Ioni NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 913 of 5121

BRAKE PEDAL

BR-17

< ON-VEHICLE REPAIR >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

ON-VEHICLE REPAIR

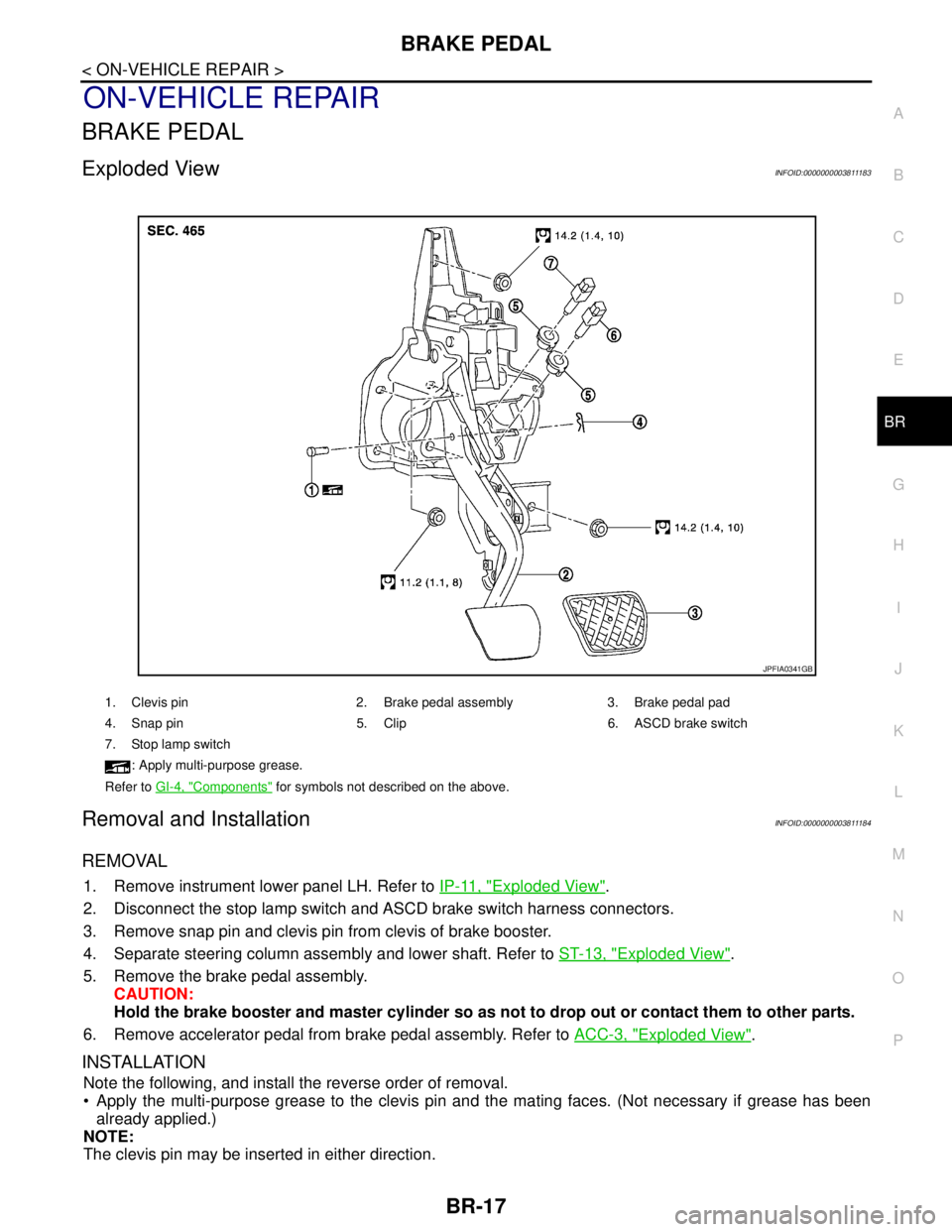

BRAKE PEDAL

Exploded ViewINFOID:0000000003811183

Removal and InstallationINFOID:0000000003811184

REMOVAL

1. Remove instrument lower panel LH. Refer to IP-11, "Exploded View".

2. Disconnect the stop lamp switch and ASCD brake switch harness connectors.

3. Remove snap pin and clevis pin from clevis of brake booster.

4. Separate steering column assembly and lower shaft. Refer to ST-13, "

Exploded View".

5. Remove the brake pedal assembly.

CAUTION:

Hold the brake booster and master cylinder so as not to drop out or contact them to other parts.

6. Remove accelerator pedal from brake pedal assembly. Refer to ACC-3, "

Exploded View".

INSTALLATION

Note the following, and install the reverse order of removal.

Apply the multi-purpose grease to the clevis pin and the mating faces. (Not necessary if grease has been

already applied.)

NOTE:

The clevis pin may be inserted in either direction.

1. Clevis pin 2. Brake pedal assembly 3. Brake pedal pad

4. Snap pin 5. Clip 6. ASCD brake switch

7. Stop lamp switch

: Apply multi-purpose grease.

Refer to GI-4, "

Components" for symbols not described on the above.

JPFIA0341GB

Page 917 of 5121

BRAKE PIPINGBR-21

< ON-VEHICLE REPAIR >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

FRONT : Removal and InstallationINFOID:0000000003811188

REMOVAL

CAUTION:

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

1. Remove tires.

2. Drain brake fluid. Refer to BR-9, "

Draining".

3. Loosen the flare nut with a flare nut wrenc h and separate the brake tube from the hose.

CAUTION:

Never scratch the flare nut and the brake tube.

Never bend sharply, twist or strong ly pull out the brake hoses and tubes.

Cover open end of brake tub es and hoses when disconnecting to prevent entrance of dirt.

4. Remove the union bolt and copper washers, and remove the brake hose from the brake caliper assembly.

5. Remove the lock plate and remove the brake hose.

INSTALLATION

CAUTION:

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

1. Assemble the union bolt and the copper washers to the brake hose. CAUTION:

Never reuse the copper washer.

2. Align the brake hose pin to the projection (A) of the brake caliper assembly and tighten the union bolt (1) to the specified torque.

3. Install the brake tube to the brake hose, temporarily tighten the flare nut by hand until it does not rotate further, and fix the brake

hose to the bracket with the lock plate.

CAUTION:

Check that all brake hoses and tubes are not twisted and

bent.

4. Tighten the flare nut to the specified torque with a crowfoot and torque wrench.

CAUTION:

Never scratch the flare nut and the brake tube.

5. Refill with new brake fluid and perform the air bleeding. Refer to BR-10, "

Bleeding Brake System".

CAUTION:

Never reuse drained brake fluid.

FRONT : InspectionINFOID:0000000003811189

INSPECTION AFTER INSTALLATION

1. Check the brake hoses and tubes for the following: no scratches; no twist and deformation; no interfer-

ence with other components when steering the steering wheel; no looseness at connections.

2. Depress the brake pedal with a force of 785N (80 kg, 177 lb) and hold down the pedal for approximately 5

seconds with the engine running. Check for any fluid leakage.

CAUTION:

Retighten the applicable connect ion to the specified torque and repair any abnormal (damaged,

worn or deformed) part if any brake fluid leakage is present.

1. ABS actuator and electric unit (con-

trol unit) 2. Front disc brake 3. Master cylinder assembly

4. Brake booster 5. Connector 6. Rear disc brake

A. Brake tube B. Brake hose : Flare nut

: Union bolt

JPFIA0099ZZ

Page 919 of 5121

BRAKE PIPINGBR-23

< ON-VEHICLE REPAIR >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

REAR : Removal and InstallationINFOID:0000000003811192

REMOVAL

CAUTION:

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

1. Remove tires.

2. Drain brake fluid. Refer to BR-9, "

Draining".

3. Loosen the flare nut with a flare nut wrenc h and separate the brake tube from the hose.

CAUTION:

Never scratch the flare nut and the brake tube.

Never sharply bend, twist or strongly pull the brake hoses and tubes.

Cover the open end of brake tubes and hoses wh en disconnecting to prevent entrance of dirt.

4. Remove the union bolt and copper washers, and remove the brake hose from the brake caliper assembly.

5. Remove the lock plate and remove the brake hose from the vehicle.

INSTALLATION

CAUTION:

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

1. Assemble the union bolt and the copper washers to the brake hose. CAUTION:

Never reuse copper washer.

2. Install the brake hose L-pin by aligning it with the brake caliper assembly positioning hole, and tighten the union bolt (1) to the

specified torque.

3. Connect the hose to the brake tube, temporarily tighten the flare nut by hand until it does not rotate further, and fix the brake hose

to the bracket with the lock plate.

CAUTION:

Check that the brake hoses and tubes are not twisted and

bent.

4. Tighten the flare nut to the specified torque with a crowfoot and torque wrench.

CAUTION:

Never scratch the flare nut and the brake tube.

5. Refill with new brake fluid and perform the air bleeding. Refer to BR-10, "

Bleeding Brake System".

CAUTION:

Never reuse drained brake fluid.

REAR : InspectionINFOID:0000000003811193

INSPECTION AFTER INSTALLATION

1. Check the brake hoses and tubes for the following: no scratches; no twist and deformation; no interfer-

ence with other components when steering the steering wheel; no looseness at connections.

2. Depress the brake pedal with a force of 785N (80

kg, 177 lb) and hold down the pedal for approximately 5

seconds with the engine running. Check for any fluid leakage.

CAUTION:

1. ABS actuator and electric unit (con- trol unit) 2. Front disc brake 3. Master cylinder assembly

4. Brake booster 5. Connector 6. Rear disc brake

A. Brake tube B. Brake hose : Flare nut

: Union bolt

JPFIA0012ZZ

Page 921 of 5121

BRAKE MASTER CYLINDER

BR-25

< ON-VEHICLE REPAIR >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

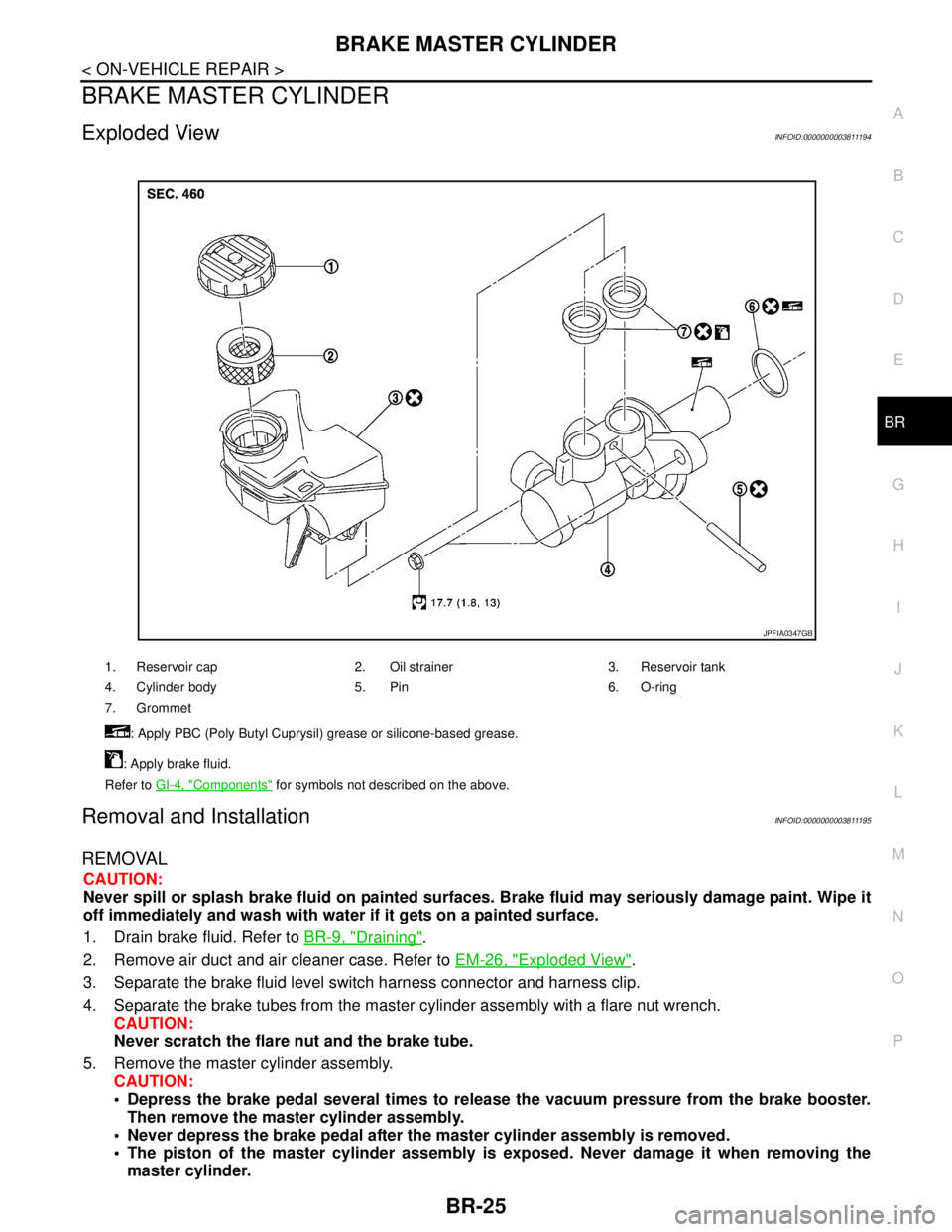

BRAKE MASTER CYLINDER

Exploded ViewINFOID:0000000003811194

Removal and InstallationINFOID:0000000003811195

REMOVAL

CAUTION:

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with water if it gets on a painted surface.

1. Drain brake fluid. Refer to BR-9, "

Draining".

2. Remove air duct and air cleaner case. Refer to EM-26, "

Exploded View".

3. Separate the brake fluid level switch harness connector and harness clip.

4. Separate the brake tubes from the master cylinder assembly with a flare nut wrench.

CAUTION:

Never scratch the flare nut and the brake tube.

5. Remove the master cylinder assembly.

CAUTION:

Depress the brake pedal several times to release the vacuum pressure from the brake booster.

Then remove the master cylinder assembly.

Never depress the brake pedal after the master cylinder assembly is removed.

The piston of the master cylinder assembly is exposed. Never damage it when removing the

master cylinder.

1. Reservoir cap 2. Oil strainer 3. Reservoir tank

4. Cylinder body 5. Pin 6. O-ring

7. Grommet

: Apply PBC (Poly Butyl Cuprysil) grease or silicone-based grease.

: Apply brake fluid.

Refer to GI-4, "

Components" for symbols not described on the above.

JPFIA0347GB

Page 923 of 5121

BRAKE MASTER CYLINDER

BR-27

< ON-VEHICLE REPAIR >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

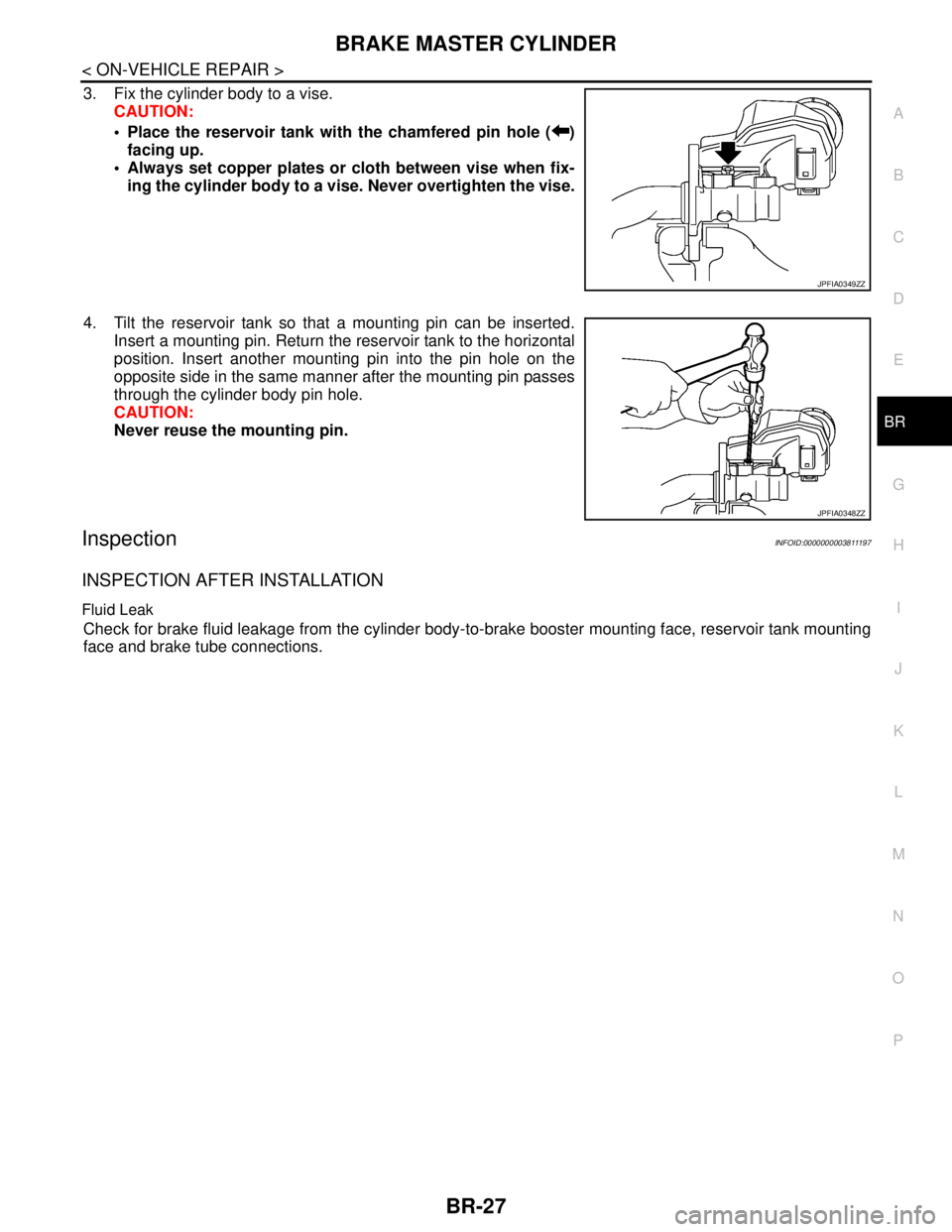

3. Fix the cylinder body to a vise.

CAUTION:

Place the reservoir tank with the chamfered pin hole ( )

facing up.

Always set copper plates or cloth between vise when fix-

ing the cylinder body to a vise. Never overtighten the vise.

4. Tilt the reservoir tank so that a mounting pin can be inserted.

Insert a mounting pin. Return the reservoir tank to the horizontal

position. Insert another mounting pin into the pin hole on the

opposite side in the same manner after the mounting pin passes

through the cylinder body pin hole.

CAUTION:

Never reuse the mounting pin.

InspectionINFOID:0000000003811197

INSPECTION AFTER INSTALLATION

Fluid Leak

Check for brake fluid leakage from the cylinder body-to-brake booster mounting face, reservoir tank mounting

face and brake tube connections.

JPFIA0349ZZ

JPFIA0348ZZ

Page 924 of 5121

BR-28

< ON-VEHICLE REPAIR >

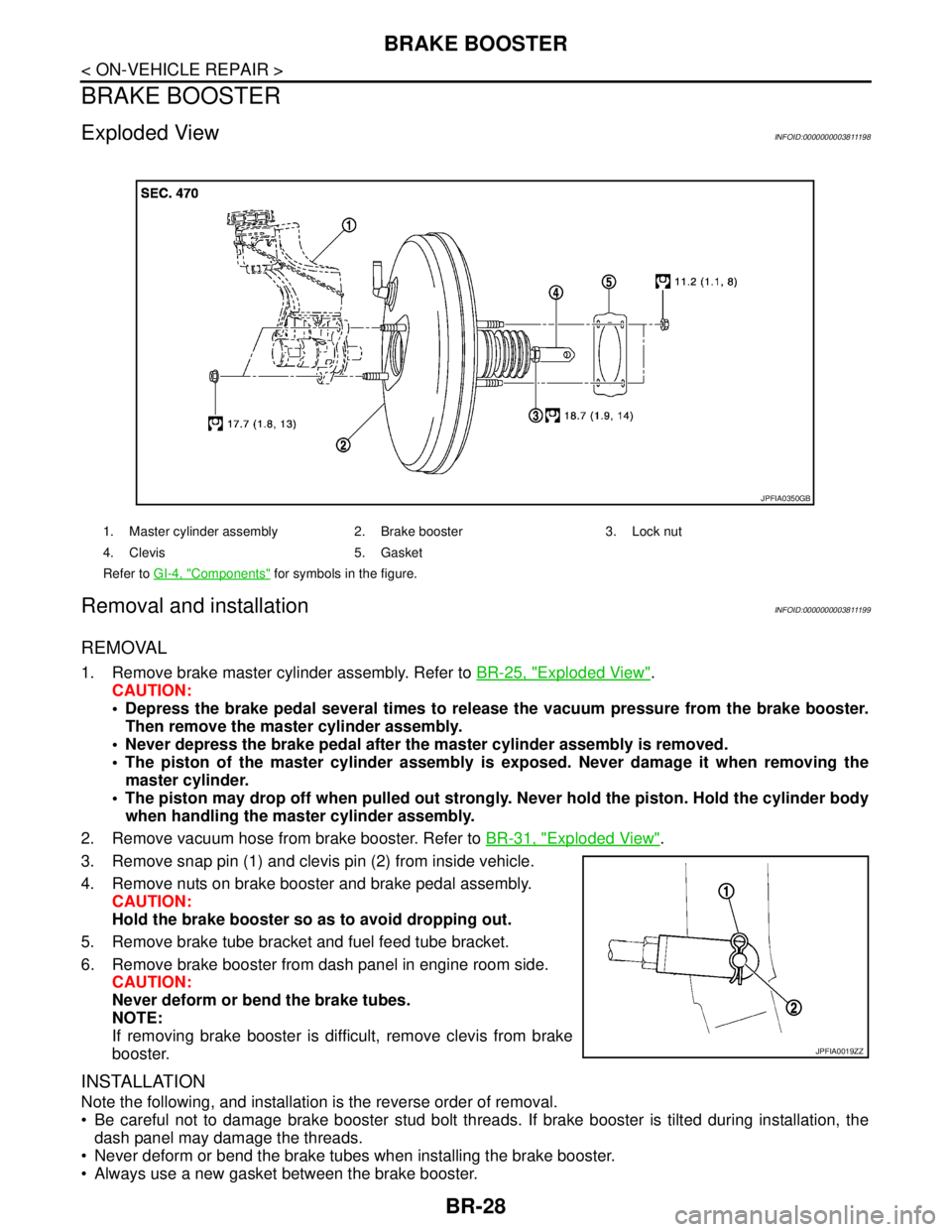

BRAKE BOOSTER

BRAKE BOOSTER

Exploded ViewINFOID:0000000003811198

Removal and installationINFOID:0000000003811199

REMOVAL

1. Remove brake master cylinder assembly. Refer to BR-25, "Exploded View".

CAUTION:

Depress the brake pedal several times to release the vacuum pressure from the brake booster.

Then remove the master cylinder assembly.

Never depress the brake pedal after the master cylinder assembly is removed.

The piston of the master cylinder assembly is exposed. Never damage it when removing the

master cylinder.

The piston may drop off when pulled out strongly. Never hold the piston. Hold the cylinder body

when handling the master cylinder assembly.

2. Remove vacuum hose from brake booster. Refer to BR-31, "

Exploded View".

3. Remove snap pin (1) and clevis pin (2) from inside vehicle.

4. Remove nuts on brake booster and brake pedal assembly.

CAUTION:

Hold the brake booster so as to avoid dropping out.

5. Remove brake tube bracket and fuel feed tube bracket.

6. Remove brake booster from dash panel in engine room side.

CAUTION:

Never deform or bend the brake tubes.

NOTE:

If removing brake booster is difficult, remove clevis from brake

booster.

INSTALLATION

Note the following, and installation is the reverse order of removal.

Be careful not to damage brake booster stud bolt threads. If brake booster is tilted during installation, the

dash panel may damage the threads.

Never deform or bend the brake tubes when installing the brake booster.

Always use a new gasket between the brake booster.

1. Master cylinder assembly 2. Brake booster 3. Lock nut

4. Clevis 5. Gasket

Refer to GI-4, "

Components" for symbols in the figure.

JPFIA0350GB

JPFIA0019ZZ

Page 927 of 5121

VACUUM LINES

BR-31

< ON-VEHICLE REPAIR >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

VACUUM LINES

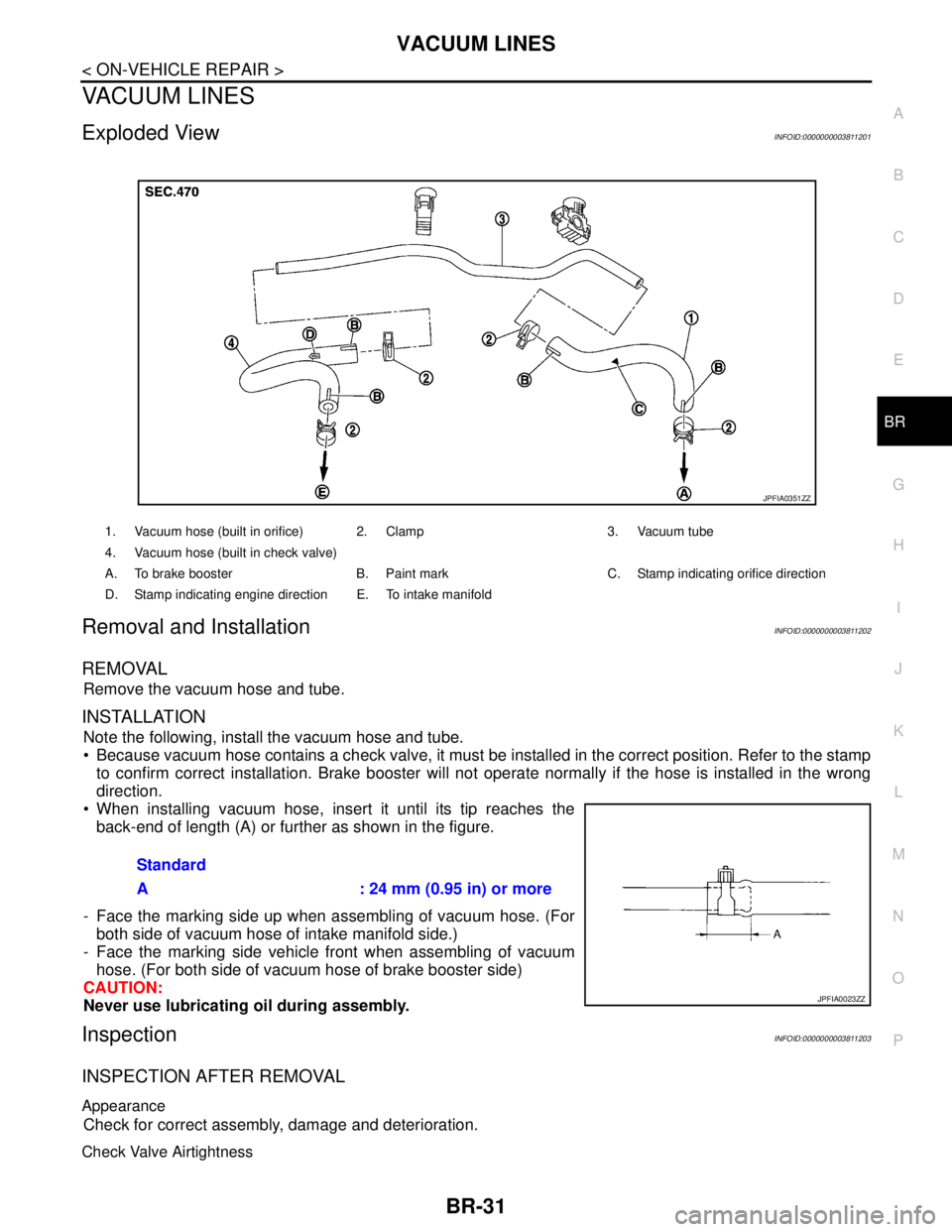

Exploded ViewINFOID:0000000003811201

Removal and InstallationINFOID:0000000003811202

REMOVAL

Remove the vacuum hose and tube.

INSTALLATION

Note the following, install the vacuum hose and tube.

Because vacuum hose contains a check valve, it must be installed in the correct position. Refer to the stamp

to confirm correct installation. Brake booster will not operate normally if the hose is installed in the wrong

direction.

When installing vacuum hose, insert it until its tip reaches the

back-end of length (A) or further as shown in the figure.

- Face the marking side up when assembling of vacuum hose. (For

both side of vacuum hose of intake manifold side.)

- Face the marking side vehicle front when assembling of vacuum

hose. (For both side of vacuum hose of brake booster side)

CAUTION:

Never use lubricating oil during assembly.

InspectionINFOID:0000000003811203

INSPECTION AFTER REMOVAL

Appearance

Check for correct assembly, damage and deterioration.

Check Valve Airtightness

1. Vacuum hose (built in orifice) 2. Clamp 3. Vacuum tube

4. Vacuum hose (built in check valve)

A. To brake booster B. Paint mark C. Stamp indicating orifice direction

D. Stamp indicating engine direction E. To intake manifold

JPFIA0351ZZ

Standard

A : 24 mm (0.95 in) or more

JPFIA0023ZZ

Page 928 of 5121

BR-32

< ON-VEHICLE REPAIR >

VACUUM LINES

Use a handy vacuum pump (A) to check.

Replace vacuum hose assembly if vacuum hose and check valve

are malfunctioning.When connected to the brake booster side (B)

: Vacuum should decrease within 1.3 kPa (10 mmHg,

0.39 inHg, 0.013 bar) for 15 seconds under a vacuum

of −66.7 kPa (−500 mmHg, −19.70 inHg, −0.667 bar).

When connected to the engine side (C):

: Vacuum should not exist.

JPFIA0024ZZ

Page 929 of 5121

FRONT DISC BRAKE

BR-33

< ON-VEHICLE REPAIR >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

FRONT DISC BRAKE

BRAKE PAD

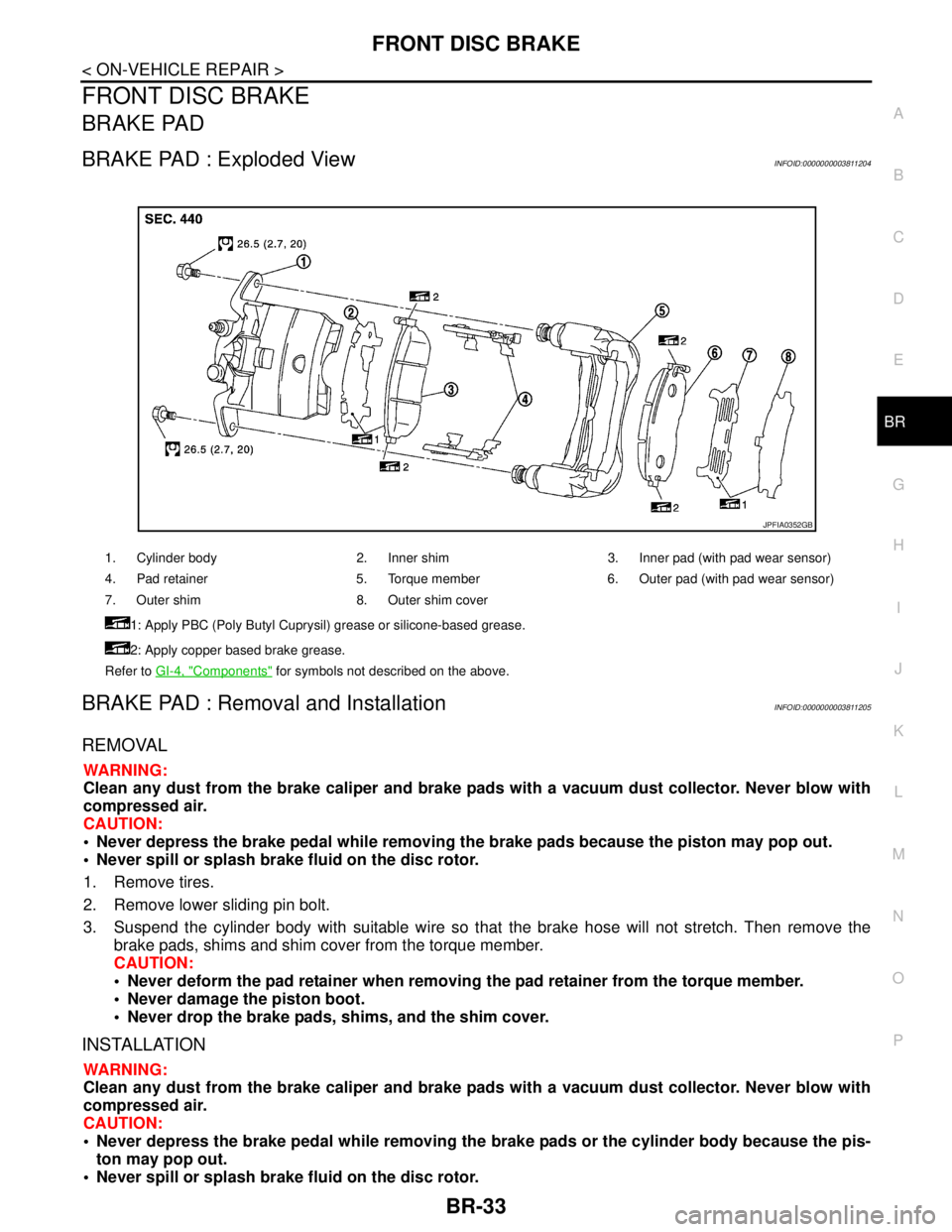

BRAKE PAD : Exploded ViewINFOID:0000000003811204

BRAKE PAD : Removal and InstallationINFOID:0000000003811205

REMOVAL

WARNING:

Clean any dust from the brake caliper and brake pads with a vacuum dust collector. Never blow with

compressed air.

CAUTION:

Never depress the brake pedal while removing the brake pads because the piston may pop out.

Never spill or splash brake fluid on the disc rotor.

1. Remove tires.

2. Remove lower sliding pin bolt.

3. Suspend the cylinder body with suitable wire so that the brake hose will not stretch. Then remove the

brake pads, shims and shim cover from the torque member.

CAUTION:

Never deform the pad retainer when removing the pad retainer from the torque member.

Never damage the piston boot.

Never drop the brake pads, shims, and the shim cover.

INSTALLATION

WARNING:

Clean any dust from the brake caliper and brake pads with a vacuum dust collector. Never blow with

compressed air.

CAUTION:

Never depress the brake pedal while removing the brake pads or the cylinder body because the pis-

ton may pop out.

Never spill or splash brake fluid on the disc rotor.

1. Cylinder body 2. Inner shim 3. Inner pad (with pad wear sensor)

4. Pad retainer 5. Torque member 6. Outer pad (with pad wear sensor)

7. Outer shim 8. Outer shim cover

1: Apply PBC (Poly Butyl Cuprysil) grease or silicone-based grease.

2: Apply copper based brake grease.

Refer to GI-4, "

Components" for symbols not described on the above.

JPFIA0352GB

Page 930 of 5121

BR-34

< ON-VEHICLE REPAIR >

FRONT DISC BRAKE

1. Install the pad retainer to the torque member if the pad retainers has been removed.

CAUTION:

Securely assemble the pad retainers so that it will not be lifted up from the torque member.

Never deform the pad retainers.

2. Apply copper based brake grease to the mating faces between the brake pads and pad retainers.

3. Apply PBC (Poly Butyl Cuprysil) grease or silicone-based grease to the mating faces between the brake

pads, shims and shim cover, and install them to the brake pad.

CAUTION:

Always replace the shims together with the shim cover when replacing the brake pad.

4. Install the cylinder body and brake pads to the torque member.

CAUTION:

Never damage the piston boot.

When replacing a pad with new one, check a brake fluid level in the reservoir tank because brake

fluid returns to master cylinder reservoir tank when pressing piston in.

NOTE:

Use a disc brake piston tool to easily press piston.

5. Install the lower sliding pin bolt and tighten it to the specified torque.

6. Depress the brake pedal several times to check that no drag feel is present for the front disc brake. Refer

to BR-34, "

BRAKE PAD : Inspection".

BRAKE PAD : InspectionINFOID:0000000003811206

INSPECTION AFTER REMOVAL

Replace the shims and the shim cover if rust is excessively attached.

INSPECTION AFTER INSTALLATION

1. Check a drag of front disc brake. If any drag is found, follow the procedure described below.

2. Remove brake pads.

3. Press the piston.

CAUTION:

Never damage the piston boot.

When replacing a pad with new one, check a brake fluid level in the reservoir tank because brake

fluid returns to master cylinder reservoir tank when pressing piston in.

NOTE:

Use a disc brake piston tool to easily press piston.

4. Install brake pads.

5. Depress the brake pedal several times.

6. Check a drag of front disc brake again. If any drag is found, disassemble the cylinder body. Refer to BR-

36, "BRAKE CALIPER ASSEMBLY : Disassembly and Assembly".

7. Burnish contact surfaces after refinishing or replacing pads, or if a soft pedal occurs at very low mileage.

Refer to BR-13, "

BRAKE PAD : Inspection and Adjustment".

BRAKE CALIPER ASSEMBLY

BRAKE CALIPER ASSEMBLY : Exploded ViewINFOID:0000000003811207

REMOVAL