Ioni NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 931 of 5121

FRONT DISC BRAKE

BR-35

< ON-VEHICLE REPAIR >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

DISASSEMBLY

BRAKE CALIPER ASSEMBLY : Removal and InstallationINFOID:0000000003811208

REMOVAL

WARNING:

Clean any dust from the brake caliper and brake pads with a vacuum dust collector. Never blow with

compressed air.

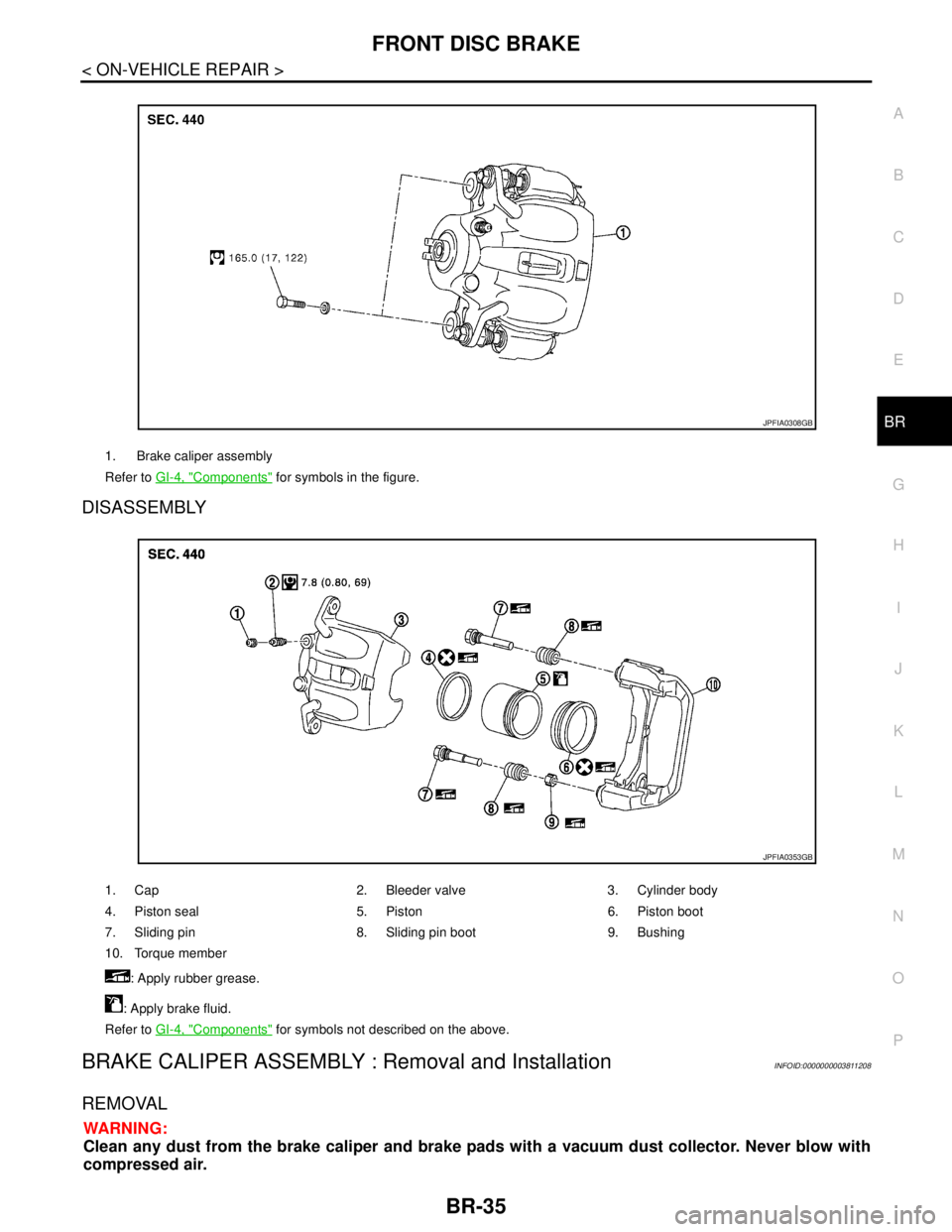

1. Brake caliper assembly

Refer to GI-4, "

Components" for symbols in the figure.

JPFIA0308GB

1. Cap 2. Bleeder valve 3. Cylinder body

4. Piston seal 5. Piston 6. Piston boot

7. Sliding pin 8. Sliding pin boot 9. Bushing

10. Torque member

: Apply rubber grease.

: Apply brake fluid.

Refer to GI-4, "

Components" for symbols not described on the above.

JPFIA0353GB

Page 934 of 5121

BR-38

< ON-VEHICLE REPAIR >

FRONT DISC BRAKE

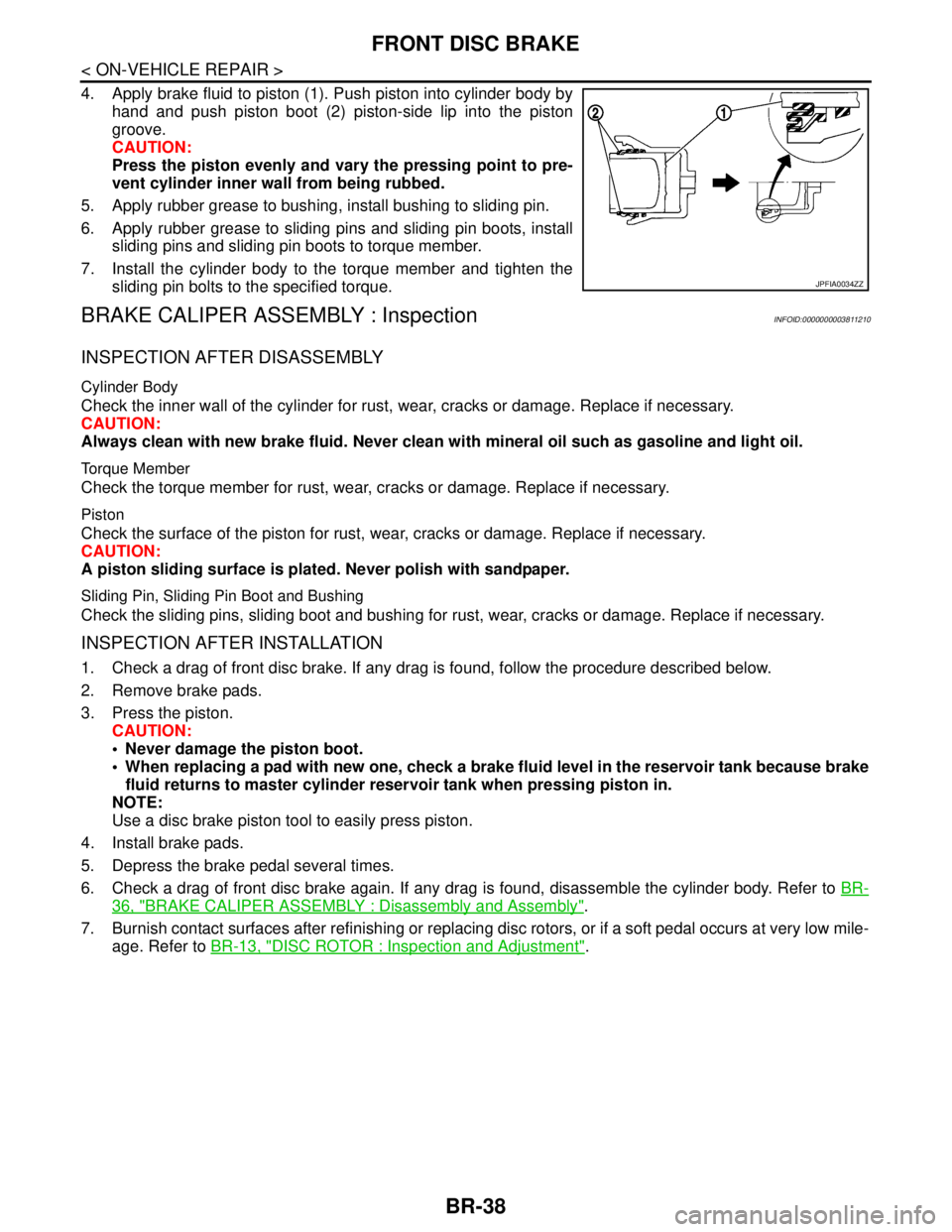

4. Apply brake fluid to piston (1). Push piston into cylinder body by

hand and push piston boot (2) piston-side lip into the piston

groove.

CAUTION:

Press the piston evenly and vary the pressing point to pre-

vent cylinder inner wall from being rubbed.

5. Apply rubber grease to bushing, install bushing to sliding pin.

6. Apply rubber grease to sliding pins and sliding pin boots, install

sliding pins and sliding pin boots to torque member.

7. Install the cylinder body to the torque member and tighten the

sliding pin bolts to the specified torque.

BRAKE CALIPER ASSEMBLY : InspectionINFOID:0000000003811210

INSPECTION AFTER DISASSEMBLY

Cylinder Body

Check the inner wall of the cylinder for rust, wear, cracks or damage. Replace if necessary.

CAUTION:

Always clean with new brake fluid. Never clean with mineral oil such as gasoline and light oil.

Torque Member

Check the torque member for rust, wear, cracks or damage. Replace if necessary.

Piston

Check the surface of the piston for rust, wear, cracks or damage. Replace if necessary.

CAUTION:

A piston sliding surface is plated. Never polish with sandpaper.

Sliding Pin, Sliding Pin Boot and Bushing

Check the sliding pins, sliding boot and bushing for rust, wear, cracks or damage. Replace if necessary.

INSPECTION AFTER INSTALLATION

1. Check a drag of front disc brake. If any drag is found, follow the procedure described below.

2. Remove brake pads.

3. Press the piston.

CAUTION:

Never damage the piston boot.

When replacing a pad with new one, check a brake fluid level in the reservoir tank because brake

fluid returns to master cylinder reservoir tank when pressing piston in.

NOTE:

Use a disc brake piston tool to easily press piston.

4. Install brake pads.

5. Depress the brake pedal several times.

6. Check a drag of front disc brake again. If any drag is found, disassemble the cylinder body. Refer to BR-

36, "BRAKE CALIPER ASSEMBLY : Disassembly and Assembly".

7. Burnish contact surfaces after refinishing or replacing disc rotors, or if a soft pedal occurs at very low mile-

age. Refer to BR-13, "

DISC ROTOR : Inspection and Adjustment".

JPFIA0034ZZ

Page 935 of 5121

REAR DISC BRAKE

BR-39

< ON-VEHICLE REPAIR >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

REAR DISC BRAKE

BRAKE PAD

BRAKE PAD : Exploded ViewINFOID:0000000003811211

BRAKE PAD : Removal and InstallationINFOID:0000000003811212

REMOVAL

WARNING:

Clean any dust from the brake caliper and brake pads with a vacuum dust collector. Never blow with

compressed air.

CAUTION:

Never depress the brake pedal while removing the brake pads or the cylinder body because the pis-

ton may pop out.

Never spill or splash brake fluid on the disc rotor.

1. Remove tires.

2. Remove the upper sliding pin bolt.

3. Suspend the cylinder body with suitable wire so that the brake hose will not stretch. Remove the brake

pads and shims from the torque member.

CAUTION:

Never deform the pad retainers if removing the pad retainers.

Never damage the piston boot.

Never drop the brake pad and shims.

INSTALLATION

WARNING:

Clean any dust from the brake caliper and brake pads with a vacuum dust collector. Never blow with

compressed air.

CAUTION:

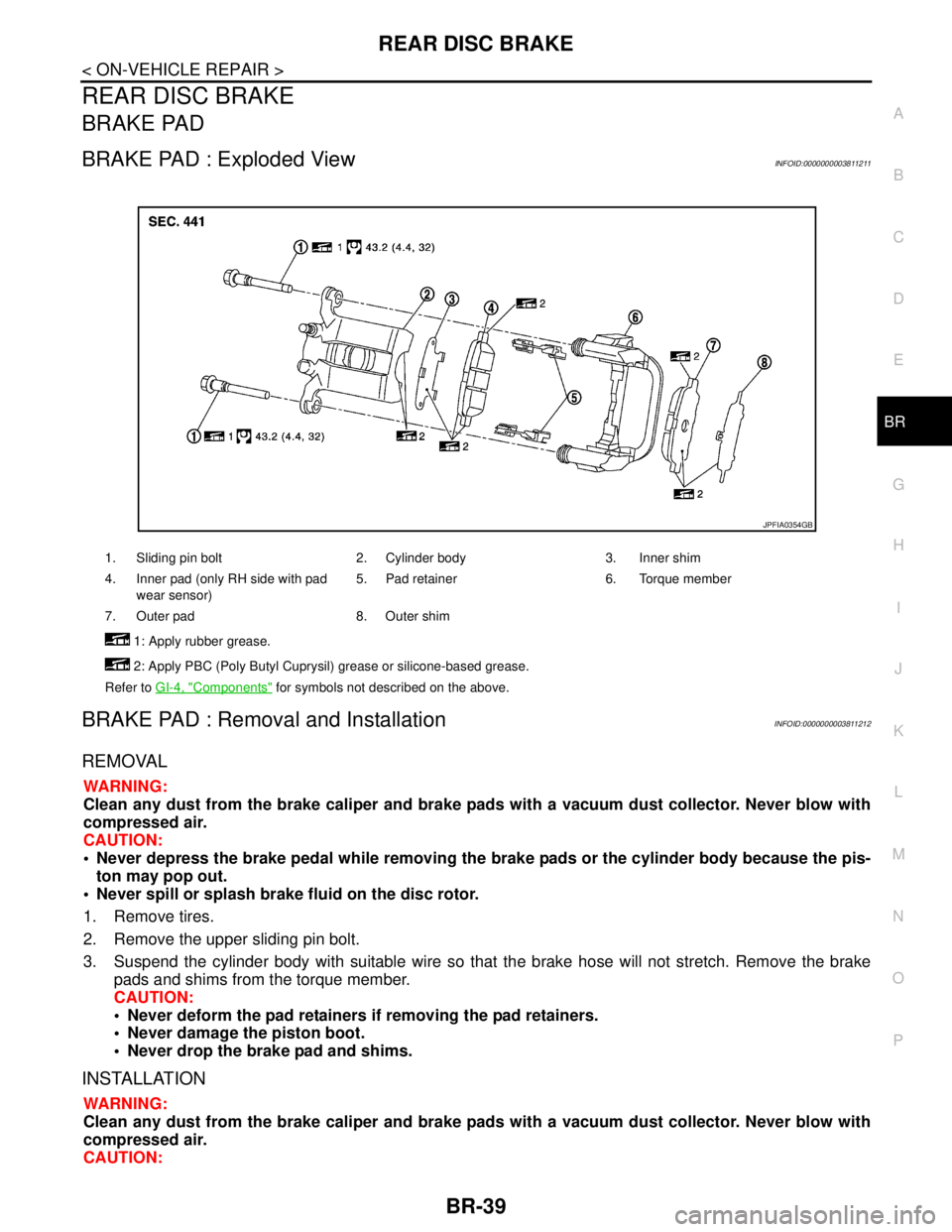

1. Sliding pin bolt 2. Cylinder body 3. Inner shim

4. Inner pad (only RH side with pad

wear sensor)5. Pad retainer 6. Torque member

7. Outer pad 8. Outer shim

1: Apply rubber grease.

2: Apply PBC (Poly Butyl Cuprysil) grease or silicone-based grease.

Refer to GI-4, "

Components" for symbols not described on the above.

JPFIA0354GB

Page 936 of 5121

BR-40

< ON-VEHICLE REPAIR >

REAR DISC BRAKE

Never depress the brake pedal while removing the brake pads or the cylinder body because the pis-

ton may pop out.

Never spill or splash brake fluid on the disc rotor.

1. Install the pad retainers to the torque member if the pad retainers has been removed.

CAUTION:

Securely assemble the pad retainers not to be lifted up from the torque member.

Never deform the pad retainers.

2. Apply PBC (Poly Butyl Cuprysil) grease or silicone-based grease to the mating faces between the brake

pads, the shims and pawls part of cylinder body, and install them to the brake pad.

CAUTION:

Always replace the shims together when replacing the brake pad.

3. Install cylinder body and brake pads to torque member.

CAUTION:

Never damage the piston boot.

When replacing pads with new one, check a brake fluid level in the reservoir tank because brake

fluid returns to master cylinder reservoir tank when pressing piston in.

NOTE:

Use a disc brake piston tool to easily press piston.

4. Install the upper sliding pin bolt and tighten it to the specified torque.

5. Depress the brake pedal several times to check that no drag feel is present for the rear disc brake. Refer

to BR-40, "

BRAKE PAD : Inspection".

BRAKE PAD : InspectionINFOID:0000000003811213

INSPECTION AFTER REMOVAL

Replace the shims if rust is excessively attached.

INSPECTION AFTER INSTALLATION

1. Check a drag of rear disc brake. If any drag is found, follow the procedure described below.

2. Remove brake pads.

3. Press the piston.

CAUTION:

Never damage the piston boot.

When replacing a pad with new one, check a brake fluid level in the reservoir tank because brake

fluid returns to master cylinder reservoir tank when pressing piston in.

NOTE:

Use a disc brake piston tool to easily press piston.

4. Install brake pads.

5. Depress the brake pedal several times.

6. Check a drag of rear disc brake again. If any drag is found, disassemble the cylinder body. Refer to BR-

42, "BRAKE CALIPER ASSEMBLY : Disassembly and Assembly".

7. Burnish contact surfaces after refinishing or replacing pads, or if a soft pedal occurs at very low mileage.

Refer to BR-15, "

BRAKE PAD : Inspection and Adjustment".

BRAKE CALIPER ASSEMBLY

BRAKE CALIPER ASSEMBLY : Exploded ViewINFOID:0000000003811214

REMOVAL

Page 937 of 5121

REAR DISC BRAKE

BR-41

< ON-VEHICLE REPAIR >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

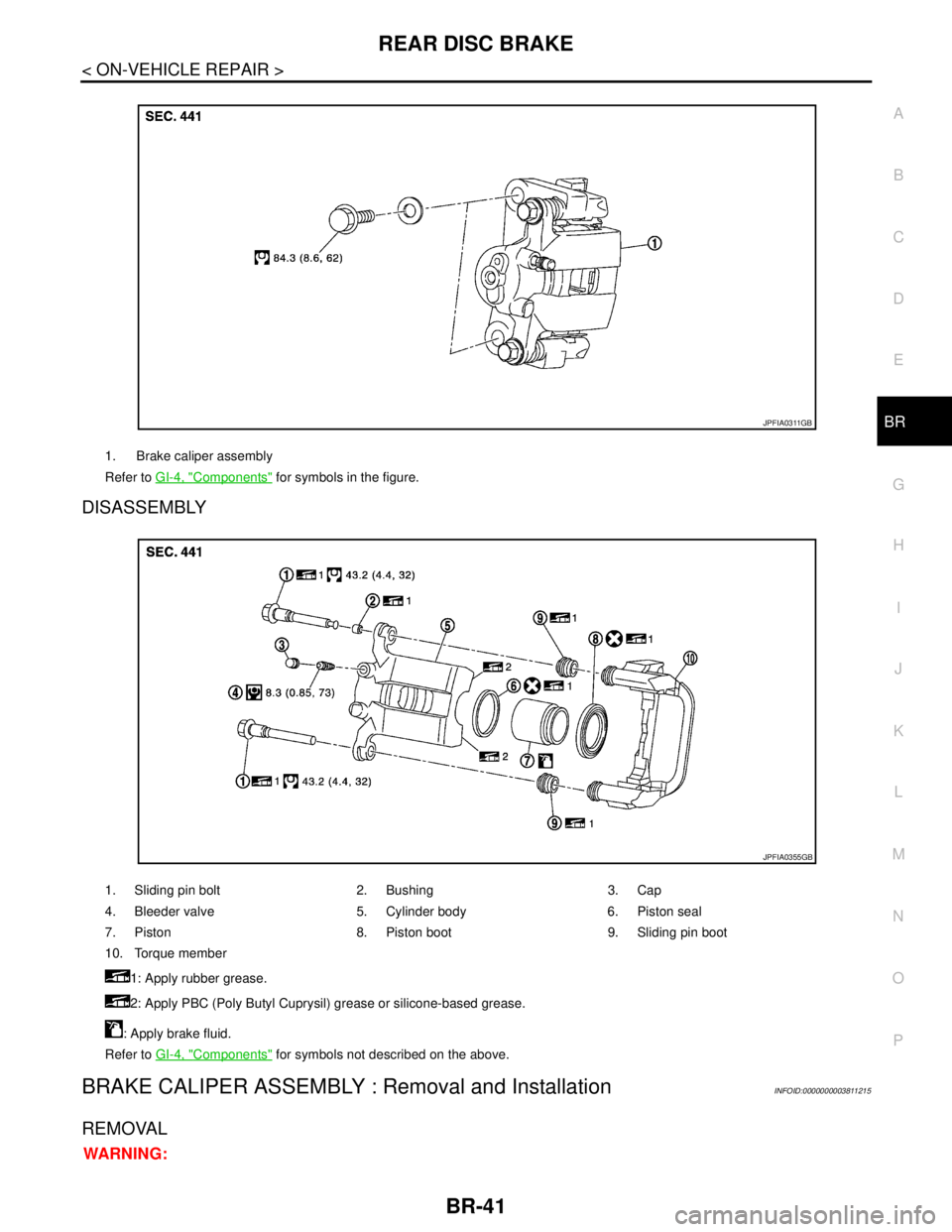

DISASSEMBLY

BRAKE CALIPER ASSEMBLY : Removal and InstallationINFOID:0000000003811215

REMOVAL

WARNING:

1. Brake caliper assembly

Refer to GI-4, "

Components" for symbols in the figure.

JPFIA0311GB

1. Sliding pin bolt 2. Bushing 3. Cap

4. Bleeder valve 5. Cylinder body 6. Piston seal

7. Piston 8. Piston boot 9. Sliding pin boot

10. Torque member

1: Apply rubber grease.

2: Apply PBC (Poly Butyl Cuprysil) grease or silicone-based grease.

: Apply brake fluid.

Refer to GI-4, "

Components" for symbols not described on the above.

JPFIA0355GB

Page 940 of 5121

BR-44

< ON-VEHICLE REPAIR >

REAR DISC BRAKE

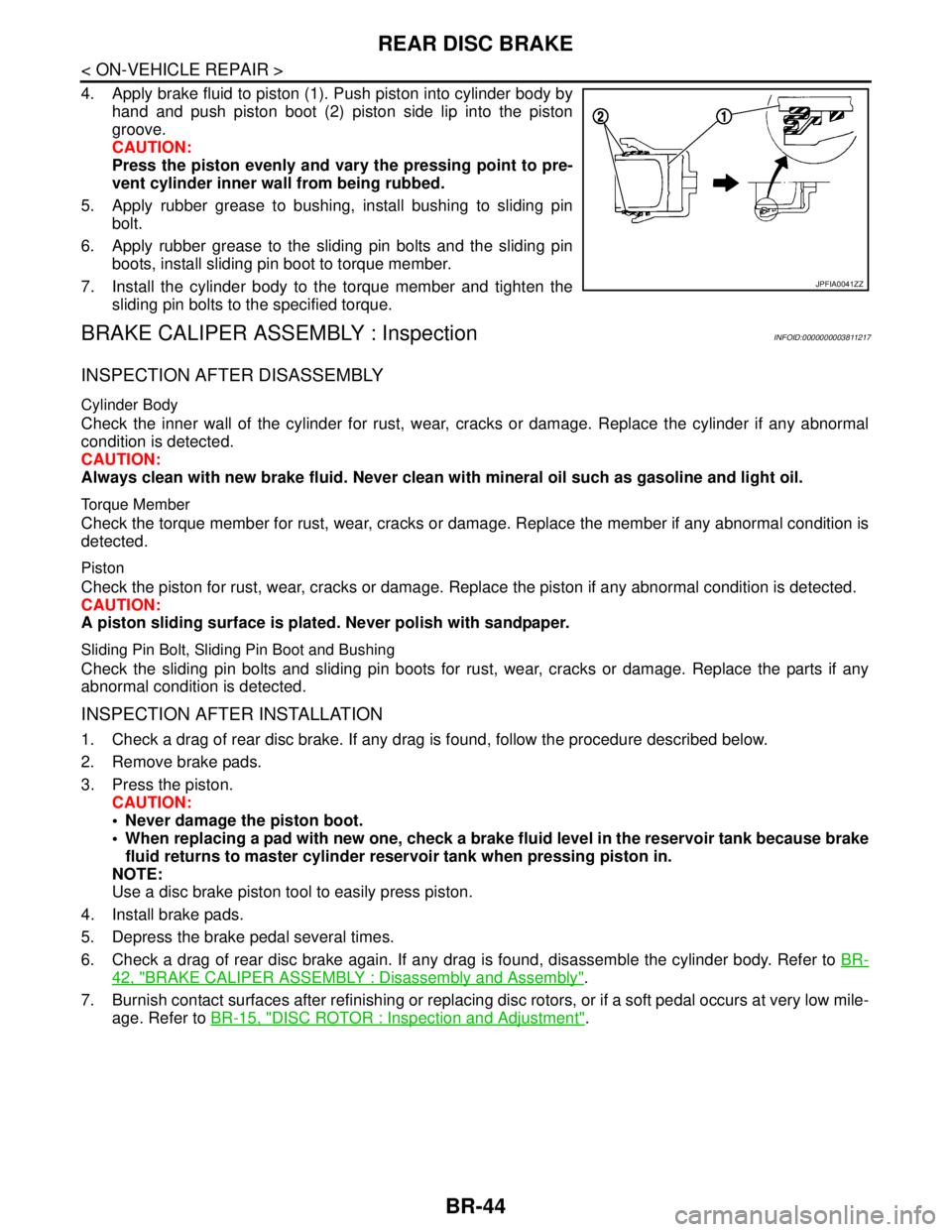

4. Apply brake fluid to piston (1). Push piston into cylinder body by

hand and push piston boot (2) piston side lip into the piston

groove.

CAUTION:

Press the piston evenly and vary the pressing point to pre-

vent cylinder inner wall from being rubbed.

5. Apply rubber grease to bushing, install bushing to sliding pin

bolt.

6. Apply rubber grease to the sliding pin bolts and the sliding pin

boots, install sliding pin boot to torque member.

7. Install the cylinder body to the torque member and tighten the

sliding pin bolts to the specified torque.

BRAKE CALIPER ASSEMBLY : InspectionINFOID:0000000003811217

INSPECTION AFTER DISASSEMBLY

Cylinder Body

Check the inner wall of the cylinder for rust, wear, cracks or damage. Replace the cylinder if any abnormal

condition is detected.

CAUTION:

Always clean with new brake fluid. Never clean with mineral oil such as gasoline and light oil.

Torque Member

Check the torque member for rust, wear, cracks or damage. Replace the member if any abnormal condition is

detected.

Piston

Check the piston for rust, wear, cracks or damage. Replace the piston if any abnormal condition is detected.

CAUTION:

A piston sliding surface is plated. Never polish with sandpaper.

Sliding Pin Bolt, Sliding Pin Boot and Bushing

Check the sliding pin bolts and sliding pin boots for rust, wear, cracks or damage. Replace the parts if any

abnormal condition is detected.

INSPECTION AFTER INSTALLATION

1. Check a drag of rear disc brake. If any drag is found, follow the procedure described below.

2. Remove brake pads.

3. Press the piston.

CAUTION:

Never damage the piston boot.

When replacing a pad with new one, check a brake fluid level in the reservoir tank because brake

fluid returns to master cylinder reservoir tank when pressing piston in.

NOTE:

Use a disc brake piston tool to easily press piston.

4. Install brake pads.

5. Depress the brake pedal several times.

6. Check a drag of rear disc brake again. If any drag is found, disassemble the cylinder body. Refer to BR-

42, "BRAKE CALIPER ASSEMBLY : Disassembly and Assembly".

7. Burnish contact surfaces after refinishing or replacing disc rotors, or if a soft pedal occurs at very low mile-

age. Refer to BR-15, "

DISC ROTOR : Inspection and Adjustment".

JPFIA0041ZZ

Page 948 of 5121

![NISSAN TEANA 2008 Service Manual DIAGNOSIS AND REPAIR WORK FLOW

BRC-7

< BASIC INSPECTION >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

1.COLLECT THE INFORMATION FROM THE CUSTOMER

Get the detailed information from the customer about the sym NISSAN TEANA 2008 Service Manual DIAGNOSIS AND REPAIR WORK FLOW

BRC-7

< BASIC INSPECTION >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

1.COLLECT THE INFORMATION FROM THE CUSTOMER

Get the detailed information from the customer about the sym](/img/5/57391/w960_57391-947.png)

DIAGNOSIS AND REPAIR WORK FLOW

BRC-7

< BASIC INSPECTION >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

1.COLLECT THE INFORMATION FROM THE CUSTOMER

Get the detailed information from the customer about the symptom (the condition and the environment when

the incident/malfunction occurred) using the diagnosis work sheet. Refer to BRC-8, "

Diagnostic Work Sheet".

>> GO TO 2.

2.PERFORM THE SELF-DIAGNOSIS

Check the DTC display with the self-diagnosis function.

Is there any DTC displayed?

YES >> GO TO 3.

NO >> GO TO 4.

3.PERFORM THE SYSTEM DIAGNOSIS

Perform the diagnosis applicable to the displayed DTC. Refer to BRC-48, "

DTC No. Index".

>> GO TO 7.

4.CHECK THE SYMPTOM THAT IS NOT CONSIDERED A SYSTEM MALFUNCTION

Check that the symptom is a normal operation that is not considered a system malfunction. Refer to BRC-54,

"Description".

Is the symptom a normal operation?

YES >> INSPECTION END

NO >> GO TO 5.

5.CHECK THE WARNING LAMP FOR ILLUMINATION

Check that the warning lamp illuminate.

• ABS warning lamp: Refer to BRC-40, "

Description".

Brake warning lamp: Refer to BRC-41, "

Description".

Is ON/OFF timing normal?

YES >> GO TO 6.

NO >> GO TO 2.

6.PERFORM THE DIAGNOSIS BY SYMPTOM

Perform the diagnosis applicable to the symptom.

>> GO TO 7.

7.REPAIR OR REPLACE THE MALFUNCTIONING PARTS

Repair or replace the specified malfunctioning parts.

>> GO TO 8.

8.MEMORY CLEAR

Perform self-diagnosis memory clear.

>> GO TO 9.

9.FINAL CHECK

Perform the self-diagnosis again, and check that the malfunction is repaired completely.

Is no other DTC present and the repair completed?

YES >> INSPECTION END

NO >> GO TO 3.

Page 950 of 5121

![NISSAN TEANA 2008 Service Manual ABS

BRC-9

< FUNCTION DIAGNOSIS >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

FUNCTION DIAGNOSIS

ABS

System DiagramINFOID:0000000003766722

System DescriptionINFOID:0000000003766723

Anti-Lock Braking System NISSAN TEANA 2008 Service Manual ABS

BRC-9

< FUNCTION DIAGNOSIS >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

FUNCTION DIAGNOSIS

ABS

System DiagramINFOID:0000000003766722

System DescriptionINFOID:0000000003766723

Anti-Lock Braking System](/img/5/57391/w960_57391-949.png)

ABS

BRC-9

< FUNCTION DIAGNOSIS >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

FUNCTION DIAGNOSIS

ABS

System DiagramINFOID:0000000003766722

System DescriptionINFOID:0000000003766723

Anti-Lock Braking System detects wheel revolution while braking, electronically controls braking force, and

prevents wheel locking during sudden braking. It improves handling stability and maneuverability for avoid-

ing obstacles.

Electrical system diagnosis by CONSULT-III is available.

JSFIA0257GB

Page 951 of 5121

![NISSAN TEANA 2008 Service Manual BRC-10

< FUNCTION DIAGNOSIS >[ABS]

ABS

Component Parts Location

INFOID:0000000003766724

Component DescriptionINFOID:0000000003766725

1. ABS warning lamp 2. Brake warning lamp 3.ABS actuator and electr NISSAN TEANA 2008 Service Manual BRC-10

< FUNCTION DIAGNOSIS >[ABS]

ABS

Component Parts Location

INFOID:0000000003766724

Component DescriptionINFOID:0000000003766725

1. ABS warning lamp 2. Brake warning lamp 3.ABS actuator and electr](/img/5/57391/w960_57391-950.png)

BRC-10

< FUNCTION DIAGNOSIS >[ABS]

ABS

Component Parts Location

INFOID:0000000003766724

Component DescriptionINFOID:0000000003766725

1. ABS warning lamp 2. Brake warning lamp 3.ABS actuator and electric unit (con-

trol unit)

4. Front wheel sensor 5. Rear wheel sensor

A. Combination meter B. Engine room right side C. Steering knuckle

D. Rear axle

JSFIA0258ZZ

Component parts Reference

ABS actuator and electric unit (control unit)Pump

BRC-25, "

Description"Motor

Actuator relay (main relay)BRC-36, "

Description"

Solenoid valveBRC-32, "Description"

Wheel sensorBRC-16, "Description"

ABS warning lampBRC-40, "Description"

Brake warning lampBRC-41, "Description"

Page 952 of 5121

![NISSAN TEANA 2008 Service Manual EBD

BRC-11

< FUNCTION DIAGNOSIS >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

EBD

System DiagramINFOID:0000000003767309

System DescriptionINFOID:0000000003766727

Electric Brake force Distribution is a fol NISSAN TEANA 2008 Service Manual EBD

BRC-11

< FUNCTION DIAGNOSIS >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

EBD

System DiagramINFOID:0000000003767309

System DescriptionINFOID:0000000003766727

Electric Brake force Distribution is a fol](/img/5/57391/w960_57391-951.png)

EBD

BRC-11

< FUNCTION DIAGNOSIS >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

EBD

System DiagramINFOID:0000000003767309

System DescriptionINFOID:0000000003766727

Electric Brake force Distribution is a following function. ABS actuator and electric unit (control unit) detects

subtle slippages between the front and rear wheels during braking. Then is electronically controls the rear

braking force (brake fluid pressure) to reducing and reduces rear wheel slippage. Accordingly it improves

vehicle stability.

Electrical system diagnosis by CONSULT-III is available.

JSFIA0257GB