Ioni NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 4399 of 5121

STEERING WHEEL

ST-9

< ON-VEHICLE MAINTENANCE >

C

D

E

F

H

I

J

K

L

MA

B

ST

N

O

P

STEERING WHEEL

InspectionINFOID:0000000003806313

STEERING WHEEL AXIAL END PLAY

1. Check installation conditions of steering gear assembly, front suspension assembly, axle and steering col-

umn assembly.

2. Check if movement exists when steering wheel is moved up and down, to the left and right and to the axial

direction.

3. Check the following items when steering wheel axial end play is out of the standard.

Check the steering column assembly mounting condition. Refer to ST-13, "

Exploded View".

Check steering gear assembly mounting condition for looseness. Refer to ST-18, "

Exploded View".

STEERING WHEEL PLAY

1. Turn steering wheel so that front wheels come to the straight-ahead position.

2. Start the engine and lightly turn steering wheel to the left and right until front wheels start to move.

3. Measure steering wheel movement on the outer circumference.

4. Check the following items when steering wheel play is out of the standard.

Check backlash for each joint of steering column assembly.

Check installation condition of steering gear assembly.

NEUTRAL POSITION STEERING WHEEL

1. Check that steering gear assembly, steering column assembly and steering wheel are installed in the cor-

rect position.

2. Perform neutral position inspection after wheel alignment. Refer to FSU-7, "

Wheel Alignment Inspection".

3. Set the vehicle to the straight-ahead position and confirm steering wheel is in the neutral position.

4. Loosen outer socket lock nut and turn inner socket to left and right equally to make fine adjustments if

steering wheel is not in the neutral position.

STEERING WHEEL TURNING FORCE

1. Park the vehicle on a level and dry surface, set parking brake.

2. Tires need to be inflated normal pressure. Refer to WT-5, "

Tire Air Pressure".

3. Start the engine.

4. Bring power steering fluid up to adequate operating temperature.Standard

Steering wheel axial end

play: Refer to ST-37, "

Steering

Wheel Axial End Play and

Play".

Standard

Steering wheel play : Refer to ST-37, "

Steering

Wheel Axial End Play and

Play".

Fluid temperature : 50 – 80°C (122 – 176°F)

Page 4402 of 5121

ST-12

< ON-VEHICLE REPAIR >

STEERING WHEEL

ON-VEHICLE REPAIR

STEERING WHEEL

Exploded ViewINFOID:0000000003806314

Removal and InstallationINFOID:0000000003806315

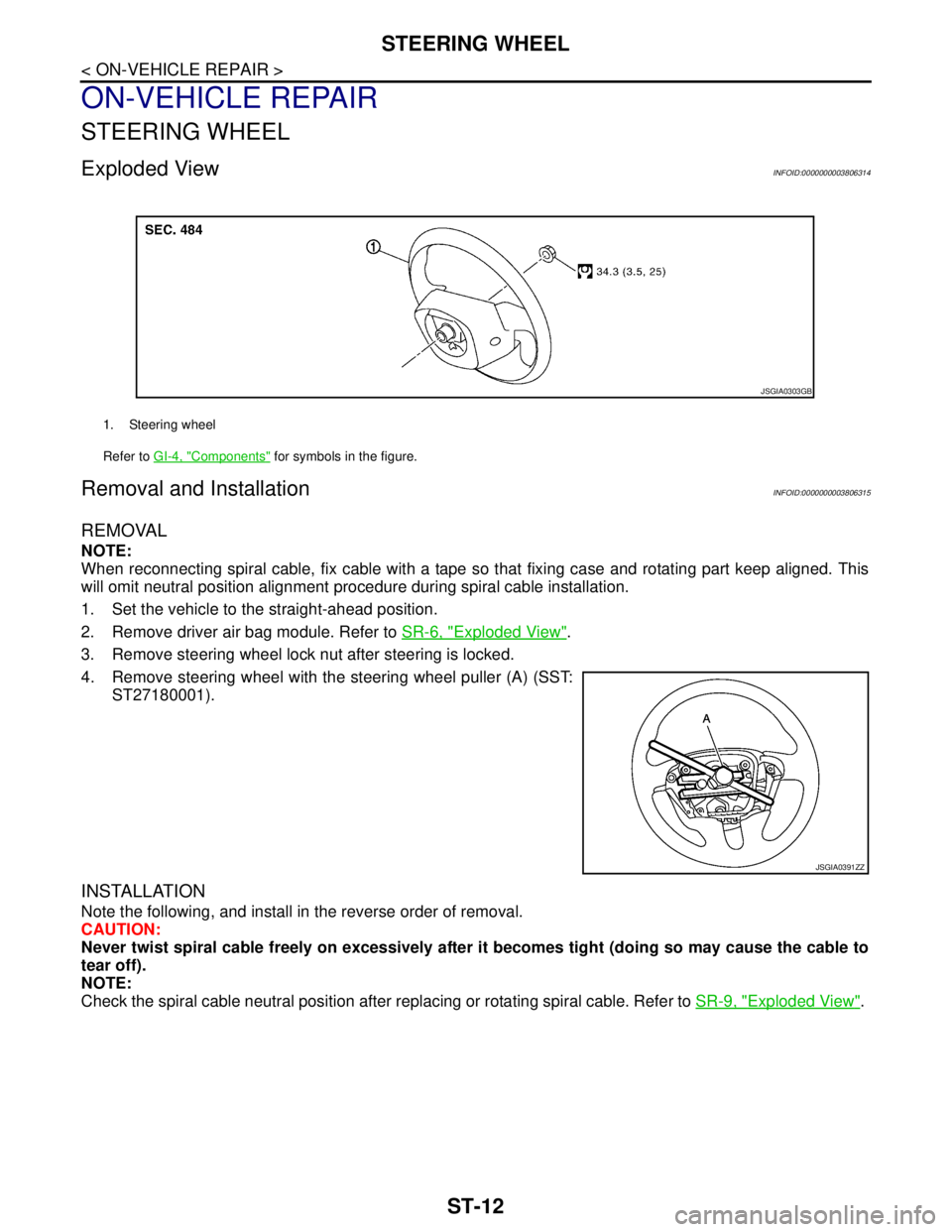

REMOVAL

NOTE:

When reconnecting spiral cable, fix cable with a tape so that fixing case and rotating part keep aligned. This

will omit neutral position alignment procedure during spiral cable installation.

1. Set the vehicle to the straight-ahead position.

2. Remove driver air bag module. Refer to SR-6, "

Exploded View".

3. Remove steering wheel lock nut after steering is locked.

4. Remove steering wheel with the steering wheel puller (A) (SST:

ST27180001).

INSTALLATION

Note the following, and install in the reverse order of removal.

CAUTION:

Never twist spiral cable freely on excessively after it becomes tight (doing so may cause the cable to

tear off).

NOTE:

Check the spiral cable neutral position after replacing or rotating spiral cable. Refer to SR-9, "

Exploded View".

1. Steering wheel

Refer to GI-4, "

Components" for symbols in the figure.

JSGIA0303GB

JSGIA0391ZZ

Page 4403 of 5121

STEERING COLUMN

ST-13

< ON-VEHICLE REPAIR >

C

D

E

F

H

I

J

K

L

MA

B

ST

N

O

P

STEERING COLUMN

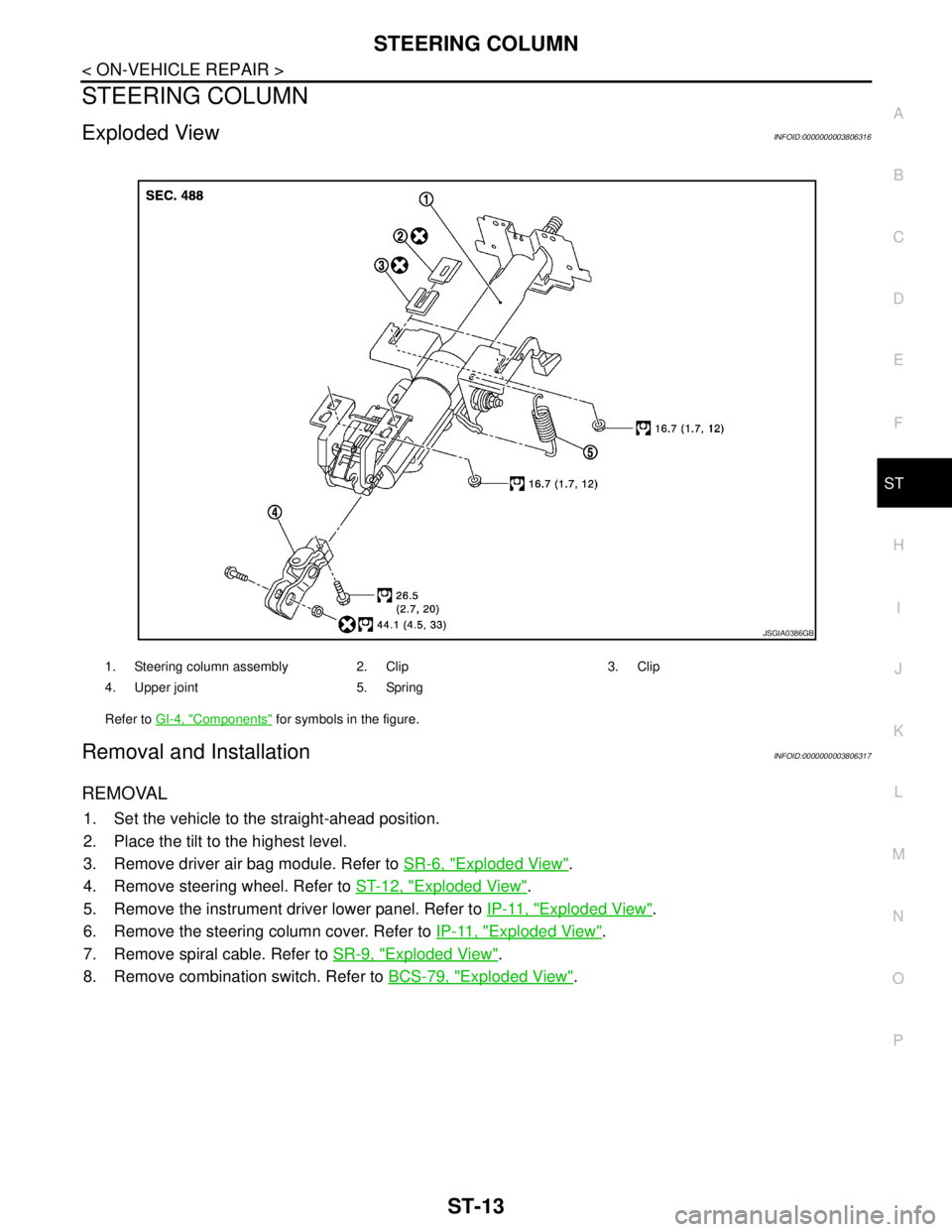

Exploded ViewINFOID:0000000003806316

Removal and InstallationINFOID:0000000003806317

REMOVAL

1. Set the vehicle to the straight-ahead position.

2. Place the tilt to the highest level.

3. Remove driver air bag module. Refer to SR-6, "

Exploded View".

4. Remove steering wheel. Refer to ST-12, "

Exploded View".

5. Remove the instrument driver lower panel. Refer to IP-11, "

Exploded View".

6. Remove the steering column cover. Refer to IP-11, "

Exploded View".

7. Remove spiral cable. Refer to SR-9, "

Exploded View".

8. Remove combination switch. Refer to BCS-79, "

Exploded View".

1. Steering column assembly 2. Clip 3. Clip

4. Upper joint 5. Spring

Refer to GI-4, "

Components" for symbols in the figure.

JSGIA0386GB

Page 4404 of 5121

ST-14

< ON-VEHICLE REPAIR >

STEERING COLUMN

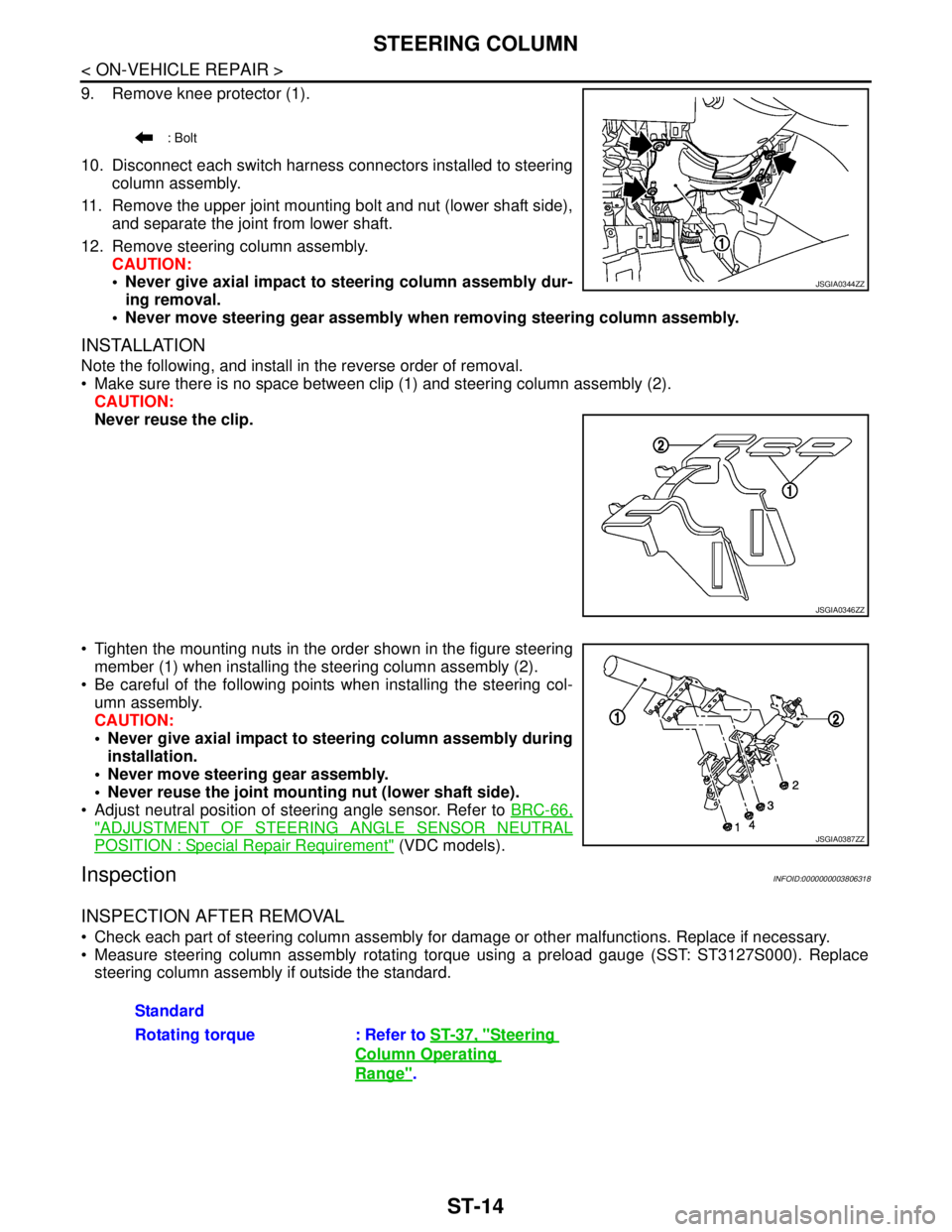

9. Remove knee protector (1).

10. Disconnect each switch harness connectors installed to steering

column assembly.

11. Remove the upper joint mounting bolt and nut (lower shaft side),

and separate the joint from lower shaft.

12. Remove steering column assembly.

CAUTION:

Never give axial impact to steering column assembly dur-

ing removal.

Never move steering gear assembly when removing steering column assembly.

INSTALLATION

Note the following, and install in the reverse order of removal.

Make sure there is no space between clip (1) and steering column assembly (2).

CAUTION:

Never reuse the clip.

Tighten the mounting nuts in the order shown in the figure steering

member (1) when installing the steering column assembly (2).

Be careful of the following points when installing the steering col-

umn assembly.

CAUTION:

Never give axial impact to steering column assembly during

installation.

Never move steering gear assembly.

Never reuse the joint mounting nut (lower shaft side).

Adjust neutral position of steering angle sensor. Refer to BRC-66,

"ADJUSTMENT OF STEERING ANGLE SENSOR NEUTRAL

POSITION : Special Repair Requirement" (VDC models).

InspectionINFOID:0000000003806318

INSPECTION AFTER REMOVAL

Check each part of steering column assembly for damage or other malfunctions. Replace if necessary.

Measure steering column assembly rotating torque using a preload gauge (SST: ST3127S000). Replace

steering column assembly if outside the standard.

: Bolt

JSGIA0344ZZ

JSGIA0346ZZ

JSGIA0387ZZ

Standard

Rotating torque : Refer to ST-37, "

Steering

Column Operating

Range".

Page 4406 of 5121

ST-16

< ON-VEHICLE REPAIR >

LOWER SHAFT

LOWER SHAFT

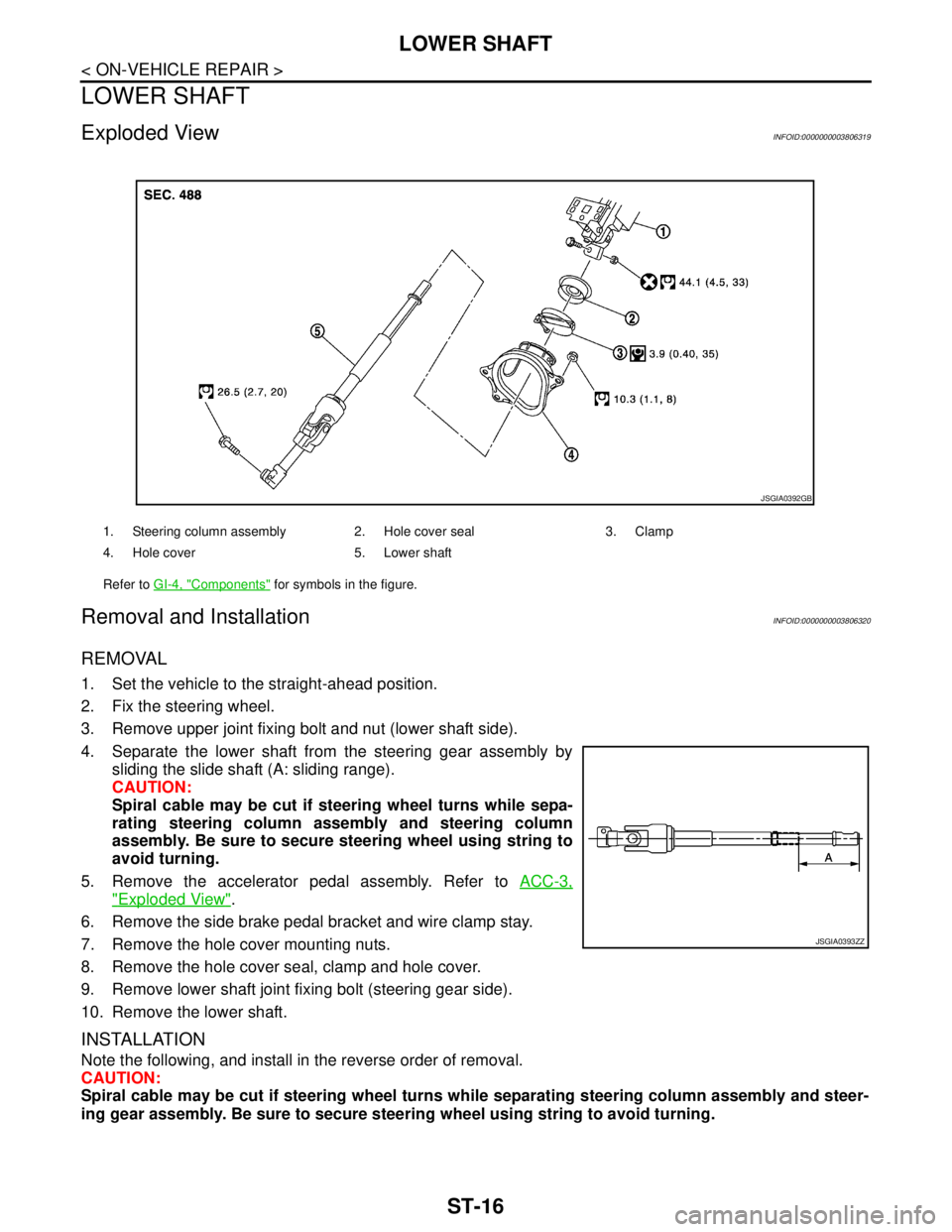

Exploded ViewINFOID:0000000003806319

Removal and InstallationINFOID:0000000003806320

REMOVAL

1. Set the vehicle to the straight-ahead position.

2. Fix the steering wheel.

3. Remove upper joint fixing bolt and nut (lower shaft side).

4. Separate the lower shaft from the steering gear assembly by

sliding the slide shaft (A: sliding range).

CAUTION:

Spiral cable may be cut if steering wheel turns while sepa-

rating steering column assembly and steering column

assembly. Be sure to secure steering wheel using string to

avoid turning.

5. Remove the accelerator pedal assembly. Refer to ACC-3,

"Exploded View".

6. Remove the side brake pedal bracket and wire clamp stay.

7. Remove the hole cover mounting nuts.

8. Remove the hole cover seal, clamp and hole cover.

9. Remove lower shaft joint fixing bolt (steering gear side).

10. Remove the lower shaft.

INSTALLATION

Note the following, and install in the reverse order of removal.

CAUTION:

Spiral cable may be cut if steering wheel turns while separating steering column assembly and steer-

ing gear assembly. Be sure to secure steering wheel using string to avoid turning.

1. Steering column assembly 2. Hole cover seal 3. Clamp

4. Hole cover 5. Lower shaft

Refer to GI-4, "

Components" for symbols in the figure.

JSGIA0392GB

JSGIA0393ZZ

Page 4407 of 5121

LOWER SHAFT

ST-17

< ON-VEHICLE REPAIR >

C

D

E

F

H

I

J

K

L

MA

B

ST

N

O

P

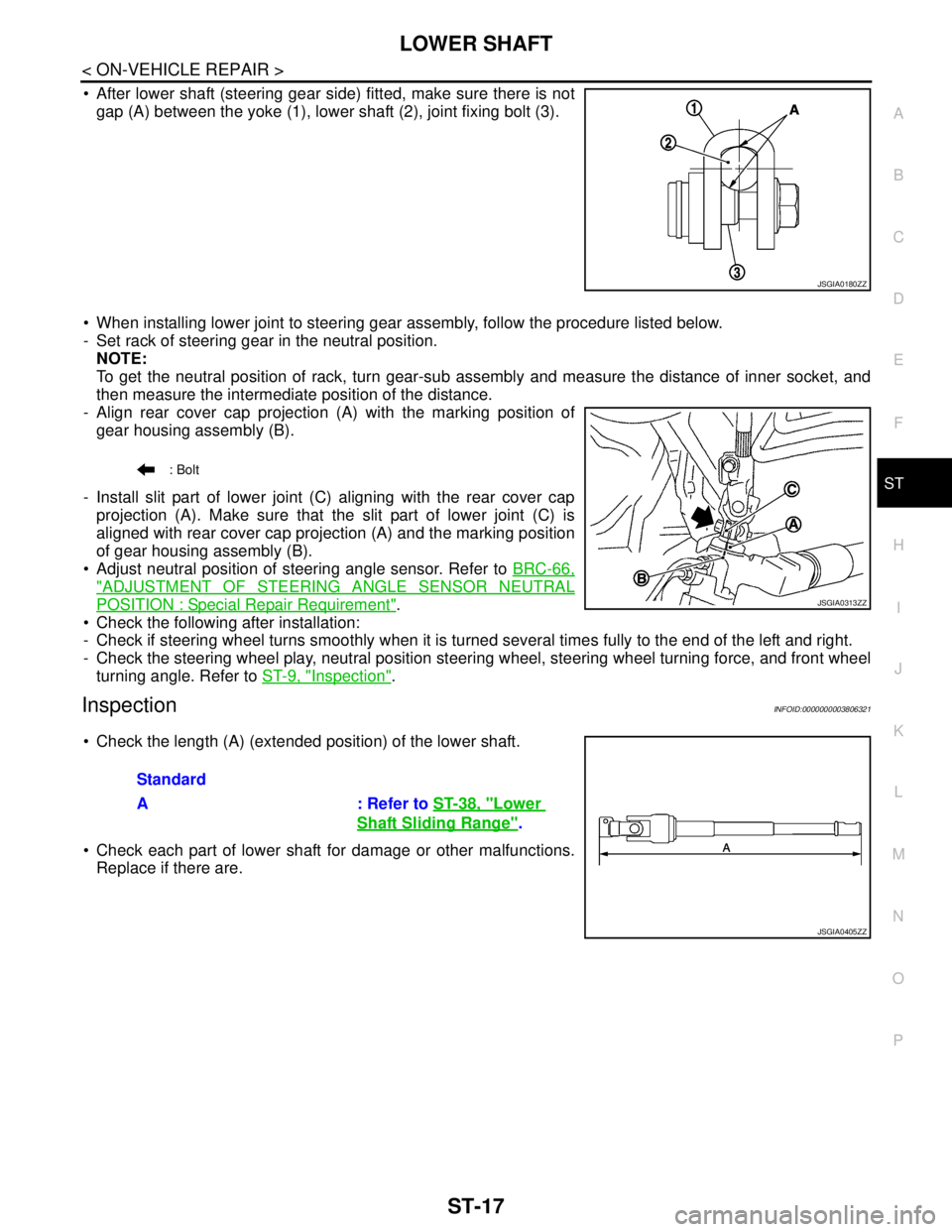

After lower shaft (steering gear side) fitted, make sure there is not

gap (A) between the yoke (1), lower shaft (2), joint fixing bolt (3).

When installing lower joint to steering gear assembly, follow the procedure listed below.

- Set rack of steering gear in the neutral position.

NOTE:

To get the neutral position of rack, turn gear-sub assembly and measure the distance of inner socket, and

then measure the intermediate position of the distance.

- Align rear cover cap projection (A) with the marking position of

gear housing assembly (B).

- Install slit part of lower joint (C) aligning with the rear cover cap

projection (A). Make sure that the slit part of lower joint (C) is

aligned with rear cover cap projection (A) and the marking position

of gear housing assembly (B).

Adjust neutral position of steering angle sensor. Refer to BRC-66,

"ADJUSTMENT OF STEERING ANGLE SENSOR NEUTRAL

POSITION : Special Repair Requirement".

Check the following after installation:

- Check if steering wheel turns smoothly when it is turned several times fully to the end of the left and right.

- Check the steering wheel play, neutral position steering wheel, steering wheel turning force, and front wheel

turning angle. Refer to ST-9, "

Inspection".

InspectionINFOID:0000000003806321

Check the length (A) (extended position) of the lower shaft.

Check each part of lower shaft for damage or other malfunctions.

Replace if there are.

JSGIA0180ZZ

: Bolt

JSGIA0313ZZ

Standard

A : Refer to ST-38, "

Lower

Shaft Sliding Range".

JSGIA0405ZZ

Page 4409 of 5121

STEERING GEAR AND LINKAGE

ST-19

< ON-VEHICLE REPAIR >

C

D

E

F

H

I

J

K

L

MA

B

ST

N

O

P

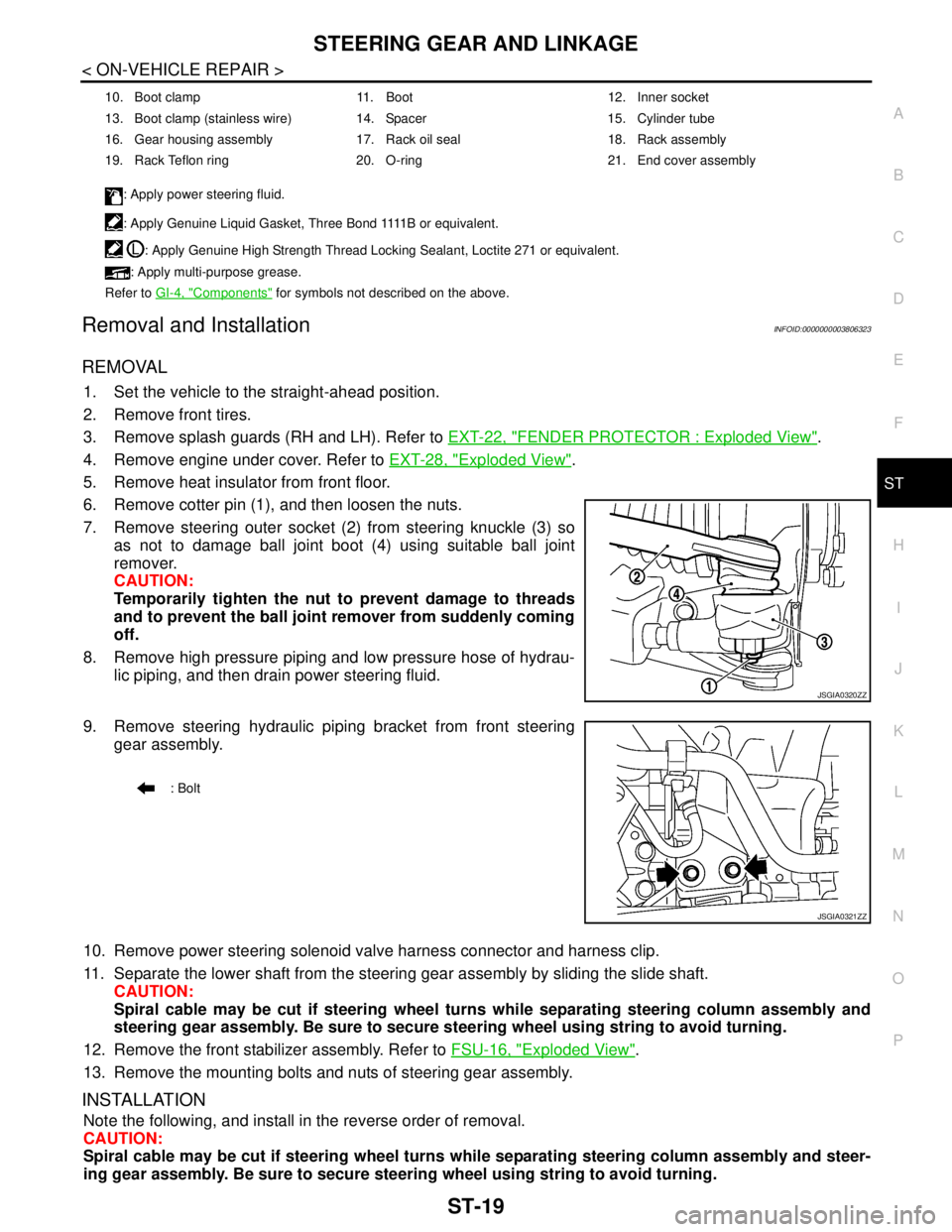

Removal and InstallationINFOID:0000000003806323

REMOVAL

1. Set the vehicle to the straight-ahead position.

2. Remove front tires.

3. Remove splash guards (RH and LH). Refer to EXT-22, "

FENDER PROTECTOR : Exploded View".

4. Remove engine under cover. Refer to EXT-28, "

Exploded View".

5. Remove heat insulator from front floor.

6. Remove cotter pin (1), and then loosen the nuts.

7. Remove steering outer socket (2) from steering knuckle (3) so

as not to damage ball joint boot (4) using suitable ball joint

remover.

CAUTION:

Temporarily tighten the nut to prevent damage to threads

and to prevent the ball joint remover from suddenly coming

off.

8. Remove high pressure piping and low pressure hose of hydrau-

lic piping, and then drain power steering fluid.

9. Remove steering hydraulic piping bracket from front steering

gear assembly.

10. Remove power steering solenoid valve harness connector and harness clip.

11. Separate the lower shaft from the steering gear assembly by sliding the slide shaft.

CAUTION:

Spiral cable may be cut if steering wheel turns while separating steering column assembly and

steering gear assembly. Be sure to secure steering wheel using string to avoid turning.

12. Remove the front stabilizer assembly. Refer to FSU-16, "

Exploded View".

13. Remove the mounting bolts and nuts of steering gear assembly.

INSTALLATION

Note the following, and install in the reverse order of removal.

CAUTION:

Spiral cable may be cut if steering wheel turns while separating steering column assembly and steer-

ing gear assembly. Be sure to secure steering wheel using string to avoid turning.

10. Boot clamp 11. Boot 12. Inner socket

13. Boot clamp (stainless wire) 14. Spacer 15. Cylinder tube

16. Gear housing assembly 17. Rack oil seal 18. Rack assembly

19. Rack Teflon ring 20. O-ring 21. End cover assembly

: Apply power steering fluid.

: A p p l y G e n u i n e L i q u i d G a s k e t , T h r e e B o n d 1111 B o r e q u i v a l e n t .

: Apply Genuine High Strength Thread Locking Sealant, Loctite 271 or equivalent.

: Apply multi-purpose grease.

Refer to GI-4, "

Components" for symbols not described on the above.

JSGIA0320ZZ

: Bolt

JSGIA0321ZZ

Page 4416 of 5121

ST-26

< ON-VEHICLE REPAIR >

STEERING GEAR AND LINKAGE

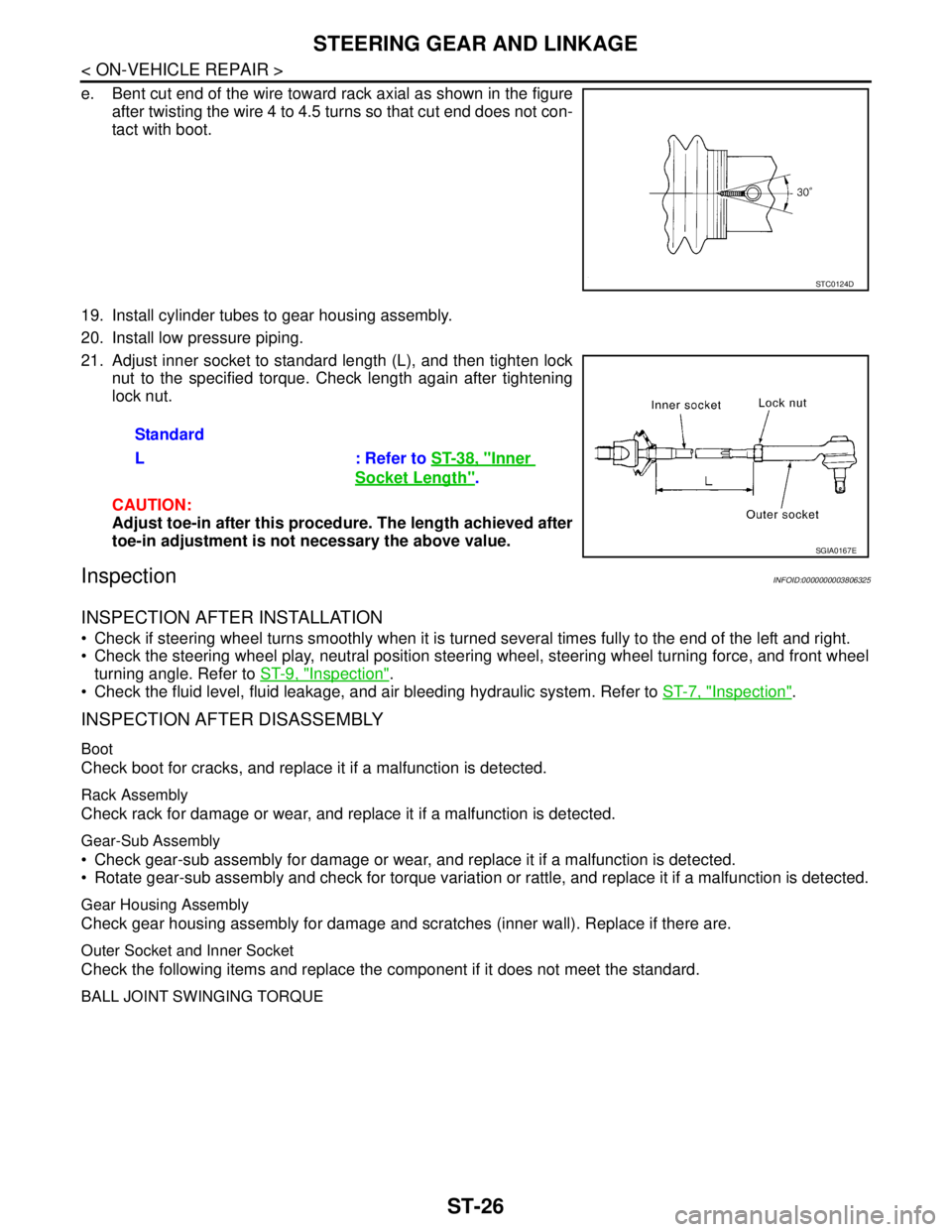

e. Bent cut end of the wire toward rack axial as shown in the figure

after twisting the wire 4 to 4.5 turns so that cut end does not con-

tact with boot.

19. Install cylinder tubes to gear housing assembly.

20. Install low pressure piping.

21. Adjust inner socket to standard length (L), and then tighten lock

nut to the specified torque. Check length again after tightening

lock nut.

CAUTION:

Adjust toe-in after this procedure. The length achieved after

toe-in adjustment is not necessary the above value.

InspectionINFOID:0000000003806325

INSPECTION AFTER INSTALLATION

Check if steering wheel turns smoothly when it is turned several times fully to the end of the left and right.

Check the steering wheel play, neutral position steering wheel, steering wheel turning force, and front wheel

turning angle. Refer to ST-9, "

Inspection".

Check the fluid level, fluid leakage, and air bleeding hydraulic system. Refer to ST-7, "

Inspection".

INSPECTION AFTER DISASSEMBLY

Boot

Check boot for cracks, and replace it if a malfunction is detected.

Rack Assembly

Check rack for damage or wear, and replace it if a malfunction is detected.

Gear-Sub Assembly

Check gear-sub assembly for damage or wear, and replace it if a malfunction is detected.

Rotate gear-sub assembly and check for torque variation or rattle, and replace it if a malfunction is detected.

Gear Housing Assembly

Check gear housing assembly for damage and scratches (inner wall). Replace if there are.

Outer Socket and Inner Socket

Check the following items and replace the component if it does not meet the standard.

BALL JOINT SWINGING TORQUE

STC0124D

Standard

L : Refer to ST-38, "

Inner

Socket Length".

SGIA0167E

Page 4419 of 5121

POWER STEERING OIL PUMP

ST-29

< ON-VEHICLE REPAIR >

C

D

E

F

H

I

J

K

L

MA

B

ST

N

O

P

Removal and InstallationINFOID:0000000003806327

REMOVAL

1. Drain power steering fluid from reservoir tank.

2. Remove front tires.

3. Remove splash guard. Refer to EXT-22, "

FENDER PROTECTOR : Exploded View".

4. Loosen drive belt. Refer to EM-12, "

Removal and Installation".

5. Remove drive belt from oil pump pulley.

6. Remove copper washers and eye bolt (drain fluid from their pipings).

7. Remove suction hose (drain fluid from their pipings).

8. Remove oil pump mounting bolts, and then remove oil pump.

CAUTION:

Never damage drive shaft boot.

INSTALLATION

Note the following, and install in the reverse order of removal.

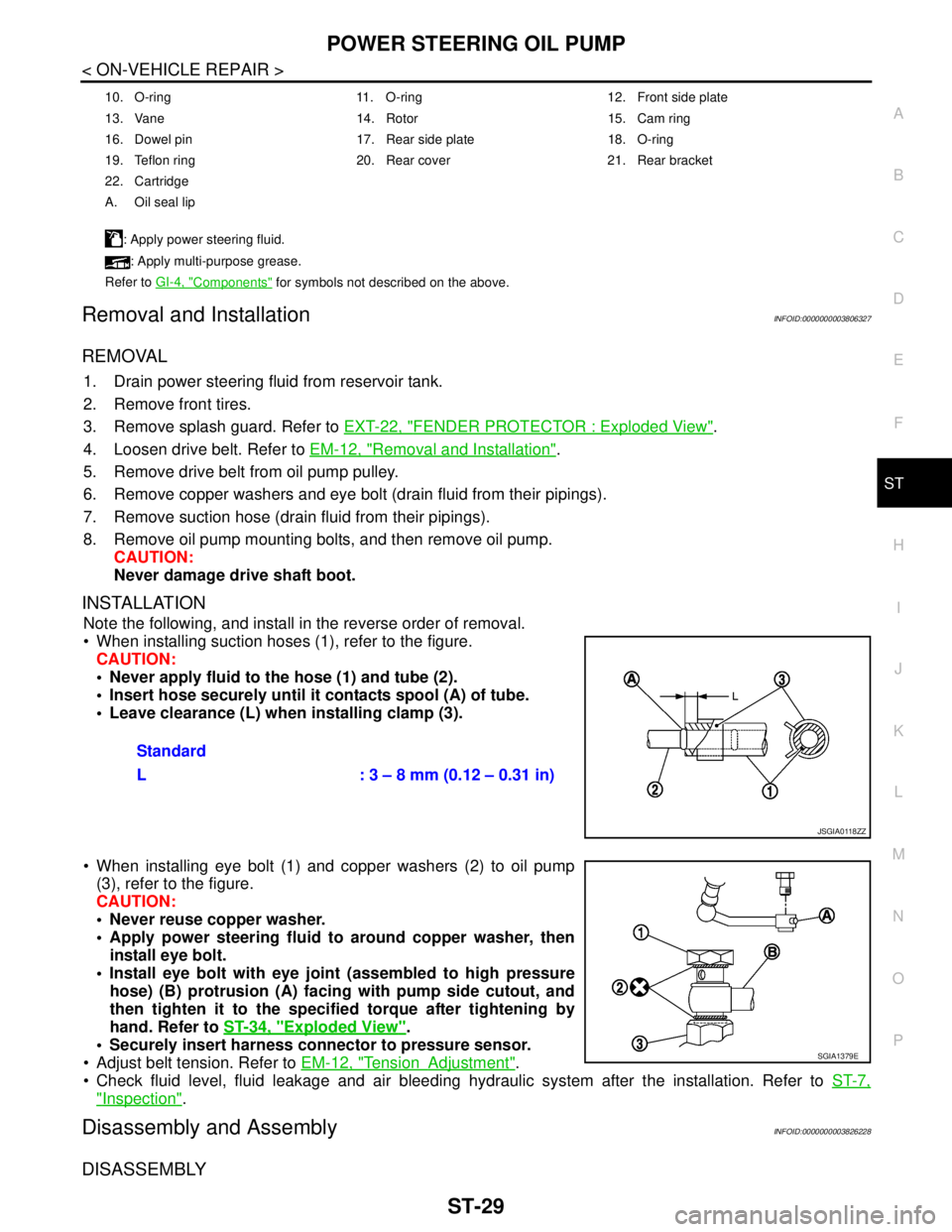

When installing suction hoses (1), refer to the figure.

CAUTION:

Never apply fluid to the hose (1) and tube (2).

Insert hose securely until it contacts spool (A) of tube.

Leave clearance (L) when installing clamp (3).

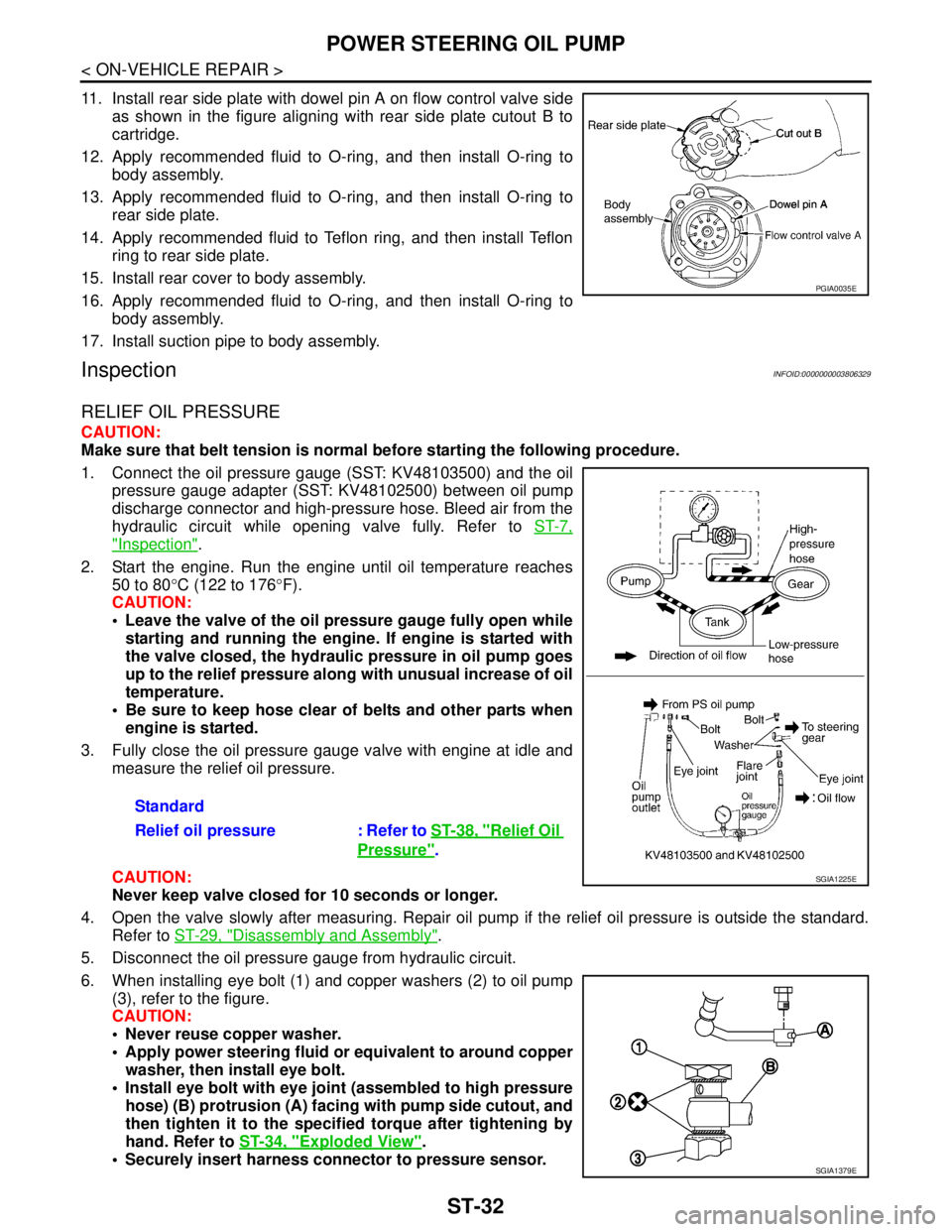

When installing eye bolt (1) and copper washers (2) to oil pump

(3), refer to the figure.

CAUTION:

Never reuse copper washer.

Apply power steering fluid to around copper washer, then

install eye bolt.

Install eye bolt with eye joint (assembled to high pressure

hose) (B) protrusion (A) facing with pump side cutout, and

then tighten it to the specified torque after tightening by

hand. Refer to ST-34, "

Exploded View".

Securely insert harness connector to pressure sensor.

Adjust belt tension. Refer to EM-12, "

TensionAdjustment".

Check fluid level, fluid leakage and air bleeding hydraulic system after the installation. Refer to ST-7,

"Inspection".

Disassembly and AssemblyINFOID:0000000003826228

DISASSEMBLY

10. O-ring 11. O-ring 12. Front side plate

13. Vane 14. Rotor 15. Cam ring

16. Dowel pin 17. Rear side plate 18. O-ring

19. Teflon ring 20. Rear cover 21. Rear bracket

22. Cartridge

A. Oil seal lip

: Apply power steering fluid.

: Apply multi-purpose grease.

Refer to GI-4, "

Components" for symbols not described on the above.

Standard

L : 3 – 8 mm (0.12 – 0.31 in)

JSGIA0118ZZ

SGIA1379E

Page 4422 of 5121

ST-32

< ON-VEHICLE REPAIR >

POWER STEERING OIL PUMP

11. Install rear side plate with dowel pin A on flow control valve side

as shown in the figure aligning with rear side plate cutout B to

cartridge.

12. Apply recommended fluid to O-ring, and then install O-ring to

body assembly.

13. Apply recommended fluid to O-ring, and then install O-ring to

rear side plate.

14. Apply recommended fluid to Teflon ring, and then install Teflon

ring to rear side plate.

15. Install rear cover to body assembly.

16. Apply recommended fluid to O-ring, and then install O-ring to

body assembly.

17. Install suction pipe to body assembly.

InspectionINFOID:0000000003806329

RELIEF OIL PRESSURE

CAUTION:

Make sure that belt tension is normal before starting the following procedure.

1. Connect the oil pressure gauge (SST: KV48103500) and the oil

pressure gauge adapter (SST: KV48102500) between oil pump

discharge connector and high-pressure hose. Bleed air from the

hydraulic circuit while opening valve fully. Refer to ST-7,

"Inspection".

2. Start the engine. Run the engine until oil temperature reaches

50 to 80°C (122 to 176°F).

CAUTION:

Leave the valve of the oil pressure gauge fully open while

starting and running the engine. If engine is started with

the valve closed, the hydraulic pressure in oil pump goes

up to the relief pressure along with unusual increase of oil

temperature.

Be sure to keep hose clear of belts and other parts when

engine is started.

3. Fully close the oil pressure gauge valve with engine at idle and

measure the relief oil pressure.

CAUTION:

Never keep valve closed for 10 seconds or longer.

4. Open the valve slowly after measuring. Repair oil pump if the relief oil pressure is outside the standard.

Refer to ST-29, "

Disassembly and Assembly".

5. Disconnect the oil pressure gauge from hydraulic circuit.

6. When installing eye bolt (1) and copper washers (2) to oil pump

(3), refer to the figure.

CAUTION:

Never reuse copper washer.

Apply power steering fluid or equivalent to around copper

washer, then install eye bolt.

Install eye bolt with eye joint (assembled to high pressure

hose) (B) protrusion (A) facing with pump side cutout, and

then tighten it to the specified torque after tightening by

hand. Refer to ST-34, "

Exploded View".

Securely insert harness connector to pressure sensor.

PGIA0035E

Standard

Relief oil pressure : Refer to ST-38, "

Relief Oil

Pressure".

SGIA1225E

SGIA1379E