NISSAN TEANA 2008 Service Manual

Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 3291 of 5121

MWI

U1000 CAN COMM CIRCUIT

MWI-37

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

MB A

O

P

COMPONENT DIAGNOSIS

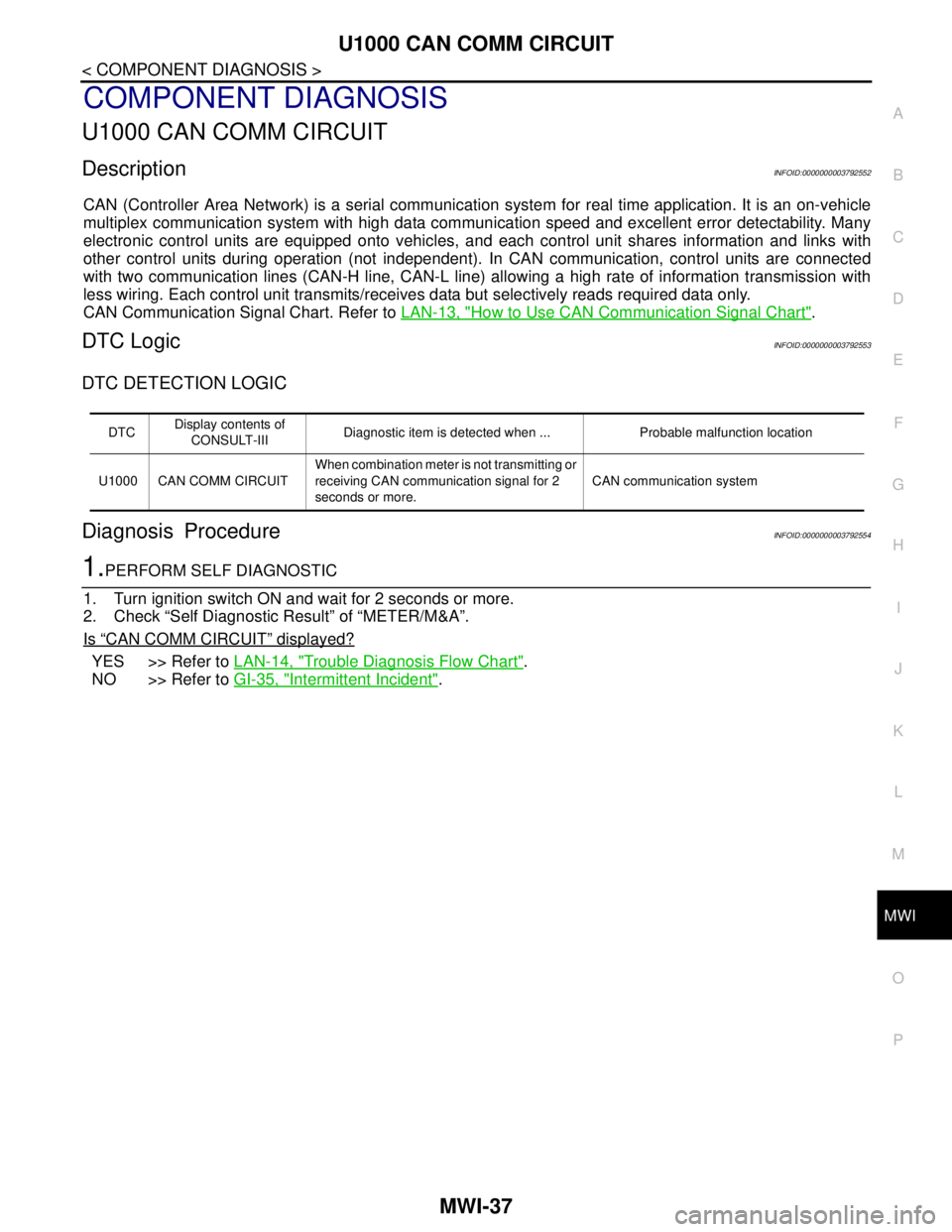

U1000 CAN COMM CIRCUIT

DescriptionINFOID:0000000003792552

CAN (Controller Area Network) is a serial communication system for real time application. It is an on-vehicle

multiplex communication system with high data communication speed and excellent error detectability. Many

electronic control units are equipped onto vehicles, and each control unit shares information and links with

other control units during operation (not independent). In CAN communication, control units are connected

with two communication lines (CAN-H line, CAN-L line) allowing a high rate of information transmission with

less wiring. Each control unit transmits/receives data but selectively reads required data only.

CAN Communication Signal Chart. Refer to LAN-13, "

How to Use CAN Communication Signal Chart".

DTC LogicINFOID:0000000003792553

DTC DETECTION LOGIC

Diagnosis ProcedureINFOID:0000000003792554

1.PERFORM SELF DIAGNOSTIC

1. Turn ignition switch ON and wait for 2 seconds or more.

2. Check “Self Diagnostic Result” of “METER/M&A”.

Is

“CAN COMM CIRCUIT” displayed?

YES >> Refer to LAN-14, "Trouble Diagnosis Flow Chart".

NO >> Refer to GI-35, "

Intermittent Incident".

DTCDisplay contents of

CONSULT-IIIDiagnostic item is detected when ... Probable malfunction location

U1000 CAN COMM CIRCUITWhen combination meter is not transmitting or

receiving CAN communication signal for 2

seconds or more.CAN communication system

Page 3292 of 5121

MWI-38

< COMPONENT DIAGNOSIS >

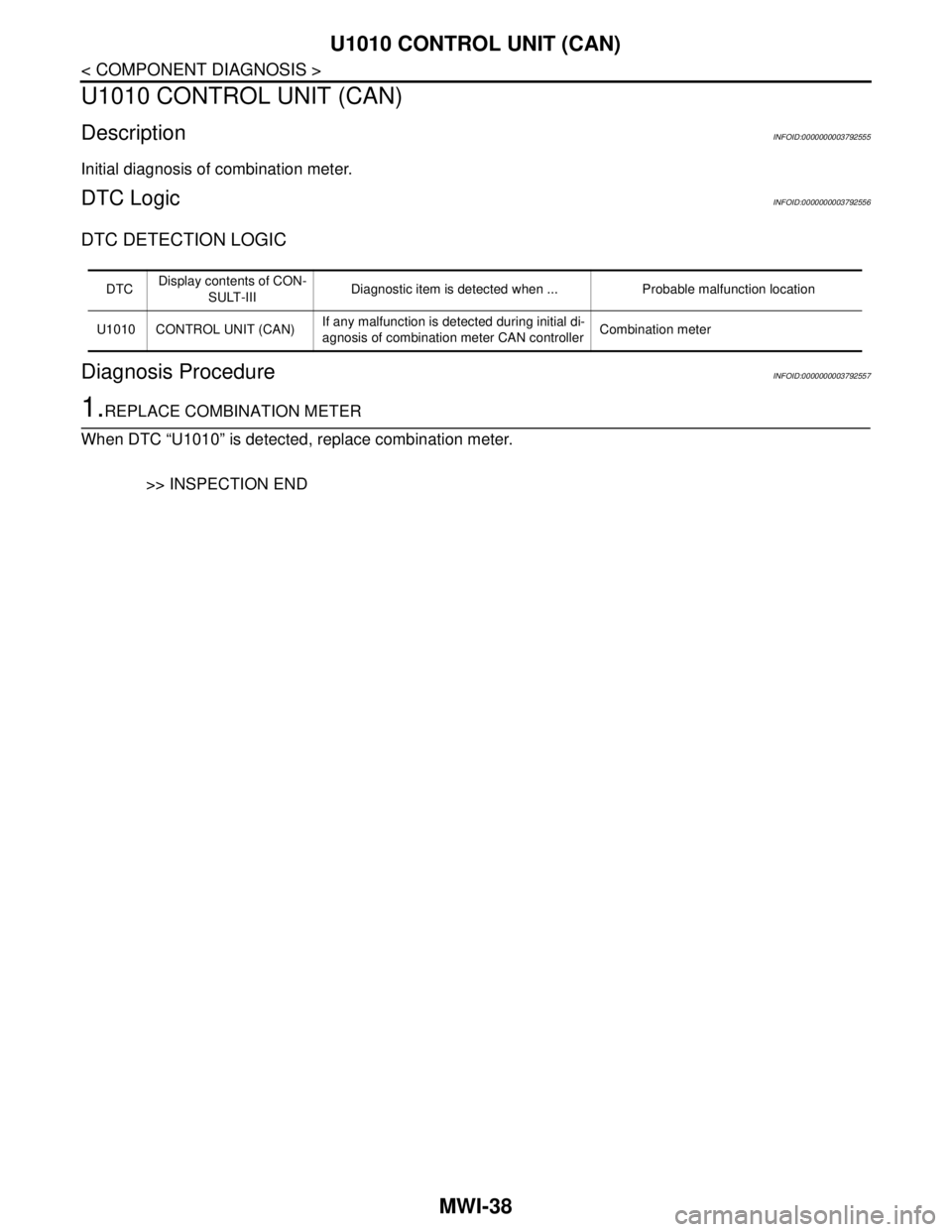

U1010 CONTROL UNIT (CAN)

U1010 CONTROL UNIT (CAN)

DescriptionINFOID:0000000003792555

Initial diagnosis of combination meter.

DTC LogicINFOID:0000000003792556

DTC DETECTION LOGIC

Diagnosis ProcedureINFOID:0000000003792557

1.REPLACE COMBINATION METER

When DTC “U1010” is detected, replace combination meter.

>> INSPECTION END

DTCDisplay contents of CON-

SULT-IIIDiagnostic item is detected when ... Probable malfunction location

U1010 CONTROL UNIT (CAN)If any malfunction is detected during initial di-

agnosis of combination meter CAN controllerCombination meter

Page 3293 of 5121

MWI

B2205 VEHICLE SPEED

MWI-39

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

MB A

O

P

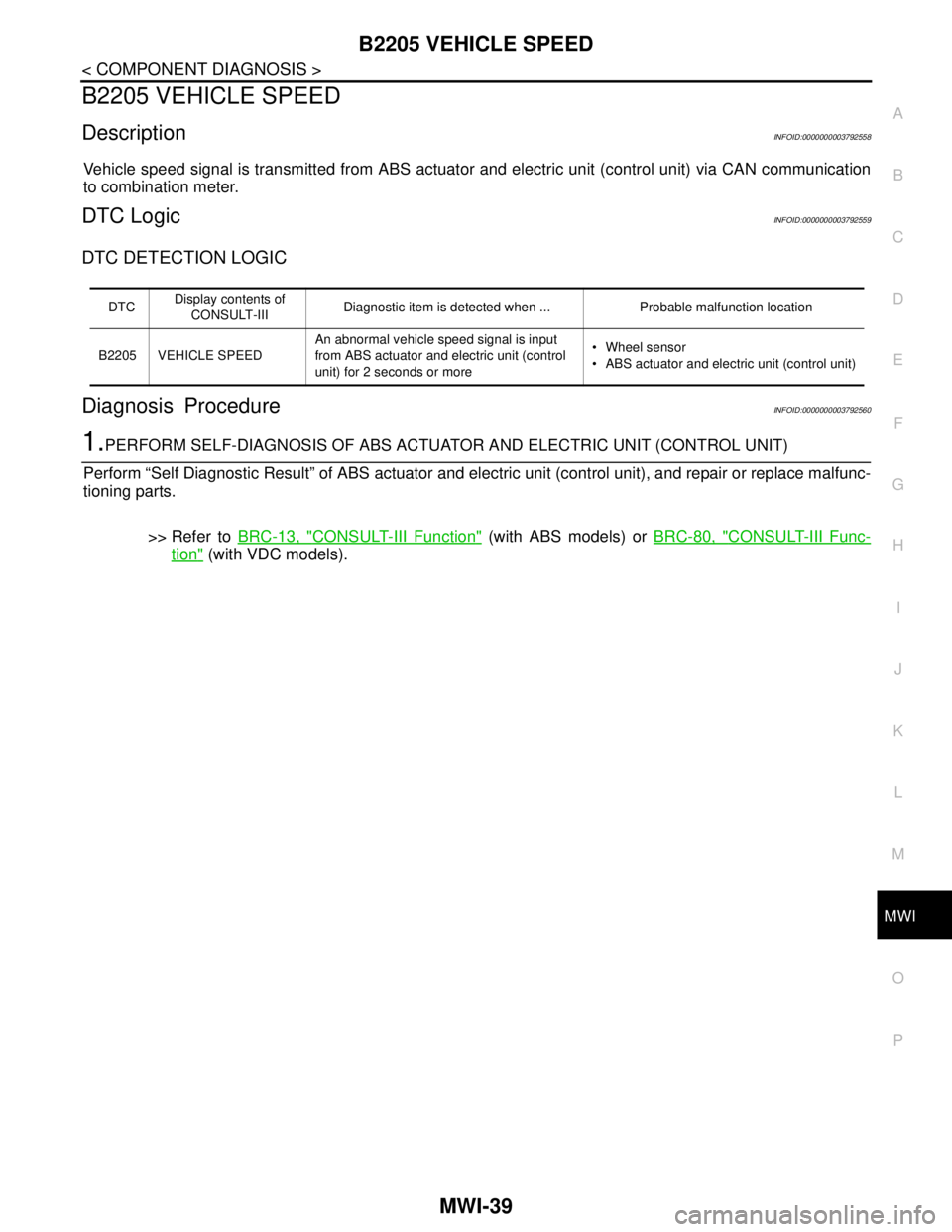

B2205 VEHICLE SPEED

DescriptionINFOID:0000000003792558

Vehicle speed signal is transmitted from ABS actuator and electric unit (control unit) via CAN communication

to combination meter.

DTC LogicINFOID:0000000003792559

DTC DETECTION LOGIC

Diagnosis ProcedureINFOID:0000000003792560

1.PERFORM SELF-DIAGNOSIS OF ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

Perform “Self Diagnostic Result” of ABS actuator and electric unit (control unit), and repair or replace malfunc-

tioning parts.

>> Refer to BRC-13, "

CONSULT-III Function" (with ABS models) or BRC-80, "CONSULT-III Func-

tion" (with VDC models).

DTCDisplay contents of

CONSULT-IIIDiagnostic item is detected when ... Probable malfunction location

B2205 VEHICLE SPEEDAn abnormal vehicle speed signal is input

from ABS actuator and electric unit (control

unit) for 2 seconds or more Wheel sensor

ABS actuator and electric unit (control unit)

Page 3294 of 5121

MWI-40

< COMPONENT DIAGNOSIS >

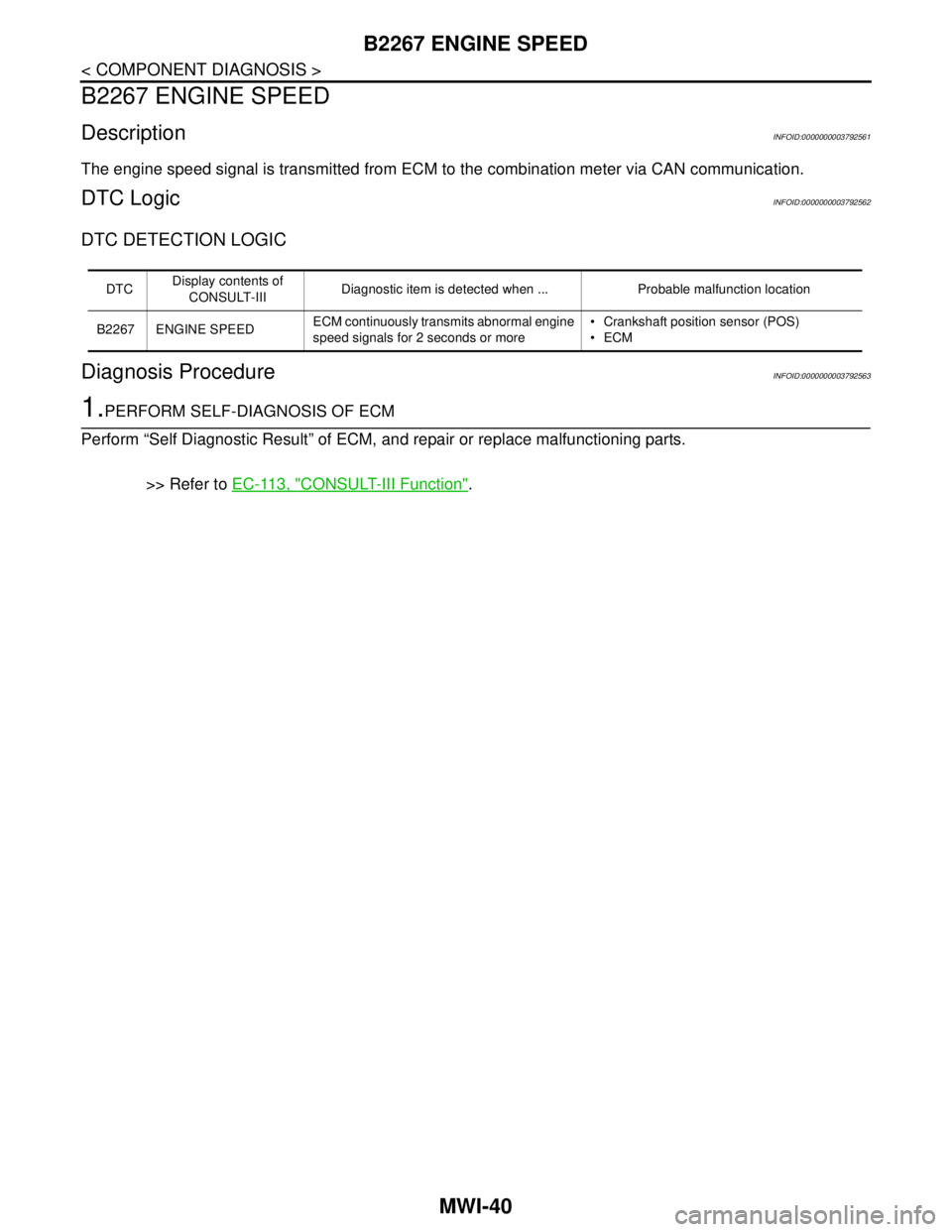

B2267 ENGINE SPEED

B2267 ENGINE SPEED

DescriptionINFOID:0000000003792561

The engine speed signal is transmitted from ECM to the combination meter via CAN communication.

DTC LogicINFOID:0000000003792562

DTC DETECTION LOGIC

Diagnosis ProcedureINFOID:0000000003792563

1.PERFORM SELF-DIAGNOSIS OF ECM

Perform “Self Diagnostic Result” of ECM, and repair or replace malfunctioning parts.

>> Refer to EC-113, "

CONSULT-III Function".

DTCDisplay contents of

CONSULT-IIIDiagnostic item is detected when ... Probable malfunction location

B2267 ENGINE SPEEDECM continuously transmits abnormal engine

speed signals for 2 seconds or more Crankshaft position sensor (POS)

ECM

Page 3295 of 5121

MWI

B2268 WATER TEMP

MWI-41

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

MB A

O

P

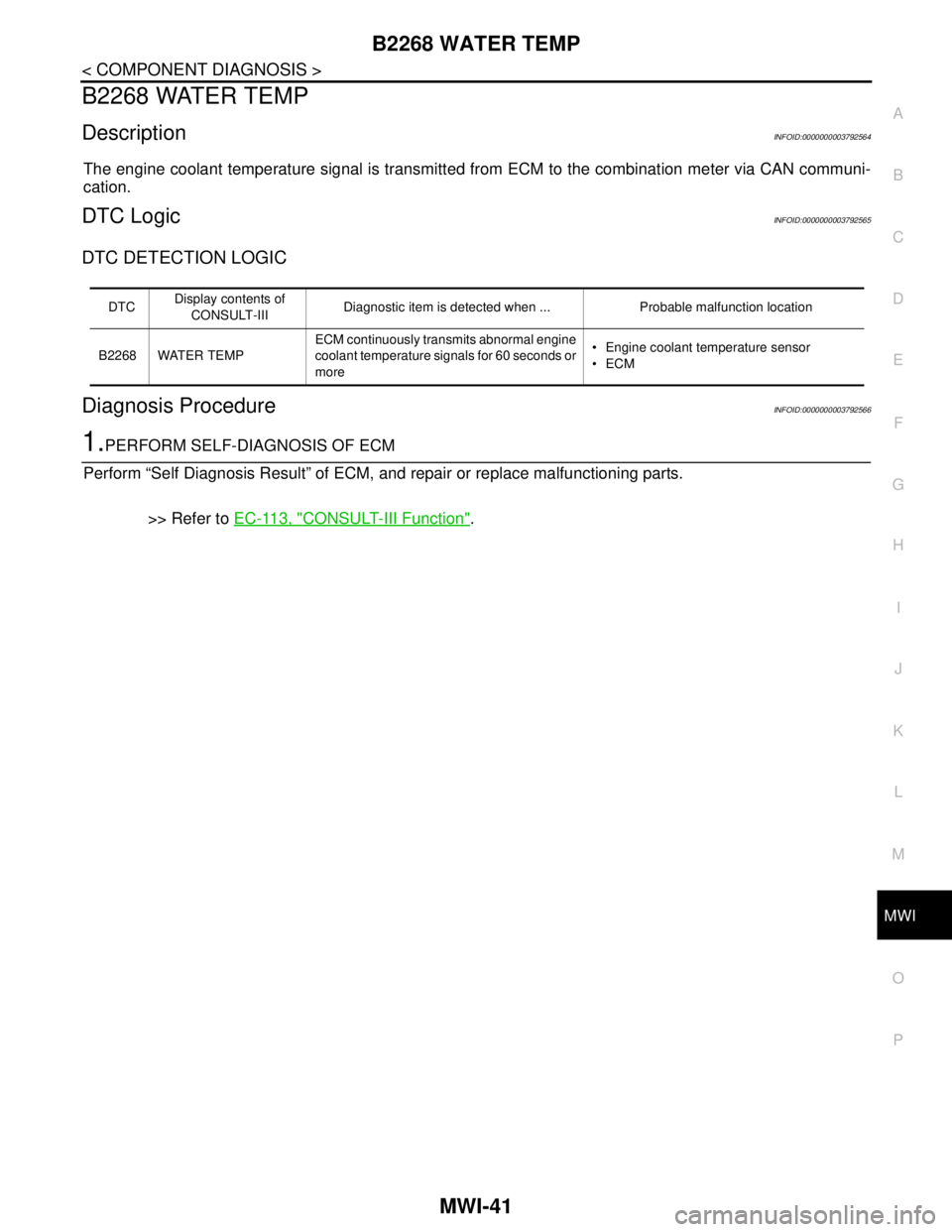

B2268 WATER TEMP

DescriptionINFOID:0000000003792564

The engine coolant temperature signal is transmitted from ECM to the combination meter via CAN communi-

cation.

DTC LogicINFOID:0000000003792565

DTC DETECTION LOGIC

Diagnosis ProcedureINFOID:0000000003792566

1.PERFORM SELF-DIAGNOSIS OF ECM

Perform “Self Diagnosis Result” of ECM, and repair or replace malfunctioning parts.

>> Refer to EC-113, "

CONSULT-III Function".

DTCDisplay contents of

CONSULT-IIIDiagnostic item is detected when ... Probable malfunction location

B2268 WATER TEMPECM continuously transmits abnormal engine

coolant temperature signals for 60 seconds or

more Engine coolant temperature sensor

ECM

Page 3296 of 5121

MWI-42

< COMPONENT DIAGNOSIS >

POWER SUPPLY AND GROUND CIRCUIT

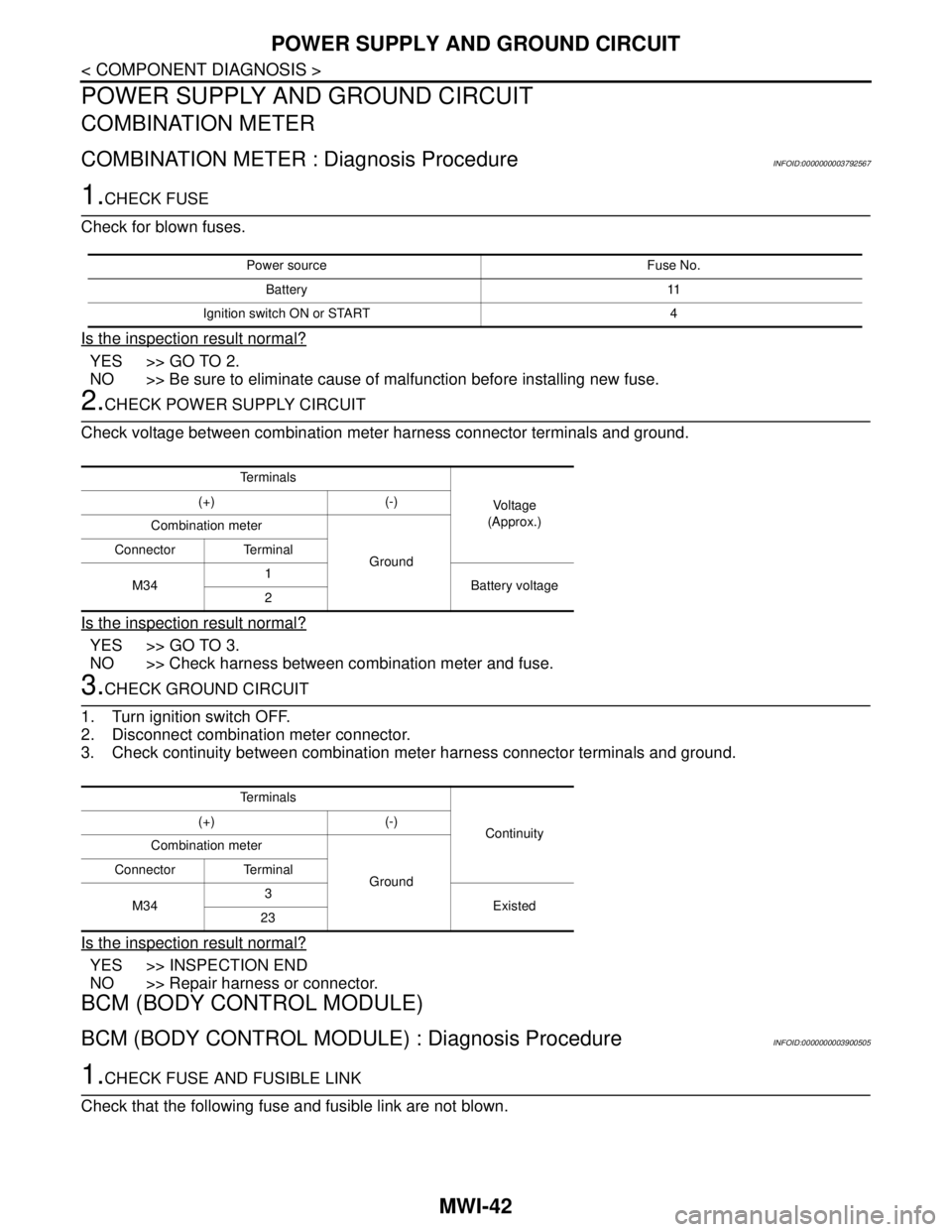

POWER SUPPLY AND GROUND CIRCUIT

COMBINATION METER

COMBINATION METER : Diagnosis ProcedureINFOID:0000000003792567

1.CHECK FUSE

Check for blown fuses.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Be sure to eliminate cause of malfunction before installing new fuse.

2.CHECK POWER SUPPLY CIRCUIT

Check voltage between combination meter harness connector terminals and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Check harness between combination meter and fuse.

3.CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect combination meter connector.

3. Check continuity between combination meter harness connector terminals and ground.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Repair harness or connector.

BCM (BODY CONTROL MODULE)

BCM (BODY CONTROL MODULE) : Diagnosis ProcedureINFOID:0000000003900505

1.CHECK FUSE AND FUSIBLE LINK

Check that the following fuse and fusible link are not blown.

Power source Fuse No.

Battery 11

Ignition switch ON or START 4

Te r m i n a l s

Vol tag e

(Approx.) (+) (-)

Combination meter

Ground Connector Terminal

M341

Battery voltage

2

Te r m i n a l s

Continuity (+) (-)

Combination meter

Ground Connector Terminal

M343

Existed

23

Page 3297 of 5121

MWI

POWER SUPPLY AND GROUND CIRCUIT

MWI-43

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

MB A

O

P

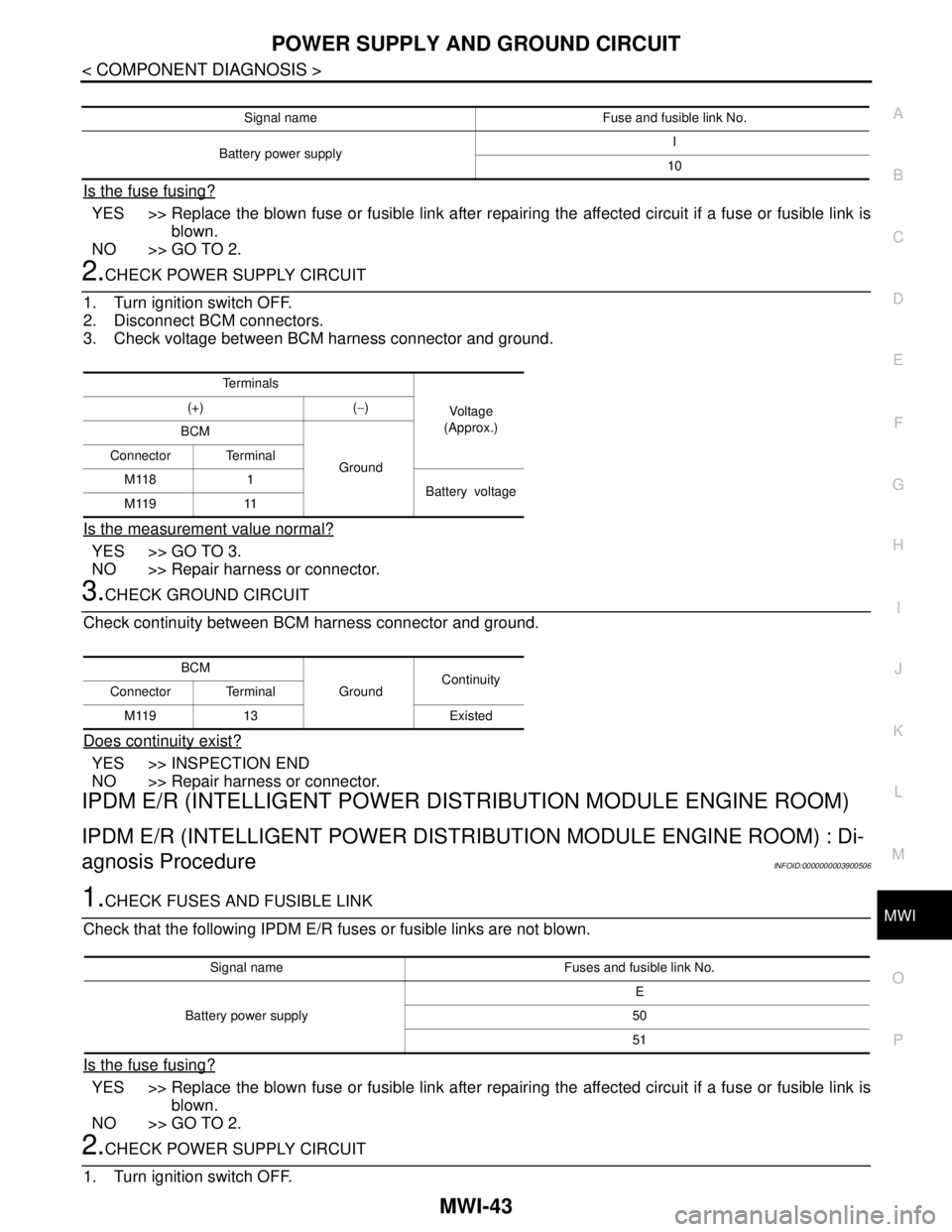

Is the fuse fusing?

YES >> Replace the blown fuse or fusible link after repairing the affected circuit if a fuse or fusible link is

blown.

NO >> GO TO 2.

2.CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connectors.

3. Check voltage between BCM harness connector and ground.

Is the measurement value normal?

YES >> GO TO 3.

NO >> Repair harness or connector.

3.CHECK GROUND CIRCUIT

Check continuity between BCM harness connector and ground.

Does continuity exist?

YES >> INSPECTION END

NO >> Repair harness or connector.

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM) : Di-

agnosis Procedure

INFOID:0000000003900506

1.CHECK FUSES AND FUSIBLE LINK

Check that the following IPDM E/R fuses or fusible links are not blown.

Is the fuse fusing?

YES >> Replace the blown fuse or fusible link after repairing the affected circuit if a fuse or fusible link is

blown.

NO >> GO TO 2.

2.CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

Signal name Fuse and fusible link No.

Battery power supplyI

10

Te r m i n a l s

Vo l ta g e

(Approx.) (+) (−)

BCM

Ground Connector Terminal

M118 1

Battery voltage

M119 11

BCM

GroundContinuity

Connector Terminal

M119 13 Existed

Signal name Fuses and fusible link No.

Battery power supplyE

50

51

Page 3298 of 5121

MWI-44

< COMPONENT DIAGNOSIS >

POWER SUPPLY AND GROUND CIRCUIT

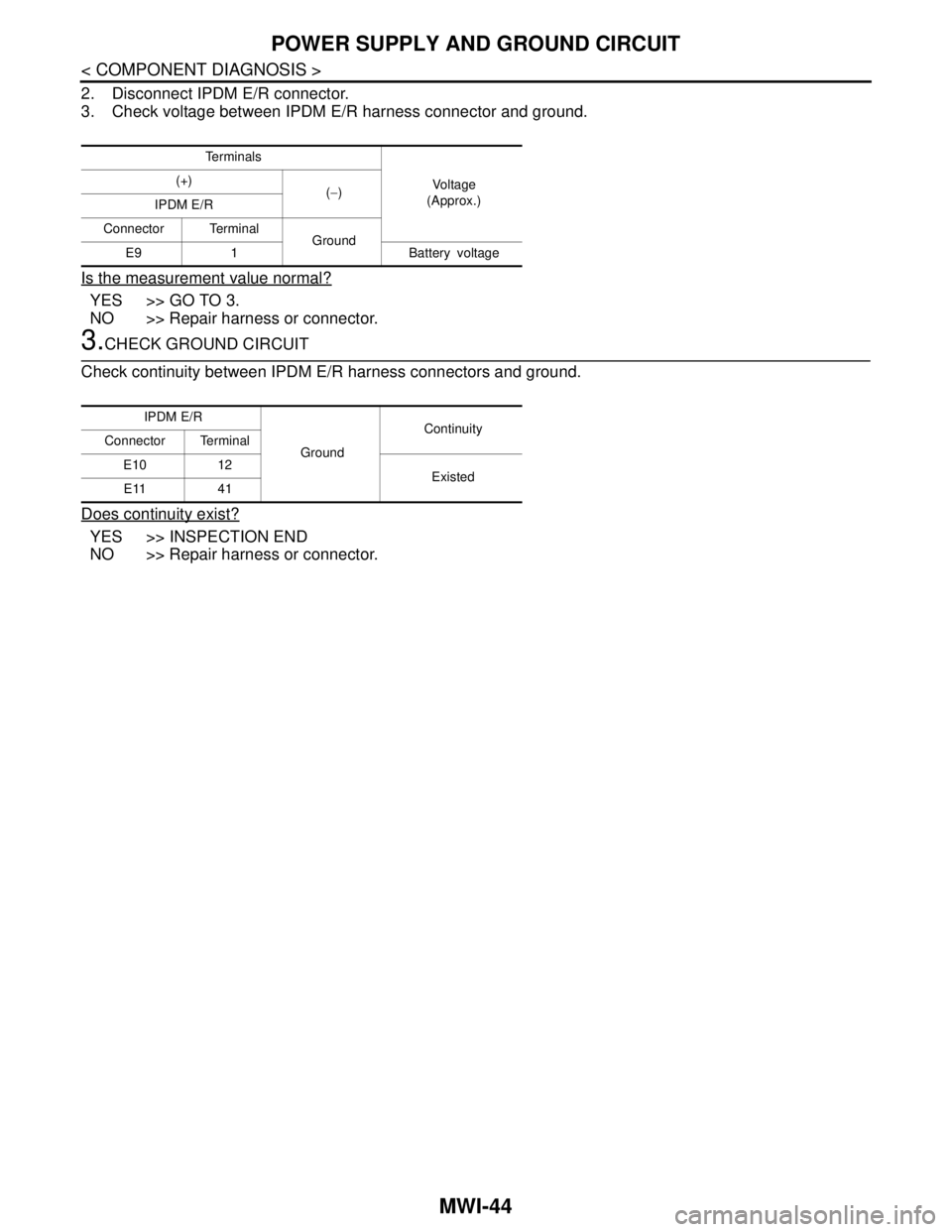

2. Disconnect IPDM E/R connector.

3. Check voltage between IPDM E/R harness connector and ground.

Is the measurement value normal?

YES >> GO TO 3.

NO >> Repair harness or connector.

3.CHECK GROUND CIRCUIT

Check continuity between IPDM E/R harness connectors and ground.

Does continuity exist?

YES >> INSPECTION END

NO >> Repair harness or connector.

Te r m i n a l s

Vo l ta g e

(Approx.) (+)

(−)

IPDM E/R

Connector Terminal

Ground

E9 1 Battery voltage

IPDM E/R

GroundContinuity

Connector Terminal

E10 12

Existed

E11 41

Page 3299 of 5121

MWI

FUEL LEVEL SENSOR SIGNAL CIRCUIT

MWI-45

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

MB A

O

P

FUEL LEVEL SENSOR SIGNAL CIRCUIT

DescriptionINFOID:0000000003792570

The fuel level sensor unit and fuel pump detect the fuel level in the fuel tank and transmit the fuel gauge signal

to the combination meter.

Component Function CheckINFOID:0000000003792571

1.CHECK COMBINATION METER OUTPUT SIGNAL

Select the “Data Monitor” for the “METER/M&A” and compare the “FUEL METER” monitor value with the fuel

gauge reading on the combination meter.

Does monitor value match fuel gauge reading?

YES >> INSPECTION END

NO >> Replace combination meter.

Diagnosis ProcedureINFOID:0000000003792572

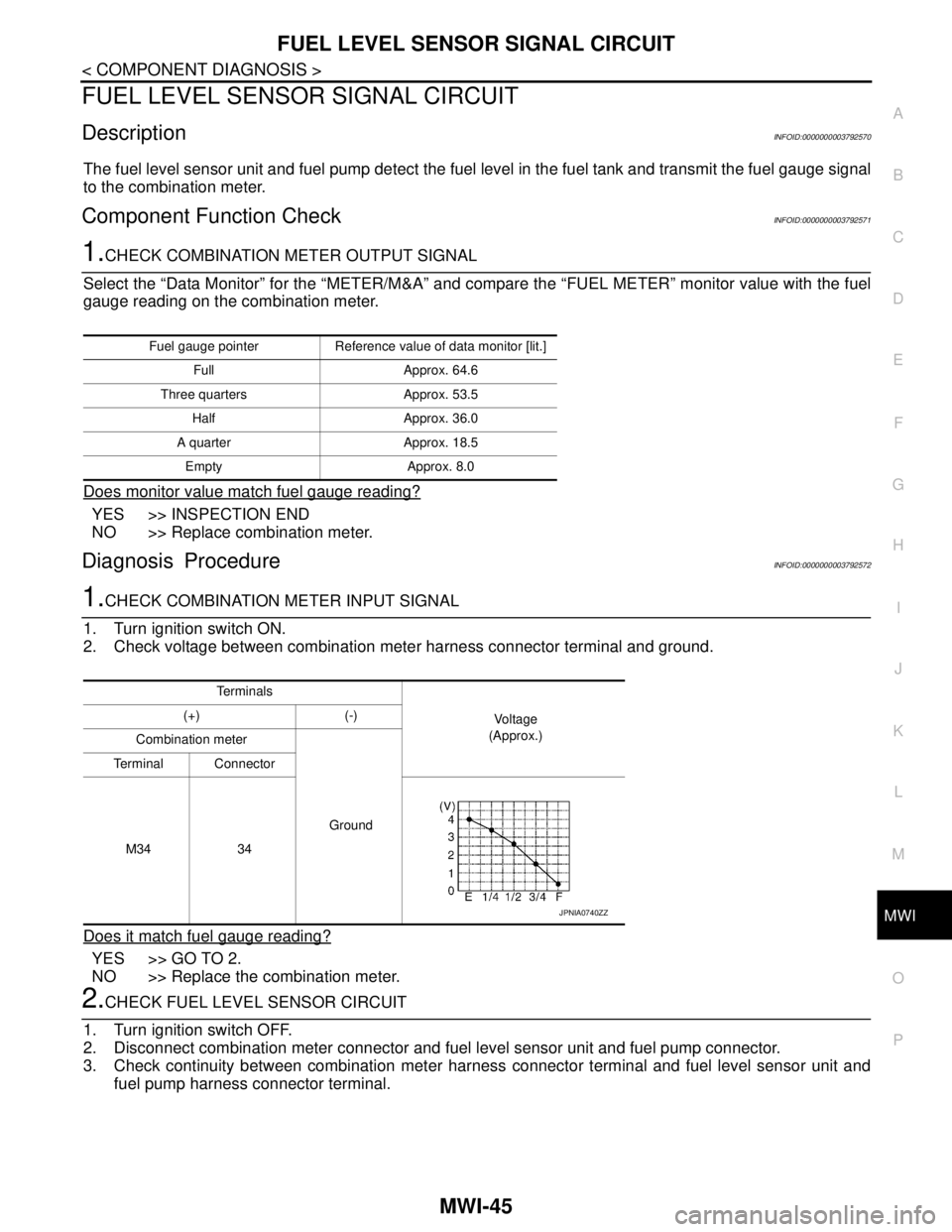

1.CHECK COMBINATION METER INPUT SIGNAL

1. Turn ignition switch ON.

2. Check voltage between combination meter harness connector terminal and ground.

Does it match fuel gauge reading?

YES >> GO TO 2.

NO >> Replace the combination meter.

2.CHECK FUEL LEVEL SENSOR CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect combination meter connector and fuel level sensor unit and fuel pump connector.

3. Check continuity between combination meter harness connector terminal and fuel level sensor unit and

fuel pump harness connector terminal.

Fuel gauge pointer Reference value of data monitor [lit.]

Full Approx. 64.6

Three quarters Approx. 53.5

Half Approx. 36.0

A quarter Approx. 18.5

Empty Approx. 8.0

Te r m i n a l s

Vo l ta g e

(Approx.) (+) (-)

Combination meter

Ground Terminal Connector

M34 34

JPNIA0740ZZ

Page 3300 of 5121

MWI-46

< COMPONENT DIAGNOSIS >

FUEL LEVEL SENSOR SIGNAL CIRCUIT

4. Check continuity between combination meter harness connector terminal and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair harness or connector.

3.CHECK FUEL LEVEL SENSOR GROUND CIRCUIT

Check continuity between fuel level sensor unit and fuel pump harness connector terminal and combination

meter harness connector terminal.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Repair harness or connector.

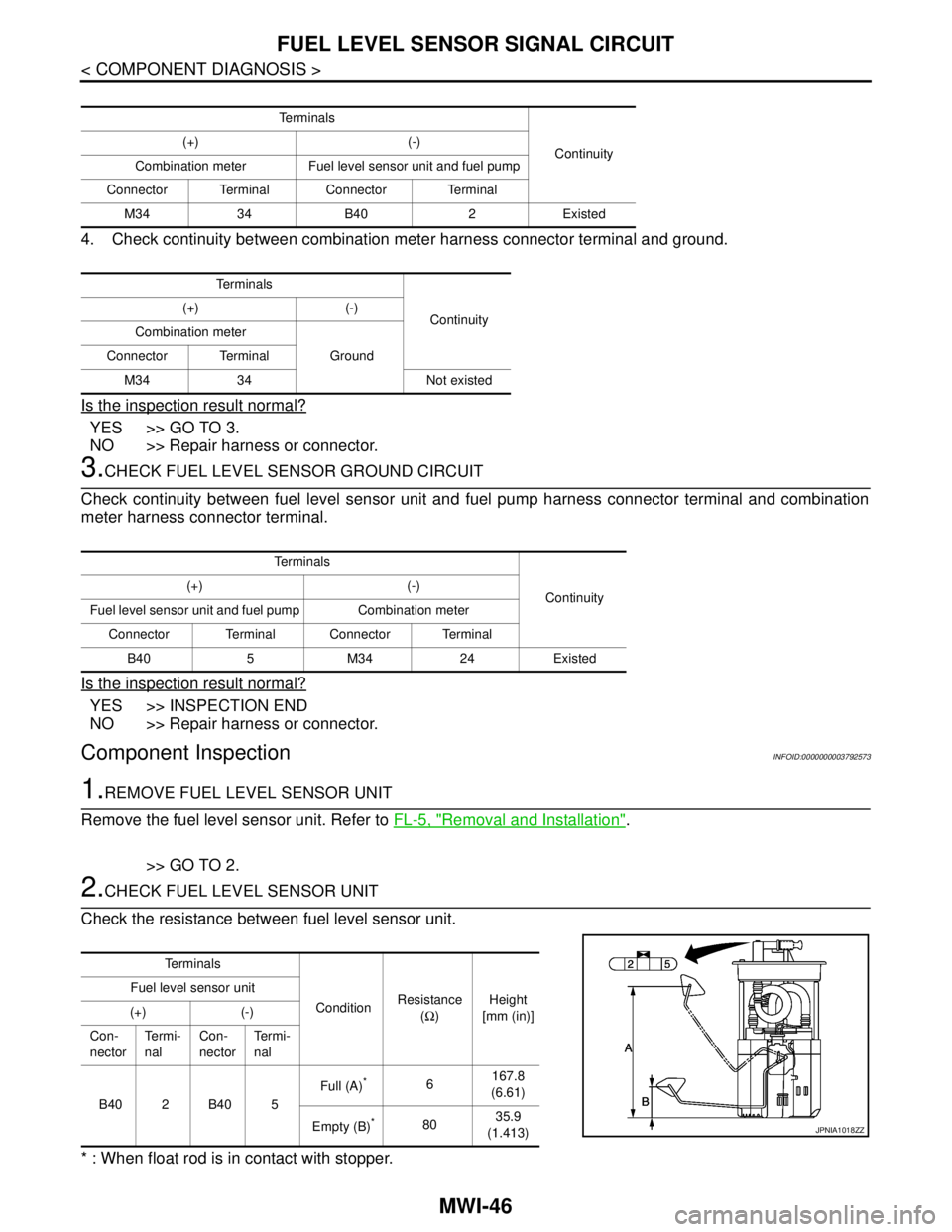

Component InspectionINFOID:0000000003792573

1.REMOVE FUEL LEVEL SENSOR UNIT

Remove the fuel level sensor unit. Refer to FL-5, "

Removal and Installation".

>> GO TO 2.

2.CHECK FUEL LEVEL SENSOR UNIT

Check the resistance between fuel level sensor unit.

* : When float rod is in contact with stopper.

Te r m i n a l s

Continuity (+) (-)

Combination meter Fuel level sensor unit and fuel pump

Connector Terminal Connector Terminal

M34 34 B40 2 Existed

Te r m i n a l s

Continuity (+) (-)

Combination meter

Ground Connector Terminal

M34 34 Not existed

Te r m i n a l s

Continuity (+) (-)

Fuel level sensor unit and fuel pump Combination meter

Connector Terminal Connector Terminal

B40 5 M34 24 Existed

Te r m i n a l s

ConditionResistance

(Ω)Height

[mm (in)] Fuel level sensor unit

(+) (-)

Con-

nectorTe r m i -

nalCon-

nectorTe r m i -

nal

B402B405Full (A)

*6167.8

(6.61)

Empty (B)

*8035.9

(1.413)JPNIA1018ZZ