NISSAN TEANA 2008 Service Manual

Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 2571 of 5121

HA-2

LOW-PRESSURE PIPE .....................................42

Exploded View ........................................................42

Removal and Installation ........................................42

HIGH-PRESSURE PIPE ....................................44

Exploded View ........................................................44

Removal and Installation ........................................44

CONDENSER ....................................................46

Exploded View ........................................................46

Removal and Installation ........................................46

CONDENSER PIPE ASSEMBLY ......................48

Exploded View ........................................................48

Removal and Installation ........................................48

LIQUID TANK ....................................................50

Exploded View ........................................................50

Removal and Installation ........................................50

REFRIGERANT PRESSURE SENSOR ............51

Exploded View ........................................................51

Removal and Installation ........................................51

EVAPORATOR ..................................................52

Exploded View ........................................................52

Removal and Installation .........................................53

EVAPORATOR PIPE ASSEMBLY ....................54

Exploded View ........................................................54

Removal and Installation .........................................55

EXPANSION VALVE .........................................57

Exploded View ........................................................57

Removal and Installation .........................................58

SERVICE DATA AND SPECIFICATIONS

(SDS) ..........................................................

59

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

59

Compressor ............................................................59

Lubricant .................................................................59

Refrigerant ..............................................................59

Engine Idling Speed ................................................59

Belt Tension ............................................................59

Page 2572 of 5121

DIAGNOSIS AND REPAIR WORK FLOW

HA-3

< BASIC INSPECTION >

C

D

E

F

G

H

J

K

L

MA

B

HA

N

O

P

BASIC INSPECTION

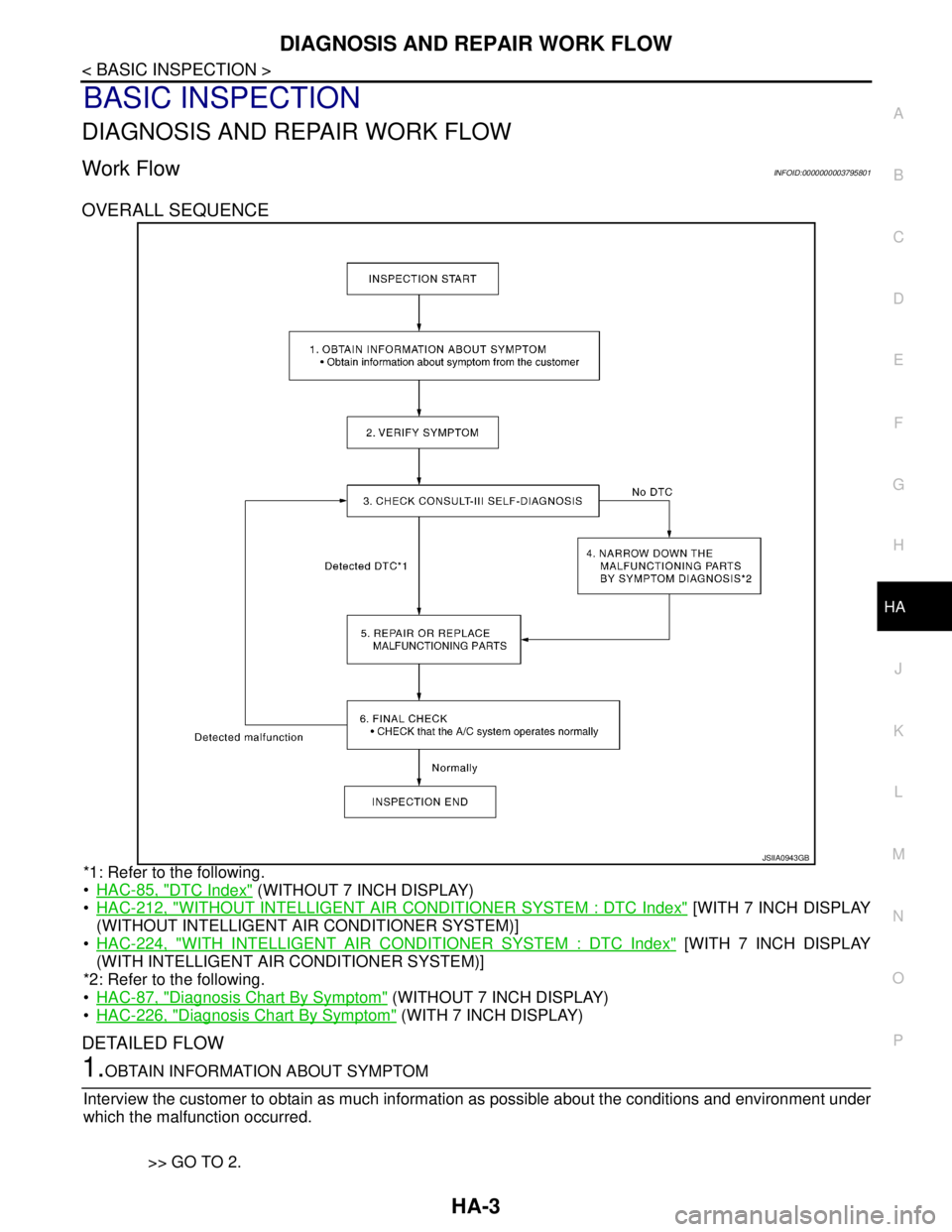

DIAGNOSIS AND REPAIR WORK FLOW

Work FlowINFOID:0000000003795801

OVERALL SEQUENCE

*1: Refer to the following.

•HAC-85, "

DTC Index" (WITHOUT 7 INCH DISPLAY)

HAC-212, "

WITHOUT INTELLIGENT AIR CONDITIONER SYSTEM : DTC Index" [WITH 7 INCH DISPLAY

(WITHOUT INTELLIGENT AIR CONDITIONER SYSTEM)]

HAC-224, "

WITH INTELLIGENT AIR CONDITIONER SYSTEM : DTC Index" [WITH 7 INCH DISPLAY

(WITH INTELLIGENT AIR CONDITIONER SYSTEM)]

*2: Refer to the following.

HAC-87, "

Diagnosis Chart By Symptom" (WITHOUT 7 INCH DISPLAY)

HAC-226, "

Diagnosis Chart By Symptom" (WITH 7 INCH DISPLAY)

DETAILED FLOW

1.OBTAIN INFORMATION ABOUT SYMPTOM

Interview the customer to obtain as much information as possible about the conditions and environment under

which the malfunction occurred.

>> GO TO 2.

JSIIA0943GB

Page 2573 of 5121

HA-4

< BASIC INSPECTION >

DIAGNOSIS AND REPAIR WORK FLOW

2.VERIFY SYMPTOM

Verify the symptom with operational check based on the information obtained from the customer. Refer to the

following.

HAC-8, "

Description & Inspection" (WITHOUT 7 INCH DISPLAY)

HAC-108, "

WITHOUT INTELLIGENT AIR CONDITIONER SYSTEM : Description & Inspection" [WITH 7

INCH DISPLAY (WITHOUT INTELLIGENT AIR CONDITIONER SYSTEM)]

HAC-112, "

WITH INTELLIGENT AIR CONDITIONER SYSTEM : Description & Inspection" [WITH 7 INCH

DISPLAY (WITH INTELLIGENT AIR CONDITIONER SYSTEM)]

>> GO TO 3.

3.CHECK WITH SELF-DIAGNOSIS FUNCTION OF CONSULT-III

Using CONSULT-III, perform “SELF-DIAGNOSIS RESULTS” of HVAC. Refer to the following.

HAC-85, "

DTC Index" (WITHOUT 7 INCH DISPLAY)

HAC-212, "

WITHOUT INTELLIGENT AIR CONDITIONER SYSTEM : DTC Index" [WITH 7 INCH DISPLAY

(WITHOUT INTELLIGENT AIR CONDITIONER SYSTEM)]

HAC-224, "

WITH INTELLIGENT AIR CONDITIONER SYSTEM : DTC Index" [WITH 7 INCH DISPLAY

(WITH INTELLIGENT AIR CONDITIONER SYSTEM)]

Are self

-diagnosis results normal?

YES >> GO TO 4.

NO >> GO TO 5.

4.NARROW DOWN THE MALFUNCTIONING PARTS BY SYMPTOM DIAGNOSIS

Perform symptom diagnosis and narrow down the malfunctioning parts. Refer to the following.

HAC-87, "

Diagnosis Chart By Symptom" (WITHOUT 7 INCH DISPLAY)

HAC-226, "

Diagnosis Chart By Symptom" (WITH 7 INCH DISPLAY)

>> GO TO 5.

5.REPAIR OR REPLACE

Repair or replace malfunctioning parts.

NOTE:

If DTC is displayed, erase DTC after repairing or replacing malfunctioning parts.

>> GO TO 6.

6.FINAL CHECK

Check that the A/C system operates normally.

Is the inspection result normal?

YES >> INSPECTION END

NO >> GO TO 3.

Page 2574 of 5121

REFRIGERATION SYSTEM

HA-5

< FUNCTION DIAGNOSIS >

C

D

E

F

G

H

J

K

L

MA

B

HA

N

O

P

FUNCTION DIAGNOSIS

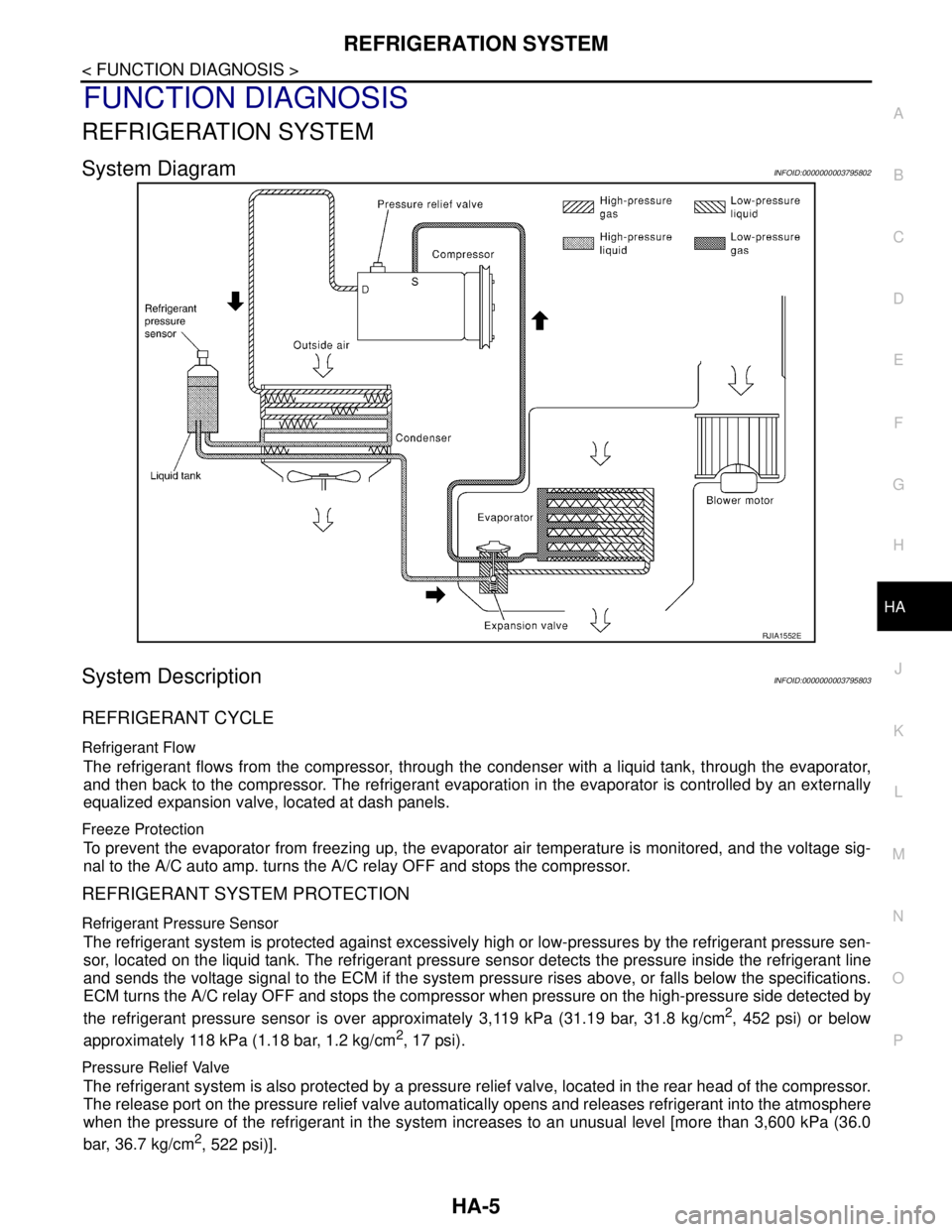

REFRIGERATION SYSTEM

System DiagramINFOID:0000000003795802

System DescriptionINFOID:0000000003795803

REFRIGERANT CYCLE

Refrigerant Flow

The refrigerant flows from the compressor, through the condenser with a liquid tank, through the evaporator,

and then back to the compressor. The refrigerant evaporation in the evaporator is controlled by an externally

equalized expansion valve, located at dash panels.

Freeze Protection

To prevent the evaporator from freezing up, the evaporator air temperature is monitored, and the voltage sig-

nal to the A/C auto amp. turns the A/C relay OFF and stops the compressor.

REFRIGERANT SYSTEM PROTECTION

Refrigerant Pressure Sensor

The refrigerant system is protected against excessively high or low-pressures by the refrigerant pressure sen-

sor, located on the liquid tank. The refrigerant pressure sensor detects the pressure inside the refrigerant line

and sends the voltage signal to the ECM if the system pressure rises above, or falls below the specifications.

ECM turns the A/C relay OFF and stops the compressor when pressure on the high-pressure side detected by

the refrigerant pressure sensor is over approximately 3,119 kPa (31.19 bar, 31.8 kg/cm

2, 452 psi) or below

approximately 118 kPa (1.18 bar, 1.2 kg/cm

2, 17 psi).

Pressure Relief Valve

The refrigerant system is also protected by a pressure relief valve, located in the rear head of the compressor.

The release port on the pressure relief valve automatically opens and releases refrigerant into the atmosphere

when the pressure of the refrigerant in the system increases to an unusual level [more than 3,600 kPa (36.0

bar, 36.7 kg/cm

2, 522 psi)].

RJIA1552E

Page 2575 of 5121

HA-6

< FUNCTION DIAGNOSIS >

REFRIGERATION SYSTEM

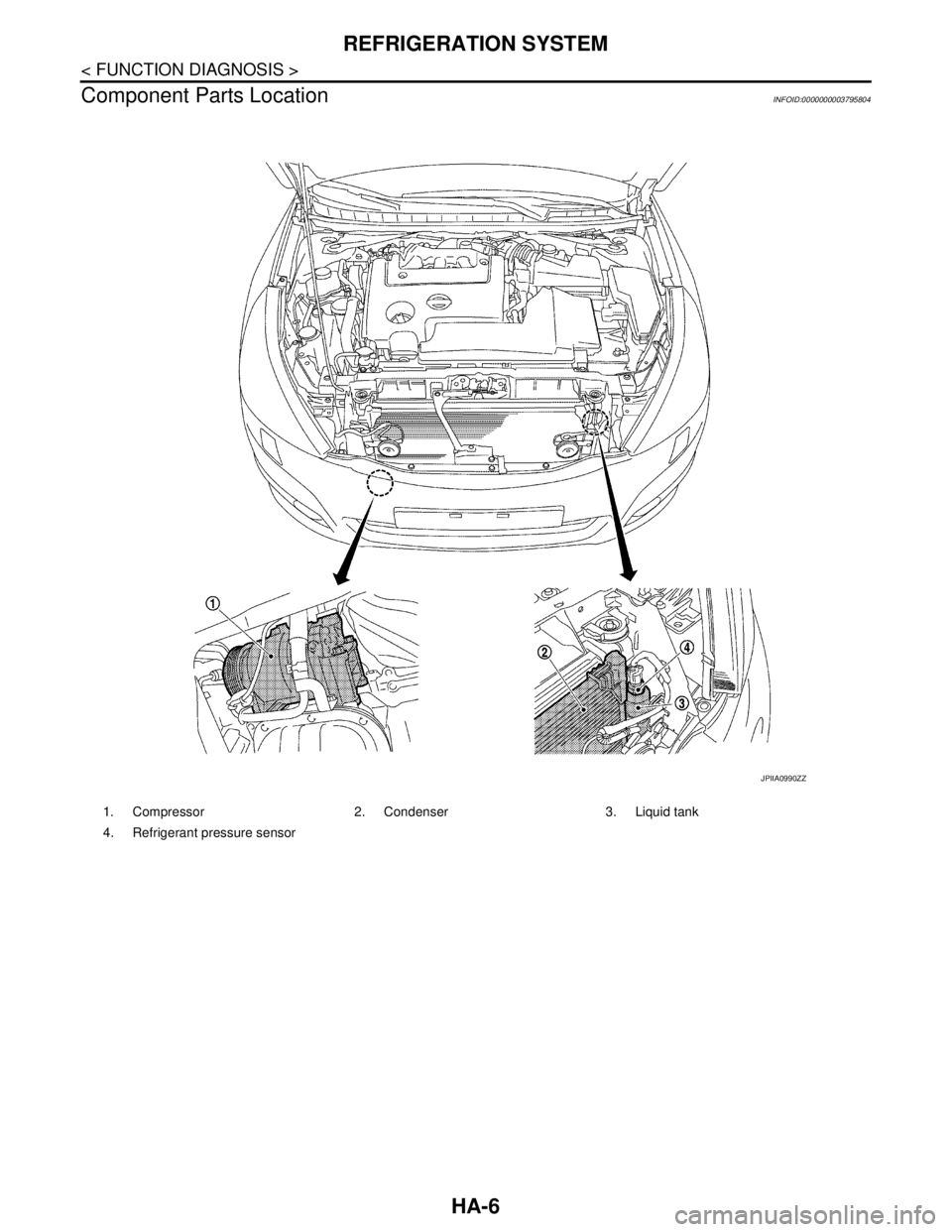

Component Parts Location

INFOID:0000000003795804

1. Compressor 2. Condenser 3. Liquid tank

4. Refrigerant pressure sensor

JPIIA0990ZZ

Page 2576 of 5121

REFRIGERATION SYSTEM

HA-7

< FUNCTION DIAGNOSIS >

C

D

E

F

G

H

J

K

L

MA

B

HA

N

O

P

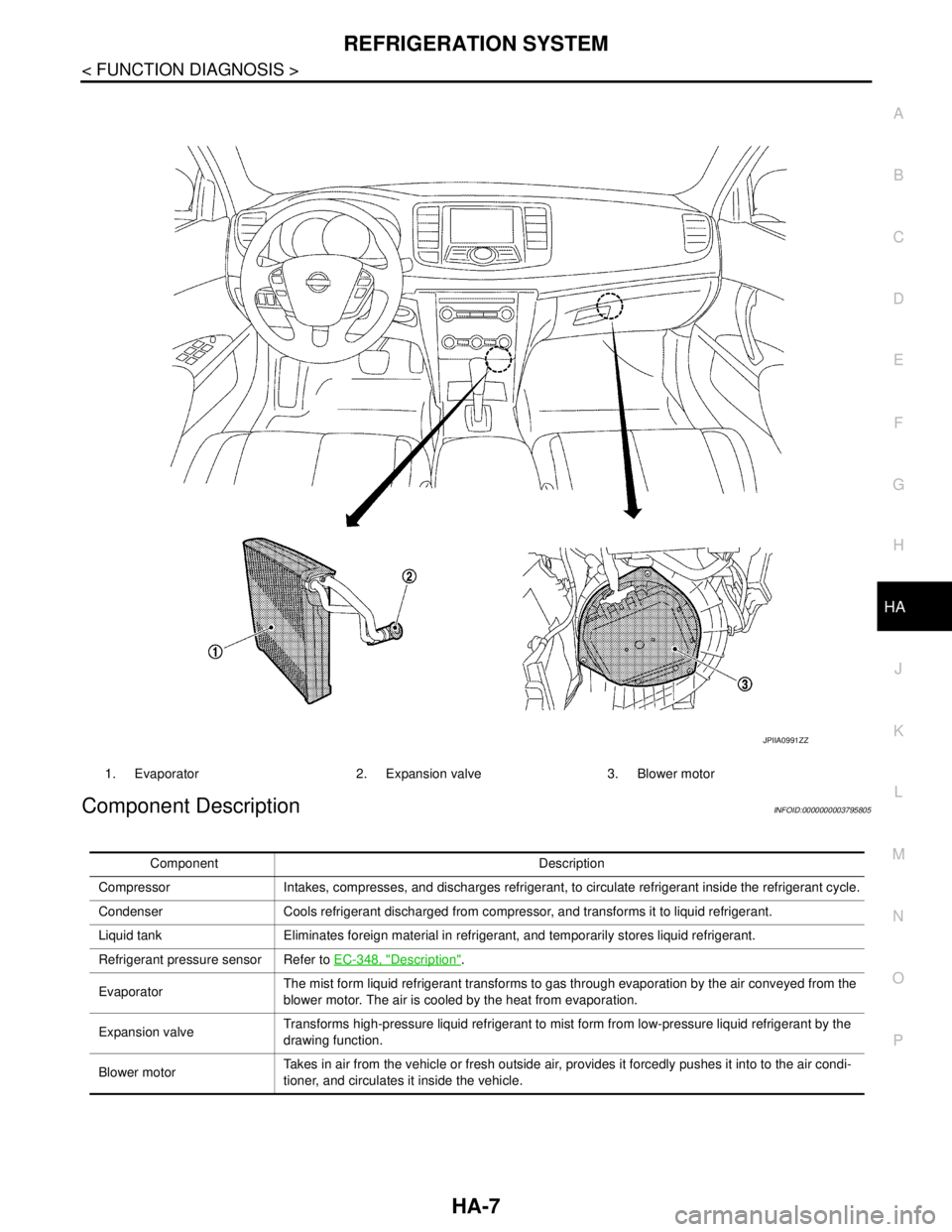

Component DescriptionINFOID:0000000003795805

1. Evaporator 2. Expansion valve 3. Blower motor

JPIIA0991ZZ

Component Description

Compressor Intakes, compresses, and discharges refrigerant, to circulate refrigerant inside the refrigerant cycle.

Condenser Cools refrigerant discharged from compressor, and transforms it to liquid refrigerant.

Liquid tank Eliminates foreign material in refrigerant, and temporarily stores liquid refrigerant.

Refrigerant pressure sensor Refer to EC-348, "

Description".

EvaporatorThe mist form liquid refrigerant transforms to gas through evaporation by the air conveyed from the

blower motor. The air is cooled by the heat from evaporation.

Expansion valveTransforms high-pressure liquid refrigerant to mist form from low-pressure liquid refrigerant by the

drawing function.

Blower motorTakes in air from the vehicle or fresh outside air, provides it forcedly pushes it into to the air condi-

tioner, and circulates it inside the vehicle.

Page 2577 of 5121

HA-8

< SYMPTOM DIAGNOSIS >

REFRIGERATION SYSTEM SYMPTOMS

SYMPTOM DIAGNOSIS

REFRIGERATION SYSTEM SYMPTOMS

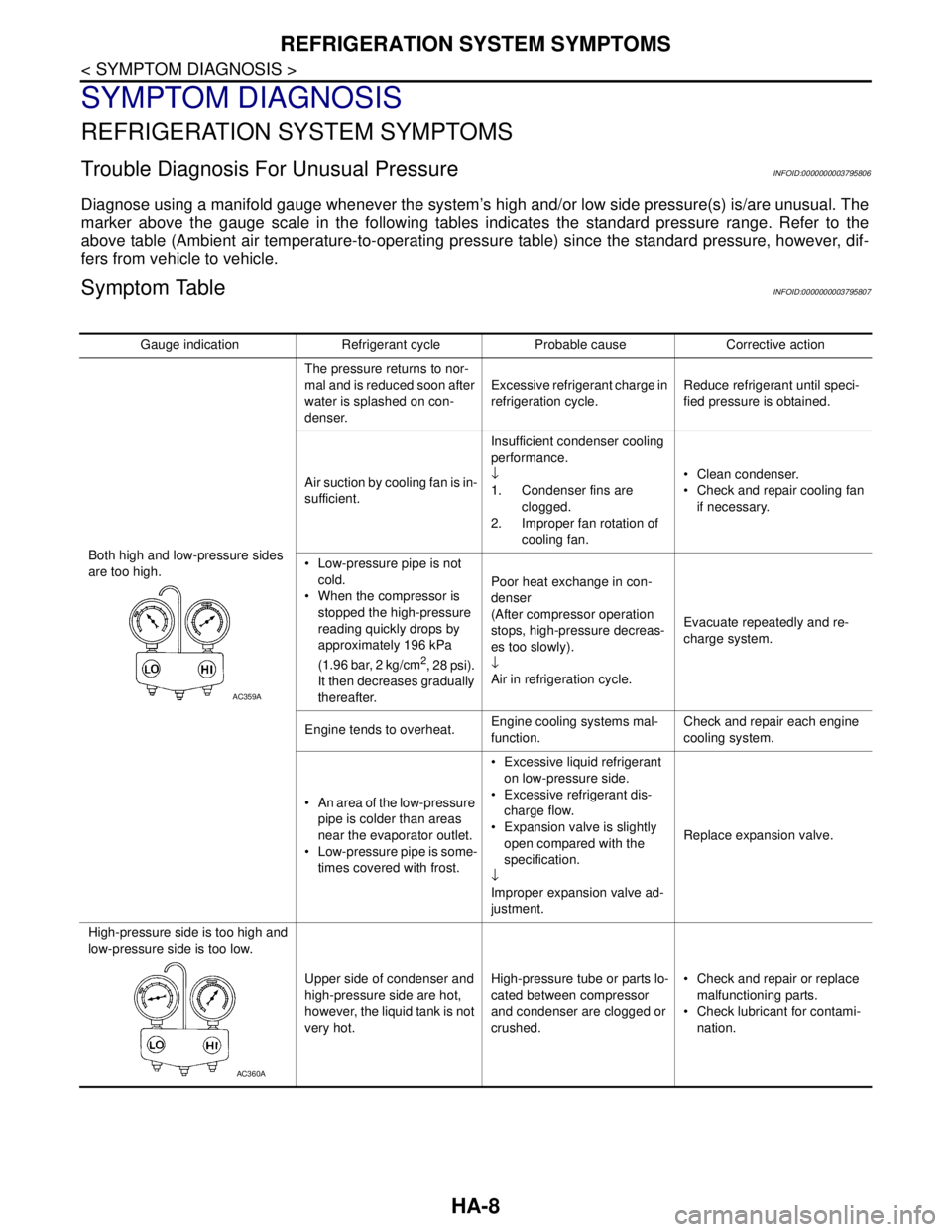

Trouble Diagnosis For Unusual PressureINFOID:0000000003795806

Diagnose using a manifold gauge whenever the system’s high and/or low side pressure(s) is/are unusual. The

marker above the gauge scale in the following tables indicates the standard pressure range. Refer to the

above table (Ambient air temperature-to-operating pressure table) since the standard pressure, however, dif-

fers from vehicle to vehicle.

Symptom TableINFOID:0000000003795807

Gauge indication Refrigerant cycle Probable cause Corrective action

Both high and low-pressure sides

are too high.The pressure returns to nor-

mal and is reduced soon after

water is splashed on con-

denser.Excessive refrigerant charge in

refrigeration cycle.Reduce refrigerant until speci-

fied pressure is obtained.

Air suction by cooling fan is in-

sufficient.Insufficient condenser cooling

performance.

↓

1. Condenser fins are

clogged.

2. Improper fan rotation of

cooling fan. Clean condenser.

Check and repair cooling fan

if necessary.

Low-pressure pipe is not

cold.

When the compressor is

stopped the high-pressure

reading quickly drops by

approximately 196 kPa

(1.96 bar, 2 kg/cm

2, 28 psi).

It then decreases gradually

thereafter.Poor heat exchange in con-

denser

(After compressor operation

stops, high-pressure decreas-

es too slowly).

↓

Air in refrigeration cycle.Evacuate repeatedly and re-

charge system.

Engine tends to overheat.Engine cooling systems mal-

function.Check and repair each engine

cooling system.

An area of the low-pressure

pipe is colder than areas

near the evaporator outlet.

Low-pressure pipe is some-

times covered with frost. Excessive liquid refrigerant

on low-pressure side.

Excessive refrigerant dis-

charge flow.

Expansion valve is slightly

open compared with the

specification.

↓

Improper expansion valve ad-

justment.Replace expansion valve.

High-pressure side is too high and

low-pressure side is too low.

Upper side of condenser and

high-pressure side are hot,

however, the liquid tank is not

very hot.High-pressure tube or parts lo-

cated between compressor

and condenser are clogged or

crushed. Check and repair or replace

malfunctioning parts.

Check lubricant for contami-

nation.

AC359A

AC360A

Page 2578 of 5121

REFRIGERATION SYSTEM SYMPTOMS

HA-9

< SYMPTOM DIAGNOSIS >

C

D

E

F

G

H

J

K

L

MA

B

HA

N

O

P

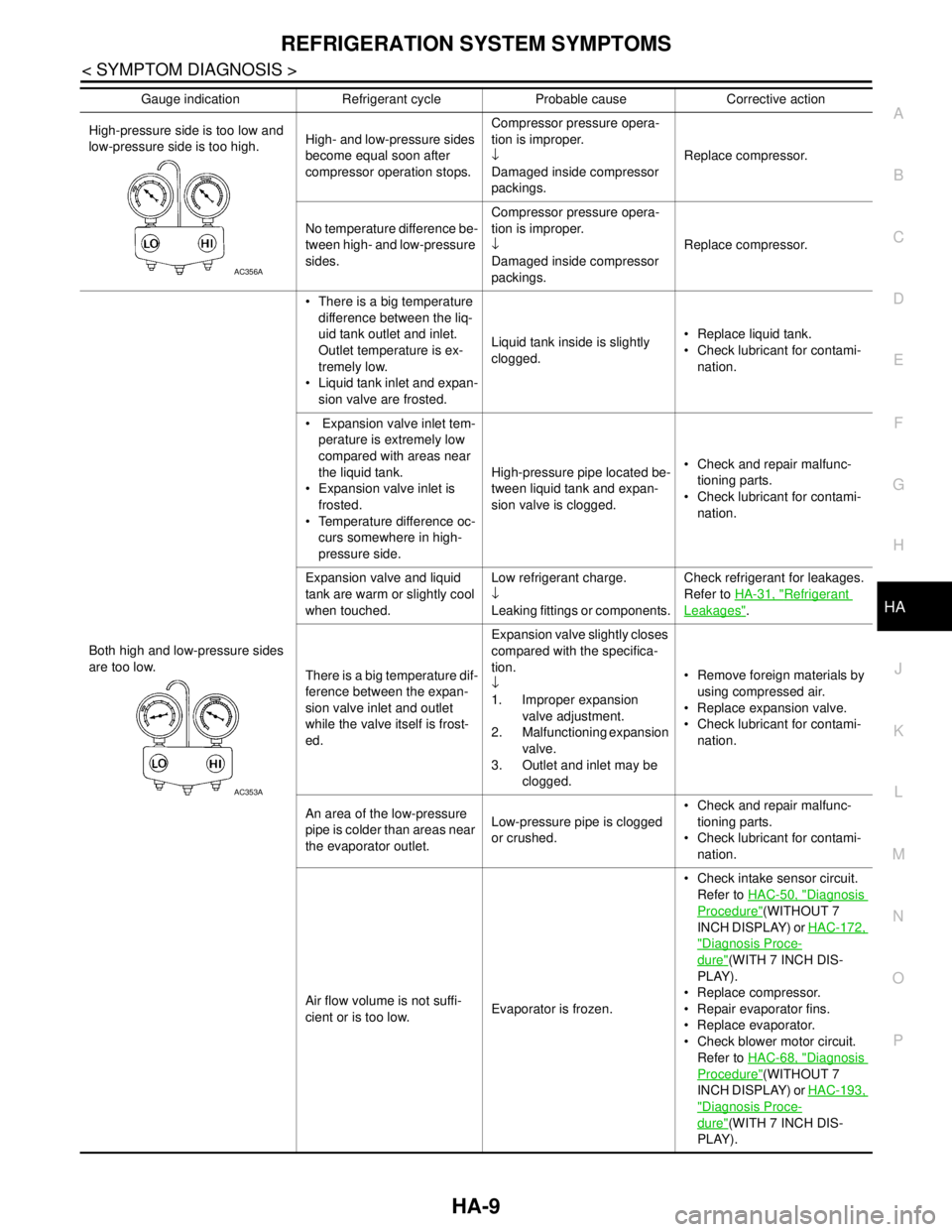

High-pressure side is too low and

low-pressure side is too high.High- and low-pressure sides

become equal soon after

compressor operation stops.Compressor pressure opera-

tion is improper.

↓

Damaged inside compressor

packings.Replace compressor.

No temperature difference be-

tween high- and low-pressure

sides.Compressor pressure opera-

tion is improper.

↓

Damaged inside compressor

packings.Replace compressor.

Both high and low-pressure sides

are too low. There is a big temperature

difference between the liq-

uid tank outlet and inlet.

Outlet temperature is ex-

tremely low.

Liquid tank inlet and expan-

sion valve are frosted.Liquid tank inside is slightly

clogged. Replace liquid tank.

Check lubricant for contami-

nation.

Expansion valve inlet tem-

perature is extremely low

compared with areas near

the liquid tank.

Expansion valve inlet is

frosted.

Temperature difference oc-

curs somewhere in high-

pressure side.High-pressure pipe located be-

tween liquid tank and expan-

sion valve is clogged. Check and repair malfunc-

tioning parts.

Check lubricant for contami-

nation.

Expansion valve and liquid

tank are warm or slightly cool

when touched.Low refrigerant charge.

↓

Leaking fittings or components.Check refrigerant for leakages.

Refer to HA-31, "

Refrigerant

Leakages".

There is a big temperature dif-

ference between the expan-

sion valve inlet and outlet

while the valve itself is frost-

ed.Expansion valve slightly closes

compared with the specifica-

tion.

↓

1. Improper expansion

valve adjustment.

2. Malfunctioning expansion

valve.

3. Outlet and inlet may be

clogged. Remove foreign materials by

using compressed air.

Replace expansion valve.

Check lubricant for contami-

nation.

An area of the low-pressure

pipe is colder than areas near

the evaporator outlet.Low-pressure pipe is clogged

or crushed. Check and repair malfunc-

tioning parts.

Check lubricant for contami-

nation.

Air flow volume is not suffi-

cient or is too low.Evaporator is frozen. Check intake sensor circuit.

Refer to HAC-50, "

Diagnosis

Procedure"(WITHOUT 7

INCH DISPLAY) or HAC-172,

"Diagnosis Proce-

dure"(WITH 7 INCH DIS-

PLAY).

Replace compressor.

Repair evaporator fins.

Replace evaporator.

Check blower motor circuit.

Refer to HAC-68, "

Diagnosis

Procedure"(WITHOUT 7

INCH DISPLAY) or HAC-193,

"Diagnosis Proce-

dure"(WITH 7 INCH DIS-

PLAY). Gauge indication Refrigerant cycle Probable cause Corrective action

AC356A

AC353A

Page 2579 of 5121

HA-10

< SYMPTOM DIAGNOSIS >

REFRIGERATION SYSTEM SYMPTOMS

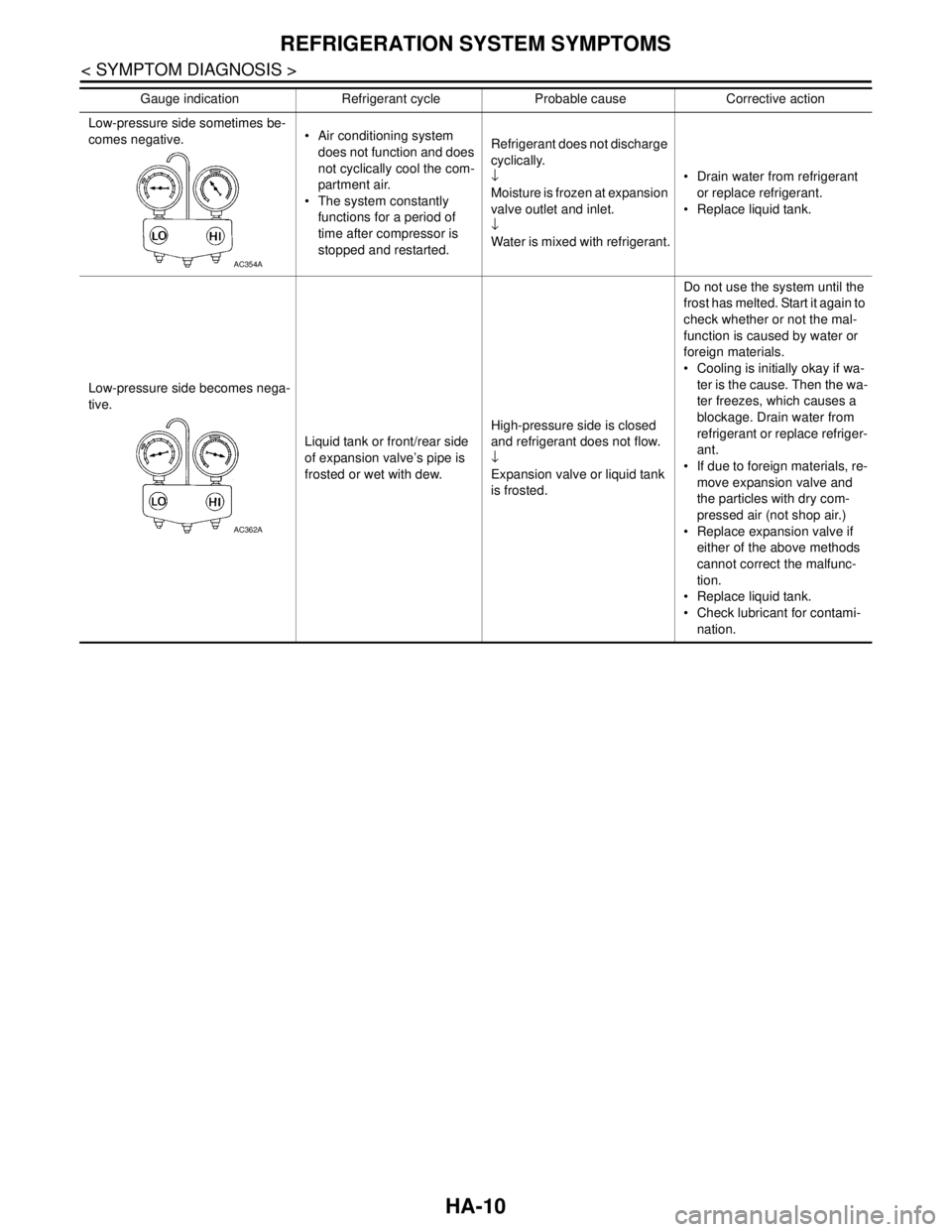

Low-pressure side sometimes be-

comes negative. Air conditioning system

does not function and does

not cyclically cool the com-

partment air.

The system constantly

functions for a period of

time after compressor is

stopped and restarted.Refrigerant does not discharge

cyclically.

↓

Moisture is frozen at expansion

valve outlet and inlet.

↓

Water is mixed with refrigerant. Drain water from refrigerant

or replace refrigerant.

Replace liquid tank.

Low-pressure side becomes nega-

tive.

Liquid tank or front/rear side

of expansion valve’s pipe is

frosted or wet with dew.High-pressure side is closed

and refrigerant does not flow.

↓

Expansion valve or liquid tank

is frosted.Do not use the system until the

frost has melted. Start it again to

check whether or not the mal-

function is caused by water or

foreign materials.

Cooling is initially okay if wa-

ter is the cause. Then the wa-

ter freezes, which causes a

blockage. Drain water from

refrigerant or replace refriger-

ant.

If due to foreign materials, re-

move expansion valve and

the particles with dry com-

pressed air (not shop air.)

Replace expansion valve if

either of the above methods

cannot correct the malfunc-

tion.

Replace liquid tank.

Check lubricant for contami-

nation. Gauge indication Refrigerant cycle Probable cause Corrective action

AC354A

AC362A

Page 2580 of 5121

COMPRESSOR SYSTEM SYMPTOMS

HA-11

< SYMPTOM DIAGNOSIS >

C

D

E

F

G

H

J

K

L

MA

B

HA

N

O

P

COMPRESSOR SYSTEM SYMPTOMS

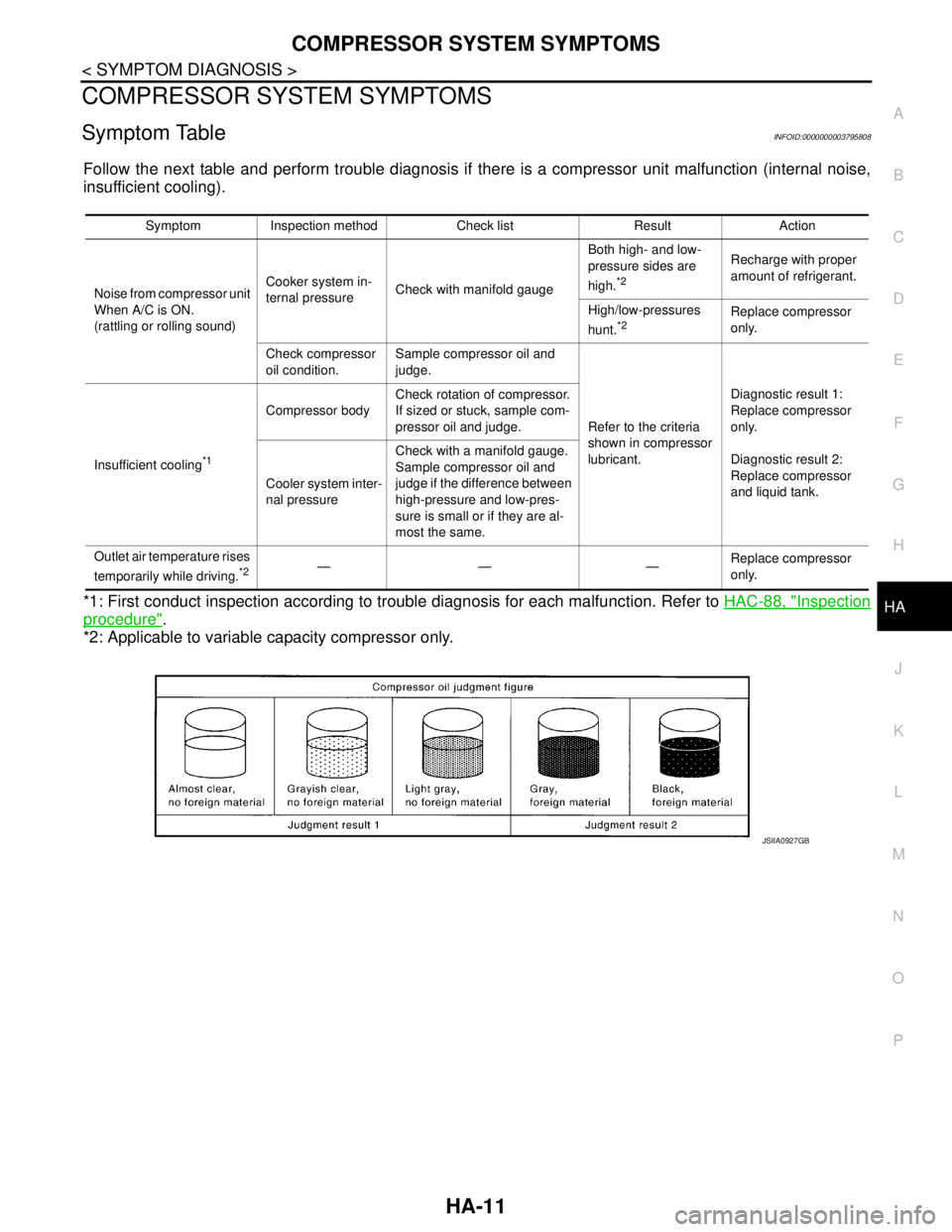

Symptom TableINFOID:0000000003795808

Follow the next table and perform trouble diagnosis if there is a compressor unit malfunction (internal noise,

insufficient cooling).

*1: First conduct inspection according to trouble diagnosis for each malfunction. Refer to HAC-88, "

Inspection

procedure".

*2: Applicable to variable capacity compressor only.

Symptom Inspection method Check list Result Action

Noise from compressor unit

When A/C is ON.

(rattling or rolling sound)Cooker system in-

ternal pressureCheck with manifold gaugeBoth high- and low-

pressure sides are

high.

*2

Recharge with proper

amount of refrigerant.

High/low-pressures

hunt.

*2Replace compressor

only.

Check compressor

oil condition.Sample compressor oil and

judge.

Refer to the criteria

shown in compressor

lubricant.Diagnostic result 1:

Replace compressor

only.

Diagnostic result 2:

Replace compressor

and liquid tank. Insufficient cooling

*1

Compressor bodyCheck rotation of compressor.

If sized or stuck, sample com-

pressor oil and judge.

Cooler system inter-

nal pressureCheck with a manifold gauge.

Sample compressor oil and

judge if the difference between

high-pressure and low-pres-

sure is small or if they are al-

most the same.

Outlet air temperature rises

temporarily while driving.

*2—— —Replace compressor

only.

JSIIA0927GB