Ioni NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 857 of 5121

BCS-40

< COMPONENT DIAGNOSIS >

COMBINATION SWITCH OUTPUT CIRCUIT

COMBINATION SWITCH OUTPUT CIRCUIT

Diagnosis ProcedureINFOID:0000000003809626

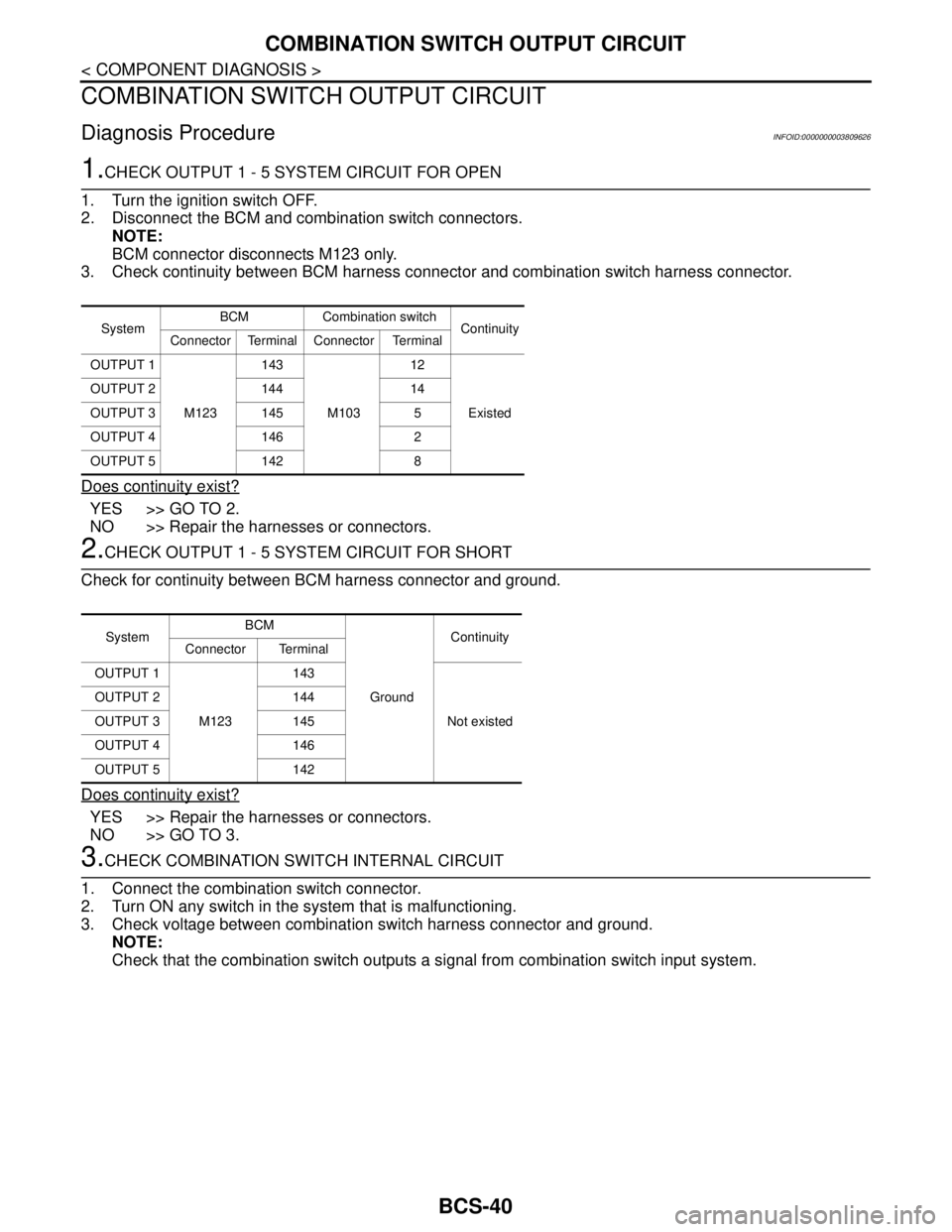

1.CHECK OUTPUT 1 - 5 SYSTEM CIRCUIT FOR OPEN

1. Turn the ignition switch OFF.

2. Disconnect the BCM and combination switch connectors.

NOTE:

BCM connector disconnects M123 only.

3. Check continuity between BCM harness connector and combination switch harness connector.

Does continuity exist?

YES >> GO TO 2.

NO >> Repair the harnesses or connectors.

2.CHECK OUTPUT 1 - 5 SYSTEM CIRCUIT FOR SHORT

Check for continuity between BCM harness connector and ground.

Does continuity exist?

YES >> Repair the harnesses or connectors.

NO >> GO TO 3.

3.CHECK COMBINATION SWITCH INTERNAL CIRCUIT

1. Connect the combination switch connector.

2. Turn ON any switch in the system that is malfunctioning.

3. Check voltage between combination switch harness connector and ground.

NOTE:

Check that the combination switch outputs a signal from combination switch input system.

SystemBCM Combination switch

Continuity

Connector Terminal Connector Terminal

OUTPUT 1

M123143

M10312

Existed OUTPUT 2 144 14

OUTPUT 3 145 5

OUTPUT 4 146 2

OUTPUT 5 142 8

SystemBCM

GroundContinuity

Connector Terminal

OUTPUT 1

M123143

Not existed OUTPUT 2 144

OUTPUT 3 145

OUTPUT 4 146

OUTPUT 5 142

Page 871 of 5121

BCS-54

< ECU DIAGNOSIS >

BCM (BODY CONTROL MODULE)

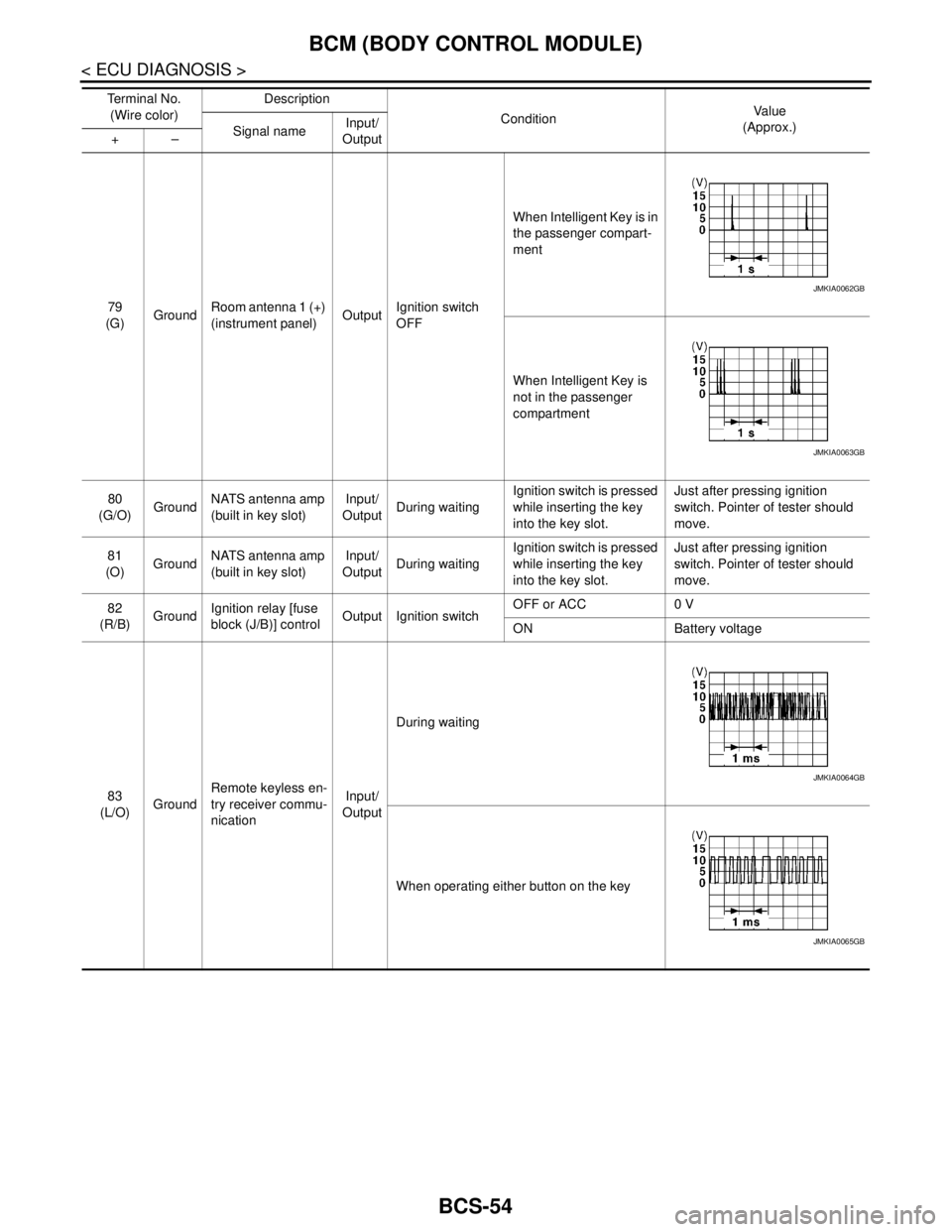

79

(G)GroundRoom antenna 1 (+)

(instrument panel)OutputIgnition switch

OFFWhen Intelligent Key is in

the passenger compart-

ment

When Intelligent Key is

not in the passenger

compartment

80

(G/O)GroundNATS antenna amp

(built in key slot)Input/

OutputDuring waitingIgnition switch is pressed

while inserting the key

into the key slot.Just after pressing ignition

switch. Pointer of tester should

move.

81

(O)GroundNATS antenna amp

(built in key slot)Input/

OutputDuring waitingIgnition switch is pressed

while inserting the key

into the key slot.Just after pressing ignition

switch. Pointer of tester should

move.

82

(R/B)GroundIgnition relay [fuse

block (J/B)] controlOutput Ignition switchOFF or ACC 0 V

ON Battery voltage

83

(L/O)GroundRemote keyless en-

try receiver commu-

nicationInput/

OutputDuring waiting

When operating either button on the key Te r m i n a l N o .

(Wire color)Description

ConditionVa l u e

(Approx.)

Signal nameInput/

Output +–

JMKIA0062GB

JMKIA0063GB

JMKIA0064GB

JMKIA0065GB

Page 878 of 5121

BCS

BCM (BODY CONTROL MODULE)

BCS-61

< ECU DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L B A

O

P N

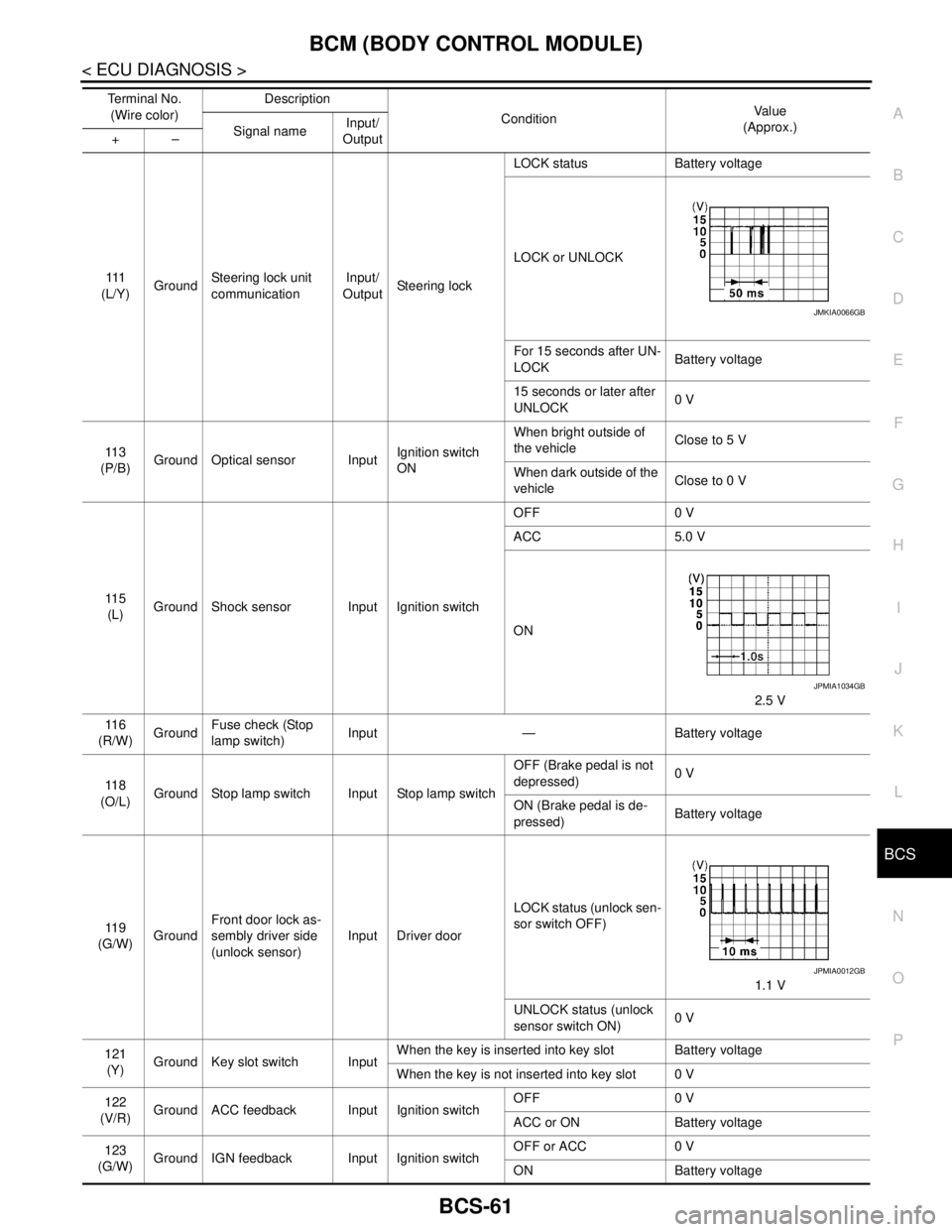

111

(L/Y)GroundSteering lock unit

communicationInput/

OutputSteering lockLOCK status Battery voltage

LOCK or UNLOCK

For 15 seconds after UN-

LOCKBattery voltage

15 seconds or later after

UNLOCK0 V

11 3

(P/B)Ground Optical sensor InputIgnition switch

ONWhen bright outside of

the vehicleClose to 5 V

When dark outside of the

vehicleClose to 0 V

11 5

(L)Ground Shock sensor Input Ignition switchOFF 0 V

ACC 5.0 V

ON

2.5 V

11 6

(R/W)GroundFuse check (Stop

lamp switch)Input — Battery voltage

11 8

(O/L)Ground Stop lamp switch Input Stop lamp switchOFF (Brake pedal is not

depressed)0 V

ON (Brake pedal is de-

pressed)Battery voltage

11 9

(G/W)GroundFront door lock as-

sembly driver side

(unlock sensor)Input Driver doorLOCK status (unlock sen-

sor switch OFF)

1.1 V

UNLOCK status (unlock

sensor switch ON)0 V

121

(Y)Ground Key slot switch InputWhen the key is inserted into key slot Battery voltage

When the key is not inserted into key slot 0 V

122

(V/R)Ground ACC feedback Input Ignition switchOFF 0 V

ACC or ON Battery voltage

123

(G/W)Ground IGN feedback Input Ignition switchOFF or ACC 0 V

ON Battery voltage Te r m i n a l N o .

(Wire color)Description

ConditionVa l u e

(Approx.)

Signal nameInput/

Output +–

JMKIA0066GB

JPMIA1034GB

JPMIA0012GB

Page 879 of 5121

BCS-62

< ECU DIAGNOSIS >

BCM (BODY CONTROL MODULE)

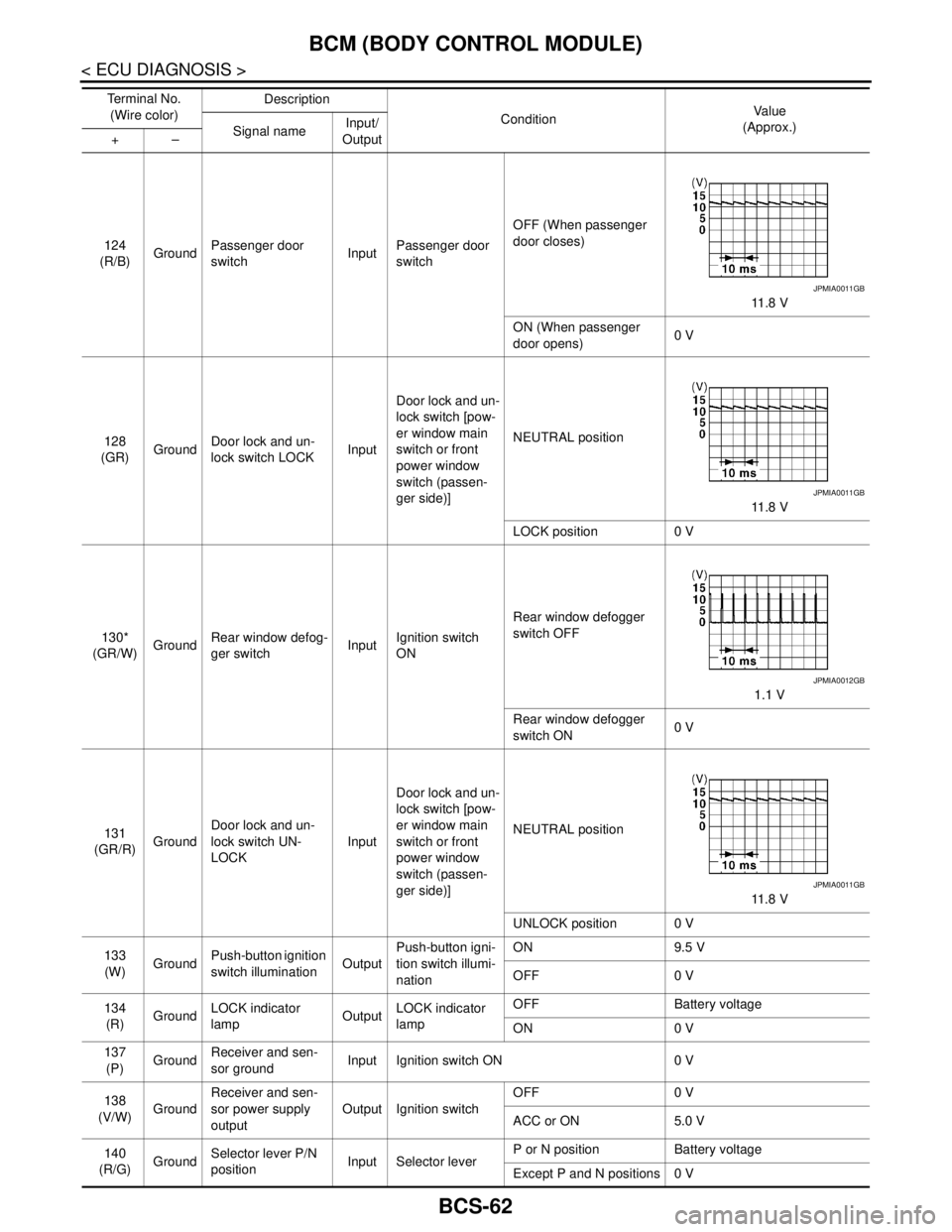

124

(R/B)GroundPassenger door

switchInputPassenger door

switchOFF (When passenger

door closes)

11 . 8 V

ON (When passenger

door opens)0 V

128

(GR)GroundDoor lock and un-

lock switch LOCKInputDoor lock and un-

lock switch [pow-

er window main

switch or front

power window

switch (passen-

ger side)]NEUTRAL position

11 . 8 V

LOCK position 0 V

130*

(GR/W)GroundRear window defog-

ger switchInputIgnition switch

ONRear window defogger

switch OFF

1.1 V

Rear window defogger

switch ON0 V

131

(GR/R)GroundDoor lock and un-

lock switch UN-

LOCKInputDoor lock and un-

lock switch [pow-

er window main

switch or front

power window

switch (passen-

ger side)]NEUTRAL position

11 . 8 V

UNLOCK position 0 V

133

(W)GroundPush-button ignition

switch illuminationOutputPush-button igni-

tion switch illumi-

nationON 9.5 V

OFF 0 V

134

(R)GroundLOCK indicator

lampOutputLOCK indicator

lampOFF Battery voltage

ON 0 V

137

(P)GroundReceiver and sen-

sor groundInput Ignition switch ON 0 V

138

(V/W)GroundReceiver and sen-

sor power supply

outputOutput Ignition switchOFF 0 V

ACC or ON 5.0 V

140

(R/G)GroundSelector lever P/N

positionInput Selector leverP or N position Battery voltage

Except P and N positions 0 V Te r m i n a l N o .

(Wire color)Description

ConditionVa l u e

(Approx.)

Signal nameInput/

Output +–

JPMIA0011GB

JPMIA0011GB

JPMIA0012GB

JPMIA0011GB

Page 893 of 5121

BCS-76

< SYMPTOM DIAGNOSIS >

COMBINATION SWITCH SYSTEM SYMPTOMS

SYMPTOM DIAGNOSIS

COMBINATION SWITCH SYSTEM SYMPTOMS

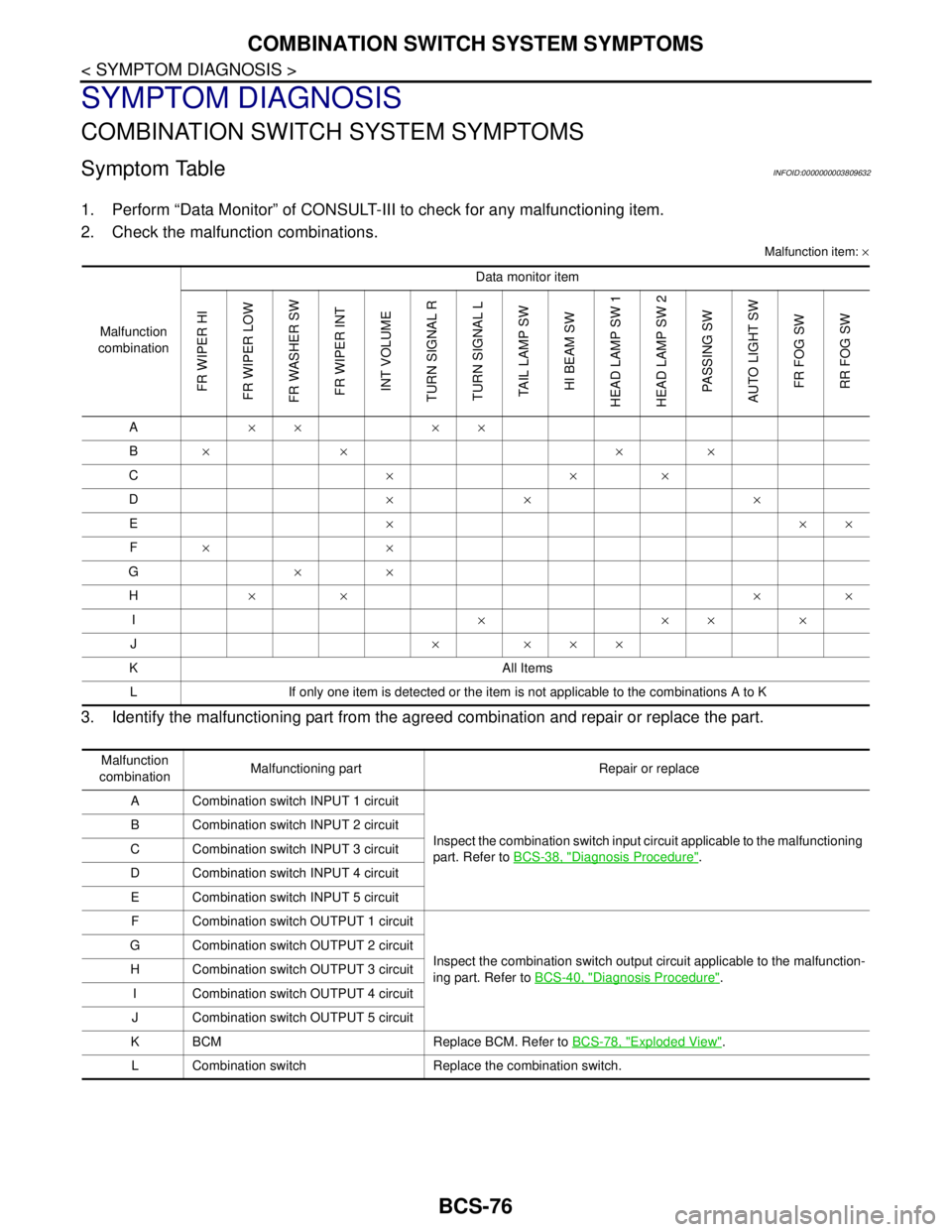

Symptom TableINFOID:0000000003809632

1. Perform “Data Monitor” of CONSULT-III to check for any malfunctioning item.

2. Check the malfunction combinations.

Malfunction item: ×

3. Identify the malfunctioning part from the agreed combination and repair or replace the part.

Malfunction

combinationData monitor item

FR WIPER HI

FR WIPER LOW

FR WASHER SW

FR WIPER INT

INT VOLUME

TURN SIGNAL R

TURN SIGNAL L

TAIL LAMP SW

HI BEAM SW

HEAD LAMP SW 1

HEAD LAMP SW 2

PASSING SW

AUTO LIGHT SW

FR FOG SW

RR FOG SW

A×× ××

B×× ××

C×××

D×× ×

E×××

F××

G××

H×× ××

I××××

J× ×××

K All Items

L If only one item is detected or the item is not applicable to the combinations A to K

Malfunction

combinationMalfunctioning part Repair or replace

A Combination switch INPUT 1 circuit

Inspect the combination switch input circuit applicable to the malfunctioning

part. Refer to BCS-38, "

Diagnosis Procedure". B Combination switch INPUT 2 circuit

C Combination switch INPUT 3 circuit

D Combination switch INPUT 4 circuit

E Combination switch INPUT 5 circuit

F Combination switch OUTPUT 1 circuit

Inspect the combination switch output circuit applicable to the malfunction-

ing part. Refer to BCS-40, "

Diagnosis Procedure". G Combination switch OUTPUT 2 circuit

H Combination switch OUTPUT 3 circuit

I Combination switch OUTPUT 4 circuit

J Combination switch OUTPUT 5 circuit

K BCM Replace BCM. Refer to BCS-78, "

Exploded View".

L Combination switch Replace the combination switch.

Page 895 of 5121

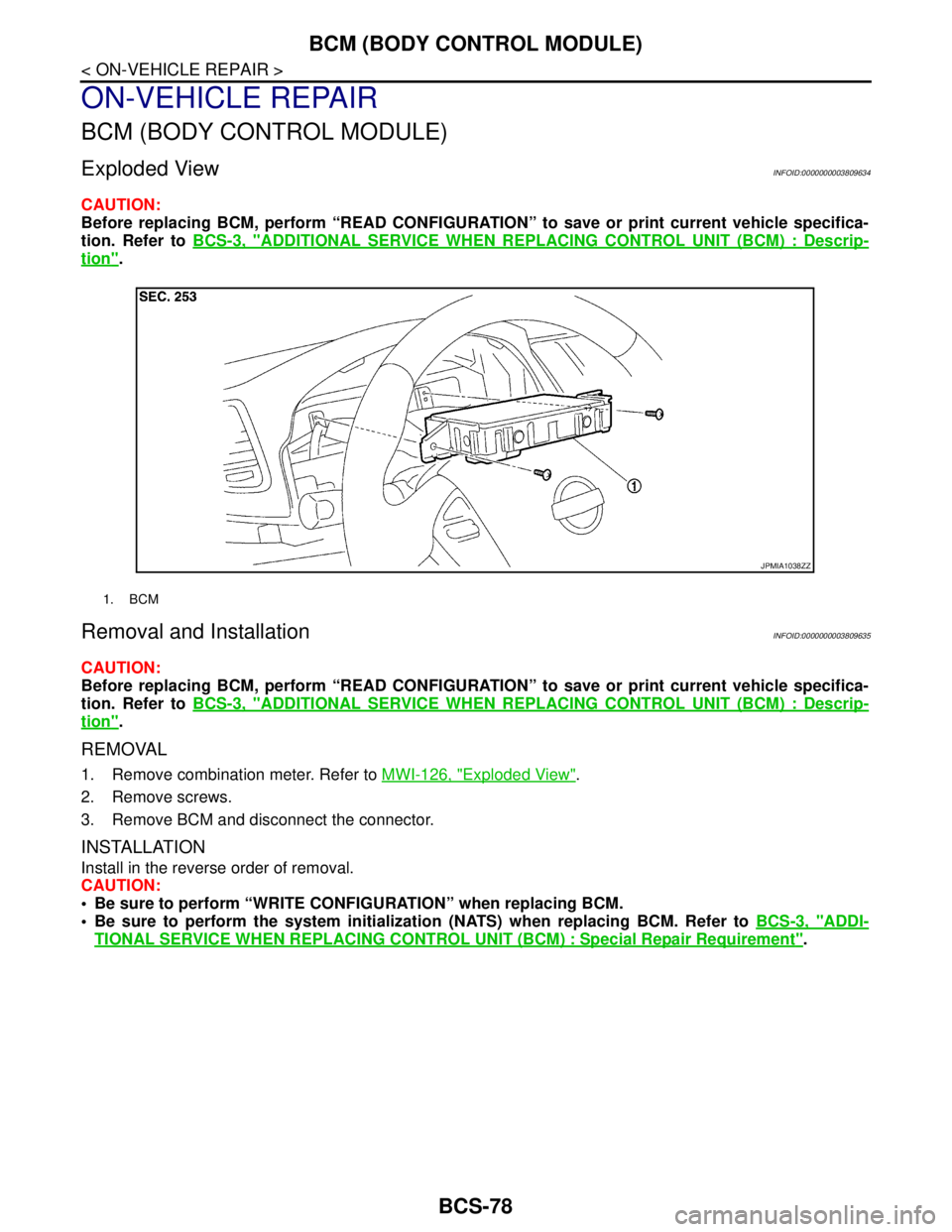

BCS-78

< ON-VEHICLE REPAIR >

BCM (BODY CONTROL MODULE)

ON-VEHICLE REPAIR

BCM (BODY CONTROL MODULE)

Exploded ViewINFOID:0000000003809634

CAUTION:

Before replacing BCM, perform “READ CONFIGURATION” to save or print current vehicle specifica-

tion. Refer to BCS-3, "

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT (BCM) : Descrip-

tion".

Removal and InstallationINFOID:0000000003809635

CAUTION:

Before replacing BCM, perform “READ CONFIGURATION” to save or print current vehicle specifica-

tion. Refer to BCS-3, "

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT (BCM) : Descrip-

tion".

REMOVAL

1. Remove combination meter. Refer to MWI-126, "Exploded View".

2. Remove screws.

3. Remove BCM and disconnect the connector.

INSTALLATION

Install in the reverse order of removal.

CAUTION:

Be sure to perform “WRITE CONFIGURATION” when replacing BCM.

Be sure to perform the system initialization (NATS) when replacing BCM. Refer to BCS-3, "

ADDI-

TIONAL SERVICE WHEN REPLACING CONTROL UNIT (BCM) : Special Repair Requirement".

1. BCM

JPMIA1038ZZ

Page 896 of 5121

BCS

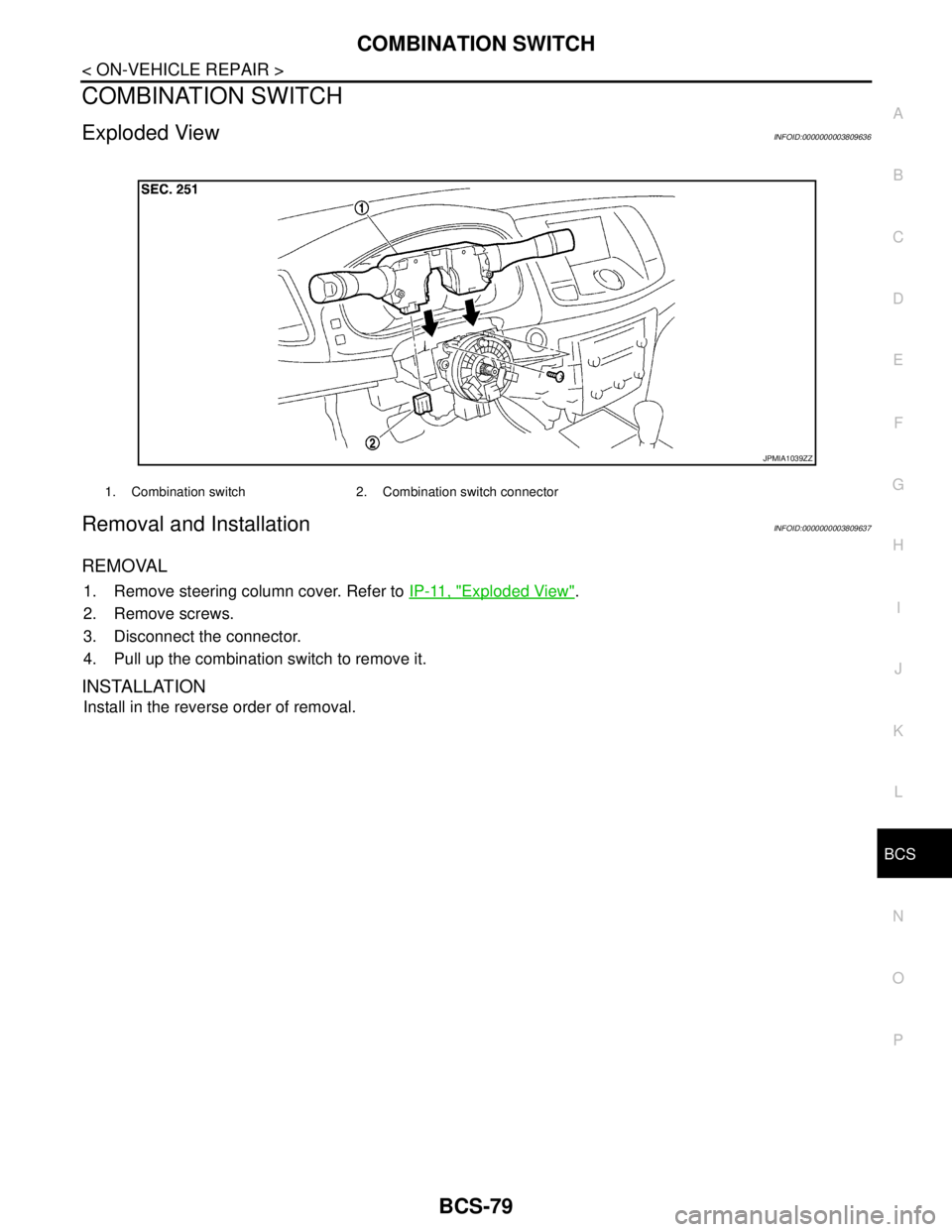

COMBINATION SWITCH

BCS-79

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

L B A

O

P N

COMBINATION SWITCH

Exploded ViewINFOID:0000000003809636

Removal and InstallationINFOID:0000000003809637

REMOVAL

1. Remove steering column cover. Refer to IP-11, "Exploded View".

2. Remove screws.

3. Disconnect the connector.

4. Pull up the combination switch to remove it.

INSTALLATION

Install in the reverse order of removal.

1. Combination switch 2. Combination switch connector

JPMIA1039ZZ

Page 905 of 5121

BRAKE FLUID

BR-9

< ON-VEHICLE MAINTENANCE >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

BRAKE FLUID

InspectionINFOID:0000000003811173

BRAKE FLUID LEVEL

Check that the fluid level in the sub tank is within the specified

range (MAX – MIN lines).

Visually check for any brake fluid leakage around the sub tank,

reservoir tank and hose.

Check the brake system for any leakage if the fluid level is

extremely low (lower than MIN).

Check the brake system for fluid leakage if the warning lamp

remains illuminated even after the parking brake is released.

BRAKE LINE

1. Check brake line (tubes and hoses) for cracks, deterioration or other damage. Replace any damaged

parts.

2. Check for fluid leakage by fully depressing brake pedal while

engine is running.

CAUTION:

If leakage occurs around joints, retighten or, if necessary,

replace damaged parts.

DrainingINFOID:0000000003811174

CAUTION:

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with water if it gets on a painted surface.

Turn the ignition switch OFF and disconnect the ABS actuator and electric unit (control unit) con-

nector or the battery negative terminal before draining.

1. Connect a vinyl tube to the bleed valve.

2. Depress the brake pedal and loosen the bleeder valve to gradu-

ally discharge brake fluid.

RefillingINFOID:0000000003811175

CAUTION:

Turn the ignition switch OFF and disconnect the ABS actuator and electric unit (control unit) connec-

tor or the battery negative terminal before refilling.

1. Check that there is no foreign material in the sub tank, and refill with new brake fluid.

CAUTION:

Never reuse drained brake fluid.

JPFIA0007ZZ

SBR389C

BRA0007D

Page 907 of 5121

BRAKE MASTER CYLINDER

BR-11

< ON-VEHICLE MAINTENANCE >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

BRAKE MASTER CYLINDER

InspectionINFOID:0000000003811177

FLUID LEAK

Check for brake fluid leakage from the master cylinder mounting face, reservoir tank mounting face, and brake

tube connections.

Page 908 of 5121

BR-12

< ON-VEHICLE MAINTENANCE >

BRAKE BOOSTER

BRAKE BOOSTER

InspectionINFOID:0000000003811178

OPERATION

Depress the brake pedal several times at 5-second intervals with the

engine stopped. Start the engine with the brake pedal fully

depressed. Check that the clearance between brake pedal and dash

lower panel decreases.

NOTE:

A slight impact with a small click may be felt on the pedal when the

brake pedal is fully depressed. This is a normal phenomenon due to

the brake system operation.

AIR TIGHT

Idle the engine for 1 minute to apply vacuum to the brake booster,

and stop the engine. Then depress the brake pedal several times

at 5-second intervals until the accumulated vacuum is released to

atmospheric pressure. Check that the clearance between brake

pedal and dash lower panel gradually increases (A → B → C) each

time the brake pedal is depressed during this operation.

Depress the brake pedal with the engine running. Then stop the

engine while holding down the brake pedal. Check that the brake

pedal stroke does not change after holding down the brake pedal

for 30 seconds or more.

NOTE:

A slight impact with a small click may be felt on the pedal when the

brake pedal is fully depressed. This is a normal phenomenon due

to the brake system operation.

BRA0037D

JPFIA0043ZZ

JPFIA0044ZZ