NISSAN TEANA 2008 Service Manual

Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 5031 of 5121

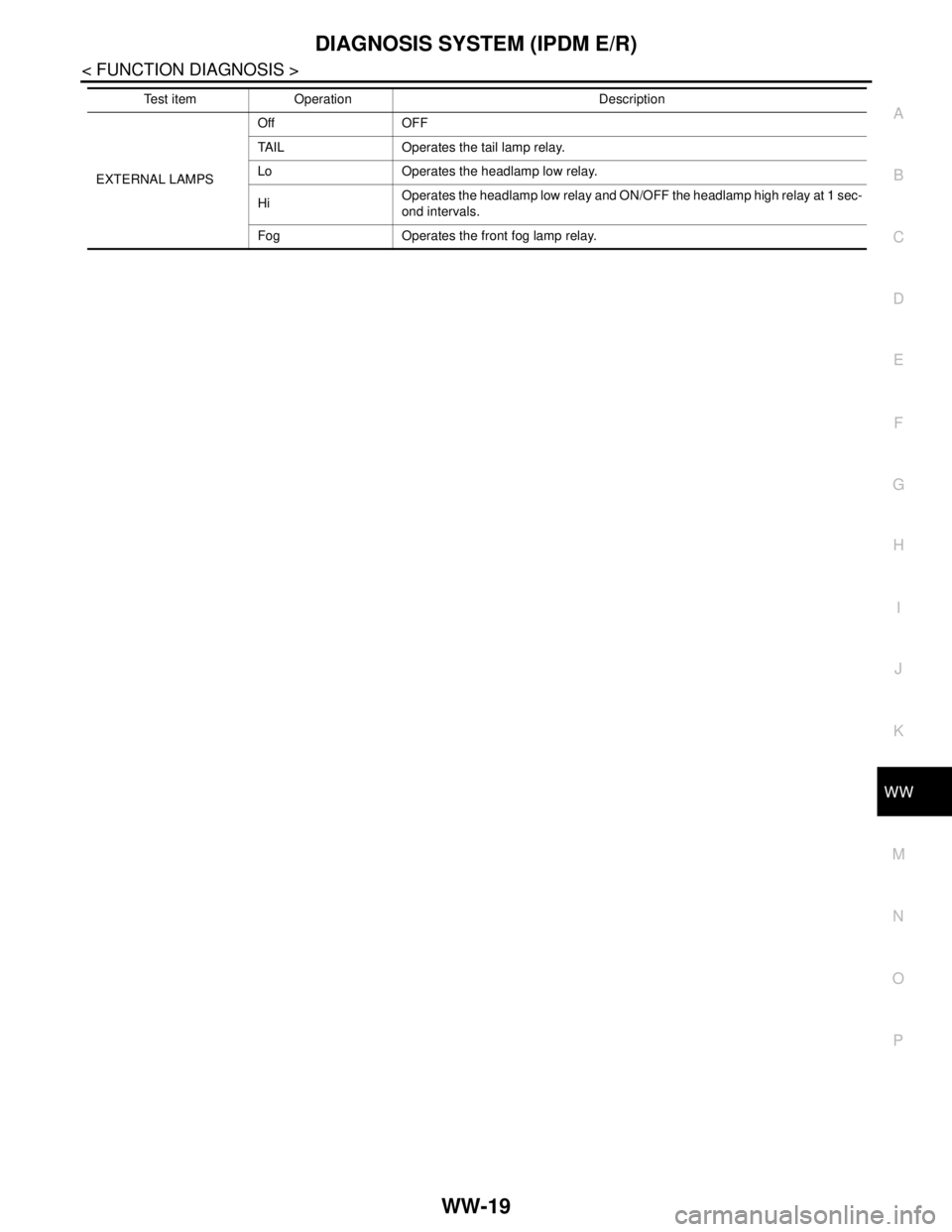

DIAGNOSIS SYSTEM (IPDM E/R)

WW-19

< FUNCTION DIAGNOSIS >

C

D

E

F

G

H

I

J

K

MA

B

WW

N

O

P

EXTERNAL LAMPSOff OFF

TAIL Operates the tail lamp relay.

Lo Operates the headlamp low relay.

HiOperates the headlamp low relay and ON/OFF the headlamp high relay at 1 sec-

ond intervals.

Fog Operates the front fog lamp relay. Test item Operation Description

Page 5032 of 5121

WW-20

< COMPONENT DIAGNOSIS >

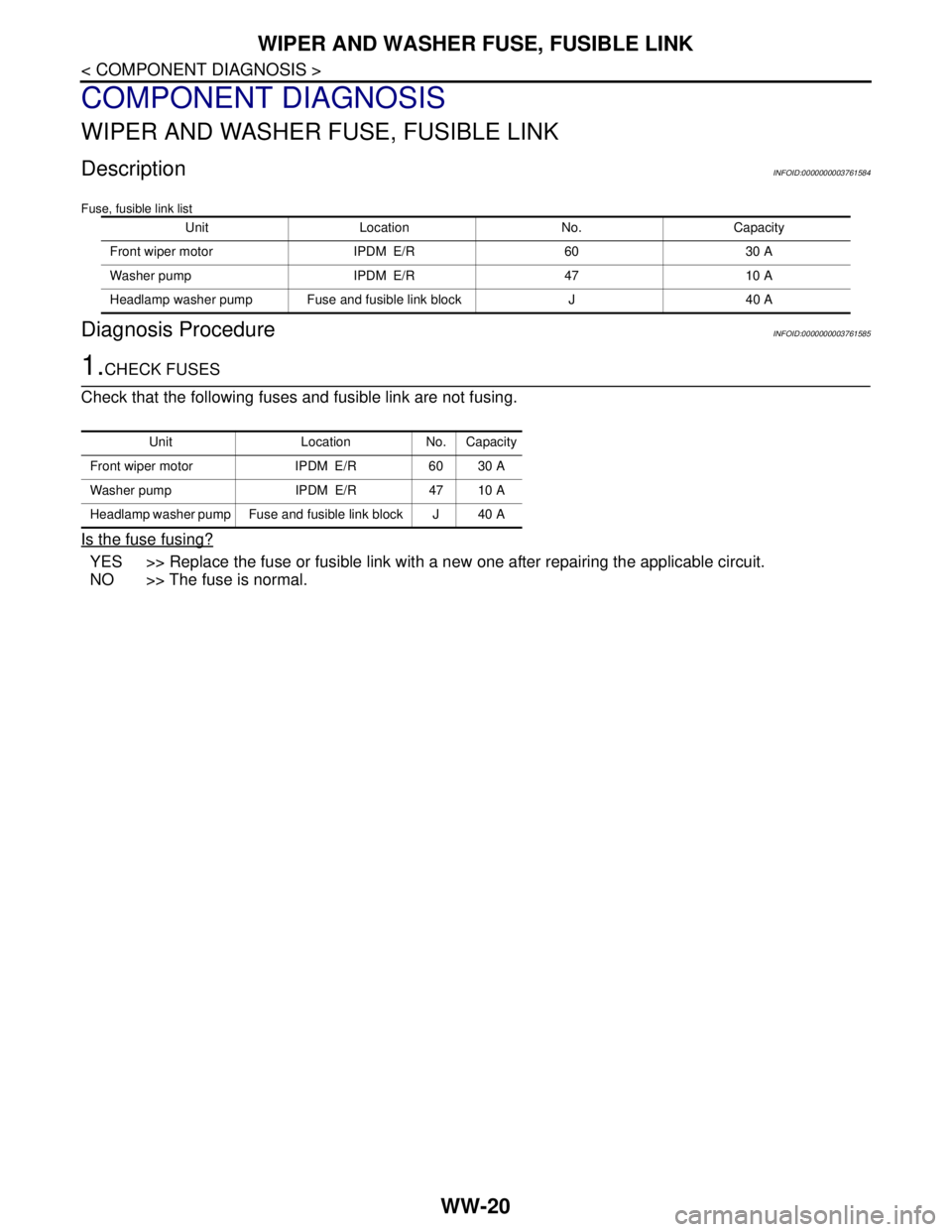

WIPER AND WASHER FUSE, FUSIBLE LINK

COMPONENT DIAGNOSIS

WIPER AND WASHER FUSE, FUSIBLE LINK

DescriptionINFOID:0000000003761584

Fuse, fusible link list

Diagnosis ProcedureINFOID:0000000003761585

1.CHECK FUSES

Check that the following fuses and fusible link are not fusing.

Is the fuse fusing?

YES >> Replace the fuse or fusible link with a new one after repairing the applicable circuit.

NO >> The fuse is normal.

Unit Location No. Capacity

Front wiper motor IPDM E/R 60 30 A

Washer pump IPDM E/R 47 10 A

Headlamp washer pump Fuse and fusible link block J 40 A

Unit Location No. Capacity

Front wiper motor IPDM E/R 60 30 A

Washer pump IPDM E/R 47 10 A

Headlamp washer pump Fuse and fusible link block J 40 A

Page 5033 of 5121

POWER SUPPLY AND GROUND CIRCUIT

WW-21

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

J

K

MA

B

WW

N

O

P

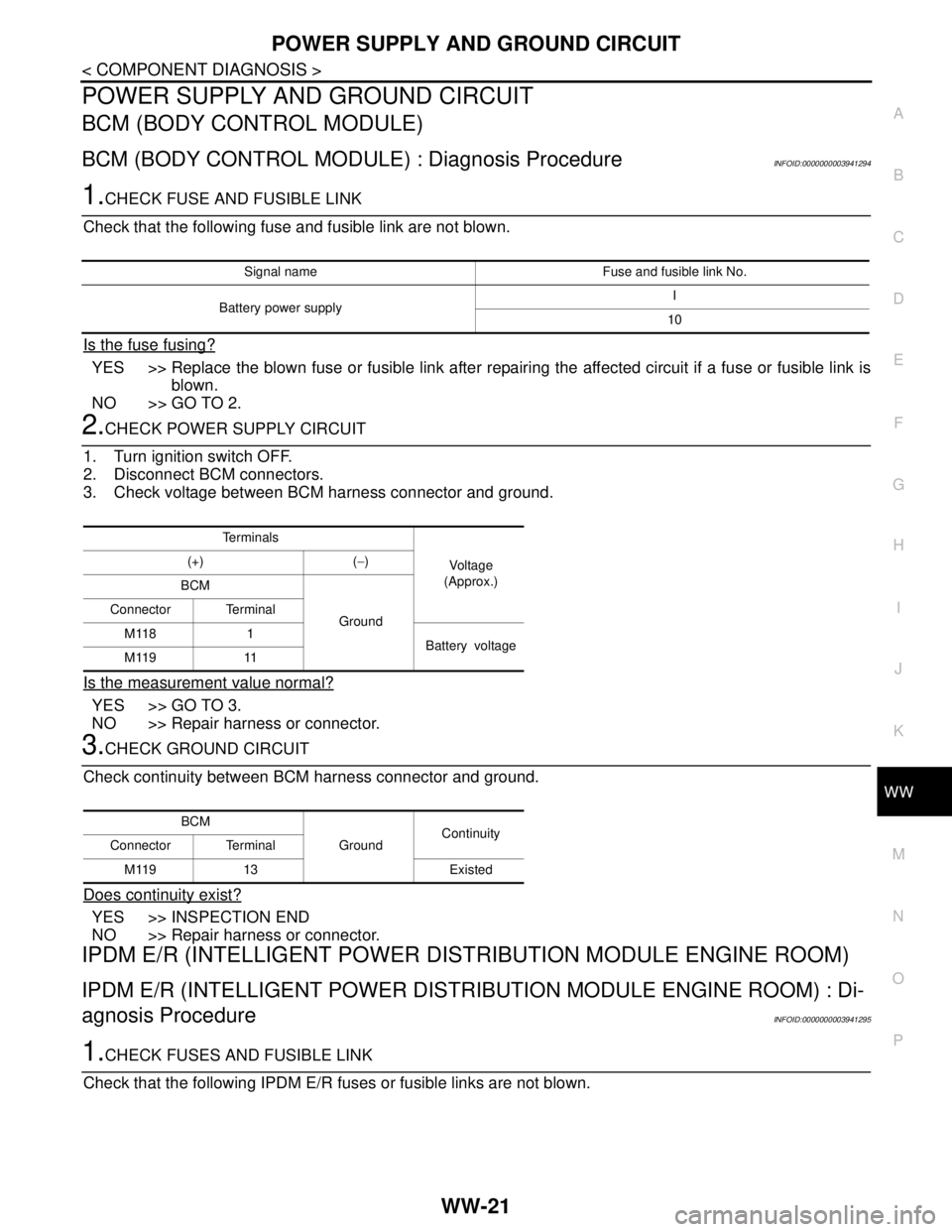

POWER SUPPLY AND GROUND CIRCUIT

BCM (BODY CONTROL MODULE)

BCM (BODY CONTROL MODULE) : Diagnosis ProcedureINFOID:0000000003941294

1.CHECK FUSE AND FUSIBLE LINK

Check that the following fuse and fusible link are not blown.

Is the fuse fusing?

YES >> Replace the blown fuse or fusible link after repairing the affected circuit if a fuse or fusible link is

blown.

NO >> GO TO 2.

2.CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connectors.

3. Check voltage between BCM harness connector and ground.

Is the measurement value normal?

YES >> GO TO 3.

NO >> Repair harness or connector.

3.CHECK GROUND CIRCUIT

Check continuity between BCM harness connector and ground.

Does continuity exist?

YES >> INSPECTION END

NO >> Repair harness or connector.

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM) : Di-

agnosis Procedure

INFOID:0000000003941295

1.CHECK FUSES AND FUSIBLE LINK

Check that the following IPDM E/R fuses or fusible links are not blown.

Signal name Fuse and fusible link No.

Battery power supplyI

10

Te r m i n a l s

Vo l ta g e

(Approx.) (+) (−)

BCM

Ground Connector Terminal

M118 1

Battery voltage

M119 11

BCM

GroundContinuity

Connector Terminal

M119 13 Existed

Page 5034 of 5121

WW-22

< COMPONENT DIAGNOSIS >

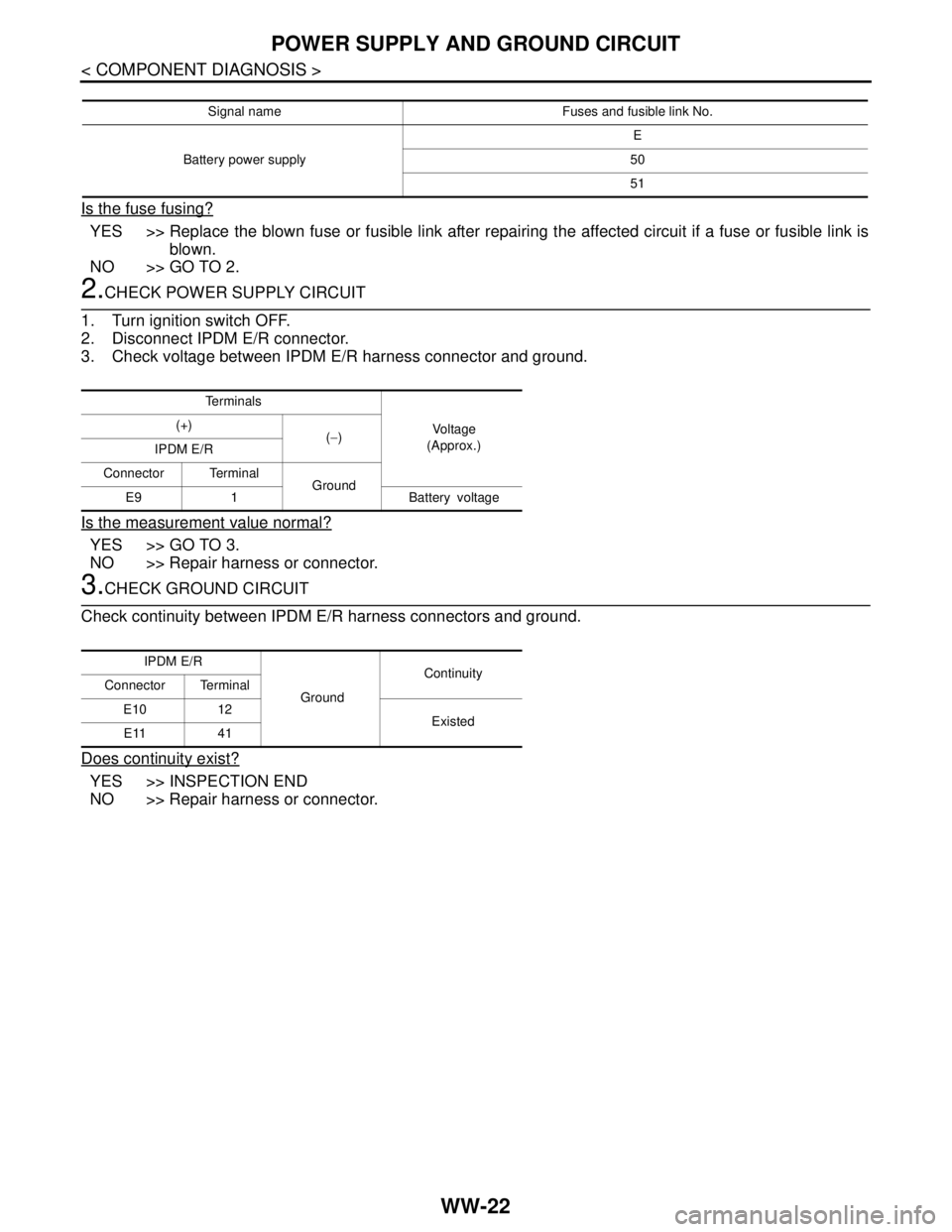

POWER SUPPLY AND GROUND CIRCUIT

Is the fuse fusing?

YES >> Replace the blown fuse or fusible link after repairing the affected circuit if a fuse or fusible link is

blown.

NO >> GO TO 2.

2.CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector.

3. Check voltage between IPDM E/R harness connector and ground.

Is the measurement value normal?

YES >> GO TO 3.

NO >> Repair harness or connector.

3.CHECK GROUND CIRCUIT

Check continuity between IPDM E/R harness connectors and ground.

Does continuity exist?

YES >> INSPECTION END

NO >> Repair harness or connector.

Signal name Fuses and fusible link No.

Battery power supplyE

50

51

Te r m i n a l s

Vo l ta g e

(Approx.) (+)

(−)

IPDM E/R

Connector Terminal

Ground

E9 1 Battery voltage

IPDM E/R

GroundContinuity

Connector Terminal

E10 12

Existed

E11 41

Page 5035 of 5121

FRONT WIPER MOTOR LO CIRCUIT

WW-23

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

J

K

MA

B

WW

N

O

P

FRONT WIPER MOTOR LO CIRCUIT

Component Function CheckINFOID:0000000003761586

1.CHECK FRONT WIPER LO OPERATION

IPDM E/R AUTO ACTIVE TEST

1. Start IPDM E/R auto active test. Refer to PCS-11, "

Diagnosis Description".

2. Check that the front wiper operates at the LO operation.

CONSULT-III ACTIVE TEST

1. Select “FRONT WIPER” of IPDM E/R active test item.

2. With operating the test item, check front wiper operation.

Is front wiper (LO) operation normally?

YES >> Front wiper motor LO circuit is normal.

NO >> Refer to WW-23, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000003761587

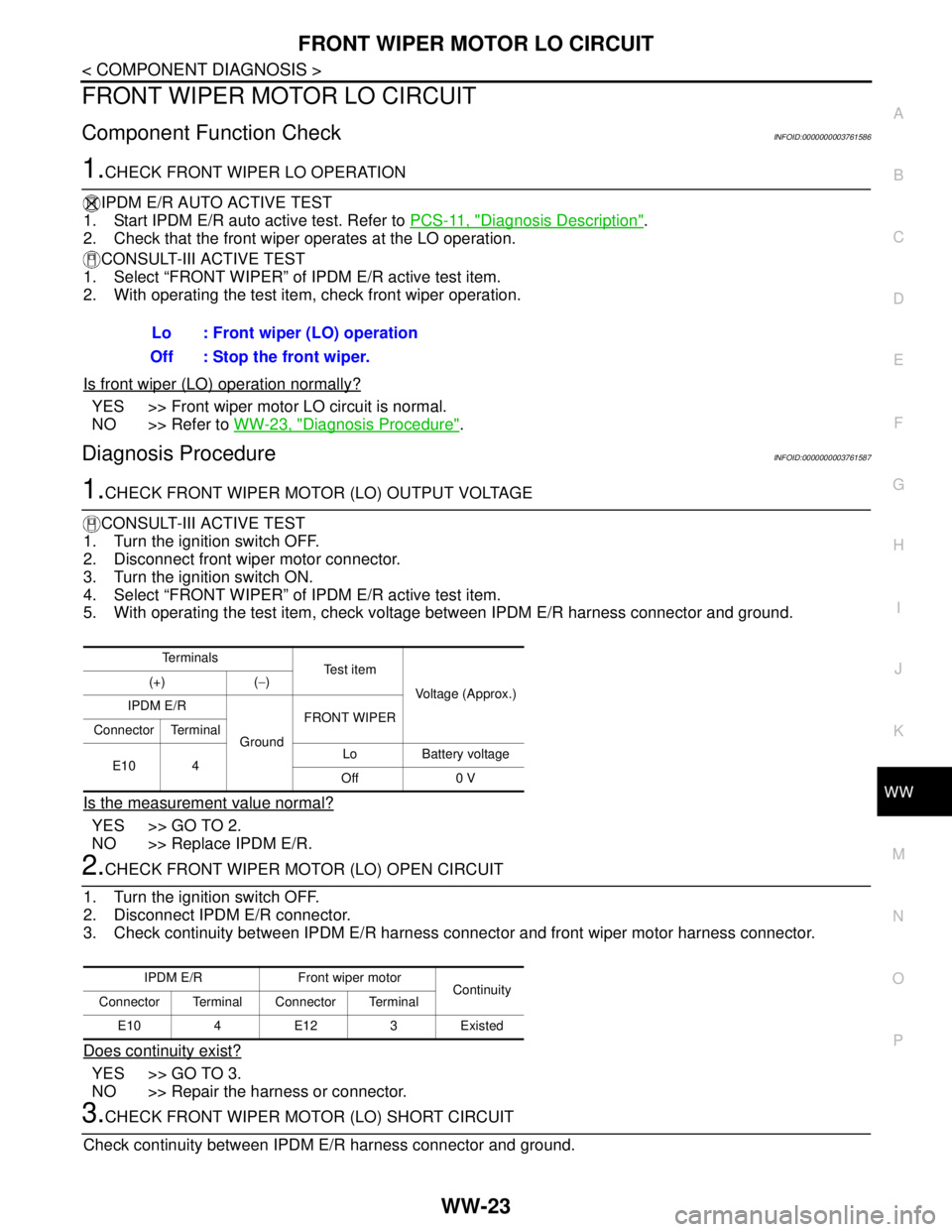

1.CHECK FRONT WIPER MOTOR (LO) OUTPUT VOLTAGE

CONSULT-III ACTIVE TEST

1. Turn the ignition switch OFF.

2. Disconnect front wiper motor connector.

3. Turn the ignition switch ON.

4. Select “FRONT WIPER” of IPDM E/R active test item.

5. With operating the test item, check voltage between IPDM E/R harness connector and ground.

Is the measurement value normal?

YES >> GO TO 2.

NO >> Replace IPDM E/R.

2.CHECK FRONT WIPER MOTOR (LO) OPEN CIRCUIT

1. Turn the ignition switch OFF.

2. Disconnect IPDM E/R connector.

3. Check continuity between IPDM E/R harness connector and front wiper motor harness connector.

Does continuity exist?

YES >> GO TO 3.

NO >> Repair the harness or connector.

3.CHECK FRONT WIPER MOTOR (LO) SHORT CIRCUIT

Check continuity between IPDM E/R harness connector and ground.Lo : Front wiper (LO) operation

Off : Stop the front wiper.

Te r m i n a l s

Te s t i t e m

Voltage (Approx.) (+) (−)

IPDM E/R

GroundFRONT WIPER

Connector Terminal

E10 4Lo Battery voltage

Off 0 V

IPDM E/R Front wiper motor

Continuity

Connector Terminal Connector Terminal

E10 4 E12 3 Existed

Page 5036 of 5121

WW-24

< COMPONENT DIAGNOSIS >

FRONT WIPER MOTOR LO CIRCUIT

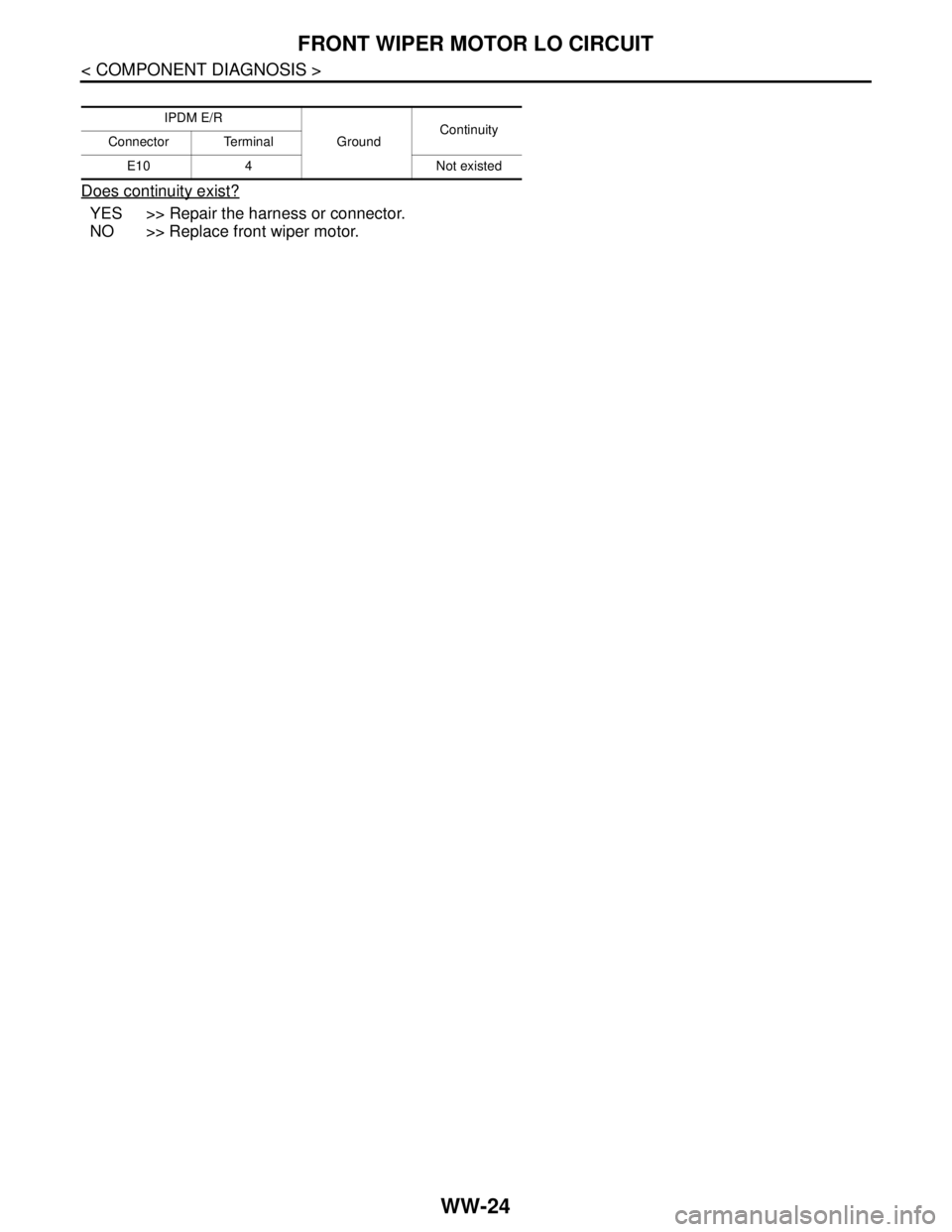

Does continuity exist?

YES >> Repair the harness or connector.

NO >> Replace front wiper motor.

IPDM E/R

GroundContinuity

Connector Terminal

E10 4 Not existed

Page 5037 of 5121

FRONT WIPER MOTOR HI CIRCUIT

WW-25

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

J

K

MA

B

WW

N

O

P

FRONT WIPER MOTOR HI CIRCUIT

Component Function CheckINFOID:0000000003761588

1.CHECK FRONT WIPER HI OPERATION

IPDM E/R AUTO ACTIVE TEST

1. Start IPDM E/R auto active test. Refer to PCS-11, "

Diagnosis Description".

2. Check that the front wiper operates at the HI operation.

CONSULT-III ACTIVE TEST

1. Select “FRONT WIPER” of IPDM E/R active test item.

2. With operating the test item, check front wiper operation.

Is front wiper (HI) operation normally?

YES >> Front wiper motor HI circuit is normal.

NO >> Refer to WW-25, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000003761589

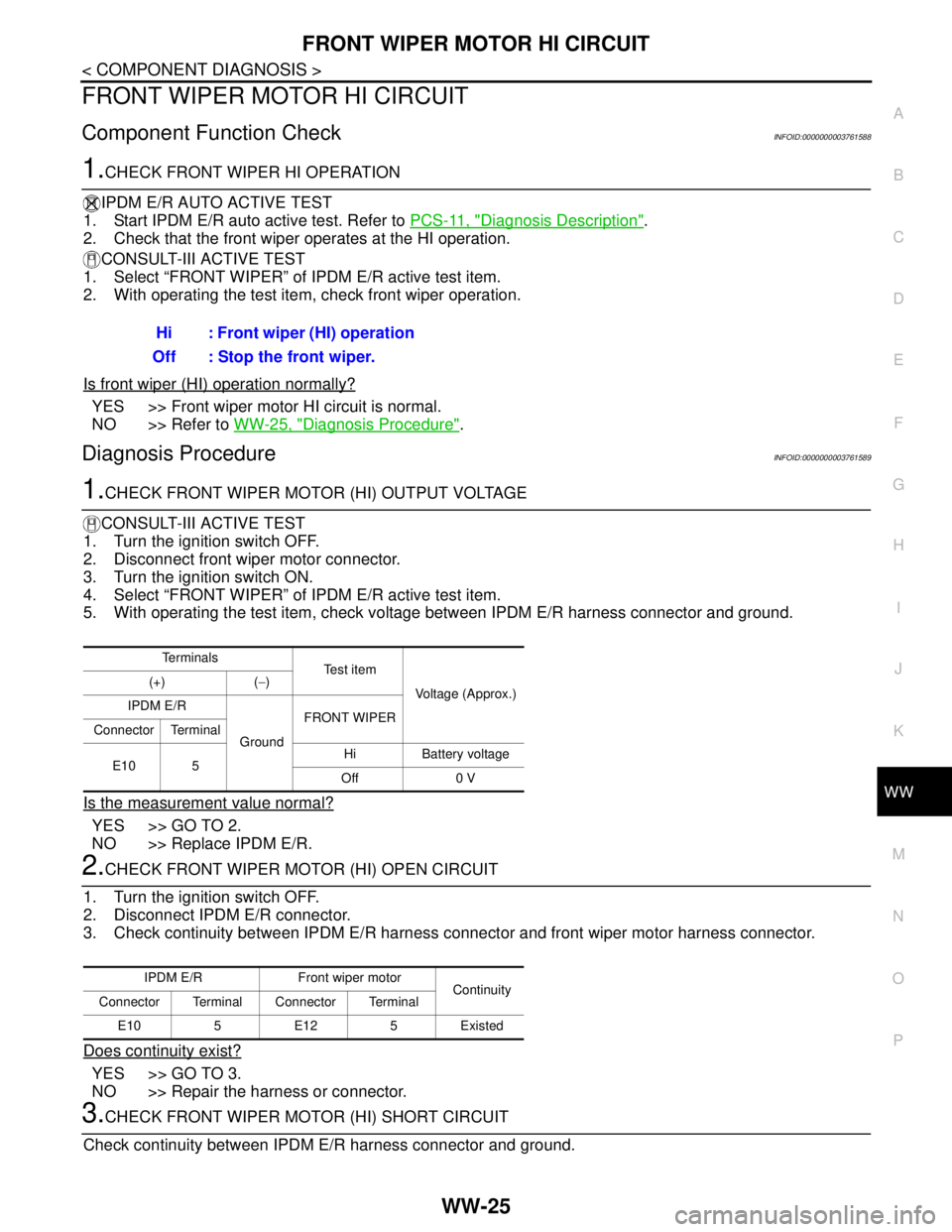

1.CHECK FRONT WIPER MOTOR (HI) OUTPUT VOLTAGE

CONSULT-III ACTIVE TEST

1. Turn the ignition switch OFF.

2. Disconnect front wiper motor connector.

3. Turn the ignition switch ON.

4. Select “FRONT WIPER” of IPDM E/R active test item.

5. With operating the test item, check voltage between IPDM E/R harness connector and ground.

Is the measurement value normal?

YES >> GO TO 2.

NO >> Replace IPDM E/R.

2.CHECK FRONT WIPER MOTOR (HI) OPEN CIRCUIT

1. Turn the ignition switch OFF.

2. Disconnect IPDM E/R connector.

3. Check continuity between IPDM E/R harness connector and front wiper motor harness connector.

Does continuity exist?

YES >> GO TO 3.

NO >> Repair the harness or connector.

3.CHECK FRONT WIPER MOTOR (HI) SHORT CIRCUIT

Check continuity between IPDM E/R harness connector and ground.Hi : Front wiper (HI) operation

Off : Stop the front wiper.

Te r m i n a l s

Te s t i t e m

Voltage (Approx.) (+) (−)

IPDM E/R

GroundFRONT WIPER

Connector Terminal

E10 5Hi Battery voltage

Off 0 V

IPDM E/R Front wiper motor

Continuity

Connector Terminal Connector Terminal

E10 5 E12 5 Existed

Page 5038 of 5121

WW-26

< COMPONENT DIAGNOSIS >

FRONT WIPER MOTOR HI CIRCUIT

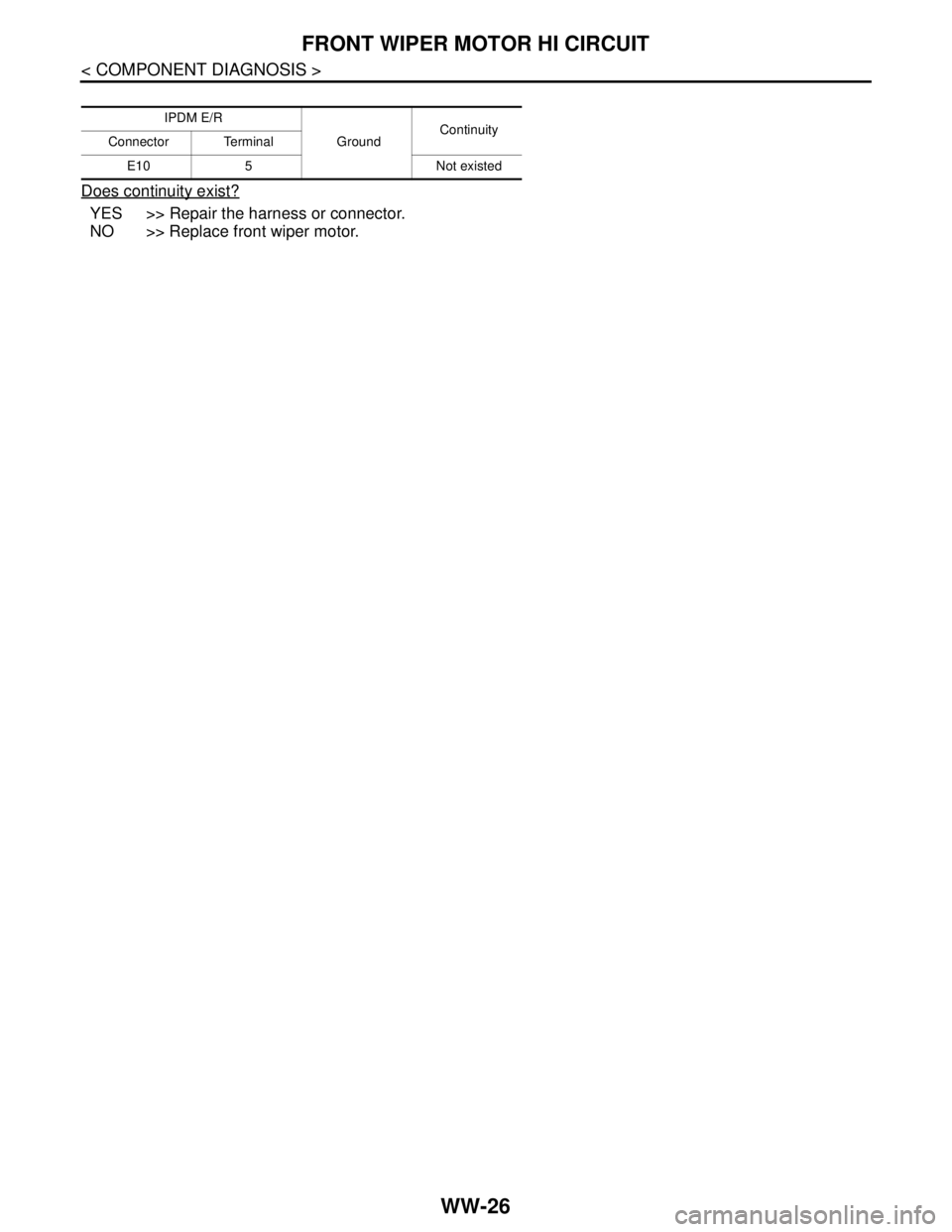

Does continuity exist?

YES >> Repair the harness or connector.

NO >> Replace front wiper motor.

IPDM E/R

GroundContinuity

Connector Terminal

E10 5 Not existed

Page 5039 of 5121

FRONT WIPER AUTO STOP SIGNAL CIRCUIT

WW-27

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

J

K

MA

B

WW

N

O

P

FRONT WIPER AUTO STOP SIGNAL CIRCUIT

Component Function CheckINFOID:0000000003761590

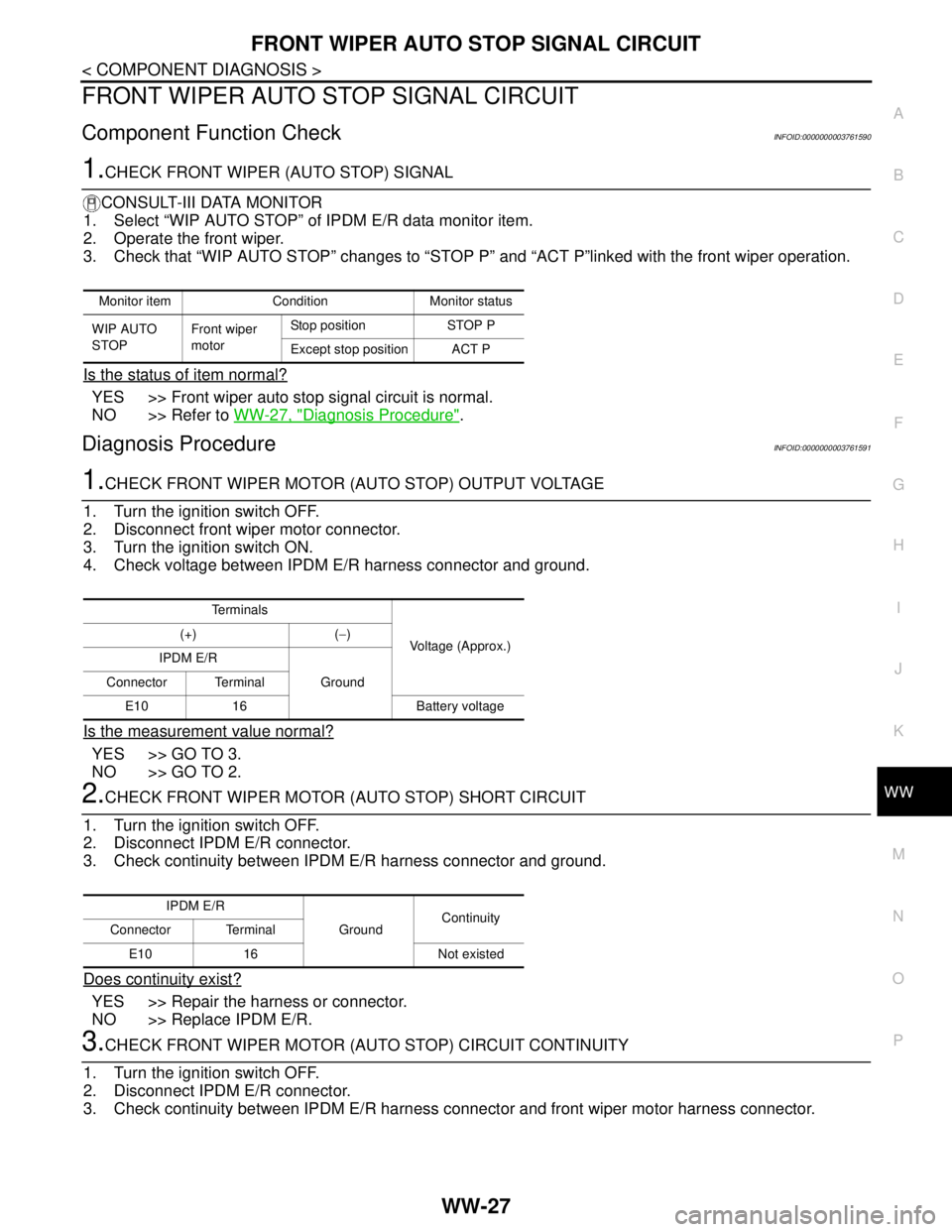

1.CHECK FRONT WIPER (AUTO STOP) SIGNAL

CONSULT-III DATA MONITOR

1. Select “WIP AUTO STOP” of IPDM E/R data monitor item.

2. Operate the front wiper.

3. Check that “WIP AUTO STOP” changes to “STOP P” and “ACT P”linked with the front wiper operation.

Is the status of item normal?

YES >> Front wiper auto stop signal circuit is normal.

NO >> Refer to WW-27, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000003761591

1.CHECK FRONT WIPER MOTOR (AUTO STOP) OUTPUT VOLTAGE

1. Turn the ignition switch OFF.

2. Disconnect front wiper motor connector.

3. Turn the ignition switch ON.

4. Check voltage between IPDM E/R harness connector and ground.

Is the measurement value normal?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK FRONT WIPER MOTOR (AUTO STOP) SHORT CIRCUIT

1. Turn the ignition switch OFF.

2. Disconnect IPDM E/R connector.

3. Check continuity between IPDM E/R harness connector and ground.

Does continuity exist?

YES >> Repair the harness or connector.

NO >> Replace IPDM E/R.

3.CHECK FRONT WIPER MOTOR (AUTO STOP) CIRCUIT CONTINUITY

1. Turn the ignition switch OFF.

2. Disconnect IPDM E/R connector.

3. Check continuity between IPDM E/R harness connector and front wiper motor harness connector.

Monitor item Condition Monitor status

WIP AUTO

STOPFront wiper

motorStop position STOP P

Except stop position ACT P

Te r m i n a l s

Voltage (Approx.) (+) (−)

IPDM E/R

Ground Connector Terminal

E10 16 Battery voltage

IPDM E/R

GroundContinuity

Connector Terminal

E10 16 Not existed

Page 5040 of 5121

WW-28

< COMPONENT DIAGNOSIS >

FRONT WIPER AUTO STOP SIGNAL CIRCUIT

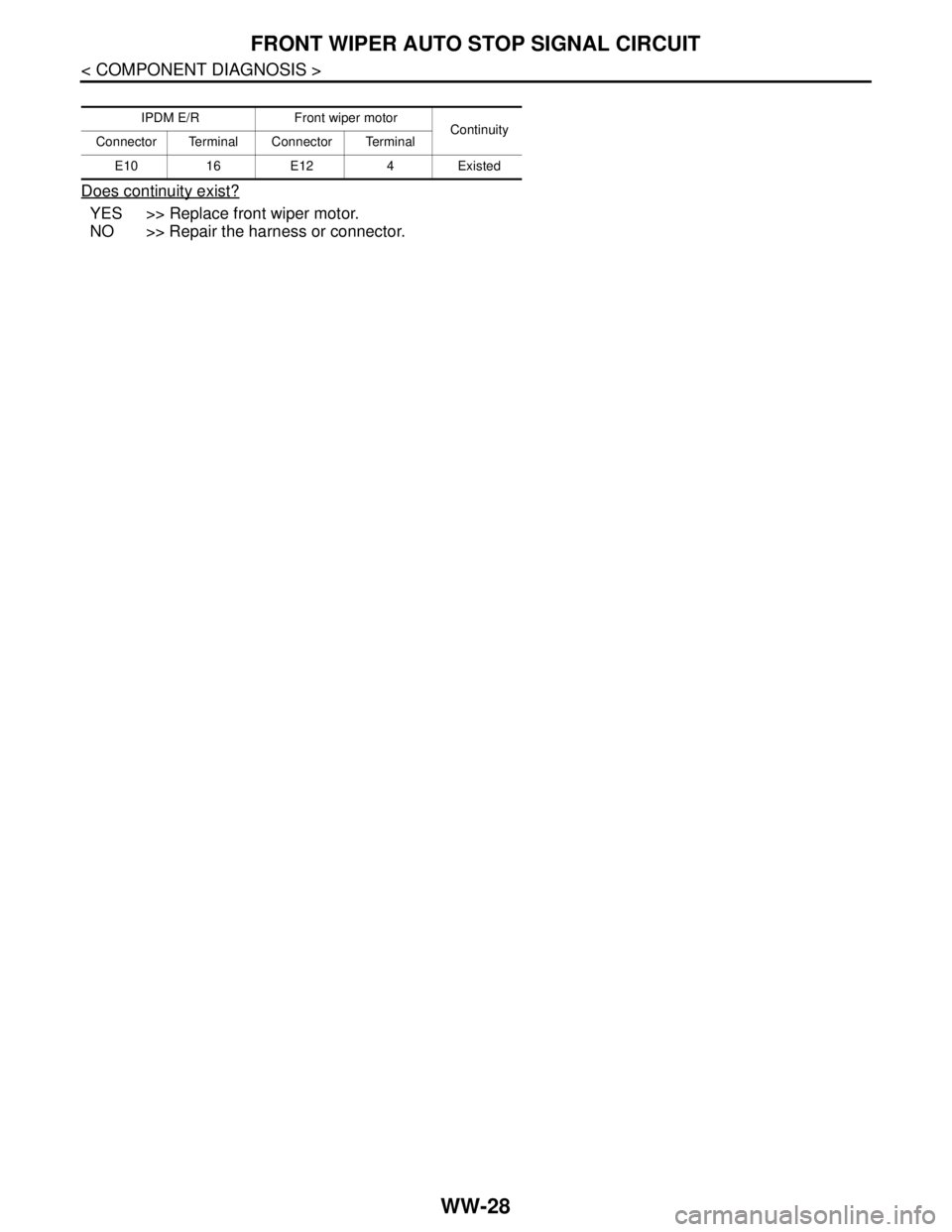

Does continuity exist?

YES >> Replace front wiper motor.

NO >> Repair the harness or connector.

IPDM E/R Front wiper motor

Continuity

Connector Terminal Connector Terminal

E10 16 E12 4 Existed