NISSAN TEANA 2008 Service Manual

Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 2611 of 5121

HA-42

< ON-VEHICLE REPAIR >

LOW-PRESSURE PIPE

LOW-PRESSURE PIPE

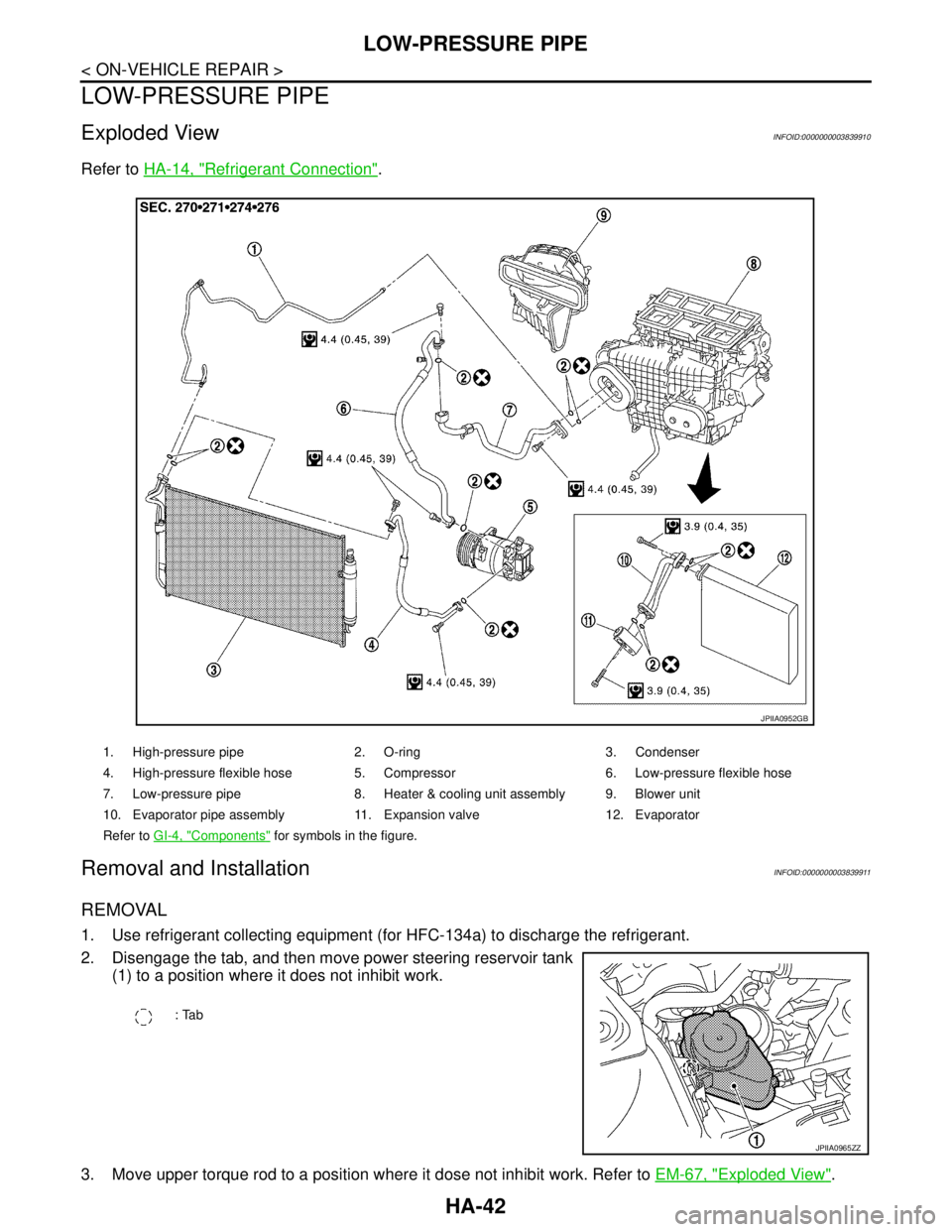

Exploded ViewINFOID:0000000003839910

Refer to HA-14, "Refrigerant Connection".

Removal and InstallationINFOID:0000000003839911

REMOVAL

1. Use refrigerant collecting equipment (for HFC-134a) to discharge the refrigerant.

2. Disengage the tab, and then move power steering reservoir tank

(1) to a position where it does not inhibit work.

3. Move upper torque rod to a position where it dose not inhibit work. Refer to EM-67, "

Exploded View".

1. High-pressure pipe 2. O-ring 3. Condenser

4. High-pressure flexible hose 5. Compressor 6. Low-pressure flexible hose

7. Low-pressure pipe 8. Heater & cooling unit assembly 9. Blower unit

10. Evaporator pipe assembly 11. Expansion valve 12. Evaporator

Refer to GI-4, "

Components" for symbols in the figure.

JPIIA0952GB

: Tab

JPIIA0965ZZ

Page 2612 of 5121

LOW-PRESSURE PIPE

HA-43

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

J

K

L

MA

B

HA

N

O

P

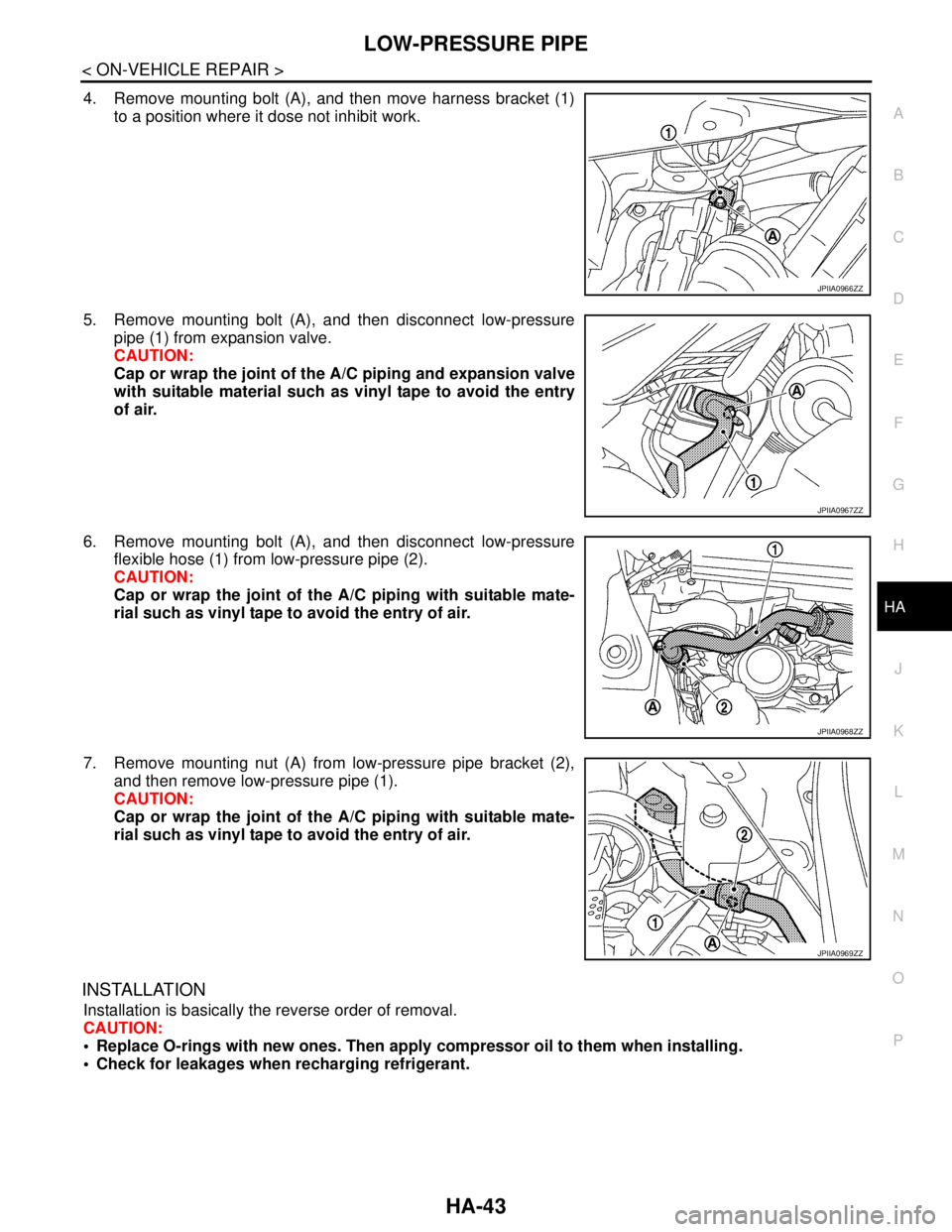

4. Remove mounting bolt (A), and then move harness bracket (1)

to a position where it dose not inhibit work.

5. Remove mounting bolt (A), and then disconnect low-pressure

pipe (1) from expansion valve.

CAUTION:

Cap or wrap the joint of the A/C piping and expansion valve

with suitable material such as vinyl tape to avoid the entry

of air.

6. Remove mounting bolt (A), and then disconnect low-pressure

flexible hose (1) from low-pressure pipe (2).

CAUTION:

Cap or wrap the joint of the A/C piping with suitable mate-

rial such as vinyl tape to avoid the entry of air.

7. Remove mounting nut (A) from low-pressure pipe bracket (2),

and then remove low-pressure pipe (1).

CAUTION:

Cap or wrap the joint of the A/C piping with suitable mate-

rial such as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is basically the reverse order of removal.

CAUTION:

Replace O-rings with new ones. Then apply compressor oil to them when installing.

Check for leakages when recharging refrigerant.

JPIIA0966ZZ

JPIIA0967ZZ

JPIIA0968ZZ

JPIIA0969ZZ

Page 2613 of 5121

HA-44

< ON-VEHICLE REPAIR >

HIGH-PRESSURE PIPE

HIGH-PRESSURE PIPE

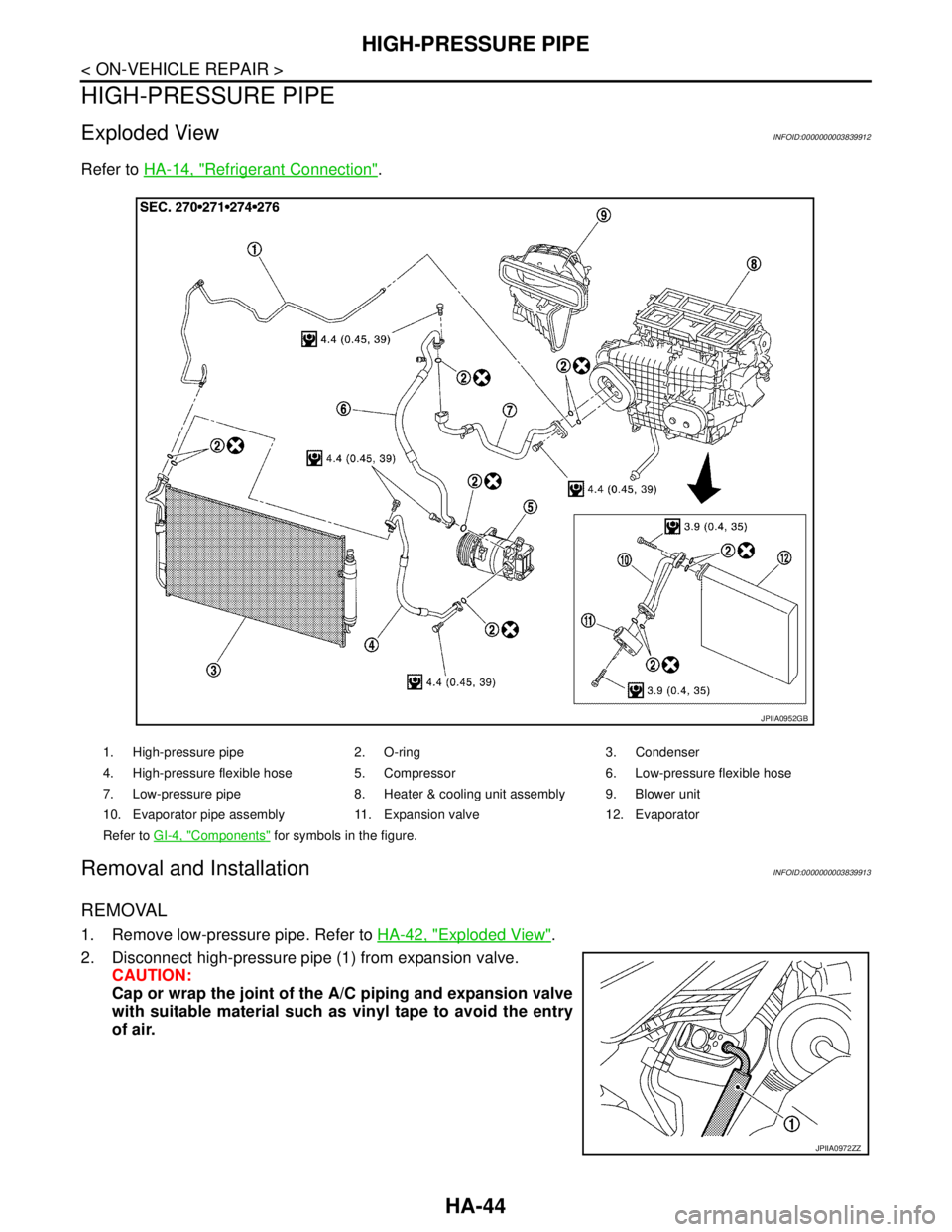

Exploded ViewINFOID:0000000003839912

Refer to HA-14, "Refrigerant Connection".

Removal and InstallationINFOID:0000000003839913

REMOVAL

1. Remove low-pressure pipe. Refer to HA-42, "Exploded View".

2. Disconnect high-pressure pipe (1) from expansion valve.

CAUTION:

Cap or wrap the joint of the A/C piping and expansion valve

with suitable material such as vinyl tape to avoid the entry

of air.

1. High-pressure pipe 2. O-ring 3. Condenser

4. High-pressure flexible hose 5. Compressor 6. Low-pressure flexible hose

7. Low-pressure pipe 8. Heater & cooling unit assembly 9. Blower unit

10. Evaporator pipe assembly 11. Expansion valve 12. Evaporator

Refer to GI-4, "

Components" for symbols in the figure.

JPIIA0952GB

JPIIA0972ZZ

Page 2614 of 5121

HIGH-PRESSURE PIPE

HA-45

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

J

K

L

MA

B

HA

N

O

P

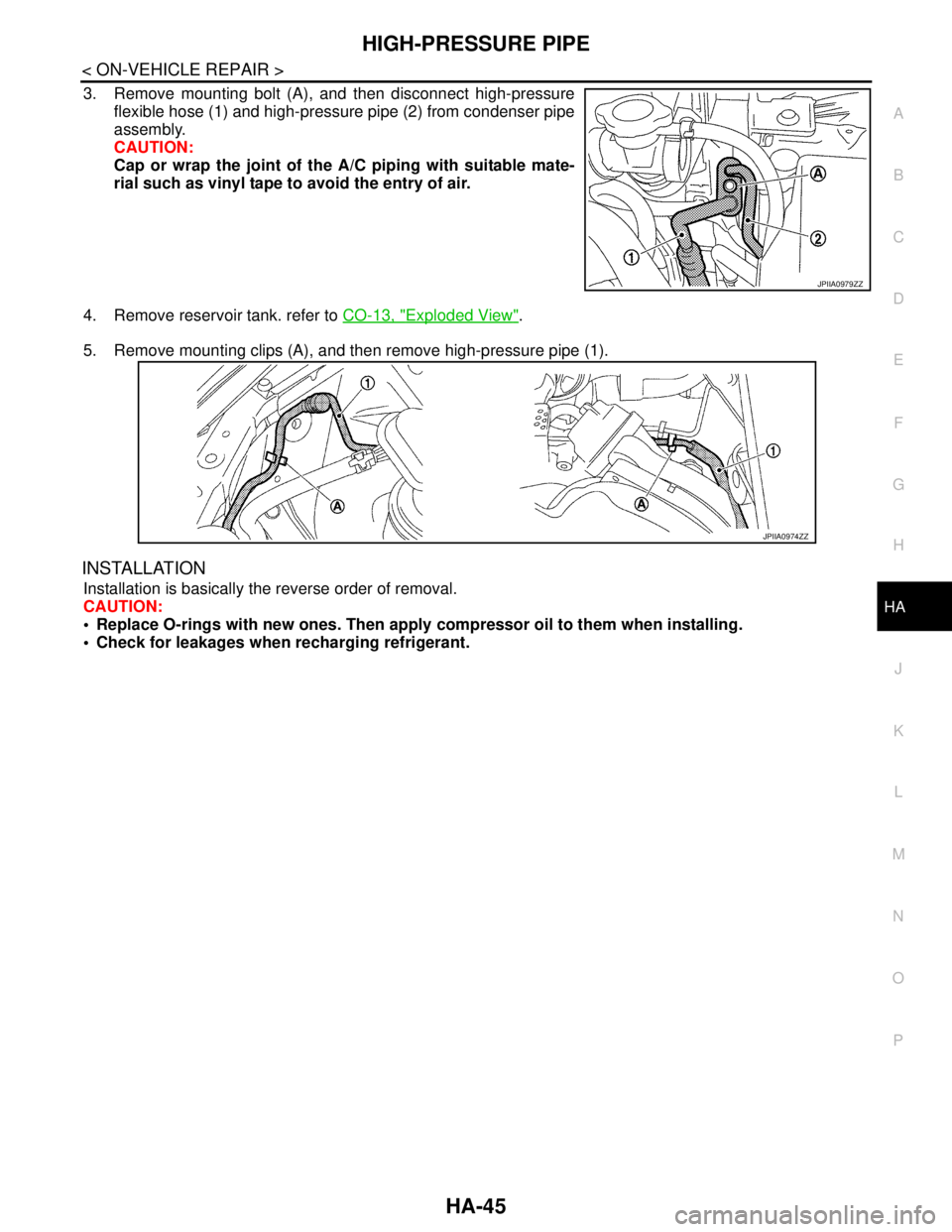

3. Remove mounting bolt (A), and then disconnect high-pressure

flexible hose (1) and high-pressure pipe (2) from condenser pipe

assembly.

CAUTION:

Cap or wrap the joint of the A/C piping with suitable mate-

rial such as vinyl tape to avoid the entry of air.

4. Remove reservoir tank. refer to CO-13, "

Exploded View".

5. Remove mounting clips (A), and then remove high-pressure pipe (1).

INSTALLATION

Installation is basically the reverse order of removal.

CAUTION:

Replace O-rings with new ones. Then apply compressor oil to them when installing.

Check for leakages when recharging refrigerant.

JPIIA0979ZZ

JPIIA0974ZZ

Page 2615 of 5121

HA-46

< ON-VEHICLE REPAIR >

CONDENSER

CONDENSER

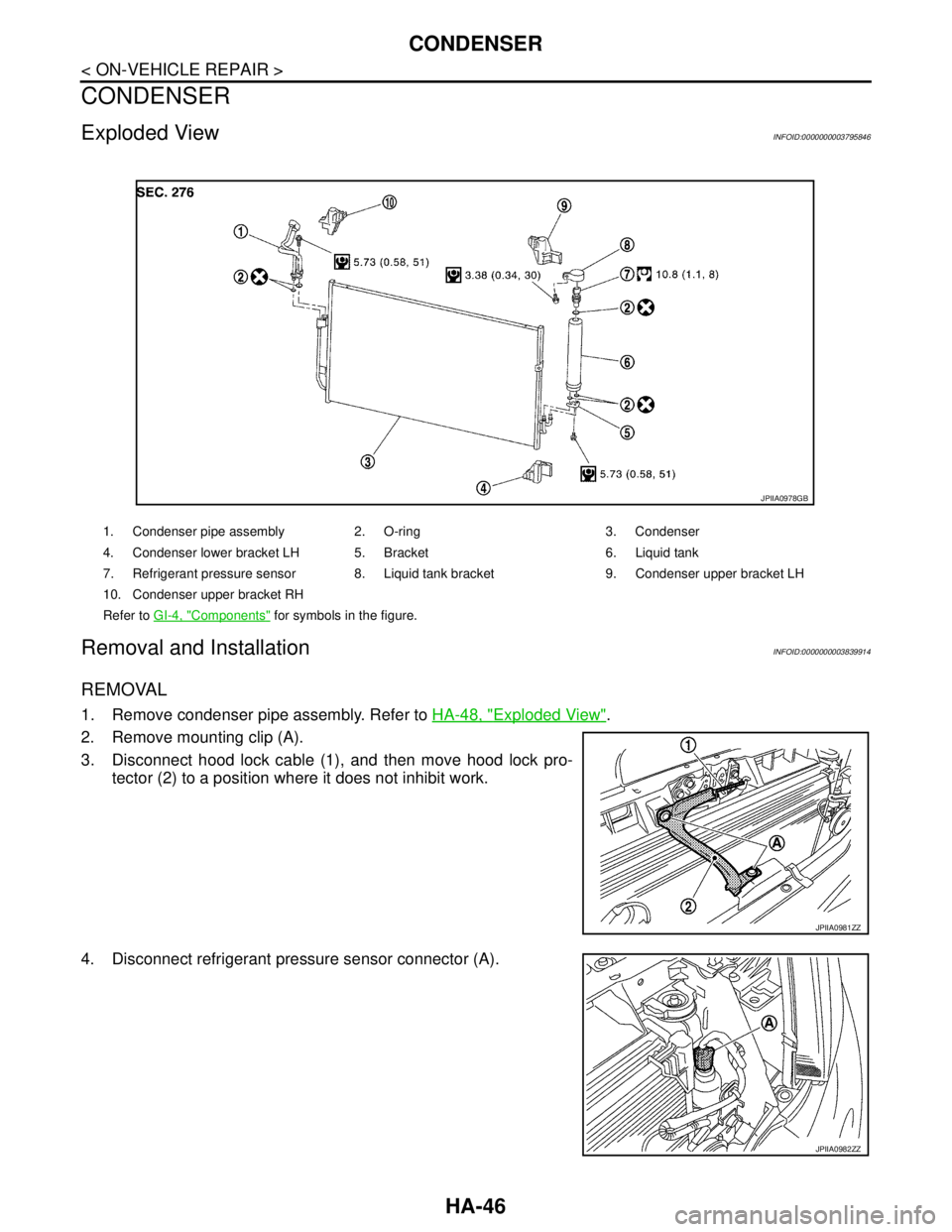

Exploded ViewINFOID:0000000003795846

Removal and InstallationINFOID:0000000003839914

REMOVAL

1. Remove condenser pipe assembly. Refer to HA-48, "Exploded View".

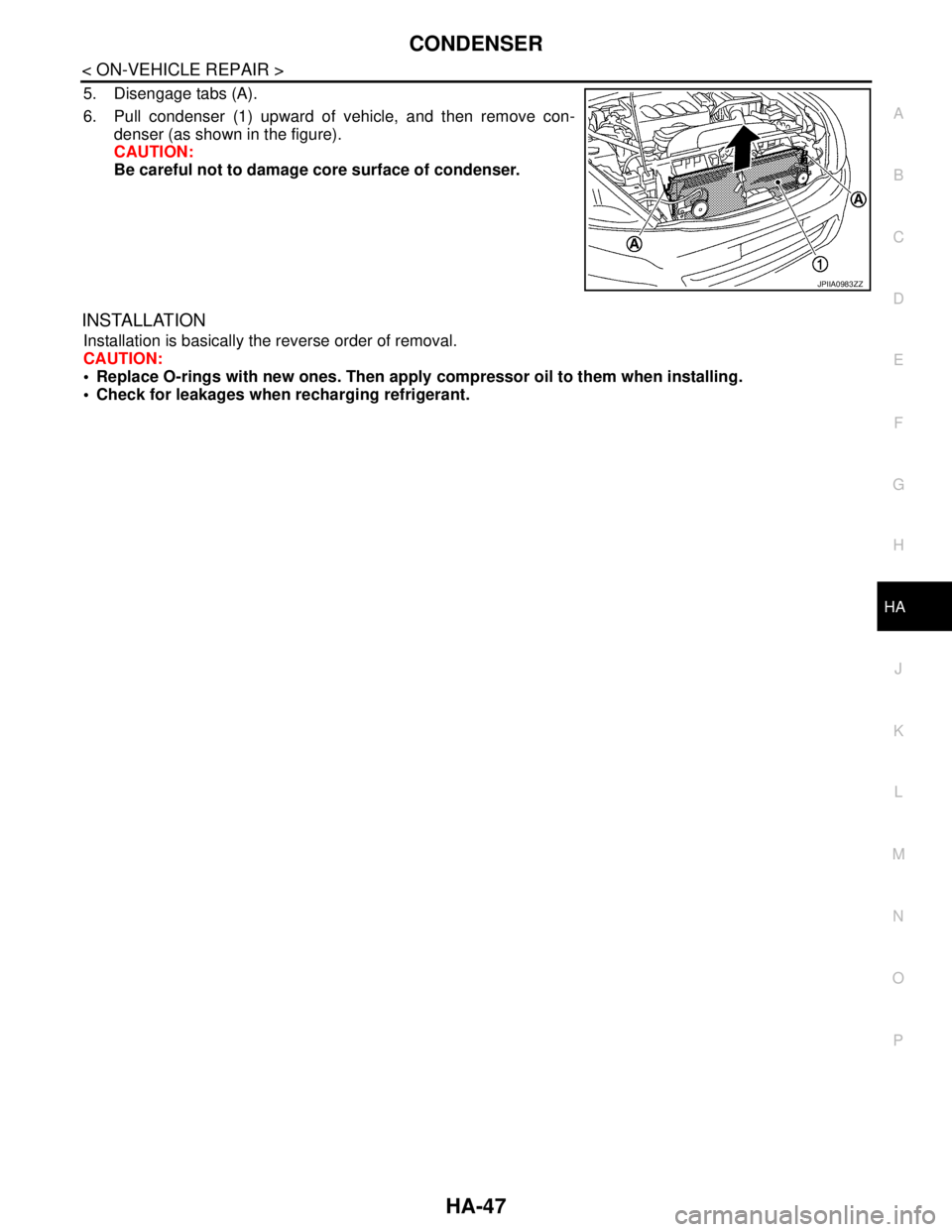

2. Remove mounting clip (A).

3. Disconnect hood lock cable (1), and then move hood lock pro-

tector (2) to a position where it does not inhibit work.

4. Disconnect refrigerant pressure sensor connector (A).

1. Condenser pipe assembly 2. O-ring 3. Condenser

4. Condenser lower bracket LH 5. Bracket 6. Liquid tank

7. Refrigerant pressure sensor 8. Liquid tank bracket 9. Condenser upper bracket LH

10. Condenser upper bracket RH

Refer to GI-4, "

Components" for symbols in the figure.

JPIIA0978GB

JPIIA0981ZZ

JPIIA0982ZZ

Page 2616 of 5121

CONDENSER

HA-47

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

J

K

L

MA

B

HA

N

O

P

5. Disengage tabs (A).

6. Pull condenser (1) upward of vehicle, and then remove con-

denser (as shown in the figure).

CAUTION:

Be careful not to damage core surface of condenser.

INSTALLATION

Installation is basically the reverse order of removal.

CAUTION:

Replace O-rings with new ones. Then apply compressor oil to them when installing.

Check for leakages when recharging refrigerant.

JPIIA0983ZZ

Page 2617 of 5121

HA-48

< ON-VEHICLE REPAIR >

CONDENSER PIPE ASSEMBLY

CONDENSER PIPE ASSEMBLY

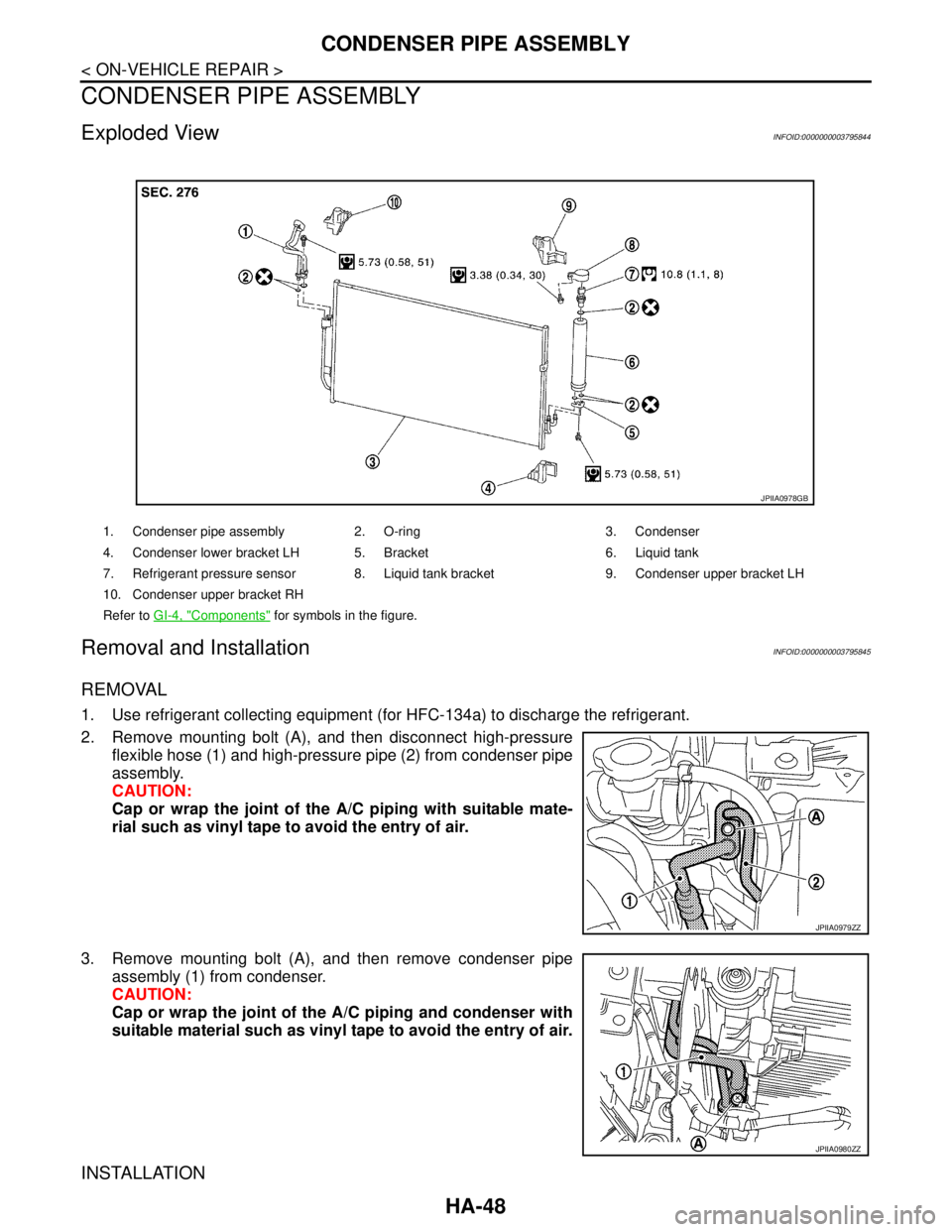

Exploded ViewINFOID:0000000003795844

Removal and InstallationINFOID:0000000003795845

REMOVAL

1. Use refrigerant collecting equipment (for HFC-134a) to discharge the refrigerant.

2. Remove mounting bolt (A), and then disconnect high-pressure

flexible hose (1) and high-pressure pipe (2) from condenser pipe

assembly.

CAUTION:

Cap or wrap the joint of the A/C piping with suitable mate-

rial such as vinyl tape to avoid the entry of air.

3. Remove mounting bolt (A), and then remove condenser pipe

assembly (1) from condenser.

CAUTION:

Cap or wrap the joint of the A/C piping and condenser with

suitable material such as vinyl tape to avoid the entry of air.

INSTALLATION

1. Condenser pipe assembly 2. O-ring 3. Condenser

4. Condenser lower bracket LH 5. Bracket 6. Liquid tank

7. Refrigerant pressure sensor 8. Liquid tank bracket 9. Condenser upper bracket LH

10. Condenser upper bracket RH

Refer to GI-4, "

Components" for symbols in the figure.

JPIIA0978GB

JPIIA0979ZZ

JPIIA0980ZZ

Page 2618 of 5121

CONDENSER PIPE ASSEMBLY

HA-49

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

J

K

L

MA

B

HA

N

O

P

Installation is basically the reverse order of removal.

CAUTION:

Replace O-rings with new ones. Then apply compressor oil to them when installing.

Check for leakages when recharging refrigerant.

Page 2619 of 5121

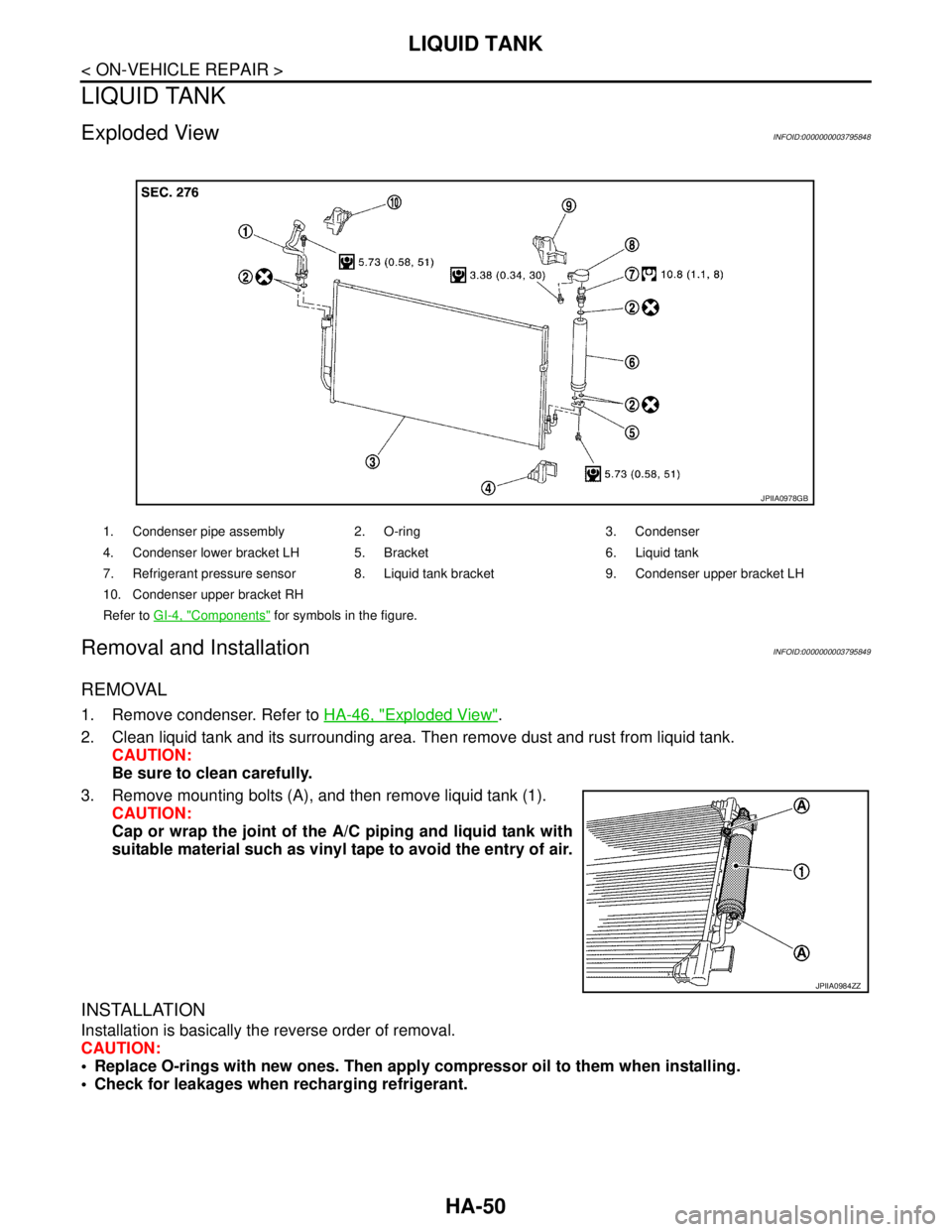

HA-50

< ON-VEHICLE REPAIR >

LIQUID TANK

LIQUID TANK

Exploded ViewINFOID:0000000003795848

Removal and InstallationINFOID:0000000003795849

REMOVAL

1. Remove condenser. Refer to HA-46, "Exploded View".

2. Clean liquid tank and its surrounding area. Then remove dust and rust from liquid tank.

CAUTION:

Be sure to clean carefully.

3. Remove mounting bolts (A), and then remove liquid tank (1).

CAUTION:

Cap or wrap the joint of the A/C piping and liquid tank with

suitable material such as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is basically the reverse order of removal.

CAUTION:

Replace O-rings with new ones. Then apply compressor oil to them when installing.

Check for leakages when recharging refrigerant.

1. Condenser pipe assembly 2. O-ring 3. Condenser

4. Condenser lower bracket LH 5. Bracket 6. Liquid tank

7. Refrigerant pressure sensor 8. Liquid tank bracket 9. Condenser upper bracket LH

10. Condenser upper bracket RH

Refer to GI-4, "

Components" for symbols in the figure.

JPIIA0978GB

JPIIA0984ZZ

Page 2620 of 5121

REFRIGERANT PRESSURE SENSOR

HA-51

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

J

K

L

MA

B

HA

N

O

P

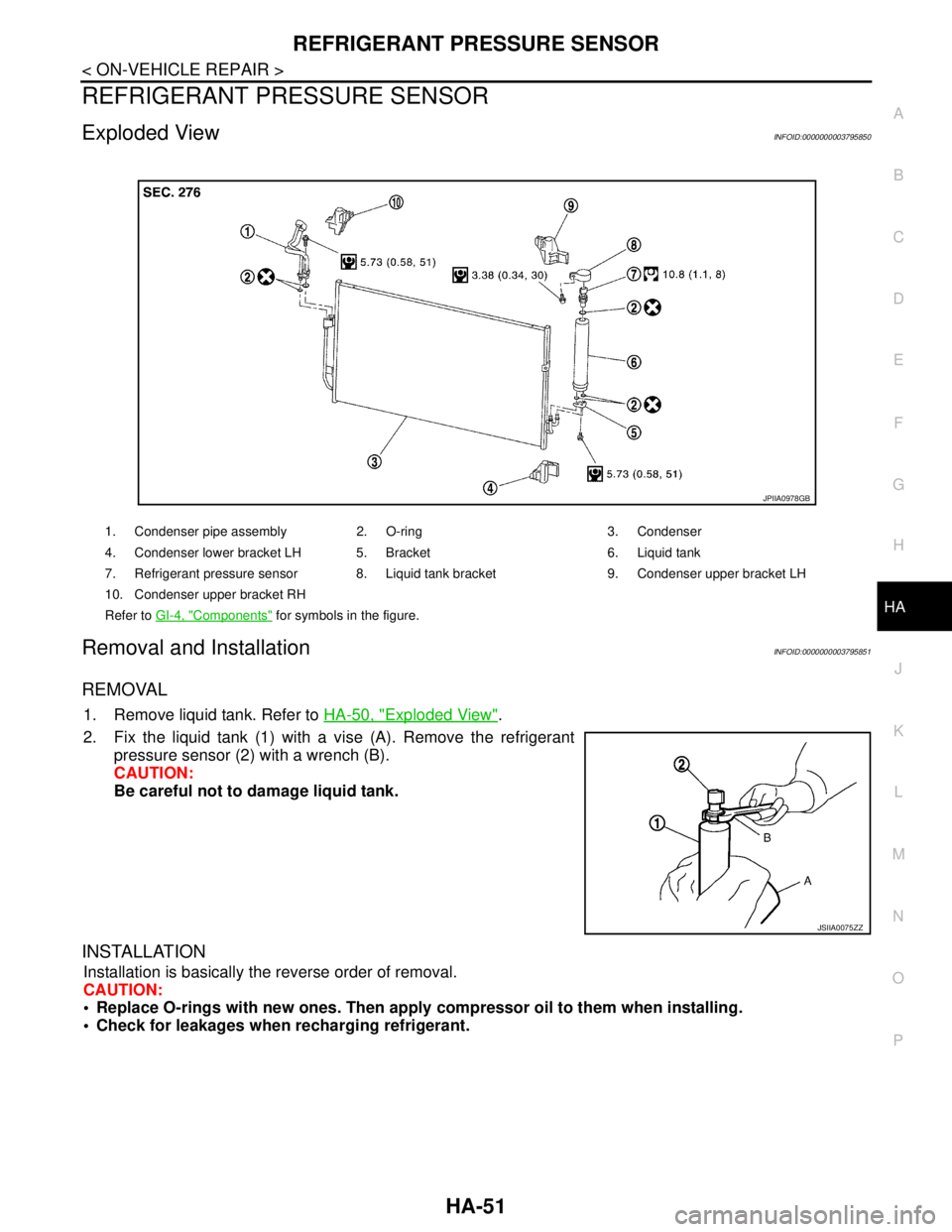

REFRIGERANT PRESSURE SENSOR

Exploded ViewINFOID:0000000003795850

Removal and InstallationINFOID:0000000003795851

REMOVAL

1. Remove liquid tank. Refer to HA-50, "Exploded View".

2. Fix the liquid tank (1) with a vise (A). Remove the refrigerant

pressure sensor (2) with a wrench (B).

CAUTION:

Be careful not to damage liquid tank.

INSTALLATION

Installation is basically the reverse order of removal.

CAUTION:

Replace O-rings with new ones. Then apply compressor oil to them when installing.

Check for leakages when recharging refrigerant.

1. Condenser pipe assembly 2. O-ring 3. Condenser

4. Condenser lower bracket LH 5. Bracket 6. Liquid tank

7. Refrigerant pressure sensor 8. Liquid tank bracket 9. Condenser upper bracket LH

10. Condenser upper bracket RH

Refer to GI-4, "

Components" for symbols in the figure.

JPIIA0978GB

JSIIA0075ZZ