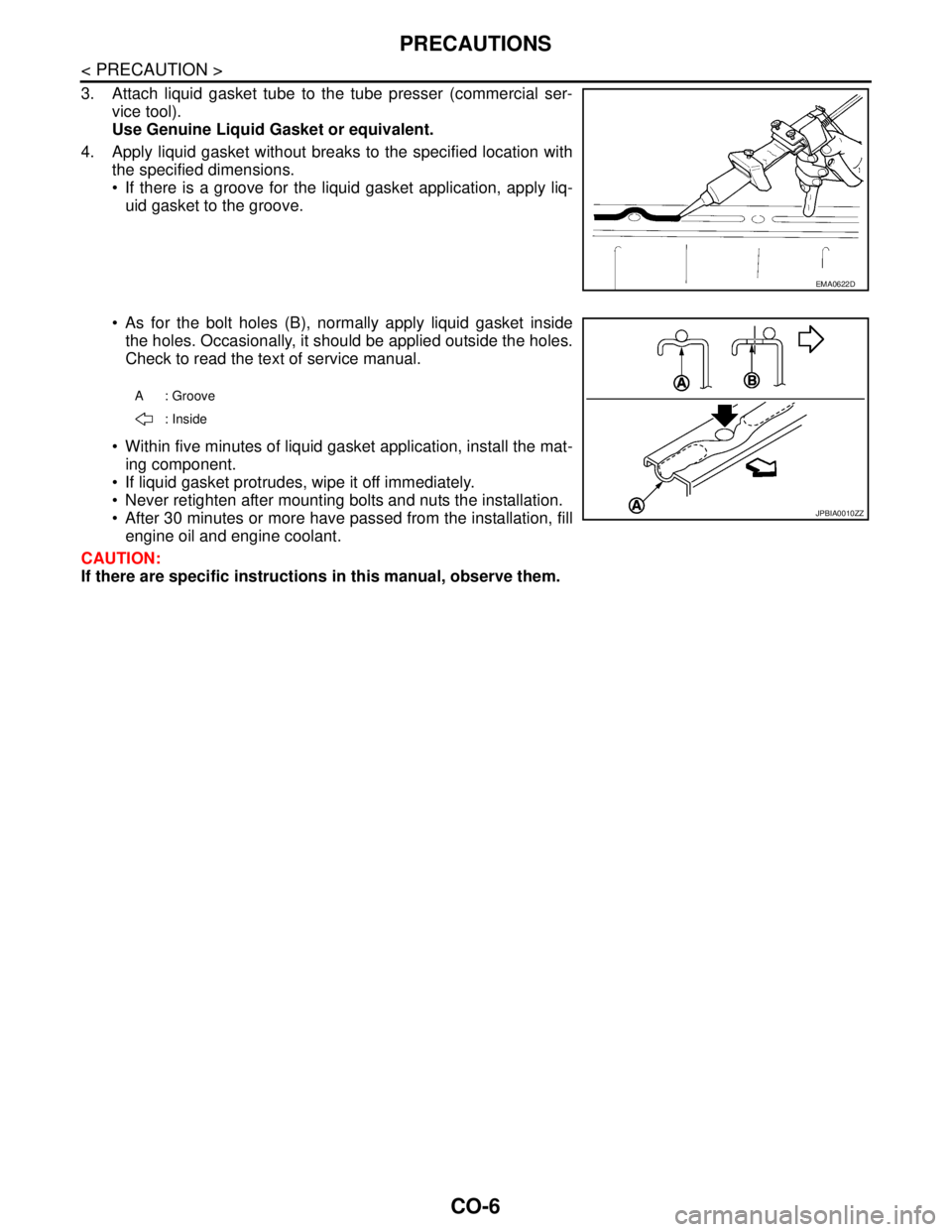

3. Attach liquid gasket tube to the tube presser (commercial ser-

vice tool).

Use Genuine Liquid Gasket or equivalent.

4. Apply liquid gasket without breaks to the specified location with

the specified dimensions.

If there is a groove for the liquid gasket application, apply liq-

uid gasket to the groove.

As for the bolt holes (B), normally apply liquid gasket inside

the holes. Occasionally, it should be applied outside the holes.

Check to read the text of service manual.

Within five minutes of liquid gasket application, install the mat-

ing component.

If liquid gasket protrudes, wipe it off immediately.

Never retighten after mounting bolts and nuts the installation.

After 30 minutes or more have passed from the installation, fill

engine oil and engine coolant.

CAUTION:

If there are specific instructions in this manual, observe them.

EMA0622D

A: Groove

: Inside

JPBIA0010ZZ

Page 1130 of 5121

PREPARATION

CO-7

< PREPARATION >

C

D

E

F

G

H

I

J

K

L

MA

CO

N

P O

PREPARATION

PREPARATION

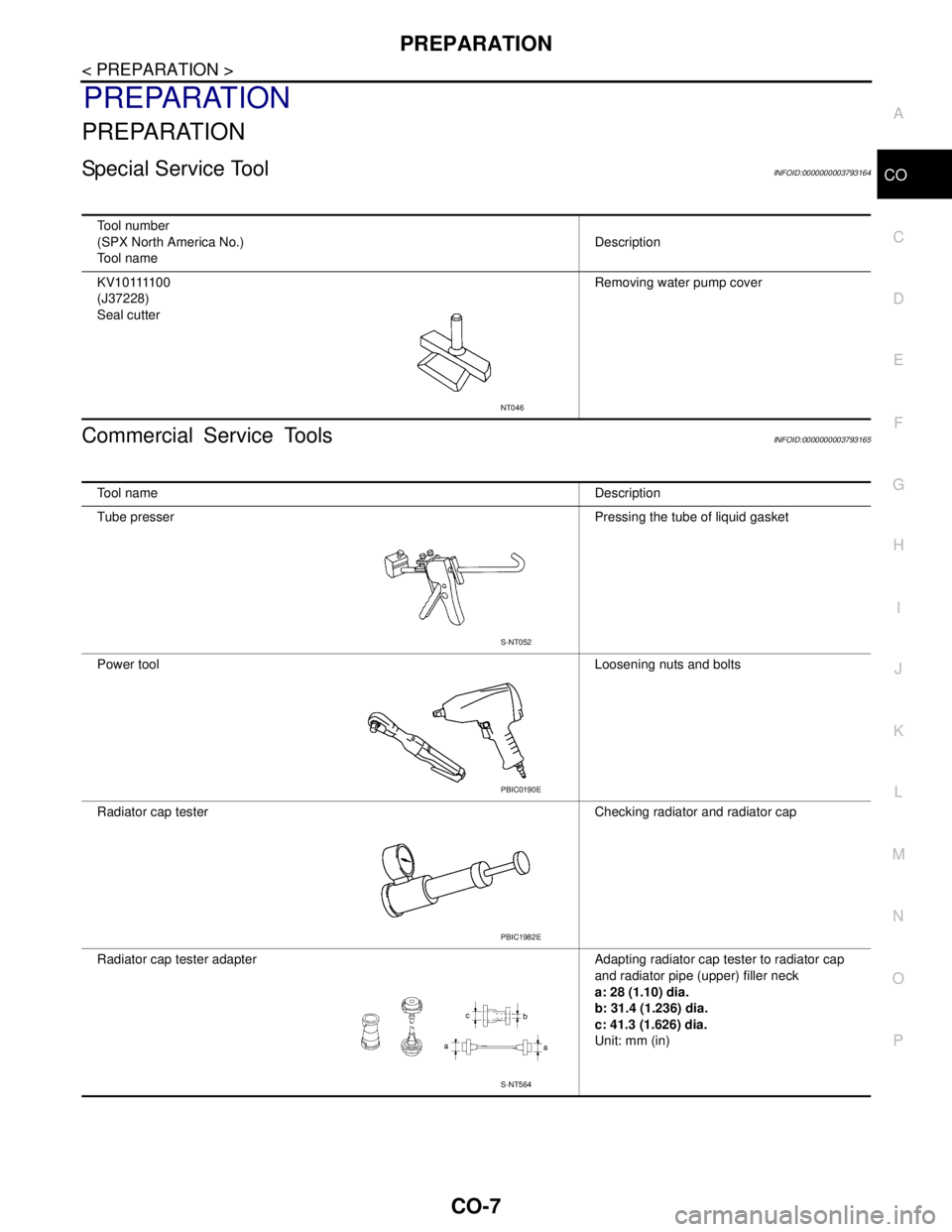

Special Service ToolINFOID:0000000003793164

Commercial Service ToolsINFOID:0000000003793165

Tool number

(SPX North America No.)

Tool nameDescription

K V 1 0 1111 0 0

(J37228)

Seal cutterRemoving water pump cover

NT046

Tool nameDescription

Tube presser Pressing the tube of liquid gasket

Power toolLoosening nuts and bolts

Radiator cap tester Checking radiator and radiator cap

Radiator cap tester adapter Adapting radiator cap tester to radiator cap

and radiator pipe (upper) filler neck

a: 28 (1.10) dia.

b: 31.4 (1.236) dia.

c: 41.3 (1.626) dia.

Unit: mm (in)

S-NT052

PBIC0190E

PBIC1982E

S-NT564