ABS NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 3122 of 5121

![NISSAN TEANA 2008 Service Manual LAN

ABS BRANCH LINE CIRCUIT

LAN-55

< COMPONENT DIAGNOSIS >[CAN SYSTEM (TYPE 2)]

C

D

E

F

G

H

I

J

K

L B A

O

P N

ABS BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000003841877

1.CHECK CONNECTOR

1. Tu NISSAN TEANA 2008 Service Manual LAN

ABS BRANCH LINE CIRCUIT

LAN-55

< COMPONENT DIAGNOSIS >[CAN SYSTEM (TYPE 2)]

C

D

E

F

G

H

I

J

K

L B A

O

P N

ABS BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000003841877

1.CHECK CONNECTOR

1. Tu](/img/5/57391/w960_57391-3121.png)

LAN

ABS BRANCH LINE CIRCUIT

LAN-55

< COMPONENT DIAGNOSIS >[CAN SYSTEM (TYPE 2)]

C

D

E

F

G

H

I

J

K

L B A

O

P N

ABS BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000003841877

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the terminals and connectors of the ABS actuator and electric unit (control unit) for damage, bend

and loose connection (unit side and connector side).

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair the terminal and connector.

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of ABS actuator and electric unit (control unit).

2. Check the resistance between the ABS actuator and electric unit (control unit) harness connector termi-

nals.

- Models with ABS

- Models with VDC

Is the measurement value within the specification?

YES >> GO TO 3.

NO >> Repair the ABS actuator and electric unit (control unit) branch line.

3.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the ABS actuator and electric unit (control unit). Refer to the

following.

Models with ABS: BRC-22, "

Diagnosis Procedure"

Models with VDC: BRC-91, "Diagnosis Procedure"

Is the inspection result normal?

YES (Present error)>>Replace the ABS actuator and electric unit (control unit).

Models with ABS: BRC-60, "

Exploded View"

Models with VDC: BRC-154, "Exploded View"

YES (Past error)>>Error was detected in the ABS actuator and electric unit (control unit) branch line.

NO >> Repair the power supply and the ground circuit.

ABS actuator and electric unit (control unit) harness connector

Resistance (Ω)

Connector No. Terminal No.

E34 26 15 Approx. 54 – 66

ABS actuator and electric unit (control unit) harness connector

Resistance (Ω)

Connector No. Terminal No.

E36 26 15 Approx. 54 – 66

Page 3128 of 5121

![NISSAN TEANA 2008 Service Manual LAN

MAIN LINE BETWEEN BCM AND ABS CIRCUITLAN-61

< COMPONENT DIAGNOSIS > [CAN SYSTEM (TYPE 4)]

C

D

E

F

G H

I

J

K L

B A

O P

N

MAIN LINE BETWEEN

BCM AND ABS CIRCUIT

Diagnosis ProcedureINFOID:00000000044 NISSAN TEANA 2008 Service Manual LAN

MAIN LINE BETWEEN BCM AND ABS CIRCUITLAN-61

< COMPONENT DIAGNOSIS > [CAN SYSTEM (TYPE 4)]

C

D

E

F

G H

I

J

K L

B A

O P

N

MAIN LINE BETWEEN

BCM AND ABS CIRCUIT

Diagnosis ProcedureINFOID:00000000044](/img/5/57391/w960_57391-3127.png)

LAN

MAIN LINE BETWEEN BCM AND ABS CIRCUITLAN-61

< COMPONENT DIAGNOSIS > [CAN SYSTEM (TYPE 4)]

C

D

E

F

G H

I

J

K L

B A

O P

N

MAIN LINE BETWEEN

BCM AND ABS CIRCUIT

Diagnosis ProcedureINFOID:0000000004459800

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cabl e from the negative terminal.

3. Check the following terminals and connectors for damage, bend and loose connection (connector side

and harness side).

- Harness connector M11

- Harness connector E105

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair the terminal and connector.

2.CHECK HARNESS CONTI NUITY (OPEN CIRCUIT)

1. Disconnect the following harness connectors.

-BCM

- Harness connectors M11 and E105

2. Check the continuity between the BC M harness connector and the harness connector.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair the main line between the BCM and the harness connector M11.

3.CHECK HARNESS CONTI NUITY (OPEN CIRCUIT)

1. Disconnect the connector of ABS actuat or and electric unit (control unit).

2. Check the continuity between the harness connector and the ABS actuator and electric unit (control unit)

harness connector.

- Models with ABS

- Models with VDC

Is the inspection result normal?

YES (Present error)>>Check CA N system type decision again.

YES (Past error)>>Error was detected in the main line between the BCM and the ABS actuator and electric

unit (control unit).

NO >> Repair the main line between the harness connec tor E105 and the ABS actuator and electric unit

(control unit).

BCM harness connector Harness connector Continuity

Connector No. Terminal No. Connector No. Terminal No.

M122 91

M11 12 Existed

90 11 Existed

Harness connector ABS actuator and electric unit (control unit)

harness connector Continuity

Connector No. Terminal No. Connector No. Terminal No.

E105 12

E34 26 Existed

11 1 5 E x i s t e d

Harness connector ABS actuator and electric unit (control unit)

harness connector Continuity

Connector No. Terminal No. Connector No. Terminal No.

E105 12

E36 26 Existed

11 1 5 E x i s t e d

Page 3136 of 5121

![NISSAN TEANA 2008 Service Manual LAN

ABS BRANCH LINE CIRCUIT

LAN-69

< COMPONENT DIAGNOSIS >[CAN SYSTEM (TYPE 4)]

C

D

E

F

G

H

I

J

K

L B A

O

P N

ABS BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000003841857

1.CHECK CONNECTOR

1. Tu NISSAN TEANA 2008 Service Manual LAN

ABS BRANCH LINE CIRCUIT

LAN-69

< COMPONENT DIAGNOSIS >[CAN SYSTEM (TYPE 4)]

C

D

E

F

G

H

I

J

K

L B A

O

P N

ABS BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000003841857

1.CHECK CONNECTOR

1. Tu](/img/5/57391/w960_57391-3135.png)

LAN

ABS BRANCH LINE CIRCUIT

LAN-69

< COMPONENT DIAGNOSIS >[CAN SYSTEM (TYPE 4)]

C

D

E

F

G

H

I

J

K

L B A

O

P N

ABS BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000003841857

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the terminals and connectors of the ABS actuator and electric unit (control unit) for damage, bend

and loose connection (unit side and connector side).

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair the terminal and connector.

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of ABS actuator and electric unit (control unit).

2. Check the resistance between the ABS actuator and electric unit (control unit) harness connector termi-

nals.

- Models with ABS

- Models with VDC

Is the measurement value within the specification?

YES >> GO TO 3.

NO >> Repair the ABS actuator and electric unit (control unit) branch line.

3.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the ABS actuator and electric unit (control unit). Refer to the

following.

Models with ABS: BRC-22, "

Diagnosis Procedure"

Models with VDC: BRC-91, "Diagnosis Procedure"

Is the inspection result normal?

YES (Present error)>>Replace the ABS actuator and electric unit (control unit).

Models with ABS: BRC-60, "

Exploded View"

Models with VDC: BRC-154, "Exploded View"

YES (Past error)>>Error was detected in the ABS actuator and electric unit (control unit) branch line.

NO >> Repair the power supply and the ground circuit.

ABS actuator and electric unit (control unit) harness connector

Resistance (Ω)

Connector No. Terminal No.

E34 26 15 Approx. 54 – 66

ABS actuator and electric unit (control unit) harness connector

Resistance (Ω)

Connector No. Terminal No.

E36 26 15 Approx. 54 – 66

Page 3143 of 5121

![NISSAN TEANA 2008 Service Manual LAN-76

< COMPONENT DIAGNOSIS >[CAN SYSTEM (TYPE 6)]

MAIN LINE BETWEEN BCM AND ABS CIRCUIT

MAIN LINE BETWEEN BCM AND ABS CIRCUIT

Diagnosis ProcedureINFOID:0000000004459803

1.CHECK CONNECTOR

1. Turn the NISSAN TEANA 2008 Service Manual LAN-76

< COMPONENT DIAGNOSIS >[CAN SYSTEM (TYPE 6)]

MAIN LINE BETWEEN BCM AND ABS CIRCUIT

MAIN LINE BETWEEN BCM AND ABS CIRCUIT

Diagnosis ProcedureINFOID:0000000004459803

1.CHECK CONNECTOR

1. Turn the](/img/5/57391/w960_57391-3142.png)

LAN-76

< COMPONENT DIAGNOSIS >[CAN SYSTEM (TYPE 6)]

MAIN LINE BETWEEN BCM AND ABS CIRCUIT

MAIN LINE BETWEEN BCM AND ABS CIRCUIT

Diagnosis ProcedureINFOID:0000000004459803

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the following terminals and connectors for damage, bend and loose connection (connector side and harness side).

- Harness connector M11

- Harness connector E105

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair the terminal and connector.

2.CHECK HARNESS CONTI NUITY (OPEN CIRCUIT)

1. Disconnect the following harness connectors.

-BCM

- Harness connectors M11 and E105

2. Check the continuity between the BC M harness connector and the harness connector.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair the main line between the BCM and the harness connector M11.

3.CHECK HARNESS CONTI NUITY (OPEN CIRCUIT)

1. Disconnect the connector of ABS actuat or and electric unit (control unit).

2. Check the continuity between the harness connector and the ABS actuator and electric unit (control unit)

harness connector.

- Models with ABS

- Models with VDC

Is the inspection result normal?

YES (Present error)>>Check CAN system type decision again.

YES (Past error)>>Error was detected in the main line between the BCM and the ABS actuator and electric

unit (control unit).

NO >> Repair the main line between the harness connec tor E105 and the ABS actuator and electric unit

(control unit).

BCM harness connector Harness connector Continuity

Connector No. Terminal No. Connector No. Terminal No.

M122 91

M11 12 Existed

90 11 Existed

Harness connector ABS actuator and electric unit (control unit)

harness connector Continuity

Connector No. Terminal No. Connector No. Terminal No.

E105 12

E34 26 Existed

11 1 5 E x i s t e d

Harness connector ABS actuator and electric unit (control unit)

harness connector Continuity

Connector No. Terminal No. Connector No. Terminal No.

E105 12

E36 26 Existed

11 1 5 E x i s t e d

Page 3152 of 5121

![NISSAN TEANA 2008 Service Manual LAN

ABS BRANCH LINE CIRCUIT

LAN-85

< COMPONENT DIAGNOSIS >[CAN SYSTEM (TYPE 6)]

C

D

E

F

G

H

I

J

K

L B A

O

P N

ABS BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000003841837

1.CHECK CONNECTOR

1. Tu NISSAN TEANA 2008 Service Manual LAN

ABS BRANCH LINE CIRCUIT

LAN-85

< COMPONENT DIAGNOSIS >[CAN SYSTEM (TYPE 6)]

C

D

E

F

G

H

I

J

K

L B A

O

P N

ABS BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000003841837

1.CHECK CONNECTOR

1. Tu](/img/5/57391/w960_57391-3151.png)

LAN

ABS BRANCH LINE CIRCUIT

LAN-85

< COMPONENT DIAGNOSIS >[CAN SYSTEM (TYPE 6)]

C

D

E

F

G

H

I

J

K

L B A

O

P N

ABS BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000003841837

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the terminals and connectors of the ABS actuator and electric unit (control unit) for damage, bend

and loose connection (unit side and connector side).

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair the terminal and connector.

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of ABS actuator and electric unit (control unit).

2. Check the resistance between the ABS actuator and electric unit (control unit) harness connector termi-

nals.

- Models with ABS

- Models with VDC

Is the measurement value within the specification?

YES >> GO TO 3.

NO >> Repair the ABS actuator and electric unit (control unit) branch line.

3.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the ABS actuator and electric unit (control unit). Refer to the

following.

Models with ABS: BRC-22, "

Diagnosis Procedure"

Models with VDC: BRC-91, "Diagnosis Procedure"

Is the inspection result normal?

YES (Present error)>>Replace the ABS actuator and electric unit (control unit).

Models with ABS: BRC-60, "

Exploded View"

Models with VDC: BRC-154, "Exploded View"

YES (Past error)>>Error was detected in the ABS actuator and electric unit (control unit) branch line.

NO >> Repair the power supply and the ground circuit.

ABS actuator and electric unit (control unit) harness connector

Resistance (Ω)

Connector No. Terminal No.

E34 26 15 Approx. 54 – 66

ABS actuator and electric unit (control unit) harness connector

Resistance (Ω)

Connector No. Terminal No.

E36 26 15 Approx. 54 – 66

Page 3159 of 5121

![NISSAN TEANA 2008 Service Manual LAN-92

< COMPONENT DIAGNOSIS >[CAN SYSTEM (TYPE 9)]

MAIN LINE BETWEEN BCM AND ABS CIRCUIT

MAIN LINE BETWEEN BCM AND ABS CIRCUIT

Diagnosis ProcedureINFOID:0000000004459806

1.CHECK CONNECTOR

1. Turn the NISSAN TEANA 2008 Service Manual LAN-92

< COMPONENT DIAGNOSIS >[CAN SYSTEM (TYPE 9)]

MAIN LINE BETWEEN BCM AND ABS CIRCUIT

MAIN LINE BETWEEN BCM AND ABS CIRCUIT

Diagnosis ProcedureINFOID:0000000004459806

1.CHECK CONNECTOR

1. Turn the](/img/5/57391/w960_57391-3158.png)

LAN-92

< COMPONENT DIAGNOSIS >[CAN SYSTEM (TYPE 9)]

MAIN LINE BETWEEN BCM AND ABS CIRCUIT

MAIN LINE BETWEEN BCM AND ABS CIRCUIT

Diagnosis ProcedureINFOID:0000000004459806

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the following terminals and connectors for damage, bend and loose connection (connector side and harness side).

- Harness connector M11

- Harness connector E105

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair the terminal and connector.

2.CHECK HARNESS CONTI NUITY (OPEN CIRCUIT)

1. Disconnect the following harness connectors.

-BCM

- Harness connectors M11 and E105

2. Check the continuity between the BC M harness connector and the harness connector.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair the main line between the BCM and the harness connector M11.

3.CHECK HARNESS CONTI NUITY (OPEN CIRCUIT)

1. Disconnect the connector of ABS actuat or and electric unit (control unit).

2. Check the continuity between the harness connector and the ABS actuator and electric unit (control unit)

harness connector.

- Models with ABS

- Models with VDC

Is the inspection result normal?

YES (Present error)>>Check CAN system type decision again.

YES (Past error)>>Error was detected in the main line between the BCM and the ABS actuator and electric

unit (control unit).

NO >> Repair the main line between the harness connec tor E105 and the ABS actuator and electric unit

(control unit).

BCM harness connector Harness connector Continuity

Connector No. Terminal No. Connector No. Terminal No.

M122 91

M11 12 Existed

90 11 Existed

Harness connector ABS actuator and electric unit (control unit)

harness connector Continuity

Connector No. Terminal No. Connector No. Terminal No.

E105 12

E34 26 Existed

11 1 5 E x i s t e d

Harness connector ABS actuator and electric unit (control unit)

harness connector Continuity

Connector No. Terminal No. Connector No. Terminal No.

E105 12

E36 26 Existed

11 1 5 E x i s t e d

Page 3168 of 5121

![NISSAN TEANA 2008 Service Manual LAN

ABS BRANCH LINE CIRCUIT

LAN-101

< COMPONENT DIAGNOSIS >[CAN SYSTEM (TYPE 9)]

C

D

E

F

G

H

I

J

K

L B A

O

P N

ABS BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000003841817

1.CHECK CONNECTOR

1. T NISSAN TEANA 2008 Service Manual LAN

ABS BRANCH LINE CIRCUIT

LAN-101

< COMPONENT DIAGNOSIS >[CAN SYSTEM (TYPE 9)]

C

D

E

F

G

H

I

J

K

L B A

O

P N

ABS BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000003841817

1.CHECK CONNECTOR

1. T](/img/5/57391/w960_57391-3167.png)

LAN

ABS BRANCH LINE CIRCUIT

LAN-101

< COMPONENT DIAGNOSIS >[CAN SYSTEM (TYPE 9)]

C

D

E

F

G

H

I

J

K

L B A

O

P N

ABS BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000003841817

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the terminals and connectors of the ABS actuator and electric unit (control unit) for damage, bend

and loose connection (unit side and connector side).

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair the terminal and connector.

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of ABS actuator and electric unit (control unit).

2. Check the resistance between the ABS actuator and electric unit (control unit) harness connector termi-

nals.

- Models with ABS

- Models with VDC

Is the measurement value within the specification?

YES >> GO TO 3.

NO >> Repair the ABS actuator and electric unit (control unit) branch line.

3.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the ABS actuator and electric unit (control unit). Refer to the

following.

Models with ABS: BRC-22, "

Diagnosis Procedure"

Models with VDC: BRC-91, "Diagnosis Procedure"

Is the inspection result normal?

YES (Present error)>>Replace the ABS actuator and electric unit (control unit).

Models with ABS: BRC-60, "

Exploded View"

Models with VDC: BRC-154, "Exploded View"

YES (Past error)>>Error was detected in the ABS actuator and electric unit (control unit) branch line.

NO >> Repair the power supply and the ground circuit.

ABS actuator and electric unit (control unit) harness connector

Resistance (Ω)

Connector No. Terminal No.

E34 26 15 Approx. 54 – 66

ABS actuator and electric unit (control unit) harness connector

Resistance (Ω)

Connector No. Terminal No.

E36 26 15 Approx. 54 – 66

Page 3182 of 5121

LU-10

< ON-VEHICLE MAINTENANCE >

OIL FILTER

OIL FILTER

Removal and InstallationINFOID:0000000003793124

REMOVAL

CAUTION:

Oil filter is provided with relief valve. Use genuine NISSAN oil filter or equivalent.

Be careful not to get burned when engine and engine oil may be hot.

When removing, prepare a shop cloth to absorb any engine oil leakage or spillage.

Never allow engine oil to adhere to drive belt.

Completely wipe off any engine oil that adheres to engine and vehicle.

1. Remove splash guard (RH). Refer to EXT-22, "

FENDER PROTECTOR : Exploded View".

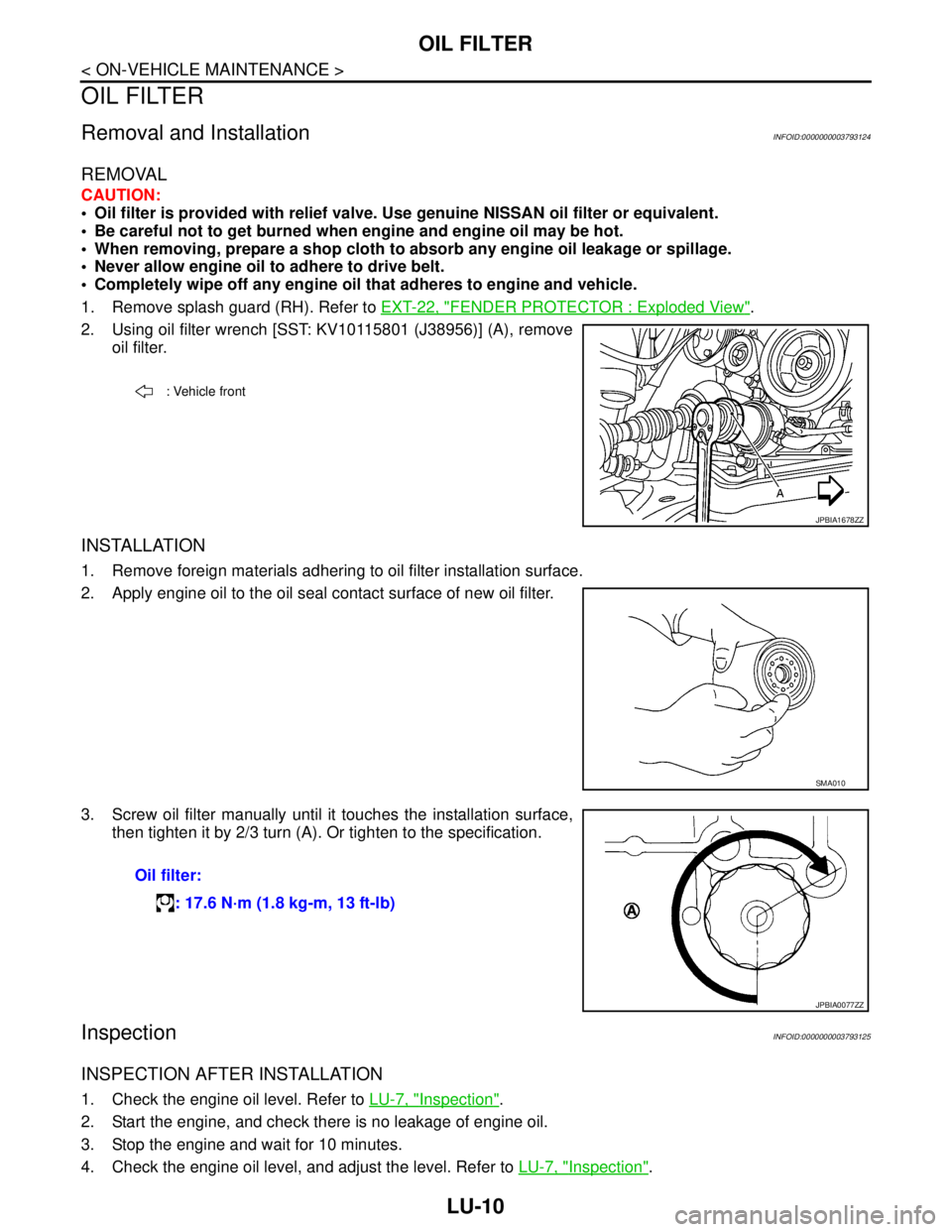

2. Using oil filter wrench [SST: KV10115801 (J38956)] (A), remove

oil filter.

INSTALLATION

1. Remove foreign materials adhering to oil filter installation surface.

2. Apply engine oil to the oil seal contact surface of new oil filter.

3. Screw oil filter manually until it touches the installation surface,

then tighten it by 2/3 turn (A). Or tighten to the specification.

InspectionINFOID:0000000003793125

INSPECTION AFTER INSTALLATION

1. Check the engine oil level. Refer to LU-7, "Inspection".

2. Start the engine, and check there is no leakage of engine oil.

3. Stop the engine and wait for 10 minutes.

4. Check the engine oil level, and adjust the level. Refer to LU-7, "

Inspection".

: Vehicle front

JPBIA1678ZZ

SMA010

Oil filter:

: 17.6 N·m (1.8 kg-m, 13 ft-lb)

JPBIA0077ZZ

Page 3207 of 5121

ENGINE MAINTENANCE

MA-19

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

MB

MAN

OA

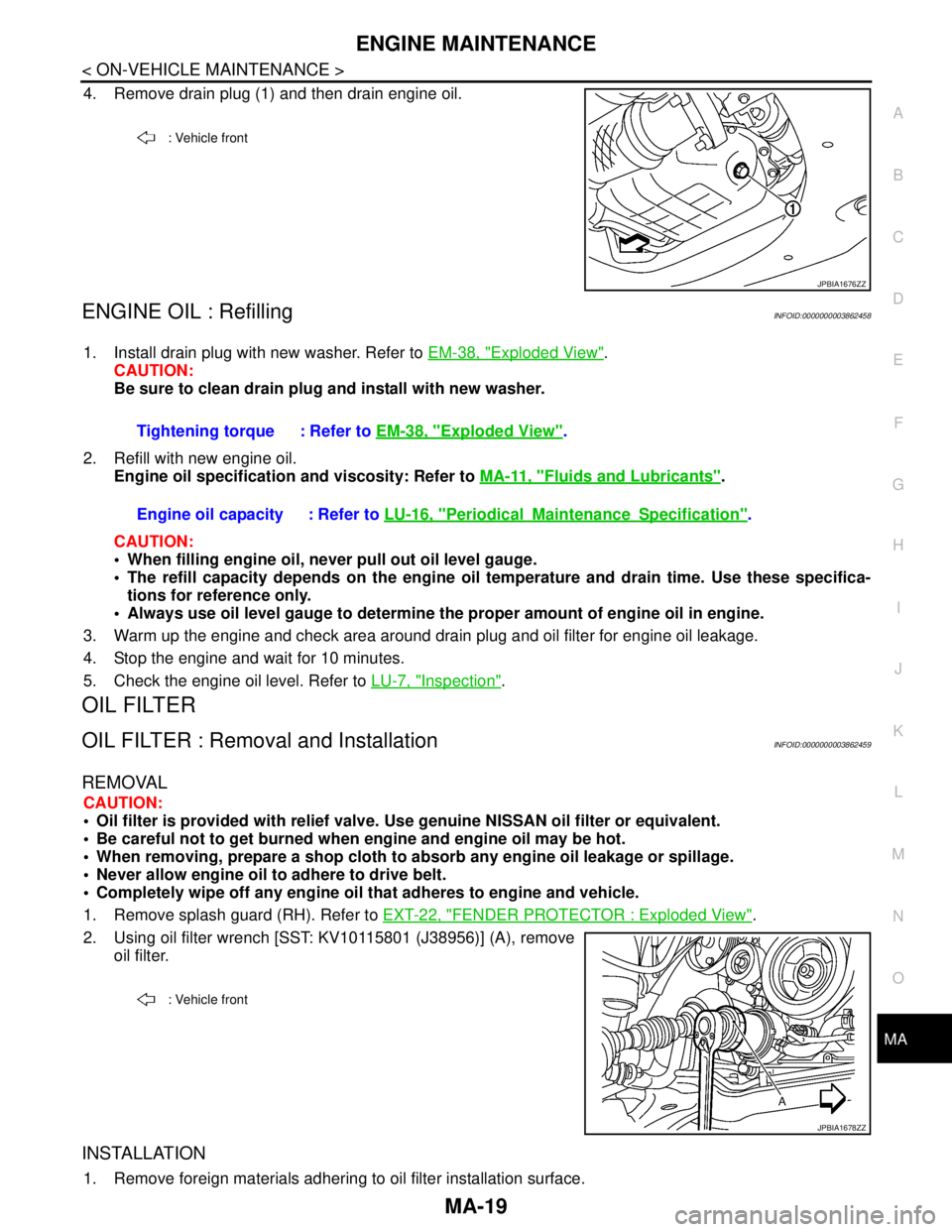

4. Remove drain plug (1) and then drain engine oil.

ENGINE OIL : RefillingINFOID:0000000003862458

1. Install drain plug with new washer. Refer to EM-38, "Exploded View".

CAUTION:

Be sure to clean drain plug and install with new washer.

2. Refill with new engine oil.

Engine oil specification and viscosity: Refer to MA-11, "

Fluids and Lubricants".

CAUTION:

When filling engine oil, never pull out oil level gauge.

The refill capacity depends on the engine oil temperature and drain time. Use these specifica-

tions for reference only.

Always use oil level gauge to determine the proper amount of engine oil in engine.

3. Warm up the engine and check area around drain plug and oil filter for engine oil leakage.

4. Stop the engine and wait for 10 minutes.

5. Check the engine oil level. Refer to LU-7, "

Inspection".

OIL FILTER

OIL FILTER : Removal and InstallationINFOID:0000000003862459

REMOVAL

CAUTION:

Oil filter is provided with relief valve. Use genuine NISSAN oil filter or equivalent.

Be careful not to get burned when engine and engine oil may be hot.

When removing, prepare a shop cloth to absorb any engine oil leakage or spillage.

Never allow engine oil to adhere to drive belt.

Completely wipe off any engine oil that adheres to engine and vehicle.

1. Remove splash guard (RH). Refer to EXT-22, "

FENDER PROTECTOR : Exploded View".

2. Using oil filter wrench [SST: KV10115801 (J38956)] (A), remove

oil filter.

INSTALLATION

1. Remove foreign materials adhering to oil filter installation surface.

: Vehicle front

JPBIA1676ZZ

Tightening torque : Refer to EM-38, "Exploded View".

Engine oil capacity : Refer to LU-16, "

PeriodicalMaintenanceSpecification".

: Vehicle front

JPBIA1678ZZ

Page 3228 of 5121

MA-40

< ON-VEHICLE MAINTENANCE >

CHASSIS MAINTENANCE

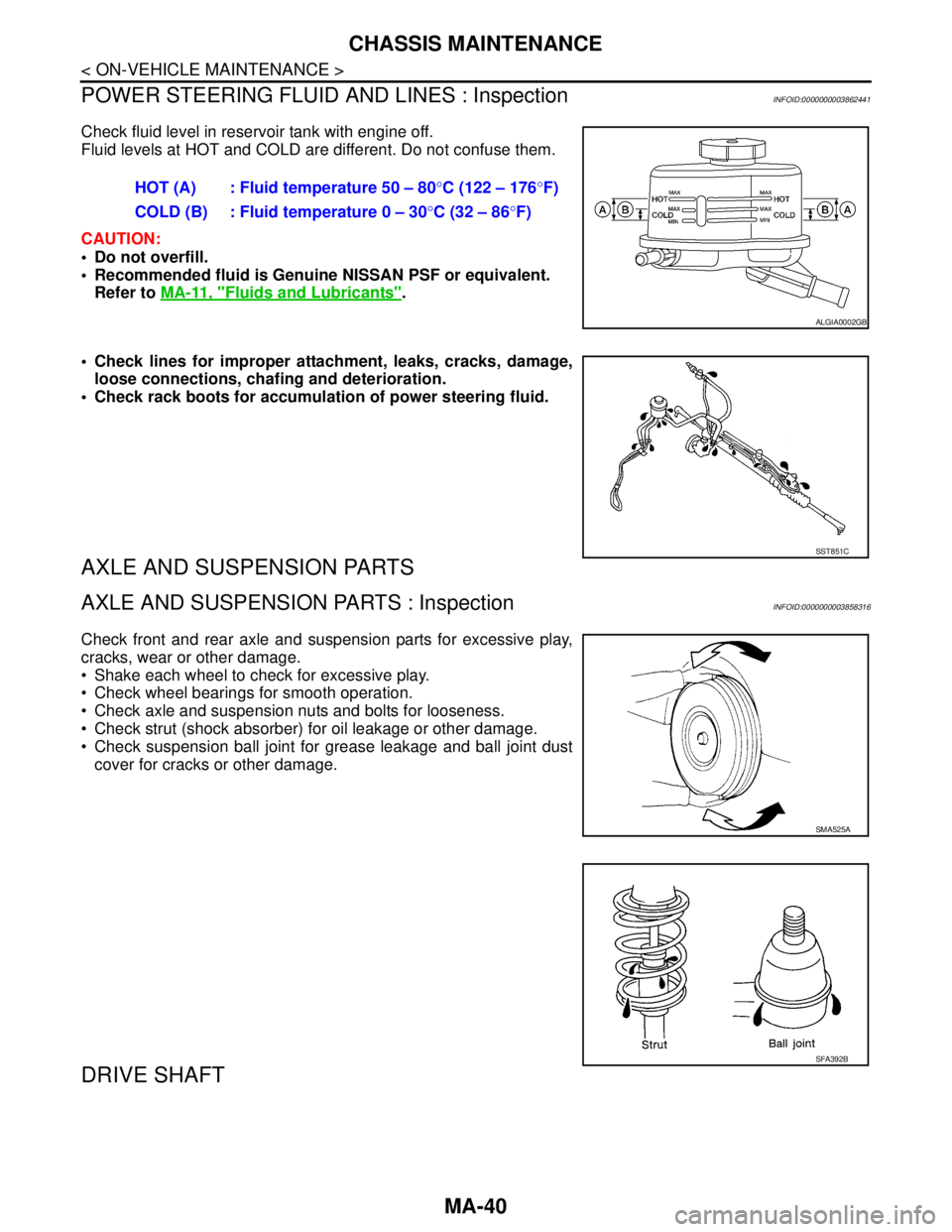

POWER STEERING FLUID AND LINES : Inspection

INFOID:0000000003862441

Check fluid level in reservoir tank with engine off.

Fluid levels at HOT and COLD are different. Do not confuse them.

CAUTION:

Do not overfill.

Recommended fluid is Genuine NISSAN PSF or equivalent.

Refer to MA-11, "

Fluids and Lubricants".

Check lines for improper attachment, leaks, cracks, damage,

loose connections, chafing and deterioration.

Check rack boots for accumulation of power steering fluid.

AXLE AND SUSPENSION PARTS

AXLE AND SUSPENSION PARTS : InspectionINFOID:0000000003858316

Check front and rear axle and suspension parts for excessive play,

cracks, wear or other damage.

Shake each wheel to check for excessive play.

Check wheel bearings for smooth operation.

Check axle and suspension nuts and bolts for looseness.

Check strut (shock absorber) for oil leakage or other damage.

Check suspension ball joint for grease leakage and ball joint dust

cover for cracks or other damage.

DRIVE SHAFT

HOT (A) : Fluid temperature 50 – 80°C (122 – 176°F)

COLD (B) : Fluid temperature 0 – 30°C (32 – 86°F)

ALGIA0002GB

SST851C

SMA525A

SFA392B