Ioni NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 4452 of 5121

STARTING SYSTEM

STR-5

< FUNCTION DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

MA

STR

N

P O

FUNCTION DIAGNOSIS

STARTING SYSTEM

VQ25DE

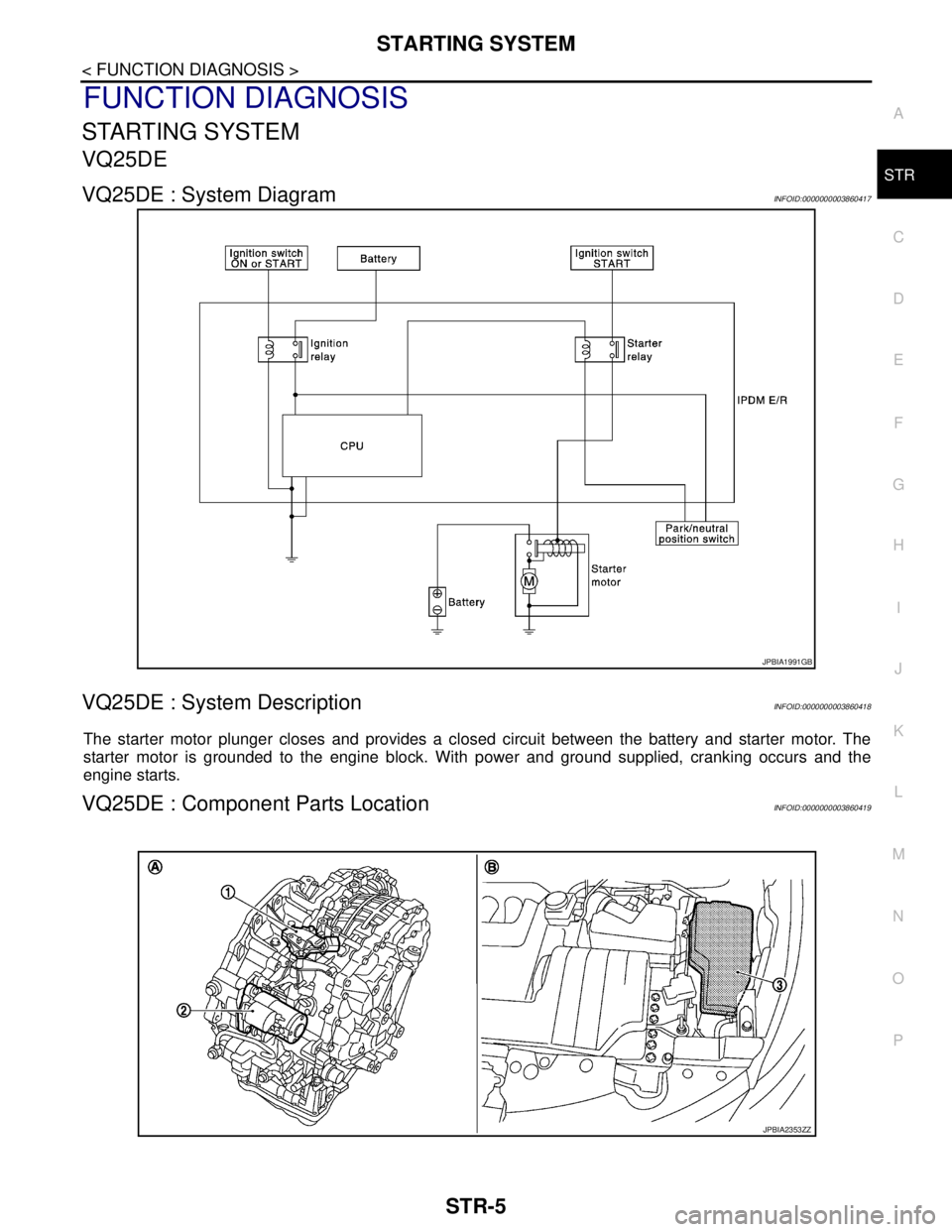

VQ25DE : System DiagramINFOID:0000000003860417

VQ25DE : System DescriptionINFOID:0000000003860418

The starter motor plunger closes and provides a closed circuit between the battery and starter motor. The

starter motor is grounded to the engine block. With power and ground supplied, cranking occurs and the

engine starts.

VQ25DE : Component Parts LocationINFOID:0000000003860419

JPBIA1991GB

JPBIA2353ZZ

Page 4453 of 5121

STR-6

< FUNCTION DIAGNOSIS >

STARTING SYSTEM

VQ25DE : Component Description

INFOID:0000000003860420

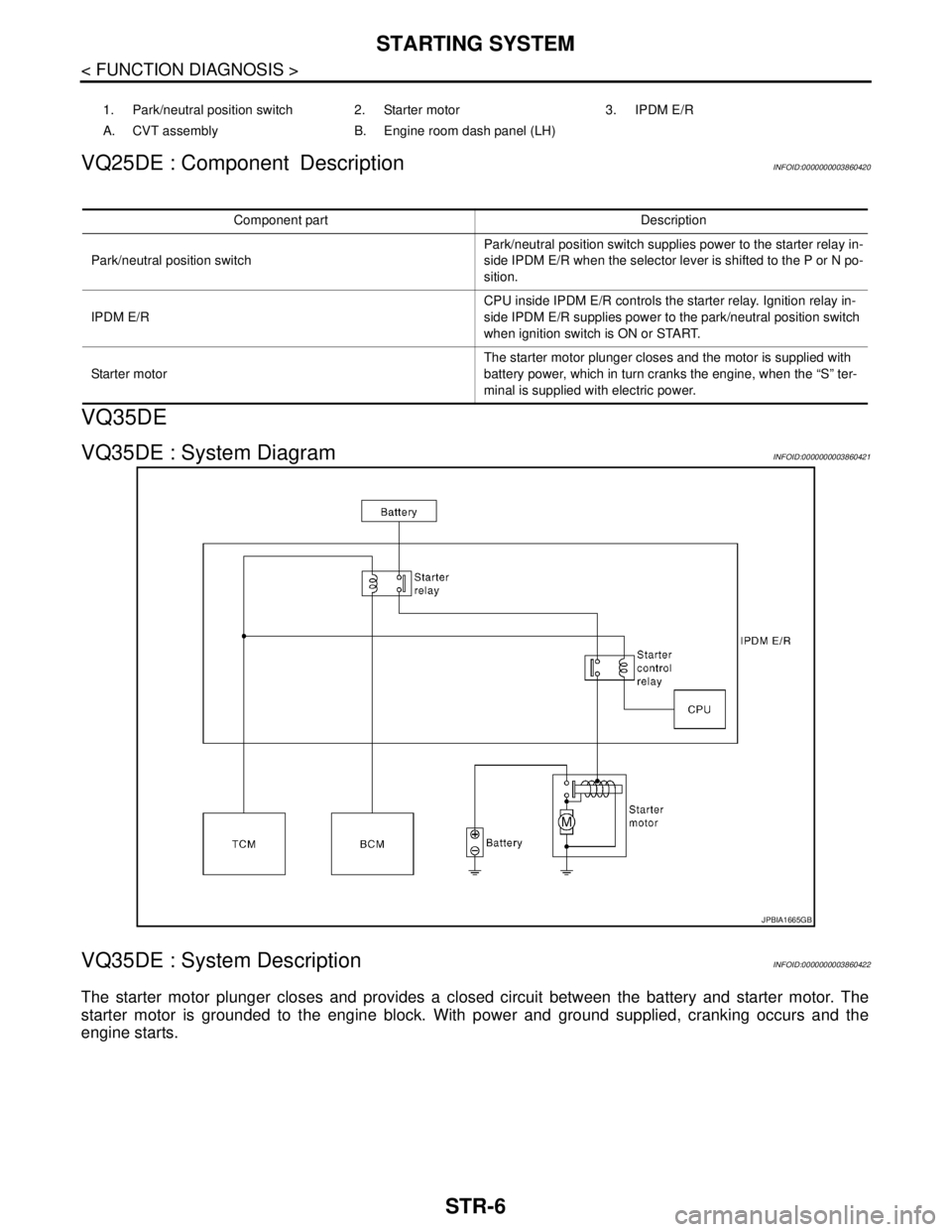

VQ35DE

VQ35DE : System DiagramINFOID:0000000003860421

VQ35DE : System DescriptionINFOID:0000000003860422

The starter motor plunger closes and provides a closed circuit between the battery and starter motor. The

starter motor is grounded to the engine block. With power and ground supplied, cranking occurs and the

engine starts.

1. Park/neutral position switch 2. Starter motor 3. IPDM E/R

A. CVT assembly B. Engine room dash panel (LH)

Component part Description

Park/neutral position switchPark/neutral position switch supplies power to the starter relay in-

side IPDM E/R when the selector lever is shifted to the P or N po-

sition.

IPDM E/RCPU inside IPDM E/R controls the starter relay. Ignition relay in-

side IPDM E/R supplies power to the park/neutral position switch

when ignition switch is ON or START.

Starter motorThe starter motor plunger closes and the motor is supplied with

battery power, which in turn cranks the engine, when the “S” ter-

minal is supplied with electric power.

JPBIA1665GB

Page 4454 of 5121

STARTING SYSTEM

STR-7

< FUNCTION DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

MA

STR

N

P O

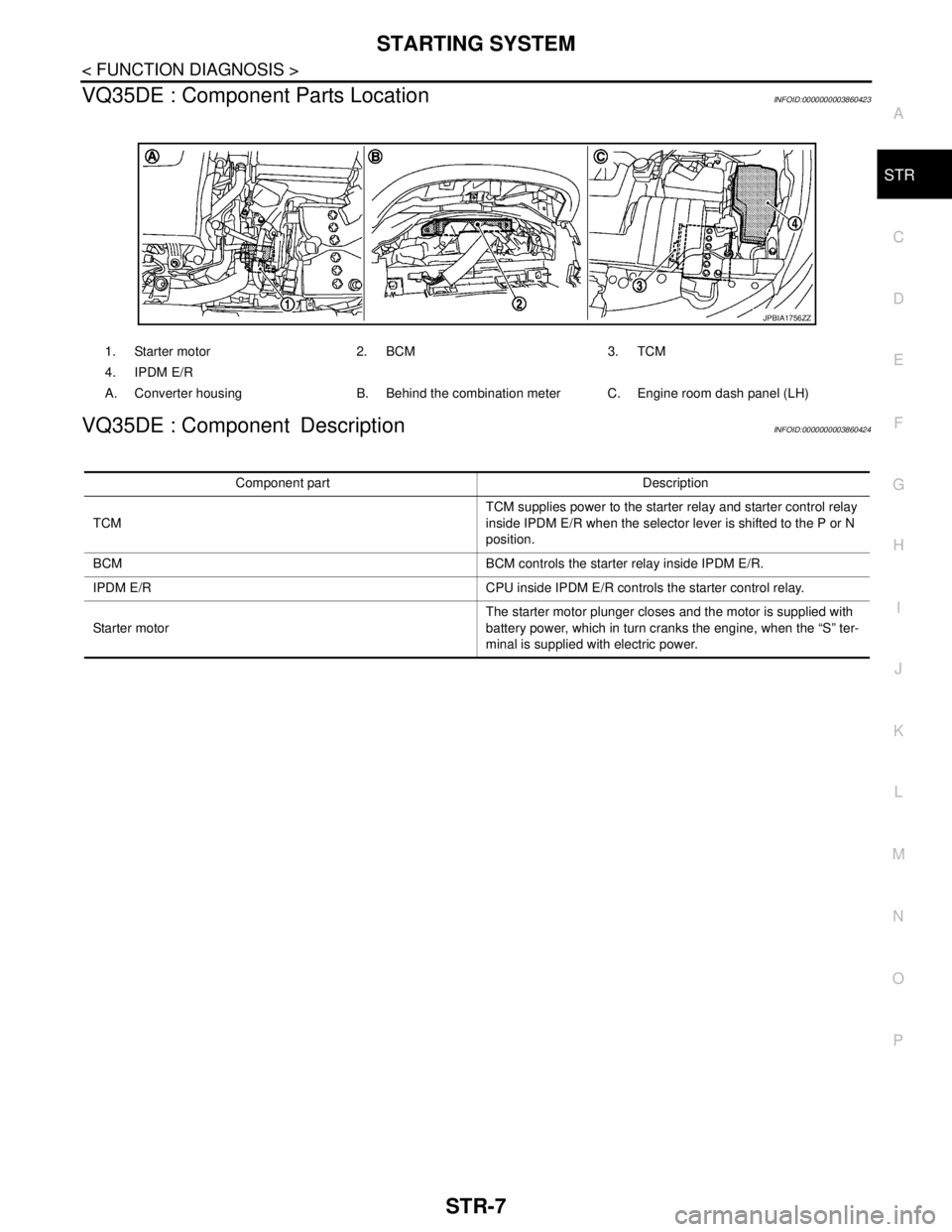

VQ35DE : Component Parts LocationINFOID:0000000003860423

VQ35DE : Component DescriptionINFOID:0000000003860424

1. Starter motor 2. BCM 3. TCM

4. IPDM E/R

A. Converter housing B. Behind the combination meter C. Engine room dash panel (LH)

JPBIA1756ZZ

Component part Description

TCMTCM supplies power to the starter relay and starter control relay

inside IPDM E/R when the selector lever is shifted to the P or N

position.

BCM BCM controls the starter relay inside IPDM E/R.

IPDM E/R CPU inside IPDM E/R controls the starter control relay.

Starter motorThe starter motor plunger closes and the motor is supplied with

battery power, which in turn cranks the engine, when the “S” ter-

minal is supplied with electric power.

Page 4455 of 5121

STR-8

< COMPONENT DIAGNOSIS >

B TERMINAL CIRCUIT

COMPONENT DIAGNOSIS

B TERMINAL CIRCUIT

DescriptionINFOID:0000000003860425

The “B” terminal is constantly supplied with battery power.

Diagnosis ProcedureINFOID:0000000003860426

CAUTION:

Perform diagnosis under the condition that engine cannot start by the following procedure.

1. Remove fuel pump fuse.

2. Crank or start the engine (where possible) until the fuel pressure is released.

1.CHECK “B” TERMINAL CIRCUIT

1. Turn ignition switch OFF.

2. Check that starter motor “B” terminal connection is clean and tight.

3. Check voltage between starter motor “B” terminal and ground.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Check harness between battery and starter motor for open circuit.

2.CHECK BATTERY CABLE CONNECTION STATUS (VOLTAGE DROP TEST)

1. Shift the selector lever to “P” or “N” position.

2. Check voltage between battery positive terminal and starter motor “B” terminal.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Check harness between the battery and the starter motor for poor continuity.

3.CHECK GROUND CIRCUIT STATUS (VOLTAGE DROP TEST)

1. Shift the selector lever to “P” or “N” position.

2. Check voltage between starter motor case and battery negative terminal.

Is the inspection result normal?

YES >> “B” terminal circuit is OK. Further inspection is necessary. Refer to STR-2, "Work Flow".

NO >> Check the starter motor case and ground for poor continuity.

Te r m i n a l s

Voltage (Approx.) (+)

(–)

Starter motor “B” terminal Terminal

F49 (VQ25DE)

F10 (VQ35DE)2 Ground Battery voltage

Te r m i n a l s

Condition Voltage (Approx.)

(+)(–)

Starter motor

“B” terminalTerminal

Battery positive terminalF49 (VQ25DE)

F10 (VQ35DE)2 When the ignition switch is

in START positionLess than

0.5 V

Te r m i n a l s

Condition Voltage (Approx.)

(+) (–)

Starter motor case Battery negative terminalWhen the ignition switch is in

START positionLess than 0.2 V

Page 4456 of 5121

S TERMINAL CIRCUIT

STR-9

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

MA

STR

N

P O

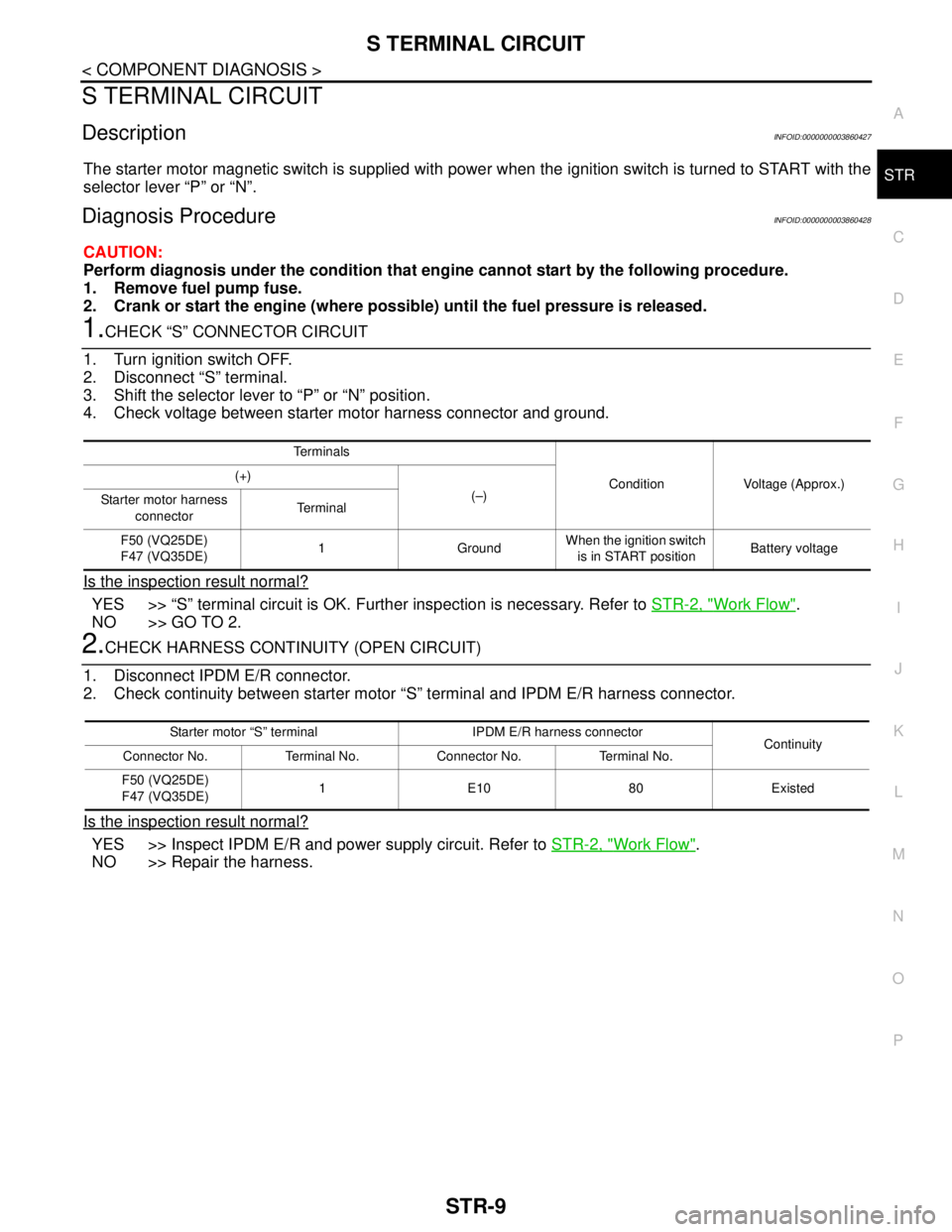

S TERMINAL CIRCUIT

DescriptionINFOID:0000000003860427

The starter motor magnetic switch is supplied with power when the ignition switch is turned to START with the

selector lever “P” or “N”.

Diagnosis ProcedureINFOID:0000000003860428

CAUTION:

Perform diagnosis under the condition that engine cannot start by the following procedure.

1. Remove fuel pump fuse.

2. Crank or start the engine (where possible) until the fuel pressure is released.

1.CHECK “S” CONNECTOR CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect “S” terminal.

3. Shift the selector lever to “P” or “N” position.

4. Check voltage between starter motor harness connector and ground.

Is the inspection result normal?

YES >> “S” terminal circuit is OK. Further inspection is necessary. Refer to STR-2, "Work Flow".

NO >> GO TO 2.

2.CHECK HARNESS CONTINUITY (OPEN CIRCUIT)

1. Disconnect IPDM E/R connector.

2. Check continuity between starter motor “S” terminal and IPDM E/R harness connector.

Is the inspection result normal?

YES >> Inspect IPDM E/R and power supply circuit. Refer to STR-2, "Work Flow".

NO >> Repair the harness.

Te r m i n a l s

Condition Voltage (Approx.) (+)

(–)

Starter motor harness

connectorTe r m i n a l

F50 (VQ25DE)

F47 (VQ35DE)1 GroundWhen the ignition switch

is in START positionBattery voltage

Starter motor “S” terminal IPDM E/R harness connector

Continuity

Connector No. Terminal No. Connector No. Terminal No.

F50 (VQ25DE)

F47 (VQ35DE)1E1080Existed

Page 4463 of 5121

STR-16

< ON-VEHICLE REPAIR >

STARTER MOTOR

Type: S114-936

VQ25DE : Removal and InstallationINFOID:0000000003860437

REMOVAL

1. Remove the battery. Refer to PG-109, "Removal and Installation".

2. Remove the air cleaner assembly and air ducts.

3. Disconnect the following unit connectors:

ECM

IPDM E/R

4. Remove the battery tray.

5. Remove the “B”terminal nut and “S” terminal nut.

6. Remove the starter motor mounting bolts.

7. Remove the starter motor upward from the vehicle.

INSTALLATION

Installation is in the reverse order of removal.

VQ25DE : InspectionINFOID:0000000003860438

MAGNETIC SWITCH

Before starting to check, disconnect the battery cable from the negative terminal.

JSAIA0936GB

1. Magnetic switch assembly 2. Adjusting plate 3. Dust cover

4. Shift lever set 5. Pinion stopper clip 6. Pinion stopper

7. Pinion 8. Pinion spring 9. Gear case assembly

10. Center bracket (A) 11. Yoke assembly 12. Armature assembly

13. Brush holder assembly 14. Thrust washer 15. Rear cover

16. Internal gear 17. Planetary gear 18. Pinion stopper

19. Packing 20. Thrust washer 21. Center bracket (P)

22. Thrust washer 23. E-ring 24. Clutch gear assembly

Refer to GI-4, "

Components" for symbols not described on the above.

Page 4466 of 5121

STARTER MOTOR

STR-19

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

L

MA

STR

N

P O

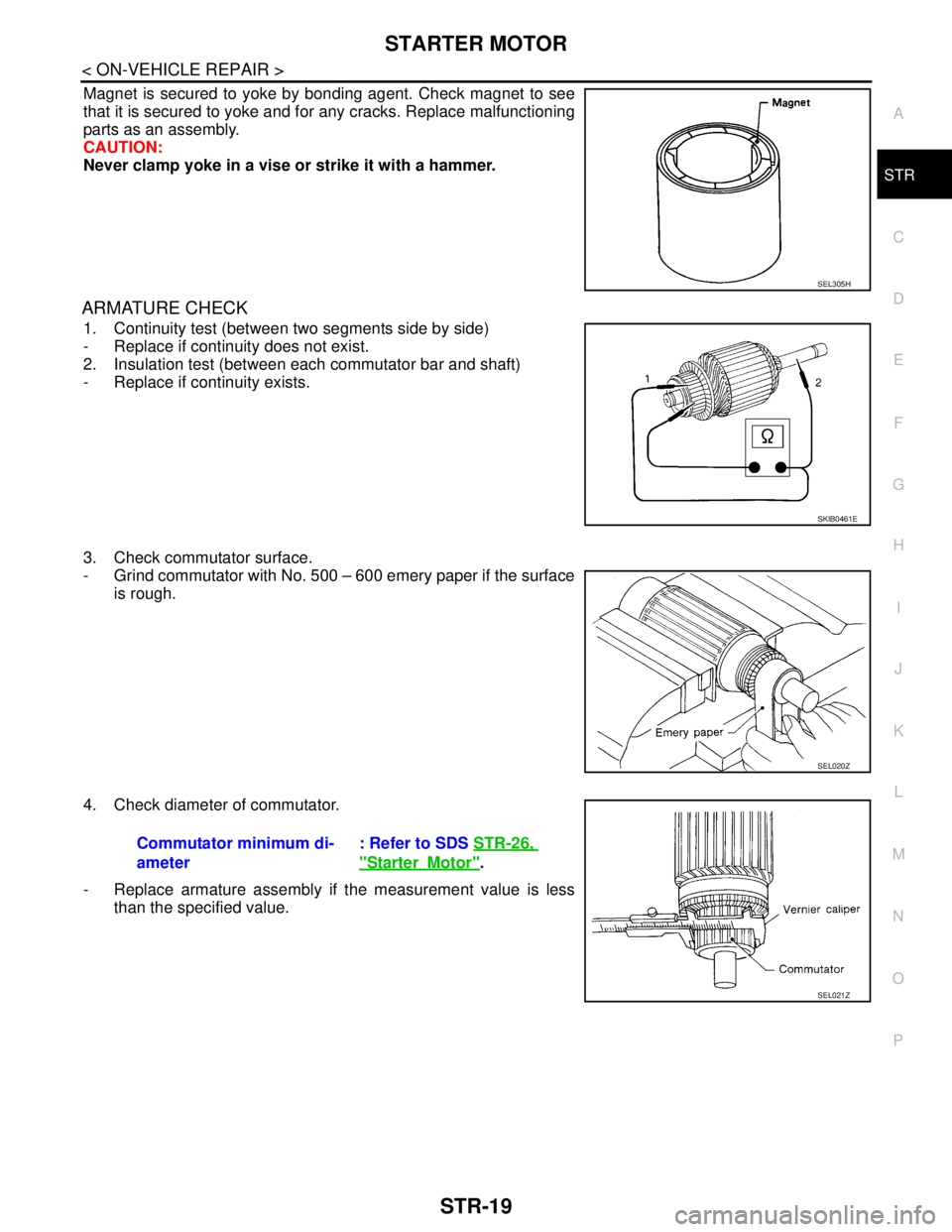

Magnet is secured to yoke by bonding agent. Check magnet to see

that it is secured to yoke and for any cracks. Replace malfunctioning

parts as an assembly.

CAUTION:

Never clamp yoke in a vise or strike it with a hammer.

ARMATURE CHECK

1. Continuity test (between two segments side by side)

- Replace if continuity does not exist.

2. Insulation test (between each commutator bar and shaft)

- Replace if continuity exists.

3. Check commutator surface.

- Grind commutator with No. 500 – 600 emery paper if the surface

is rough.

4. Check diameter of commutator.

- Replace armature assembly if the measurement value is less

than the specified value.

SEL305H

SKIB0461E

SEL020Z

Commutator minimum di-

ameter: Refer to SDS STR-26,

"StarterMotor".

SEL021Z

Page 4468 of 5121

STARTER MOTOR

STR-21

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

L

MA

STR

N

P O

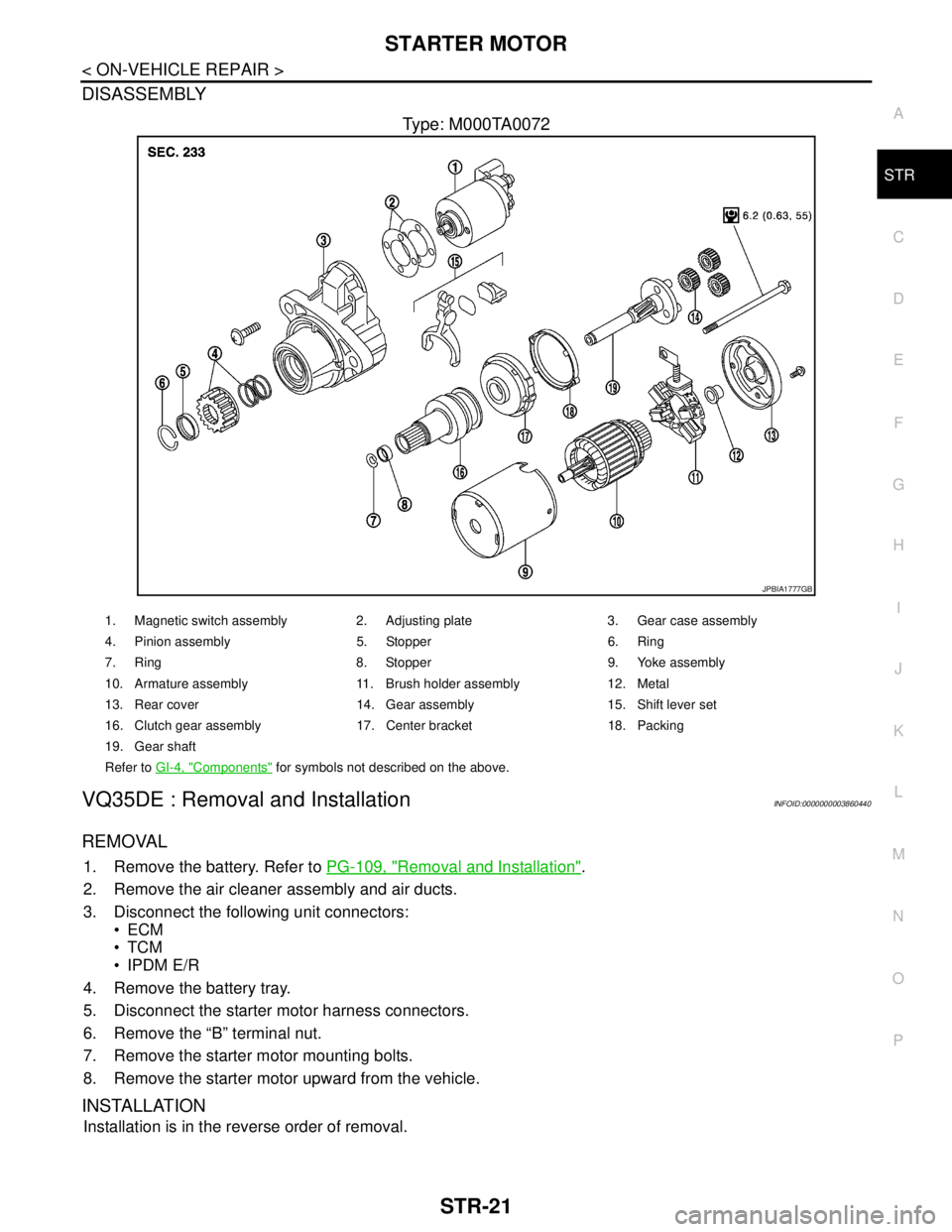

DISASSEMBLY

Type: M000TA0072

VQ35DE : Removal and InstallationINFOID:0000000003860440

REMOVAL

1. Remove the battery. Refer to PG-109, "Removal and Installation".

2. Remove the air cleaner assembly and air ducts.

3. Disconnect the following unit connectors:

ECM

TCM

IPDM E/R

4. Remove the battery tray.

5. Disconnect the starter motor harness connectors.

6. Remove the “B” terminal nut.

7. Remove the starter motor mounting bolts.

8. Remove the starter motor upward from the vehicle.

INSTALLATION

Installation is in the reverse order of removal.

JPBIA1777GB

1. Magnetic switch assembly 2. Adjusting plate 3. Gear case assembly

4. Pinion assembly 5. Stopper 6. Ring

7. Ring 8. Stopper 9. Yoke assembly

10. Armature assembly 11. Brush holder assembly 12. Metal

13. Rear cover 14. Gear assembly 15. Shift lever set

16. Clutch gear assembly 17. Center bracket 18. Packing

19. Gear shaft

Refer to GI-4, "

Components" for symbols not described on the above.

Page 4471 of 5121

STR-24

< ON-VEHICLE REPAIR >

STARTER MOTOR

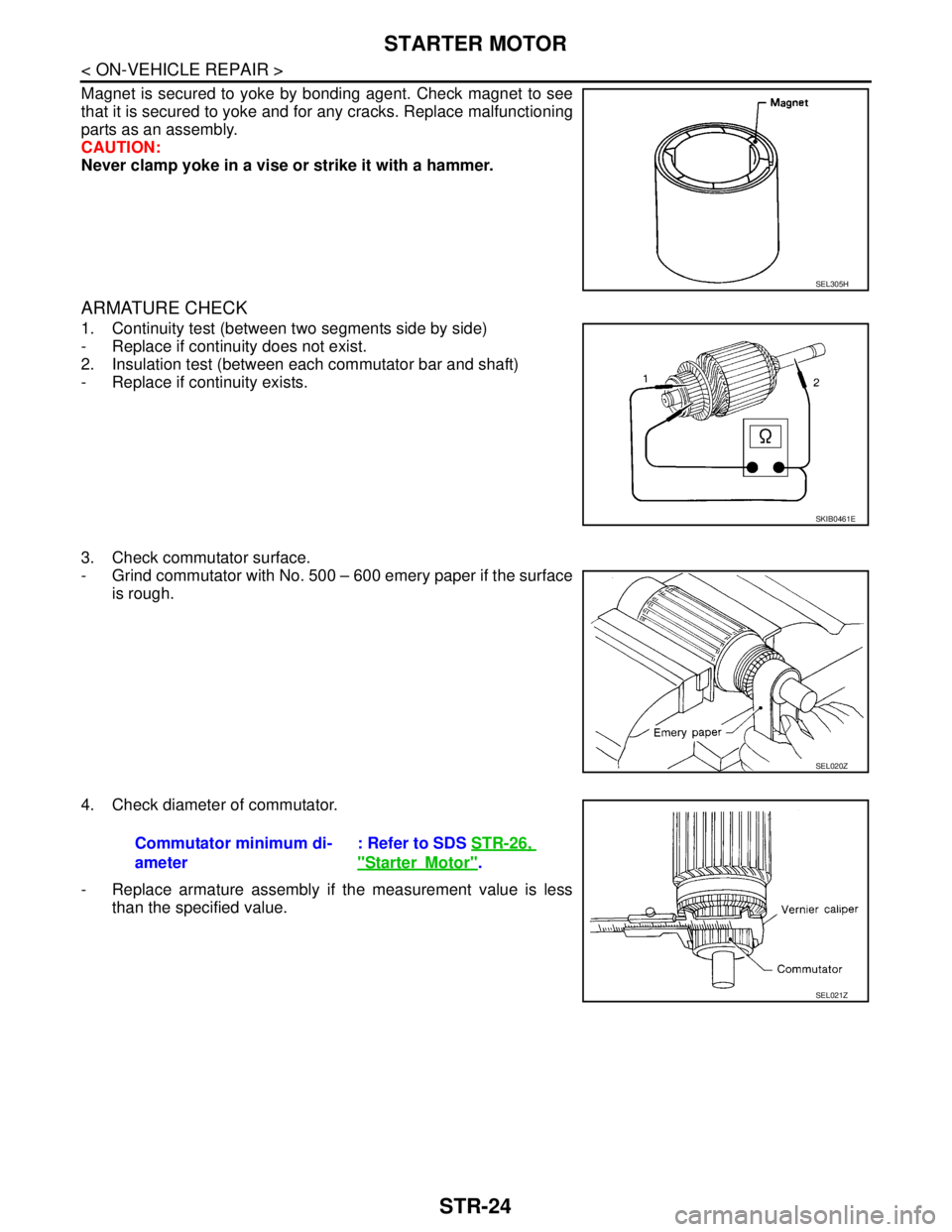

Magnet is secured to yoke by bonding agent. Check magnet to see

that it is secured to yoke and for any cracks. Replace malfunctioning

parts as an assembly.

CAUTION:

Never clamp yoke in a vise or strike it with a hammer.

ARMATURE CHECK

1. Continuity test (between two segments side by side)

- Replace if continuity does not exist.

2. Insulation test (between each commutator bar and shaft)

- Replace if continuity exists.

3. Check commutator surface.

- Grind commutator with No. 500 – 600 emery paper if the surface

is rough.

4. Check diameter of commutator.

- Replace armature assembly if the measurement value is less

than the specified value.

SEL305H

SKIB0461E

SEL020Z

Commutator minimum di-

ameter: Refer to SDS STR-26,

"StarterMotor".

SEL021Z

Page 4482 of 5121

![NISSAN TEANA 2008 Service Manual DIAGNOSIS AND REPAIR WORK FLOW

TM-9

< BASIC INSPECTION >[CVT: RE0F09B]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORK FLOW

Work FlowINFOID:0000000003848914

INTRODUCTION

The NISSAN TEANA 2008 Service Manual DIAGNOSIS AND REPAIR WORK FLOW

TM-9

< BASIC INSPECTION >[CVT: RE0F09B]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORK FLOW

Work FlowINFOID:0000000003848914

INTRODUCTION

The](/img/5/57391/w960_57391-4481.png)

DIAGNOSIS AND REPAIR WORK FLOW

TM-9

< BASIC INSPECTION >[CVT: RE0F09B]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORK FLOW

Work FlowINFOID:0000000003848914

INTRODUCTION

The TCM receives signals from the vehicle speed sensor and PNP switch. Then it provides shift control or

lock-up control via CVT solenoid valves.

The TCM also communicates with the ECM by means of signals

sent from sensing elements used with the OBD-related parts of the

CVT system for malfunction-diagnostic purposes. The TCM is capa-

ble of diagnosing malfunctioning parts while the ECM can store mal-

functions in its memory.

Input and output signals must always be correct and stable in the

operation of the CVT system. The CVT system must be in good

operating condition and be free of valve seizure, solenoid valve mal-

function, etc.

It is much more difficult to diagnose a malfunction that occurs inter-

mittently rather than continuously. Most intermittent malfunctions are

caused by poor electric connections or improper wiring. In this case,

careful checking of suspected circuits may help prevent the replace-

ment of good parts.

A visual check only may not find the cause of the malfunctions. A

road test with CONSULT-III (or GST) or a circuit tester connected

should be performed. Follow the “DETAILED FLOW”.

Before undertaking actual checks, take a few minutes to talk with a

customer who approaches with a driveability complaint. The cus-

tomer can supply good information about such malfunctions, espe-

cially intermittent ones. Find out what symptoms are present and

under what conditions they occur. A “Diagnostic Work Sheet” as

shown on the example (Refer to TM-10

) should be used.

Start your diagnosis by looking for “conventional” malfunctions first.

This will help troubleshoot driveability malfunctions on an electroni-

cally controlled engine vehicle.

Also check related Service Bulletins.

DETAILED FLOW

1.COLLECT THE INFORMATION FROM THE CUSTOMER

Get the detailed information from the customer about the symptom (the condition and the environment when

the incident/malfunction occurred) using the diagnosis work sheet. Refer to TM-10, "

Diagnostic Work Sheet".

>> GO TO 2.

2.CHECK SYMPTOM 1

Check the following items based on the information obtained from the customer.

Fail-safe. Refer to TM-120, "

Fail-safe".

CVT fluid inspection. Refer to TM-142, "

Inspection".

Line pressure test. Refer to TM-146, "

Inspection and Judgment".

SAT631IB

SAT632I

SEF234G